1. Introduction

Global carbon dioxide emissions reduction is becoming a key target for government policies, which is resulting in a reduction of fossil fuel usage [

1]. Global greenhouse gases are produced by several economic activities, mainly electricity generation, heat production and industry activities [

2], as well as agriculture and breeding [

3], transportation [

4], buildings [

5] and fuel extraction, processing and transportation [

6].

Greenhouse gas emissions from industry primarily involve fossil fuels burned on-site at facilities for producing energy, and the iron and steel industry is among the top five most energy-intensive industry sectors, as reported in the Energy Technology Perspectives 2014 [

7]. The main challenge for this sector is lowering energy consumption, greenhouse gas emissions and pollutant emissions [

8].

Iron and steel industries need to invest resources to limit their environmental footprint. The most used methods to determine energy consumption and efficiency of the production processes involved, are numerical thermal simulations and Life Cycle Analysis (LCA) [

9,

10].

Most of the works reported in the literature refer to walking beam furnaces and have the objective of predicting the temperature distribution in the slabs, which plays a major role in the quality of the final product, and the heating efficiency of the furnace [

11,

12,

13,

14,

15,

16,

17]. Most of these works have relied on mathematical models, since experiments are quite difficult to perform due to the large size of real furnaces, limited physical access and the harsh environmental conditions of the furnace [

18].

A recent and interesting work about the modeling of a conjugate heat transfer and fluid flows inside an industrial furnace with a CFD software, has been done [

19]. The study presents a model able to simulate the heat transfer flow of convection, conduction and radiation in a 3D furnace with the presence of six conducting steel solids [

20].

Instead, this paper focuses on the thermal analysis of a forging furnace, and discusses the results of joint research between the University of Perugia and Divisione Fucine di Acciai Speciali Terni (SdF), a worldwide leader in the steel forging industry.

At SdF the forged products are obtained through a production process, which involves furnaces and presses. Generally several cycles of heating and machinery are needed to achieve the right geometry. However these processes generate internal stresses and defects that compromise the products’ quality. For this reason, the forged steel is subjected to other thermal and finishing treatments to release stresses, modify the molecular structure and improve the quality and performance of the final materials.

From several analyses made in SdF, it has emerged that the overuse of the furnaces throughout the production processes is one of the main factors responsible for the high energy consumption. An improvement of their energy efficiency would allow the company to reduce pollutant emissions, save energy and decrease the cost of the final product.

All the furnaces in SdF are fueled with natural gas but differ from each other in their dimensions, number of burners, refractory properties and so on. It is, however, possible to classify them into two main categories. The heat treatment furnaces that are generally turned off when the processing is finished, and the forging furnaces which are always turned on at maximum temperature, and are used for the heating of the ingots. The continuous operation of the forging furnaces is the main contributory reason for the high energy consumption, since a continuous energy supply is required to compensate the energy loss during the furnace opening and maintain the operating temperature conditions.

A typical insertion/extraction operation starts with the opening of the furnace door, continues with the movement of an extractable bogie hearth, then the positioning or the picking up of the products by means of an overhead travelling crane, and finally finishing with the insertion of the bogie hearth and the door closing. The time necessary to perform these operations depends on many factors, such as the dimensions of the ingots, the maneuvering time, the presence of faults and so on. From the analysis of the data available to SdF, it emerged that the time varies from about 10 min up to 1 h. In this time interval the furnace temperature decreases by hundreds of degrees, from 300 °C for brief openings, up to 700 °C for longer openings.

To the best of our knowledge, in the literature there are no other studies on the assessment of the thermal behavior of forging furnaces during transient insertion and extraction periods, even though the evaluation of energy losses and other parameters, such as the velocity and the directions of the gases, represents a valid decisional instrument to reduce energy consumption. The complexity of the phenomena that occur in real conditions makes difficult to analyse the study where conduction, convection and radiation occur concurrently [

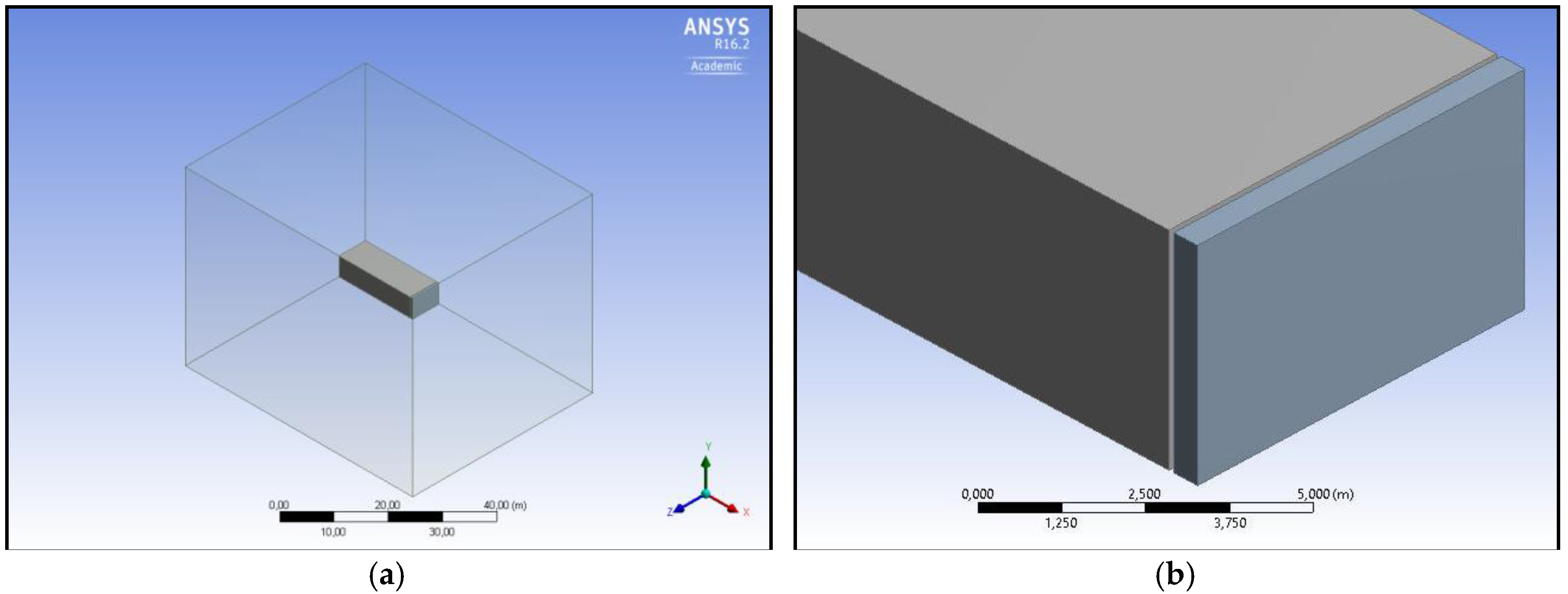

21]. For this reason, the present paper discusses the results of three dimensional transient simulations, done with CFD Software, of a forging furnace, considering a total opening time of 10 min. The first simulation was done with a lifting time of the door of 157 s, which represents the real operating condition of the furnace in SdF. The model created was then validated through an experimental test carried out in SdF with the same operating condition applied to the model. Successively, in order to improve the energy efficiency of the furnace, two other simulations with a different door opening speed were conducted and in this paper discussed. In particular, an opening time of 40 s and 60 s were considered. The results obtained were also used to determine the carbon footprint of the process.

3. Results

The period of 10 min from the opening of the door with a time step of 0.1 s was considered. In particular, the first simulation, related to the real operating condition of the furnace in the plant with a complete opening in 157 s, was conducted and validated through an experimental test done in the real furnace in SdF.

3.1. Fluids Behavior

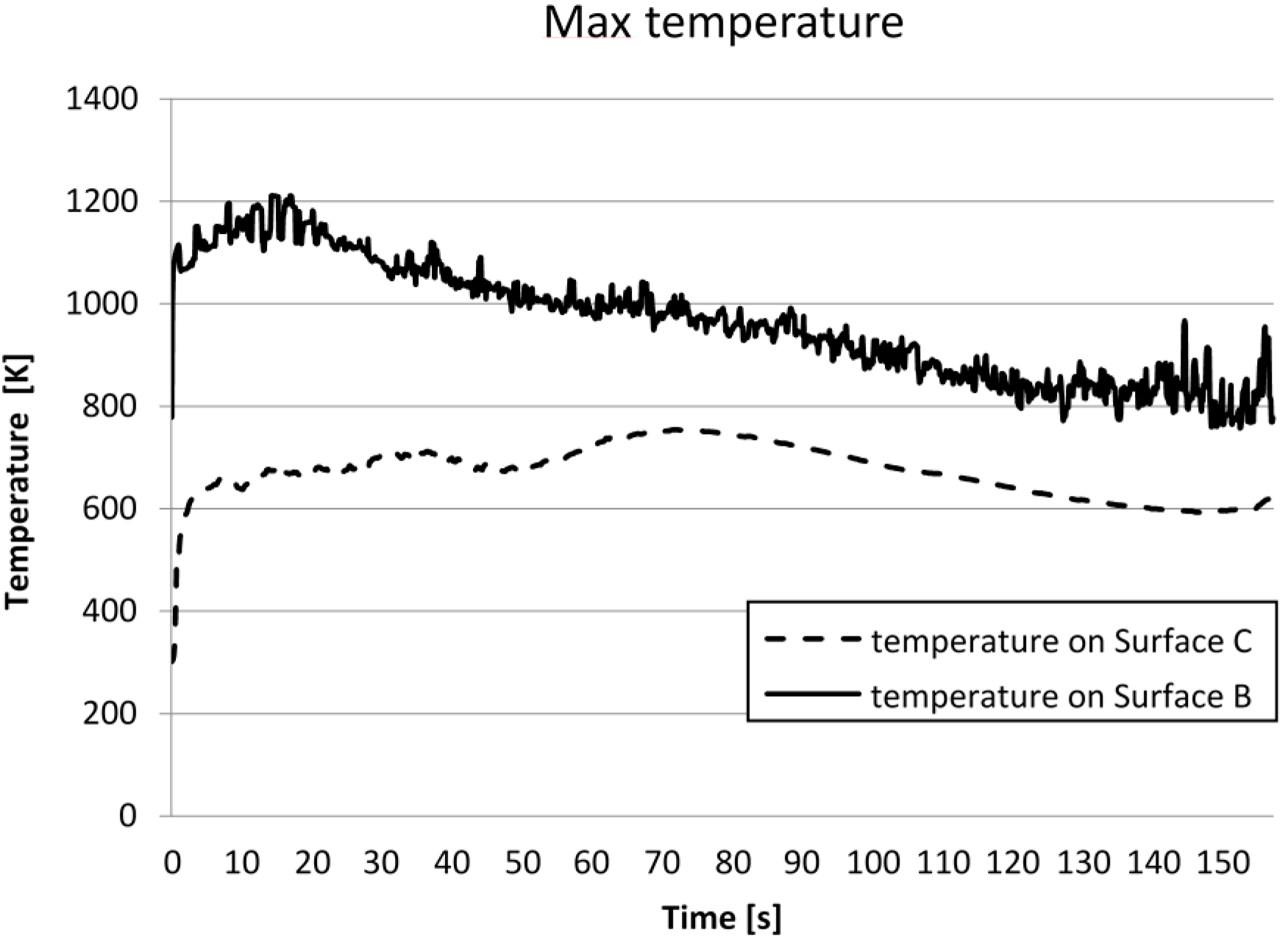

The first parameter monitored with the simulation was the maximum temperature reached on the two control surfaces B and C during the opening. This trend is shown in

Figure 4 where it is possible to see that the highest temperature is registered on surface B, which reaches values of about 1200 K after a few seconds from opening and then decreases, reaching values of 800 K. Instead, the maximum temperature registered on surface C starts from the ambient value, up to values of around 700 K.

The values of the max temperature registered in the two surfaces depend on the motion of the fluid leaving the furnace. For example

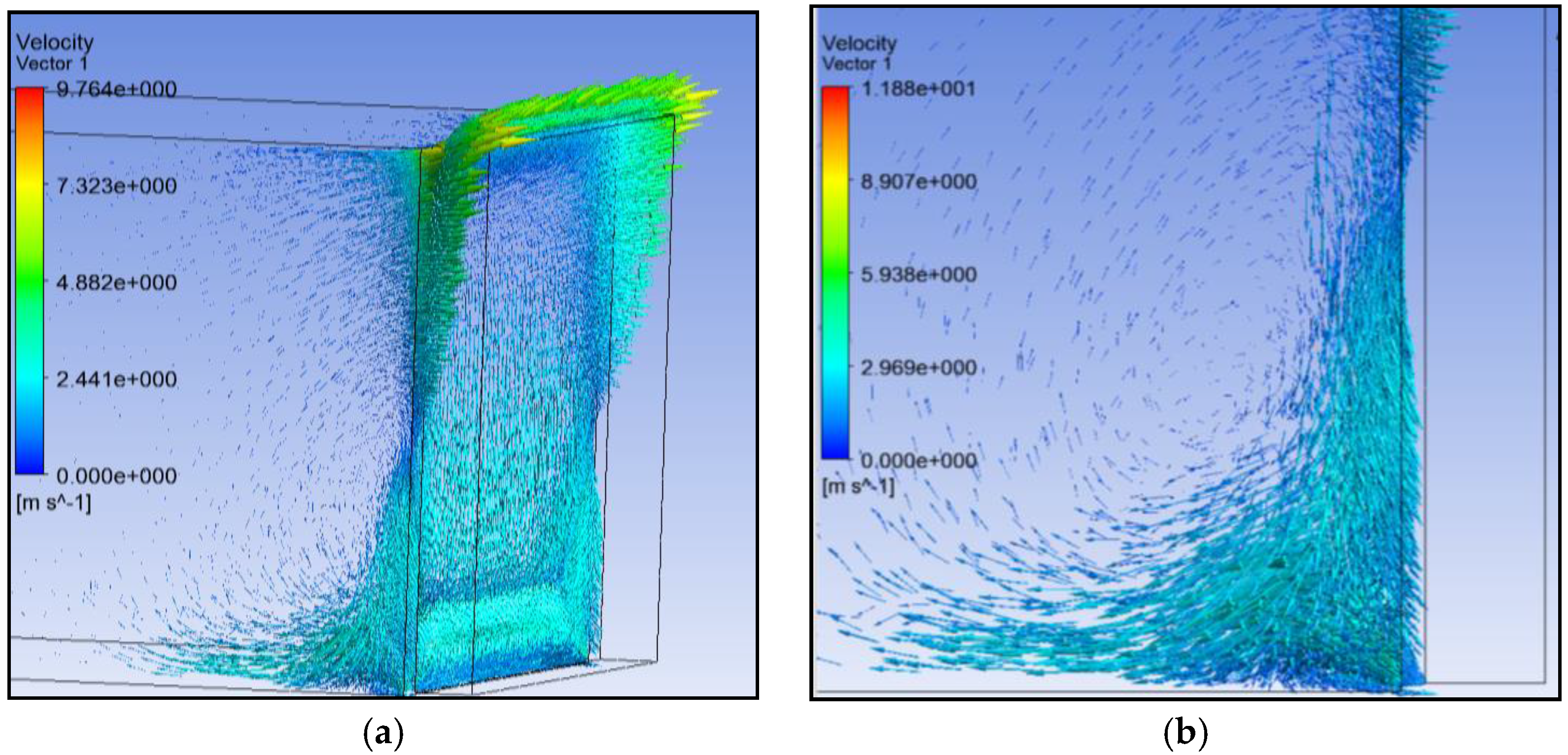

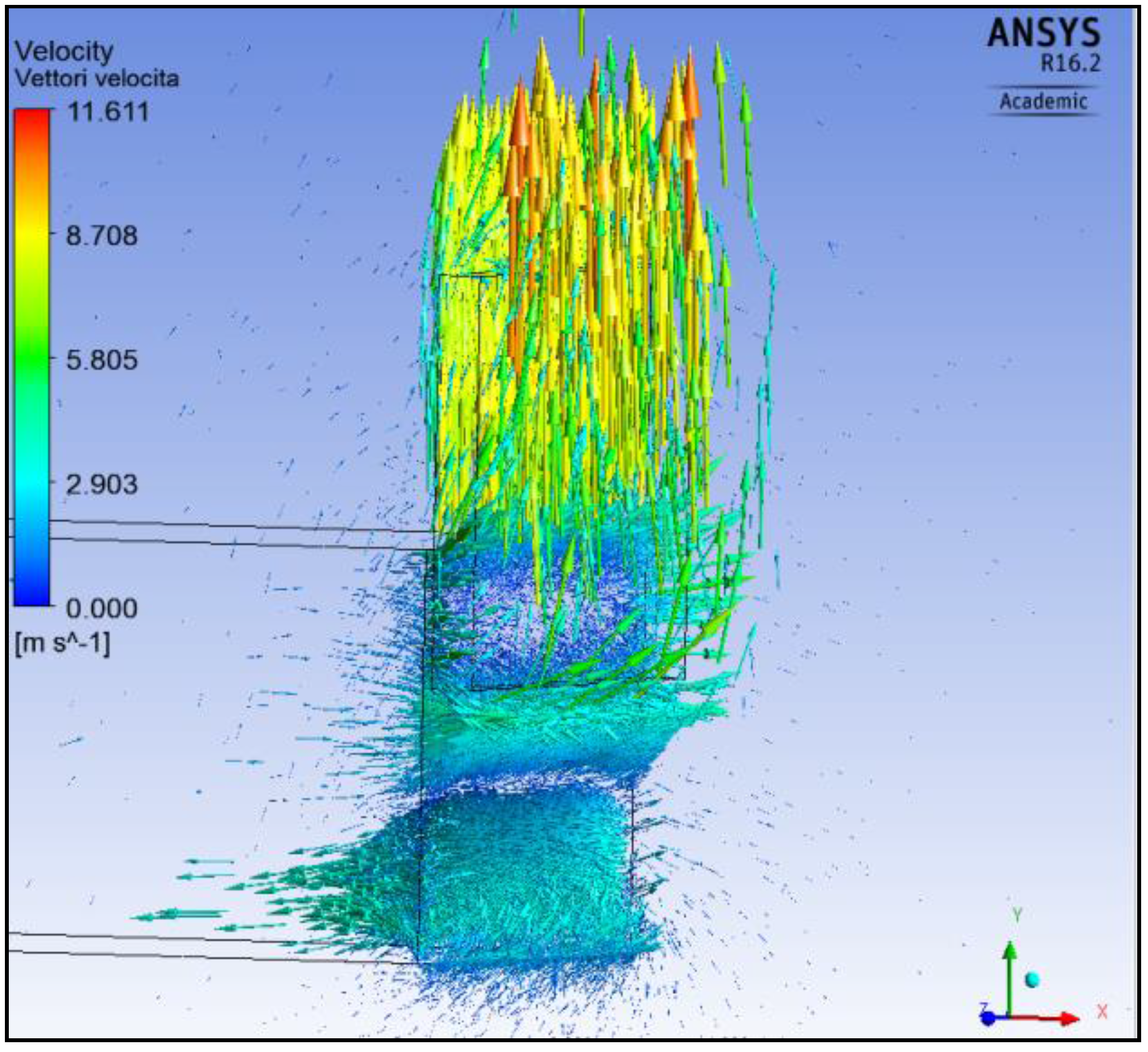

Figure 5 shows a sequence of velocity vectors from the initial time, up to 1 s. This sequence of frames demonstrates how the hot gases inside the chamber move upwards and leave the furnace through the upper section with a velocity that reaches 12 m/s. Meanwhile, the external air, at ambient temperature, moves towards the furnace through the bottom section.

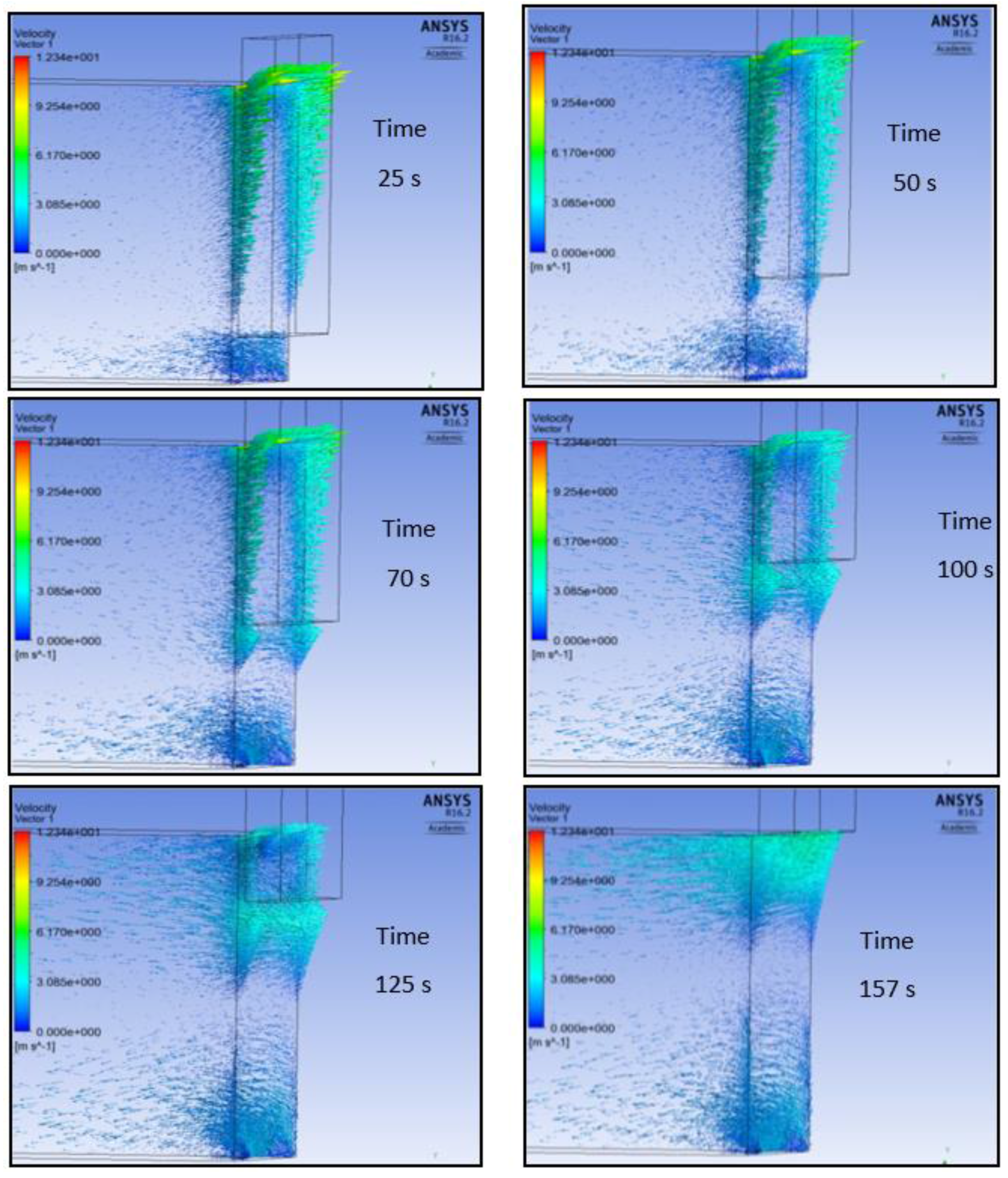

Continuing the anlyses of the fluid dynamics of the model, it can be observed from

Figure 6 that the hot gases which cannot be released from the upper section, are recalled downwards, forming a convective motion when they meet the cold air coming from outside.

As the door continues to open, the vortexes disappear, the velocity vectors decrease, and the hot gases leaving the furnace start to pass under the door (

Figure 7). The complete motion of the convective fluxes for the transient time of 157 s, relative to the furnace domain, is shown in the attached video.

It is important to underline that the vectors reported in the previous images refer to the gases that move in the furnace domain. For example, observing the picture relating to the motion of 50 s, it might seem that the vectors pass through the door. In reality this does not occur, in so far as when the gases pass through the air domain, the presence of the door deflects the motion of the vectors in other directions, as it is possible to see from

Figure 8.

3.2. Heat Flux Evaluation

In order to evaluate the energy fluxes, the contributions of the three forms of heat exchange: convection, radiation and conduction, were identified. With the aid of the CFD Software, the amount of the heat flux during the opening for convection and radiation has been evaluated, while a spreadsheet for the conduction was used.

3.2.1. Radiative Heat Flux

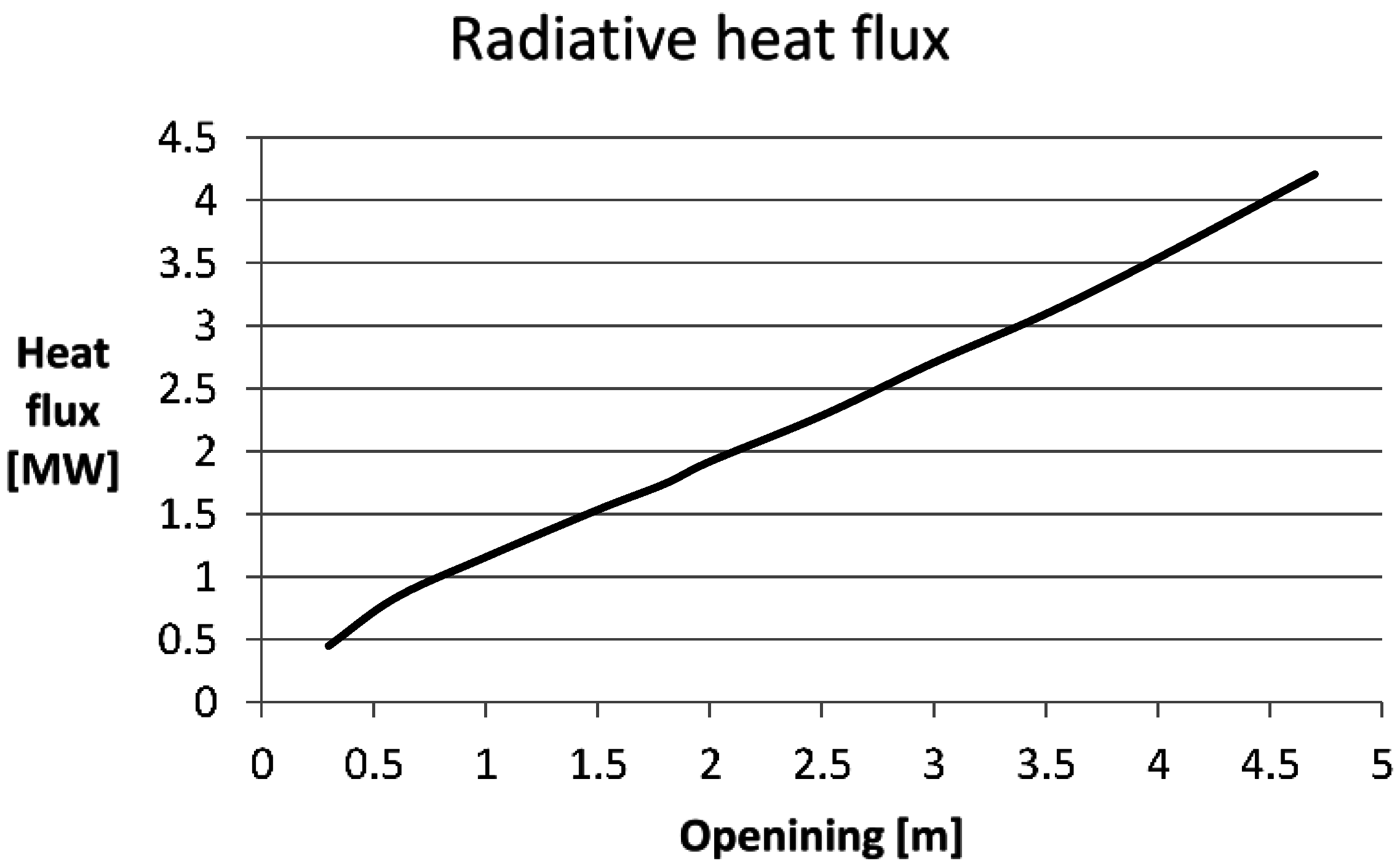

The values of the radiative energy, which passes through the opening of the door evaluated for the first 157 s and related to the complete opening of the door of 4.7 m, are reported in

Figure 9.

The values obtained show that the flux grows linearly with time and so with the opening. Even if during the opening the walls start to cool down, the radiative heat flux per unit of area remains about the same because the difference of temperature changes slightly. These values have been verified through the analytical calculation for several time steps, using the view factors given by Fluent.

3.2.2. Convective Heat Flux

The evaluation of the convective heat flux is carried out through the calculation of the mass flow rate of enthalpy as the following Equation (1):

where H is the Enthalpy, and

is the mass flow.

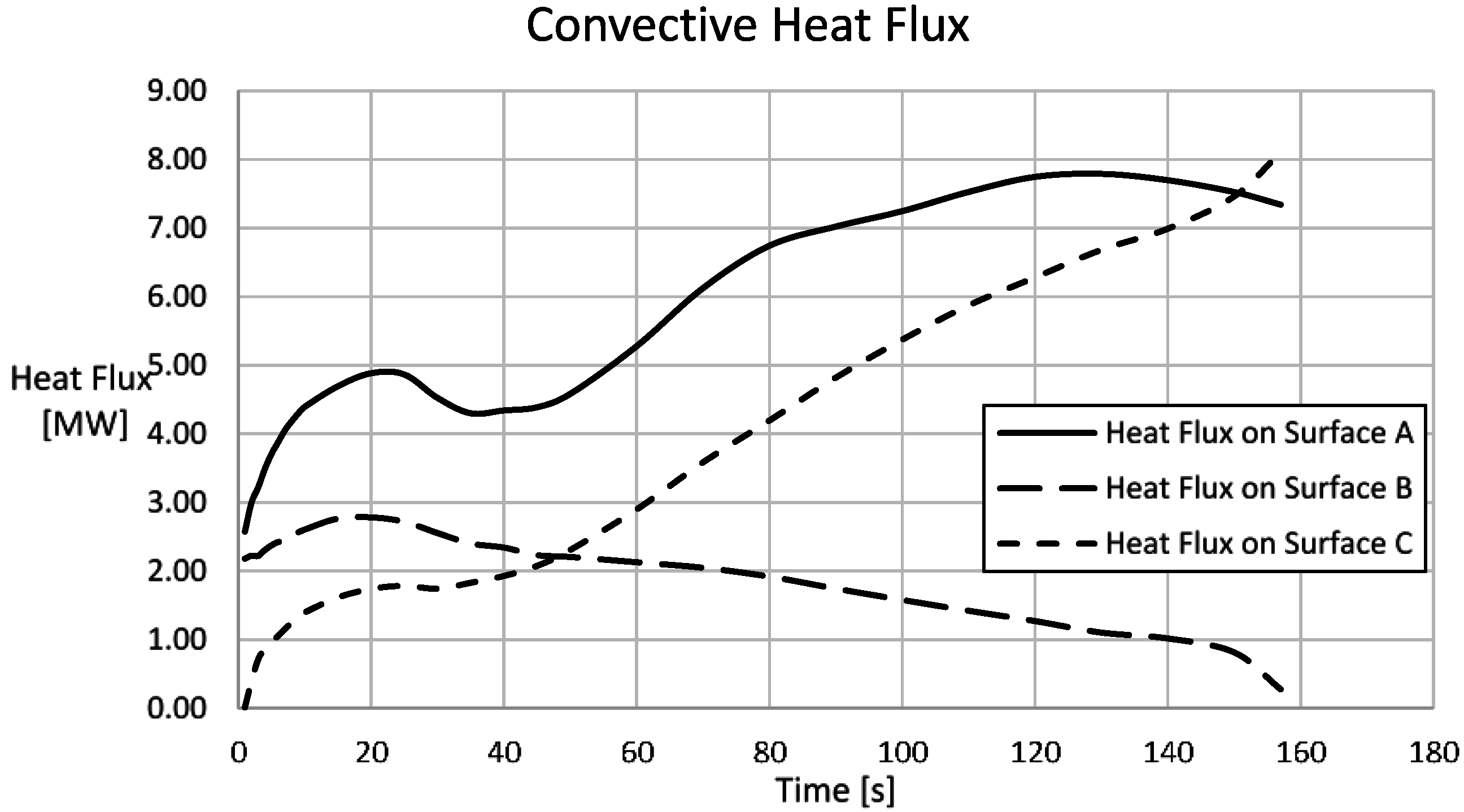

The knowledge of the values calculated for every time step in the simulation allows us to obtain the total convective heat flux. The trend of the fluxes for the complete opening of the door of 4.7 m in 157 s is shown in

Figure 10. It is possible to see that the heat flux on the door is given from the sum of the others. By comparing the two types of heat flux for the first 157 s, it is possible to see that the convective heat flux is higher than the radiative, even if the latter depends on the fourth power of the temperature. This behavior is due to the fact that the turbulence generated from the opening creates a motion of air with a high Reynolds number.

3.2.3. Conductive Heat Flux

It was possible to calculate the amount of the conductive heat flux through the walls of the furnace from data relating to the stratification of the walls as shown in

Figure 11, and from the trend of the temperature obtained from the simulation.

The application of the following gives the values of the heat flux in function of the time:

where U is the equivalent transmittance of the wall, ΔT is the difference of temperature and A is the area of the surface. However, this formulation does not consider the thermal bridges.

3.3. Total Energy Loss and Validation of the Model

The knowledge of the trends of the heat fluxes in function of the time allowed the calculation of the energy loss. In particular,

Table 2 gives the energy for the three heat fluxes.

To evaluate the accuracy of these values, an indirect analysis through the knowledge of the methane consumption of the furnace was made. Assuming a lower calorific value of the natural gas equal to 34 MJ/m3, the flow rate is equal to 165 Nm3 of methane. However the methane consumption calculated is relative to the model created with the ideal operating condition of the furnace. The real behavior instead is conditioned by many parameters such as, for example, the presence of thermal bridges and damaged refractories, which increase the heat flux through the walls. Another aspect is the presence of an interstice between the bogie hearth and the lateral walls of the furnace, which is necessary to avoid friction during movement, but allows part of the heat to exit from the furnace increasing the losses. These, and other phenomena, influence the real consumption of natural gas, increasing the total amount of fuel necessary to maintain the furnace chamber at a certain temperature.

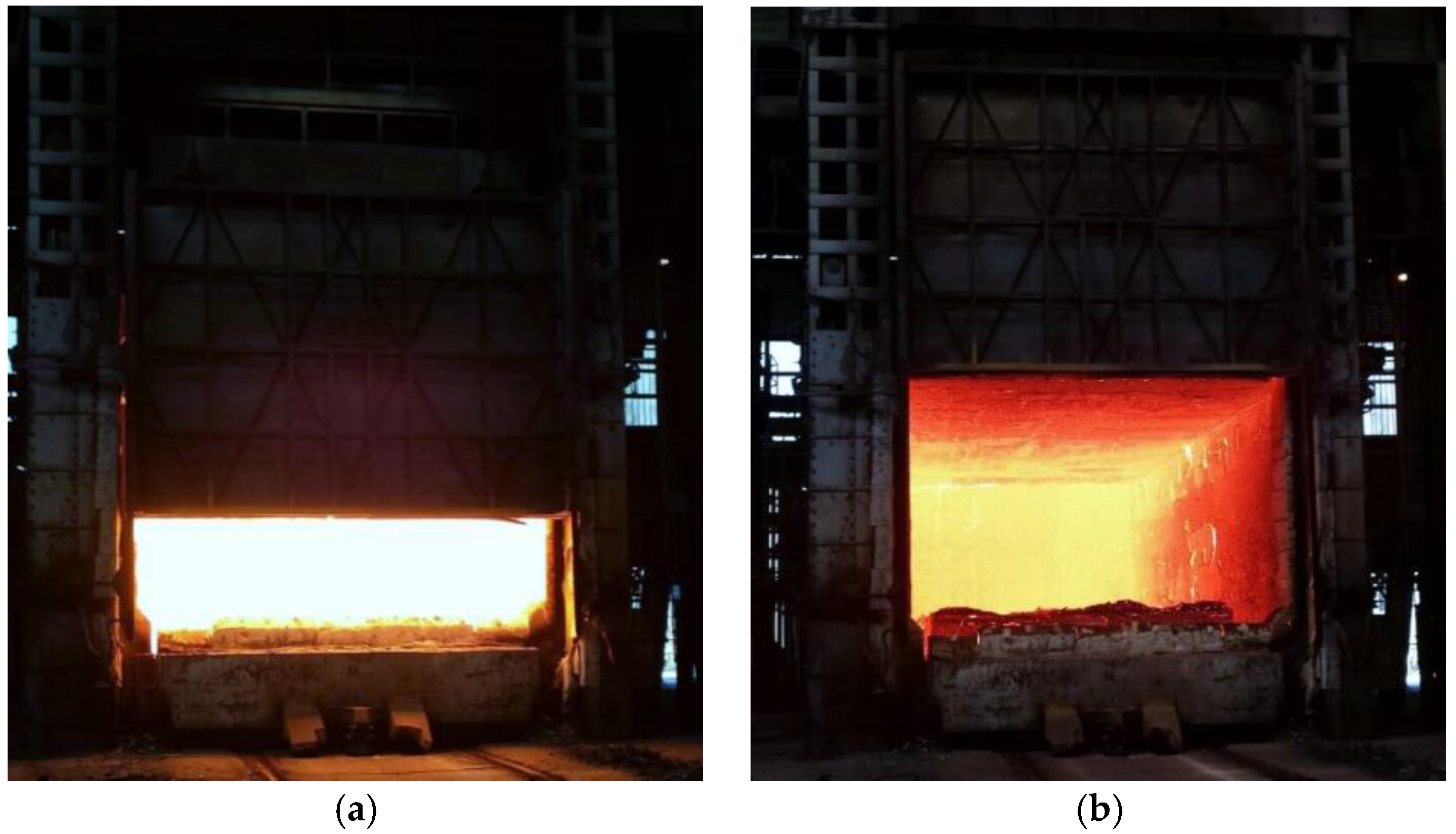

The validation of the model was carried out through an experimental test made in SdF. The test started with the opening of the door of an empty forging furnace at the operating temperature of 1230 °C. The furnace remained open for 10 min with the bogie hearth inside, and then closed again. When the door was completely closed the burners started to call up to reach again the operating temperature. Two instant photographs of this experimental test are reported in

Figure 12 from which it is possible to see the variation of the intensity of the furnace color which corresponds to a sudden fall in temperature.

The consumption of methane was monitored between the closing time, after the 10 min, and the time it takes to return at its operating conditions. Taking into account the simplification of the model, the two values of methane consumption were compared and resulted that the values are of the same order of magnitude. This validation guarantees the accuracy of the model and allows us to use it as a decisional instrument for future developments which will allow us to develop more efficient processes.

In order to characterize the footprint of this phenomenon, the emission of CO

2 caused by the combustion of the 165 Nm

3 of methane is evaluated. From the stoichiometric equation of the methane combustion results that 1 mol of CH

4 produces 1 mol of CO

2 (Equation (3)):

Being the molar mass of the methane equal to 16 g/mol and the molar mass of the CO

2 equal to 44 g/mol, results that the combustion of 1 kg of CH

4 produces 2.75 kg of CO

2. For a density of the methane equal to 0.73 kg/m

3 results that 1 kg of CH

4 corresponds to 1.4 m

3 of CH

4. So the kg of CO

2 produced by the combustion of 165 Nm

3 of methane are 331 kg, where 309 kg are due to the combustion of natural gas for the heat lost for convection.

4. Application of the Model

As shown by

Table 2, the major contribution to the total heat loss is due to convection. For this reason the model created has been applied to evaluate how an increase of the door speed can influence the convective fluxes of the furnace and the consequent global energy performance. For this reason two other simulations of a complete opening of 40 s and 60 s were carried out.

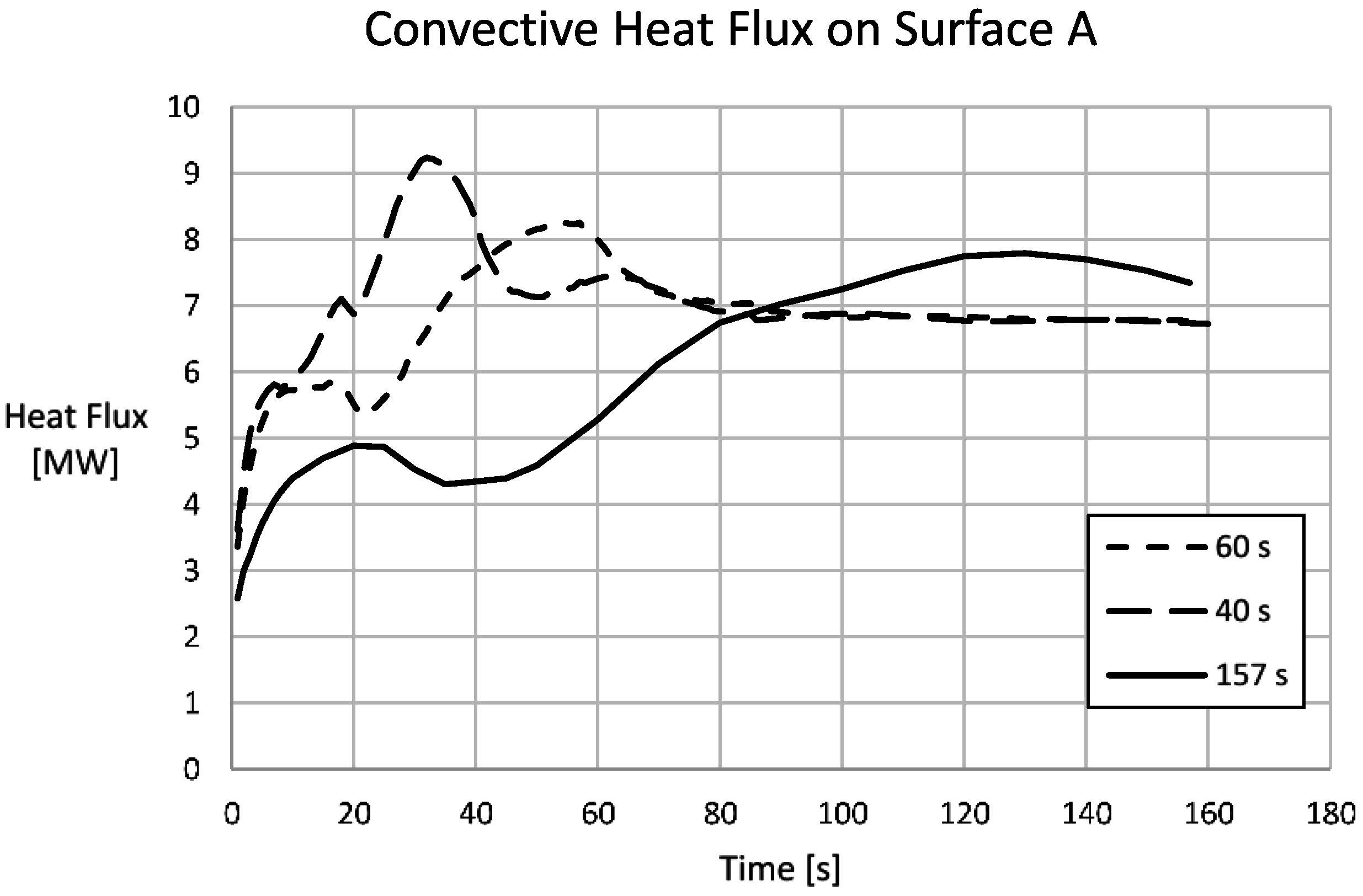

Figure 13 shows the trend of the convective heat flux on Surface A for the three different openings.

As it is possible to see, a reduction of the opening time entails an increase of the maximum value of convective heat flux calculated, which exceeds 9 MW for a 40 s opening. From the evaluation of the amount of the energy lost during the lifting time of the door and in the next 10 min for the three different case studies, the results show that the opening of 40 s minimizes the heat loss, with a total of 4324 MJ for a total time of 640 s. In the following

Table 3 the values of the convective heat flux for the different openings are shown.

Thanks to this study the company made their production process more efficient, saving fuel and limiting pollutant emissions, simply by reducing the opening time of the door, from 157 s to 40 s. An amount of about 60 kg of CO2 is saved simply with the implementation of a reduced door opening time. A further reduction of this time is not allowed due to the mechanical limits of the door lifting system. The data obtained from this study is also being used for other studies concerning the design of an air knife system to install close to the door.