Investigation of Process Variables in the Densification of Corn Stover Briquettes

Abstract

:1. Introduction

2. Materials and Methods

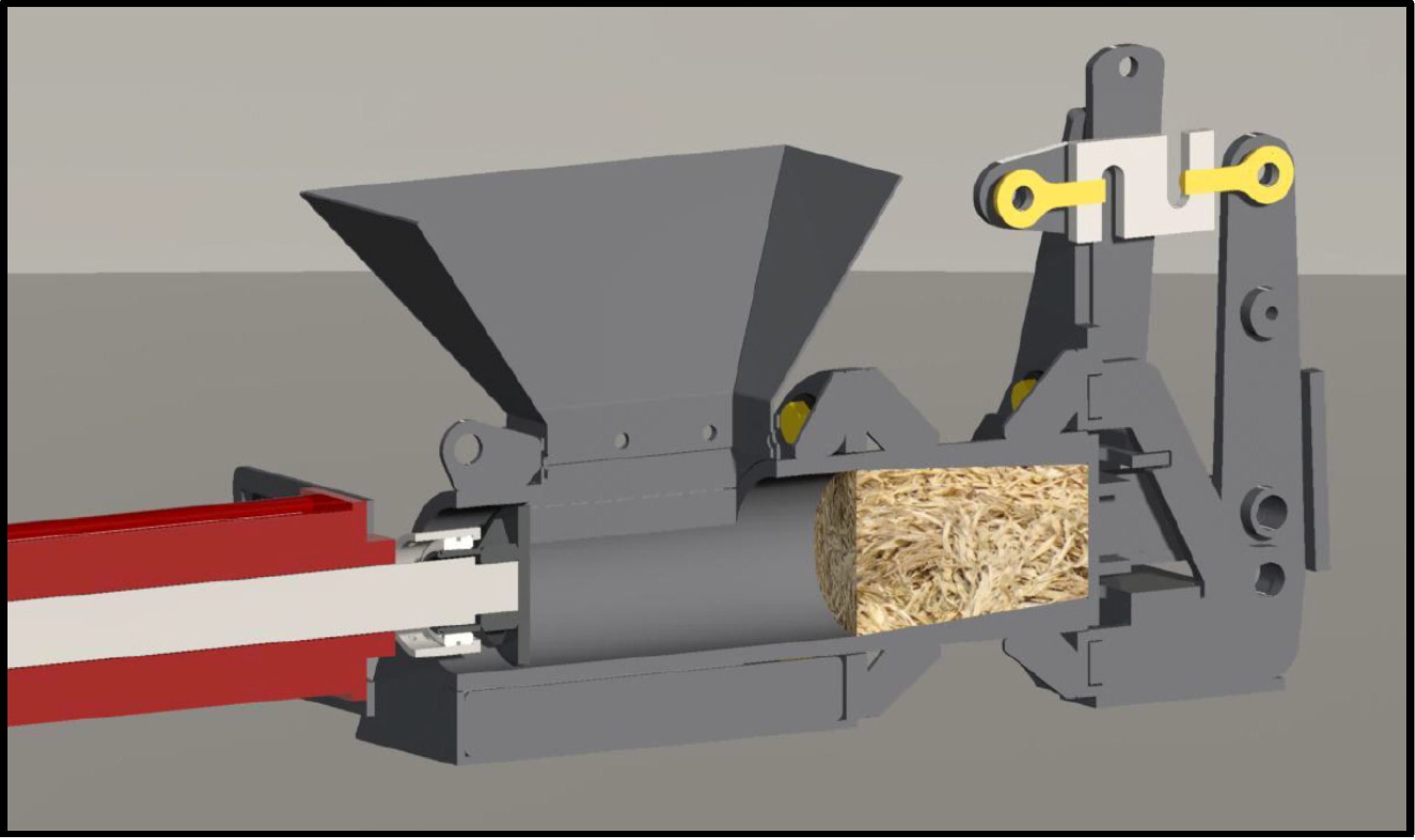

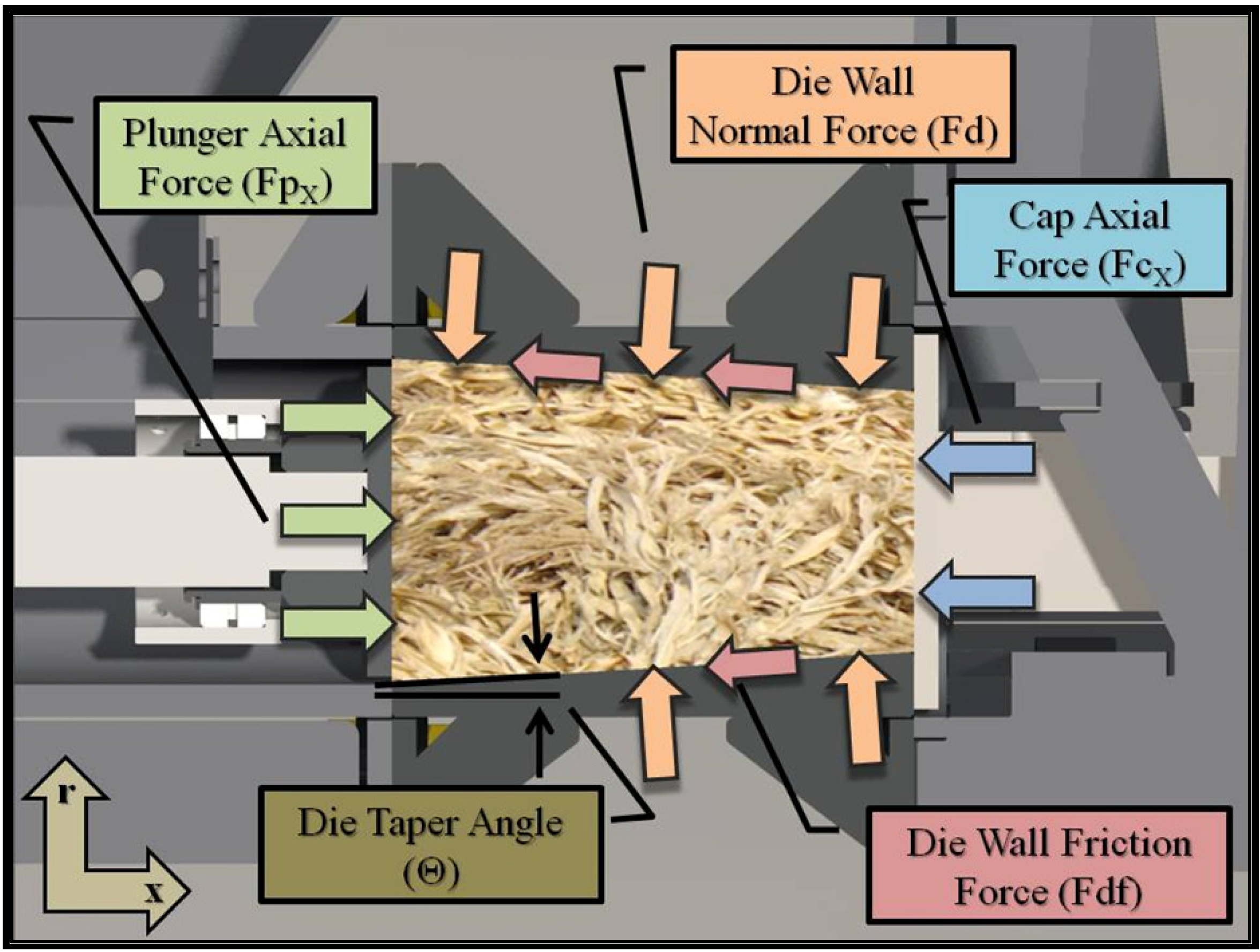

2.1. Briquette Densification Bench Development and Basic Operation

2.2. Material Harvest and Classification

- (1)

- “Corn Stover.” This material was harvested with a standard “all crop” header which cuts the plant just below the corn ear and harvests all material above the cut point. The output material primarily consisted of stalk and leaf;

- (2)

- “Material Other than Grain” (MOG). This material was harvested using a conventional corn header which generally harvests just the ear and husk. The output material primarily consisted of leaf, husk, and cob;

- (3)

- “Pure Cobs.” This material was harvested using a conventional corn header and combine with a secondary attachment for output material processing. The output material primarily consisted of cob.

- (1)

- “As Received.” This material classification passed through an integrated chopper on a combine, but underwent no further size reduction;

- (2)

- “Wood chipper.” This material classification was “As Received” above and subjected to further size reduction using a Vermeer HG200 wood chipper with dual parallel screens set at 70 and 111 mm;

- (3)

- “Hammer mill.” This material was classification was “As Received” above and subjected to further size reduction using an Arts-Way 60HP stationary hammer mill with a 19 mm round-hole screen.

2.3. Experiment Design

2.3.1. Three-Way Interaction Experiment

2.3.2. Moisture Effects Experiment

2.3.3. Material Types Experiment

2.3.4. Bulk Density Experiment

2.4. Data Analysis

3. Results and Discussion

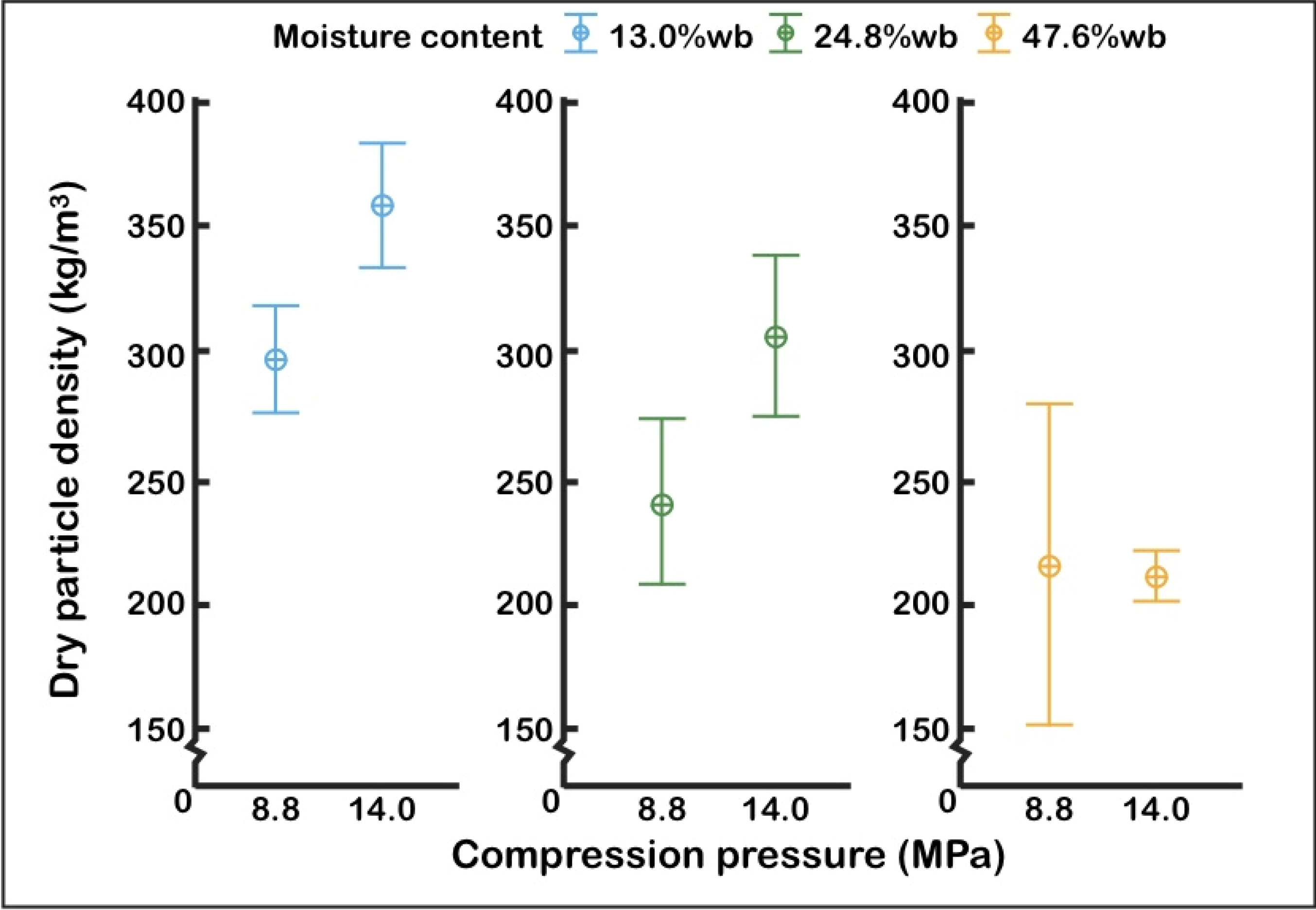

3.1. Three-Way Interaction Experiment

3.1.1. Dry Particle Density

3.1.2. Qualitative Effects

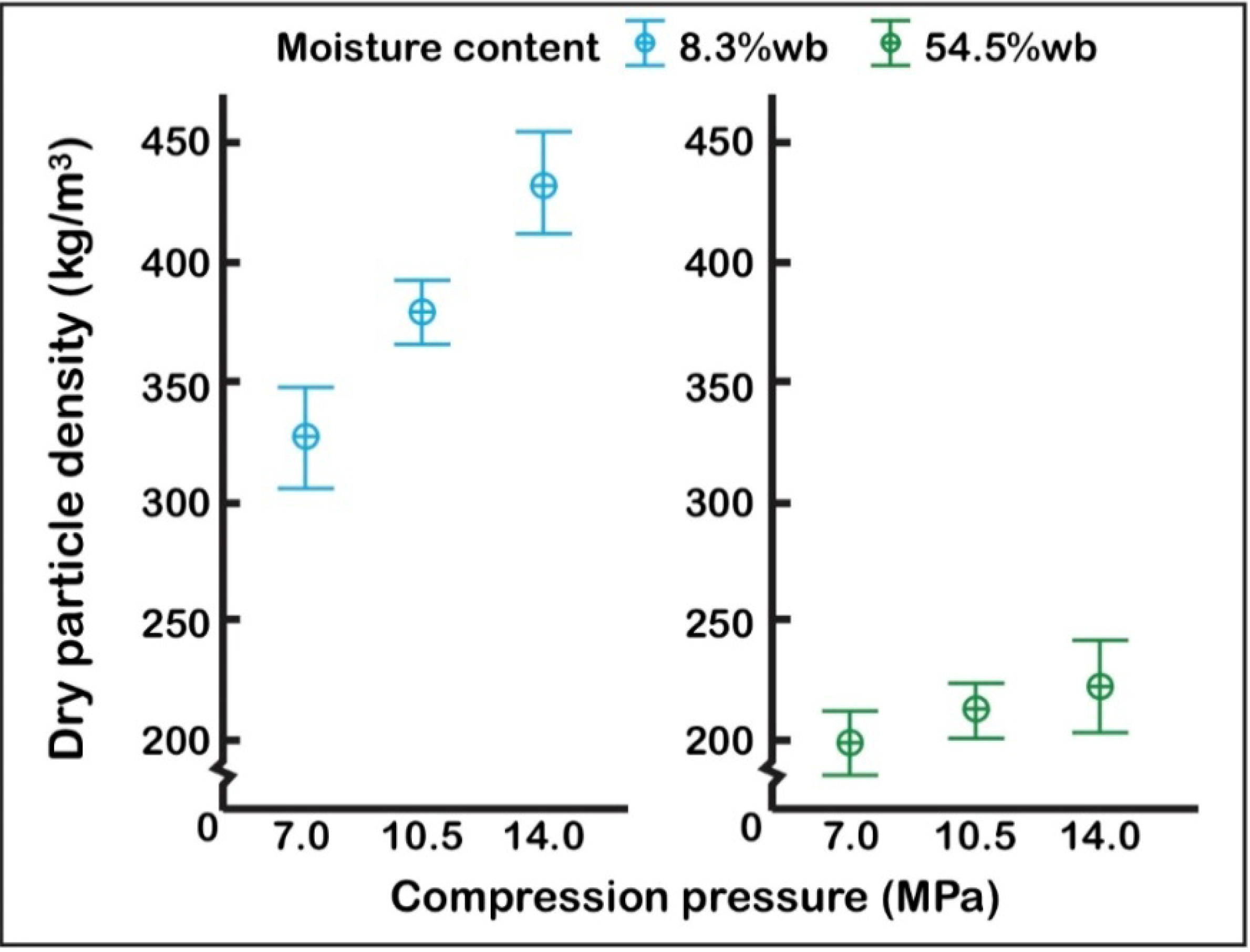

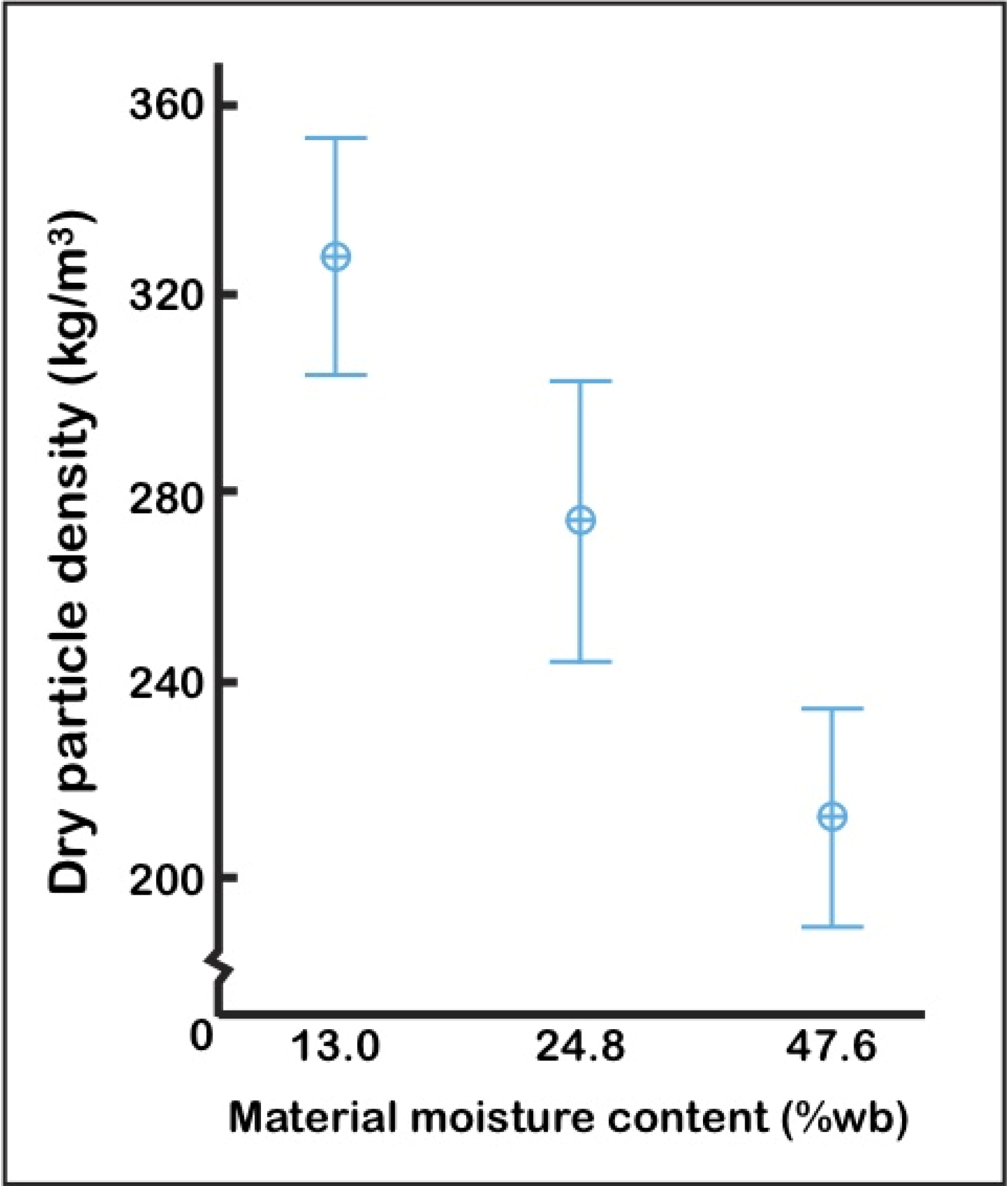

3.2. Moisture Effects Experiment

3.2.1. Dry Particle Density

3.2.2. Qualitative Effects

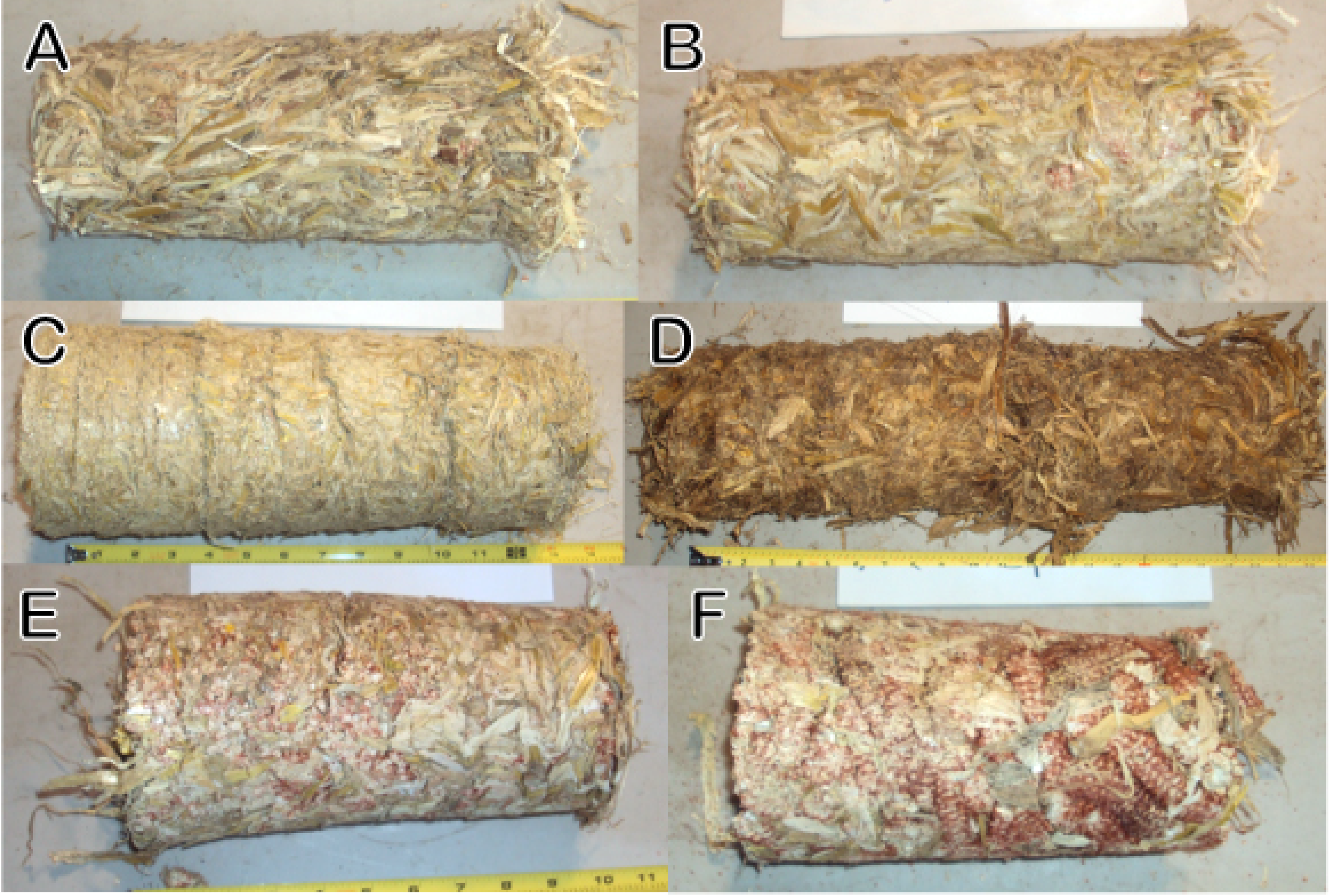

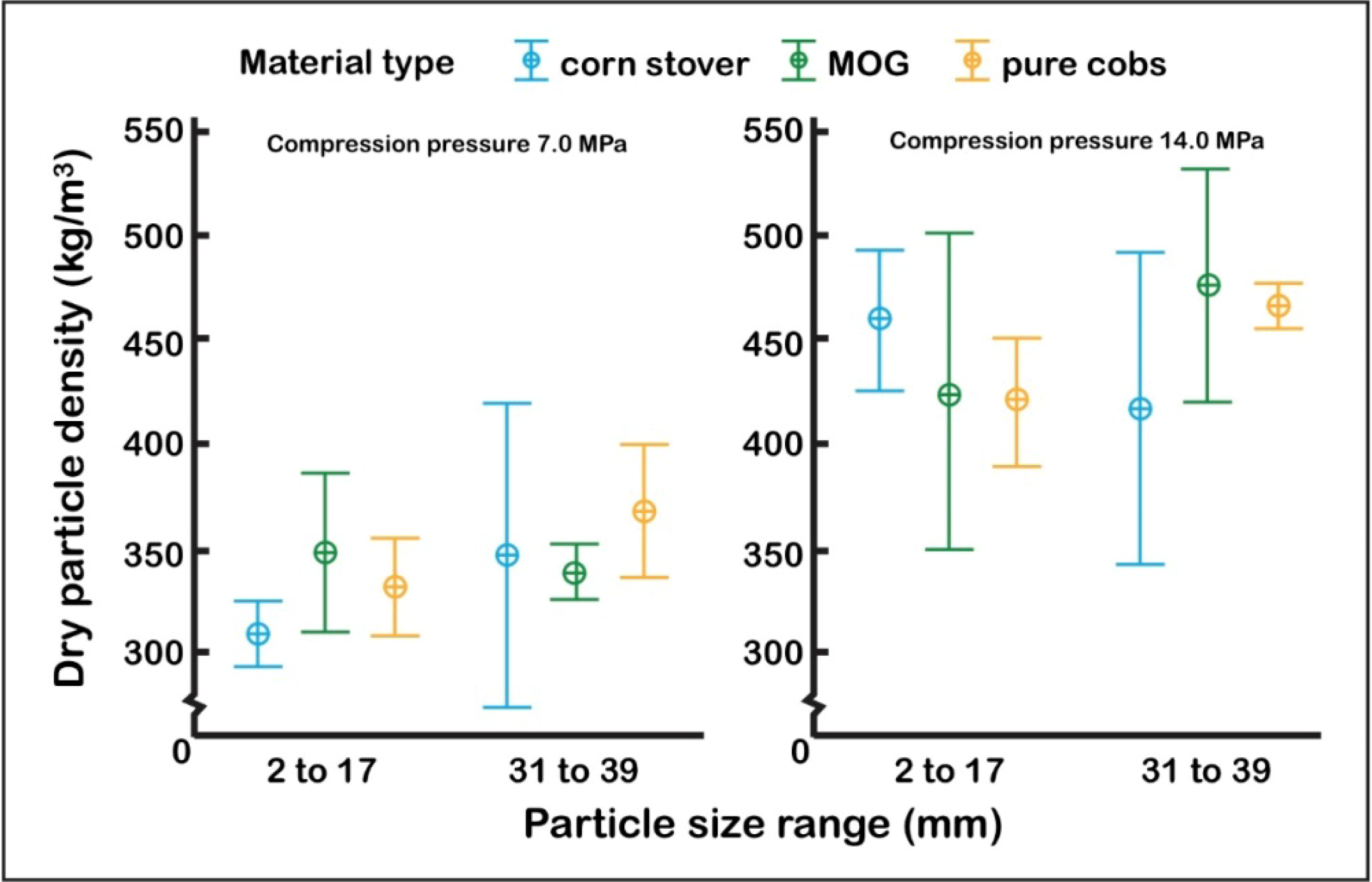

3.3. Material Types Experiment

3.3.1. Dry Particle Density

3.3.2. Qualitative Effects

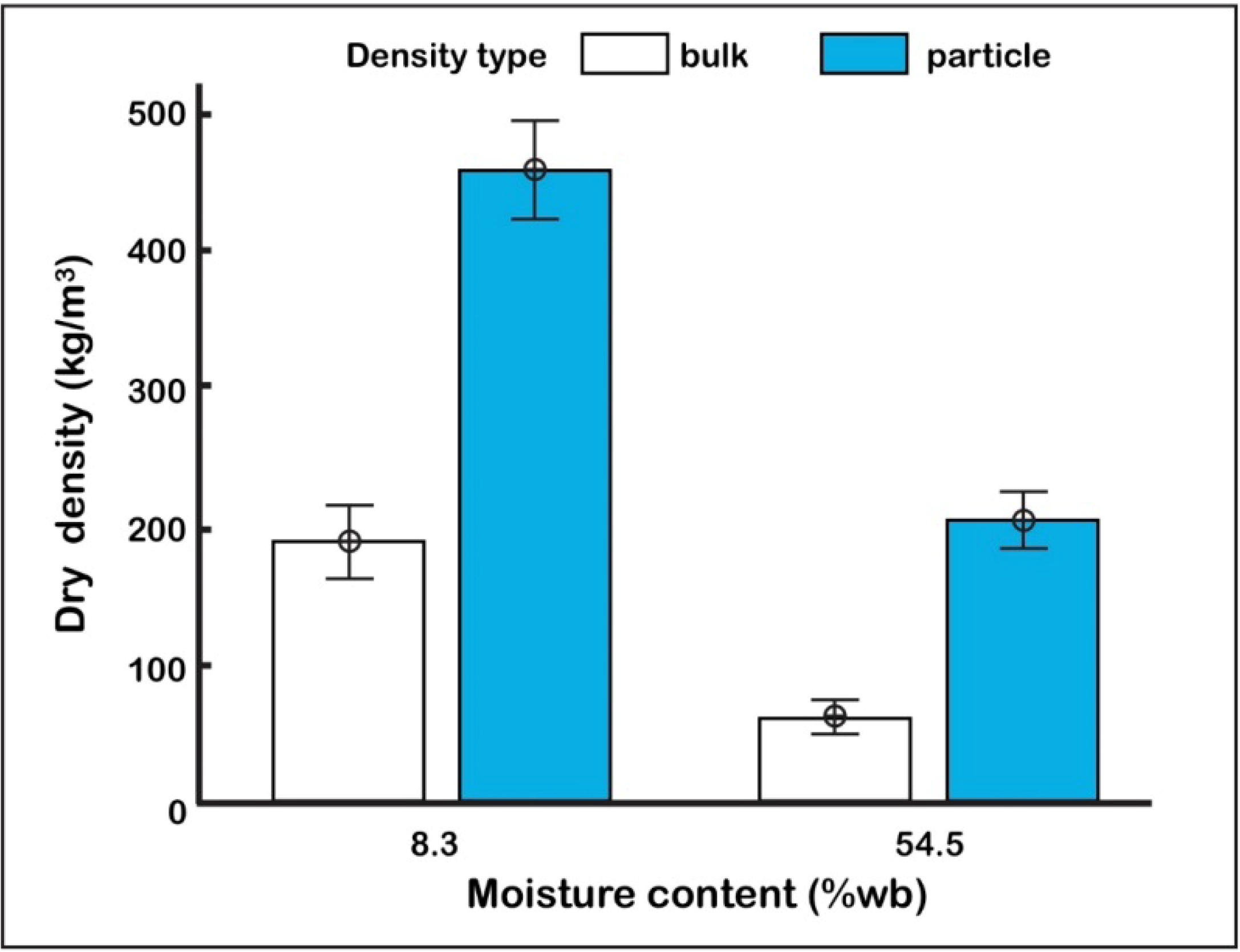

3.4. Bulk Density Experiment

3.5. Summary of Key Findings

4. Conclusions

- -

- Only “as received” material particle sizes (passed through an integrated combine chopper only) should be used to reduce briquette flake divisions;

- -

- Maximum compression pressure (14.0 MPa) was shown to maximize particle density. Future work should evaluate greater compression pressures and evaluate the relationship between compression pressure and total energy requirements in order to quantify an optimal balance of pressure and energy for a commercial implementation;

- -

- Only moisture contents below 25%wb should be used to maximize briquette density and quality. When crop conditions exceed 25%wb alternative densification methods should be implemented;

- -

- Corn stover contents with a greater cob content will improve briquette quality.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- United States Department of Energy; United States Department of Agriculture. Biomass as a Feedstock for Bioenergy and Bioproducts Industry: The Technical Feasibility of a Billion-ton Annual Supply; United States Department of Energy Office of Scientific and Technical Information: Oak Ridge, TN, USA, 2005. [Google Scholar]

- Knutson, J.; Miller, G.E. Agricultural Residues in California—Factors Affecting Utilization; Leaflet No. 21303, Cooperative Extension; University of California: Berkely, CA, USA, 1982. [Google Scholar]

- Hess, J.R.; Wright, C.T.; Kenny, K.L. Cellulosic biomass feedstocks and logistics for ethanol production. Biofuels Bioprod. Biorefin. 2007, 1, 181–190. [Google Scholar] [CrossRef]

- Kaliyan, N.; Morey, V.R. Densification Characteristics of Corn Stover and Switchgrass; ASABE Paper No. 066174; American Society of Agricultural and Biological Engineers: St. Joseph, MI, USA, 2006. [Google Scholar]

- Mani, S.; Tabil, L.G.; Sokhansani, S. Grinding Performance and Physical Properties of Selected Biomass; ASABE Paper No. 026175; American Society of Agricultural and Biological Engineers: St. Joseph, MI, USA, 2002. [Google Scholar]

- Webster, K. Productivity and Logistical Analysis of Single-Pass Stover Collection Harvest Systems; ASABE Paper No. 10008567; American Society of Agricultural and Biological Engineers: St. Joseph, MI, USA, 2010. [Google Scholar]

- Kaliyan, N.; Morey, V.R.; White, M.D. Roll press briquetting and pelleting of corn stover and switchgrass. Trans. Am. Soc. Agric. Biol. Eng. 2009, 52, 543–555. [Google Scholar]

- Thoreson, C.P. Characterization of the Impact of Process Variables on the Densification of Corn Stover. M.S. Thesis, Iowa State University, Ames, IA, USA, 2011. [Google Scholar]

- Mani, S.; Sokhansanj, S.; Xiaotao, B. Compaction of Corn Stover; ASABE Paper No. 041160; American Society of Agricultural and Biological Engineers: St. Joseph, MI, USA, 2004. [Google Scholar]

- Microsoft Corporation. Microsoft Excel 2010 for Windows; Microsoft Corporation: Redmond, WA, USA, 2010. [Google Scholar]

- ASABE Standards. S358.2—Moisture Measurement-Forages; American Society of Agricultural and Biological Engineers: St. Joseph, MI, USA, 2008. [Google Scholar]

- ASABE Standards. S424.1—Method of Determining and Expressing Particle Size of Chopped Forage Materials by Screening; American Society of Agricultural and Biological Engineers: St. Joseph, MI, USA, 2007. [Google Scholar]

- Minitab Inc. Minitab Version 14; Minitab Inc.: State College, PA, USA, 2004. [Google Scholar]

© 2014 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/3.0/).

Share and Cite

Thoreson, C.P.; Webster, K.E.; Darr, M.J.; Kapler, E.J. Investigation of Process Variables in the Densification of Corn Stover Briquettes. Energies 2014, 7, 4019-4032. https://doi.org/10.3390/en7064019

Thoreson CP, Webster KE, Darr MJ, Kapler EJ. Investigation of Process Variables in the Densification of Corn Stover Briquettes. Energies. 2014; 7(6):4019-4032. https://doi.org/10.3390/en7064019

Chicago/Turabian StyleThoreson, Curtis P., Keith E. Webster, Matthew J. Darr, and Emily J. Kapler. 2014. "Investigation of Process Variables in the Densification of Corn Stover Briquettes" Energies 7, no. 6: 4019-4032. https://doi.org/10.3390/en7064019