A Materials Life Cycle Assessment of a Net-Zero Energy Building

Abstract

:1. Introduction and Background

2. Approach and Methods

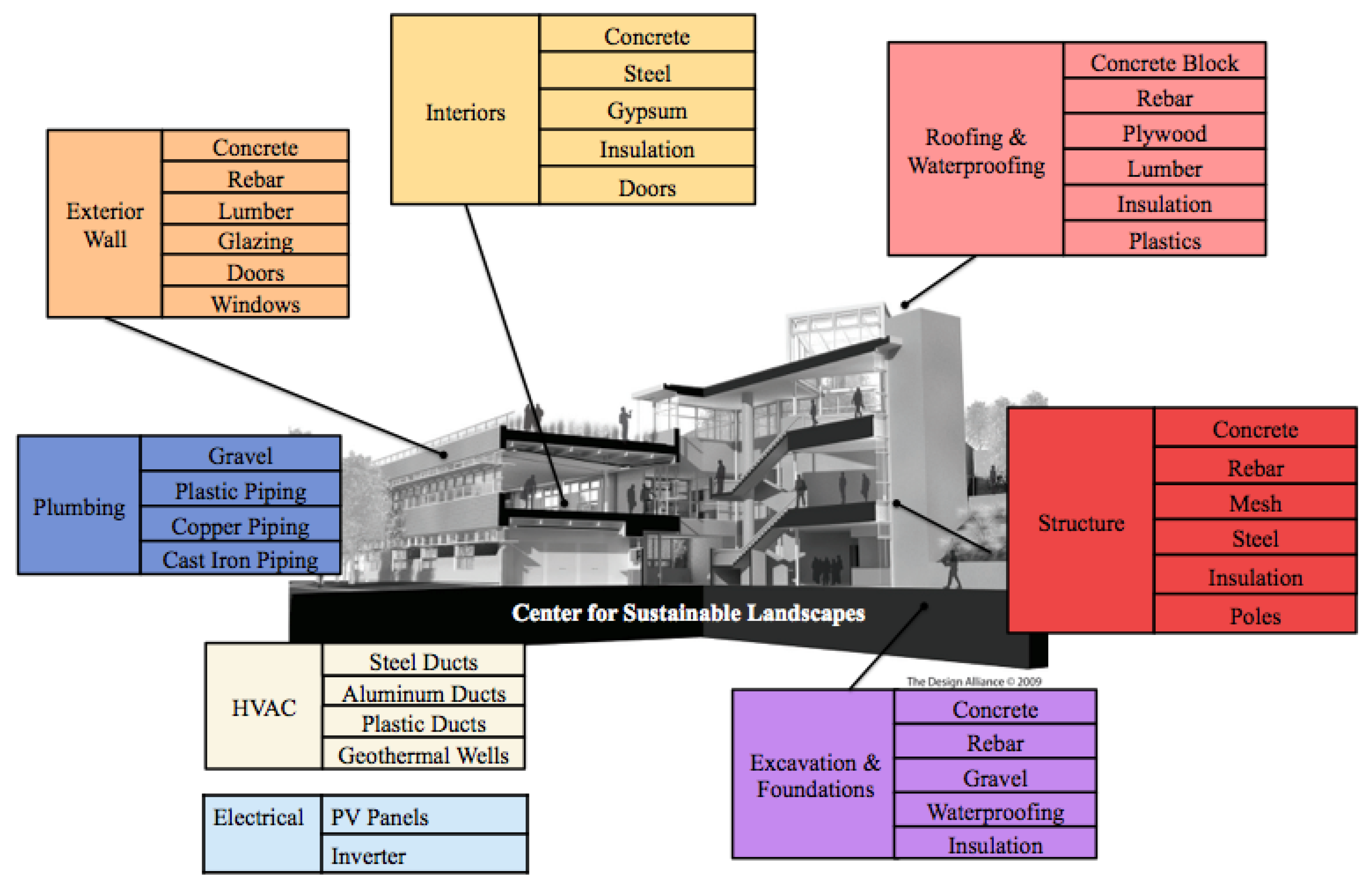

2.1. Case Study Description: Phipps Center for Sustainable Landscapes

2.2. LCA Boundary Definitions and LCI Data Sources

| Building Category | Building Material | Database | Unit Process Name |

|---|---|---|---|

| Exterior Walls | Glazing | ecoinvent Unit Process | Glazing/ecoinvent Unit Process |

| Concrete* | ETH-ESU 96 U | Concrete not reinforced ETH U | |

| Rebar | Franklin USA 98 | Steel cold rolled, EAF FAL/Franklin USA 98 | |

| Lumber | ecoinvent Unit Process | Reclaimed lumber/ecoinvent UP used | |

| Door | ecoinvent Unit Process | Door, outer, wood-aluminum, at plant/RER U/ecoinvent Unit Process | |

| Windows | ecoinvent Unit Process | Window frame, aluminum, U = 1.6 W/m2K, at plant/RER U/ecoinvent Unit Process | |

| Interior Partitions | Concrete* | ETH-ESU 96 U | Concrete not reinforced ETH U |

| Steel | Franklin USA 98 | Steel cold rolled, EAF FAL/Franklin USA 98 | |

| Insulation | ecoinvent Unit Process | Rock wool, at plant/CH U | |

| Doors | ecoinvent Unit Process | Door, inner, wood, at plant/RER U/ecoinvent Unit Process | |

| Gypsum | ecoinvent Unit Process | Gypsum plaster board, at plant/CH U/ecoinvent Unit Process | |

| Roofing and Water-proofing | Concrete Block* | ecoinvent Unit Process | Concrete block, at plant/DE U/ecoinvent Unit Process |

| Rebar | Franklin USA 98 | Steel cold rolled, EAF FAL/Franklin USA 98 | |

| Plywood | ecoinvent Unit Process | Plywood, outdoor use, at plant/RER U/ecoinvent Unit Process | |

| Lumber | ecoinvent Unit Process | Reclaimed lumber/ecoinvent UP used | |

| Insulation | ecoinvent Unit Process | Polystyrene, extruded (XPS), at plant/RER U/ecoinvent Unit Process | |

| HDPE | Franklin USA 98 | HDPE bottles FAL/Franklin USA 98 | |

| Recycled Polymer | IDEMAT 2001 | Recycling mixed polymer I’/IDEMAT 2001 | |

| LDPE | Franklin USA 98 | LDPE film FAL/Franklin USA 98 | |

| Recycled LDPE | Franklin USA 98 | LDPE film recycled FAL/Franklin USA 98 | |

| Structure | Concrete* | ETH-ESU 96 U | Concrete not reinforced ETH U |

| Rebar/Steel/Mesh | Franklin USA 98 | Steel cold rolled, EAF FAL/Franklin USA 98 | |

| Insulation | ecoinvent Unit Process | Rock wool, at plant/CH U | |

| Poles | ecoinvent Unit Process | Cladding, crossbar-pole, aluminum, at plant/RER U/ecoinvent Unit P | |

| Excavation and Foundations | Concrete* | ETH-ESU 96 U | Concrete not reinforced ETH U |

| Rebar | Franklin USA 98 | Steel cold rolled, EAF FAL/Franklin USA 98 | |

| Gravel | ecoinvent Unit Process | Gravel, crushed, at mine/CH U/ecoinvent Unit Process | |

| Waterproofing | ecoinvent Unit Process | Bitumen sealing Alu80, at plant/RER U/ecoinvent Unit Process | |

| Insulation | ecoinvent Unit Process | Polystyrene, extruded (XPS), at plant/RER U/ecoinvent Unit Process | |

| Electrical | PV Panels | ecoinvent Unit Process | Photovoltaic panel, single-Si, at plant/RER/I U |

| Inverter | ecoinvent Unit Process | Inverter, 2500 W, at plant/RER/I U | |

| HVAC | Steel Ducts | ecoinvent Unit Process | Ventilation duct, steel, 100 × 50 mm, at plant/RER U/ecoinvent Unit Process |

| Aluminum Ducts | ecoinvent Unit Process | Flexible duct, aluminum/PET, DN of 125, at plant/RER U/ecoinvent Unit Process | |

| Plastic Ducts | ecoinvent Unit Process | Ventilation duct, PE corrugated tube, DN 75, at plant/RER U/ecoinvent Unit Process | |

| Geothermal Wells | ecoinvent Unit Process | Heat geothermal probe 10 kW U—edited (no HCFC-22) | |

| Plumbing | Gravel | ecoinvent Unit Process | Gravel, crushed, at mine/CH U/ecoinvent Unit Process |

| Plastic Piping | Industry Data | HDPE pipes E/industry data 2.0 | |

| Copper Piping | ecoinvent Unit Process | Copper, primary, at refinery/RER U/ecoinvent Unit Process | |

| Cast Iron Piping | ecoinvent Unit Process | Cast iron, at plant/RER U/ecoinvent Unit Process |

2.3. Impact Assessment Methods

3. Results, Discussion, and Interpretation

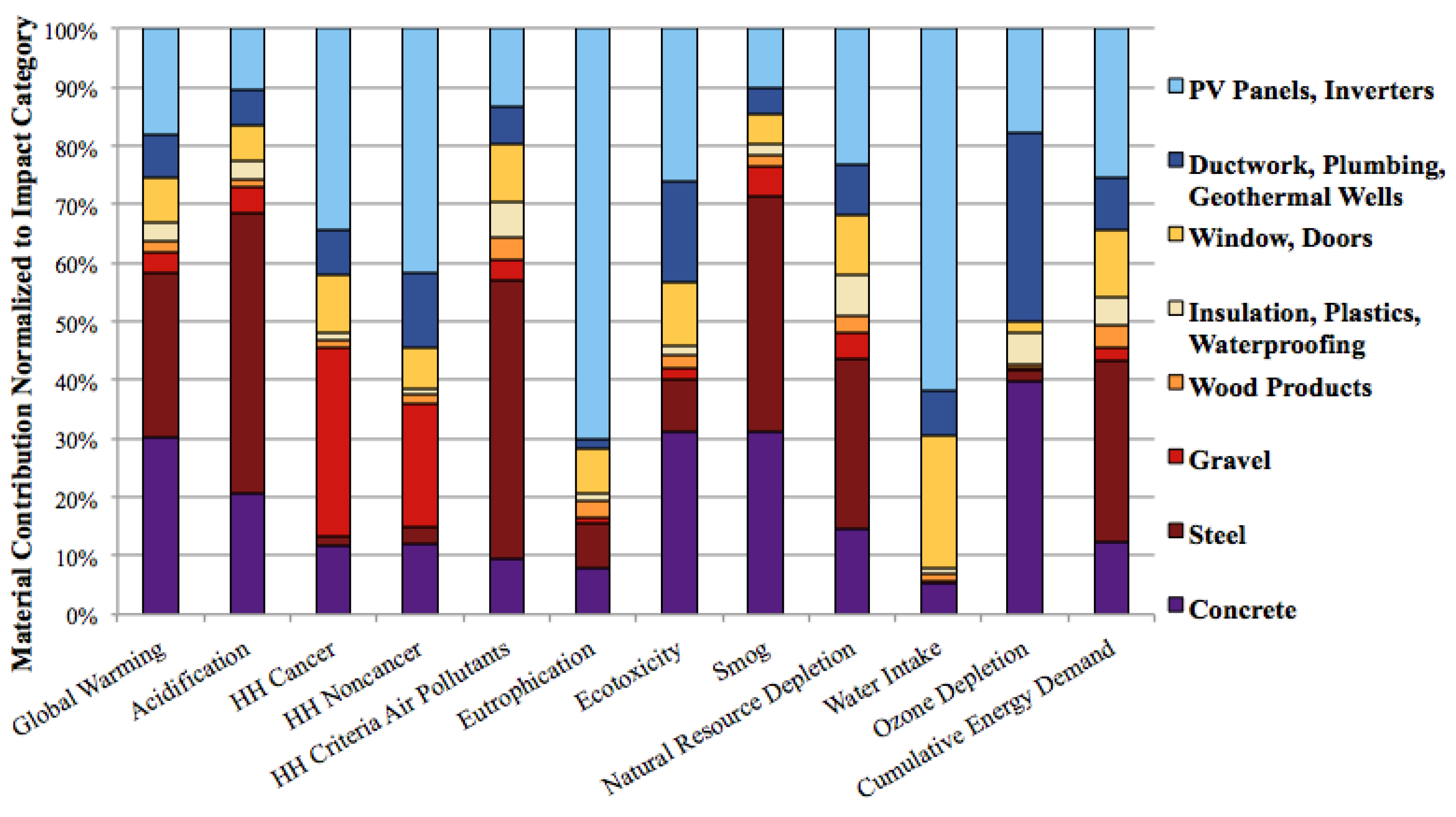

3.1. Life Cycle Environmental Impacts of LBC CSL Building Materials

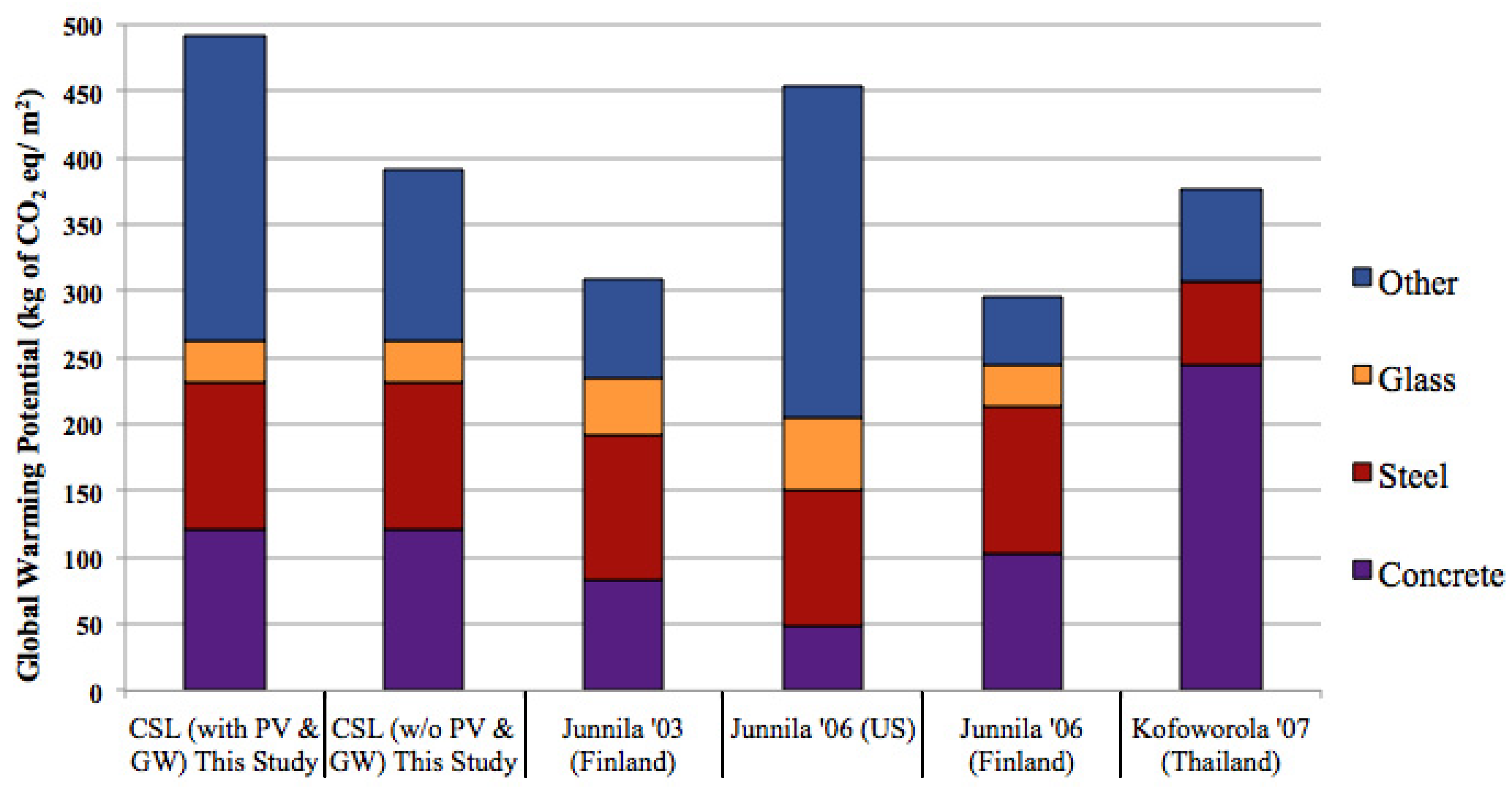

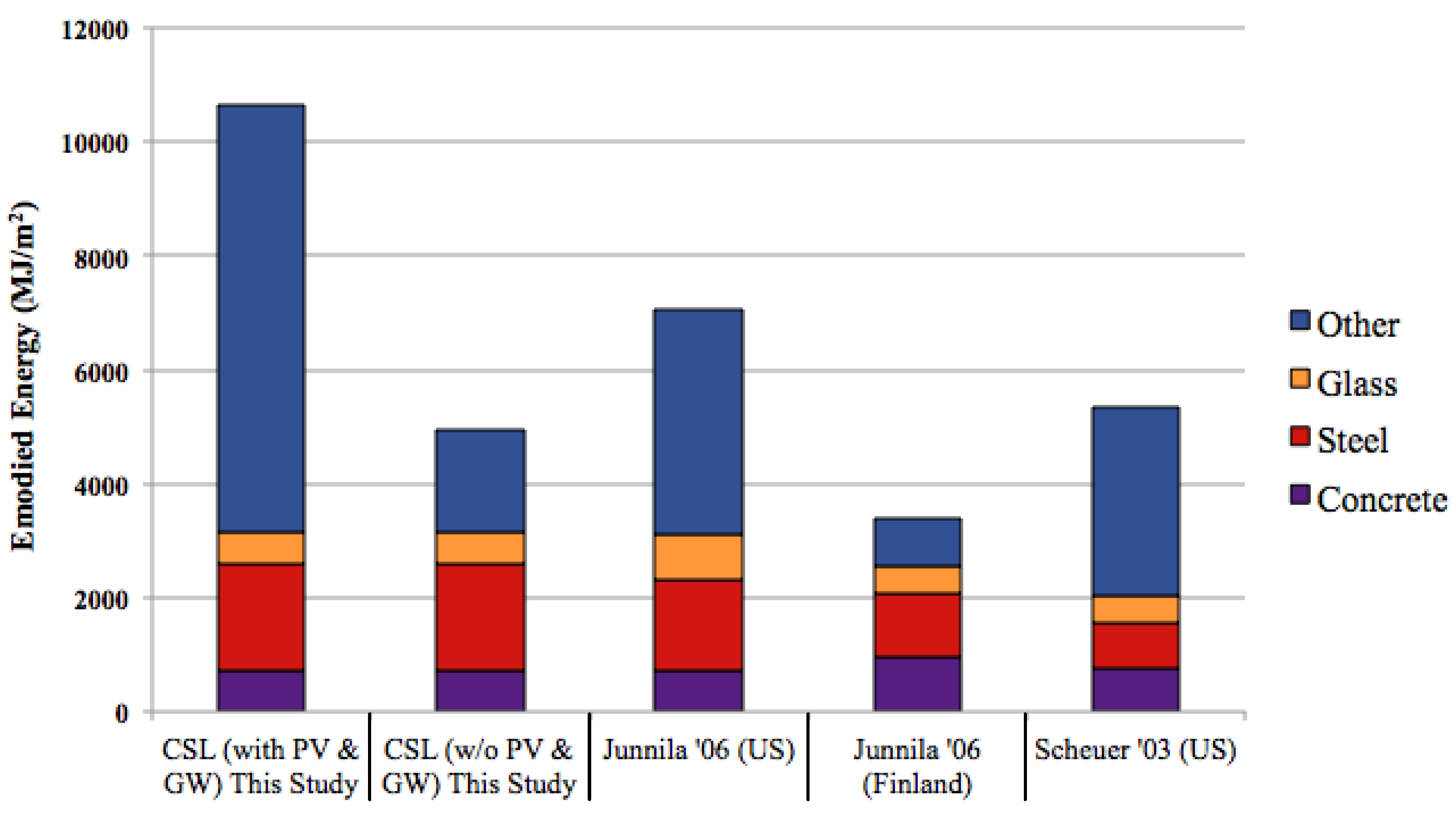

3.2. Comparison of Net-Zero Building to Standard Buildings

| CSL | Junnila ’03 [19] | Junnila ’06 [20] | Junilla ’06 [20] | Scheuer ’03 [24] | Kowoforola ’08 [21] | |

|---|---|---|---|---|---|---|

| Building Purpose | Multi-use Education/Office | High-tech organizations | Typical Office Space | Office/Laboratory Space | Educational and Residential Space | Typical Office Space |

| Building Certification /Efficiency | Living Building Challenge | 37% reduced heating energy from baseline | NR | 6% higher heating energy from baseline | NR | NR |

| Location | Pennsylvania, USA | Finland | Midwest, USA | Finland | Michigan, USA | Thailand |

| Life Expectancy | 50 Years | 50 Years | 50 Years | 50 Years | 75 Years | 50 Years |

| Total Area | 2262 m2 | 15,600 m2 | 4400 m2 | 4400 m2 | 7300 m2 | 60,000 m2 |

| Total Volume | 18,800 m3 | 61,700 m3 | 16,400 m3 | 17,300 m3 | NR | 9,120,000 m3 |

| Floors | 3 | 5 | 5 | 4 | 6 | 38 |

| Structure | Cast-in-place concrete and steel frame | Cast-in-place concrete | Steel-reinforces concrete beam-column system with shear walls | Steel-reinforced concrete mean-column system | Case-in-place concrete on corrugated, galvanized steel sheets and precast concrete with hollow core elements | Case-in-place concrete |

| Envelope | Aluminum/glass curtain wall and wood cladding | Brick/curtain wall combination | Aluminum curtain walls | NR | Aluminum/glass curtain wall and concrete masonry with brick and precast concrete planks | Brick/curtain wall combination |

4. Conclusions

Acknowledgements

References

- Blengini, G.A.; Di Carlo, T. The changing role of life cycle phases, subsystems and materials in the LCA of low energy buildings. Energy Build. 2010, 42, 869–880. [Google Scholar] [CrossRef]

- Sartori, I.; Hestnes, A.G. Energy use in the life cycle of conventional and low-energy buildings: A review article. Energy Build. 2007, 39, 249–257. [Google Scholar] [CrossRef]

- Venkatarama Reddy, B.V.; Jagadish, K.S. Embodied energy of common and alternative building materials and technologies. Energy Build. 2003, 35, 129–137. [Google Scholar] [CrossRef]

- Frischknecht, R. Öko-Inventare von Energiesystemen[in German], 3rd ed.; ETH-ESU (Eidgenössische Technische Hochschule Zürich): Zurich, Switzerland, 1996. [Google Scholar]

- Frischknecht, R.; Rebitzer, G. The ecoinvent database system: A comprehensive web-based LCA database. J. Clean Prod. 2005, 13, 1337–1343. [Google Scholar] [CrossRef]

- Wiedmann, T.; Minx, J. A definition of “Carbon Footprint”. In Ecological Economics Research Trends; Pertsova, C.C., Ed.; Nova Science Publishers: New York, NY, USA, 2008; pp. 1–11. [Google Scholar]

- ILBI (International Living Building Institute). Living Building Challenge 2.1; International Living Building Institute and Cascadia Green Building Council: Seattle, WA, USA, 2012. [Google Scholar]

- Davies, D. Climate-conscious building design: New approaches to embodied-carbon optimization. In Trim Tab 2010; Cascadia Green Building Council: Portland, OR, USA, 2010; pp. 46–51. [Google Scholar]

- Hernandez, P.; Kenny, P. From net energy to zero energy buildings: Defining life cycle zero energy buildings (LC-ZEB). Energy Build. 2010, 42, 815–821. [Google Scholar] [CrossRef]

- Citherlet, S.; Di Guglielmo, F.; Gay, J.B. Window and advanced glazing systems life cycle assessment. Energy Build. 2000, 32, 225–234. [Google Scholar] [CrossRef]

- Prek, M. Environmental impact and life cycle assessment of heating and air conditioning systems, a simplified case study. Energy Build. 2004, 36, 1021–1027. [Google Scholar] [CrossRef]

- ISO (International Organization for Standardization). Environmental Management—Life Cycle Assessment—Principles and Framwork; ISO 14040; ISO: Geneva, Switzerland, 1997. [Google Scholar]

- Goedkoop, M.; Oele, M. SimaPro 6—Introduction to LCA with SimaPro; PRe Consultants: Amersfoort, The Netherlands, 2004. [Google Scholar]

- Kaufmann, P. GaBi Build-It; PE International: Leinfelden-Echterdingen, Germany, 2010. [Google Scholar]

- NIST (National Institute of Standards and Technology). Building for Enviornmental and Economic Sustainability (BEES) 4.0; Building and Fire Research Laboratory, NIST: Boulder, CO, USA, 2007. [Google Scholar]

- Athena EcoCalcuator; ASMI (Athena Sustainable Materials Institute): Ottawa, Canada, 2012. Available online: http://www.athenasmi.org/our-software-data/ecocalculator/ (accessed on 6 February 2013).

- USGBC (United States Green Building Council). Pilot Credit 63: MR-While Building Life Cycle Assessment; USGBC: Washington, DC, USA, 2012. [Google Scholar]

- Aktas, C.; Bilec, M. Impact of lifetime on US residential building LCA results. Int. J. Life Cycle Assess. 2012, 17, 337–349. [Google Scholar] [CrossRef]

- Junnila, S.; Horvath, A. Life-Cycle Environmental Effects of an Office Building. J. Infrastruct. Syst. 2003, 9, 157–166. [Google Scholar] [CrossRef]

- Junnila, S.; Horvath, A.; Guggemos, A.A. Life-Cycle assessment of office buildings in Europe and the United States. J. Infrastruct. Syst. 2006, 12, 10–17. [Google Scholar] [CrossRef]

- Kofoworola, O.; Gheewala, S. Environmental life cycle assessment of a commercial office building in Thailand. Int. J. Life Cycle Assess. 2008, 13, 498–511. [Google Scholar] [CrossRef]

- Suzuki, M.; Oka, T. Estimation of life cycle energy consumption and CO2 emission of office buildings in Japan. Energy Build. 1998, 28, 33–41. [Google Scholar] [CrossRef]

- Ramesh, T.; Prakash, R.; Shukla, K.K. Life cycle energy analysis of buildings: An overview. Energy Build. 2010, 42, 1592–1600. [Google Scholar] [CrossRef]

- Scheuer, C.; Keoleian, G.A.; Reppe, P. Life cycle energy and environmental performance of a new university building: Modeling challenges and design implications. Energy Build. 2003, 35, 1049–1064. [Google Scholar] [CrossRef]

- Blengini, G.A.; Di Carlo, T. Energy-saving policies and low-energy residential buildings: An LCA case study to support decision makers in Piedmont (Italy). Int. J. Life Cycle Assess. 2010, 15, 652–665. [Google Scholar] [CrossRef]

- Yohanis, Y.G.; Norton, B. Life-cycle operational and embodied energy for a generic single-storey office building in the UK. Energy 2002, 27, 77–92. [Google Scholar] [CrossRef]

- Cascadia Region Green Building Council. Living Building Challenge; Cascadia Region Green Building Council: Seattle, WA, USA, 2007. [Google Scholar]

- ILBI. Case Studies. Available online: https://ilbi.org/lbc/casestudies (accessed on 6 February 2013).

- Fay, R.; Treloar, G.; Iyer-Raniga, U. Life-cycle energy analysis of buildings: A case study. Build. Res. Inf. 2000, 28, 31–41. [Google Scholar] [CrossRef]

- Phipps. About Phipps Conservatory. Available online: http://phipps.conservatory.org/about-phipps/index.aspx (accessed on 6 February 2013).

- Phipps. Phipps and Sustianability. Available online: http://phipps.conservatory.org/project-green-heart/green-heart-at-phipps/center-for-sustainable-landscapes.aspx (accessed on 6 February 2013).

- Kannan, R.; Leong, K.C.; Osman, R.; Ho, H.K.; Tso, C.P. Life cycle assessment study of solar PV systems: An example of a 2.7 kWp distributed solar PV system in Singapore. Sol. Energy 2006, 80, 555–563. [Google Scholar] [CrossRef]

- The Design Alliance Architects. Center for Systainable Landscapes: Overview of Images; The Design Alliance Architects: Pittsburgh, PA, USA, 2009. [Google Scholar]

- USA LCI Database Documentation; FranklinAssociates: Prairie Village, KS, USA, 1998.

- Frischknecht, R.; Jungbluth, N.; Hans-Jörg Althaus, H.J.; Doka, G.; Dones, R.; Heck, T.; Hellweg, S.; Hischier, R.; Nemecek, T.; Rebitzer, G.; Spielmann, M. The ecoinvent Database: Overview and Methodological Framework (7 pp). Int. J. Life Cycle Assess. 2005, 10, 3–9. [Google Scholar] [CrossRef]

- PlasticsEurope. Industry Data v2.0. Available online: http://www.pre-sustainability.com/content/databases#SimaPro%20databases (accessed on 6 February 2013).

- IDEMAT. Available online: http://www.idemat.nl/index.htm (accessed on 6 February 2013).

- Flower, D.J.M.; Sanjayan, J.G. Green house gas emissions due to concrete manufacture. Int. J. Life Cycle Assess 2007, 12, 282–288. [Google Scholar] [CrossRef]

- Frischknecht, R.; Jungbluth, N. Implementation of Life Cycle Impact Assessment Methods; Final Report Ecoinvent; Swiss Centre for LCI: Duebendorf, Switzerland, 2003. [Google Scholar]

- Frischknecht, R. Implementation of Life Cycle Impact Assessment Methods; Ecoinvent Report; Swiss Centre for LCI: Duebendorf, Switzerland, 2007. [Google Scholar]

- Bare, J. Tool for the Reduction and Assessment of Chemical and Other Environmental Impacts (TRACI); United States Environmental Protection Agency: Washington, DC, USA, 2002. Available online: http://www.epa.gov/nrmrl/std/traci/traci.html (accessed on 21 February 2013).

- Guggemos, A.A.; Horvath, A. Comparison of Environmental effects of steel- and concrete-framed buildings. J. Infrastruct. Syst. 2005, 11, 93–101. [Google Scholar] [CrossRef]

- Jonsson, A.; Bjorklund, T.; Tillman, A. LCA of concrete and steel building frames. Int. J. Life Cycle Assess. 1998, 3, 216–224. [Google Scholar] [CrossRef]

- Zapata, P.; Gambatese, J.A. Energy consumption of asphalt and reinforced concrete pavement materials and construction. J. Infrastruct. Syst. 2005, 11, 9–20. [Google Scholar] [CrossRef]

- Huntzinger, D.N.; Eatmon, T.D. A life-cycle assessment of Portland cement manufacturing: comparing the traditional process with alternative technologies. J. Clean. Prod. 2009, 17, 668–675. [Google Scholar] [CrossRef]

- O’Brien, K.; Ménaché, J.; O’Moore, L. Impact of fly ash content and fly ash transportation distance on embodied greenhouse gas emissions and water consumption in concrete. Int. J. Life Cycle Assess. 2009, 14, 621–629. [Google Scholar] [CrossRef] [Green Version]

- Reiner, M.; Rens, K. High-volume fly ash concrete: Analysis and application. Pract. Period. Struct. Des. Construct. 2006, 11, 58–64. [Google Scholar] [CrossRef]

- Keoleian, G.; Kendall, A.; Dettling, J.; Smith, V.; Chandler, R.; Lepech, M.; Li, V. Life Cycle modeling of concrete bridge design: Comparison of Engineered cementitious composite link slabs and conventional steel expansion joints. J. Infrastruct. Syst. 2005, 11, 51–60. [Google Scholar] [CrossRef]

- Johnson, J.; Reck, B.K.; Wang, T.; Graedel, T.E. The energy benefit of stainless steel recycling. Energy Policy 2008, 36, 181–192. [Google Scholar] [CrossRef]

- Al-Awadhi, J.M. Impact of gravel quarrying on the desert environment of Kuwait. Environ. Geol. 2001, 41, 365–371. [Google Scholar] [CrossRef]

- Edvardsson, K.; Magnusson, R. Monitoring of dust emission on gravel roads: Development of a mobile methodology and examination of horizontal diffusion. Atmos. Environ. 2009, 43, 889–896. [Google Scholar] [CrossRef]

- Jakucionyte, L.; Mikalajune, A. Investigation into heavy metal concentration by the gravel roadsides. J. Environ. Eng. Landsc. Manag. 2011, 19, 89–100. [Google Scholar] [CrossRef]

- Chakravarty, R. Are Solar PV Farms Polluting; Electronics For You: New Delhi, India, 2012. [Google Scholar]

- Tripanagnostopoulos, Y.; Souliotis, M.; Battisti, R.; Corrado, A. Energy, cost, and LCA results of PV and hybrid PV/T Solar systems. Prog. Photovolt. Res. Appl. 2005, 13, 235–250. [Google Scholar] [CrossRef]

- Alsema, E.; de Wild-Scholten, M. Environmental life cycle assessment of advanced silicon solar cell technologies. In Presented at the 19th European Photovoltaic Solar Energy Conference, Paris, France, 7–11 June 2004.

- Fthenakis, V. Overview of Potential Hazards. In Practical Handbook of Photovoltaics: Fundamentals and Applications; Markvart, T., Castaner, L., Eds.; Brookhaven National Laboratory: Upton, NY, USA, 2003; Chapter VII-2. [Google Scholar]

- Connelly, J. Embodied Carbon Footprint Understanding; Campion, N., Ed.; Cascadia Green Building Council: Pittsburgh, PA, USA, 2012. [Google Scholar]

- Rajagopalan, N.; Bilec, M.; Landis, A. Life cycle assessment evaluation of green product labeling systems for residential construction. Int. J. Life Cycle Assess. 2012, 17, 753–763. [Google Scholar] [CrossRef]

© 2013 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/3.0/).

Share and Cite

Thiel, C.L.; Campion, N.; Landis, A.E.; Jones, A.K.; Schaefer, L.A.; Bilec, M.M. A Materials Life Cycle Assessment of a Net-Zero Energy Building. Energies 2013, 6, 1125-1141. https://doi.org/10.3390/en6021125

Thiel CL, Campion N, Landis AE, Jones AK, Schaefer LA, Bilec MM. A Materials Life Cycle Assessment of a Net-Zero Energy Building. Energies. 2013; 6(2):1125-1141. https://doi.org/10.3390/en6021125

Chicago/Turabian StyleThiel, Cassandra L., Nicole Campion, Amy E. Landis, Alex K. Jones, Laura A. Schaefer, and Melissa M. Bilec. 2013. "A Materials Life Cycle Assessment of a Net-Zero Energy Building" Energies 6, no. 2: 1125-1141. https://doi.org/10.3390/en6021125