Slag Behavior in Gasifiers. Part I: Influence of Coal Properties and Gasification Conditions

Abstract

:1. Introduction

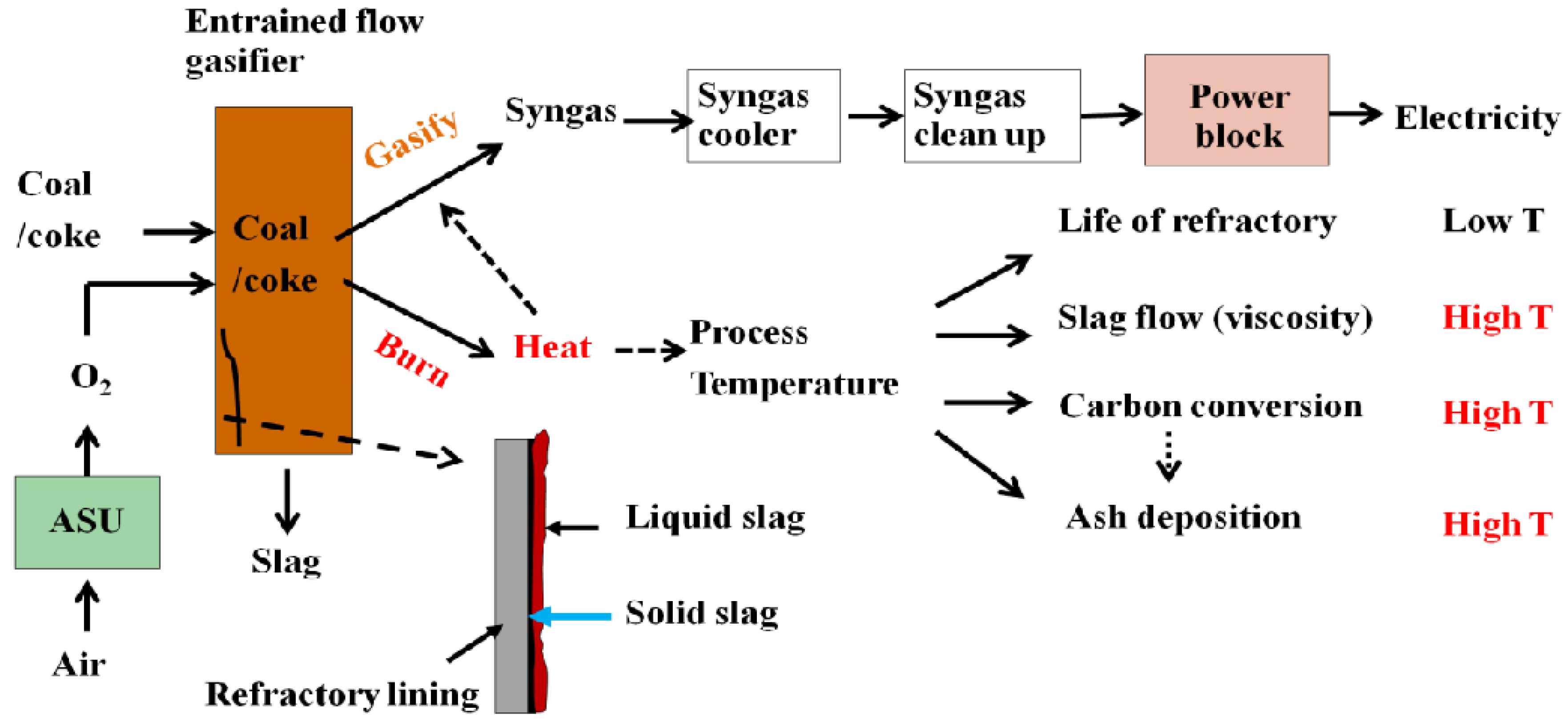

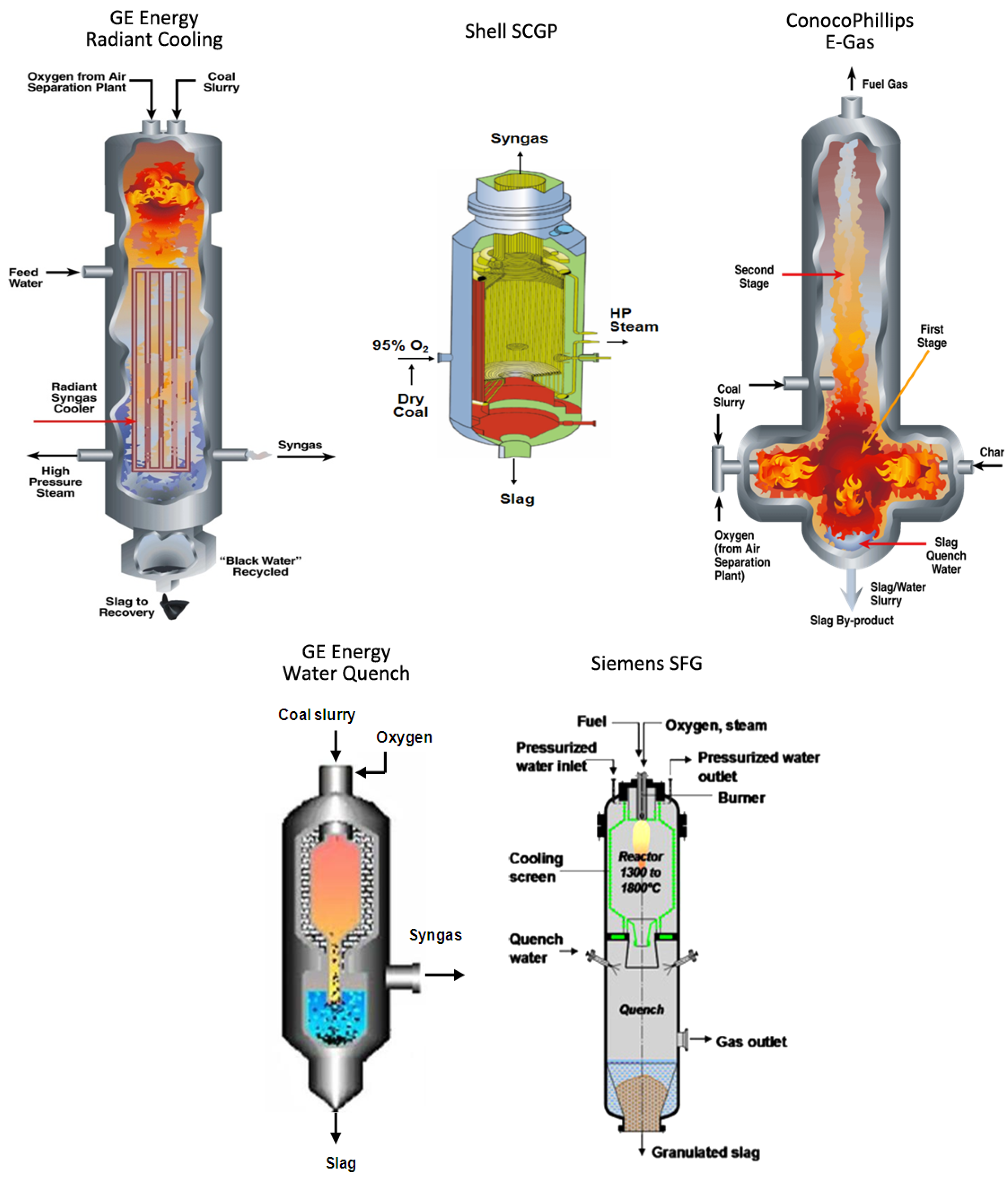

2. Major Commercial Entrained Flow Gasifiers and Operation Conditions in IGCC

2.1. Major Commercial Entrained Flow Gasifiers in IGCC

| Gasification Technology/Design feature | Ge energy with Radiant Cooling | Ge energy with Water Quench | ShellScgf | ConocophillipsE-gas | SiemensSfg |

|---|---|---|---|---|---|

| Feed system | 60%–70% coal/water slurry; top feed | 60%–70% coal/water slurry; top feed | Dry coal (~2% moisture content)/N2; bottom feed | 60 to70% coal/water slurry; bottom feed: 1st stage 80% and 2nd stage 20% | Dry feed/N2 or CO2; top feed |

| Stage and flow | Single stage downflow | Single stage downflow | Single stage upflow | Two stage upflow | Single stage downflow |

| Wall | Refractory | Refractory | Membrane | Refractory | Cooling screen (ash content > 1–2 wt%) |

| Pressure (bar) | 30–80 | 30–80 | 30–40 | ~27 | ≥ 40 |

| Hot syngas temperature (°C) | 1260–1500 | 1260–1500 | 1360–1650 | 1st stage 1340–1400; 2nd stage 1038 | 1400–1600 |

| Syngas quenching method | Radiant cooling then fire tube syngas cooler | Water quench (no syngas cooler) | Recirculated cold syngas quench then water tube syngas cooler | Chemical quench then fire tube syngas cooler | Water quench (no syngas cooler) |

| Quenched syngas temperature (°C) | ~800 | ~300 | ~900 | ~1038 | ~230 |

2.2. Fuels and Operating Conditions in Entrained Flow Gasifiers

| Proximate analysis (% wt) | HHV (MJ/kg) (MF) | Tested coal in ASTM coal rank | |||||||

|---|---|---|---|---|---|---|---|---|---|

| MC (AR)a | VM (MF) | FC (MF) | Ash (MF) | 23–33.2 | Anthracitic (Anth., semi-anth.) | Bituminous | subbituminous (A, B) | ||

| 2.11–34 | 10.6–46.6 | 39.1–88.5 | 0.5–35.0 | ||||||

| Ultimate analysis (% MF) | |||||||||

| C | H | N | S | O | Cl | Ash FT (°C) | Ash T25 (°C) | ||

| 56.4–88.7 | 3.27–5.2 | 0.86–2.24 | 0.13–4.61 | 0.1–20.20 | 0.01–0.41 | 1190->1500b | 1207–1549 | ||

| Ash mineral analysis (oxides % wt. MF) | |||||||||

| SiO2 | Fe2O3 | Al2O3 | CaO | K2O | Na2O | P2O5 | TiO2 | MgO | SO3 |

| 24.2–59.8 | 3.3–27.8 | 9.5–33.3 | 0.7–24.5 | 0.1–3.9 | 0.1–3.1 | 0.1–1.5 | 0.6–2.1 | 0.3–3.7 | 0.9–33.1 |

3. Coal Properties and Qualities for Entrained Flow Slagging Gasifiers

3.1. Ash Content and Coal Composition

| Coal ash properties | Criteria for entrained-flow gasifier | Reference |

|---|---|---|

| Ash contents | 20% slurry feeding, 40% dry feeding | [20] |

| Ash Temperature (FT) | 1500 °C flux is needed | [26] |

| Ash composition | silica ratio 100 SiO2/(SiO2+ Fe2O3 + CaO + MgO) < 80; SiO2/Al2O3 ratio of 1.6–2.0 is optimal for minimum flux amount | [26] |

| Temperature of critical viscosity (Tcv) | <1400 °C is preferred | [26] |

| Viscosity | 5–25 Pa·s at 1400 to 1500 °C; Optimum 15 Pa·s | [26] |

3.2. Chemical Composition of Ash in Coal

3.3. Ash Fusibility and Ash Flow Temperature

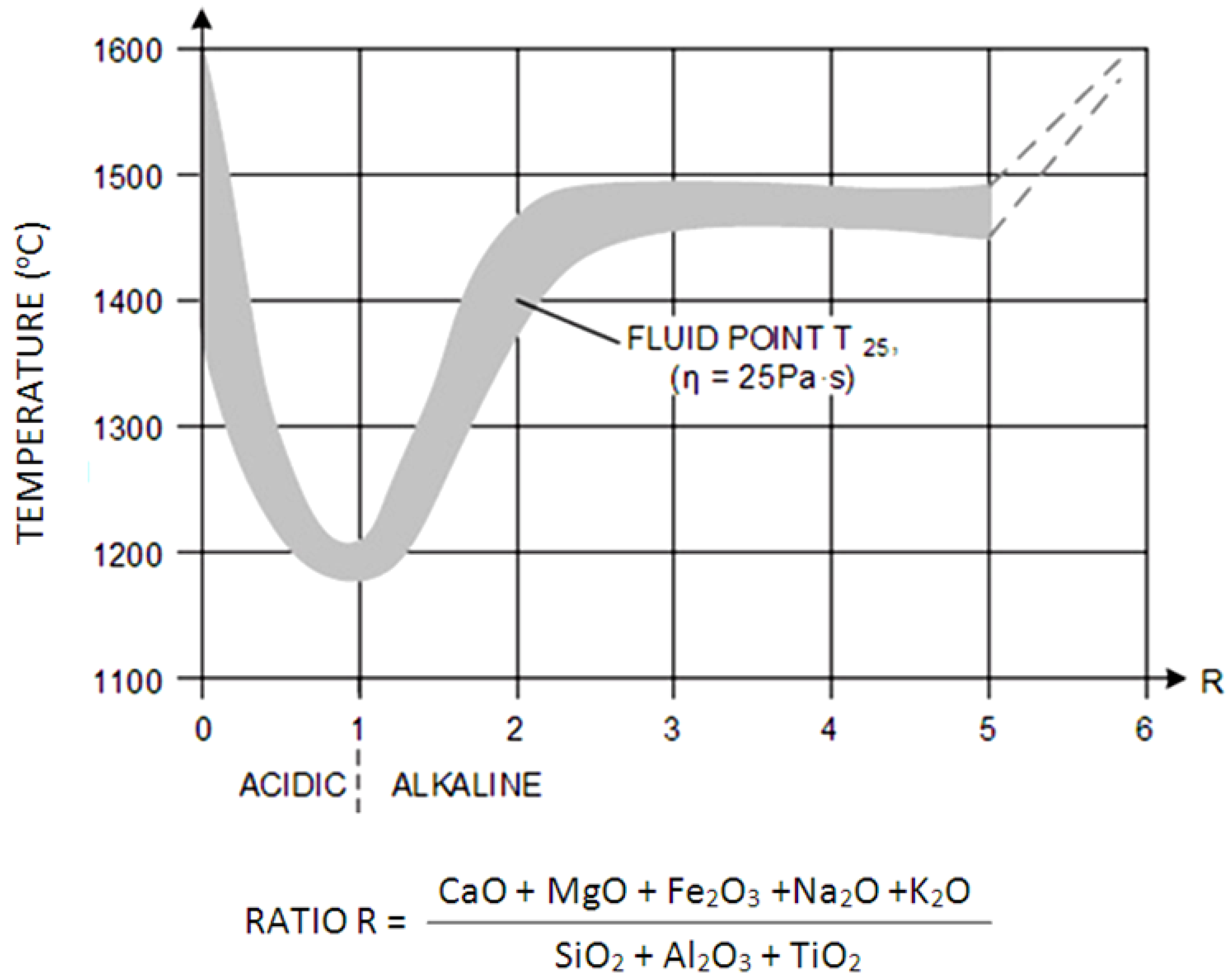

3.4. Slag Viscosity

3.5. Temperature of Critical Viscosity

4. Impact of Operating Conditions on Flow Behaviors of Coal Slag in Entrained Flow Gasifiers

4.1. Slag Viscosity with Temperature and Slag Compositions

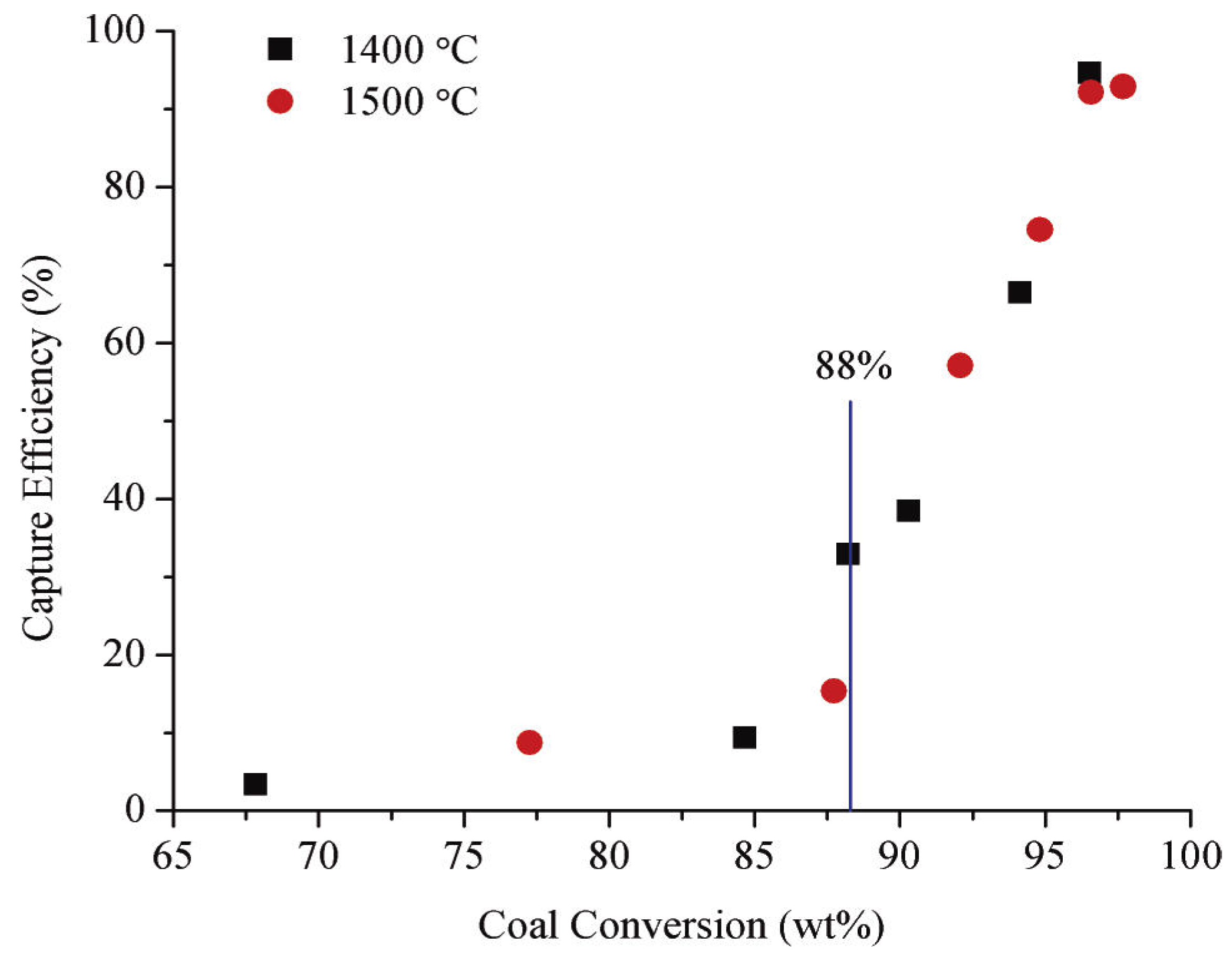

4.2. Slag Behavior with Oxygen/Carbon Ratio and Unreacted Carbon

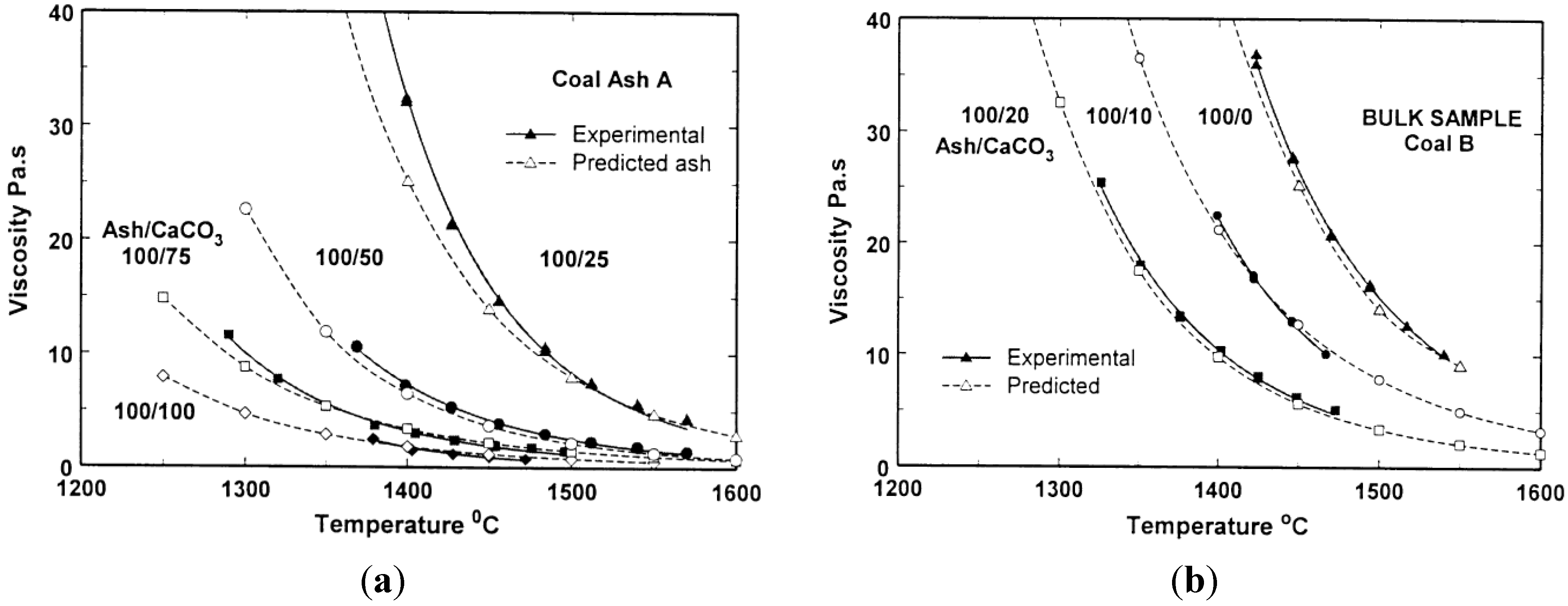

4.3. Viscosity with Flux Agents and in Reducing Gas Environments

5. Concluding Remarks

References

- Falcke, T.J.; Hoadley, A.F.A.; Brennan, D.J.; Sinclair, S.E. The sustainability of clean coal technology: IGCC with/without CCS. Process. Saf. Environ. Prot. 2011, 89, 41–52. [Google Scholar] [CrossRef]

- U.S. Department of Energy. Department of Energy. Office of Fossil Energy. Pioneering Gasification Plants. Available online: http://www.fossil.energy.gov/programs/powersystems/gasification/gasificationpioneer.html (accessed on 20 September 2012).

- Integrated Gasification Combined Cycle (IGCC) Design Considerations for High. Availability—Volume 1: Lessons from Existing Opeations; Electric Power Research Institute: Palo Alto, CA, USA, 2007.

- Higman, C.; Della Villa, S.; Steele, B. The Reliability of IGCC Power Generation Units. In Proceedings of the World Exhibition Congress on Chemical Engineering, Environmental Protection and Biotechnology (ACHEMA), Frankfurt, Germany, 18–22 May 2006.

- The Wabash River Coal Gasification Repowering Project; Topical Report Number 7; U.S. Department of Energy: Washington, DC, USA, 1995.

- The CURC-EPRI Coal Technology Roadmap; The Coal Utilization Research Council and the Electrc Power Research Instutue: Washington, DC, USA, 2012.

- Maurstad, O. An Overview of Coal Based Integrated Gasification Combined Cycle (IGCC) Technology; Massachusetts Institute of Technology: Cmabridge, MA, USA, 2005. Available online: http://sequestration.mit.edu/pdf/LFEE_2005-002_WP.pdf (accessed on 10 August 2012).

- Trapp, B.; Moock, N.; Denton, D. Coal Gasification: Ready for Prime Time Power. Available online: http://www.clean-energy.us/projects/eastman_power_magazine.htm (accessed on 15 September 2012).

- Coal Fleet RD&D Augmentation Plan for Integrated Gasification Combined Cycle (IGCC) Power Plants; Electric Power Research Institure: Palo Alto, CA, USA, 2006.

- McDaniel, J. Tampa Electric Polk Power Station Integrated Gasification Combined Cycle Project: Final Technical Report. Tampa Electric Company Polk Power Station. Available online: http://www.tampaelectric.com/data/files/PolkDOEFinalTechnicalReport.pdf (accessed on 24 July 2012).

- Mondal, P.; Dang, G.S.; Garg, M.O. Syngas production through gasification and cleanup for downstream applications—Recent developments. Fuel Process. Technol. 2011, 92, 1395–1410. [Google Scholar] [CrossRef]

- Wang, P.; Massoudi, M. Effect of Ash Properties and Operation Conditions on Flow Behavior of Coal Slag in Entrained Flow Gasifier: A Brief Review; DOE Report 1036451; U.S. Department of Energy, National Energy Technology Laboratory: Pittsburgh, PA, USA, 2011. Available online: http://www.osti.gov/servlets/purl/1036451 (accessed on12 September 2012).

- Brooker, D. Chemistry of deposit formation in a coal-gasification syngas cooler. Fuel 1993, 72, 665–670. [Google Scholar] [CrossRef]

- Brooker, D.D.; Oh, M.S. Iron sulfide deposition during coal-gasification. Fuel Process. Technol. 1995, 44, 181–190. [Google Scholar] [CrossRef]

- Erickson, T.A.; Allan, S.E.; McCollor, D.P.; Hurley, J.P.; Srinivasachar, S.; Kang, S.G.; Baker, J.E.; Morgan, M.E.; Johnson, S.A.; Borio, R. Modeling of fouling and slagging in coal-fired utility boilers. Fuel Process. Technol. 1995, 44, 155–171. [Google Scholar] [CrossRef]

- Li, S.H.; Wu, Y.X.; Whitty, K.J. Ash deposition behavior during char-slag transition under simulated gasification conditions. Energy Fuels 2010, 24, 1868–1876. [Google Scholar] [CrossRef]

- Yong, S.Z.; Ghoniem, A. Modeling the slag layer in solid fuel gasification and combustion—two-way coupling with CFD. Fuel 2012, 97, 457–466. [Google Scholar] [CrossRef]

- Wang, H.F.; Harb, J.N. Modeling of ash deposition in large-scale combustion facilities burning pulverized coal. Prog. Energy Combust. Sci. 1997, 23, 267–282. [Google Scholar] [CrossRef]

- Ni, J.J.; Yu, G.S.; Guo, Q.H.; Zhou, Z.J.; Wang, F.C. Submodel for predicting slag deposition formation in slagging gasification systems. Energy Fuels 2011, 25, 1004–1009. [Google Scholar] [CrossRef]

- Higman, C.; van der Burgt, M. Gasification, 2nd ed.; Elsevier: New York, NY, USA, 2008. [Google Scholar]

- Guo, Z.Q.; Han, B.Q.; Dong, H. Effect of coal slag on the wear rate and microstructure of the ZrO2-bearing chromia refractories. Ceram. Int. 1997, 23, 489–496. [Google Scholar] [CrossRef]

- Duchesne, M.A.; Macchi, A.; Lu, D.Y.; Hughes, R.W.; McCalden, D.; Anthony, E.J. Artificial neural network model to predict slag viscosity over a broad range of temperatures and slag compositions. Fuel Process. Technol. 2010, 91, 831–836. [Google Scholar] [CrossRef]

- Ni, J.J.; Zhou, Z.J.; Yu, G.S.; Liang, Q.F.; Wang, F.C. Molten slag flow and phase transformation behaviors in a slagging entrained-flow coal gasifier. Ind. Eng. Chem. Res. 2010, 49, 12302–12310. [Google Scholar] [CrossRef]

- Roberts, D.G.; Harris, D.J.; Tremel, A.; Ilyushechkin, A.Y. Linking laboratory data with pilot scale entrained flow coal gasification performance—Part 2: Pilot scale testing. Fuel Process. Technol. 2012, 94, 26–33. [Google Scholar] [CrossRef]

- Kinaev, N. A Review of Mineral. Matter Inssues in Coal Gasification; CSIRO Energy Technology Transfer Center: Pullenvale, Australia, 2006. [Google Scholar]

- Patterson, J.H.; Hurst, H.J. Ash and slag qualities of Australian bituminous coals for use in slagging gasifiers. Fuel 2000, 79, 1671–1678. [Google Scholar] [CrossRef]

- Hurst, H.J.; Novak, F.; Patterson, J.H. Viscosity measurements and empirical predictions for fluxed Australian bituminous coal ashes. Fuel 1999, 78, 1831–1840. [Google Scholar] [CrossRef]

- Kondratiev, A.; Jak, E.; Hayes, P.C. Slag Viscosity Prediction and Characterization Al2O3-CaO-‘Feo’-SiO2 and Al2O3-CaO-‘Feo’-MgO-SiO2 Systems; CCSD Research Report 58; The University of Queensland: Queensland, Australia, 2006. [Google Scholar]

- de Graaf, J.D. Shell Coal Gasification Technology. Shell Global Solution. Available online: http://w3.wtb.tue.nl/fileadmin/wtb/ct-pdfs/Energy_from_Biomass/Lecture_2011_gastcollege_Shell.pdf (accessed on 6 June 2012).

- Cortés, C.G.; Tzimas, E.; Peteves, S.D. Technologies for Coal Based Hydrogen and Electricity Co-production Power Plants with CO2 Capture. EUR 23661/EN-2009. 2009. Available online: http://www.energy.eu/publications/a05.pdf (accessed on 18 July 2012).

- Breault, R.W. Gasification processes old and new: a basic review of the major technologies. Energies 2010, 3, 216–40. [Google Scholar] [CrossRef]

- Gasification: Gasification in Detail Type of Gasifiers; National Energy Technology Laboratory: Morgantown, WV, USA, 2012. Available online: http://www.netl.doe.gov/technologies/coalpower/gasification/gasifipedia/4-gasifiers/4-1-2_entrainedflow.html (accessed on 20 May 2012).

- Gasification Technology Status; Electric Power Research Institute: Palo Alto, CA, USA, 2006.

- Siemans. Simens fuel gasification technology. Available online: http://www.energy.siemens.com/hq/pool/hq/power-generation/fuel-gasifier/downloads/brochure_fuel_gasifier_en.pdf2008 (accessed on 15 September 2012).

- Sundaram, S.K.; Johnson, K.I.; Matyas, J.; Williford, R.E.; Pilli, S.P.; Korolev, V.N. An integrated approach to coal gasifier testing, modeling, and process optimization. Energy Fuels 2009, 23, 4748–4754. [Google Scholar] [CrossRef]

- Kaneko, T.K.; Zhu, J.; Thomas, H.; Bennett, J.P.; Sridhar, S. Influence of oxygen partial pressure on synthetic coal slag infiltration into porous Al2O3 refractory. J. Am. Ceram. Soc. 2012, 95, 1764–1773. [Google Scholar] [CrossRef]

- Kaneko, T.K.; Bennett, J.P.; Sridhar, S. Effect of temperature gradient on industrial gasifier coal slag infiltration into alumina refractory. J. Am. Ceram. Soc. 2011, 94, 4507–4515. [Google Scholar] [CrossRef]

- Yun, Y.S.; Yoo, Y.D.; Chung, S.W. Selection of IGCC candidate coals by pilot-scale gasifier operation. Fuel Process. Technol. 2007, 88, 107–116. [Google Scholar] [CrossRef]

- Wang, P.; Massoudi, M. Impact of Coal and Operating Conditions on the Behavior of Coal Slag in Gasifiers. In Porceedings of 243rd ACS National Meeting & Exposition, San Diego, CA, USA, 25–29 March 2012.

- Ward, C.R. Analysis and significance of mineral matter in coal seams. Int. J. Coal Geol. 2002, 50, 135–168. [Google Scholar] [CrossRef]

- Miller, B.G. Coal Energy System; Elsevier: Burlington, MA, USA, 2005. [Google Scholar]

- Erickson, T.A.; Brekke, D.W.; Tibbetts, J.E.; Folkedahl, B.C. Techniques for Determining Inorganic Transformations During Entrained-Flow Coal Gasification. In The Impact of Ash Deposition on Coal Fired Plants; Williamson, J., Wigley, F., Eds.; Taylor & Francis: Washington, DC, USA, 2004. [Google Scholar]

- Van Dyk, J.C.; Benson, S.A.; Laumb, M.L.; Waanders, B. Coal and coal ash characteristics to understand mineral transformations and slag formation. Fuel 2009, 88, 1057–1063. [Google Scholar]

- Matjie, R.H.; French, D.; Ward, C.R.; Pistorius, P.C.; Li, Z.S. Behaviour of coal mineral matter in sintering and slagging of ash during the gasification process. Fuel Process. Technol. 2011, 92, 1426–1433. [Google Scholar] [CrossRef]

- Matsuoka, K.; Suzuki, Y.; Eylands, K.E.; Benson, S.A.; Tomita, A. CCSEM study of ash forming reactions during lignite gasification. Fuel 2006, 85, 2371–2376. [Google Scholar] [CrossRef]

- Reid, W.T. Its Effect on Combution System; Wiley: New York, NY, USA, 1981. [Google Scholar]

- Aineto, M.; Acosta, A.; Rincon, J.M.; Romero, M. Thermal expansion of slag and fly ash from coal gasification in IGCC power plant. Fuel 2006, 85, 2352–2358. [Google Scholar] [CrossRef]

- Font, O.; Querol, X.; Huggins, F.E.; Chimenos, J.M.; Fernandez, A.I.; Burgos, S.; Pena, F.G. Speciation of major and selected trace elements in IGCC fly ash. Fuel 2005, 84, 1364–1371. [Google Scholar] [CrossRef]

- Van Dyk, J.C.; Waanders, F.B.; Benson, S.A.; Laumb, M.L.; Hack, K. Viscosity predictions of the slag composition of gasified coal, utilizing FactSage equilibrium modelling. Fuel 2009, 88, 67–74. [Google Scholar]

- Song, W.J.; Tang, L.H.; Zhu, X.D.; Wu, Y.Q.; Rong, Y.Q.; Zhu, Z.B.; Koyama, S. Fusibility and flow properties of coal ash and slag. Fuel 2009, 88, 297–304. [Google Scholar] [CrossRef]

- Wang, H.G.; Qiu, P.H.; Zhu, Y.; Wu, S.J.; Zhao, W.H.; Wu, S.H. Effect of residence time on coal ash behavior at high temperatures in reducing atmosphere. Energy Fuels 2011, 25, 5594–604. [Google Scholar] [CrossRef]

- Su, S.; Pohl, J.H.; Holcombe, D. Fouling propensities of blended coals in pulverized coal-fired power station boilers. Fuel 2003, 82, 1653–1667. [Google Scholar] [CrossRef]

- Su, S.; Pohl, J.H.; Holcombe, D.; Hart, J.A. Slagging propensities of blended coals. Fuel 2001, 80, 1351–1360. [Google Scholar] [CrossRef]

- Xu, L.H.; Namkung, H.; Kwon, H.B.; Kim, H.T. Determination of fouling characteristics of various coals under gasification condition. J. Ind. Eng. Chem. 2009, 15, 98–102. [Google Scholar] [CrossRef]

- Speight, J.G. Handbook of Coal analysis; Wiley: New York, NY, USA, 2005. [Google Scholar]

- Bryant, G.W.; Browning, G.J.; Emanuel, H.; Gupta, S.K.; Gupta, R.P.; Lucas, J.A.; Wall, T.F. The fusibility of blended coal ash. Energy Fuels 2000, 14, 316–325. [Google Scholar] [CrossRef]

- Huffman, G.P.; Huggins, F.E.; Dunmyre, G.R. Investigation of the high-temperature behavior of coal ash in reducing and oxidizing atmospheres. Fuel 1981, 60, 585–597. [Google Scholar] [CrossRef]

- Hurst, H.J.; Novak, F.; Patterson, J.H. Phase diagram approach to the fluxing effect of additions of CaCO3 on Australian coal ashes. Energy Fuels 1996, 10, 1215–1219. [Google Scholar] [CrossRef]

- Winegartner, E.C.; Rhodes, B.T. Empirical-study of relation of chemical properties to ash fusion temperatures. J. Eng. Power Trans. ASME 1975, 97, 395–406. [Google Scholar] [CrossRef]

- Song, W.J.; Tang, L.H.; Zhu, X.D.; Wu, Y.Q.; Zhu, Z.B.; Koyama, S. Effect of coal ash composition on ash fusion temperatures. Energy Fuels 2010, 24, 182–189. [Google Scholar] [CrossRef]

- van Dyk, J.C. Understanding the influence of acidic components (Si, Al, and Ti) on ash flow temperature of South African coal sources. Miner. Eng. 2006, 19, 280–286. [Google Scholar]

- Massoudi, M.; Wang, P. A Brief Review of Viscosity Models for Slag in Coal Gasification; DOE Report 103673; U.S. Department of Energy, National Energy Technology Laboratory: Pittsburgh, PA, USA, 2012. Available online: www.osti.gov/servlets/purl/1036735 (accessed on 20 September 2012).

- Schobert, H.H.; Streeter, R.C.; Diehl, E.K. Flow properties of low-rank coal ash slags—implications for slagging gasification. Fuel 1985, 64, 1611–1617. [Google Scholar] [CrossRef]

- Yuan, H.P.; Liang, Q.F.; Gong, X. Crystallization of coal ash slags at high temperatures and effects on the viscosity. Energy Fuels 2012, 26, 3717–3722. [Google Scholar] [CrossRef]

- Ilyushechkin, A.; Kinaev, N. Part 2—Studies of the Connection Between Tcv and Phase Composition of Molten Slag; Technial Note 25. CSIRO Energy Technology: Pulenvale, Australia, 2007. Available online: http://www.ccsd.biz/publications/files/TN/TN%2025_Effects%20of%20K_web.pdf (accessed on 12 May 2012).

- Song, W.J.; Dong, Y.H.; Wu, Y.Q.; Zhu, Z.B. Prediction of temperature of critical viscosity for coal ash slag. AICHe J. 2011, 57, 2921–2925. [Google Scholar] [CrossRef]

- Jak, E.; Saulov, D.; Kondratiev, A.; Hayes, P.C. Prediction of phase equilibria and viscosity in complex coal ash slag systems. Abstr. Papers Am. Chem. Soc. 2004, 227, 1079. [Google Scholar]

- Oh, M.S.; Brooker, D.D.; Depaz, E.F.; Brady, J.J.; Decker, T.R. Effect of crystalline phase-formation on coal slag viscosity. Fuel Process. Technol. 1995, 44, 191–199. [Google Scholar] [CrossRef]

- Lin, X.C.; Ideta, K.; Miyawaki, J.; Takebe, H.; Yoon, S.H.; Mochida, I. Correlation between fluidity properties and local structures of three typical asian coal ashes. Energy Fuels 2012, 26, 136–144. [Google Scholar]

- Kinaev, N.; Ilyushechkin, A. Slag Viscosity—Effects of Potassium and Phase Composition; Technial Note 25. CSIRO Energy Technology: Pulenvale, Australia, 2007. Available online: http://www.ccsd.biz/publications/files/TN/TN%2025_Effects%20of%20K_web.pdf (accessed on 12 August 2012).

- Kato, M.; Minowa, S. Viscosity measurements of molten slag. Trans. Iron Steel Inst. Jpn. 1969, 9, 31–38. [Google Scholar]

- Hurst, H.J.; Patterson, J.H.; Quintanar, A. Viscosity measurements and empirical predictions for some model gasifier slags—II. Fuel 2000, 79, 1797–1799. [Google Scholar] [CrossRef]

- Inaba, S.; Kimura, Y. Viscosity measurement of slag formed in the carbon-bearing iron oxide during the rapid heating. Iron Steel Inst. Jpn. Int. 2004, 44, 2067–2072. [Google Scholar] [CrossRef]

- Groen, J.C.; Brooker, D.D.; Welch, P.J.; Oh, M.S. Gasification slag rheology and crystallization in titanium-rich, iron-calcium-aluminosilicate glasses. Fuel Process. Technol. 1998, 56, 103–127. [Google Scholar] [CrossRef]

- Browning, G.J.; Bryant, G.W.; Hurst, H.J.; Lucas, J.A.; Wall, T.F. An empirical method for the prediction of coal ash slag viscosity. Energy Fuels 2003, 17, 731–737. [Google Scholar] [CrossRef]

- Song, W.J.; Sun, Y.M.; Wu, Y.Q.; Zhu, Z.B.; Koyama, S. Measurement and simulation of flow properties of coal ash slag in coal gasification. AICHe J. 2011, 57, 801–818. [Google Scholar] [CrossRef]

- Zhu, J.X.; Kaneko, T.K.; Mu, H.Y.; Bennett, J.P.; Sridhar, S. Effects of measurement materials and oxygen partial pressure on the viscosity of synthetic eastern and western united states coal slags. Energy Fuels 2012, 26, 4465–4474. [Google Scholar] [CrossRef]

- Dai, Z.; Gong, X.; Guo, X.L.; Liu, H.; Wang, F.C.; Yu, Z. Pilot-trial and modeling of a new type of pressurized entrained-flow pulverized coal gasification technology. Fuel 2008, 87, 2304–2313. [Google Scholar] [CrossRef]

- Koyama, S.; Morimoto, T.; Ueda, A.; Matsuoka, H. A microscopic study of ash deposits in a two-stage entrained-bed coal gasifier. Fuel 1996, 75, 459–465. [Google Scholar] [CrossRef]

- Wu, T.; Gong, M.; Lester, E.; Wang, F.C.; Zhou, Z.J.; Yu, Z.H. Characterisation of residual carbon from entrained-bed coal water slurry gasifiers. Fuel 2007, 86, 972–82. [Google Scholar] [CrossRef]

- Li, S.H.; Whitty, K.J. Investigation of coal char-slag transition during oxidation: effect of temperature and residual carbon. Energy Fuels 2009, 23, 1998–2005. [Google Scholar] [CrossRef]

- Zhao, X.L.; Zeng, C.; Mao, Y.Y.; Li, W.H.; Peng, Y.; Wang, T.; Eiteneer, B.; Zamansky, V.; Fletcher, T. The surface characteristics and reactivity of residual carbon in coal gasification slag. Energy Fuels 2010, 24, 91–94. [Google Scholar] [CrossRef]

- Brannon, M.J.; Ollis, G.W.; Shoaf, G.L. Expanding the range of suitable gasification fuels. Fuel Process. Technol. 2012, 99, 1–5. [Google Scholar] [CrossRef]

- Vuthaluru, H.B.; French, D. Ash chemistry and mineralogy of an Indonesian coal during combustion—Part 1 drop-tube observations. Fuel Process. Technol. 2008, 89, 595–607. [Google Scholar] [CrossRef]

- Vuthaluru, H.B.; French, D. Ash chemistry and mineralogy of an Indonesian coal during combustion: Part II—Pilot scale observations. Fuel Process. Technol. 2008, 89, 608–621. [Google Scholar] [CrossRef]

- Hurley, J.; Wang, T.M.; Nowir, J.W. The Effects of Atmosphere and Additives on Coal Slag Viscosity. Available online: http://www.anl.gov/PCS/acsfuel/preprint%20archive/Files/41_2_NEW%20ORLEANS_03-96_0691.pdf (accessed on 20 June 2012).

- Wang, P.; Shuster, E.; Matuszewski, M.; Tarka, T.; Van Essendelft, D.; Berry, D. Selection of biomass type for co-gasification studies. In Proceedings of the 35th International Technical Conference on Clean Coal & Fuel Systems, Clearwater, FL, USA, 6–10 June 2010.

- Tubio, M.; Riddle, K.; Quinones, H.; Meskers, D. Opportunity Coal Slag Control at Lakeland Mclntosh Unit#3; Technical Report; GE Energy: Fairfield, CT, USA, 2011. [Google Scholar]

- Coda, B.; Cieplik, M.K.; de Wild, P.J.; Kiel, J.H.A. Slagging behavior of wood ash under entrained-flow gasification conditions. Energy Fuels 2007, 21, 3644–3652. [Google Scholar] [CrossRef]

- Matsumoto, K.; Takeno, K.; Ichinose, T.; Ogi, T.; Nakanishi, M. Behavior of alkali metals as the carbonate compounds in the biomass char obtained as a byproduct of gasification with steam and oxygen at 900–1000 degrees C. Energy Fuels 2010, 24, 1980–1986. [Google Scholar] [CrossRef]

© 2013 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/3.0/).

Share and Cite

Wang, P.; Massoudi, M. Slag Behavior in Gasifiers. Part I: Influence of Coal Properties and Gasification Conditions. Energies 2013, 6, 784-806. https://doi.org/10.3390/en6020784

Wang P, Massoudi M. Slag Behavior in Gasifiers. Part I: Influence of Coal Properties and Gasification Conditions. Energies. 2013; 6(2):784-806. https://doi.org/10.3390/en6020784

Chicago/Turabian StyleWang, Ping, and Mehrdad Massoudi. 2013. "Slag Behavior in Gasifiers. Part I: Influence of Coal Properties and Gasification Conditions" Energies 6, no. 2: 784-806. https://doi.org/10.3390/en6020784