Experimental Investigation of Thermal Behaviors in Window Systems by Monitoring of Surface Condensation Using Full-Scale Measurements and Simulation Tools

Abstract

:1. Introduction

2. Field Measurements

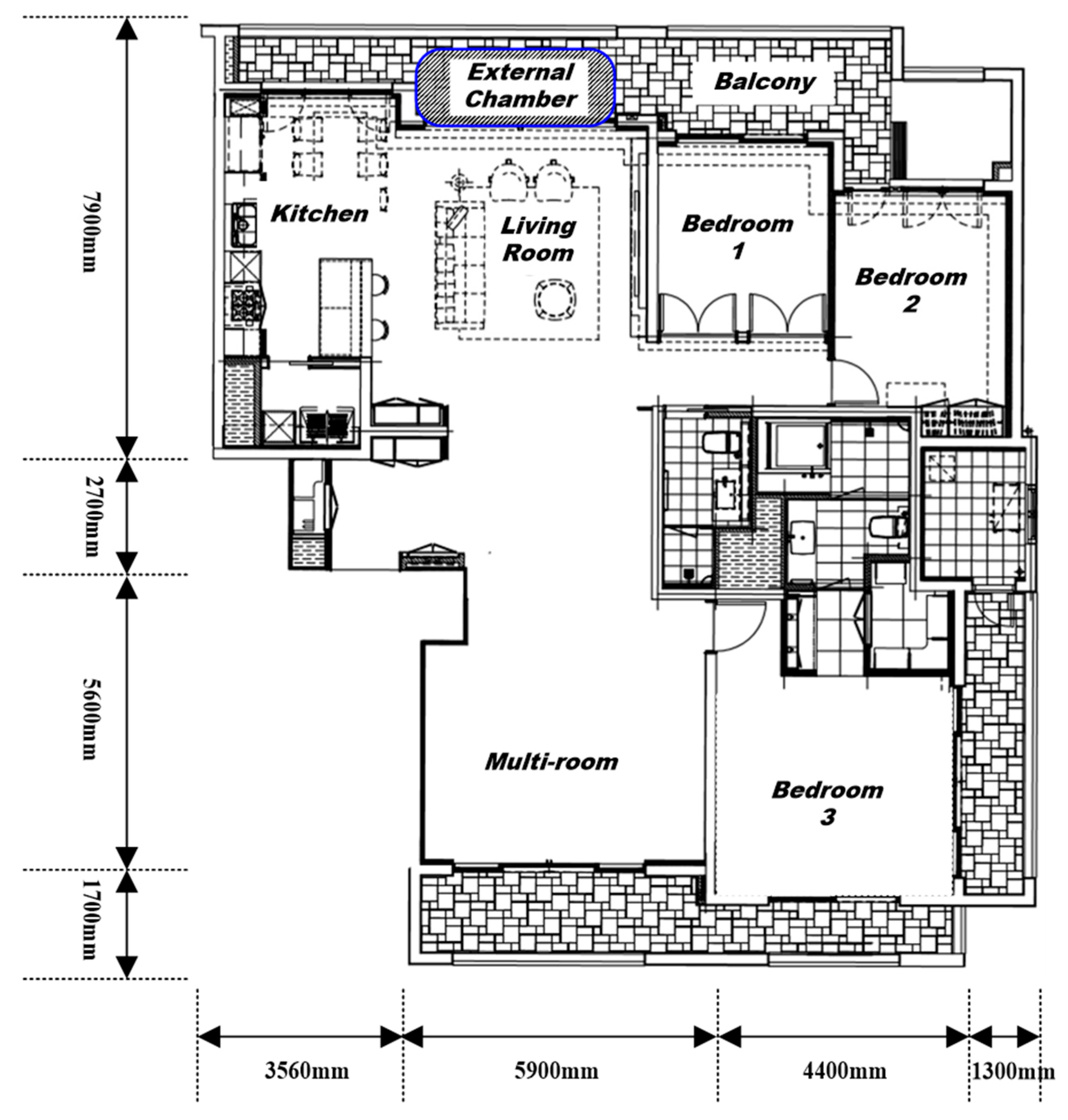

2.1. The Study Building

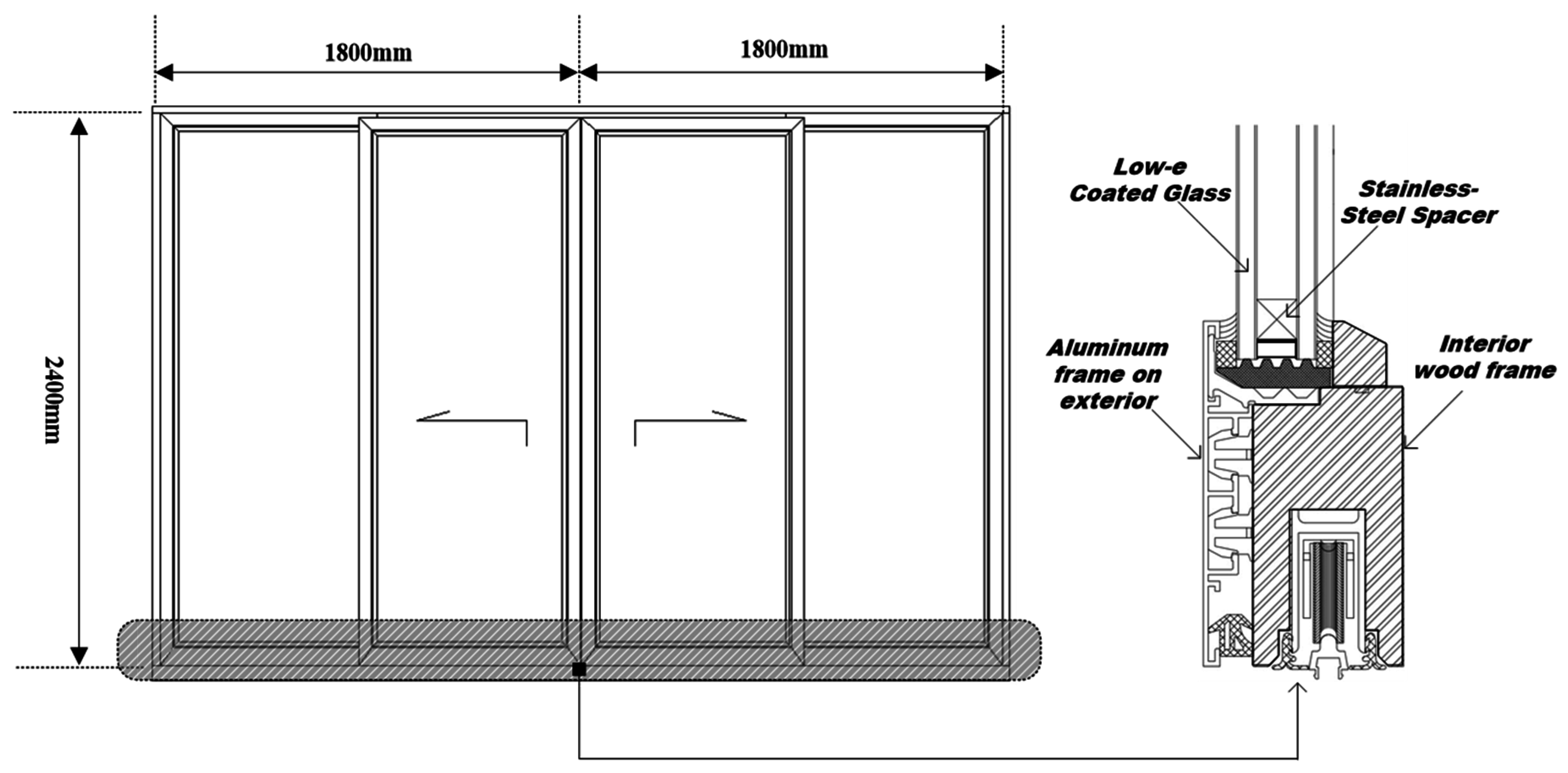

2.2. Window System

2.3. Measurement Setup

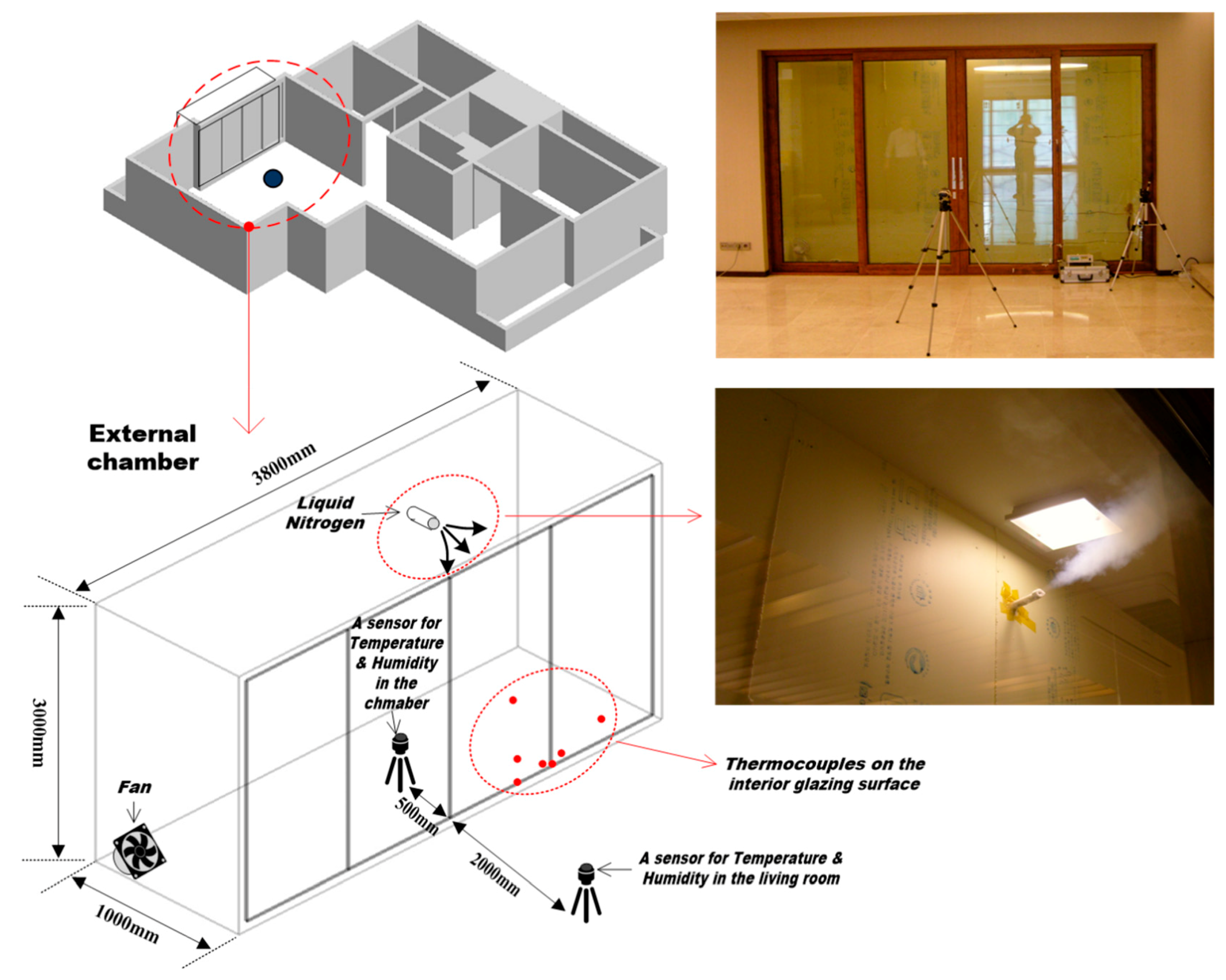

2.3.1. External Chamber

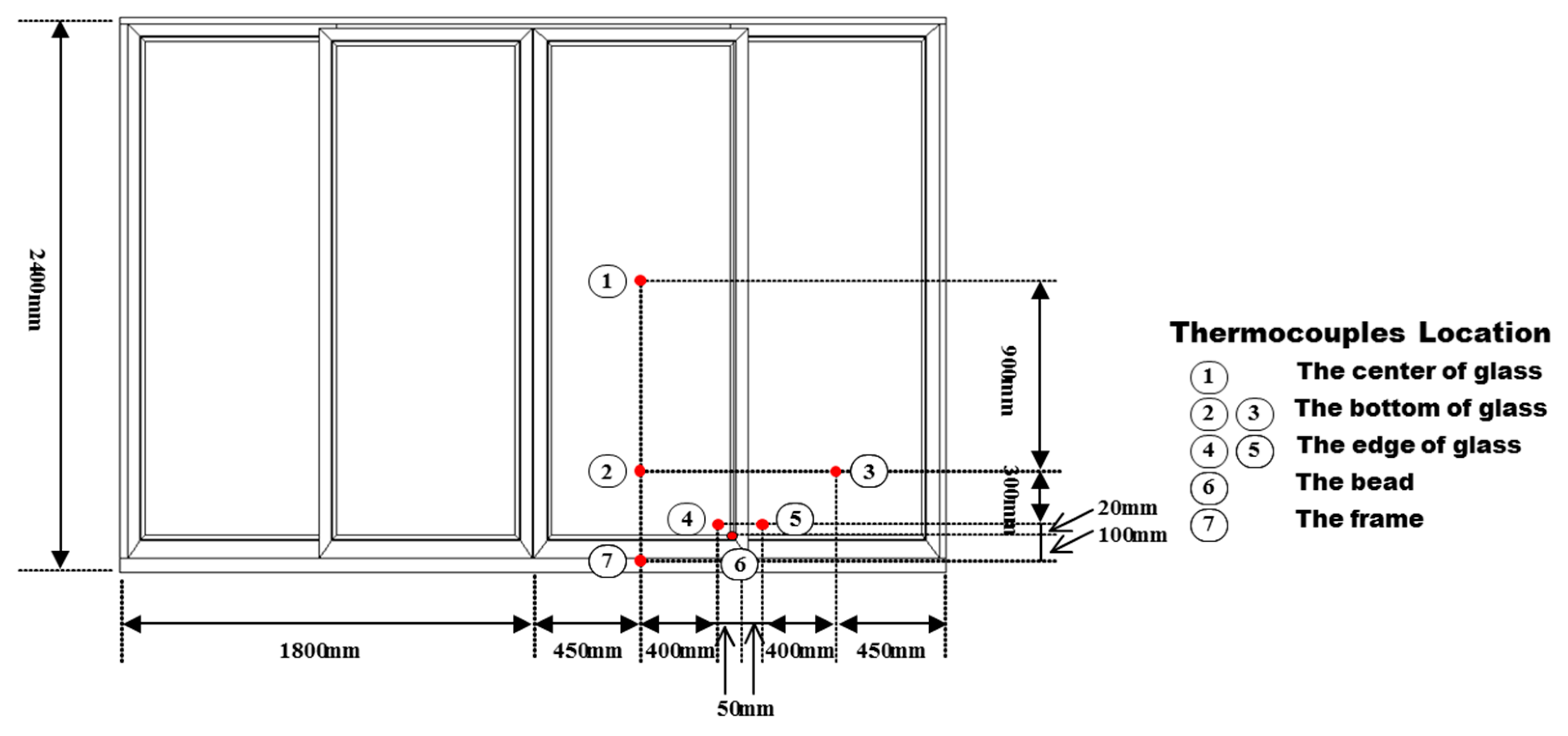

2.3.2. The Location of Sensors

2.4. Other Measurement Conditions

2.5. Simulation for the Thermal Performance of Window Systems

3. Results and Discussion

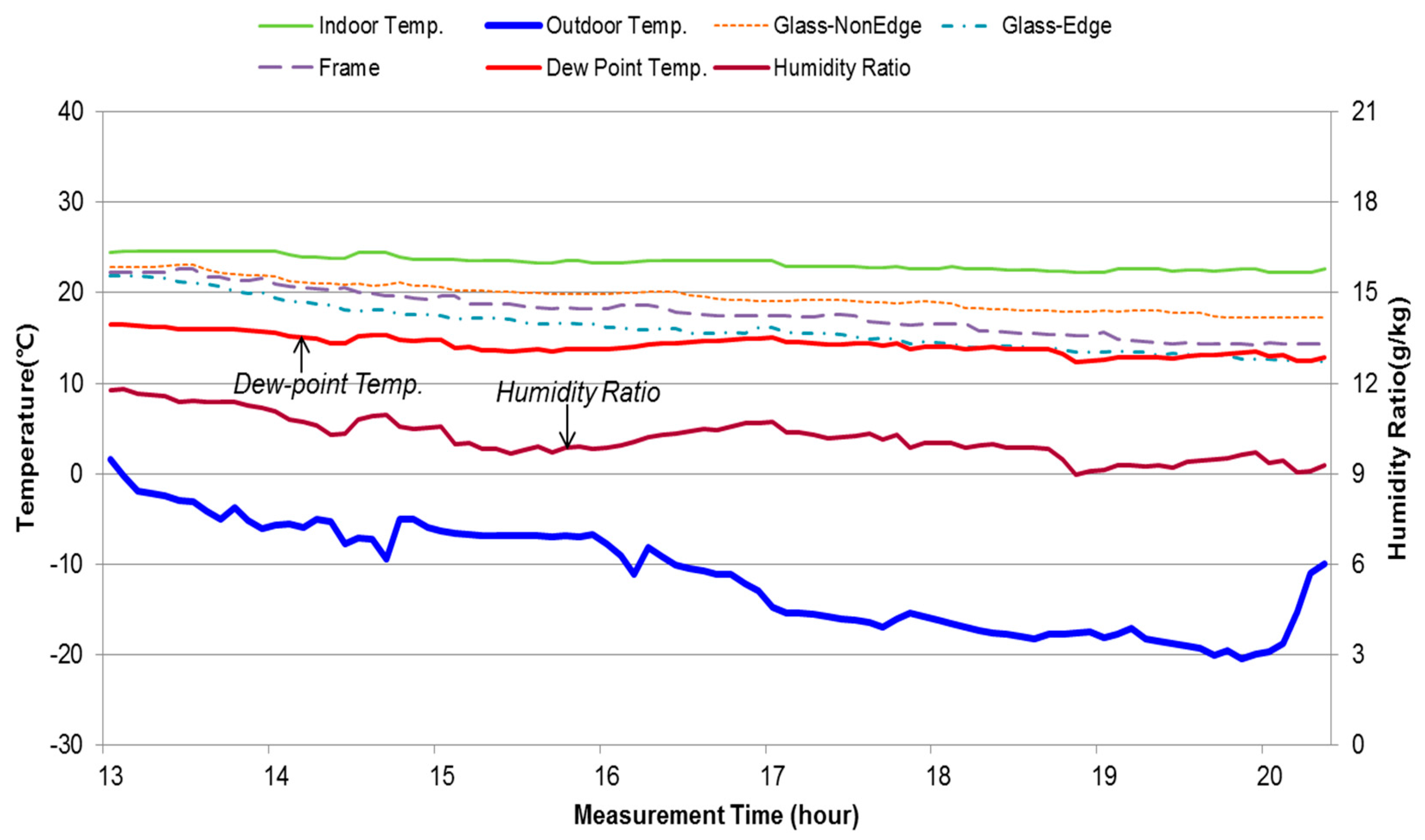

3.1. Measured Temperature and Relative Humidity

3.2. Occurrence of Condensation under the Various Temperature Conditions in the Chamber

3.3. Occurrence of Condensation with the Increased Indoor Humidity

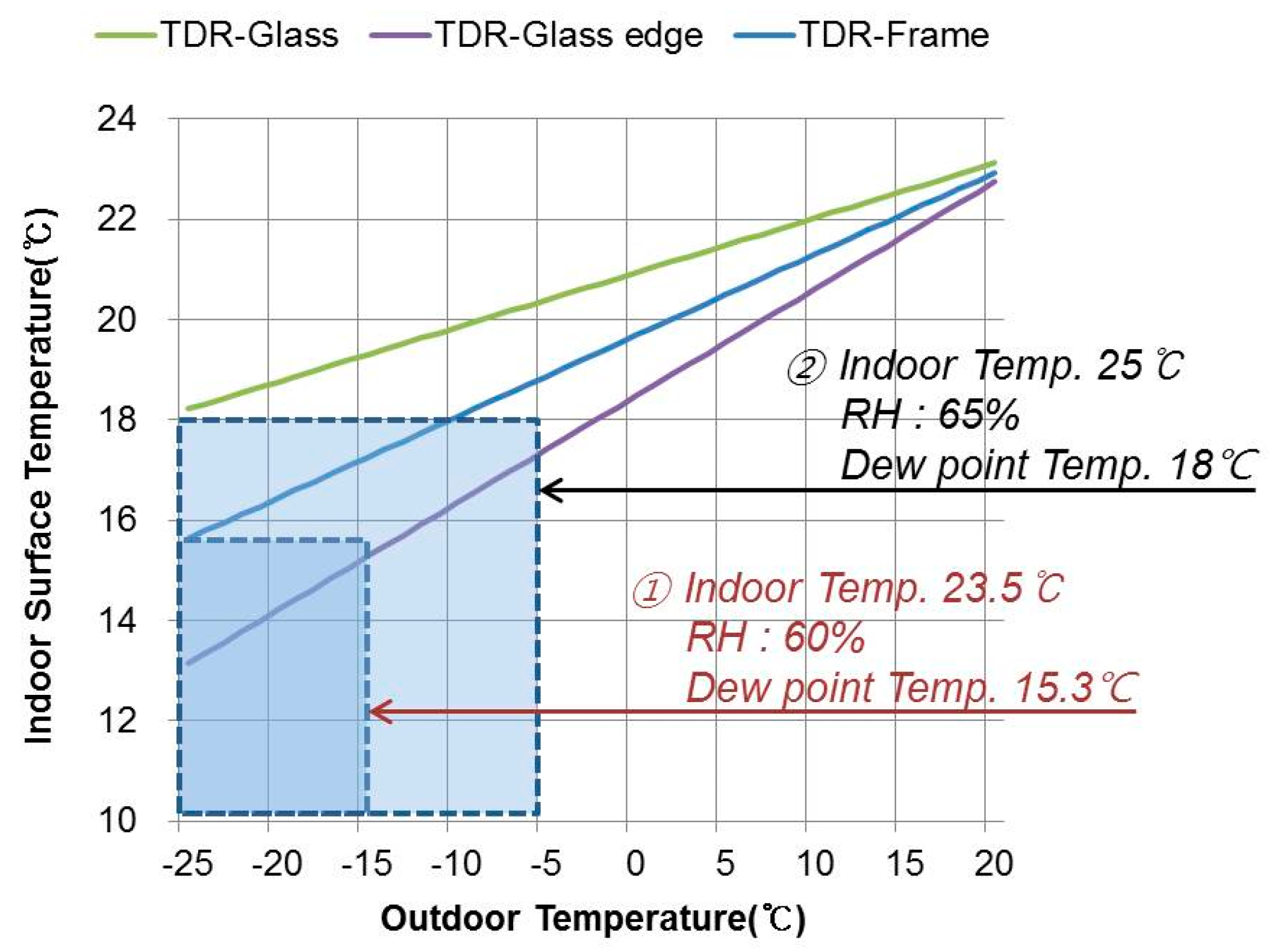

3.4. Estimation of the Occurrence of Condensation through TDR Analysis

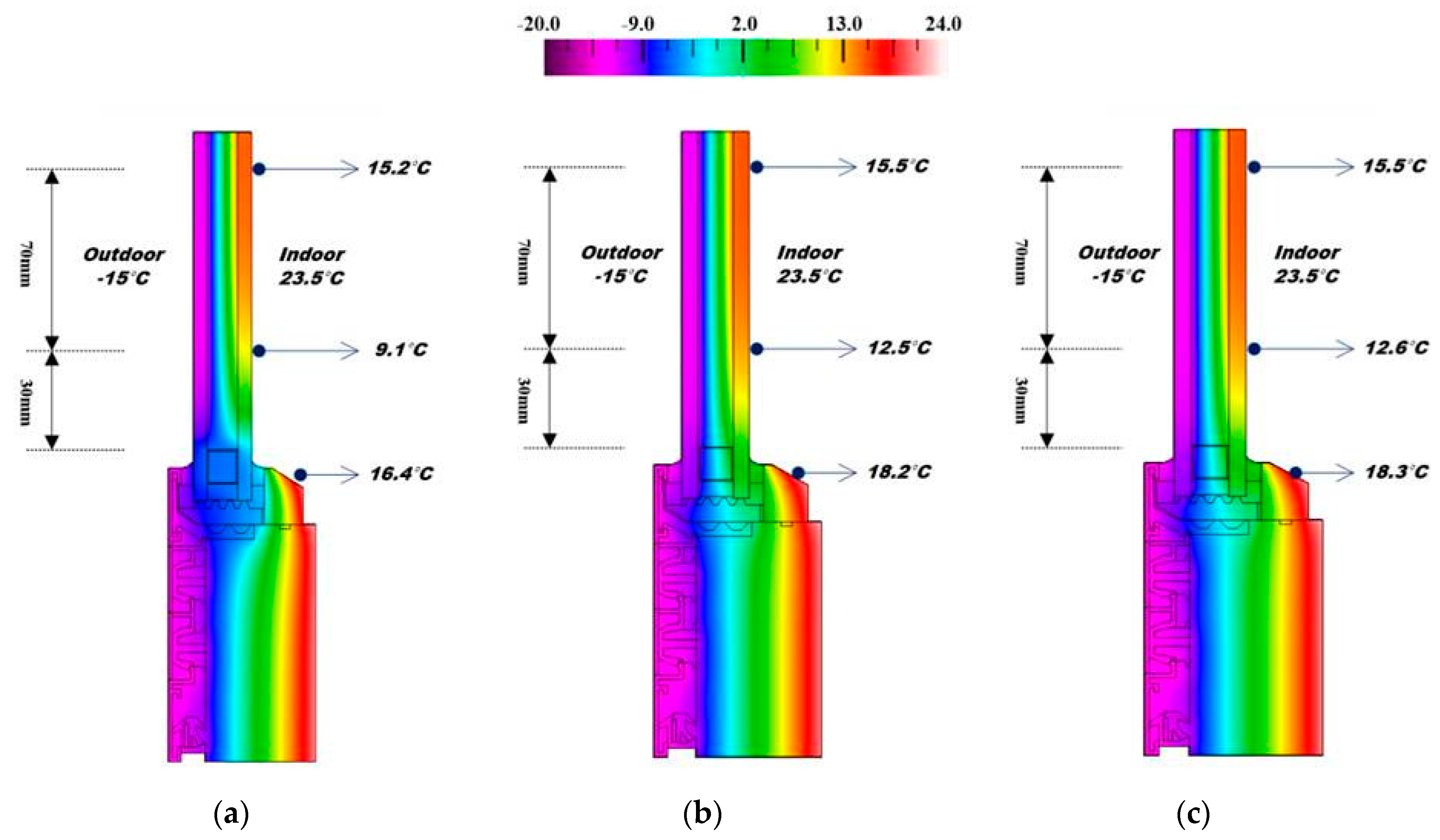

3.5. Simulation Results with the Window System and Various Spacers

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Manz, H. Total solar energy transmittance of glass double façades with free convection. Energy Build. 2004, 36, 127–136. [Google Scholar] [CrossRef]

- Goia, F.; Time, B.; Gustavsen, A. Impact of Opaque Building Envelope Configuration on the Heating and Cooling Energy Need of a Single Family House in Cold Climates. Energy Procedia 2015, 78, 2626–2631. [Google Scholar] [CrossRef] [Green Version]

- Ferdyn-Grygierek, J. Indoor environment quality in the museum building and its effect on heating and cooling demand. Energy Build. 2014, 85, 32–44. [Google Scholar] [CrossRef]

- Song, S.-Y.; Jo, J.-H.; Yeo, M.-S.; Kim, Y.-D.; Song, K.-D. Evaluation of inside surface condensation in double glazing window system with insulation spacer: A case study of residential complex. Build. Environ. 2007, 42, 940–950. [Google Scholar] [CrossRef]

- Yoo, S.; Jeong, H.; Ahn, B.-L.; Han, H.; Seo, D.; Lee, J.; Jang, C.-Y. Thermal transmittance of window systems and effects on building heating energy use and energy efficiency ratings in South Korea. Energy Build. 2013, 67, 236–244. [Google Scholar] [CrossRef]

- Li, C.; Tan, J.; Chow, T.-T.; Qiu, Z. Experimental and theoretical study on the effect of window films on building energy consumption. Energy Build. 2015, 102, 129–138. [Google Scholar] [CrossRef]

- Kucukpinar, E.; Miesbauer, O.; Carmi, Y.; Fricke, M.; Gullberg, L.; Erkey, C.; Caps, R.; Rochefort, M.; Moreno, A.G.; Delgado, C.; et al. Development of Transparent and Opaque Vacuum Insulation Panels for Energy Efficient Buildings. Energy Procedia 2015, 78, 412–417. [Google Scholar] [CrossRef]

- Lolli, N.; Andresen, I. Aerogel vs. argon insulation in windows: A greenhouse gas emissions analysis. Build. Environ. 2016, 101, 64–76. [Google Scholar] [CrossRef]

- Kim, S.-H.; Kim, S.-S.; Kim, K.-W.; Cho, Y.-H. A study on the proposes of energy analysis indicator by the window elements of office buildings in Korea. Energy Build. 2014, 73, 153–165. [Google Scholar] [CrossRef]

- Hassouneh, K.; Alshboul, A.; Al-Salaymeh, A. Influence of windows on the energy balance of apartment buildings in Amman. Energy Convers. Manag. 2010, 51, 1583–1591. [Google Scholar] [CrossRef]

- Alawadhi, E.M. Effect of an incompletely closed window shutter on indoor illuminance level and heat gain. Energy Build. 2016, 110, 112–119. [Google Scholar] [CrossRef]

- Gao, T.; Ihara, T.; Grynning, S.; Jelle, B.P.; Lien, A.G. Perspective of aerogel glazings in energy efficient buildings. Build. Environ. 2016, 95, 405–413. [Google Scholar] [CrossRef]

- Moon, H.J.; Ryu, S.H.; Kim, J.T. The effect of moisture transportation on energy efficiency and IAQ in residential buildings. Energy Build. 2014, 75, 439–446. [Google Scholar] [CrossRef]

- Bellia, L.; Minichiello, F. A simple evaluator of building envelope moisture condensation according to an European Standard. Build. Environ. 2003, 38, 457–468. [Google Scholar] [CrossRef]

- Kim, J.; Kim, T.; Leigh, S.-B. Double window system with ventilation slits to prevent window surface condensation in residential buildings. Energy Build. 2011, 43, 3120–3130. [Google Scholar] [CrossRef]

- Park, S.H.; Chung, W.J.; Yeo, M.S.; Kim, K.W. Evaluation of the thermal performance of a Thermally Activated Building System (TABS) according to the thermal load in a residential building. Energy Build. 2014, 73, 69–82. [Google Scholar] [CrossRef]

- Lim, J.-H.; Song, J.-H.; Song, S.-Y. Development of operational guidelines for thermally activated building system according to heating and cooling load characteristics. Appl. Energy 2014, 126, 123–135. [Google Scholar] [CrossRef]

- Choi, J.; Chun, C.; Sun, Y.; Choi, Y.; Kwon, S.; Bornehag, C.G.; Sundell, J. Associations between building characteristics and children’s allergic symptoms—A cross-sectional study on child's health and home in Seoul, South Korea. Build. Environ. 2014, 75, 176–181. [Google Scholar] [CrossRef]

- Ge, H.; McClung, V.R.; Zhang, S. Impact of balcony thermal bridges on the overall thermal performance of multi-unit residential buildings: A case study. Energy Build. 2013, 60, 163–173. [Google Scholar] [CrossRef]

- Kočí, V.; Maděra, J.; Černý, R. Exterior thermal insulation systems for AAC building envelopes: Computational analysis aimed at increasing service life. Energy Build. 2012, 47, 84–90. [Google Scholar] [CrossRef]

- Desta, T.Z.; Langmans, J.; Roels, S. Experimental data set for validation of heat, air and moisture transport models of building envelopes. Build. Environ. 2011, 46, 1038–1046. [Google Scholar] [CrossRef]

- Harrestrup, M.; Svendsen, S. Full-scale test of an old heritage multi-storey building undergoing energy retrofitting with focus on internal insulation and moisture. Build. Environ. 2015, 85, 123–133. [Google Scholar] [CrossRef]

- Gläser, H.J.; Ulrich, S. Condensation on the outdoor surface of window glazing—Calculation methods, key parameters and prevention with low-emissivity coatings. Thin Solid Films 2013, 532, 127–131. [Google Scholar] [CrossRef]

- Werner, A.; Roos, A. Condensation tests on glass samples for energy efficient windows. Sol. Energy Mater. Sol. Cells 2007, 91, 609–615. [Google Scholar] [CrossRef]

- Van Den Bossche, N.; Buffel, L.; Janssens, A. Thermal Optimization of Window Frames. Energy Procedia 2015, 78, 2500–2505. [Google Scholar] [CrossRef]

- Van Den Bergh, S.; Hart, R.; Jelle, B.P.; Gustavsen, A. Window spacers and edge seals in insulating glass units: A state-of-the-art review and future perspectives. Energy Build. 2013, 58, 263–280. [Google Scholar] [CrossRef]

- Mankibi, M.E.; Cantin, R.; Zoubir, A. Contribution to the Thermal Renovation of Old Buildings: Numerical and Experimental Approach for Characterizing a Double Window. Energy Procedia 2015, 78, 2470–2475. [Google Scholar] [CrossRef]

| The Window System | Values |

|---|---|

| U-factor of the window (W/m2·K) | 1.90 |

| Area of glazing (m2) | 7.28 |

| Area of frame (m2) | 1.36 |

| U-factor of the double glazing with low-e coating (W/m2·K) | 1.56 |

| Solar heat gain coefficient (SHGC) | 0.65 |

| Shading coefficient (SC) | 0.75 |

| Visible light transmission (VLT) (%) | 77.6 |

| Condition | First Day | Second Day | Third Day | Fourth Day |

|---|---|---|---|---|

| Indoor | 22 °C 30% | 23 °C–24 °C 50%–60% | 23 °C–24 °C 55%–60% | 23 °C–24 °C 60%–65% |

| Chamber (Outdoor) | 15 °C | −8 °C | −15 °C, −18 °C, −20 °C | −18 °C to −20 °C |

| Part | Conditions |

|---|---|

| Indoor Temperature | 23.5 °C |

| Inside Film Coefficient | 3.0 W/m2·K |

| Outdoor Temperature | −15 °C, −18 °C, −20 °C |

| Outside Film Coefficient | 24.0 W/m2·K |

| Glass cutting plane | Adiabatic |

| Spacer | Stainless steel |

| Outdoor Temp. (°C) | −15 | −18 | −20 |

|---|---|---|---|

| Glass-edge (°C) | 14.4–15.6 | 13.5–14.1 | 12.5–13.5 |

| Glass (°C) | 18.8–19.1 | 17.9–18.3 | 17.2–17.8 |

| Frame (°C) | 16.6–17.6 | 14.8–15.8 | 14.4–14.6 |

| Outdoor Temp. (°C) | −15 | −18 | −20 | |||

|---|---|---|---|---|---|---|

| Measured | Simulated | Measured | Simulated | Measured | Simulated | |

| Glass-edge (°C) | 14.4–15.6 | 10.0 | 13.5–14.1 | 8.9 | 12.5–13.5 | 8.2 |

| Glass (°C) | 18.8–19.1 | 15.3 | 17.9–18.3 | 14.6 | 17.2–17.8 | 14.2 |

| Frame (°C) | 16.6–17.6 | 16.8 | 14.8–15.8 | 16.3 | 14.4–14.6 | 16.0 |

| Spacer | Value (W/m·K) |

|---|---|

| Steel-Stainless | 17 |

| Aluminum | 160 |

| Thermally broken | 0.20 |

| Thick-walled plastic | 0.16 |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hong, G.; Kim, D.D.; Kim, B.S. Experimental Investigation of Thermal Behaviors in Window Systems by Monitoring of Surface Condensation Using Full-Scale Measurements and Simulation Tools. Energies 2016, 9, 979. https://doi.org/10.3390/en9110979

Hong G, Kim DD, Kim BS. Experimental Investigation of Thermal Behaviors in Window Systems by Monitoring of Surface Condensation Using Full-Scale Measurements and Simulation Tools. Energies. 2016; 9(11):979. https://doi.org/10.3390/en9110979

Chicago/Turabian StyleHong, Goopyo, Daeung Danny Kim, and Byungseon Sean Kim. 2016. "Experimental Investigation of Thermal Behaviors in Window Systems by Monitoring of Surface Condensation Using Full-Scale Measurements and Simulation Tools" Energies 9, no. 11: 979. https://doi.org/10.3390/en9110979