4.1. Electromagnetic Performance

The proposed FTFM machine is designed as listed in

Table 1. Its electromagnetic performance is investigated using TS-FEM.

Table 1.

Design parameters.

Table 1.

Design parameters.

| Items | Value | Items | Value |

|---|

| Thickness of rotor PMs (mm) | 8 | Number of inner stator pole-pairs | 10 |

| Thickness of outer stator PMs (mm) | 7 | Number of rotor pole-pairs | 19 |

| Length of air-gap (mm) | 0.6 | Number of outer stator pole-pairs | 9 |

| Inner stator outside diameter (mm) | 216 | Number of inner stator slots | 20 |

| Outer stator outside diameter (mm) | 280 | Number of outer stator slots | 18 |

| Stack length (mm) | 80 | Number of AC conductors | 20 |

| Number of phases | 5 | Number of DC conductors | 20 |

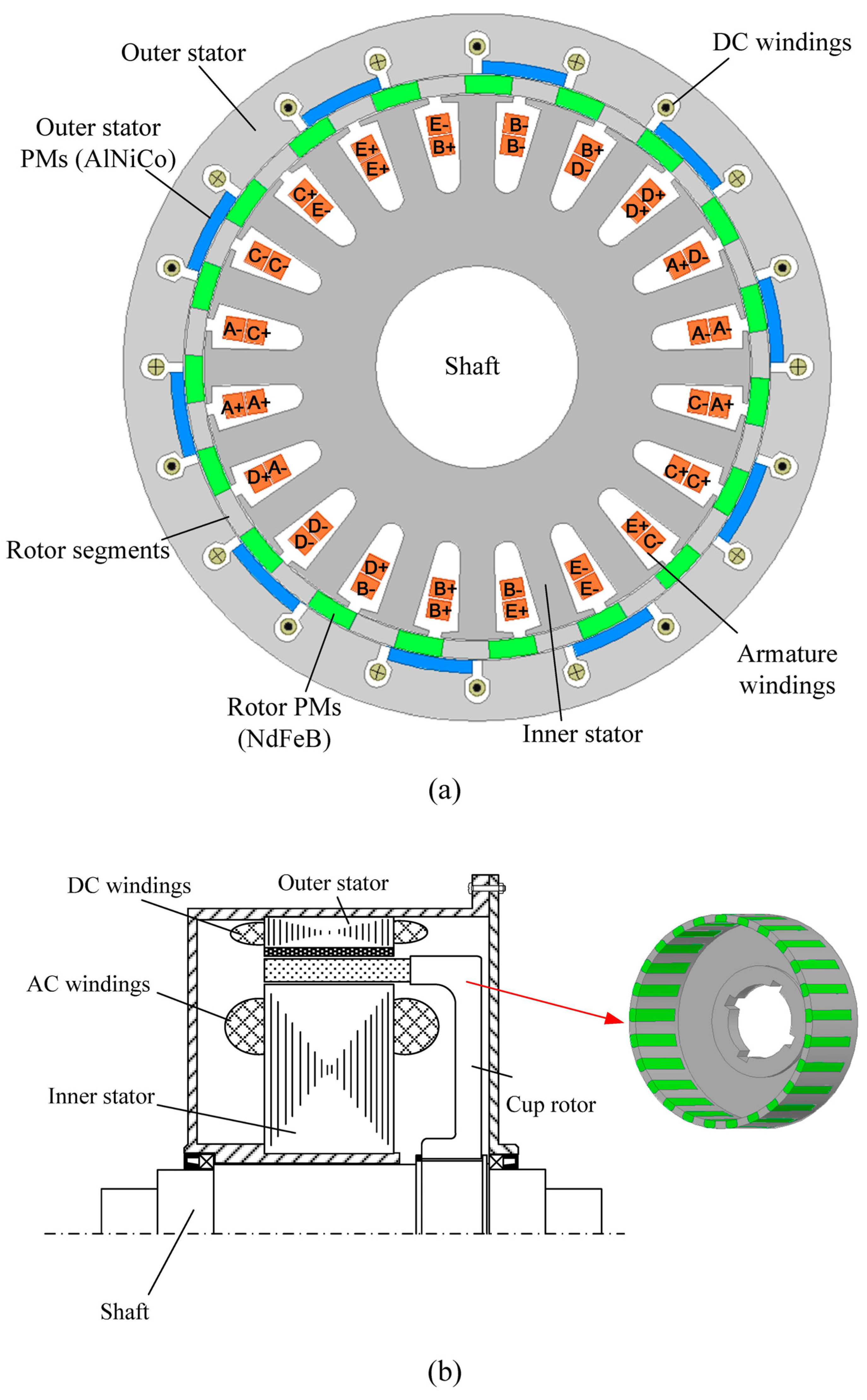

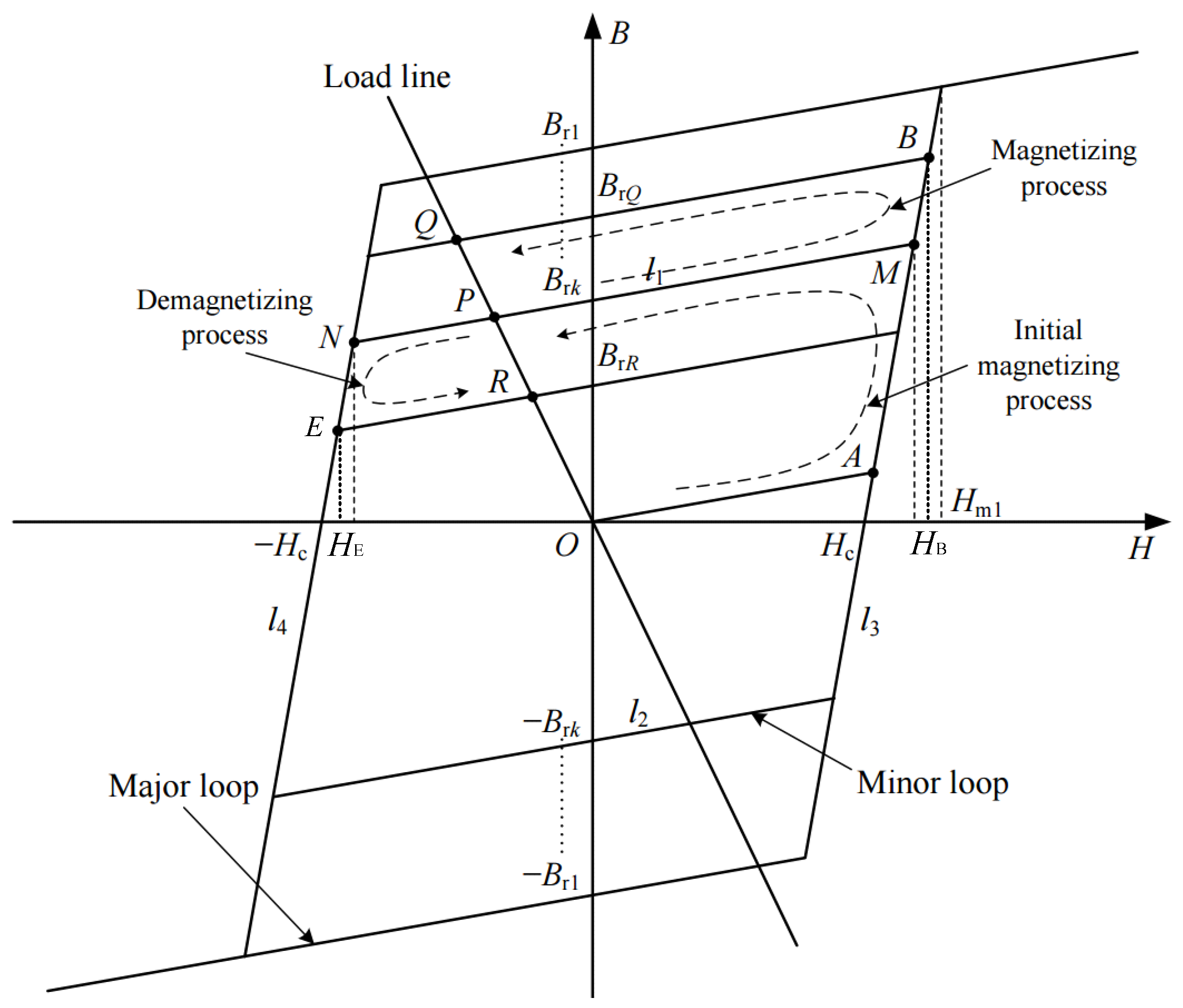

As mentioned before, one of the most attractive features of this machine is the air-gap flux controllability. By applying DC current pulse, the AlNiCo magnet can be magnetized/demagnetized effectively. The control strategy used in the proposed FTFM machine is much simpler than the AC vector control used in the traditional PM machine, since only the amplitude and direction of the DC current need to be controlled. The DC external circuit of the proposed machine is shown in

Figure 4, which is used for re-/de-magnetizing the AlNiCo PMs. Since there exists mutual coupling between the AC windings and DC windings, a rectifying circuit is integrated into the DC external circuit to reduce the mutual coupling effect. By setting the AC voltage in the DC external circuit to zero, the current in the DC windings with and without the rectifying components (capacitor C1 and inductance L) is calculated, as shown in

Figure 5. The result shows that there indeed exists mutual coupling between the AC windings and DC windings, but the amplitude of this current can be greatly reduced after the use of rectifying components.

Figure 4.

External circuit of DC windings.

Figure 4.

External circuit of DC windings.

Figure 5.

Mutual current waveforms of the DC windings.

Figure 5.

Mutual current waveforms of the DC windings.

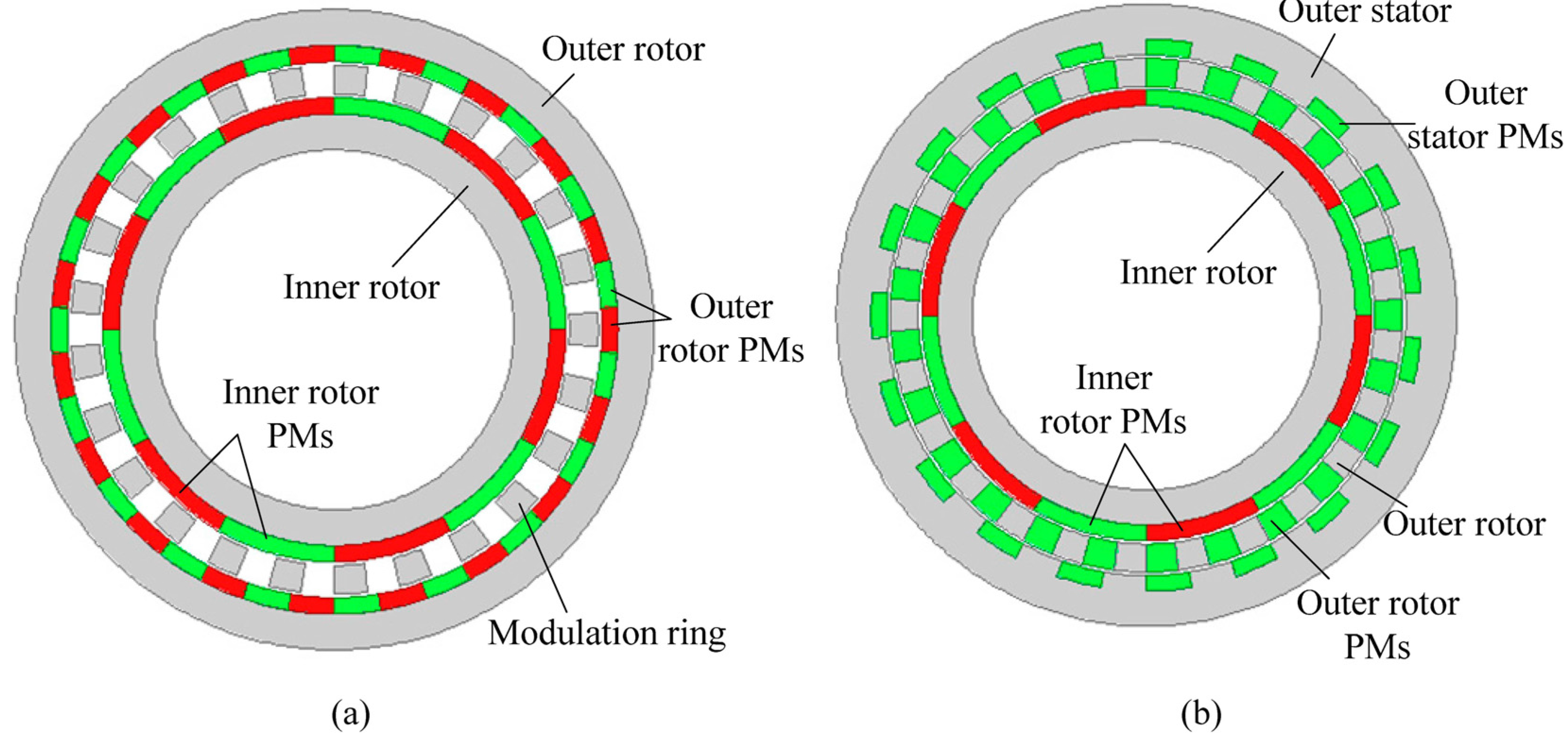

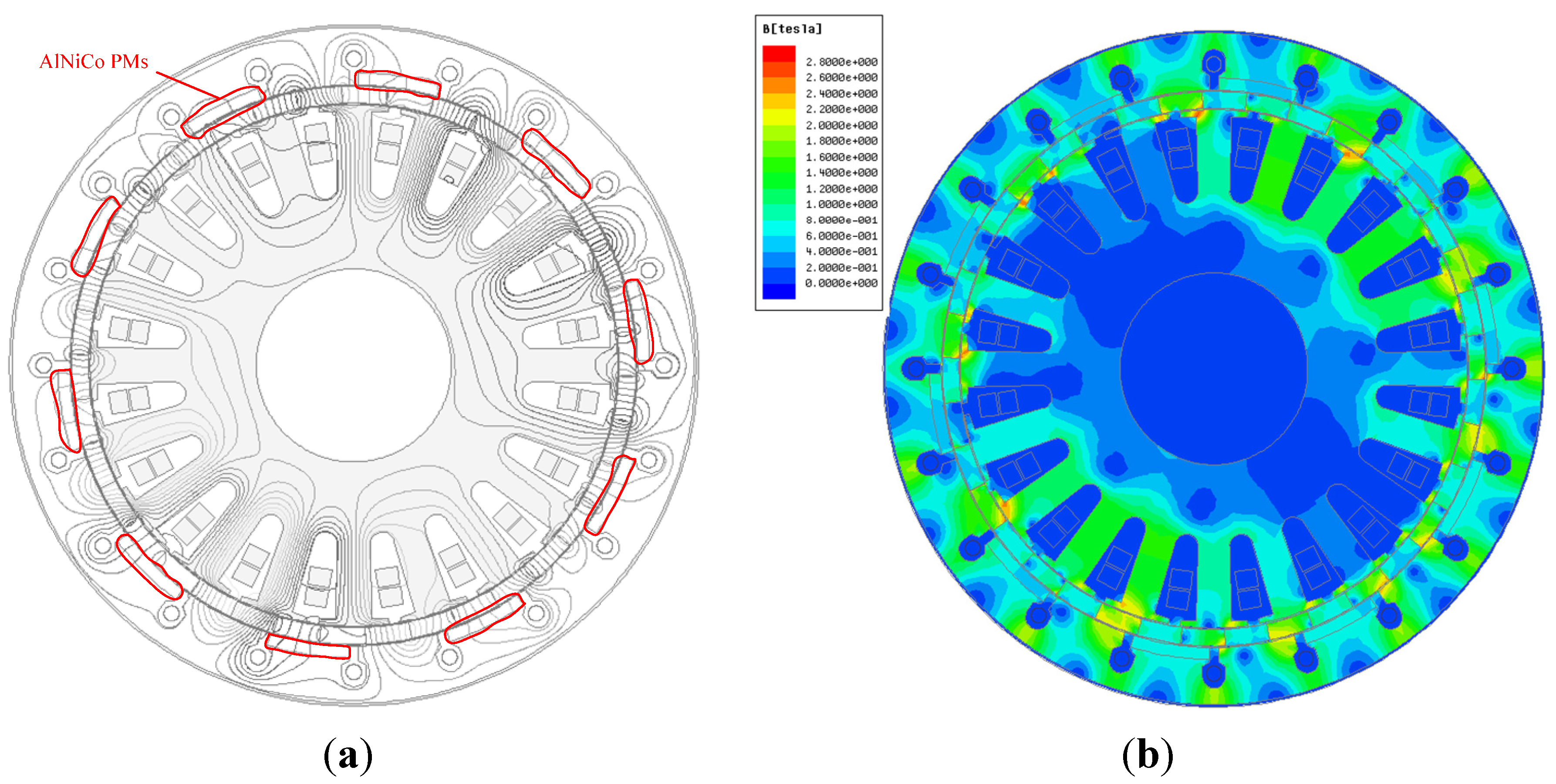

When the power switches S1 and S4 are turned on, a magnetizing current is produced, while when the power switches S2 and S3 are turned on, a demagnetizing current is generated. According to the magnitudes of magnetizing/demagnetizing current pulses, the magnetization level can be divided into three groups, which is a full level using a magnetizing magnetomotive force (MMF) of 2000 A-turns, then a half level using a demagnetizing MMF of 600 A-turns and a weak level using a demagnetizing MMF of 1000 A-turns. Firstly, the magnetic field distributions of the proposed FTFM machine under different magnetization levels are investigated, as shown in

Figure 6.

Figure 6.

No-load magnetic field distributions of the fault-tolerant flux-modulated memory (FTFM) machine at different magnetization levels: (a) Full level; (b) half level; (c) weak level.

Figure 6.

No-load magnetic field distributions of the fault-tolerant flux-modulated memory (FTFM) machine at different magnetization levels: (a) Full level; (b) half level; (c) weak level.

From

Figure 6, one can see clearly that the magnetic flux line distribution is densest when a magnetizing current (+2000 A-turns) is applied, and it becomes sparsest when a demagnetizing current (−1000 A-turns) is applied. This phenomenon is especially significant in the outer stator and reflects a good field regulating effect. The corresponding air-gap flux density distributions in the air-gap are shown in

Figure 7, illustrating that an air-gap flux regulation range of 2.5-times can be realized. Since all of the PMs are magnetized in the same direction, the flux density waveforms are not symmetrical.

Figure 7.

Air-gap flux density distribution under different magnetizing level: (a) Inner air-gap; (b) outer air-gap.

Figure 7.

Air-gap flux density distribution under different magnetizing level: (a) Inner air-gap; (b) outer air-gap.

The flux line distribution excited by the full load AC current and rotor PMs is studied, as shown in

Figure 8a, in which the AlNiCo PMs are replaced with air during simulation. It can be seen that only very few flux lines pass through the area of AlNiCo PMs; most of the flux lines pass through the outer stator teeth instead; as the reluctance of AlNiCo PMs is much larger than the stator teeth. Therefore, the AlNiCo PMs will not be demagnetized by the armature reaction field during the machine operation. The full load flux density distribution is also investigated as shown in

Figure 8b.

Figure 8.

Flux line distribution and flux density distribution. (a) Flux line excited by the full load AC current and rotor PMs; (b) flux density distribution at full load.

Figure 8.

Flux line distribution and flux density distribution. (a) Flux line excited by the full load AC current and rotor PMs; (b) flux density distribution at full load.

Figure 9a shows the torque-angle characteristics of the proposed machine with and without flux control when excited with a 40-A sinusoidal and balanced AC current. One can see a clear regulation effect on the torque. The maximum torque reaches 157 Nm when applied with a magnetizing current of +2000 A-turns. The maximum transmitted torque with the same current when the machine runs at the rated speed of 500 rpm are shown in

Figure 9b, and the torque ripple is 6.64 Nm, 4.66 Nm and 5.1 Nm, corresponding to the three magnetizing level, respectively, which is very small compared to the maximum transmitted torque.

Figure 9.

Torque characteristic of the proposed machine. (a) Torque-angle waveforms; (b) torque-time waveforms.

Figure 9.

Torque characteristic of the proposed machine. (a) Torque-angle waveforms; (b) torque-time waveforms.

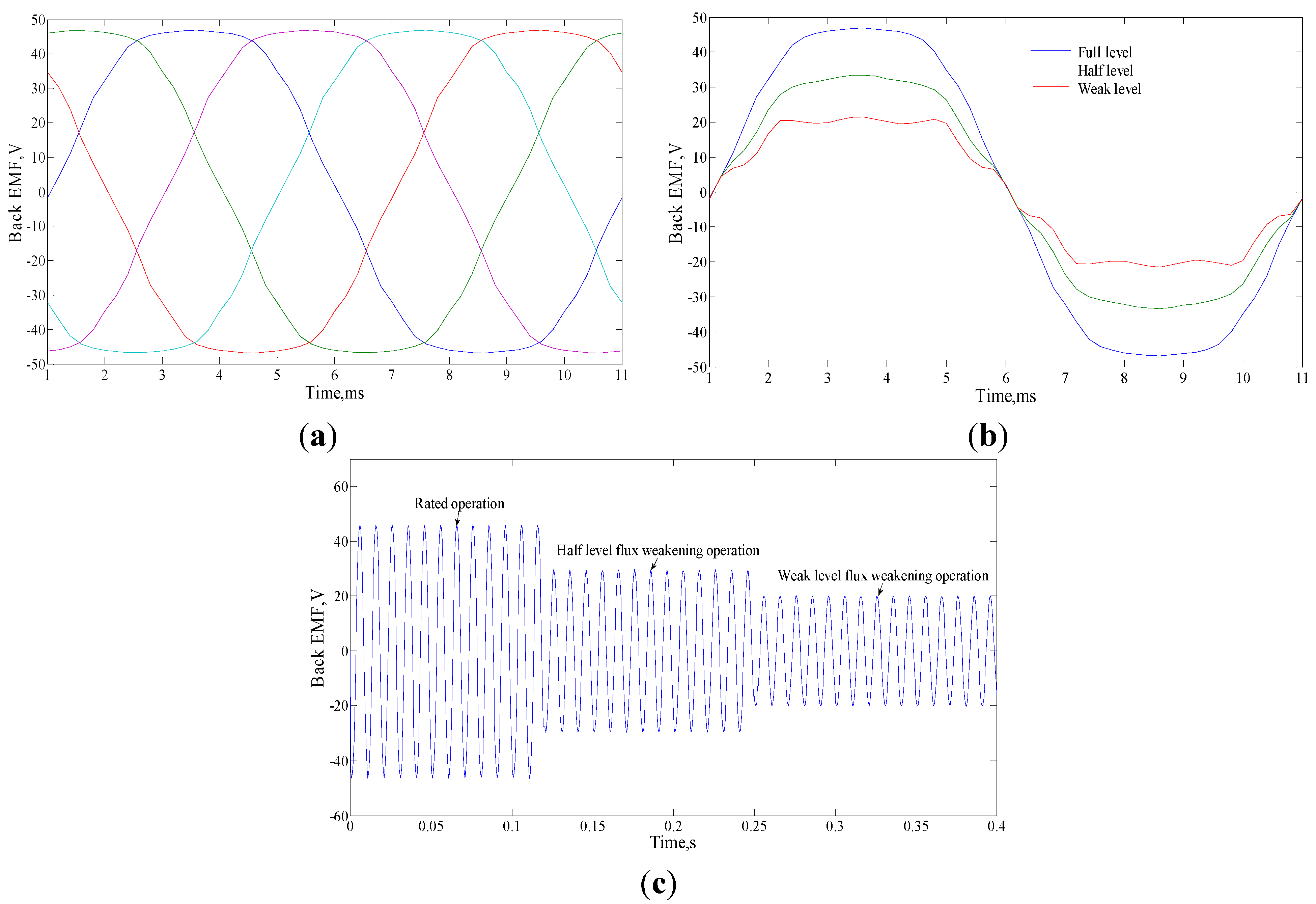

The no-load back electromotive force (EMF) of the proposed FTFM machine without flux control is shown in

Figure 10a, and the A-phase back EMF with flux control is shown in

Figure 10b, which illustrates that the back EMF can be regulated effectively. Transient analysis of back EMF from rated operation to flux weakening operation is also studied, the transient back EMF of Phase A is depicted and shown in

Figure 10c, which also shows a good flux regulating effect.

Figure 10.

Back electromotive force (EMF) of the proposed machine. (a) Five-phase back EMF; (b) back EMF of Phase A with flux control; (c) transient back EMF of Phase A.

Figure 10.

Back electromotive force (EMF) of the proposed machine. (a) Five-phase back EMF; (b) back EMF of Phase A with flux control; (c) transient back EMF of Phase A.

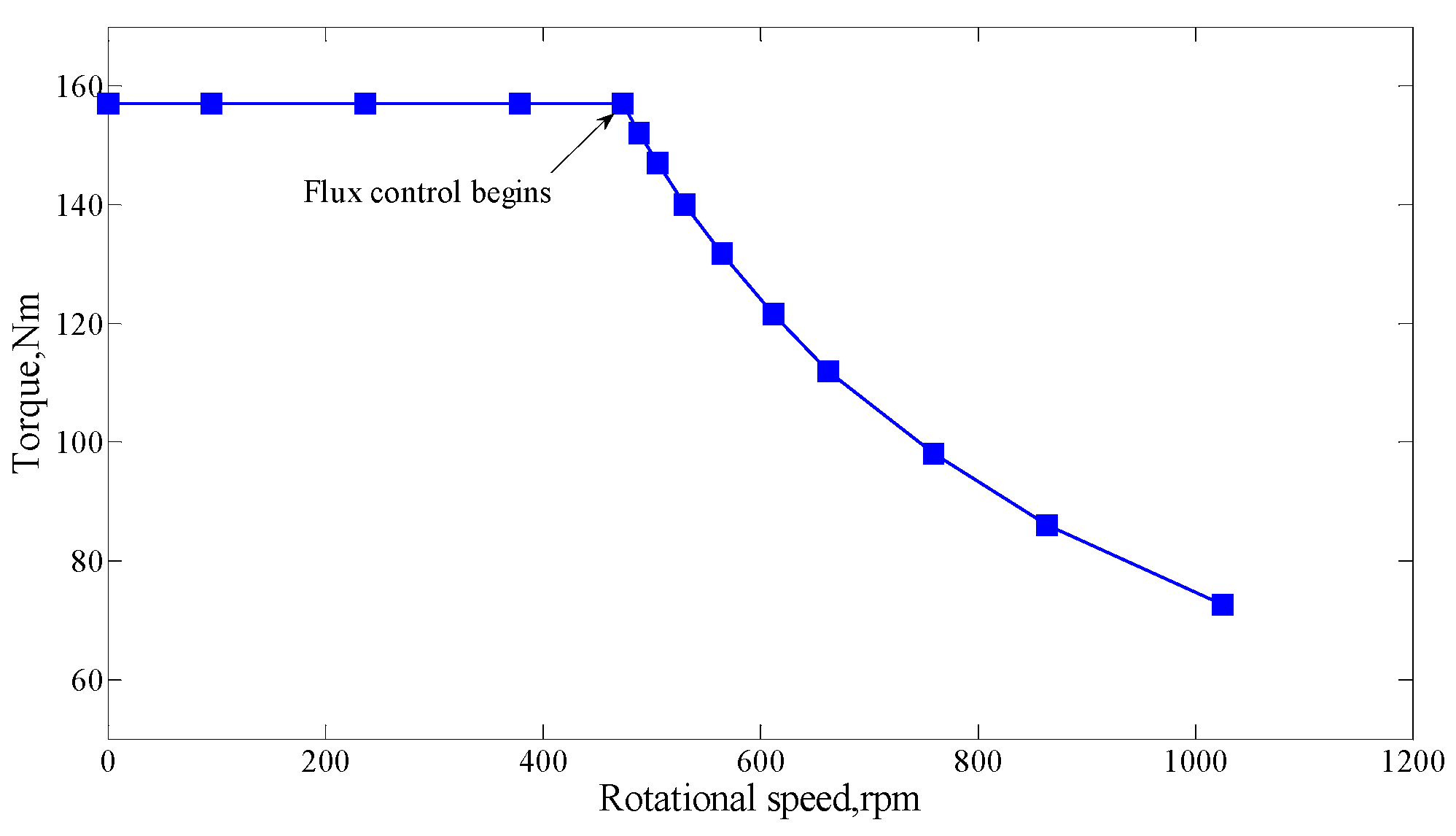

Figure 11 shows the torque-speed characteristic over the whole operating region of the proposed machine. In the low speed region, this machine will work in a constant torque state. As the speed increases, the amplitude of back EMF becomes larger, so flux weakening control is needed to maintain a constant back EMF, and the machine will work in a constant power state.

Figure 11.

Torque speed characteristic of the proposed machine.

Figure 11.

Torque speed characteristic of the proposed machine.

Furthermore, the machine efficiency is investigated. Since the input power remains unknown during FEM, the efficiency cannot be calculated by dividing the output power with the input power. In this paper, the machine efficiency is calculated by:

where

Pcoreloss refers to the core loss and calculated by FEM.

Poutput and

Pcopperloss can be computed by:

where

T and ω refer to the output torque and angular velocity,

Nslot is the slot number,

Nac is the number of AC conductors,

Sslot is the slot area,

K refers to the slot filling factor, and ρ and

l represent the resistivity of copper and axial length of AC windings, respectively.

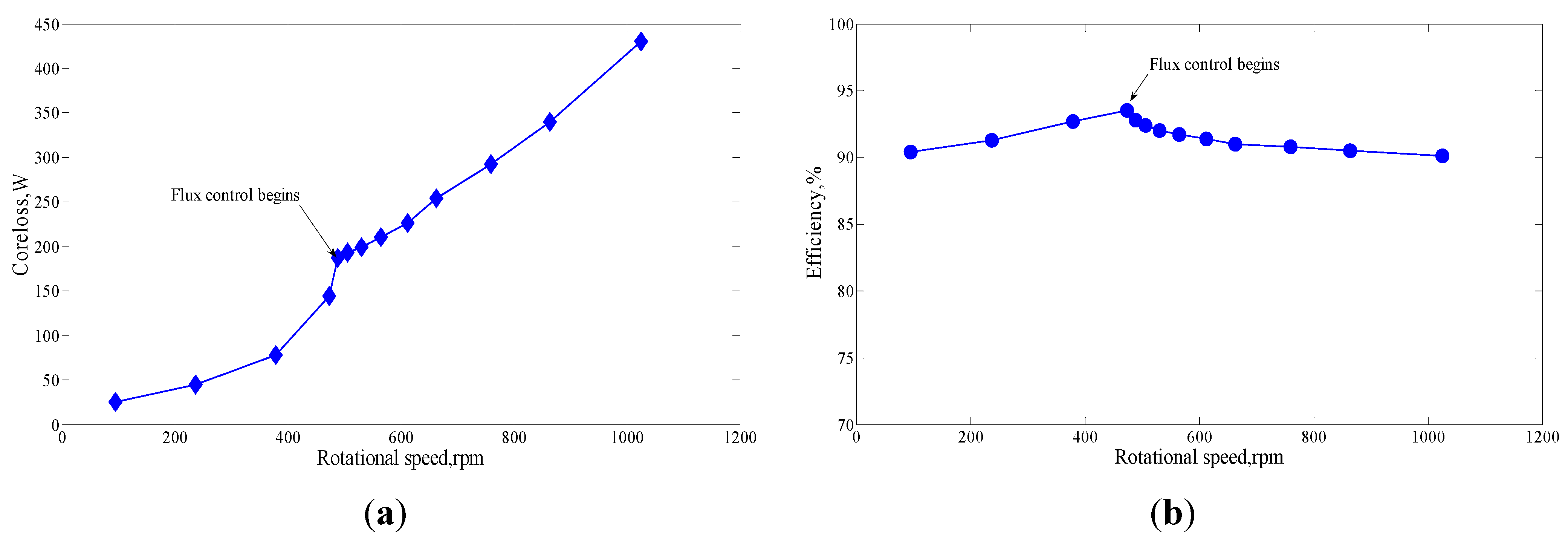

The core losses and machine efficiency are shown in

Figure 12. One can see that there is an obvious increase of core loss along with the rotational speed rise. Additionally, this machine enjoys a very high efficiency over 90% in the whole operating region.

Figure 12.

Core loss and efficiency of the proposed machine. (a) Core loss; (b) efficiency.

Figure 12.

Core loss and efficiency of the proposed machine. (a) Core loss; (b) efficiency.

4.2. Fault-Tolerant Analysis

Fault-tolerant capability is one of the most important features of multiphase machines, which means that they can continue to operate in a satisfactory manner even under fault conditions. As the machine output torque is proportional to its interacting field, so the same torque can be maintained as long as the rotating MMF produced by the variations of all five-phase currents keeps unchanged in both time and space.

When one-phase open-circuited (for example, Phase A is open-circuited), to maintain a proper operating condition, the magnetic field produced by the remaining four healthy phases should remain unchanged. The MMF is produced by the remaining four phases:

For the sake of getting a unique solution and to guarantee that the summation of four current phases is zero, the phase currents are governed by:

and the new phase currents can be expressed as:

It can be seen that the remediation is to regulate the Phase B current retarded by 36° and the Phase E current advanced by 36°, while keeping the angles of Phase C and Phase D currents unchanged. Furthermore, the current amplitudes of all pf the remaining phases are increased to 1.382-times their pre-fault values.

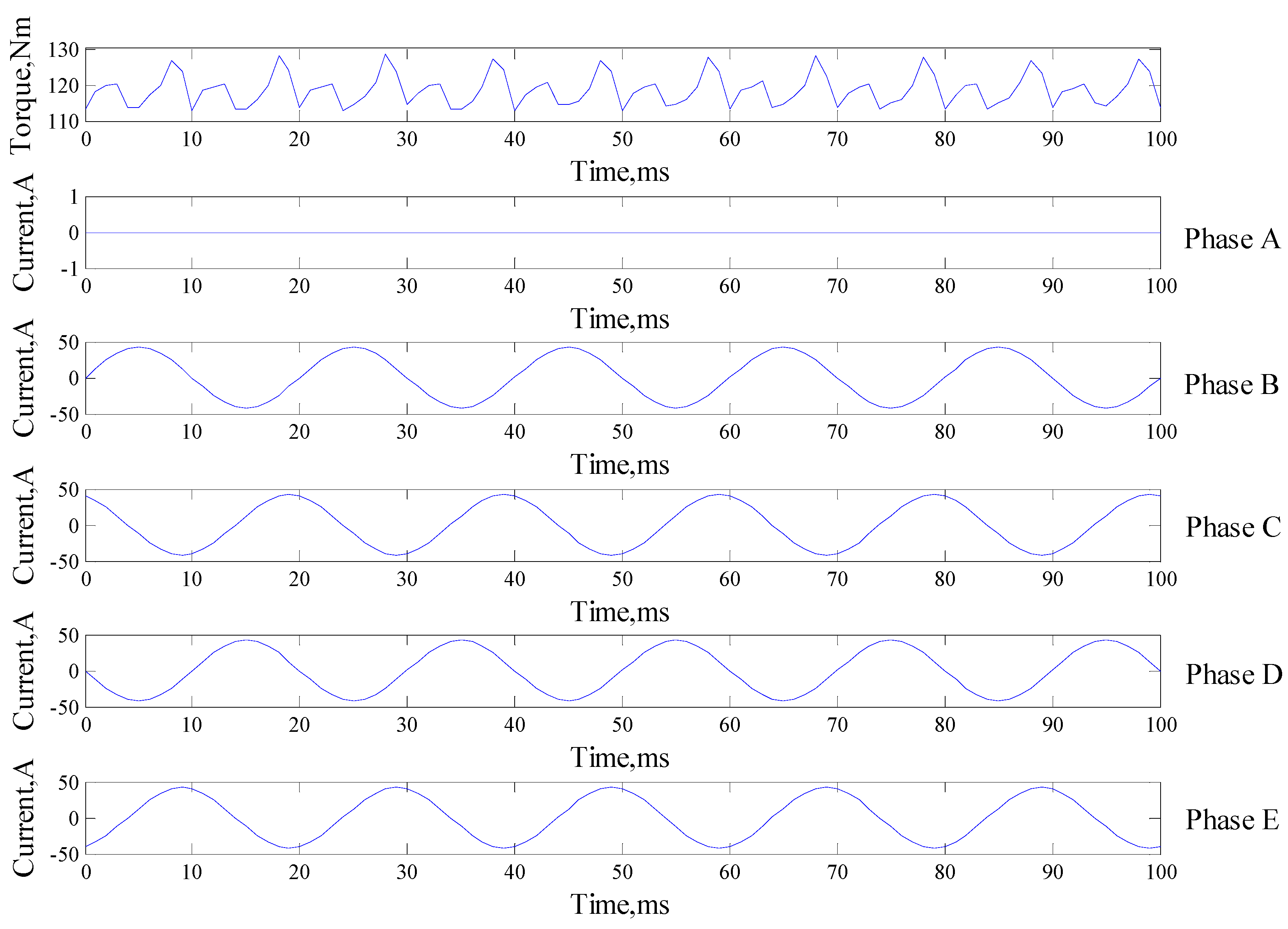

Figure 13 shows the output torque and armature current waveforms at full load when under one-phase open-circuit condition, where we can see that this machine can still output steady torque when one-phase open-circuit, but the torque ripple is relatively higher.

Figure 13.

Output torque and armature current waveforms of this machine under one-phase open-circuit condition.

Figure 13.

Output torque and armature current waveforms of this machine under one-phase open-circuit condition.

When two adjacent phases open-circuited (for example, both Phase A and Phase B are open-circuited), the MMF will be generated by the remaining three healthy phases:

and the current of the remaining three phases are purposely governed by:

Therefore, the current of the remaining three phases can be expressed as:

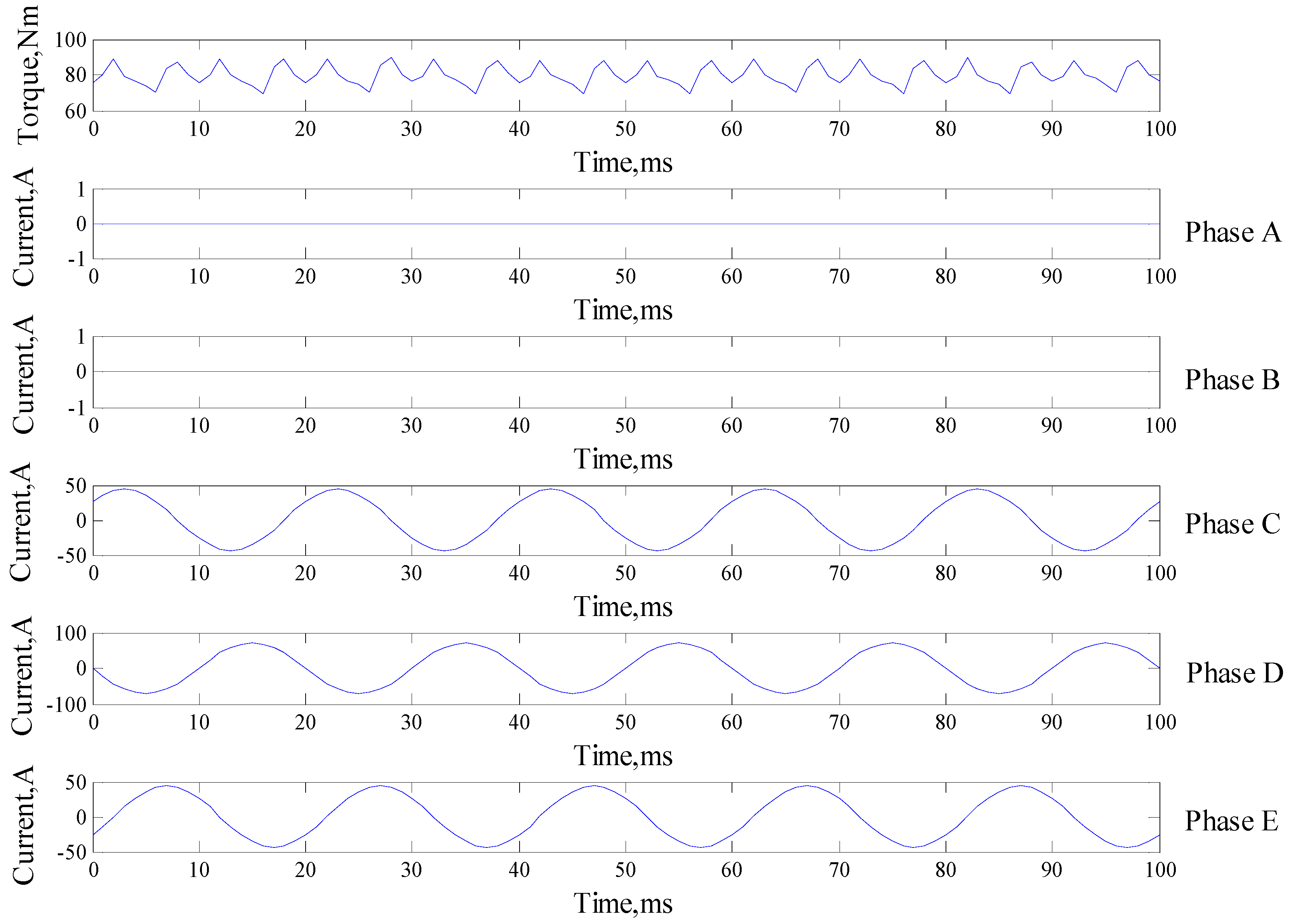

It can be seen that the angles of Phase C and Phase E currents are regulated to that of the pre-fault Phase B and Phase A currents, respectively, while the angle of Phase D current is unchanged. The current amplitudes of Phase C and Phase E are 2.236-times and Phase D is 3.618-times their pre-fault values. The output torque and armature current waveforms when the machine works at full load are shown in

Figure 14. Again, we can find that this machine can work well under two-phase open-circuit operation. For the case of two nonadjacent phases open-circuited, the corresponding analysis is similar to that of two adjacent phases that are open-circuited.

Figure 14.

Output torque and armature current waveforms of this machine under two-phase open-circuit condition.

Figure 14.

Output torque and armature current waveforms of this machine under two-phase open-circuit condition.

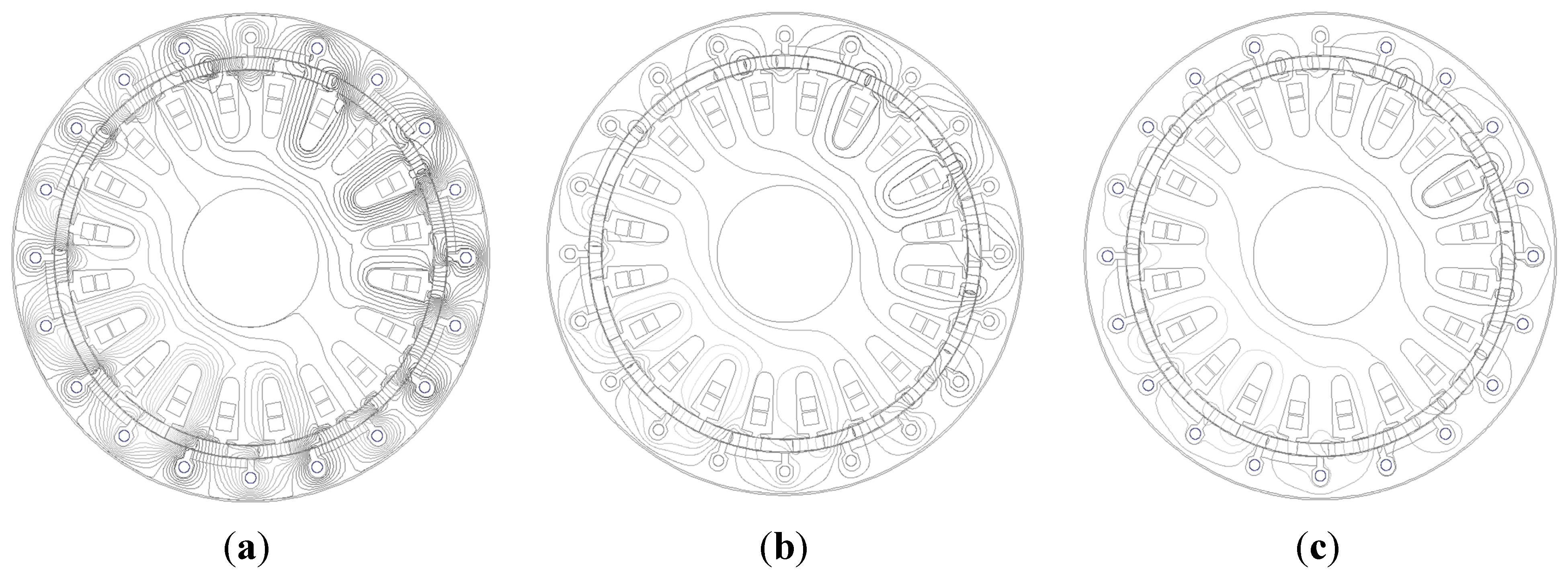

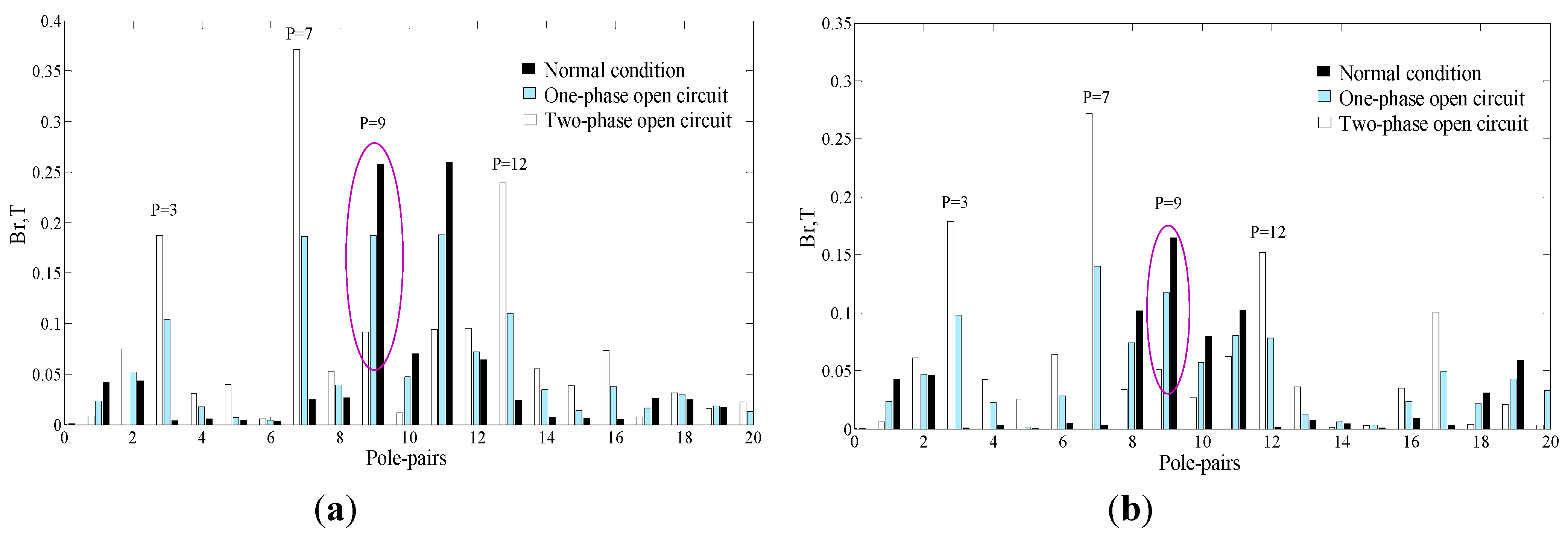

The torque characteristic of the proposed machine under fault-tolerant operation are investigated and compared with torque when working at normal conditions, as shown in

Figure 15, which show that the torque density decreases during fault-tolerant operation; the maximum torque is 157 Nm, 119 Nm and 81 Nm for normal condition, one-phase open circuit condition and two-phase open circuit condition, respectively. However, the torque ripple increases during fault-tolerant operation; the torque ripple is 4.9 Nm 15.8 Nm and 19.5 Nm for these three conditions, respectively. In this proposed machine, the armature windings are designed with nine pole pairs, which will contribute to the average torque; other harmonics will cause the torque ripple. The field harmonics excited only by the armature windings in both normal condition and open circuit conditions are investigated, as shown in

Figure 16. One can see clearly that the dominant harmonic in generating average torque with nine pole pairsis weakened during fault-tolerant operation, which leads to the reduction of the torque density; while other harmonics with 3, 7 and 12 pole pairs, which will not contribute to the average torque, but only causes torque ripple, are strengthened during fault-tolerant operation, which is responsible for the increase of the ripple torque when one or two phases open circuit. The electromagnetic performances of the proposed machine are given in

Table 2.

Figure 15.

Torque characteristic of the FTFM machine at normal condition and fault conditions. (a) Torque-angle waveforms; (b) maximum torque-time waveforms.

Figure 15.

Torque characteristic of the FTFM machine at normal condition and fault conditions. (a) Torque-angle waveforms; (b) maximum torque-time waveforms.

Figure 16.

Field harmonics excited only by armature windings when working at normal condition and fault conditions. (a) Inner air-gap; (b) outer air-gap.

Figure 16.

Field harmonics excited only by armature windings when working at normal condition and fault conditions. (a) Inner air-gap; (b) outer air-gap.

Table 2.

Machine parameters.

Table 2.

Machine parameters.

| Items | Value | Items | Value |

|---|

| Power (kW) | 7.8 | Maximum torque (Nm) | 157 |

| Rated speed (rpm) | 500 | Maximum torque when one-phase open-circuited (Nm) | 119 |

| Efficiency | >90% | Maximum torque when two-phase open-circuited (Nm) | 81 |