1. Introduction

Recently, green technology has gained much attention because of its necessity and importance for the future of humankind. Especially, energy harvesting or energy saving technology has become a major research area in the green technology [

1,

2].

The triboelectric effect refers to the electrical charging of different materials because of friction occurring when the materials are rubbed or pressed together. The triboelectric effect is usually regarded as potentially hazardous, especially for MOSFET transistors and CMOS integrated circuits, because it induces an undesirable static charge that can lead to ignition in the presence of dust or volatile, flammable gases. Nevertheless, the triboelectric effect has gained much attention in recent years because of its high potential for supplying power to standalone devices and for energy-harvesting applications [

3].

The principle of electricity generation by the triboelectric effect is based on the transfer of charge due to friction when different materials are rubbed or pressed [

4,

5,

6,

7,

8,

9,

10,

11,

12]. When such materials are in contact charge is transferred in order to maintain electrochemical equilibrium at the interface. However, when the materials are separated, some of the bonded atoms could have extra electrons. When such electrons are released, flow of charge occurs.

Research on the triboelectric effect dates back to ancient Greece, when Thales observed that a piece of amber could attract light objects after being rubbed. Through this discovery, elektron, which means amber in Greek, emerged as the origin of electricity. Several centuries later, Otto von Gueriche developed an electrostatic generator that produced electricity with a rotating sulfur ball. This device inspired many researchers to develop different forms of electricity generators using friction. Although triboelectric machines, such as the Leiden jar, were of fundamental importance for electricity generation, they were eventually replaced by batteries and modern electric generators based on Faraday’s law.

In recent research, TEG has attracted considerable attention with the growing demand for nanopower generators and storage of mechanical energy. Noting the abundance of the triboelectric phenomena in daily life, Fan

et al. [

7] developed a triboelectric nanogenerator using two thin plates of Kapton and polyester (PET). They showed that the nanogenerator could produce a power density of 10.4 mW/cm

3 and voltage of 3.3 V, which is suitable for LEDs, self-powered devices, and wearable electronic devices. Since the materials used are easy to fabricate, inexpensive, and scalable, such nanogenerators have considerable potential for powering mobile and personal electronics for healthcare, surveillance, and mitigation systems as well as for comfortable environments.

Therefore, owing to their simple structure and high efficiency, nanogenerators have motivated studies for further improving their efficiency and widening their application.

The primary TEG research issues that need to be addressed are enhancing the efficiency of electricity generation and simplifying the manufacturing process.

Efforts to improve the power density of a TEG have focused on adopting different materials and surface structures. Kim

et al. [

5] employed graphene film, owing to its ultra-high electron mobility characteristics. Lee

et al. [

6] constructed a porous sponge structure on the surface of aluminum film, which produced nearly 10 times more power than the bare, flat film.

Furthermore, studies on enhancing the electrical output of TEGs have focused on increasing the friction contact area. Fan

et al. [

7] and Yang

et al. [

8] adopted a MEMS photolithographic method to increase the contact area between two films. In addition, the optimal surface patterning to maximize electricity generation was investigated using cubic, linear, and pyramidal patterns; the pyramidal pattern showed the highest sensitivity and electrical output. Microscale particles were photolithographically added by Wang

et al. [

9] on the TEG surface in order to obtain a pattern for maximizing the friction contact area. In addition, nanoscale gold particles were assembled to the TEG surface using a specific chemical sequence to further increase the friction contact area [

10,

11,

12].

The aforementioned studies have shown that applying micro- and nanoscale patterns and particles on the TEG surface can increase the overall friction contact area, thus enhancing the efficiency of triboelectric charging. Furthermore, TEG also showed the concept of sensitive sensors due to enhancing of triboelectric charge [

13,

14,

15]. However, the main limitation of this technology is the cost and complexity of the manufacturing process by which micro- and nanoscale patterns are applied. Although novel, simple methods of micro-patterning exist, the patterning methods of TEG use the aforementioned complex process. Microscale patterns are obtained by photolithography, which requires a series of complicated processes such as drying, etching, mixing, degassing, and spin coating [

7,

8,

9], while nanoscale patterns are obtained by adhering gold nanoparticles in another complicated process [

13,

14,

15]. In addition, the production speeds of these manufacturing processes are limited.

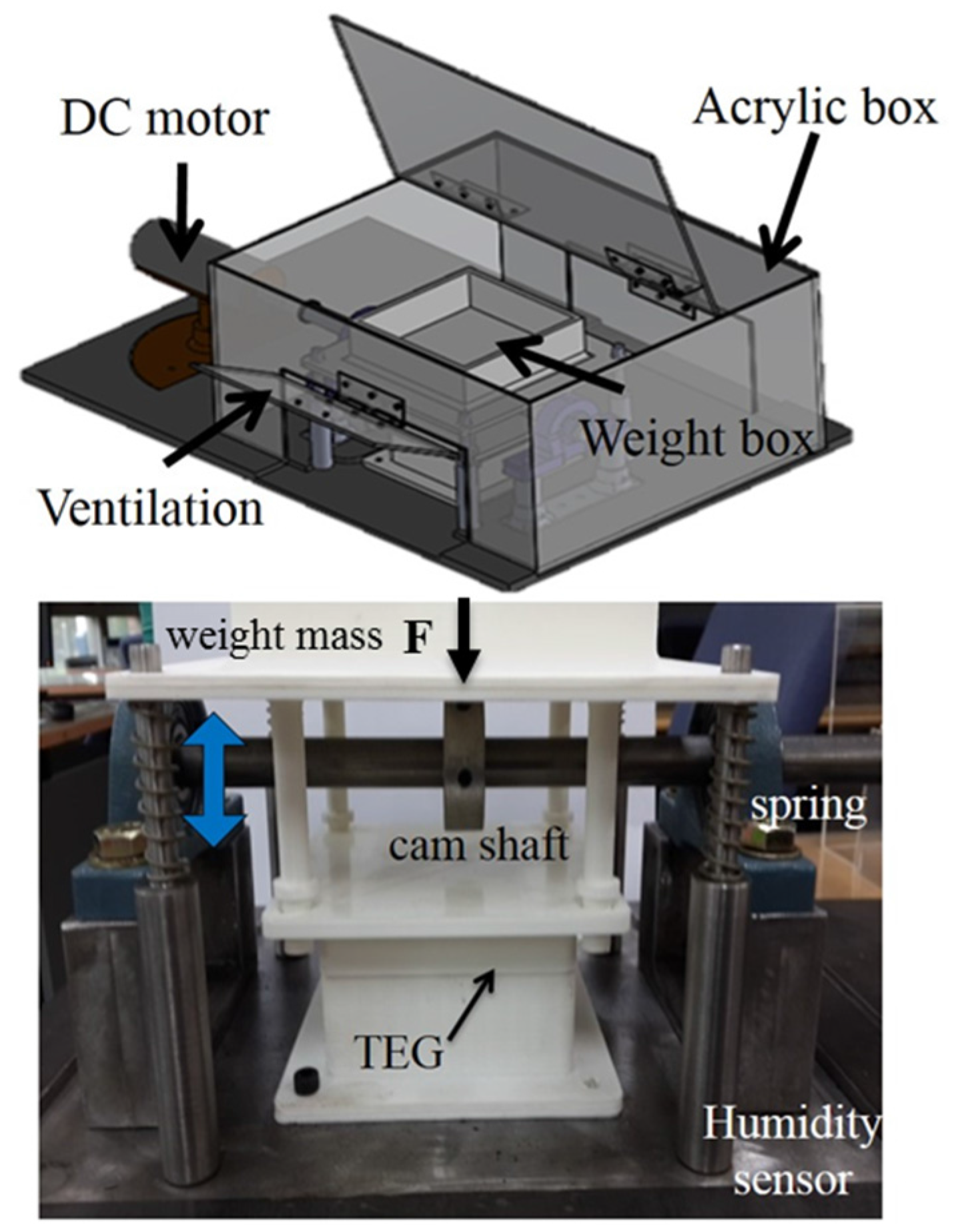

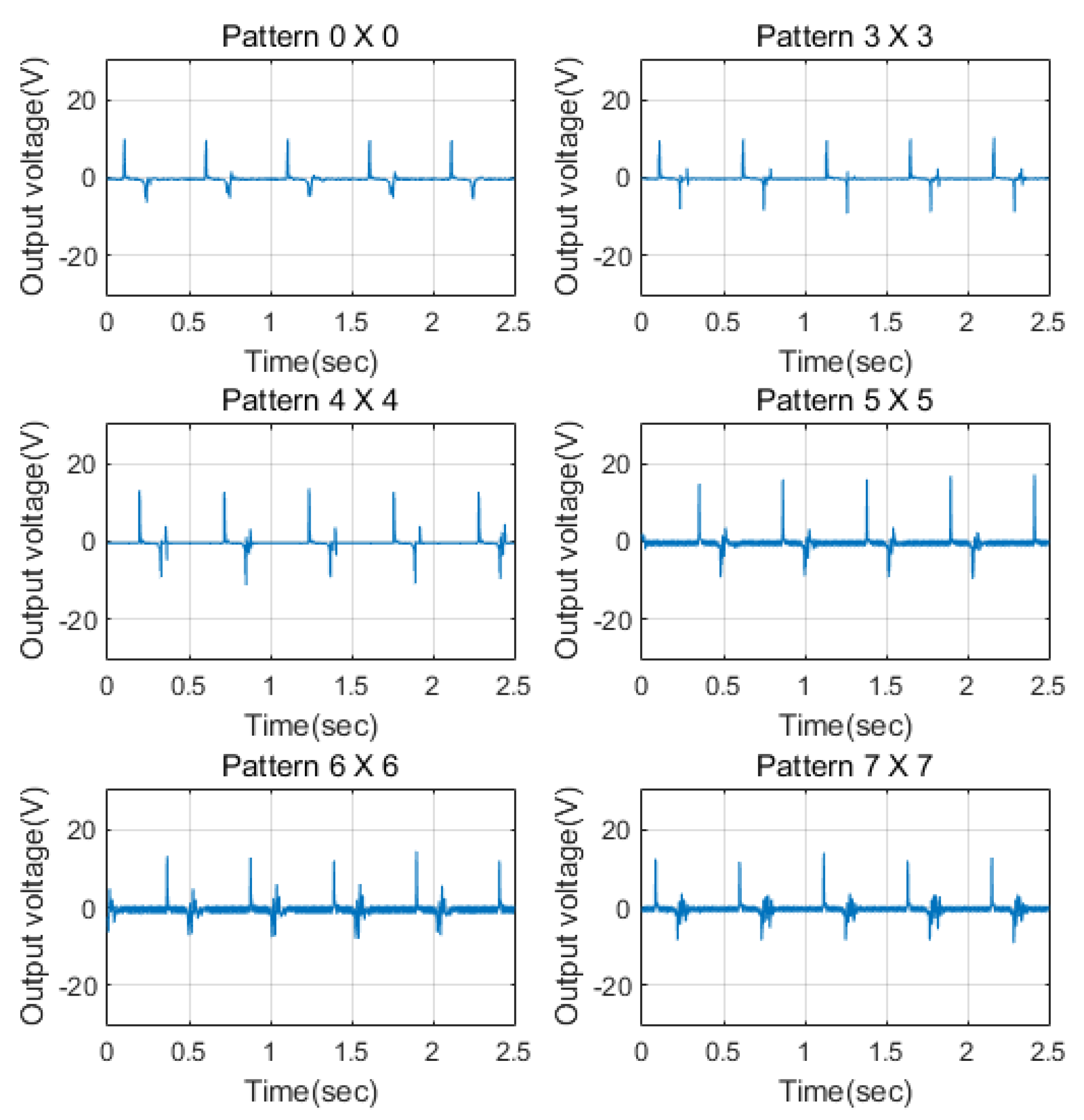

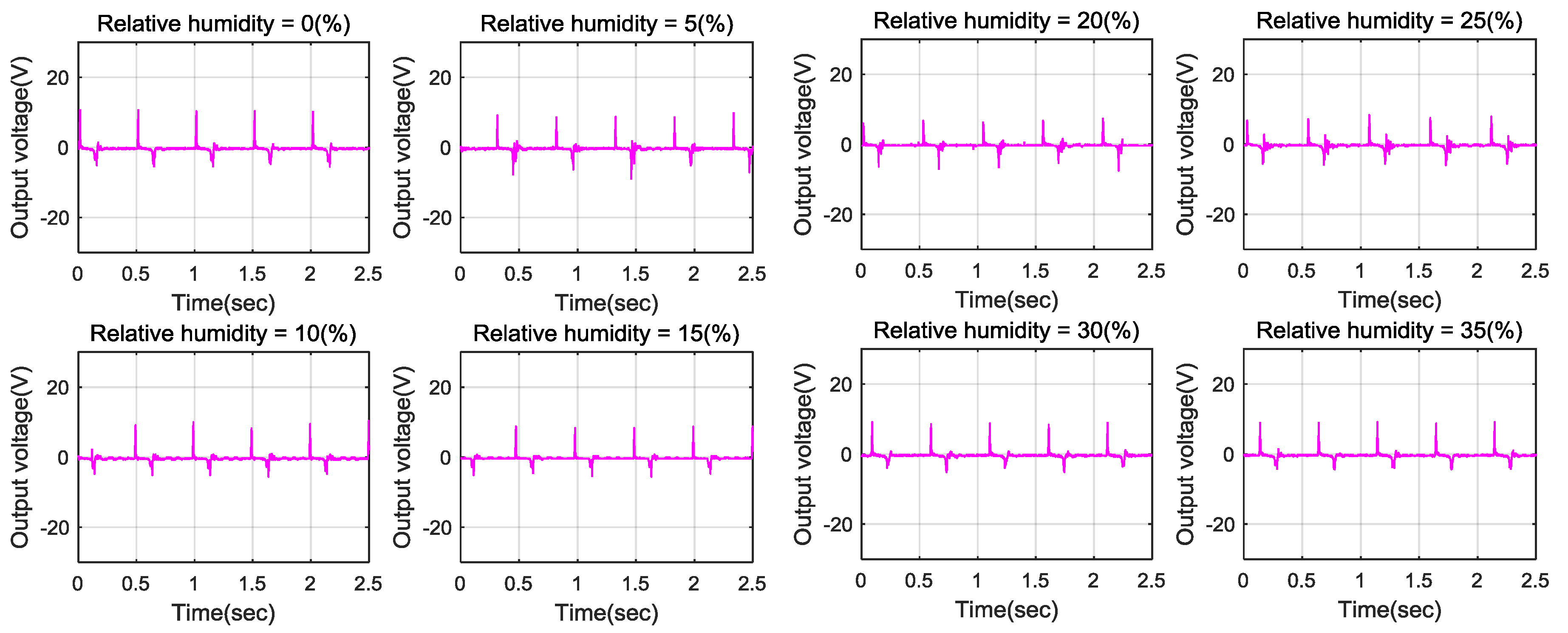

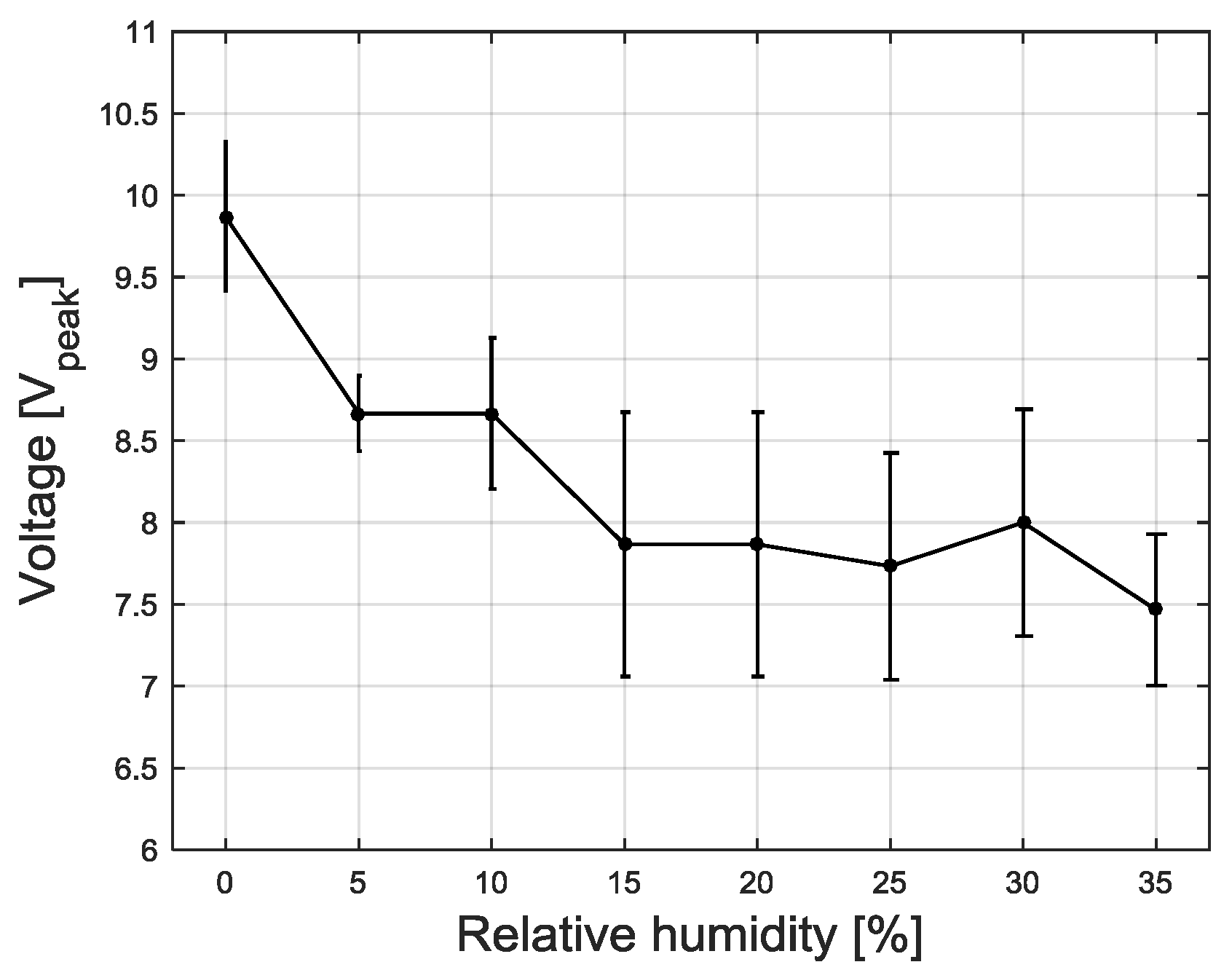

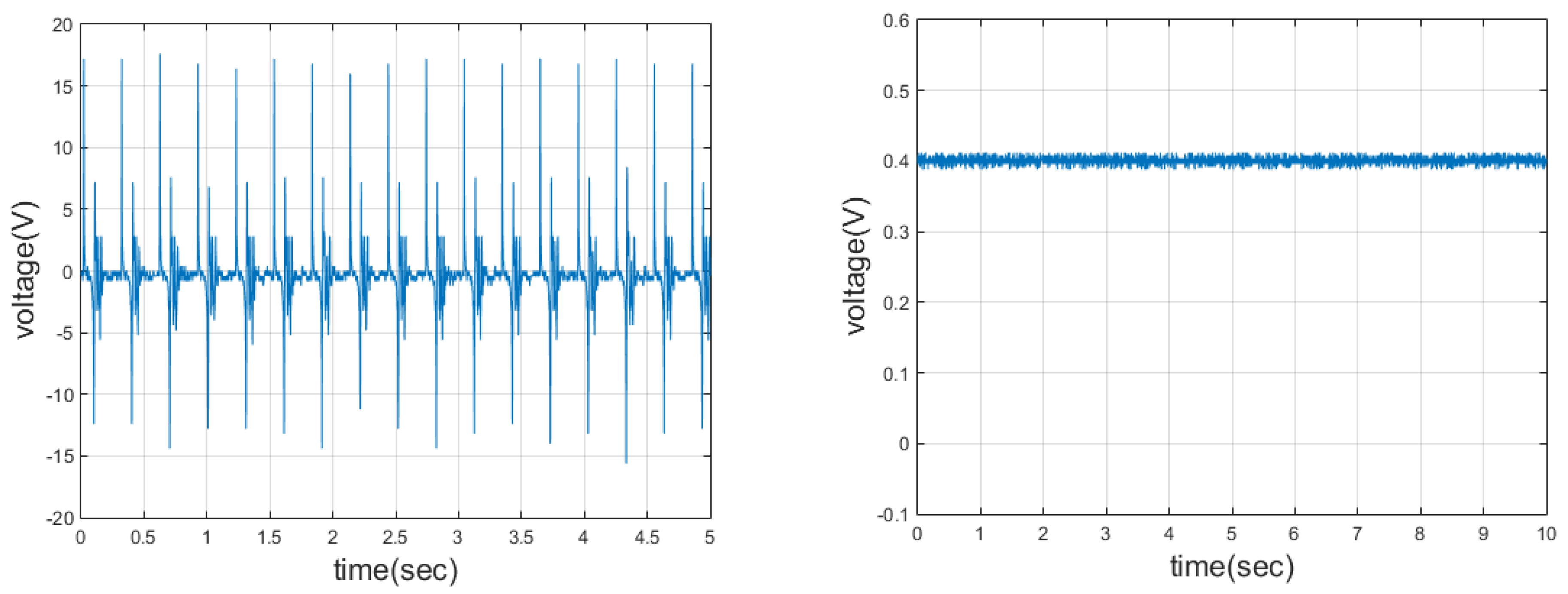

Therefore, this paper proposes an affordable manufacturing process to enhance the overall TEG efficiency using 3D printers, which are easily accessible. The proposed method can be classified as macroscale surface patterning, in contrast to micro- and nanoscale patterning proposed in previous studies. The surface patterns are inscribed on a TEG with a mold created using a 3D printer. Since the proposed method uses a 3D printer for the patterning, it is a fast, cost-effective, and simple process for enhancing the TEG efficiency. The patterns were designed to have a square pyramid shape in order to achieve maximum power generation. A test-bed system was designed to validate the performance of the proposed system under controllable force (magnitude and frequency) and humidity. Finally, the conditions for optimal TEG operation were proposed on the basis of the experiments.

The remainder of this paper is organized as follows.

Section 2 describes the process for manufacturing the macroscale patterns.

Section 3 discusses the design of the test-bed system and presents the experimental analysis of the TEG. Finally,

Section 4 summarizes our findings and concludes the paper.

2. Design of TEG with Macroscale Patterns

2.1. Modeling of TEG

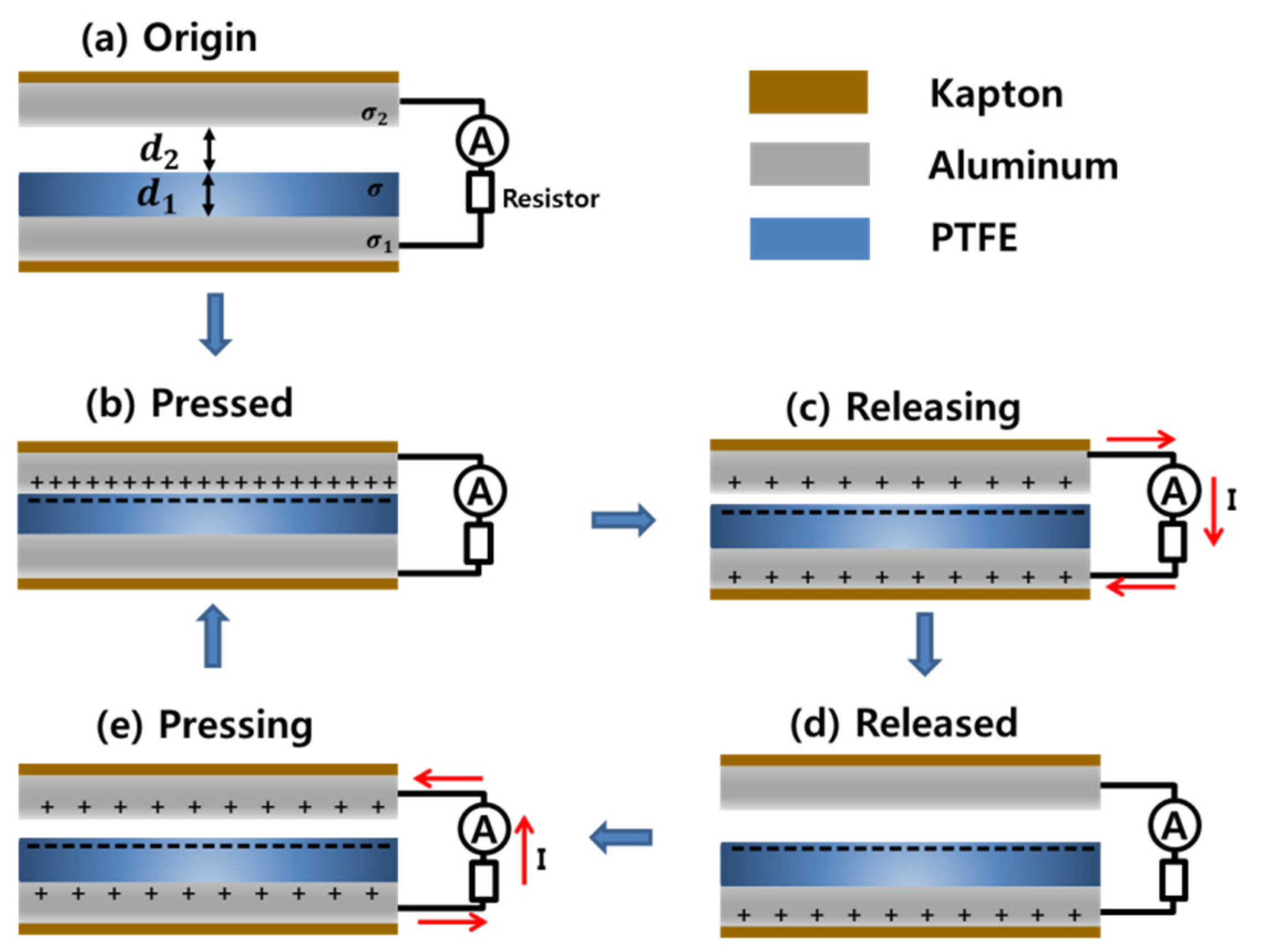

A TEG produces electricity based on the principle of the triboelectric effect, by which electric charge is induced by contacting between two different materials. In this study, the materials used to generate tribo-electric effect are aluminum and polytetrafluoroethylene (PTFE). The outer surfaces of aluminum and PTFE are coated by Kapton thin film to protect the material from any damage, as shown in

Figure 1 and

Figure 2. Kapton film is chosen as the coating substrate due its flexibility, light weight, and high insulation. A patch of aluminum electrode is placed between PTFE and Kapton film for the charge conduction. Aluminum electrodes are coated with insulation film to avoid the two electrodes touching each other when TEG is pressed, as shown in

Figure 2.

Figure 1.

Principle of electricity generation in a TEG.

Figure 1.

Principle of electricity generation in a TEG.

Figure 2.

Aluminum and PTFE films of the employed TEG.

Figure 2.

Aluminum and PTFE films of the employed TEG.

When aluminum and PTFE surfaces are rubbed or pressed together, the electrostatic charge causes electrons to migrate such that the aluminum film becomes positively charged and the PTFE film becomes negatively charged.

The PTFE surface is charged with negative charge with density of σ and the electrode of PTFE and aluminum are charged with positive charge with density of σ1 and σ2, respectively.

At the equilibrium state, the electrical potential of the aluminum electrode (

UAE) and the PTFE electrode (

UPE) can be defined as [

14]

where

ε0 is the vacuum permittivity, and

εrp is the relative permittivity of PTFE film (

εrp = 1.93),

d1 is the thickness of PTFE film (

d1 = 0.2 mm), and

d2 is the distance between the aluminum and PTFE.

Since the total charges are conserved, (

i.e., −

σ −

σ1 =

σ2) the charge density of PTFE electrode

σ1 can be defined as a function of the gap distance (

d2) between the PTFE and aluminum surface as [

14]

Thus, the gap distance d2 is the principal factor that affect the distribution and flow of the electrical charges from one electrode to the other.

2.2. Method of Patterning on the TEG Surface

To enhance the electricity generation by a TEG, the overall contact surface of the TEG should be maximized. Previous studies have inscribed micro- and nanoscale patterns onto the TEG, effectively amplifying the output voltage generation at the cost of a complex and time-consuming manufacturing process. Nanoscale patterning has been accomplished photolithographically through a multi-step process that involves drying, etching, mixing, degassing, and spin coating.

Therefore, in this paper, a simple yet effective manufacturing process is proposed to enhance the TEG electricity generation using macroscale patterns inscribed on a TEG with a patterned mold created using a 3D printer. Instead of using chemicals and complicated processes, the proposed technique simply prints the patterns by pressing the mold onto the TEG surface. The ease and rapidity of this process render it suitable for mass production of TEGs. Subsequent sections of this paper describe how the proposed technique is validated. The results show that macroscale patterns can significantly amplify the voltage output of TEGs for practical applications.

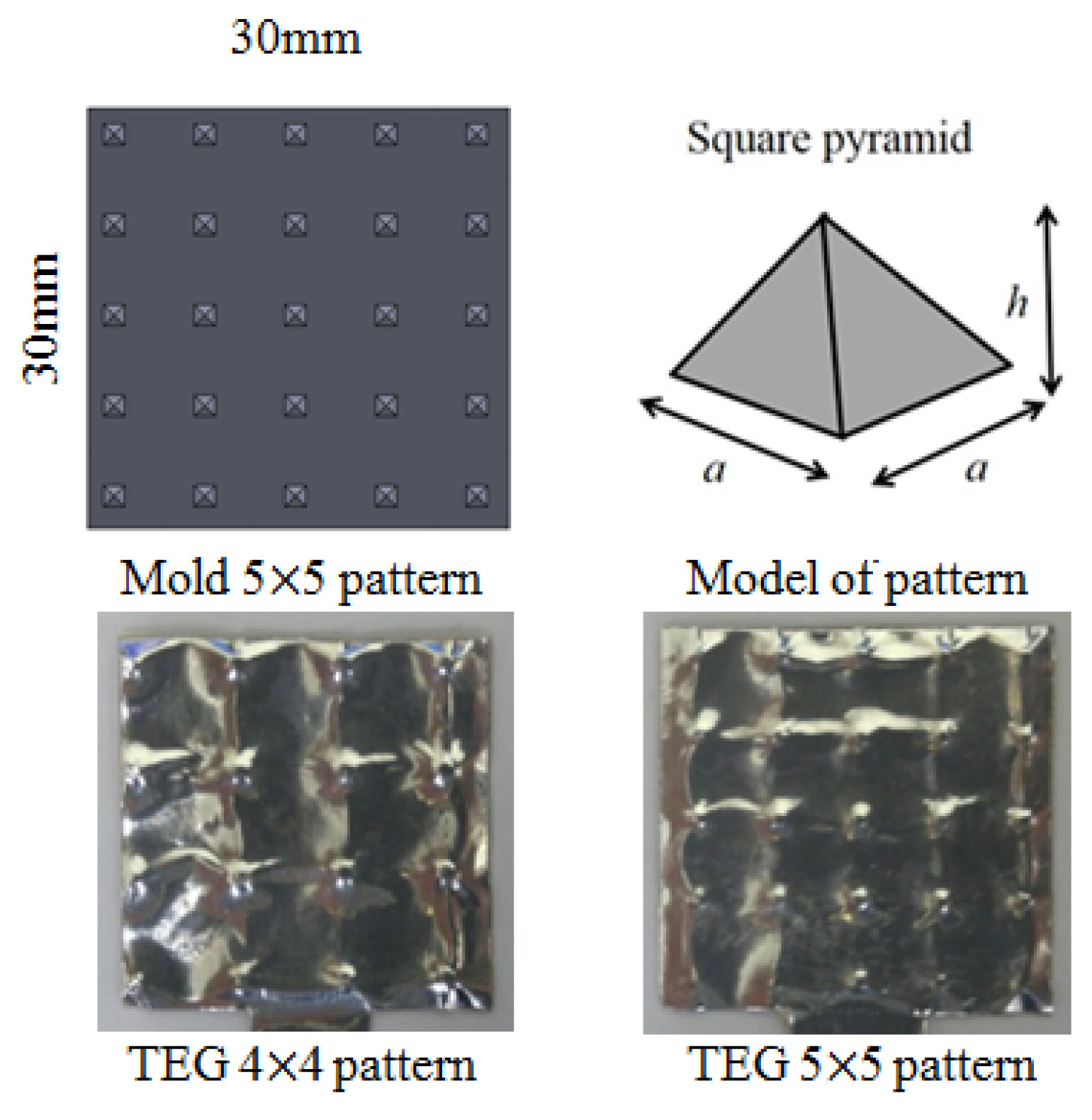

For the pattering of TEG, the mold is placed on top of the back side of the aluminum square patch and is pressed with hand to inscribe the patterns. Thus, the patterns are extrude out on the front side of aluminum surface as shown in

Figure 2 and

Figure 3.

Figure 3.

Patterning mold made using a 3D printer (above); and the inscribed patterns on the TEG surface (below).

Figure 3.

Patterning mold made using a 3D printer (above); and the inscribed patterns on the TEG surface (below).

The mold containing the patterns was fabricated using a 3D printer. The mold was firmly pressed onto the TEG to engrave the patterns, as shown in

Figure 2 and

Figure 3. The patterns were designed to have a square pyramid shape with base length

a and height

h. Assuming that there are

n patterns on the TEG with square base surface area

l ×

l mm

2, the overall surface area of the TEG is calculated as

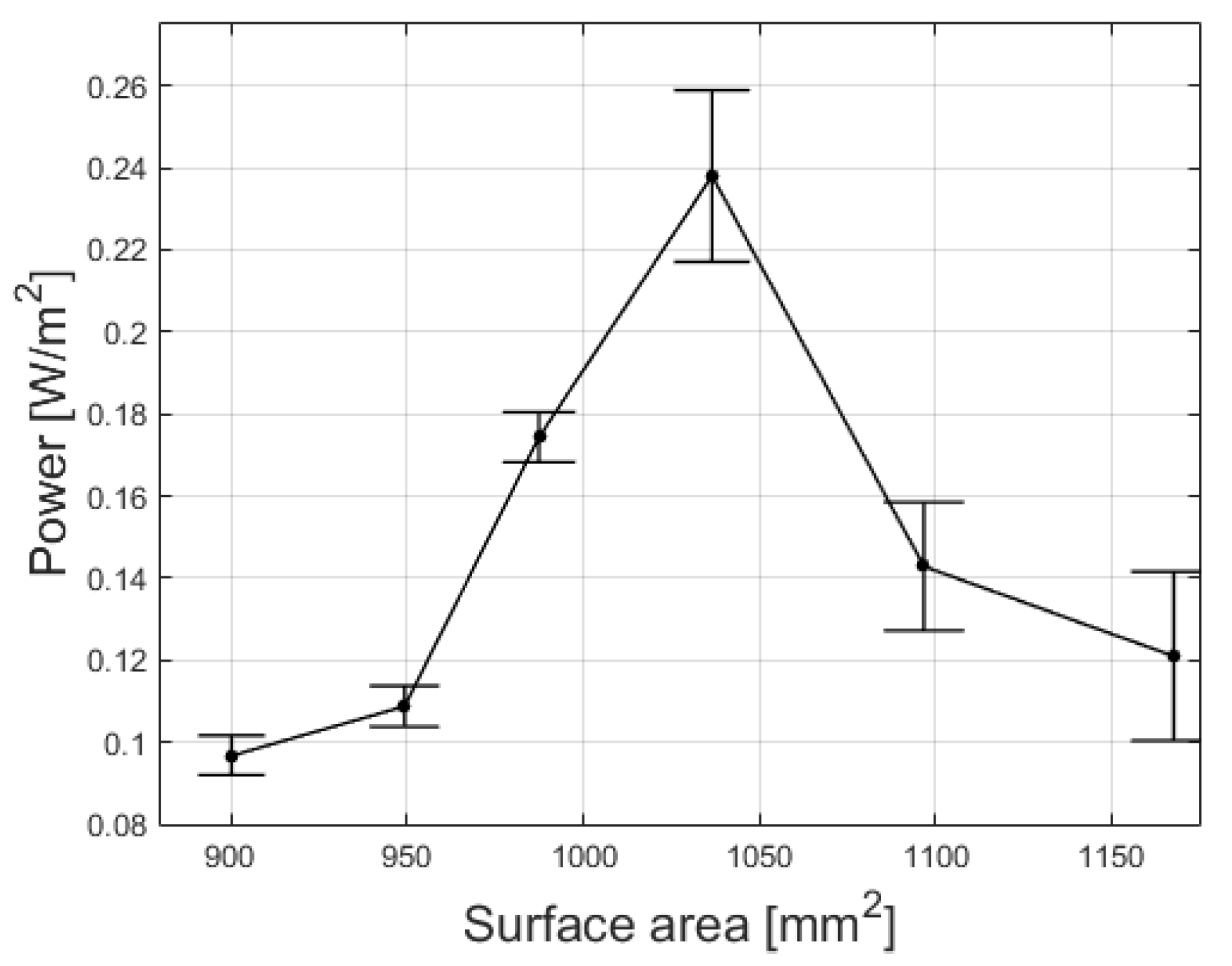

In this experiment, the size of the TEG film was set at 30 × 30 mm, and a single pattern was designed to have both base length (a) and height (h) equal to 2 mm. When n = 36, the effective contact area was increased from 900 mm2 to 1024 mm2, which is an increment of approximately 14%.