Energy Utilization and Environmental Aspects of Rice Processing Industries in Bangladesh

Abstract

:1. Introduction

2. Results and Discussion

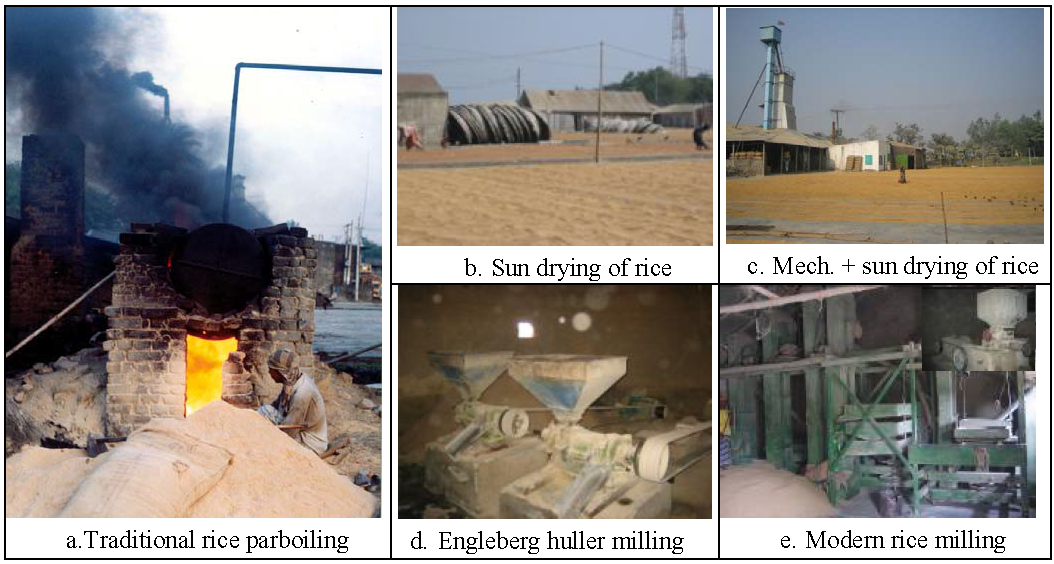

2.1. Energy Consumption in Different Operations of Rice Processing

| Activity level | Rice husk energy (kg/tonne) | Solar (MJ/tonne) | Electricity (kWh/tonne) |

|---|---|---|---|

| Parboiling | 120 (1,680 MJ/tonne) | - | - |

| Sun Drying | - | 556* | - |

| Sun + Mechanical drying | 70** (980 MJ/tonne) | 340* | 8.7 (31.32 MJe/tonne) |

| Mechanical drying | 110** (1,540 MJ/tonne) | - | 17.4 (62.64 MJe/tonne) |

| Steel huller milling (Engleberg) | - | - | 19.0 (68.40 MJe/tonne) |

| Modern milling | - | - | 29.26 (105.33 MJe/tonne) |

| Activity | Average load (kW)* | No. of rice mills** | Total peak load (MW) |

|---|---|---|---|

| Steel Huller Mill (Engleberg) | 30.4 | 25,000 | 760.0 |

| Modern rubber roll mill | 150.6 | 500 | 75.3 |

| Total peak load | 835.3 |

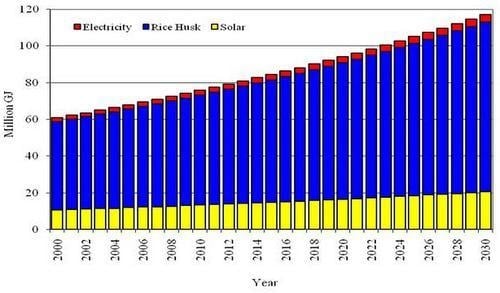

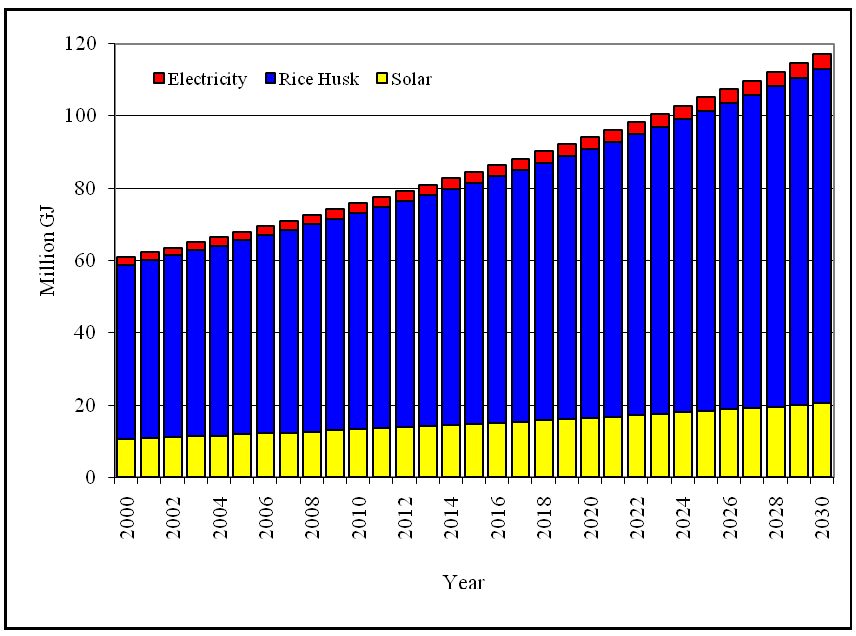

| Unit operation \\ Year | 2000 | 2010 | 2030 |

| Parboiling operation | |||

| Rice Husk (Million GJ) | 40.5 | 50.3 | 77.8 |

| Drying operation | |||

| Rice Husk (Million GJ) | 7.7 | 9.5 | 14.7 |

| Electricity (Million GJ) | 0.3 | 0.4 | 0.6 |

| Solar (Million GJ) | 10.7 | 13.3 | 20.5 |

| Milling operation | |||

| Electricity (Million GJ) | 1.83 | 2.27 | 3.51 |

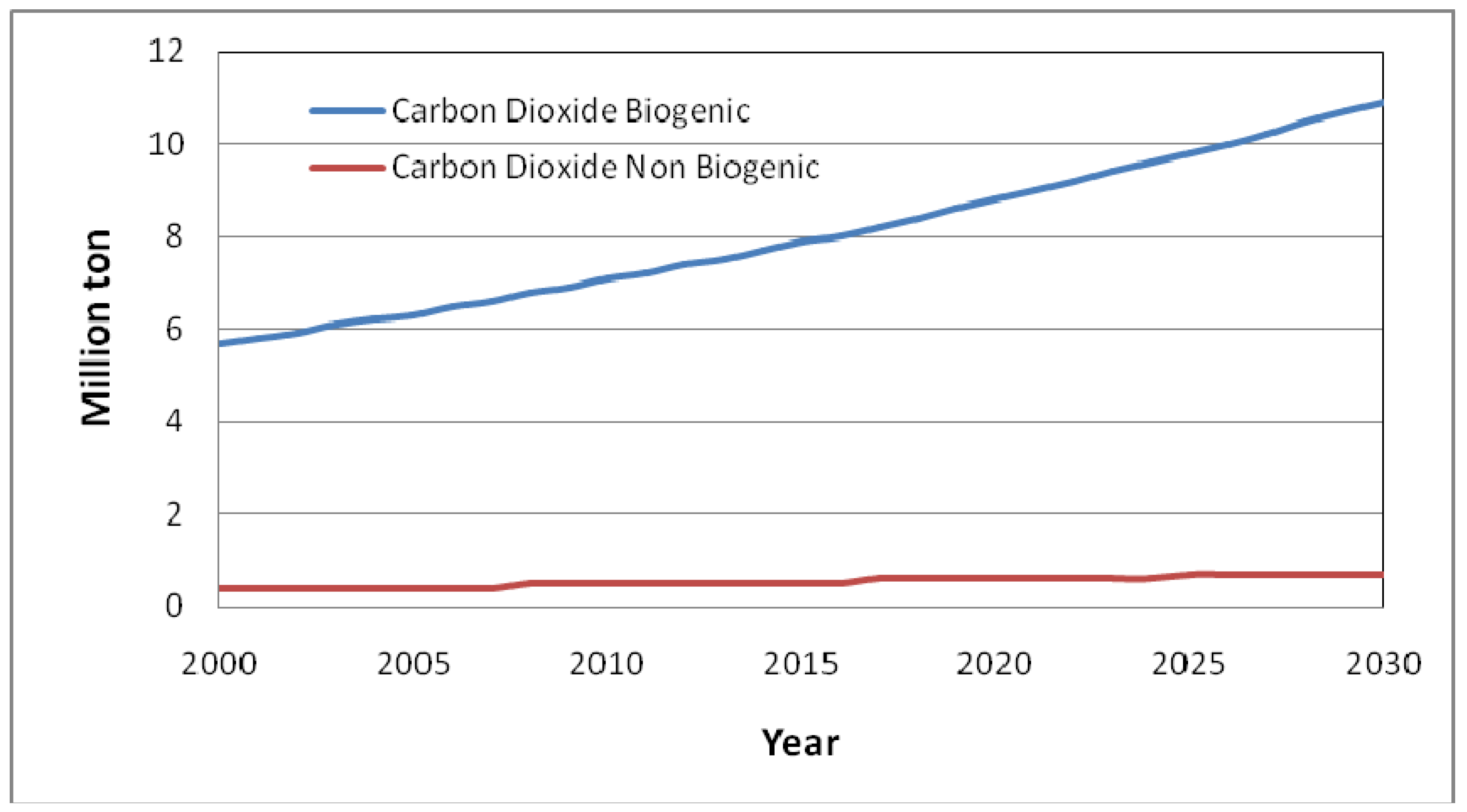

2.2. Global Warming Potential

3. Materials and Methods

- Eparboil = energy required for parboiling of paddy, kJ/tonne

- Whusk = weight of husk required for parboiling, kg

- Wpaddy = weight of paddy parboiled, tonne

- Chusk = calorific value of rice husk, kJ/kg

- Ww = water removed from paddy, kg

- Mw = moisture content in paddy, decimal

- Wd = weight of dry mass of paddy, kg

- Esun_drying = energy required for sun drying, kJ

- Ww = water removed from paddy, kg

- L = latent heat of evaporation of water, kJ/kg

- Eheat_drying = heat energy required for mechanical drying of paddy, kJ/tonne

- Whusk = weight of husk required for mechanical drying, kg

- Wpaddy = weight of paddy dried, tonne

- Chusk = calorific value of rice husk, kJ/kg

- Eelec_drying = energy required for mechanical drying, kWh/tonne

- EkWh = electricity consumed during mechanical drying operation, kWh

- Wpaddy = weight of paddy dried, tone

- Emilling = energy required for milling, kWh/tonne

- EkWh = electricity consumed during milling operation, kWh

- Wpaddy = weight of paddy milled, tonne

- Edemand = energy demand, GJ

- A = activity level, tonne paddy processed

- EI = energy intensity for the activity, GJ/tonne

- LoadingCO2 = carbon dioxide emission, kg

- Ccontent = carbon content in specified fuel, kg

- FO = fraction oxidized

- CO2, C = constant

- Econsumption = energy consumption

- Ef = emission factor

4. Conclusions

References

- Ninno, C.D.; Dorosh, P.A.; Smith, L.C. Public policy, markets and household coping strategies in Bangladesh: Avoiding a food security crisis following the 1998 flood. 2003. Available online: http://ideas.repec.org/a/eee/wdevel/v31y2003i7p1221-1238.html.

- FAOSTAT. World rice production data base. 2005, pp. 1–6. Available online: http://www.irri.org/science/ricestat/pdfs/WRS2005-Table01.pdf.

- BBS. Statistical pocket book of Bangladesh, Bangladesh Bureau of statistics; Planning division, ministry of planning, government of the People’s Republic of Bangladesh: Dhaka, 2006.

- Dasgupta, N. Socio-economic aspects of small-scale rice milling. Benefits from improved rice husk combustion efficiency, DFID project: R7659; Natural Resources Institute, The University of Greenwich: Greenwich, UK, 2001. [Google Scholar]

- Quaak, M.; Knoef, H.; Stassen, H. Energy from biomass: a review of combustion and gasification technology (World Bank Technical Report); Work Bank Pubilications: Washington DC., USA, 1999; No. 422; p. 5. [Google Scholar]

- Long-range Energy Alternatives Planning System (LEAP); Stockholm Environment Institute: Boston, MA, USA, 2008. Available online: http://www.sei.se, http://www.sei-us.org/.

- Roy, P.; Shimizu, N.; Shiina, T.; Kimura, T. Energy consumption and cost analysis of local parboiling processes. J. Food Eng. 2006, 76, 646–655. [Google Scholar] [CrossRef]

- Amarjit, S.; Bakshi, R.; Paul, S. Kinetics of water wiffusion and starch gelatinization during rice parboiling. J. Food Sci. 2006, 45, 1387–1392. [Google Scholar]

- Bakker-Arkema, F.W.; Fontana, C.; Kalchik, S.J.; Westelaken, C.M. Drying in commercial rice parboiling plants. CAB Abs. 1983/1984, 2, 423–433. [Google Scholar]

- Araullo, E.V.; de Padua, D.B.; Graham, M. RICE postharvest technology; IDRC-053e; International Development Research Centre: Ottawa, Canada, 1985; pp. 198–200. [Google Scholar]

- Ahiduzzaman, M. Rice husk energy technologies in Bangladesh. Agric. Eng. Int. CIGR E-J. 2007, 9, 4. [Google Scholar]

- Roy, P.; Shimizu, N.; Shiina, T.; Kimura, T. Life-cycle inventory analysis of local parboiling processes. 2008. Available online: http://www.irri.org/publications/wrrc/wrrcPDF/session10-08.pdf (accessed on 30.11.08).

- Kapur, T.; Kandpal, T.C.; Garg, H.P. Rice processing in india: a generalized framework for energy demand estimation. Int. J. Energy Res. 1997, 21, 309–325. [Google Scholar] [CrossRef]

- Register of list of rice mill owners; Directorate General of Food, Ministry of Food and Disaster Management, Govt. of Bangladesh: Dhaka, 2005.

- Padua, A.B.; Juliano, B.O. Effect of parboiling on thiamnin, protein and fat of rice. J. Sci. Food Agric. 1974, 25, 697–701. [Google Scholar] [CrossRef] [PubMed]

- FAO. Rice in human nutrition. FAO Food and Nutrition Series 26, 1993. Available online: http://www.fao.org/docrep/t0567e/T0567E0h.htm (accessed on 30/11/2008).

- Grewal, P.; Sangha, J.K. Effect of processing on thiamin and riboflavin contents of some highyielding rice varieties of Punjab. J. Sci. Food Agric. 1990, 52, 387–391. [Google Scholar] [CrossRef]

- Kik, M.C.; Williams, R.R. The nutritional improvement of white rice. In Nat. Acad. Sci. Bull; National Research Council: Washington, D.C, 1945; volume 112. [Google Scholar]

- FAOSTAT. Food and agriculture organization of the United Nations, FAO statistical database; Rome: Italy, 2001; Available online: http://apps.fao.org/.

- Ahiduzzaman, M. Survey of major rice mill clusters of Rajshahi division: a survey report submitted to GTZ; German Technical Cooperation: Dhaka, Bangladesh, May 2008. [Google Scholar]

- Sareepuang, K.; Siriamornpun, S.; Wiset, L.; Meeso, N. Effect of soaking temperature on physical, chemical and cooking properties of parboiled fragrant rice. World J. Agric Sci. 2008, 4(4), 409–415. Available online: http://www.idosi.org/wjas/wjas4(4)/1.pdf. [Google Scholar]

- Kar, N.; Jain, R.K.; Srivastav, P.P. Parboiling of dehusked rice. J. Food Eng. 1999, 39, 17–22. [Google Scholar] [CrossRef]

- Fakhrul Islam, S.M.; Bangabandhu Sheikh Mujibur Rahman Agricultural University: Gazipur, Bangladesh. Personal communication, 30 June 2008.

- Srzednicki, G.; Driscoll, R.H. Implementation of a two-stage drying system for grain in Asia; Food Science and Technology Group, School of Chemical Sciences and Engineering, The University of New South Wales: Sydney, Australia; International Union of Food Science and Technology: Oakville, Ontario, Toronto, Canada, 2008; Chapter 7; p. 5, (E-mail: [email protected].). [Google Scholar]

- Meeso, N.; Soponronnarit, S.; Wetchacama, S. Evaluation of drying system performance in rice mills, quality assurance in agricultural produce. In ACIAR Proceedings 100; Australia, 2000; pp. 286–291. [Google Scholar]

- A global report: reducing disaster risk: a challenge for development; UNDP: New York, USA. Available online: http://www.undp.org/bcpr.

- National adaptation programme of action; Ministry of Environment and Forests: Dhaka, Bangladesh, 2005.

- Consolidated damage and loss assessment, lesson learnt from the flood 2007 and future action plan; Disaster Management Bureau: Dhaka, Bangladesh, 2007.

- Bangladesh climate change strategy and action plan 2008; Ministry of Environment and Forests: Dhaka, Bangladesh, Sept. 2008.

- Bangladesh: Rice is life. Available online: http://www.worldbank.org/html/cgiar/newsletter/june97/9bang.html (accessed on 16.02.2006).

- Bangladesh census results at a glance. Available online: http://www.bbs.gov.bd/dataindex/census/bang_atg.pdf (accessed on 01.03.2009).

- The World Factbook. Available online: https://www.cia.gov/library/publications/the-world-factbook/print/bg.html (accessed on 01.03.2009).

© 2009 by the authors; licensee Molecular Diversity Preservation International, Basel, Switzerland. This article is an open-access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/3.0/).

Share and Cite

Ahiduzzaman, M.; Sadrul Islam, A.K.M. Energy Utilization and Environmental Aspects of Rice Processing Industries in Bangladesh. Energies 2009, 2, 134-149. https://doi.org/10.3390/en20100134

Ahiduzzaman M, Sadrul Islam AKM. Energy Utilization and Environmental Aspects of Rice Processing Industries in Bangladesh. Energies. 2009; 2(1):134-149. https://doi.org/10.3390/en20100134

Chicago/Turabian StyleAhiduzzaman, Mohammed, and Abul K. M. Sadrul Islam. 2009. "Energy Utilization and Environmental Aspects of Rice Processing Industries in Bangladesh" Energies 2, no. 1: 134-149. https://doi.org/10.3390/en20100134