A Review on Concepts, Applications, and Models of Aquifer Thermal Energy Storage Systems

Abstract

:1. Introduction

2. Basic Concepts and Applications

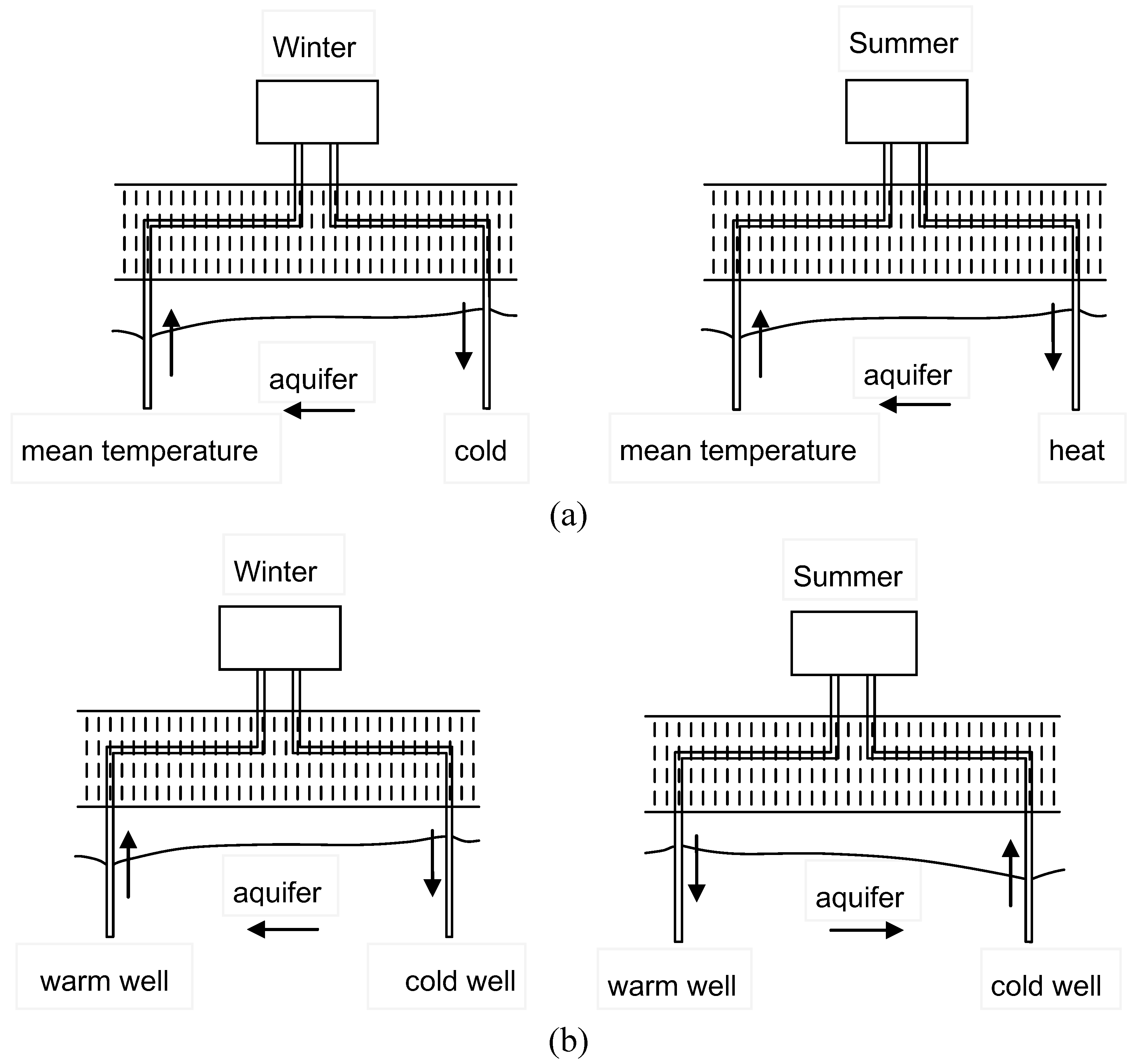

2.1. Operational Principles

2.2. History and Current Status

3. Design and Construction

3.1. Design Procedure

- (1)

- pre feasibility studies to describe the principal issues,

- (2)

- feasibility study to tell the technical and economical feasibility and environmental impact compared to more than one reference systems,

- (3)

- the first permit applications to local authorities,

- (4)

- definition of hydrogeological conditions by site investigations and measurements of loads and temperatures, etc on the user side,

- (5)

- evaluation of results and modeling for technical, legal, and environmental purposes,

- (6)

- final design for tender documents,

- (7)

- final permit application for court procedures.

3.2. Field Investigation

- (1)

- geological mapping

- (2)

- geophysical investigations

- (3)

- test drillings

- (4)

- pumping tests

4. Numerical Simulations

4.1. Mathematical Theory

4.2. Simulation Models

| Model | Creator | Numerical Scheme | Description |

|---|---|---|---|

| AQUA3D | Vatnaskil Consulting Engineers, Reykjavik, Iceland | finite-element method | developed mainly for simulation of mass transport problems, but can be adapted to model heat transport without density-dependent groundwater flow |

| HST3D | United States Geological Survey (USGS) | finite-difference method | capable of simulating mass and heat transport in variable-density groundwater flow system |

| FEFLOW | DHI-WASY GmbH, Berlin, Germany | finite-element method | capable of simulating both mass and heat transport in density-dependent groundwater flow systems |

| SUTRA-MS | United States Geological Survey (USGS) | hybrid finite-element and finite-difference method | simulated fluid movement and the transport of either energy or dissolved substances in the subsurface environment |

| THETA 3.0 | Nuclear Engineering Laboratory, Helsinki University of Technology, Finland | finite-difference method | coupled transport of fluid and energy in porous media |

| TOUGH2 | Earth Sciences Division, Lawrence Berkeley National Laboratory | integral finite difference method | simulating the coupled transport of water, vapor, non-condensable gas, and heat in porous and fractured media |

| SHEMAT | Applied Geophysics and Geothermal Energy E.ON Energy Research Center, RWTH Aachen University | finite difference method | simulating coupled flow, heat transfer, transport and chemical water-rock interaction in hydro-geothermal reservoirs in two and three dimensions |

| UTCHEM | Center for Petroleum and Geosystems Engineering, Austin, Texas, U.S.A. | finite difference method | developed mainly for modeling multiphase, multicomponent, compositional simulation of chemical flooding processes, but can be used to model heat transport |

- (1)

- the type of boundary conditions handled by the code

- (2)

- the solution scheme employed by the code

- (3)

- verification of the code

- (4)

- cost

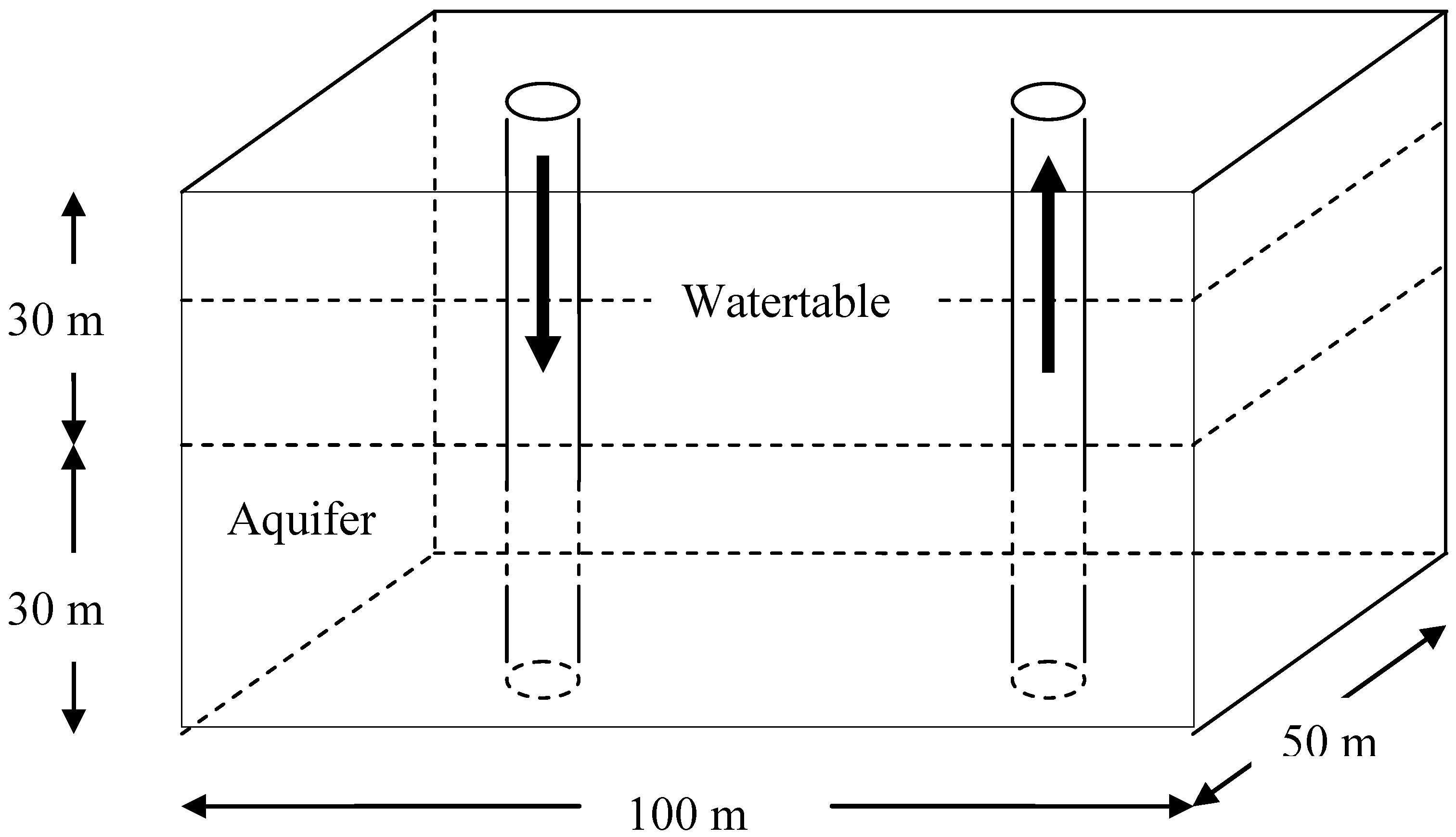

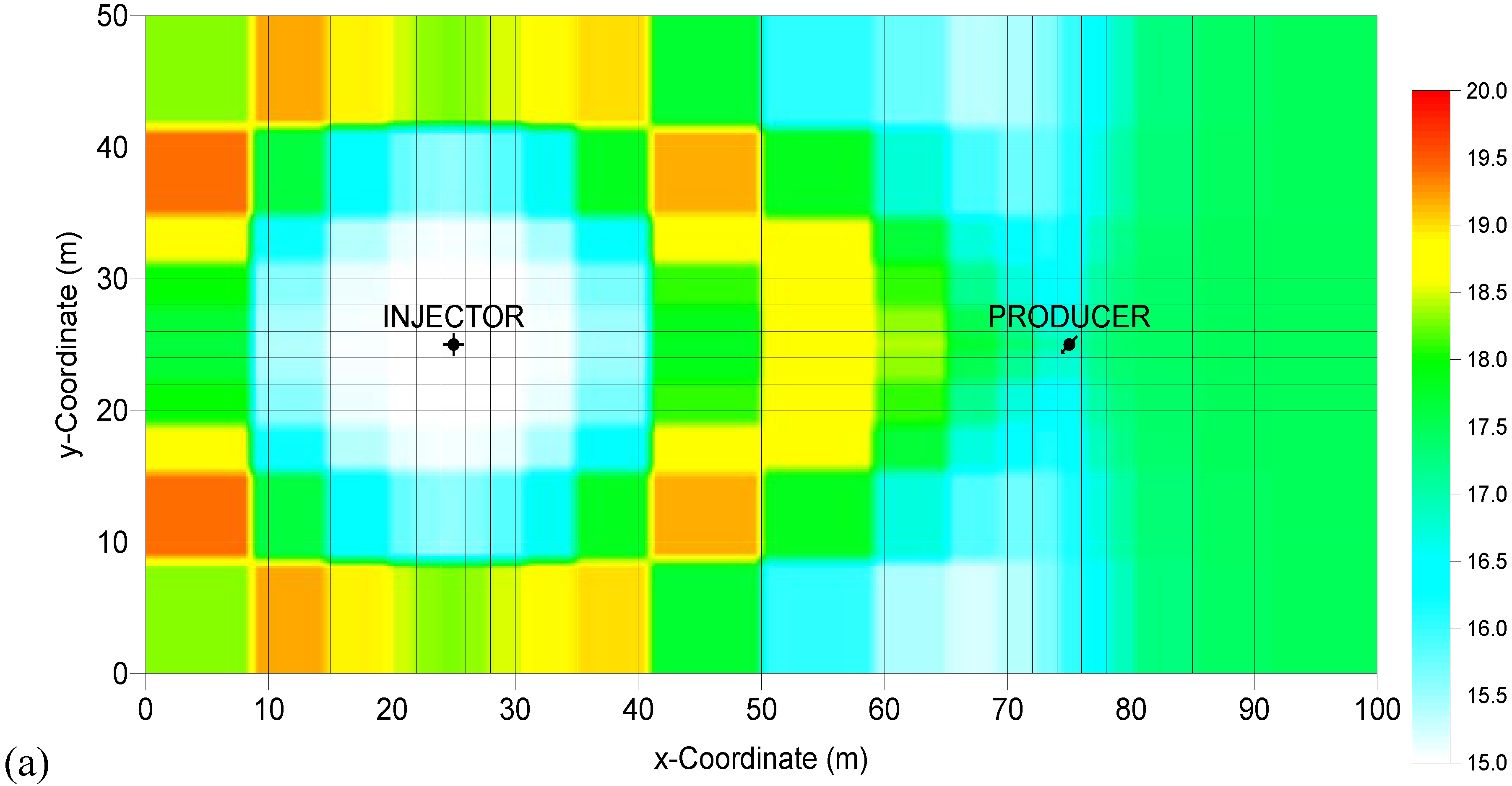

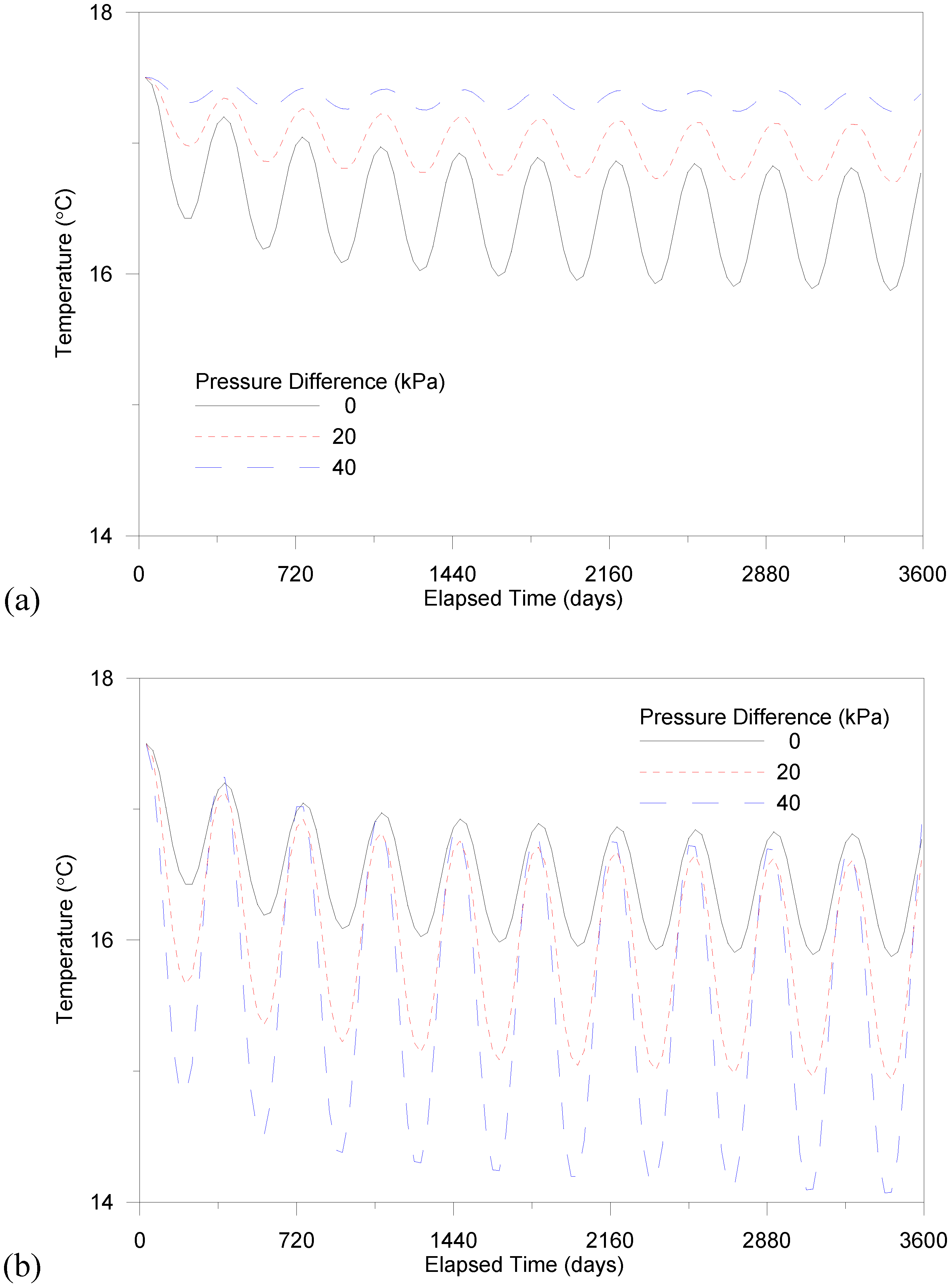

4.3. Simulation Example

5. Conclusions

References

- Paksoy, H.O.; Gurbuz, Z.; Turgut, B.; Dikici, D.; Evliya, H. Aquifer thermal storage (ATES) for air-conditioning of supermarket in Turkey. Renew. Energy 2004, 29, 1991–1996. [Google Scholar] [CrossRef]

- Dincer, I.; Rosen, M.A. Energetic, exergetic, environmental and sustainability aspects of thermal energy storage systems. In Thermal Energy Storage for Sustainable Energy Consumption; Paksoy, H.O., Ed.; Springer: Dordrecht, The Netherlands, 2007; pp. 23–46. [Google Scholar]

- Nielsen, K. Thermal Energy Storage, A State-of-the-Art; NTNU: Trondheim, Norway, 2003. [Google Scholar]

- Novo, A.V.; Bayon, J.R.; Castro-Fresno, D.; Rodriguez-Hernandez, J. Review of seasonal heat storage in large basins: Water tanks and gravel-water pits. Appl. Energy 2010, 87, 390–397. [Google Scholar] [CrossRef]

- Sanner, B. Shallow geothermal energy. GHC Bullet. 2001, 22, 19–25. [Google Scholar]

- Rafferty, K. Ground water issues in geothermal heat pump systems. Groundwater 2003, 41, 408–410. [Google Scholar] [CrossRef]

- Probert, T.; Hellsröm, G.; Claesson, J. Thermohydraulic evaluation of two ATES projects in southern Sweden. In Proceedings of International Symposium on Aquifer Thermal Energy Storage, Tuscaloosa, AL, USA, 14–15 November 1994; pp. 73–81.

- Paksoy, H.O.; Andersson, O.; Abaci, H.; Evliya, H.; Turgut, B. Heating and cooling of a hospital using solar energy coupled with seasonal thermal energy storage in aquifer. Renew. Energy 2000, 19, 177–122. [Google Scholar] [CrossRef]

- Allen, D.M.; Ghomshei, M.M.; Sadler-Brown, T.L.; Dakin, A.; Holtz, D. The current status of geothermal exploration and development in Canada. In Proceedings of World Geothermal Congress 2000, Kyushu-Tohoku, Japan, 28 May–10 June 2000; pp. 55–58.

- Schmidt, T.; Mangold, D.; Muller-Steinhagen, H. Seasonal thermal energy storage in Germany. In Proceedings of ISES Solar World Congress 2003, Göteborg, Schweden, 14–19 June 2003; pp. 1–7.

- Courtois, N.; Grisey, A.; Grasselly, D.; Menjoz, A.; Noel, Y.; Petit, V.; Thiery, D. Application of aquifer thermal energy storage for heating and cooling of greenhouses in France: A pre-feasibility study. In Proceedings of European Geothermal Congress 2007, Unterhaching, Germany, 30 May–1 June 2007; pp. 1–8.

- Morofsky, E.L. ATES-energy efficiency, economics, and the environment. In Proceedings of International Symposium on Aquifer Thermal Energy Storage, Tuscaloosa, Alabama, USA, 14–15 November 1994; pp. 1–8.

- Gao, Q.; Li, M.; Yu, M.; Spitler, J.D.; Yan, Y.Y. Review of development from GSHP to UTES in China and other countries. Renew. Sustain. Energy Rev. 2009, 13, 1383–1394. [Google Scholar] [CrossRef]

- Hendriks, M.; Snijdersl, A.; Boid, N. Underground thermal energy storage for efficient heating and cooling of buildings. In I3CON Conference, Loughborough, UK, 14–16 May 2008.

- Andersson, O.; Hellström, G.; Nordell, B. Heating and cooling with UTES in Sweden—Current situation and potential market development. In Proceedings of the 9th International Conference on Thermal Energy Storage, Warsaw, Poland, 1–4 September 2003; pp. 359–366.

- Desmedt, J.; Hoes, H.; Van Bael, J. Status of underground thermal energy storage in Belgium. In 2006 Ecostock Conference, Pomona, NJ, USA, 31 May–2 June 2006.

- Paksoy, H. Underground Thermal Energy Storage—A Choice for Sustainable Future. World Energy Council Publications. Available online: htttp://www.worldenergy.org/wec-geis/publications (accessed on 9 June 2010).

- Andersson, O. Aquifer thermal energy storage. In Thermal Energy Storage for Sustainable Energy Consumption; Paksoy, H.O., Ed.; Springer: Dordrecht, The Netherlands, 2007; pp. 155–176. [Google Scholar]

- Claesson, J.; Hellström, G.; Probert, T. Simulation models for ATES. In Proceedings of International Symposium on Aquifer Thermal Energy Storage, Tuscaloosa, AL, USA, 14–15 November 1994; pp. 131–137.

- Breger, D.B.; Hubbell, J.E.; Hasnaoui, H.E.; Sunderland, J.E. Thermal energy storage in the ground: Comparative analysis of heat transfer modeling using U-tubes and boreholes. Solar Energy 1996, 56, 493–503. [Google Scholar] [CrossRef]

- O’Sullivan, M.J.; Pruess, K.; Lippmann, M.J. State of the art of geothermal reservoir simulation. Geothermics 2001, 30, 395–429. [Google Scholar] [CrossRef]

- Molson, J.W.; Frind, E.O.; Palmer, C.D. Thermal energy storage in an unconfined aquifer. 2. Model development, validation, and application. Water Resour. Res. 1992, 28, 2857–2867. [Google Scholar] [CrossRef]

- Rosen, M.A. Second-law analysis of aquifer thermal energy storage systems. Energy 1999, 24, 167–182. [Google Scholar] [CrossRef]

- Chavalier, S.; Banton, B. Modelling of heat transfer with the random walk method. Part 1. Application to thermal storage in porous aquifers. J. Hydr. 1999, 222, 129–139. [Google Scholar] [CrossRef]

- Tenma, N.; Yasukawa, K.; Zyvoloski, G. Model study of thermal storage system by FEHM code. Geothermics 2003, 32, 603–607. [Google Scholar] [CrossRef]

- Lee, K.S.; Jeong, S.J. Numerical modeling on the performance of aquifer thermal energy storage system under cyclic flow regime. Int. J. Green Energy 2008, 5, 1–14. [Google Scholar] [CrossRef]

- Nagano, K.; Mochida, T.; Ochifuji, K. Influence of natural convection on forced horizontal flow in saturated porous media for aquifer thermal energy storage. Appl. Thermal Eng. 2002, 22, 1299–1311. [Google Scholar] [CrossRef]

- Fan, R.; Jiang, Y.; Yao, Y.; Shiming, D.; Ma, Z. A study on the performance of geothermal heat exchanger under coupled heat conduction and groundwater advection. Energy 2007, 32, 2199–2209. [Google Scholar] [CrossRef]

- Deng, Z. Modeling of Standing Column Wells in Ground Source Heat Pump Systems. Ph.D. dissertation, Oklahoma State University, Stillwater, OK, USA, 2004. [Google Scholar]

- Schmidt, T.; Hellström, G. Ground Source Cooling—Working Paper on Usable Tools and Methods; COWI A/S: Kongens Lyngby, Denmark, 2005. [Google Scholar]

- Chiasson, A. Advances in Modeling of Ground-Source Heat Pump Systems. Master’s thesis, Oklahoma State University, Stillwater, OK, USA, 1999. [Google Scholar]

- Center for Petroleum and Geosystems Engineering. UTCHEM-9.0 A Three-Dimensional Chemical Flood Simulator; Uiversity of Texas at Austin: Austin, TX, USA, 2000. [Google Scholar]

© 2010 by the authors; licensee MDPI, Basel, Switzerland. This article is an Open Access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/3.0/).

Share and Cite

Lee, K.S. A Review on Concepts, Applications, and Models of Aquifer Thermal Energy Storage Systems. Energies 2010, 3, 1320-1334. https://doi.org/10.3390/en3061320

Lee KS. A Review on Concepts, Applications, and Models of Aquifer Thermal Energy Storage Systems. Energies. 2010; 3(6):1320-1334. https://doi.org/10.3390/en3061320

Chicago/Turabian StyleLee, Kun Sang. 2010. "A Review on Concepts, Applications, and Models of Aquifer Thermal Energy Storage Systems" Energies 3, no. 6: 1320-1334. https://doi.org/10.3390/en3061320