Design and Output Performance Model of Turbodrill Blade Used in a Slim Borehole

Abstract

:1. Introduction

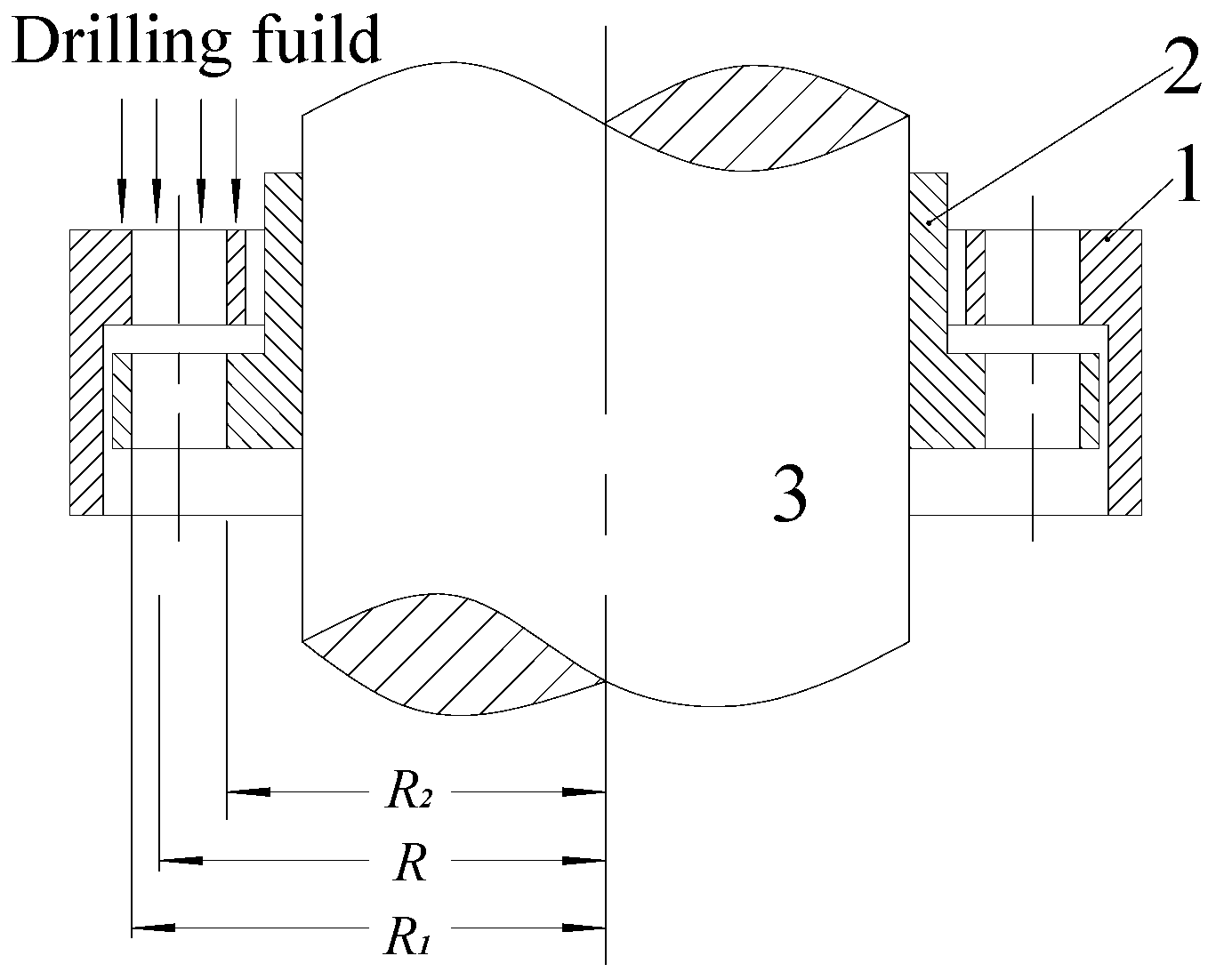

2. Hydrodynamic Model of a Turbodrill Blade

2.1. Hypothesis of the Model

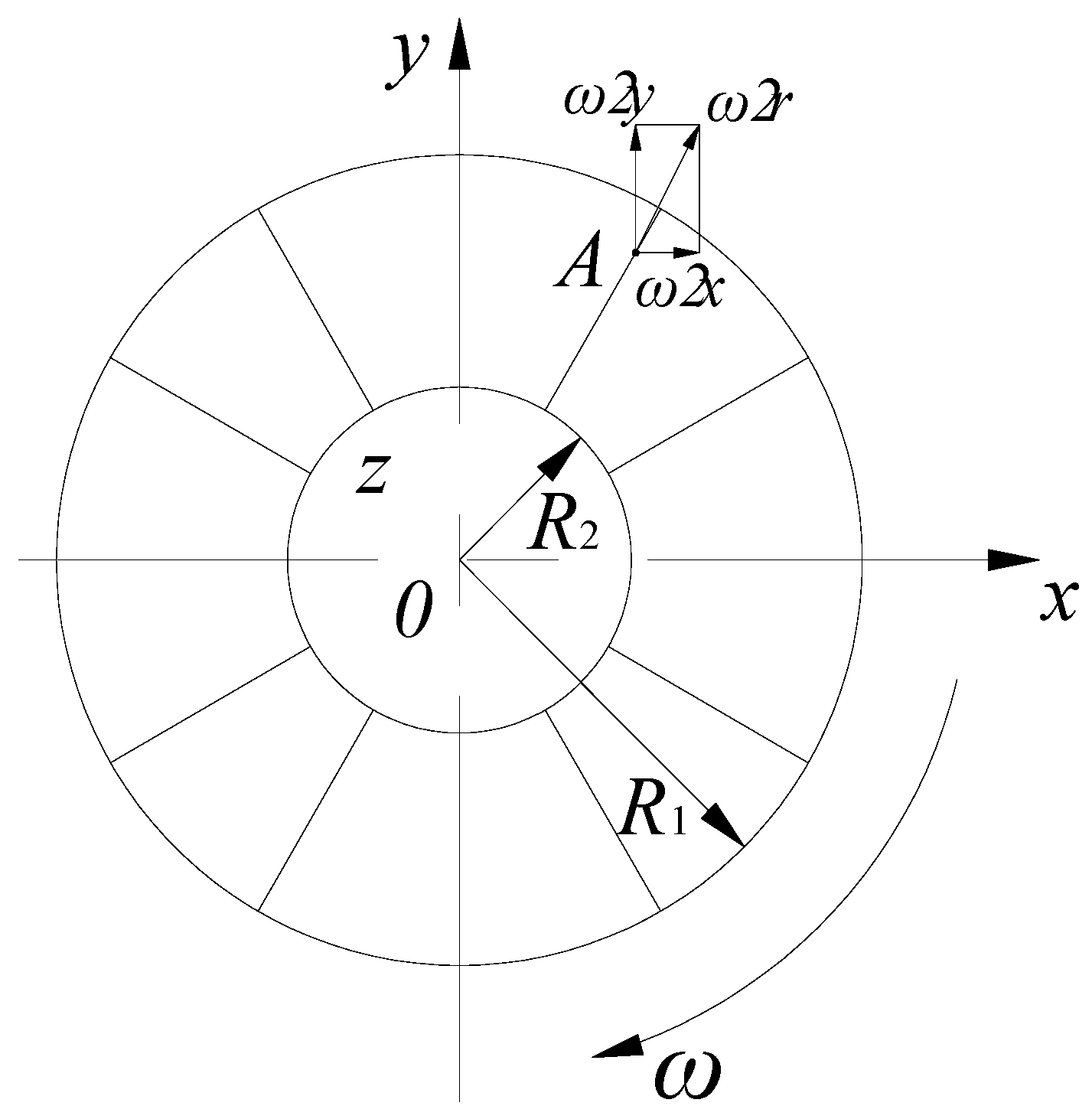

2.2. Inertial Force Field

2.3. Energy Transformation Model

3. Design of the Turbodrill

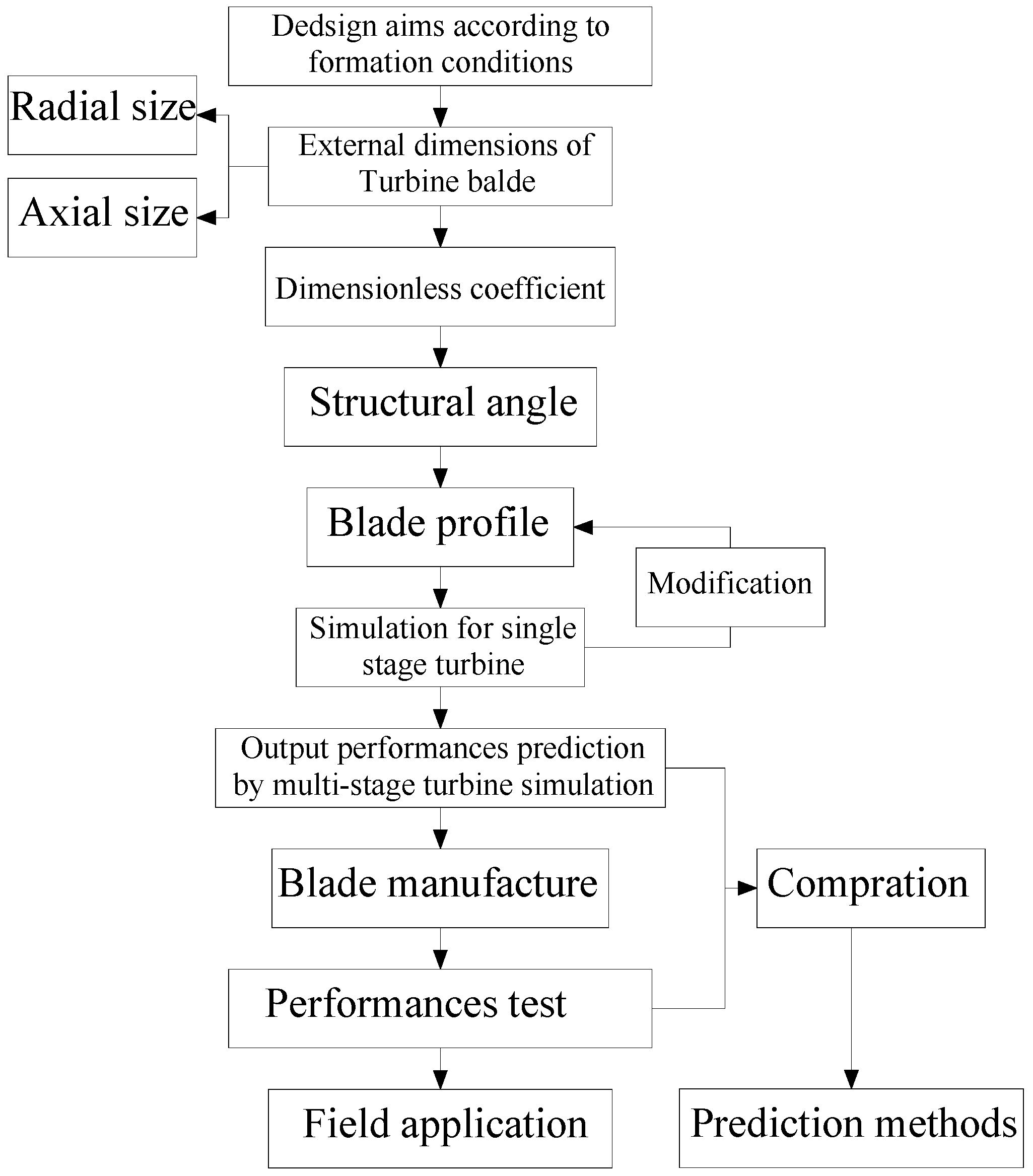

3.1. Design Process of the Turbodrill Blade

3.2. Structure Design of the Turbodrill Blade

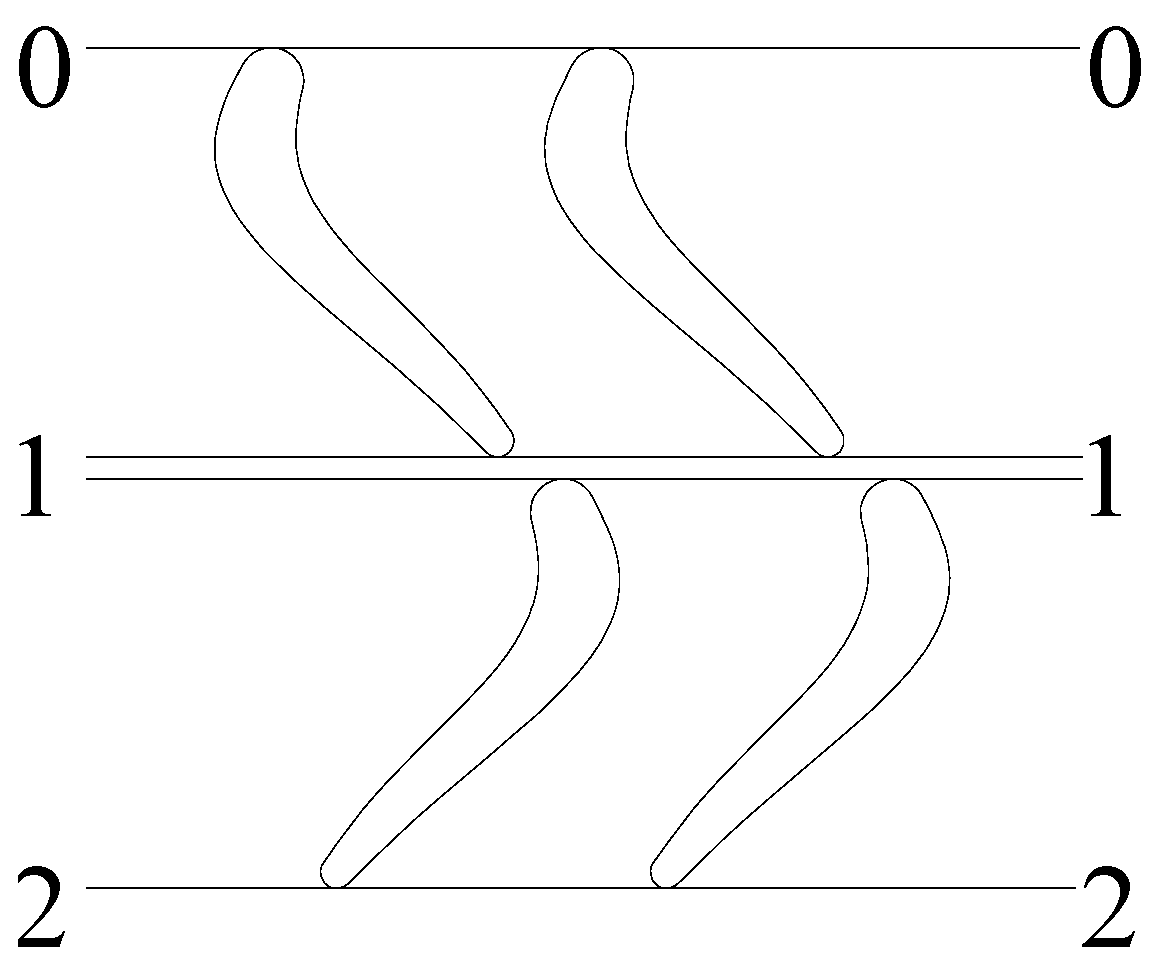

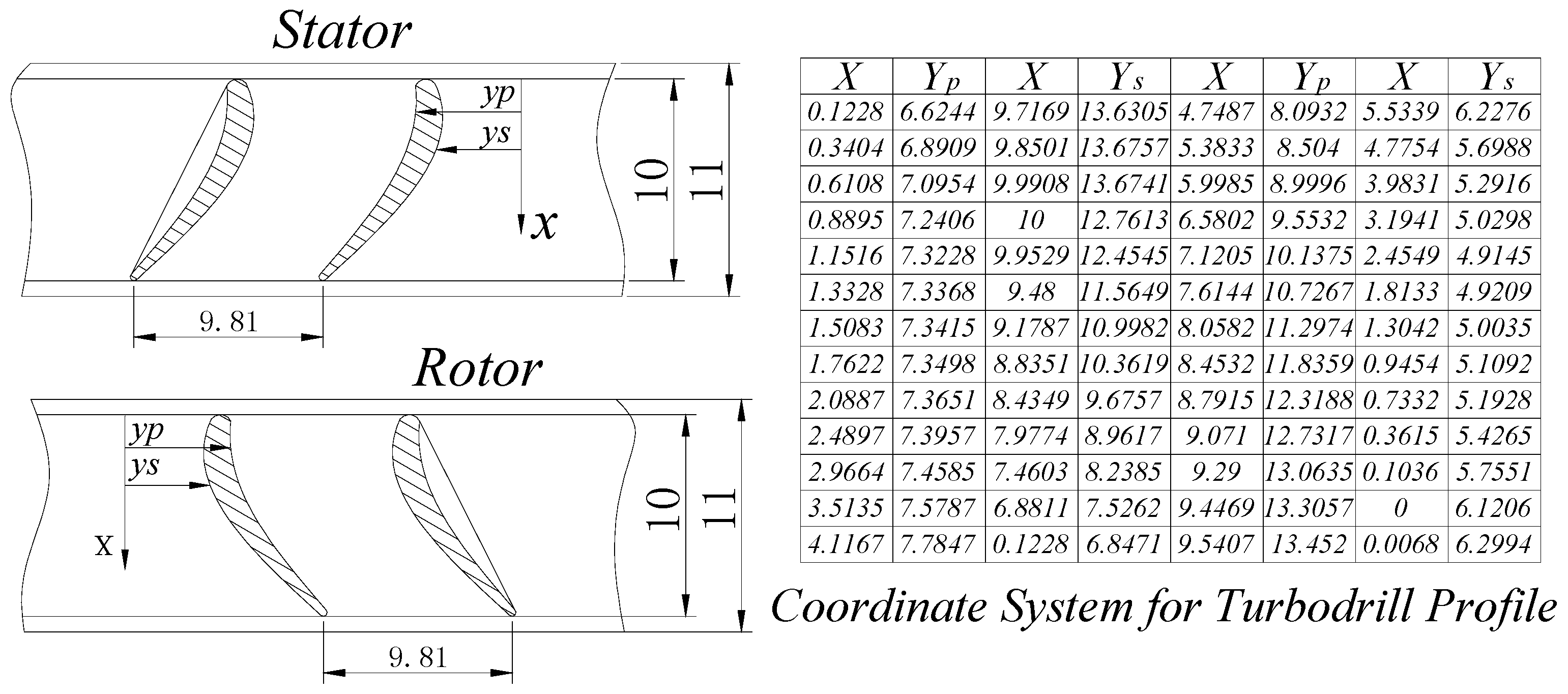

3.3. Turbine Blade Profile Design

4. Numerical Simulation and Test

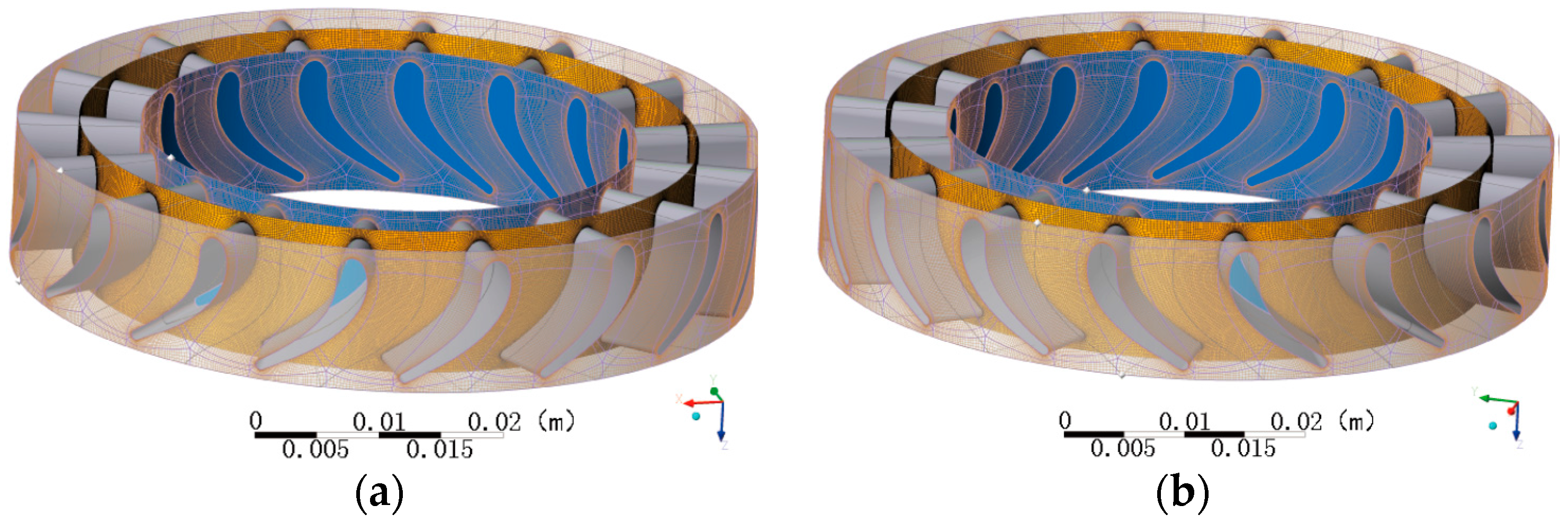

4.1. CFD Model of the Turbodrill Blade

4.2. Meshing and Boundary Conditions

4.3. Test Principle of the Turbodrill

5. Result and Discussion

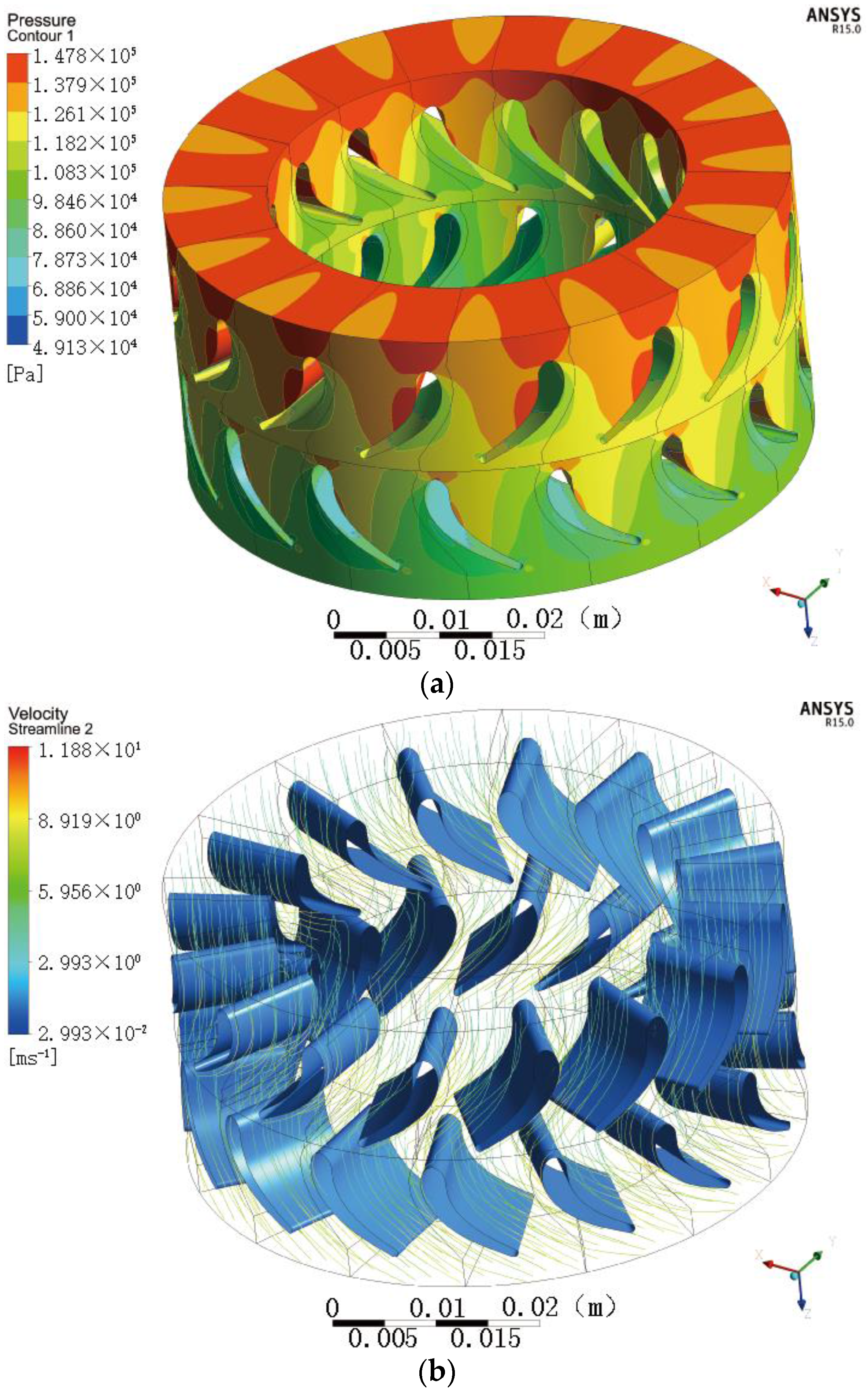

5.1. Simulation of a Single-Stage Turbodrill Blade

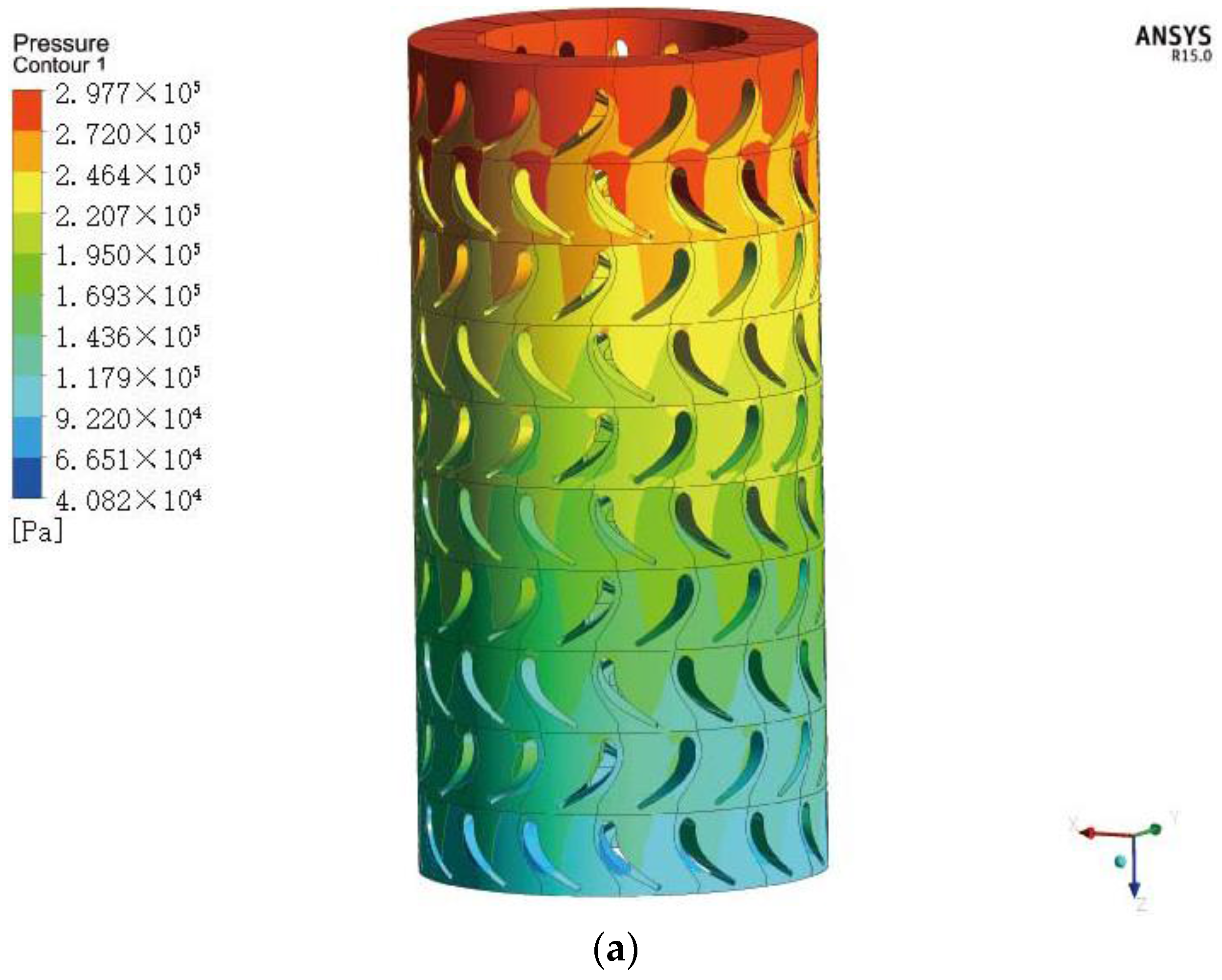

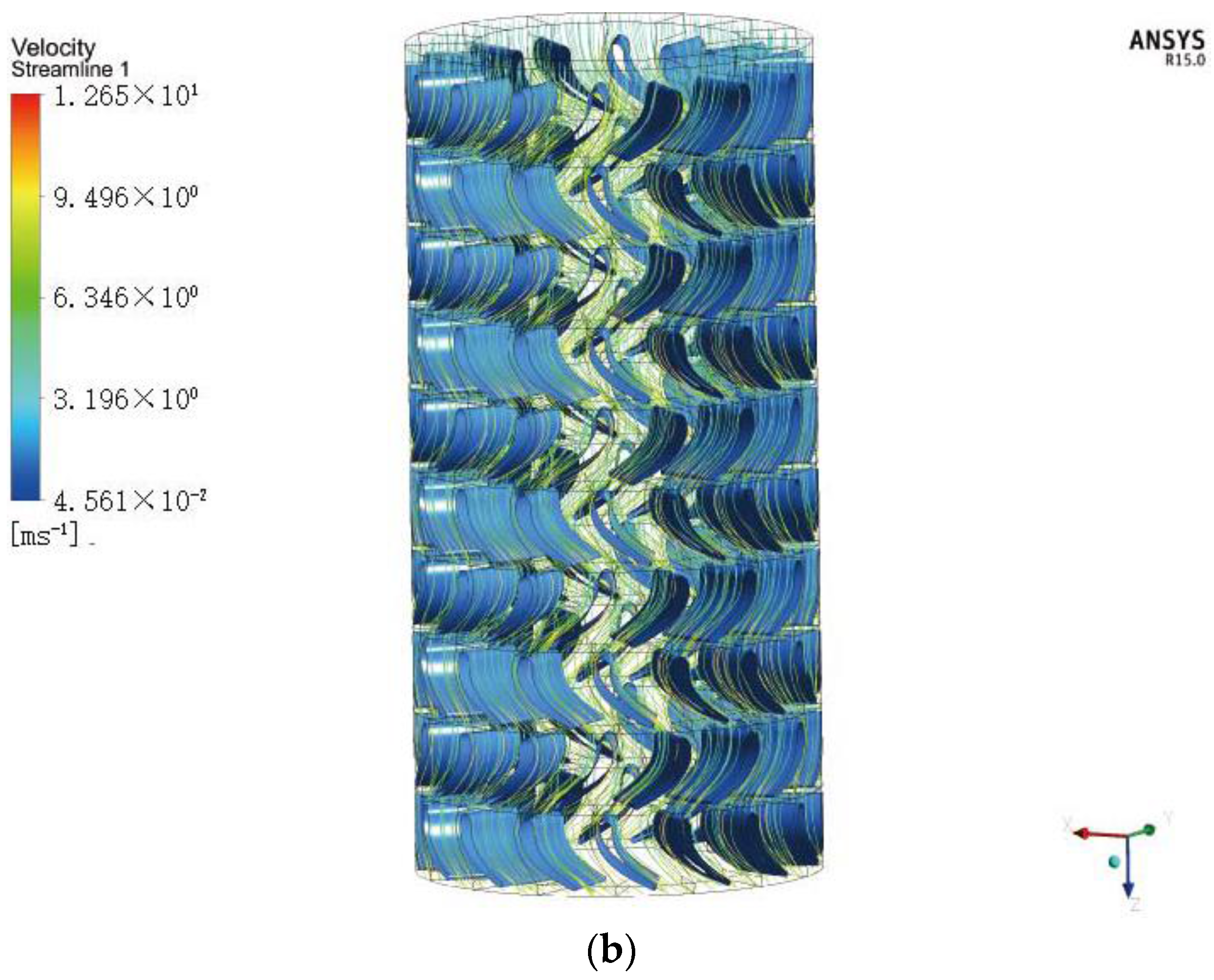

5.2. Simulation of the Multistage Turbodrill Blade

5.3. Comparison with the Experimental Results

6. Conclusions

- (1)

- A Φ89 mm turbodrill blade was developed for high-temperature geothermal drilling of granite formations using a Bezier curve design. The single- and multi-blade turbine simulation was used to achieve the optimization and correction of the turbine profile. The relevant manufacturing and assembly work were also completed.

- (2)

- The output characteristics of a turbine blade model were established based on the gravitational and rotation centrifugal field, using the Bernoulli equation and the momentum theorem. The traditional model was modified, and the accuracy of turbine performance prediction was improved.

- (3)

- The turbodrill has 200 stages. The braking torque can reach 341 N·m. The maximum speed is approximately 3800 r/min, and the maximum power is approximately 38 kW. The rated speed is approximately 1800 r/min, and the pressure drop is less than 8 MPa, consistent with the theoretical design and meeting the design requirements. Based on the multi-stage simulation and optimization interval theory, the entire range of fluctuation of the optimum operating actual speed is 900–1800 r/min, and the torque fluctuates in the range of 200–300 N·m. The power fluctuates over the range of 25–38 KW, which reaches the level of the highest efficiency turbine, i.e., it is the best working range.

- (4)

- The multi-stage simulation was used to predict the turbodrill output performance by comparing the single-stage turbine simulation and the entire real analysis; the multi-stage simulation was found to be closer to the truth, i.e., it is more accurate than the single-stage simulation. The multi-stage simulation is a suitable method for predicting the performance parameters.

Acknowledgments

Author Contributions

Conflicts of Interest

Nomenclature

| , , and | unit mass gravity of the x-axis, y-axis and z-axis, respectively, |

| angular velocity of the revolving turbodrill blade, | |

| radius of the point A, | |

| potential function produced by mass, | |

| height of point A, | |

| pressure of point A, | |

| flow rate of the drilling mud with respect to the turbodrill blade, | |

| and | energy of the drilling mud at the inlet and outlet of the first-stage turbodrill stator, respectively |

| p0 and p1 | pressure of the drilling mud at the inlet and outlet of the first-stage turbodrill stator, respectively, Pa |

| c0 and c1 | absolute speed of the drilling mud at the inlet and outlet of the first-stage turbodrill stator, respectively, m/s |

| z0 and z1 | height of the drilling mud at the inlet and outlet of the first-stage turbodrill stator, respectively, |

| mechanical energy loss of the first-stage turbodrill stator, | |

| energy of the drilling mud at the outlet of the first-stage turbodrill rotor | |

| pressure of the drilling mud at the outlet of the first-stage turbodrill rotor, Pa | |

| absolute speed of the drilling mud at outlet of the first-stage turbodrill rotor, m/s | |

| height of the drilling mud at outlet of the first-stage turbodrill rotor, | |

| mechanical energy loss of the first-stage turbodrill rotor, | |

| series of the multi-stage turbodrill blades | |

| total mechanical energy loss of the turbodrill | |

| total pressure loss of turbodrill, | |

| absolute speed of the drilling mud at the outlet of the stage turbodrill rotor, m/s | |

| height of the drilling mud at outlet of the stage turbodrill rotor, | |

| diameter of the rotor shaft, mm | |

| torque on the rotor shaft, N·mm | |

| safety factor of the shaft materials | |

| allowable twisting stress, MPa | |

| weight on the bit, | |

| reduction factor according to the flexibility of the shaft | |

| allowable stress for the strength calculation, | |

| WOB | weight on bit |

| ROP | rate of penetration |

References

- Frash, L.P.; Gutierrez, M.; Hampton, J. True-triaxial apparatus for simulation of hydraulically fractured multi-borehole hot dry rock reservoirs. Int. J. Rock Mech. Min. 2014, 70, 496–506. [Google Scholar] [CrossRef]

- Gnatus, N.A.; Khutorskoy, M.D. Hot dry rocks: An inexhaustible and renewable source of energy. Lithol. Miner. Resour. 2010, 45, 593–600. [Google Scholar] [CrossRef]

- Kamyab, M.; Rasouli, V. Experimental and numerical simulation of cuttings transportation in coiled tubing drilling. J. Nat. Gas Sci. Eng. 2016, 29, 284–302. [Google Scholar] [CrossRef]

- Livescu, S.; Craig, S. Increasing lubricity of downhole fluids for coiled-tubing operations. SPE J. 2015, 20, 396–404. [Google Scholar] [CrossRef]

- Jones, S.; Feddema, C.; Sugiura, J. A gear-reduced drilling turbine provides game changing results: An alternative to downhole positive displacement motor. In Proceedings of the IADC/SPE Drilling Conference and Exhibition, Fort Worth, TX, USA, 1–3 March 2016.

- Pantoja, R.; Britto, G.; Buzzá, J.; Vieira, A.M.; Laroca, F.; Appelshaeuser, G. Pioneer turbodrilling with 16 ½ impregnated bit in deep pre-salt well in Santos Basin. In Proceedings of the SPE/IADC Drilling Conference and Exhibition, London, UK, 17–19 March 2015.

- Wang, Y.; Liu, B.L.; Zhu, H.Y.; Yan, C.L.; Li, Z.J.; Wang, Z.Q. Thermophysical and mechanical properties of Granite and its effects on borehole stability in high temperature and three-dimensional stress. Sci. World J. 2014, 2014, 95–104. [Google Scholar]

- Varela, R.; Guzman, F.; Cruz, D.; Atencio, N.; Iturrizaga, F.; May, R.; Solano, R.; Perez, R. First application of turbodrill and hybrid bit to optimize drilling times in Cretaceous Formations with high chert content in Mexico South Region. In Proceedings of the IADC/SPE Drilling Conference and Exhibition, Fort Worth, TX, USA, 4–6 March 2014.

- Eskin, M.; Maurer, W.C. (Eds.) Former USSSR R&D on Advanced Downhole Drilling Motors; TR97–31; Maurer Engineering Inc.: Austin, TX, USA, 1997.

- Mokaramian, A.; Rasouli, V.; Cavanough, G. Adapting oil and gas downhole motors for deep mineral exploration drilling. In Proceedings of the Sixth International Seminar on Deep and High Stress Mining, Perth, Australia, 28–30 March 2012.

- Zhang, X.; Feng, J. Research on the effect of fluid media on the mechanical property of high speed turbo-drill. China Pet. Mach. 2012, 40, 38–42. [Google Scholar]

- Mokaramian, A.; Rasouli, V.; Cavanough, G. Turbodrill design and performance analysis. J. Appl. Fluid Mech. 2015, 8, 377–390. [Google Scholar]

- Hu, L.; Gao, D. A new orientation design model and numerical solution for coiled tubing drilling. J. Nat. Gas Sci. Eng. 2015, 27, 1274–1278. [Google Scholar] [CrossRef]

- Jin, F.; Daliang, F. New design method of turbine blade shape of turbodrill. China Pet. Mach. 2000, 28, 9–12. [Google Scholar]

- Seale, R.; Beaton, T.; Flint, G. Optimizing turbodrill designs for coiled tubing application. In Proceedings of the SPE Eastern Regional Meeting, Charleston, WV, USA, 15–17 September 2004.

- Beaton, T.; Seale, R. The use of turbodrills in coiled tubing applications. In Proceedings of the SPE/ICOTA Coiled Tubing Conference and Exhibition, Houston, TX, USA, 23–24 March 2004.

- Ding, L.Y.; Feng, J.; Liu, X.G.; Zhang, M.L. Application CFX-BladeGen in modelling turbine blade. J. Eng. Des. 2005, 12, 109–112. [Google Scholar]

- Hu, X.D.; Liu, Q.; Liu, Y.L.; Zhao, F. The application of using Bezier curve to design turbine blade. Oil Field Equip. 2007, 36, 1–3. [Google Scholar]

- Calnan, D.; Seale, R.; Beaton, T. Identifying applications for turbodrilling and evaluating historical performances in North America. J. Can. Pet. Technol. 2007, 46, 34–39. [Google Scholar] [CrossRef]

- Grigor, C.; Conroy, D.; Henderson, M. Expanding the use of turbodrills in coiled tubing and workover applications. In Proceedings of the SPE/ICOTA Coiled Tubing and Well Intervention Conference and Exhibition, Woodlands, TX, USA, 1–2 April 2008.

- Mokaramian, A.; Rasouli, V.; Cavanough, G. CFD simulations of turbodrill performance with asymmetric stator and rotor blades congiguration. In Proceedings of the Ninth International Conference on CFD in the Minerals and Process Industries CSIRO, Melbourne, Australia, 10–12 December 2012.

- Tan, C.F.; Zhang, S.F.; Zhang, R.L.; Yu, L.W. Research on the effect of turbine blade profile line structure on cascade flow field. China Pet. Mach. 2012, 40, 6–9. [Google Scholar]

- Zhao, H.B.; Liu, B.L.; Wang, J.Q.; Wang, Y. Study on turbine blade of turbodrill design and simulation of flow field, exploration engineering. Rock Soil Drill. Tunn. 2012, 39, 29–32. [Google Scholar]

- Zhao, Z.T.; Weng, W.; Huang, Y.W.; Yang, P.; Yue, W.M.; Xu, J.J. Cascade design and performance prediction of the Φ89 turbodrill. Geol. Explor. 2013, 49, 1176–1180. [Google Scholar]

- Wang, Y.; Yao, J.; Li, Z. Design and development of turbodrill blade used in crystallized section. Sci. World J. 2014, 2014, 682963. [Google Scholar]

- Miyazaki, E.; Shinmoto, Y.; Kyo, M.; Suzuki, T. Development of turbine driven coring system for hard rock sampling. In Proceedings of the Offshore Technology Conference, Houston, TX, USA, 5–8 May 2014.

- Zhang, X.; Yu, S.; Gong, Y.; Li, Y. Optimization design for turbodrill blades based on response surface method. Adv. Mech. Eng. 2016, 8, 1–12. [Google Scholar] [CrossRef]

- Zhang, Q.; Chen, Z.; Luo, K.J.; Wen, J.; Dong, X.H. Coiled tubing small size turbodrill three-dimensional cascade design. Sci. Technol. Eng. 2016, 16, 186–189. [Google Scholar]

- Wu, C.; Wen, G.; Wu, X.; Wang, W.; Han, L.; Zhang, F. Using acoustic sensor and accelerometer to measure the downhole impact frequency of a hydraulic impactor. J. Nat. Gas Sci. Eng. 2015, 27, 1296–1303. [Google Scholar] [CrossRef]

| Items/Unit | Value | Items/Unit | Value |

|---|---|---|---|

| Outside diameter/mm | 89 | Pressure drop/MPa | 6–8 |

| Working flow/L·s−1 | 6–7 | Rated torque/N·m | 350 |

| Rotation speed/r·min−1 | 1800 | Drilling fluid density/kg·m−3 | 1000–2000 |

| Grid | Number of Nodes | Number of Units | Number of Hexahedrons |

|---|---|---|---|

| Single flow passage of stator | 133,325 | 121,920 | 121,920 |

| Full flow passage of stator | 133,325 × 16 | 121,920 × 16 | 121,920 × 16 |

| Single flow passage of rotor | 133,325 | 121,920 | 121,920 |

| Full flow passage of rotor | 133,325 × 16 | 121,920 × 16 | 121,920 × 16 |

| Flow passage of single stage multi-blade | 1,333,250 × 32 | 1,219,200 × 32 | 1,219,200 × 32 |

| Flow passage of multi-stage multi-blade | 1,333,250 × 160 | 1,219,200 × 160 | 1,219,200 × 160 |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Y.; Xia, B.; Wang, Z.; Wang, L.; Zhou, Q. Design and Output Performance Model of Turbodrill Blade Used in a Slim Borehole. Energies 2016, 9, 1035. https://doi.org/10.3390/en9121035

Wang Y, Xia B, Wang Z, Wang L, Zhou Q. Design and Output Performance Model of Turbodrill Blade Used in a Slim Borehole. Energies. 2016; 9(12):1035. https://doi.org/10.3390/en9121035

Chicago/Turabian StyleWang, Yu, Bairu Xia, Zhiqiao Wang, Liguang Wang, and Qin Zhou. 2016. "Design and Output Performance Model of Turbodrill Blade Used in a Slim Borehole" Energies 9, no. 12: 1035. https://doi.org/10.3390/en9121035