Suitability Assessment of an ICE-Based Micro-CCHP Unit in Different Spanish Climatic Zones: Application of an Experimental Model in Transient Simulation

Abstract

:1. Introduction

2. Methodology

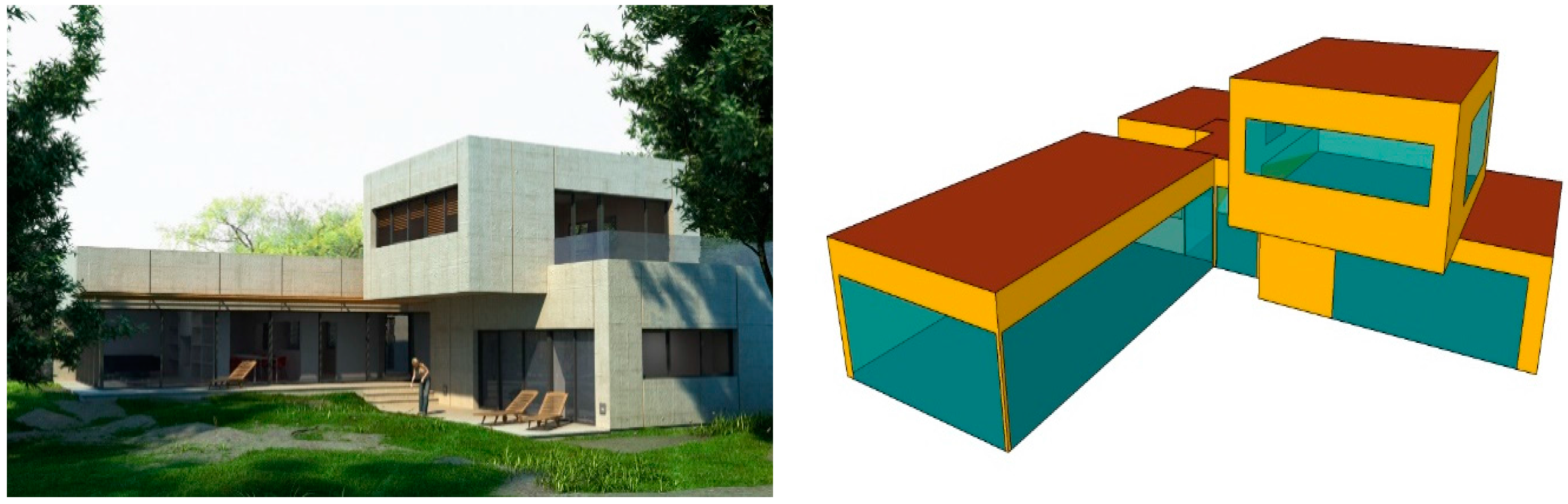

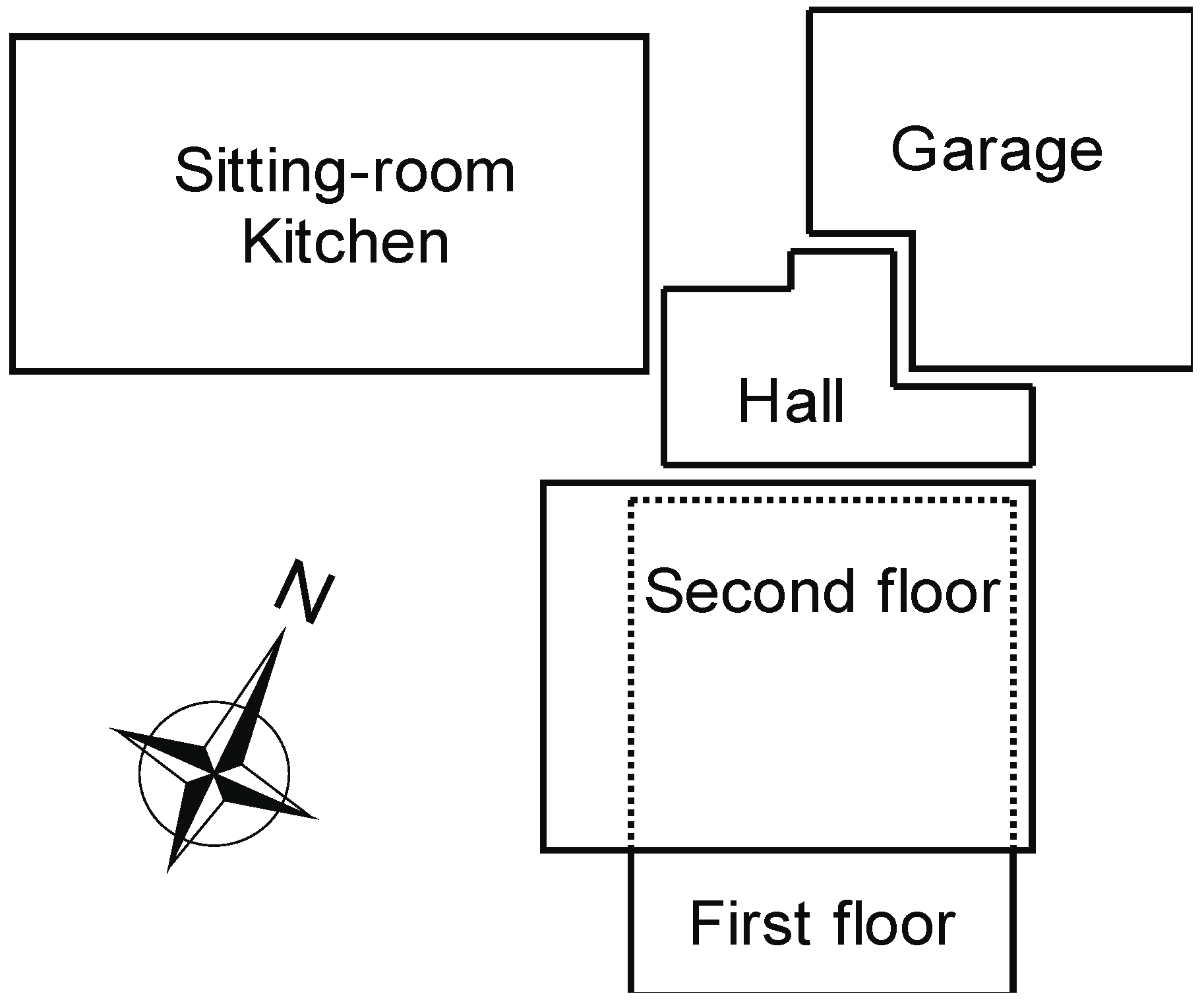

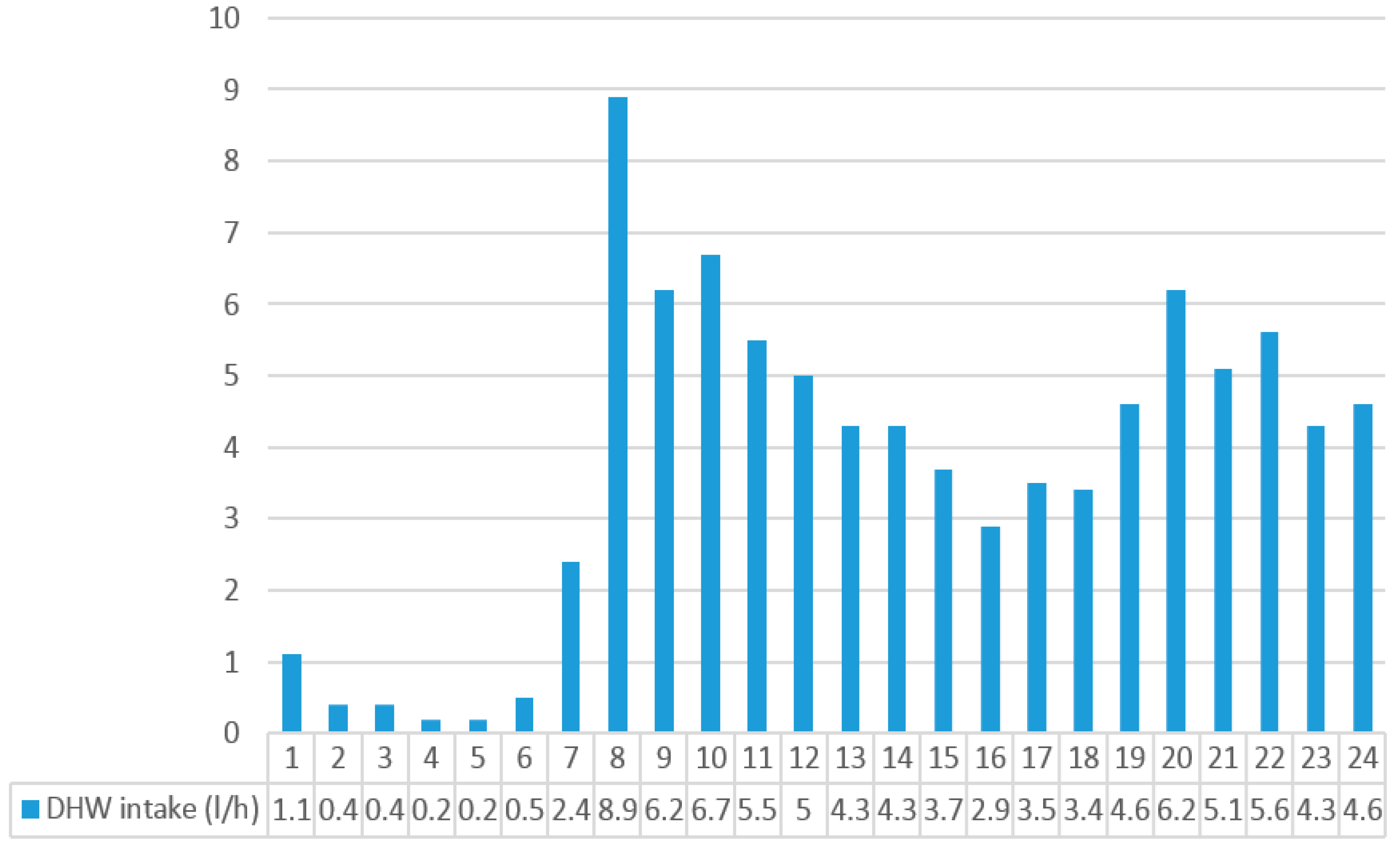

2.1. Building Description, Energy Demands and Climate Conditions

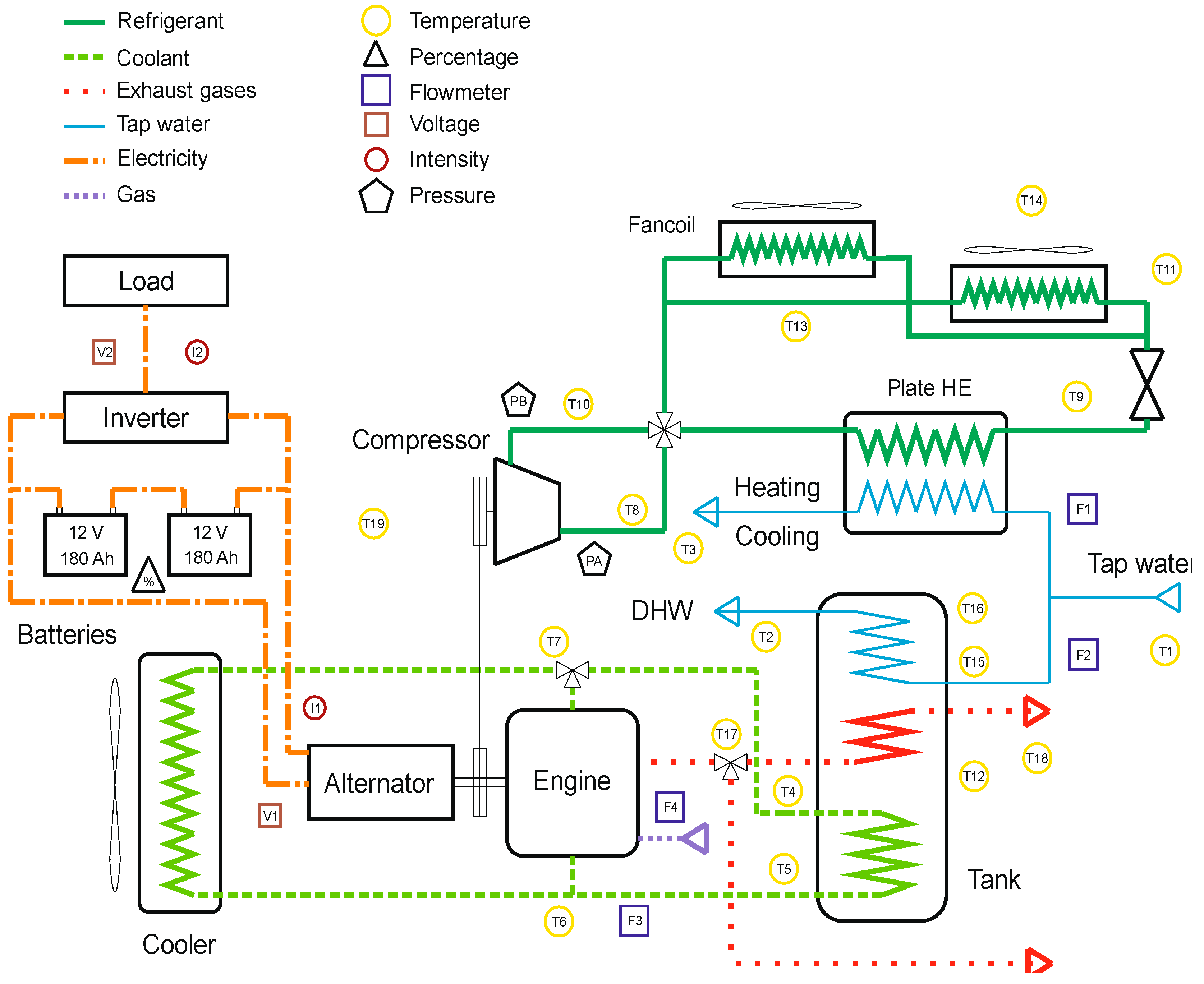

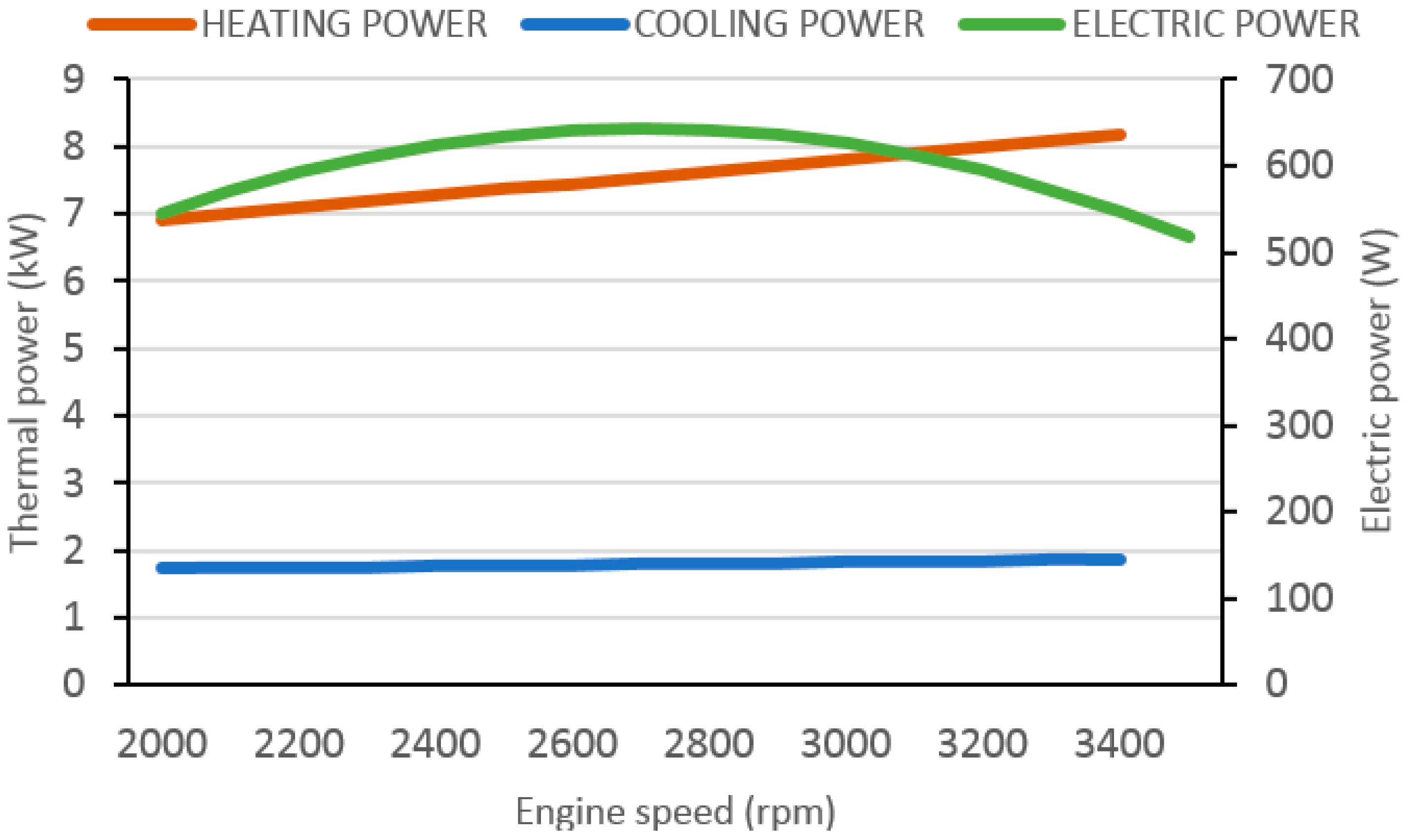

2.2. Micro-CCHP System Description and Performance

2.3. TRNSYS Simulation

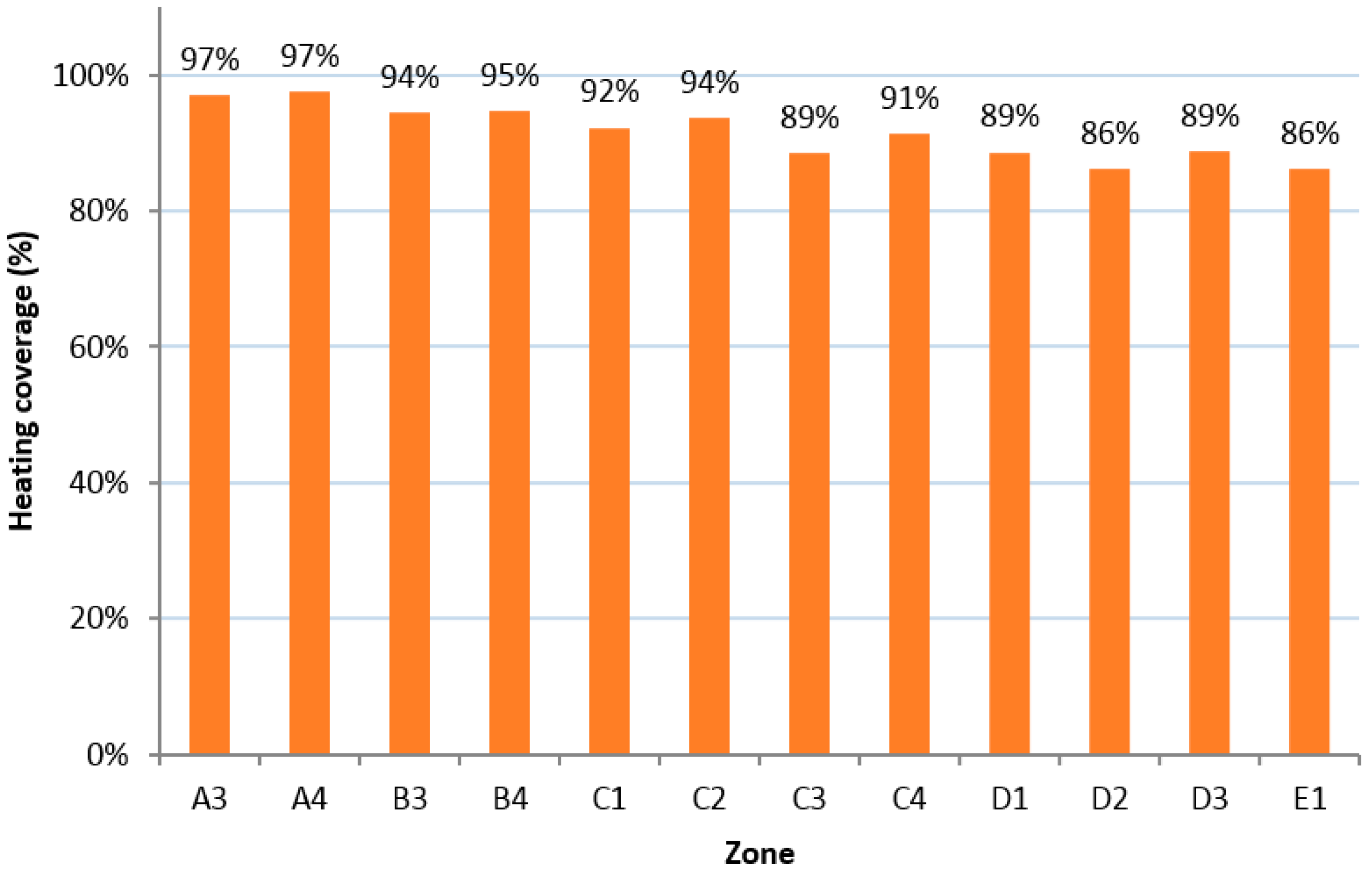

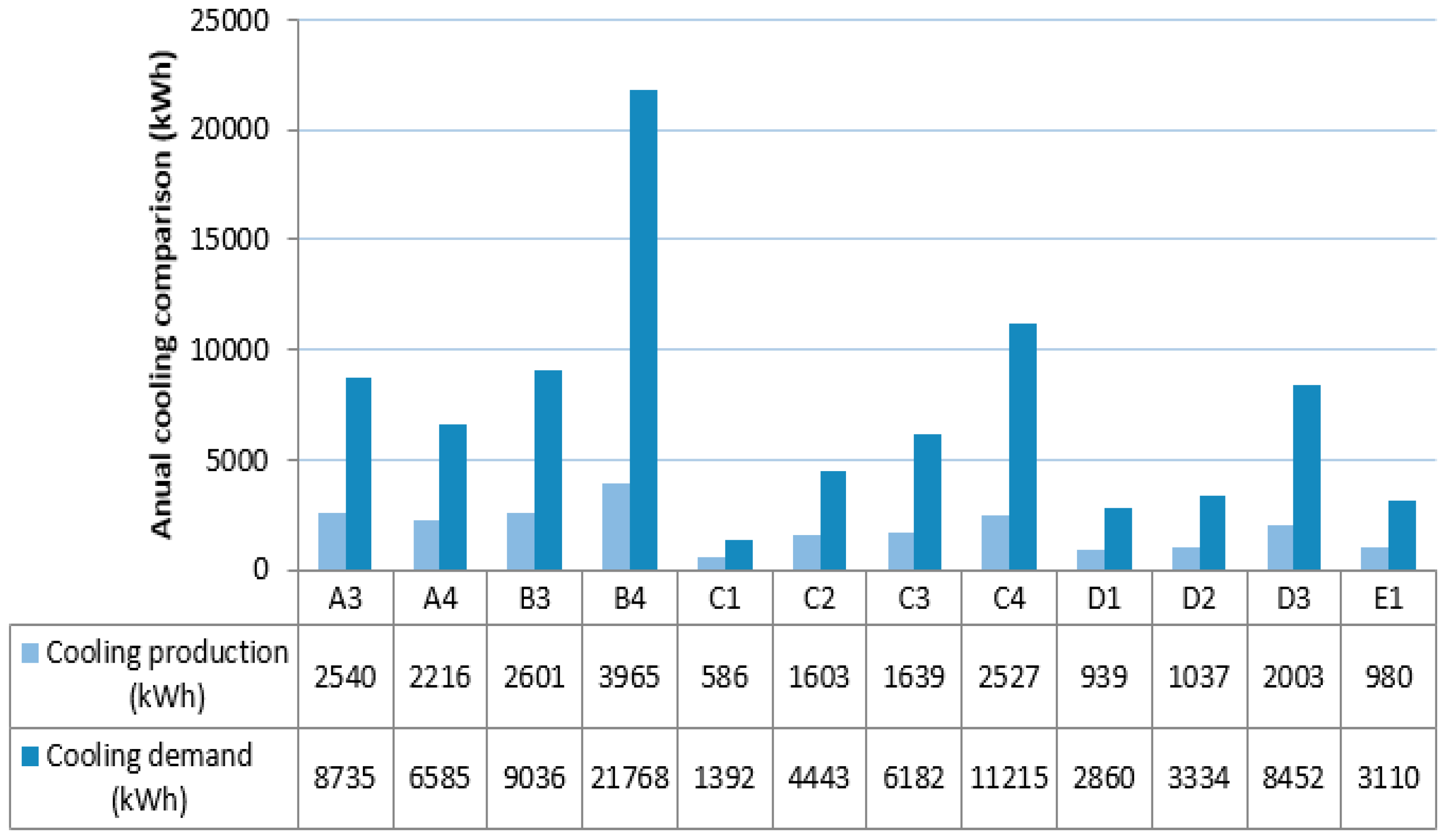

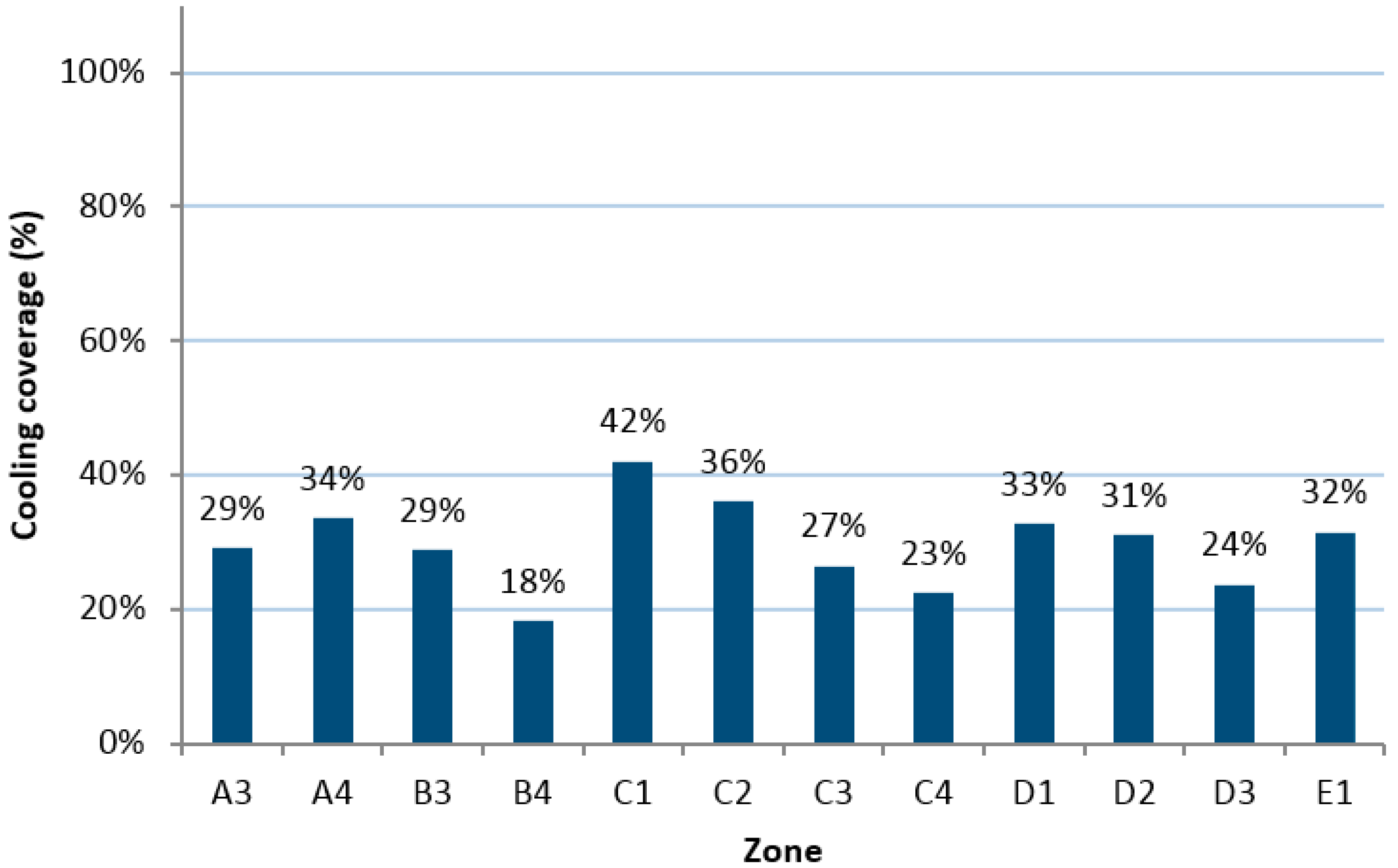

3. Results

Heating and Cooling Demand and Production

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Chesi, A.; Ferrara, G.; Ferrari, L.; Magnani, S.; Tarani, F. Influence of the heat storage size on the plant performance in a smart user case study. Appl. Energy 2013, 112, 1454–1465. [Google Scholar] [CrossRef]

- Barbieri, E.S.; Melino, F.; Morini, M. Influence of the thermal energy storage on the profitability of micro-CHP systems for residential building applications. Appl. Energy 2012, 97, 714–722. [Google Scholar] [CrossRef]

- Monteiro, E.; Moreira, N.A.; Ferreira, S. Planning of micro-combined heat and power systems in the Portuguese scenario. Appl. Energy 2009, 86, 290–298. [Google Scholar] [CrossRef]

- Campos Celador, A.; Erkoreka, A.; Martin Escudero, K.; Sala, J. Feasibility of small-scale gas engine-based residential cogeneration in Spain. Energy Policy 2011, 39, 3813–3821. [Google Scholar] [CrossRef]

- Wu, D.; Wang, R. Combined cooling, heating and power: A review. Prog. Energy Combust. Sci. 2006, 32, 459–495. [Google Scholar] [CrossRef]

- Cho, H.; Smith, A.D.; Mago, P. Combined cooling, heating and power: A review of performance improvement and optimization. Appl. Energy 2014, 136, 168–185. [Google Scholar] [CrossRef]

- Mıguez, J.; Murillo, S.; Porteiro, J.; López, L. Feasibility of a new domestic CHP trigeneration with heat pump: I. Design and development. Appl. Therm. Eng. 2004, 24, 1409–1419. [Google Scholar] [CrossRef]

- Porteiro, J.; Mıguez, J.; Murillo, S.; López, L. Feasibility of a new domestic CHP trigeneration with heat pump: II. Availability analysis. Appl. Therm. Eng. 2004, 24, 1421–1429. [Google Scholar] [CrossRef]

- Jradi, M.; Riffat, S. Tri-generation systems: Energy policies, prime movers, cooling technologies, configurations and operation strategies. Renew. Sustain. Energy Rev. 2014, 32, 396–415. [Google Scholar] [CrossRef]

- Chen, X.; Gong, G.; Wan, Z.; Luo, L.; Wan, J. Performance analysis of 5 kW PEMFC-based residential micro-CCHP with absorption chiller. Int. J. Hydrog. Energy 2015, 40, 10647–10657. [Google Scholar] [CrossRef]

- Wu, J.; Wang, J.; Li, S.; Wang, R. Experimental and simulative investigation of a micro-CCHP (micro combined cooling, heating and power) system with thermal management controller. Energy 2014, 68, 444–453. [Google Scholar] [CrossRef]

- Horvath, C.; Hwang, Y.; Radermacher, R.; Gerstler, W.; Tang, C. Waste heat and electrically driven hybrid cooling systems for a high ambient temperature, off-grid application. Energy 2014, 66, 711–721. [Google Scholar] [CrossRef]

- Klein, S.A.; Beckman, W.A.; Mitchell, J.W.; Duffie, J.A.; Duffie, N.A.; Freeman, T.L.; Mitchell, J.C.; Braun, J.E.; Evans, B.L.; Kummer, J.P.; et al. TRNSYS 16–A TRaNsient System Simulation Program, User Manual; Solar Energy Laboratory, University of Wisconsin-Madison: Madison, WI, USA, 2004. [Google Scholar]

- Mago, P.; Chamra, L.; Ramsay, J. Micro-combined cooling, heating and power systems hybrid electric-thermal load following operation. Appl. Therm. Eng. 2010, 30, 800–806. [Google Scholar] [CrossRef]

- Han, G.; You, S.; Ye, T.; Sun, P.; Zhang, H. Analysis of combined cooling, heating, and power systems under a compromised electric–thermal load strategy. Energy Build. 2014, 84, 586–594. [Google Scholar] [CrossRef]

- Zheng, C.; Wu, J.; Zhai, X. A novel operation strategy for CCHP systems based on minimum distance. Appl. Energy 2014, 128, 325–335. [Google Scholar] [CrossRef]

- Li, L.; Mu, H.; Li, N.; Li, M. Analysis of the integrated performance and redundant energy of CCHP systems under different operation strategies. Energy Build. 2015, 99, 231–242. [Google Scholar] [CrossRef]

- Wang, J.; Jing, Y.; Zhang, C.; Zhai, Z.J. Performance comparison of combined cooling heating and power system in different operation modes. Appl. Energy 2011, 88, 4621–4631. [Google Scholar] [CrossRef]

- Mago, P.J.; Hueffed, A.K. Evaluation of a turbine driven CCHP system for large office buildings under different operating strategies. Energy Build. 2010, 42, 1628–1636. [Google Scholar] [CrossRef]

- Askari, I.B.; Sadegh, M.O.; Ameri, M. Effect of heat storage and fuel price on energy management and economics of micro CCHP cogeneration systems. J. Mech. Sci. Technol. 2014, 28, 2003–2014. [Google Scholar] [CrossRef]

- Wang, J.; Wu, J.; Zheng, C. Simulation and evaluation of a CCHP system with exhaust gas deep-recovery and thermoelectric generator. Energy Convers. Manag. 2014, 86, 992–1000. [Google Scholar] [CrossRef]

- Ulloa, C.; Porteiro, J.; Eguía, P.; Pousada-Carballo, J.M. Application model for a stirling engine micro-generation system in caravans in different European locations. Energies 2013, 6, 717–732. [Google Scholar] [CrossRef]

- Ulloa, C.; Eguía, P.; Miguez, J.L.; Porteiro, J.; Pousada-Carballo, J.M.; Cacabelos, A. Feasibility of using a stirling engine-based micro-CHP to provide heat and electricity to a recreational sailing boat in different European ports. Appl. Therm. Eng. 2013, 59, 414–424. [Google Scholar] [CrossRef]

- Spanish Technical Building Code, Basic Document HE 1: Energy Demand: Characteristic Parameters of the Envelope; Ministry of Development, Spanish Government: Madrid, Spain, 2013.

- Spanish Technical Building Code, Reference Climates Descriptive Document; Ministry of Development, Spanish Government: Madrid, Spain, 2015.

- González-Pino, I.; Campos-Celador, A.; Pérez-Iribarren, E.; Terés-Zubiaga, J.; Sala, J. Parametric study of the operational and economic feasibility of stirling micro-cogeneration devices in Spain. Appl. Therm. Eng. 2014, 71, 821–829. [Google Scholar] [CrossRef]

- Global Meteorological Database for Solar Application and System Design, version 7; Meteonorm: Bern, Switzerland, 2015.

- Energy Rating of Existing Buildings Technical Handbook; Institute for Energy Diversification and Saving (IDEA), Spanish Government: Madrid, Spain, 2015.

- Spanish Technical Building Code, Basic Document HE 4: Energy Savings; Ministry of Development, Spanish Government: Madrid, Spain, 2013.

- Conditions of Acceptance of Alternative Procedures to LIDER and CALENER. Available online: http://www.minetur.gob.es/energia/desarrollo/EficienciaEnergetica/CertificacionEnergetica/DocumentosReconocidos/OtrosDocumentos/Calificaci%C3%B3n%20energ%C3%A9tica.%20Viviendas/Guia-8_Condiciones_Alternativos.pdf (accessed on 16 September 2015).

- Conditions of Acceptance of Alternative Procedures to LIDER and CALENER. Annexes. Available online: http://www.minetur.gob.es/energia/desarrollo/EficienciaEnergetica/CertificacionEnergetica/DocumentosReconocidos/OtrosDocumentos/Calificaci%C3%B3n%20energ%C3%A9tica.%20Viviendas/Cond_acept_anexos.pdf (accessed on 16 September 2015).

- National Energy Efficiency Action Plan 2011–2020; Institute for Energy Diversification and Saving (IDAE), Spanish Government: Madrid, Spain, 2011.

- Spanish Technical Building Code, Basic Document HS; Ministry of Development, Spanish Government: Madrid, Spain, 2015.

- Institute for Energy Diversification and Saving (IDAE). Technical Guide Central DHW; Industry, Tourism and Trade, Spanish Government: Madrid, Spain, 2010.

- Institute for Energy Diversification and Saving (IDAE). SECH-SPAHOUSEC Project: Analysis of the Energy Consumption in the Spanish Households; Final Report; Ministry of Industry, Tourism and Trade, Spanish Government: Madrid, Spain, 2011.

- REE, Spanish Electricity Grid. Available online: http://www.ree.es (accessed on 16 September 2015).

- Rey, G.; Ulloa, C.; Cacabelos, A.; Barragáns, B. Performance analysis, model development and validation with experimental data of an ICE-based micro-CCHP system. Appl. Therm. Eng. 2015, 76, 233–244. [Google Scholar] [CrossRef]

- DKV, Deutscher Kälte- und Klimatechnischer Verein e.V. Available online: http://www.dkv.org (accessed on 11 November 2016).

| Dwelling Geometrical Parameter | Value |

|---|---|

| Gross Volume of Heated Rooms (V) | 779.67 m3 |

| External surface (S) | 655.36 m2 |

| Ratio S/V | 1.19 |

| Internal surface (Su) | 97.22 m2 |

| External glazing | 128.26 m2 |

| Transmittance (W/m2·K) | Thickness (m) | |

|---|---|---|

| External wall | 0.37 | 0.65 |

| Ground floor | 0.43 | 0.65 |

| Roof | 0.39 | 0.39 |

| Internal wall | 0.12 | 0.12 |

| Adjacent ceiling | 0.59 | 0.32 |

| Windows | 2.76 | - |

| 1 | 2 | 3 | 4 | |

|---|---|---|---|---|

| A | Málaga | Almería | ||

| B | Castellón | Córdoba | ||

| C | Bilbao | Barcelona | Granada | Jaén |

| D | Pamplona | Valladolid | Albacete | |

| E | León |

| Climatic Zone | City | Jan. | Feb. | Mar. | Apr. | May | Jun. | Jul. | Aug. | Sep. | Oct. | Nov. | Dec. | Annual |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| A3 | Málaga | 11 | 12 | 13 | 14 | 16 | 18 | 20 | 20 | 19 | 16 | 13 | 12 | 15 |

| A4 | Almería | 12 | 12 | 13 | 14 | 16 | 18 | 20 | 21 | 19 | 17 | 14 | 12 | 16 |

| B3 | Castellón | 10 | 11 | 12 | 13 | 15 | 18 | 19 | 20 | 18 | 16 | 11 | 12 | 15 |

| B4 | Córdoba | 10 | 11 | 12 | 14 | 16 | 19 | 21 | 21 | 19 | 16 | 12 | 10 | 15 |

| C1 | Bilbao | 9 | 10 | 10 | 11 | 13 | 15 | 17 | 17 | 16 | 14 | 11 | 10 | 13 |

| C2 | Barcelona | 9 | 10 | 11 | 12 | 14 | 17 | 19 | 19 | 17 | 15 | 12 | 10 | 14 |

| C3 | Granada | 8 | 9 | 10 | 12 | 14 | 17 | 20 | 19 | 17 | 14 | 11 | 8 | 13 |

| C4 | Jaén | 9 | 10 | 11 | 13 | 16 | 19 | 21 | 21 | 19 | 15 | 12 | 9 | 15 |

| D1 | Pamplona | 7 | 8 | 9 | 10 | 11 | 13 | 15 | 15 | 14 | 12 | 9 | 8 | 11 |

| D2 | Valladolid | 6 | 7 | 8 | 10 | 13 | 16 | 18 | 18 | 16 | 12 | 9 | 7 | 12 |

| D3 | Albacete | 7 | 8 | 9 | 11 | 14 | 17 | 19 | 19 | 17 | 13 | 9 | 7 | 13 |

| E1 | León | 6 | 6 | 8 | 9 | 12 | 14 | 16 | 16 | 15 | 11 | 8 | 6 | 11 |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rey, G.; Ulloa, C.; Míguez, J.L.; Cacabelos, A. Suitability Assessment of an ICE-Based Micro-CCHP Unit in Different Spanish Climatic Zones: Application of an Experimental Model in Transient Simulation. Energies 2016, 9, 969. https://doi.org/10.3390/en9110969

Rey G, Ulloa C, Míguez JL, Cacabelos A. Suitability Assessment of an ICE-Based Micro-CCHP Unit in Different Spanish Climatic Zones: Application of an Experimental Model in Transient Simulation. Energies. 2016; 9(11):969. https://doi.org/10.3390/en9110969

Chicago/Turabian StyleRey, Guillermo, Carlos Ulloa, José Luís Míguez, and Antón Cacabelos. 2016. "Suitability Assessment of an ICE-Based Micro-CCHP Unit in Different Spanish Climatic Zones: Application of an Experimental Model in Transient Simulation" Energies 9, no. 11: 969. https://doi.org/10.3390/en9110969

APA StyleRey, G., Ulloa, C., Míguez, J. L., & Cacabelos, A. (2016). Suitability Assessment of an ICE-Based Micro-CCHP Unit in Different Spanish Climatic Zones: Application of an Experimental Model in Transient Simulation. Energies, 9(11), 969. https://doi.org/10.3390/en9110969