Cost Benefit Analysis of Using Clean Energy Supplies to Reduce Greenhouse Gas Emissions of Global Automotive Manufacturing

Abstract

:1. Introduction

2. Clean Energy Power Systems

2.1. Solar PV System

- ACout: actual power output, AC electricity (kWh)

- nm: number of PV modules

- Iave: average annual solar insolation (kWh/m2/year)

- Am: surface area of one PV module (m2)

- em: module efficiency

- fDC-AC: DC-AC conversion efficiency

| Solar PV Module | Manufacturer | Rated Module Power (W) | Module Efficiency | Module Surface Area (m2) |

|---|---|---|---|---|

| Suntech STP210-18/Ud | Suntech | 210 | 14.30% | 1.47 |

| Sharp ND-224uC1 | Sharp | 224 | 13.74% | 1.63 |

| Qcells Q.BPPARROSOE 225 | Q-Cells | 225 | 17.00% | 1.67 |

| YL 210 P-26b/1495x990 | Yingli Solar | 210 | 14.20% | 1.48 |

| Trina Solar TSM-PC05 | Trina Solar | 230 | 14.70% | 1.64 |

2.2. Wind Energy

- vz: wind speed at z m height above the ground (m/s)

- v0: wind speed at specified height of z0 (m/s)

- z0: specified height (m)

- k: Hellman exponent (k = 0.34)

- W: wind power density (W/m2)

- P: air pressure (Pa or N/m2)

- A: area (m2)

- ρ: air density (kg/m3)

- vz: wind speed at z m height (m/s)

- λ: the dimensionless Weibull shape parameter

| Wind Turbine | Manufacturer | Rated Capacity (kW) | Rotor Diameter (m) | Sweep Area (m2) |

|---|---|---|---|---|

| 1.5XLE | GE | 1500 | 82.5 | 5346.00 |

| SL1500/77 | Sinovel | 1500 | 77.4 | 4705.13 |

| S82 1.5 MW | Suzlon | 1500 | 82 | 5281.02 |

| S77 1.5 MW | Nordex | 1500 | 82 | 5281.02 |

2.3. Fuel Cell

| Stationary Fuel Cells | Manufacturer | Fuel Type | Rated Power (kW) |

|---|---|---|---|

| PureCell 200 | UTC Power | Natural gas | 200 |

| Nedstack PS100 | Nedstack | Hydrogen | 100 |

3. GHG Emission Mitigation through Clean Energy Supply

| Detroit | Mexico city | Sao Paulo | Shanghai | Cairo | Bochum | |

|---|---|---|---|---|---|---|

| Solar insolation (kw/m2/year) | 1269.90 | 1890.70 | 1661.36 | 1410.73 | 1929.03 | 986.11 |

| Wind power density (w/m2) | 356.36 | 76.50 | 116.59 | 352.08 | 213.01 | 591.78 |

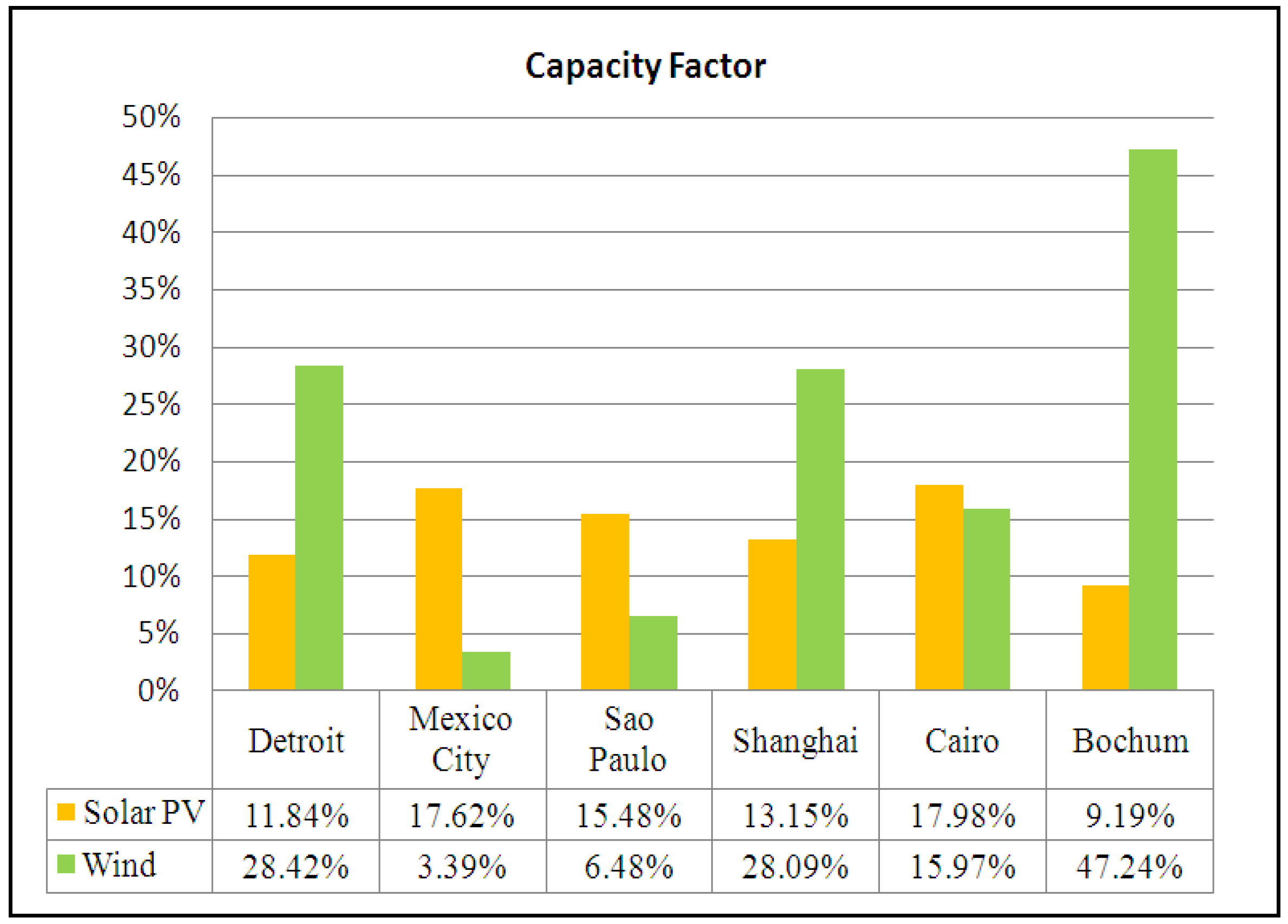

3.1. Capacity Factor of Solar and Wind Power Systems

- CF: capacity factor of a power supply system

- Poutput: actual power output of the supply system (kW)

- Psystem: rated power of the supply system (kW)

- Pi: input power of a wind turbine (W)

- Dw: the wind power density (W/m2)

- AS: the sweeping area of turbine blades (m2)

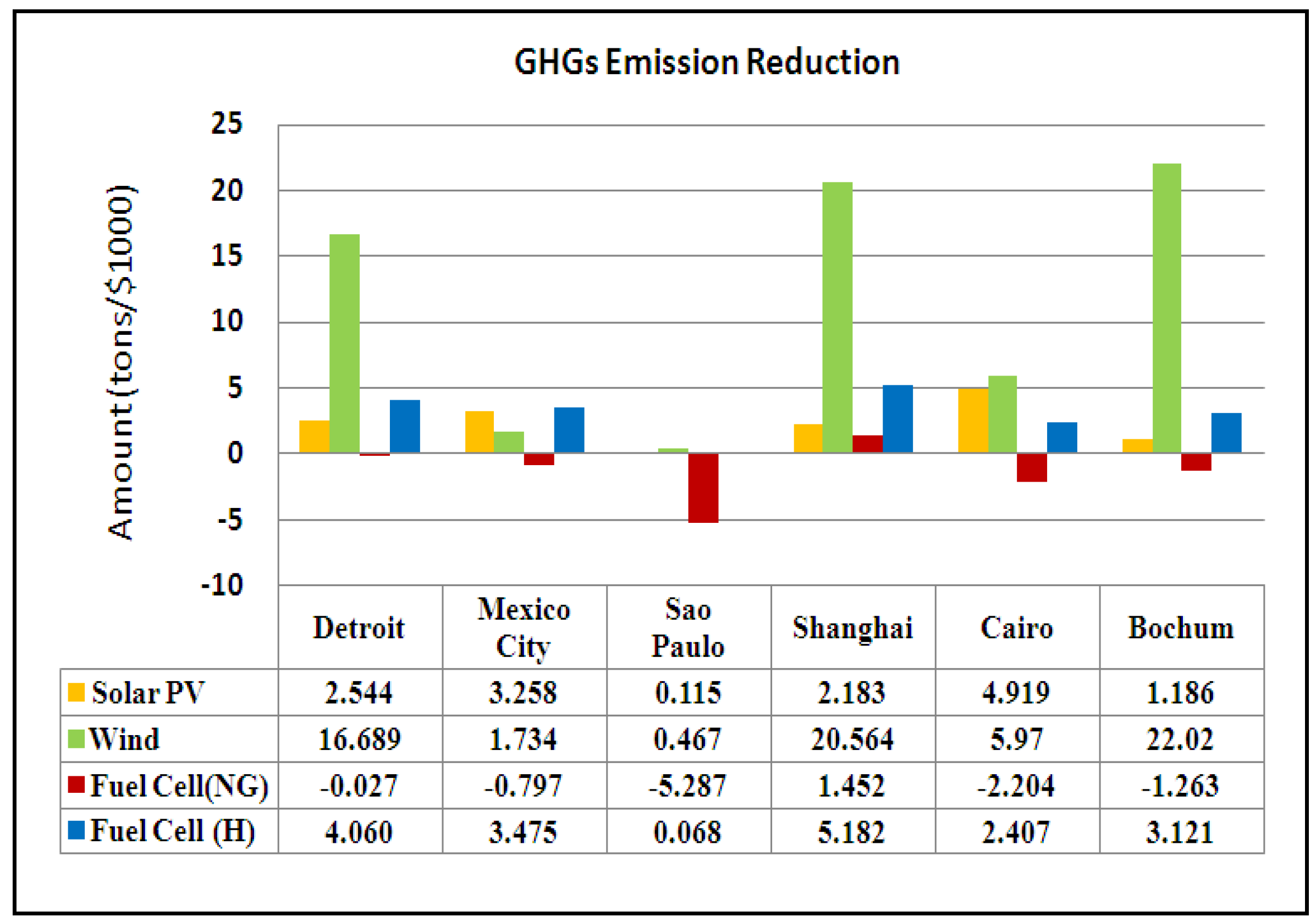

3.2. Economic Analysis of GHG Mitigation

| Overnight Cost ($/kW) | Variable O&M ($/kWh) | Fixed O&M ($/kW) | LCA GHG Emissions (g/kWh) | |

|---|---|---|---|---|

| Solar PV | 6171 | 0.00 | 11.94 | 72.4 1 |

| Wind | 1966 | 0.00 | 30.98 | 10.84 2 |

| Fuel Cell (NG) | 5478 | 0.049 | 5.78 | 683 3 |

| Fuel Cell (H2) | 10,735 5 | 0.00 5 | 2147 5 | 83 4 |

- G: the amount of GHG reduction (ton/$1,000)

- Elocal: emission factor of GHGs from local grid power supply (kg/kWh)

- Ei: the life cycle GHG emissions of clean energy i (kg/kWh)

- Ai: total installed capacity of clean energy power system i

- Ti: operational life time of clean power system i (h)

- CNi: overnight cost of clean power system i ($/kW)

- Cvi: variable O&M cost of clean power system i ($/kWh)

- CFi: fixed O&M cost of clean power system i ($/kWh)

| Region | Emission Inventory (g/kWh) | |||

|---|---|---|---|---|

| CO2 | CH4 | N2O | CO2eq 3 | |

| USA 1 | 676 | 0.01815 | 0.01053 | 680 |

| Mexico 2 | 593 | 0.01676 | 0.00230 | 594 |

| Brazil 2 | 93 | 0.00251 | 0.00106 | 93 |

| China 2 | 839 | 0.01458 | 0.01841 | 845 |

| Egypt 2 | 436 | 0.01365 | 0.00177 | 437 |

| Germany 2 | 539 | 0.00637 | 0.00779 | 542 |

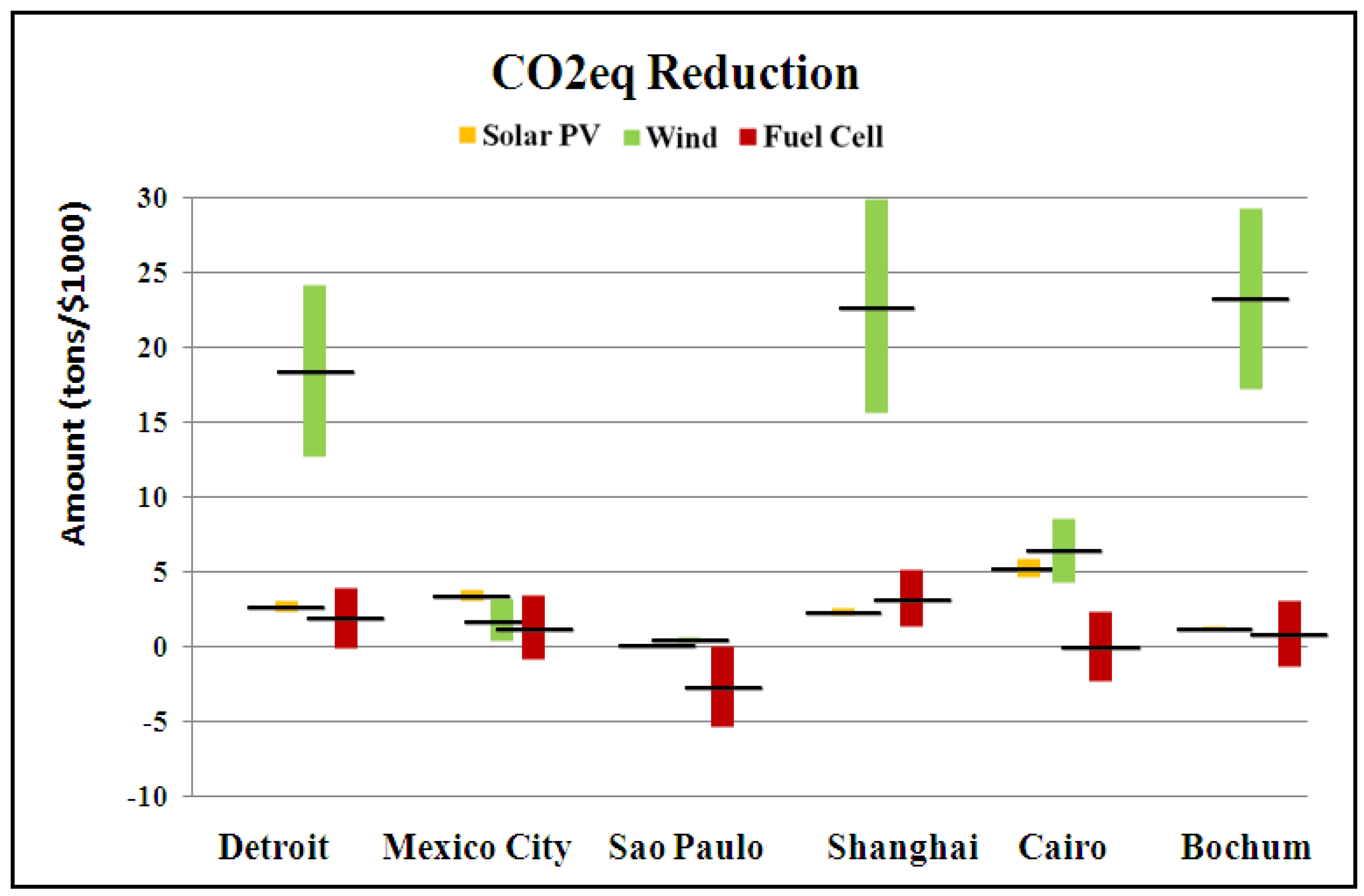

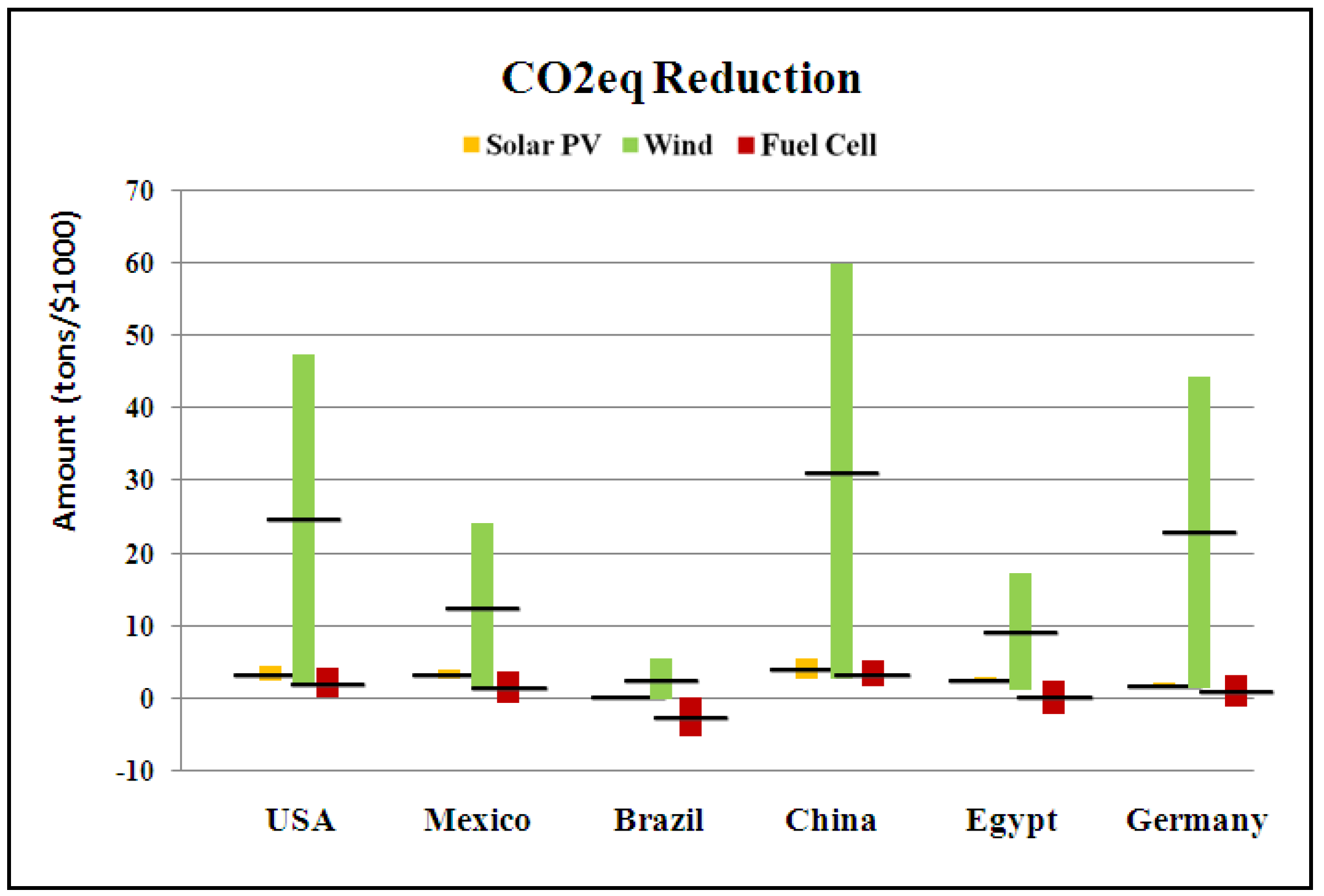

3.3. Range of GHG Mitigation Potential at Different Regions

4. Concluding Remarks

Acknowledgements

References

- Yuan, C.; Zhang, T.; Rangarajan, A.; Dornfeld, D.; Ziemba, B.; Whitbeck, R. A decision-based analysis of compressed air usage patterns in automotive manufacturing. J. Manuf. Syst. 2006, 25, 293–300. [Google Scholar] [CrossRef]

- Maclean, H.; Lave, L. A life-cycle model of an automobile. Environ. Policy Anal. 1998, 3, 322A–330A. [Google Scholar]

- General Motors Company. Public Policy Center Environment and Energy. Voluntary Reporting of General Motors Corporation United States Greenhouse Gas (GHG) Emissions for Calendar Year (1990–2007). 2008. Available online: http://www.gm.com/corporate/responsibility/environment/reports/greenhouse_gas_emissions/ghgreport_2007.pdf (accessed on 5 October 2010).

- U.S. D.O.E. (Department of Energy). Climate Vision Progress Report 2007. Available online: http://www.doe.gov/media/Climate_Vision_Progress_Report.pdf (accessed on 2 October 2010).

- Yuan, C.; Dornfeld, D. Reducing the environmental footprint and economic costs of automotive manufacturing through an alternative energy supply. Trans. North Am. Manuf. Res. Inst. 2009, 37, 427–434. [Google Scholar]

- General Motors Company. General Motors: About GM 2010. Available online: http://www.gm.com/corporate/about/ (accessed on 12 October 2010).

- REN21. Renewables Global Status Report. 2009. Available online: http://www.ren21.net/pdf/RE_GSR_2009_Update.pdf (accessed on 4 October 2010).

- Renewable Energy World. Top 10: Ten Largest Solar PV Companies, 2010. Available online: http://www.renewableenergyworld.com/rea/blog/post/2010/06/top-10-ten-largest-solar-pv-companies (accessed on 23 October 2010).

- Simiu, E.; Scanlan, R.H. Wind Effects on Structures; Wiley: New York, NY, USA, 1978; p. 47. [Google Scholar]

- Kaltschmitt, M.; Streicher, W.; Wiese, A. Renewable Energy: Technology, Economics, and Environment; Springer: New York, NY, USA, 2007; p. 55. [Google Scholar]

- Chang, T.J.; Wu, Y.T.; Hsu, H.Y.; Chu, C.R.; Liao, C.M. Assessment of wind characteristics and wind turbine characteristics in Taiwan. Renew. Energy 2003, 28, 851–871. [Google Scholar] [CrossRef]

- My Wind Power System. The 10 Major Wind Power Companies in the World. Available online: http://www.mywindpowersystem.com/2009/04/the-10-major-wind-power-companies-in-the-world/ (accessed on 23 October 2010).

- NASA Atmospheric Science Data Center. Surface Meteorology and Solar Energy, A Renewable Energy Resource Web Site (Release 6.0), 2008. Available online: http://eosweb.larc.nasa.gov/cgi-bin/sse/sse.cgi?na+s01+s06#s01 (accessed on 12 October 2010).

- Marion, B.; Anderberg, M.; Gray-Hann, P. Recent Revisions to PVWATTS. NREL/CP-520-38975; National Renewable Energy Laboratory: Golden, CO, USA, 2005.

- NASA Atmospheric Science Data Center. Surface Meteorology and Solar Energy, A Renewable Energy Resource Web Site (release 5 Data Set), 2005. Available online: http://eosweb.larc.nasa.gov/sse/global/text/10yr_wspd50m (accessed on 12 October 2010).

- U.S. E.I.A. (Energy Information Administration). Cost and Performance Characteristics of New Central Station Electricity Generating Technologies, 2010. Available online: http://www.eia.doe.gov/oiaf/aeo/excel/aeo2010%20tab8%202.xls (accessed on 12 September 2010).

- Azzopardi, B.; Mutale, J. Life cycle analysis for future photovoltaic systems using hybrid solar cells. Renew. Sustain. Energy Rev. 2010, 14, 1130–1134. [Google Scholar] [CrossRef]

- Pehnt, M. Dynamic life cycle assessment (LCA) of renewable energy technologies. Renew. Energy 2006, 31, 55–71. [Google Scholar] [CrossRef]

- Jaap, V.; Rooijen, A. Life Cycle Assessment of the PureCellTM Stationary Fuel Cell System: Providing a Guide for Environmental Improvement. M.Sc. Thesis, Delft University of Technology, Delft, The Netherlands, 2006. [Google Scholar]

- Viebahn, P.; Krewitt, W. Environmental and Ecological Life Cycle Inventories for Present and Future Power Systems in Europe (ECLIPSE); European Commission, DG Research (Project No. NNE5-2001-00071): Brussels, Belgium, 2003. [Google Scholar]

- Gerboni, R.; Pehnt, M.; Viebahn, P.; Lavagno, E. Final Report on Technical Data, Costs and Life Cycle Inventories of Fuel Cells. New Energy Externalities Developments for Sustainability (NEEDS); NEEDS Project: Rome, Italy, 2008; Available online: http://www.needs-project.org/RS1a/RS1a%20D9.2%20Final%20report%20on%20fuel%20cells.pdf (accessed on 15 September 2011).

- U.S. E.I.A. (Energy Information Administration). Domestic Electricity Emission Factors, 1999–2002; EIA: Washington, DC, USA, 2007. Available online: http://www.eia.doe.gov/oiaf/1605/excel/electricity_factors_99-02region.xls (accessed on 10 September 2010).

- U.S. E.I.A. (Energy Information Administration). International Electricity Emission Factors by Country, 1999–2002; EIA: Washington, DC, USA, 2007. Available online: http://www.eia.doe.gov/oiaf/1605/excel/electricity_factors_99-02country.xls (accessed on 10 September 2010).

- IPCC. IPCC Fourth Assessment Report (AR4) by Working Group 1 (WG1); IPCC: Geneva, Switzerland, 2007; Available online: http://www.ipcc.ch/pdf/assessment-report/ar4/wg1/ar4-wg1-chapter2.pdf (accessed on 10 September 2010).

- American Wind Energy Association (AWEA). 2010. Available online: http://www.awea.org/faq/rsdntqa.html (accessed on 13 September 2010).

© 2011 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/3.0/).

Share and Cite

Zhai, Q.; Cao, H.; Zhao, X.; Yuan, C. Cost Benefit Analysis of Using Clean Energy Supplies to Reduce Greenhouse Gas Emissions of Global Automotive Manufacturing. Energies 2011, 4, 1478-1494. https://doi.org/10.3390/en4101478

Zhai Q, Cao H, Zhao X, Yuan C. Cost Benefit Analysis of Using Clean Energy Supplies to Reduce Greenhouse Gas Emissions of Global Automotive Manufacturing. Energies. 2011; 4(10):1478-1494. https://doi.org/10.3390/en4101478

Chicago/Turabian StyleZhai, Qiang, Huajun Cao, Xiang Zhao, and Chris Yuan. 2011. "Cost Benefit Analysis of Using Clean Energy Supplies to Reduce Greenhouse Gas Emissions of Global Automotive Manufacturing" Energies 4, no. 10: 1478-1494. https://doi.org/10.3390/en4101478

APA StyleZhai, Q., Cao, H., Zhao, X., & Yuan, C. (2011). Cost Benefit Analysis of Using Clean Energy Supplies to Reduce Greenhouse Gas Emissions of Global Automotive Manufacturing. Energies, 4(10), 1478-1494. https://doi.org/10.3390/en4101478