1. Introduction

Because of the relatively high thermal inertia of the ground, temperatures in the ground lag those at the surface, and their fluctuations decrease with depth below grade; moreover, soil temperature gets closer to the mean annual ambient air temperature with increasing depth [

1]. This raises the possibility of using the ground for heating air when ambient temperatures are lower than the ground temperature. and cooling air when they are higher. Systems providing this function are referred to as “earth-air heat exchangers” (EAHE) and as “earth tubes” (ET). Much of the literature has focused on (1) cooling applications, (2) smaller (approximately 300 mm) diameter systems, and (3) mild to hot climates (e.g., [

2,

3]). Relatively little has been published on heating applications of large diameter systems (approximately 900 mm or greater) in cold climates. This review focuses on that application.

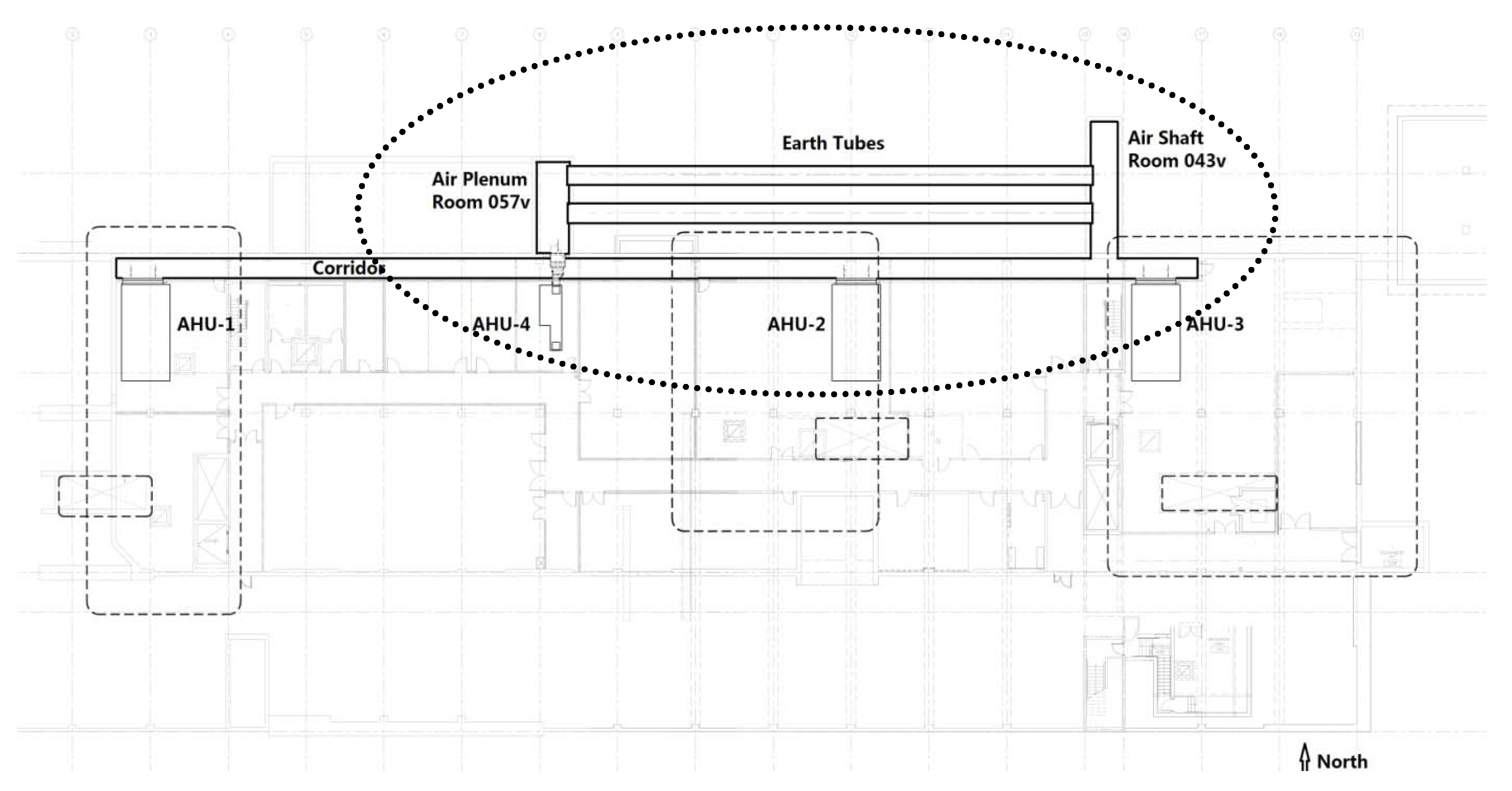

Figure 1 shows the above ground air intakes for a large diameter (plan in

Figure 2).

Figure 3 shows an EAHE under construction.

Figure 1.

Above ground air intakes for a large diameter earth air heat exchanger.

Figure 1.

Above ground air intakes for a large diameter earth air heat exchanger.

Figure 2.

Plan of a large diameter earth air heat exchanger. The two 1 m diameter earth tubes are about 2 m below grade and serve air supply unit AHU-4.

Figure 2.

Plan of a large diameter earth air heat exchanger. The two 1 m diameter earth tubes are about 2 m below grade and serve air supply unit AHU-4.

Figure 3.

A large diameter earth air heat exchanger under construction. Phot by R. Lay, Enermodal Engineering, by permission.

Figure 3.

A large diameter earth air heat exchanger under construction. Phot by R. Lay, Enermodal Engineering, by permission.

2. Performance of Large Diameter Earth-Air Heat Exchangers

Tjelflaat [

4] collected data on a 1.5 × 2 × 13.5 m (

w ×

h ×

l ) EAHE serving an addition to the Mediå School in Grong, Norway, about 200 km north of Trondheim, which has a mean annual temperature of 5.0 °C [

5]. The “hybrid” system design was intended to heavily exploit wind and stack forces to drive air flow, supplemented by a supply fan and an exhaust fan controlled by the building management system. Tjelflaat’s analysis focused on cooling performance, but Jeong [

6] and Wachenfeldt [

7] used the data to support validation of a simulation model of the system.

One of Jeong’s simulations in [

6] indicated that the EAHE raised the supply air temperature by as much as 12 °C (from −7 °C to 5 °C). However, the simulation seemed to result in a supply air (duct discharge) temperature equal to the duct surface temperatures, which were set to a constant 6.1 °C duct wall boundary condition. The duct wall temperatures used by Jeong differed from measured conditions (discussed below). This will be discussed below following the two paragraphs immediately below that address Wachenfeldt’s research. Jeong provided few details to explain this. In a second simulation of both building thermal performance and airflow, Jeong [

6] reported that the EAHE raised supply air temperature by as much as 11 °C (from −7 °C to 4 °C). Although the temperature rise from the two simulations was similar, the second simulation produced a supply air temperature profile that fluctuated with the inlet air temperature. Overall, Jeong focused on the whole building simulation.

Wachenfeldt [

7] simulated the performance of the addition to the Mediå School, using data collected by [

4], focusing on the simulation of the EAHE air flows. As with [

4], the analysis primarily addressed cooling performance. Wachenfeldt highlighted the difficulty of predicting energy performance of natural (wind- and buoyancy-driven) ventilation systems, because of variations in airflow paths and rates, sensitive to both internal parameters and the outdoor environment. He noted the importance of fans in enhancing convective heat transfer between air and duct walls. He also indicated that, during a hot period in June, more than 60% of the cooling effect of the embedded intake duct was due to conduction to the ground, the remainder being due to diurnal energy storage and lag in the duct walls. Wachenfeldt [

7] concluded that many empirical correlations from previous research produced convective heat transfer coefficients that were only useful for small diameter EAHE systems. If the correlations were used on large diameter systems, the convective heat transfer would be substantially underestimated.

While Wachenfeldt [

7] provided no information on temperature rise through the Mediå School EAHE during the heating season, Zhang and Haghighat [

8], using data collected by Tjelflaat’s group for validation of simulation models of the EAHE, reported a temperature rise of about 18 °C with an ambient air temperature of −10 °C. Zhang and Haghighat compared the heat transfer coefficients from this analysis with those Wachenfeldt determined from measurements and stated that they were in close agreement. Zhang and Haghighat [

9] also conducted lab-based experimental testing of a 1 m by 1.5 m lab system, the equivalent of a section of the Mediå School EAHE, to validate a simulation model. They noted that using large ducts lowered the pressure drop, thus reducing the fan power and related energy use. The authors developed several CFD models that produced results with maximum errors of 8% in estimation of discharge air temperature. They identified a need for further research in order to accurately simulate large cross-sectional area hybrid EAHE ventilation systems.

Heiselberg [

10] also addressed the heating potential of the Mediå School EAHE system. He indicated that the duct air temperature variation from bottom to top of the EAHE was as much as 7 °C. Duct surface temperature variations at the inlet side of the EAHE were shown in an infrared photo. The maximum temperature difference was 3 °C. This showed that Jeong’s assumption of constant duct wall surface temperatures of 6.1 °C [

6] led to a misestimation of the performance. Heiselberg found that cold air was flowing in the bottom half of the duct and warmer air was pushed to the top. As the discharge vents to the classrooms were positioned near the top of the duct, the temperature of the air flowing from the EAHE into the classrooms was much higher than the average temperature in the EAHE, reducing heating energy use relative to the requirement based on the average air temperature in the ET. Heiselberg concluded that the heat transfer models then available missed this temperature variation and were therefore insufficient to estimate the heat transfer with reasonable accuracy. Heiselberg’s account lacked details of experimental procedures and data [

10].

Zhang

et al. [

11] performed a study on the Mediå School EAHE using CFD simulations and compared their results with data from field measurements in cooling mode, with features such as automatic control of the supply fan disabled to provide more stable conditions during the measurements. They found that heat transfer coefficients commonly used to analyze EAHEs would have greatly underestimated the performance of the system in cooling air.

Schild [

12] provided notes on eleven buildings with EAHE systems in Norway, from its west coast to subarctic regions, with mean annual temperatures varying from about 9 to 1 °C. Most (eight) of the buildings were schools, including the Mediå School. Dimensions of the EAHEs were omitted; the only details provided were some evaluations of Jaer School in Nesodden, Norway. According to Zhang [

13], the Jaer School EAHE system had two parts, a 1.6 m diameter and 20 m length duct, and a 2 m width, 3 m height and 35 m length duct. Duct depths were not reported. Schild [

14] reported that the Jaer School EAHE was coupled with a supply air preheat system near the duct inlet, which precluded measurement of the temperature rise through the duct in winter because of the heating effect on the inlet temperature readings.

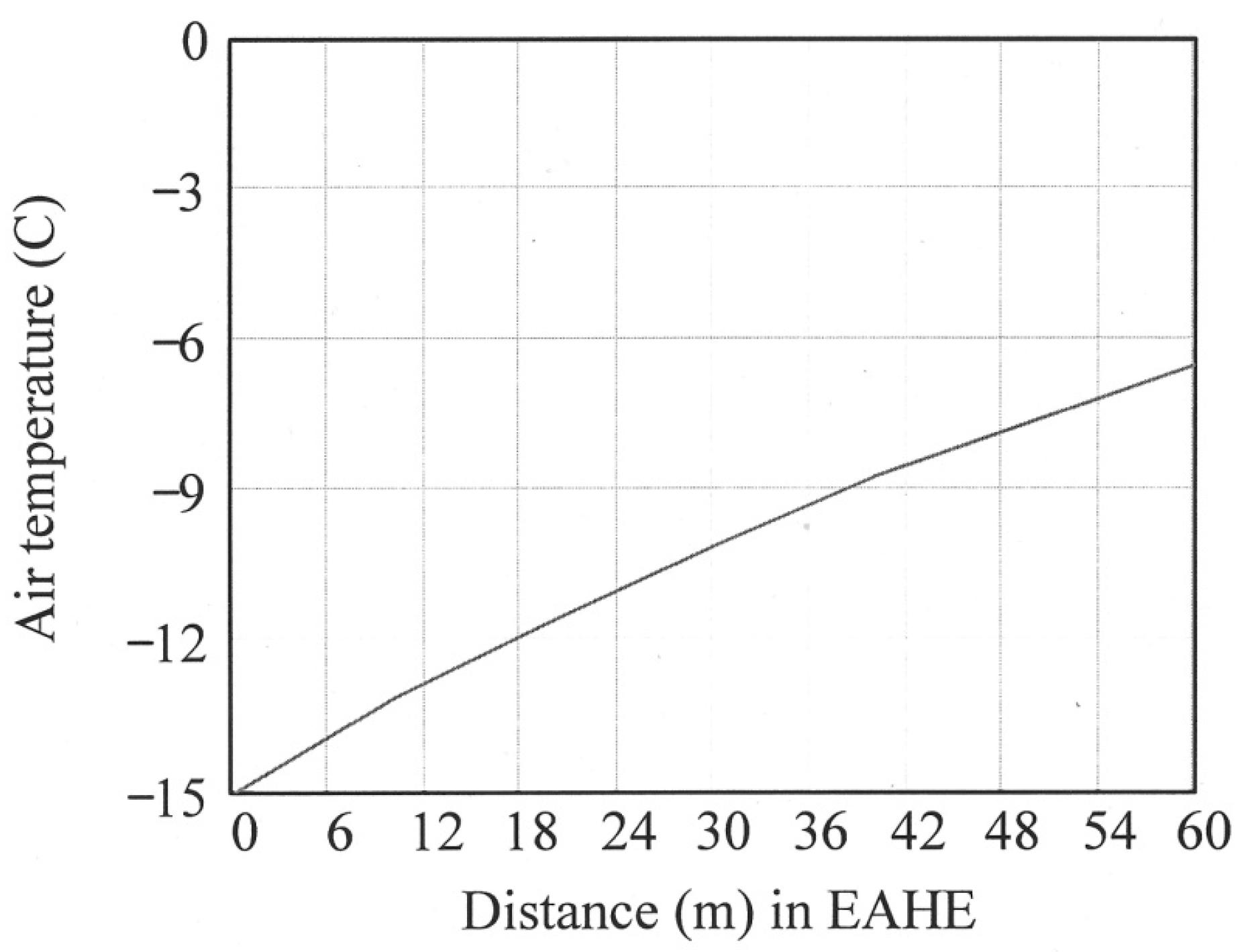

Athienitis

et al. [

15] provided information on the performance of a large diameter EAHE system built in Montreal (mean annual temperature 6.2 °C [

16]). The system was built with 4700 L/s design ambient airflow through two 1 m diameter, 60 m long ducts. The researchers developed a numerical model and simulated the heating performance of the EAHE system (

Figure 4). They estimated a temperature rise of 9 °C (from −15 °C to −6 °C for a winter day) and indicated the system was often capable of providing one-third or more of the building’s heating needs without stating how they reached this conclusion.

Performance of an EAHE composed of nine 1 m diameter, 20 m long parallel tubes buried 2 m deep and supplying 7000 L/s (25,200 m

3/h) was reported for the Earth Rangers Centre [

17,

18] near Toronto, Canada (mean annual temperature 10.8 °C [

16]). Parsons [

17] reported it to be the largest EAHE system in North America. A temperature rise of up to 15 °C through the ETs was measured [

19]. The building operator also reported a temperature rise of 19 °C through the EAHE system with an ambient air temperature of −17 °C [

17]. It was also estimated a temperature rise of 10 °C to 15 °C could be achieved with ambient air temperature of −10 °C. However, neither article provided other EAHE performance information such as the cross sectional temperature distributions in the ducts. The measured temperature rise for the Earth Rangers system was about 5 times the simulated temperature rise reported by Athienitis

et al. for the 20 m point in the EAHE they modelled (

Figure 4) [

15] for ETs with similar diameter. The flow for the Earth Rangers’ system was about 800 L/s per tube versus about 2300 L/s for the system modeled by Athienitis

et al.

Figure 4.

Variation of supply air temperature in earth air heat exchanger with distance from inlet in January with outdoor air temperature of −15 °C and exchanger wall temperature of 3.3 °C (from Athienitis

et al. [

15], with permission of the authors).

Figure 4.

Variation of supply air temperature in earth air heat exchanger with distance from inlet in January with outdoor air temperature of −15 °C and exchanger wall temperature of 3.3 °C (from Athienitis

et al. [

15], with permission of the authors).

The number of installations of large diameter EAHE systems reported for cold European countries and for North America is small. Even less has been reported on their heating performance, but the available information suggests that further rigorous assessment is warranted to determine whether the much better than expected temperature rise found for some systems is supported and, if so, the reasons for this. Thevenard [

20] provided what seems to be the most detailed financial analysis for heating with small diameter earth tubes. With better performance data, such an analysis could be carried out for large diameter earth tubes.

3. Effect of Ground Heat Exchangers on Temperature of the Surrounding Ground

In cold climates, there is the possibility that average annual ground temperature around EAHE systems might decrease after several years of heating operation. As a result, discharge air temperature and the effectiveness of EAHE systems would decrease.

3.1. Effect of Earth-Air Heat Exchangers

Accurate estimates of ground temperature effects are essential factors for predicting the sustainability of EAHE systems. Both the long-term air-ground heat transfer and the ground temperature should be studied in order to comprehensively evaluate EAHE systems. Relatively little has been published on EAHE ground temperature effects in cold climates for EAHE systems of any size.

Baxter [

21] evaluated heating with a small diameter EAHE system in Knoxville, Tennessee (mean annual temperature 14.2 °C [

16]). This is a cool rather than cold climate, but the comprehensiveness of Baxter’s ground temperature measurements is of interest. A single 150 mm diameter, 64 m long corrugated metal pipe was buried 1.8 m underground from grade to pipe centre, with a 1% slope from inlet to discharge. In heating mode, an average temperature increase of 6 °C was achieved during the one month of measurements. Peak heating temperature rise during a very cold day was as much as 22 °C. Baxter placed sensors in both lateral and longitudinal directions to collect ground temperatures. Nine thermocouples were installed in a horizontal plane (one at the centre, one on each side of the duct, and three in the ground on each side of the duct spaced 5 cm apart) at each of six stations along the duct. Near the midpoint of the EAHE, seven thermocouples were placed in the ground at 0.3 m intervals from depths of 0.3 m to 2.1 m. Data were recorded hourly for four weeks in the heating study.

Baxter found that the duct wall temperature near the inlet was −5 °C and the temperature of soil 5 cm away was 1.7 °C. This was a large difference of 6.7 °C in a short distance. Moreover, the inlet duct wall temperature indicated the soil could be frozen. If so, latent heat exchange would be involved.

Baxter showed a probable freezing soil region that almost reached half the total length of the duct. It would have been informative if the duct wall sensors had been installed in the soil instead of in the duct to evaluate freezing of the ground and additional sensors in the horizontal plane would have allowed better characterization of the soil freeze-thaw pattern. Baxter neglected results from some vertically-arranged sensors during his discussion of soil temperature inversion. It is unclear whether the intermediate vertical sensors failed to provide any extra information.

Pfafferott [

22] conducted one-year experimental measurements on small diameter EAHEs at three office buildings in Germany. Although the configurations of the three varied greatly, they all achieved similar maximum temperature rise of about 16 °C. This article was one of the very few EAHE assessments that addressed ground temperature. However, the soil temperature was only included as a design input parameter and the impact of EAHE operation on soil temperature was only addressed peripherally—Pfafferott mentioned in the conclusion that thermal recovery was good enough to maintain performance.

Trzaski and Zawada [

23] performed a simulation study of a base case EAHE system for a single family dwelling in Warsaw, Poland (mean annual temperature 8.1 °C [

24]). The duct was 0.2 m in diameter, 35 m long and had an inlet depth of 1.5 m and discharge depth of 2 m. They modeled discharge air temperature and temperature of the soil surrounding the discharge relative to ambient air temperature and found the system was able to increase the supply air temperature by as much as 15 °C during heating season, consistent with Pfafferott’s experimental findings for similar climate conditions. The simulation showed little change in temperature of the ground surrounding the discharge after one year of operation. Since most heat exchange takes place near the inlet, any notable change in soil conditions would likely occur there. It would have been more helpful if the authors had extended the analysis for a longer period than one year.

3.2. Effect of Ground Source Heat Pump Exchangers

Given the lack of literature on heat depletion due to EAHE operation, investigations related to heat depletion with ground source heat pumps (GSHPs) were included in the review. There are two basic types of GSHP systems, horizontal and vertical. The horizontal type is installed much shallower than the vertical type, and is more similar to an EAHE system. Previous research on soil heat depletion surrounding the horizontal GSHPs could be good references for the effect of EAHE systems.

Among the studies in Japan, Tarnawski

et al.’s research [

25] was for the coldest location. They used data from Sapporo, Japan (mean annual temperature 8 °C [

16]). They simulated three horizontal GSHP systems for a typical house for a ten-year period. The two single-layer GSHPs both used 16 cm diameter, 300 m length pipes. One was installed at 0.5 m depth, the other at 1 m depth. The double-layer GSHP had an 80 mm diameter, 300 m length duct at 0.5 m and 1 m depths. Ground temperatures at 0.5 m and 1 m depths on 14 June (the end of heating season), and 30 September (the end of cooling season) ten years after start up were compared with undisturbed ground temperatures. Compared with the undisturbed soil temperature, after the heating season, in the vicinity of the GSHP pipe, soil temperatures for the single-layer GSHP at 0.5 m and 1 m depth, and double-layer GSHP at 0.5 m and 1 m depths decreased by 2.5 °C, 4.6 °C and 6.4 °C respectively. After the cooling season, temperatures of soil surrounding the pipes were close to the undisturbed soil temperature of 14.6 °C, differences being 1.1 °C, 2.7 °C and 3.0 °C respectively. The single-layer GSHP (0.5 m depth) had the best soil heat replenishment. Its soil temperature was barely lower than the undisturbed soil temperature.

Wu

et al. [

26] studied the effects of a horizontal GSHP system on ground temperature near London, UK (mean annual temperature 10.7 °C [

16]). They used both experimental and simulation methods. The system included four parallel “slinky” heat exchanger loops buried 1.2 m underground in an 80 m long by 20 m wide paddock area. To monitor the soil temperature, they dug one hole above a portion of the system and a reference hole, 2 m from the first hole. Eighteen thermistors were installed in the holes at various depths. Monitoring began on 6 November 2009, one month after the system started operating. Sensors were read every 10 s and values were averaged over 30 min intervals. Using 7 November 2009 as an example, they measured and analyzed the ambient air temperature and the soil temperature. They compared the temperatures at a range of corresponding depths and at various times during the day and found noticeable differences between the heat exchanger and the reference conditions after only one month of system operation. The heat exchanger lowered the surrounding soil temperature by over 3 °C and the impact could be observed as far as 0.9 m vertically away from the heat exchanger. In the simulation, the system was set as 4 cm diameter, 80 m long and 1.8 m deep. Wu at al. predicted the soil temperature change at various depths after 1, 10, 100 and 600 h in both horizontal and vertical directions. By 600 h, the heat extraction rate had declined about 75%. This suggests that, without heat replenishment in the area around the ground heat exchanger, system performance would decline over successive heating seasons. Gonzalez

et al. [

27] (the same group of researchers) reported results for the same GSHP system after almost a year, which further supported these conclusions. The soil temperature difference between the heat exchanger and reference location was 3 °C lower than when measurement began. However, the authors neglected to investigate the potential for heat replenishment. They mentioned Tarnawski’s system [

25] was working in both heating and cooling mode, which helped to compensate for some heat loss by “recharging” the ground. The system studied by Gonzalez

et al. operated in heating mode only, being in a region with only 94 cooling degree days [

16]. Also, shutting down the system during the summer instead of heating domestic hot water and a swimming pool would also have reduced heat extraction, especially when the difference between soil temperature at heat exchanger and reference location was almost zero by July.

The four articles reviewed for horizontal GSHP soil heat depletion had conflicting findings. Tarnawski

et al.’s experiment [

25] was for the coldest location, was conducted over a long period and the simulated systems were sustainable. Only the UK study [

26,

27] found soil temperatures that declined and did not rebound over periods of 600 h to 1 year.

4. Conclusions

While most of the literature on earth air heat exchangers has focused on: (1) cooling applications; (2) smaller (approximately 300 mm) diameter systems; and (3) mild to hot climates (e.g., [

2,

3]), some publications suggest that the heating performance of large diameter systems (approximately 900 mm or greater) in cold climates has been much better than expected. A 2007 review by Thevenard [

2] concluded that “smaller diameters (usually 10–30 cm in diameter) are preferable from a thermal point of view, but they also correspond (at equal flow rate) to higher friction losses”. A 2013 review of earth air heat exchangers for a hot climate by Bisoniya

et al. [

3] observed that “Commonly, the thermal performance of EAHE system [sic] [declines] with increase in pipe diameter”. However, the studies considered in this literature review suggest that large diameter EAHEs can perform comparatively well in heating supply air in cold climates. Wachenfeldt [

7] concluded that many empirical correlations from previous research produced convective heat transfer coefficients that underestimated the heat gains for large diameter EAHE systems. Substantial outdoor air temperature rise in cold weather was reported for other systems [

15,

18]. Given this, further experimental work on heating performance would be worthwhile. It would be highly desirable to better understand whether the complex air flows reported by Heiselberg [

10] are common or an anomaly, and to better characterize these flows.

Only a couple of short-term experimental studies of ground temperature effects of heating with EAHEs were found and these were for cool, as opposed to cold, climates. Three studies that addressed ground temperature effects with horizontal ground source heat pump exchangers had conflicting findings regarding changes in ground temperatures around the heat exchangers. It would also be useful to better understand the degree of heat depletion that occurs in the soil surrounding large earth air heat exchangers.