2. From EMS to Cloud EMS

The evolution of cloud EMS could be illustrated schematically in

Figure 1. The EMS, working within intranet, is the information system for managing the site or facilities, and connects to the database of enterprise or remote PC through the internet. Yet, the cloud EMS adopts the cloud server as the core of management and connects the specific controllers and the related sensors, such as digital power meters, through the internet for the energy saving control. The cloud structure with secured data I/O is also applicable to the remote PC or mobile phone for easy access. Energy management can be spread widely by cloud.

Figure 1.

The evolution of cloud EMS.

Figure 1.

The evolution of cloud EMS.

The main difference between the EMS and the cloud EMS is similar to that between the operating system (OS) of the traditional personal computer (PC) and the cloud APP of the smart phone or the tablet PC. The advantages of cloud EMS are: (1) shared software resources could reduce the facility cost; (2) with a cloud service, the cloud EMS could be upgraded continuously till the optimization of function. However, the disadvantage is from the normalized application layer of cloud server, because the energy management functions may not be tuned finely for the specific hardware of the distributed sites. How to promote the advantages, overcome the disadvantages and yield an evolution, i.e., a successful commercialization of cloud EMS, is the main issue in this study.

3. iEN, the Cloud EMS Developed and Deployed at Taiwan

iEN, the cloud EMS launched by Chunghwa Telecom, Taiwan in 2011, is a commercial cloud service system for energy management [

12]. After one year pilot run, the Chunghwa Telecom cooperated with the academic team, Energy Technology Research Center (ETRC) of NTUT, for improving this product. The main goal of this cooperation was to overcome the disadvantage and promote the advantages as illustrated in the previous section. The modified results and the application of the improved cloud service on the distributed sites will be discussed in the following sections.

3.1. Three Integrated Service Modes of the Cloud EMS

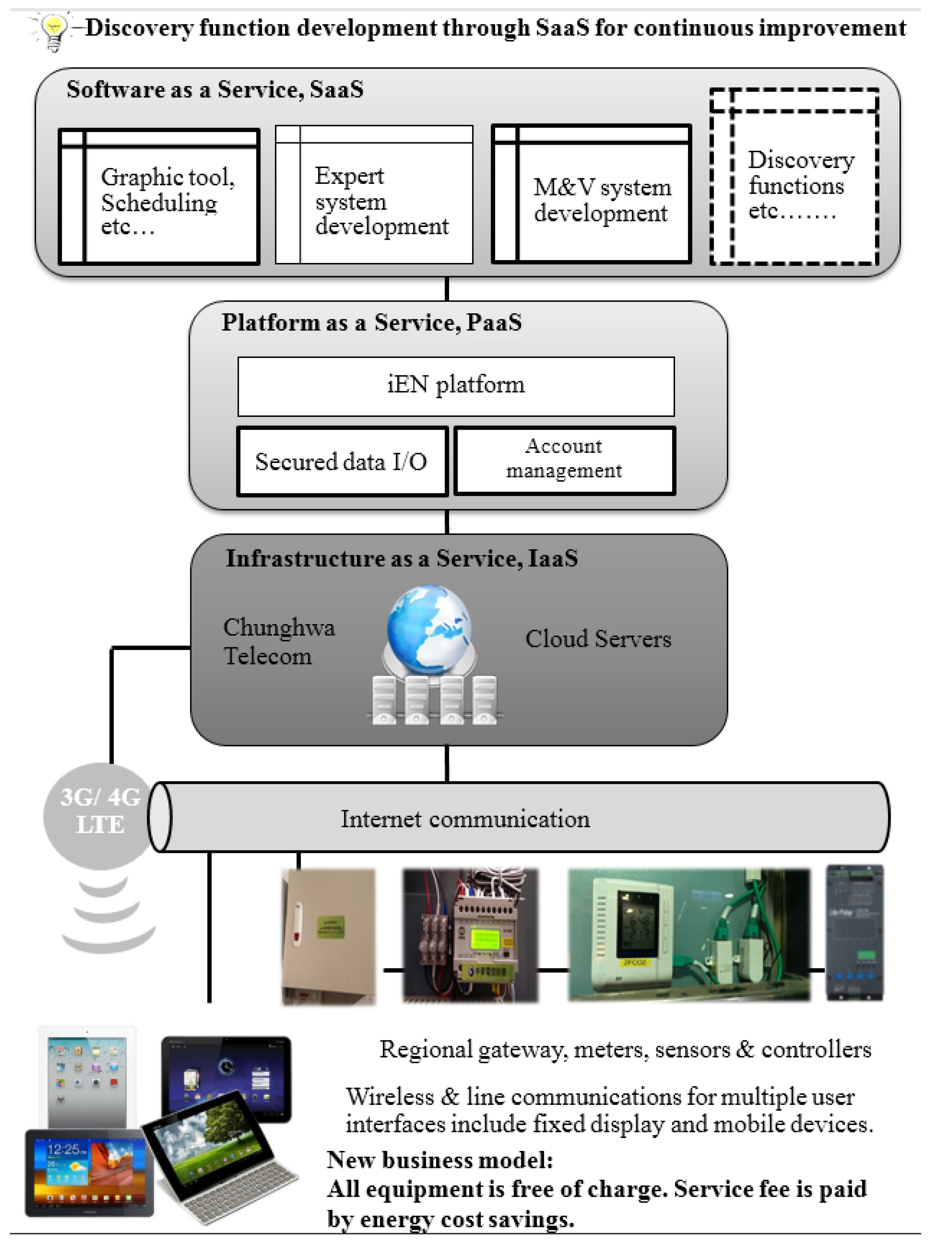

The cloud EMS consists of three service modes, including the software as a service (SaaS), the platform as a service (PaaS), and the infrastructure as a service (IaaS). The SaaS was first demonstrated in February 2001 [

13]. It is a software license and delivery model, in which the software is licensed on a subscription basis and hosted centrally on the cloud. With SaaS, the application software is guaranteed to work with hardware provided by the cloud service. The mentioned main disadvantage of the cloud EMS could be conquered by SaaS. The details will be presented in

Section 3.5.

The PaaS denotes a computing platform and a solution stack as a service. In this model, the consumer could create an application or service by using the tools/libraries from the cloud service provider. PaaS provides the computing resources for application design, development, test, and deployment as well as web services.

The IaaS is a provision model in which the equipment used for services is organized. IaaS offers additional resources, such as a virtual-machine disk image library, raw block storage, and file or object storage, firewalls, load balancers, IP addresses, virtual local area networks (VLANs), and software bundles. By integrating these three service models, the service structure of iEN is illustrated in

Figure 2.

Figure 2.

Cloud EMS and an iEN platform, consists of three service models, i.e., SaaS, PaaS, and IaaS.

Figure 2.

Cloud EMS and an iEN platform, consists of three service models, i.e., SaaS, PaaS, and IaaS.

3.2. Energy Management Functions Enabled by PaaS

As shown in

Figure 2, PaaS works as the middle layer, which could provide the management of login and secured data for the energy saving management sites. Here, the iEN platform works as the core of performing energy management functions developed by the top layer of SaaS. Through reviewing the developing history of EMS, three main functions are identified for effective energy management and performed by the iEN platform as follows:

- (1)

Energy usage and related information monitored by connecting to the gateway, digital power meters, related sensors and controllers.

- (2)

Multi-graphic display function includes (a) real time power meter reading plot; (b) pie chart for energy usage analysis; (c) energy related sensor reading displays; and (d) statistical regression analysis.

- (3)

Scheduling control function includes (a) setting energy saving target and scheduling on online calendar; and (b) setting time schedule and control parameters for energy saving of single facility.

3.3. Optimized Service by SaaS

As illustrated in

Section 2, the main advantage of the cloud EMS is its capability for upgrading continuously to the optimized version. The SaaS works as the core of this optimization. In this software layer, various energy saving operation models would be developed. The management structure of SaaS server is a hi-cloud system, denominated by Chunghwa Telecom. The developing program of the service platform and the database system are XML and the NoSQL system, respectively. The testing sites could also be connected with SaaS through the PaaS and IaaS for practicing energy management. The function development is achieved through SaaS as shown at the top of

Figure 2.

In this study, two advanced functions, including an expert system for model-based control and a measurement and verification (M&V) system for measuring the saved energy, were developed in the layer of SaaS, and deployed by the iEN platform for testing energy conservation effects.

3.4. A new Business Model Created by the M&V System

The M&V system can measure the reserved energy under the management of cloud service. It creates a new business model for energy conservation. As shown at the bottom of

Figure 2, all the equipment of cloud EMS is free of charge. Service fee is paid by the saved energy cost.

The reserved energy could be estimated according to the standard of the International Performance Measurement and Verification Protocol (IPMVP) [

14]. Cloud EMS would assist users to build up enough sensing points for the calculation of energy conservation. The operation of the M&V system includes the following steps:

- (1)

Login: users should log in to the system here.

- (2)

Target type: choose the target type, such as company, institute, and building, for calculating the energy saving amount. At the same time, the users could choose the measuring point of energy saving efficiency.

- (3)

Energy baseline period: according to the monitoring condition of iEN, this is a complete recording period before the application of energy saving procedure.

- (4)

Modeling list: if there is no data for calculating the energy baseline, the program would provide the modeling method for calculating it.

- (5)

Defined reporting period: after the application of energy saving procedure, the energy saving amount could be calculated according to the energy usage difference between the energy baseline period and the defined reporting period. This period could be short as three months, or similar to the energy baseline period. The starting point of defined reporting period would be decided based on the differential method. After the application of energy saving procedure, the energy saving effect would be manifested by the increment of differential value of energy usage. Therefore, after the application of energy saving procedure, the timing of the maximum differential value of energy usage would be the starting point of the defined reporting period.

The energy saving amount is the deduced amount of energy usage after adopting the energy saving instrument or procedure. The calculated energy saving results may include the information of energy saving amount and saved energy usage. Some details related to energy savings comparison between the sensor platform and IPMVP can be referred to our previous work [

15].

3.5. Fine-Tuned Service by Expert System

As illustrated in

Section 2, the disadvantage of cloud EMS may be due to the normalized application layer of cloud server. Energy management functions may not be fine-tuned to meet the specific hardware of the distributed sites. In order to conquer this situation, the expert system was developed to perform the modeling control. Based on proper model, the scheduling and related control can be tuned finely to fit the requirements of the distributed sites.

Based on the operational conditions, the expert system could simulate a simplified factory energy management system. This model treats a factory as a grey box with energy cost, E, raw materials, R, and the created product value, V. The unit of the energy cost, E, raw materials, R, and the created product value, V is US$. Referring to the optional pricing model, a modified Black-Scholes equation [

16] could be used to simulate the factory energy usages by:

If there are several products manufactured by the same factory with several raw material, the model would be enlarged as a multi-parameters one. The utilized energy could be electricity, gasoline, oil or other energy types. Three coefficients, , denote the increment rates of energy consumption, material usages and product values, respectively. The coefficient, , denotes the economic fluctuation of the product market.

The cloud service could gather the energy usage information automatically. By connecting to the enterprise resources planning (ERP) system, the product values and raw material usages could be obtained. All coefficients would be determined from websites, including future price, stock’s price and economic signs announced by government. With all these data, daily energy usage target can be calculated by:

For modeling and optimization of buildings, including residential, commercial and complex buildings, the software development could refer to a review work for building optimization [

17]. The algorithms of air conditioning system were modified based on the hot and humid weathers at Taiwan. The optimal energy supply of the air conditioner could be calculated by Linear Quadratic Gaussian (LQG) method. The predictive control based on mobile communication is suggested for the air conditioning energy conservation. The calculating details and smart sensors with their contribution on smart air conditioning control for providing a comfortable environment and achieving the goals of energy conservation and environmental protection could be obtained from our previous work [

18].

For lighting systems of buildings, the optimization of light intensity is based on the adjustable luminance control with the feedback from the light intensity sensors distributed at the site. Not only is the light intensity, according to the Chinese National Standard (CNS) 12112 for the lighting requirement of indoor work places, the light bulb number is also required to fit a suitable indoor light intensity. The Chinese National Standard (CNS) 12112 is published by the Bureau of Standards, Metrology and Inspection (BSMI), Ministry of Economic Affairs, Taiwan. The fine-tuned service of the expert system could be practiced by an APP program to reduce the energy consumption. The example of improving the service quality by SaaS would be illustrated in

Section 5.

5. Results and Discussion

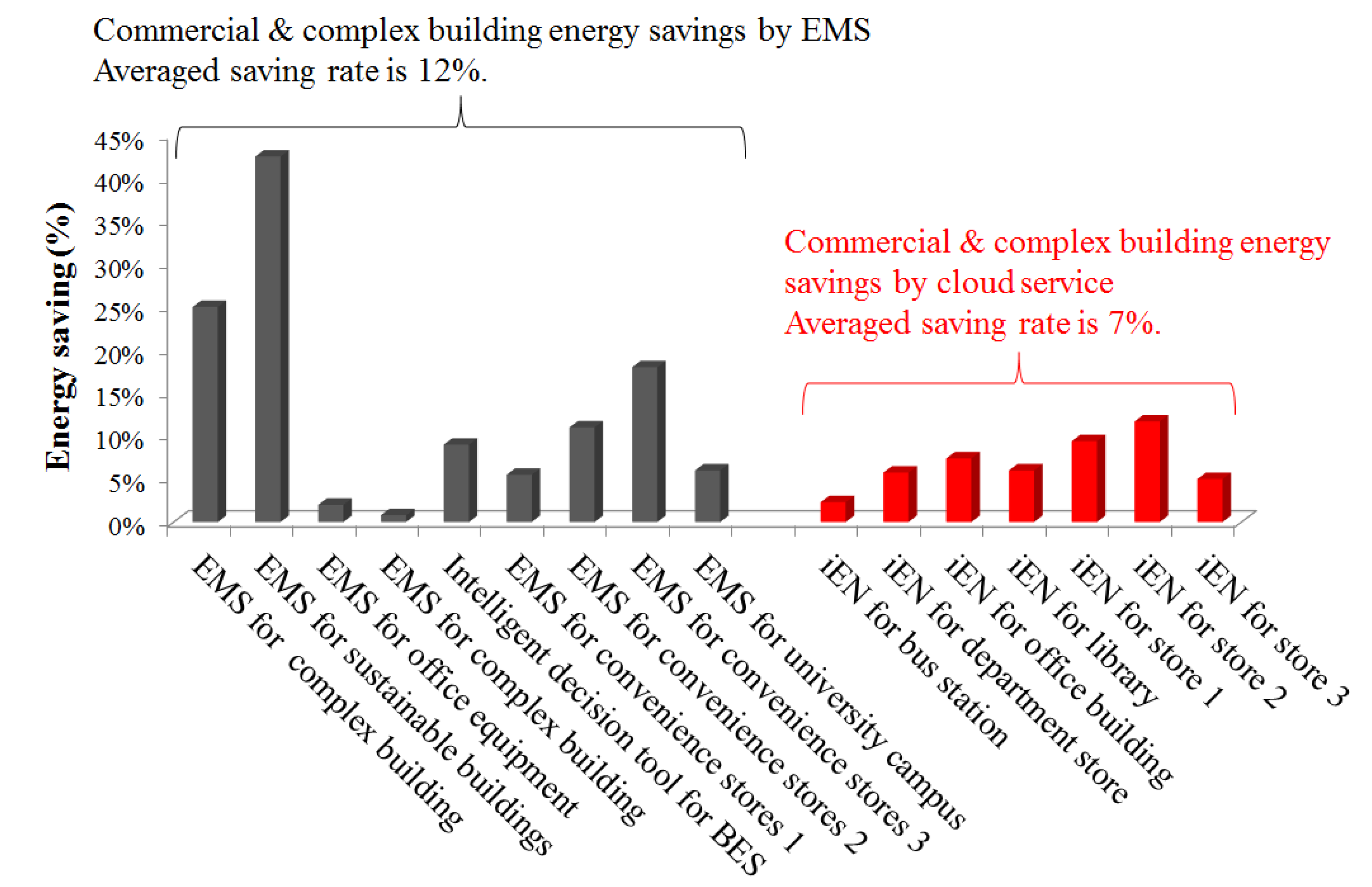

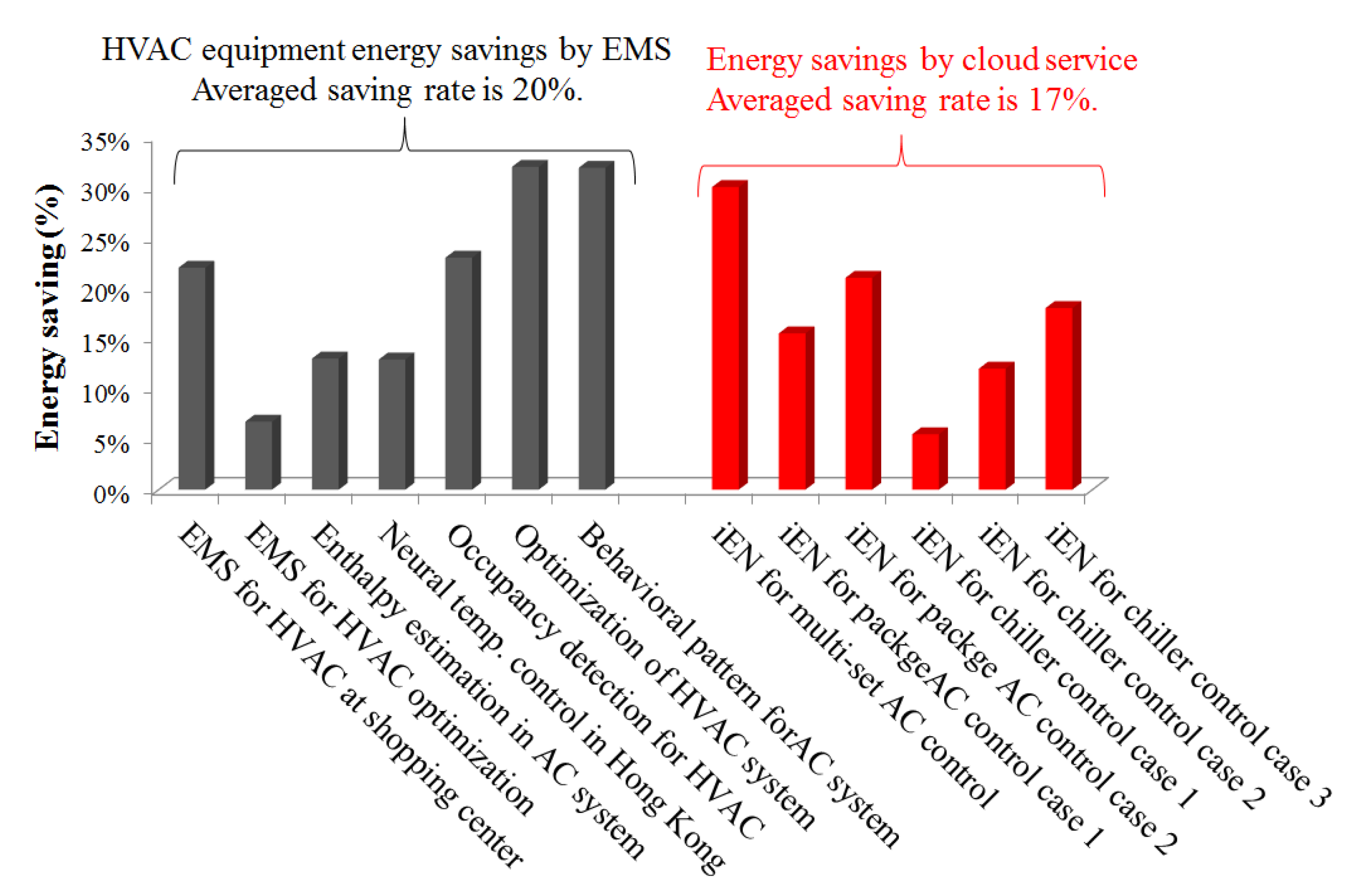

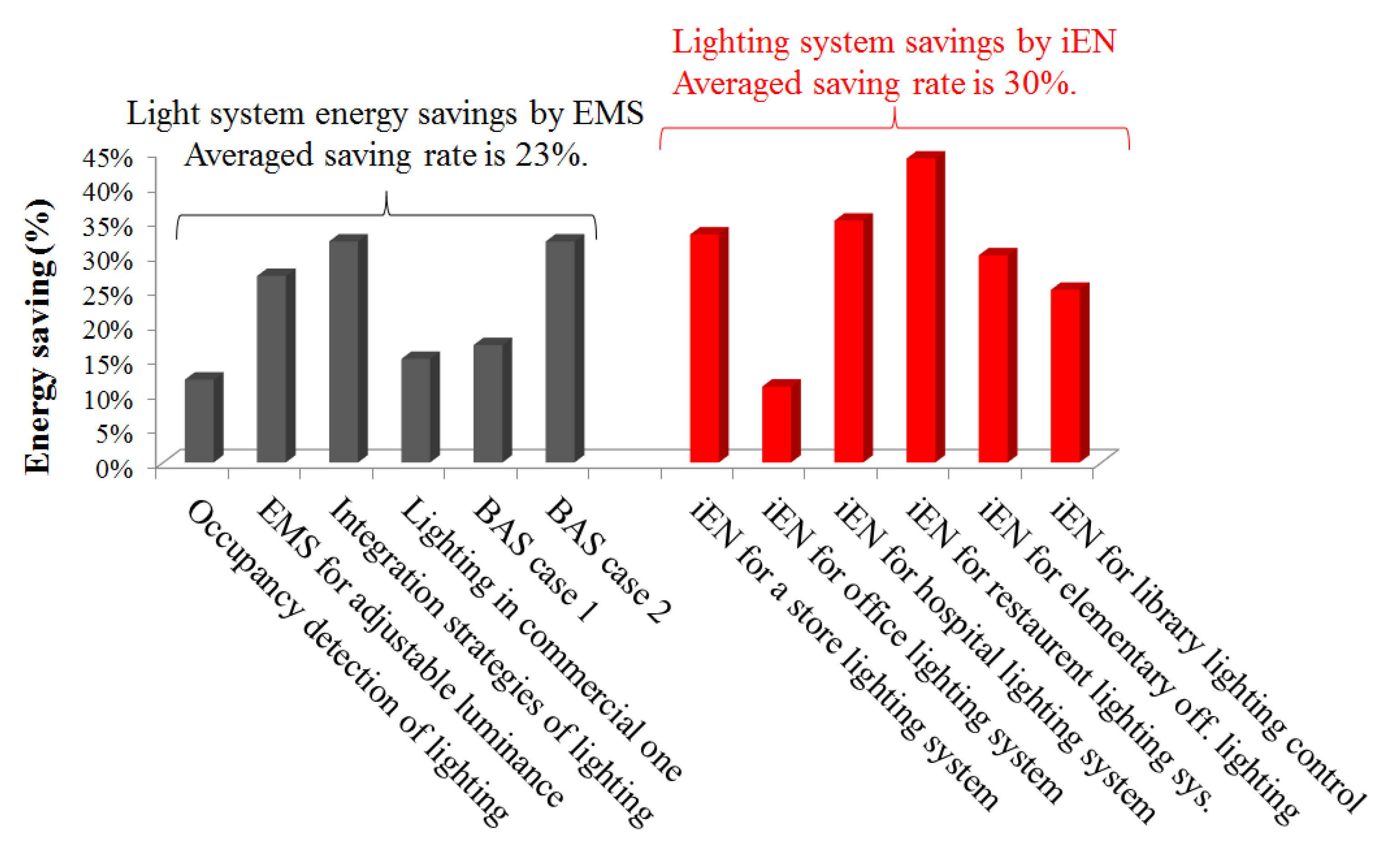

It is interesting to compare the energy savings of sites and facilities managed by EMS and cloud EMS. The comparing results are presented in

Figure 3,

Figure 4,

Figure 5,

Figure 6 and

Figure 7 for the factory, commercial and complex building, home, and single facility, including HVAC equipment and light system, respectively.

The comparison of energy savings of factories in

Figure 3 includes company, steel group, chemical factory, machining factory, and bearing factory. The highest energy saving effect is the bearing factory, 30%, by applying cloud service of iEN. The averaged energy savings of factory is 21.2% and 16% for applying EMS and iEN, respectively.

Figure 3.

Comparison of energy savings of factories by applying EMS and iEN.

Figure 3.

Comparison of energy savings of factories by applying EMS and iEN.

Figure 4.

Comparison of energy savings of commercial and complex buildings by applying EMS and iEN.

Figure 4.

Comparison of energy savings of commercial and complex buildings by applying EMS and iEN.

The comparing results of the commercial and complex building are shown in

Figure 4. Those sites include EMS for a complex building in Saudi Arabia, EMS integrated design for sustainable buildings, EMS for office equipment, intelligent decision support tools for building energy saving, and EMS for convenience stores and for university campus. Sites also include iEN for a bus station, department store, office building, library and convenience stores. The site with the highest energy saving effect, 43%, is the EMS integrated design for a sustainable building. The average energy savings of commercial and complex buildings are 12% and 7% for applying EMS and iEN, respectively.

Figure 5.

Comparison of energy savings for home-type buildings by applying EMS and iEN.

Figure 5.

Comparison of energy savings for home-type buildings by applying EMS and iEN.

The home-type buildings in

Figure 5 include home EMS, intelligent decision support tools for building energy saving, energy-consumption information system for home energy conservation, home EMS based on automatic meter reading and home EMS for assessing overall lifecycle. The sites also include iEN for three residential buildings and for a dormitory. The highest energy saving effect is the intelligent decision support tool, 9%, by applying EMS. The average energy savings of home-type buildings are 5% and 7% for applying EMS and iEN, respectively.

Figure 6.

Comparison of energy savings of HVAC equipment by applying EMS and iEN.

Figure 6.

Comparison of energy savings of HVAC equipment by applying EMS and iEN.

The energy saving control cases of HVAC equipment, in

Figure 6, include the EMS for a HVAC system at a shopping center, the EMS for HVAC system optimization, enthalpy estimation for thermal comfort control and energy saving in an air conditioning system, neural temperature control and a management system in subtropical Hong Kong, occupancy detection based control for a HVAC system, optimization of a HVAC system, and a behavioral pattern for air conditioning energy saving. The cases also include iEN for multi-set air conditioners control, iEN for three package air conditioner control cases and for chiller control cases. The highest energy saving effect is, 32%, the optimization of HVAC system by applying EMS. The average energy savings of HVAC equipment are 20% and 17% for applying EMS and iEN, respectively.

Figure 7.

Comparison of energy savings of lighting system by applying EMS and iEN.

Figure 7.

Comparison of energy savings of lighting system by applying EMS and iEN.

Lighting systems in

Figure 7 include EMS development for adjustable luminance control at each location of the building, integration strategies between daylight and electric lighting and strategies based on the occupancy of spaces, building automation and control system in commercial buildings. The other cases are iEN for a store lighting system control, iEN for office lighting system control, iEN for hospital lighting system control, iEN for restaurant lighting system control, iEN for elementary school lighting control and iEN for library lighting control. The highest energy saving effect is, 44%, the restaurant lighting system control by applying cloud service of iEN. The average energy savings of lighting system are 23% and 30% for applying EMS and iEN, respectively.

In summary, the comparative analysis results indicate that the average energy savings by applying iEN are 8.9% and 23.5% for the whole site and single facility, respectively. Those by applying EMS are 11.6% and 21.4%, respectively. Compared with the EMS cases, it is found that the energy savings of the whole site by applying the cloud service are 76% of that by applying EMS.

Even though the energy savings by applying cloud EMS are not the same as those by applying EMS, the significant contribution of cloud EMS is to provide an evaluation structure, including a M&V system. It helps users to calculate the energy savings in real-time, and creates a new business model. For the cloud energy management service, users do not need to purchase the energy saving equipment, and only need to pay the monthly service fee. The energy management related hardware and software are provided by the telecom company, such as the Chunghwa Telecom in this study. Since the equipment belongs to Telecom Company, only depreciation expenses are counted on monthly billing charged with telecom fee. If the monthly service fee is around 80% ± 5% of the saved energy cost, the cloud energy management service is recommended to keep. This is due to that the monthly service fee is almost equal to the energy saving fee. This is the immediate payback case.

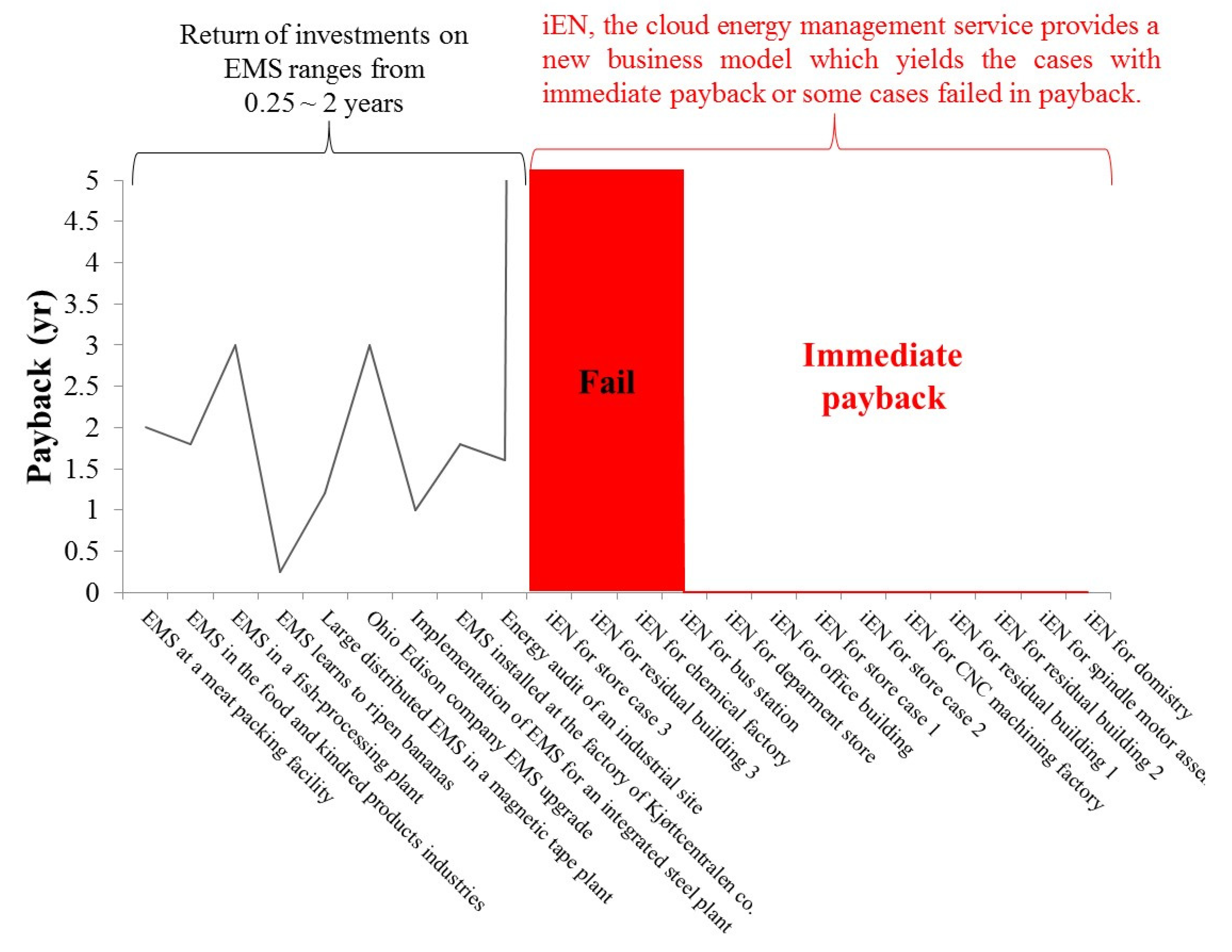

Figure 8 shows the payback period of investment by applying EMS and cloud EMS, iEN. The payback range of the cases applying EMS is 0.25–2 years, with the average of 1.7 years. However, iEN, the cloud energy management service, provides a new business model, which yields the cases with immediate payback or never payback (monthly service fee >80% ± 5% of the saved energy cost). Over 70% of the specific sites and facilities are the cases of immediate payback, whose monthly service fee may return back from the energy saving fee. The major benefit of the cloud EMS is the innovation of the business model, which could cost down the energy saving service, and approach the immediate payback for the popularization of energy saving management service.

Figure 8.

Payback period of investment by applying EMS and cloud EMS. The payback time of EMS is 0.25–2 years. However, the Cloud EMS, iEN, yields the cases with immediate payback or never payback (Fail cases as shown in Red bar).

Figure 8.

Payback period of investment by applying EMS and cloud EMS. The payback time of EMS is 0.25–2 years. However, the Cloud EMS, iEN, yields the cases with immediate payback or never payback (Fail cases as shown in Red bar).

6. Conclusions

The development of cloud EMS demonstrated an innovative tool, iEN, launched by Chunghwa Telecom in 2011, for energy conservation. It was composed of three service modes, including Infrastructure as a Service (IaaS), Platform as a Service (PaaS) and Software as a Service (SaaS). IaaS is a provision model in which organizes the equipment used for services. PaaS offered the deployment of applications or services without the complexity of buying and managing the underlying hardware and software. SaaS presented a development platform for improving cloud service continuously. The expert system was developed for optimizing the energy saving control. Furthermore, based on IPMVP, the M&V system was included in iEN to create a new business model.

In total, 55 test sites distributed in Taiwan were effectively managed by the cloud EMS. The experimental results indicated that the cloud EMS may have relatively poor energy savings as compared with the EMS cases. However, over 70% of the managed sites and facilities by iEN are the cases of immediate payback, whose monthly service fee may return back from the saved energy cost. Therefore, the major benefit of cloud EMS is the innovation of the business model, which could cost down the service and approach the immediate payback for the popularization of energy saving management service.