Overview of the M-Cycle Technology for Air Conditioning and Cooling Applications

Abstract

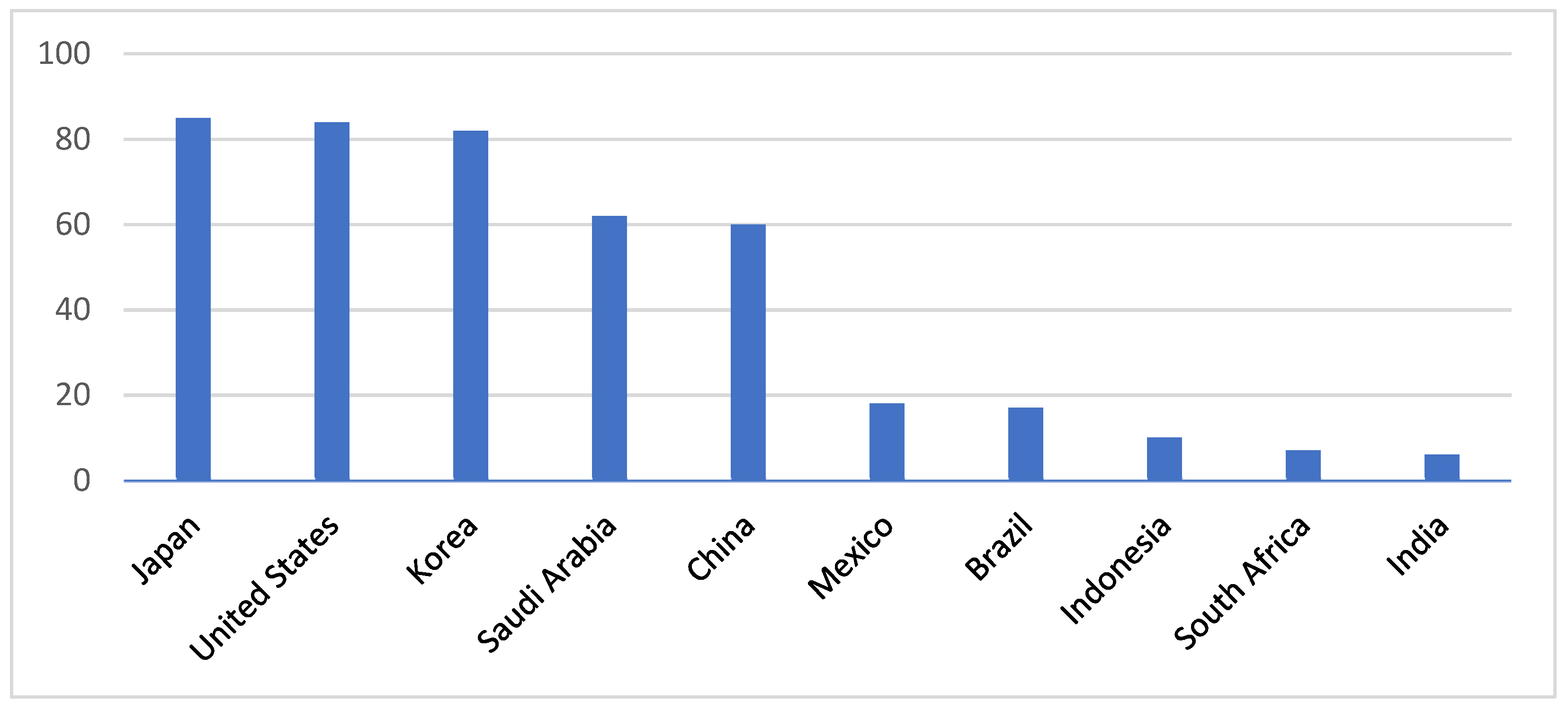

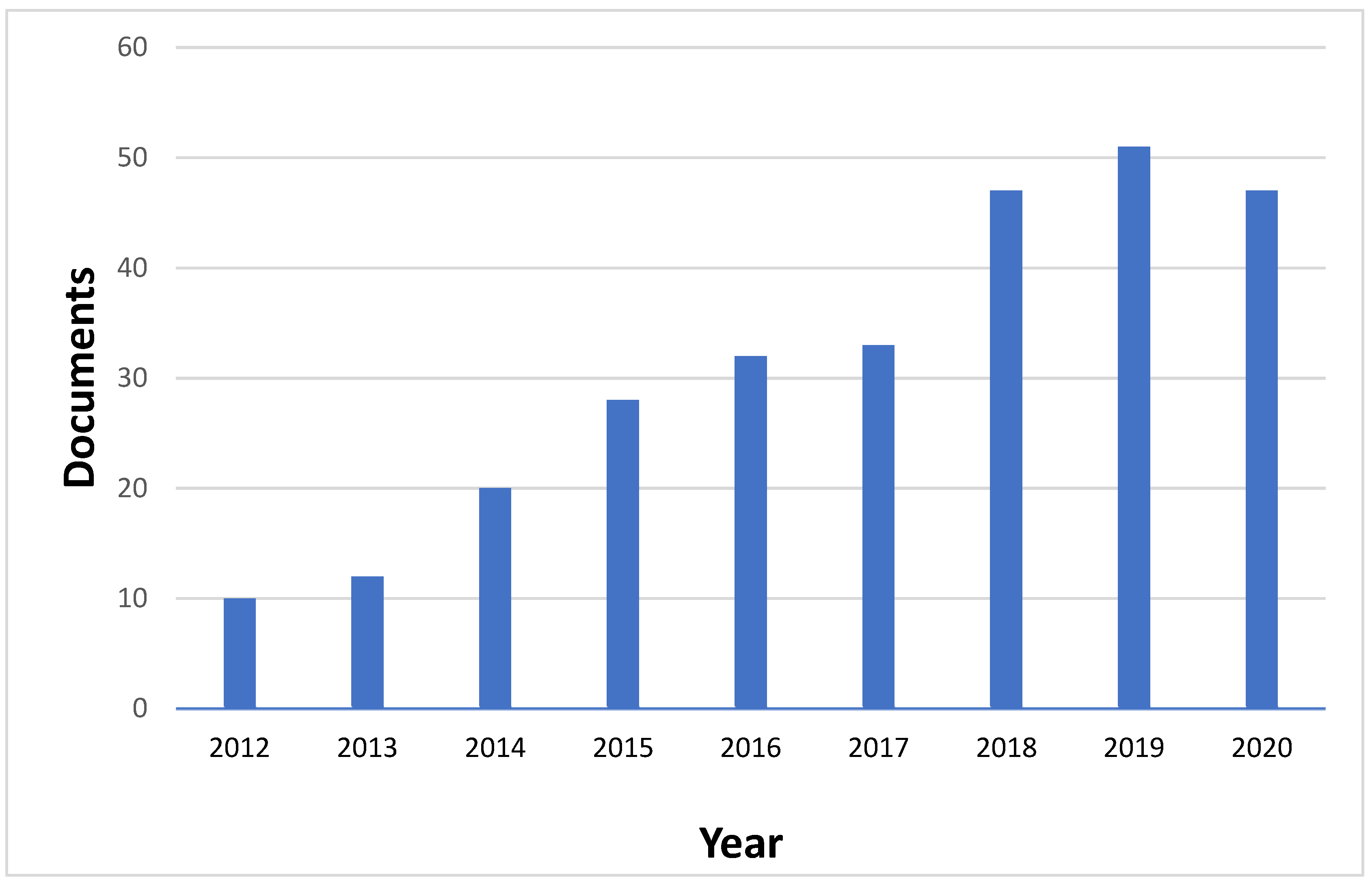

:1. Introduction

- Direct evaporative coolers (DEC).

- Indirect evaporative coolers (IEC).

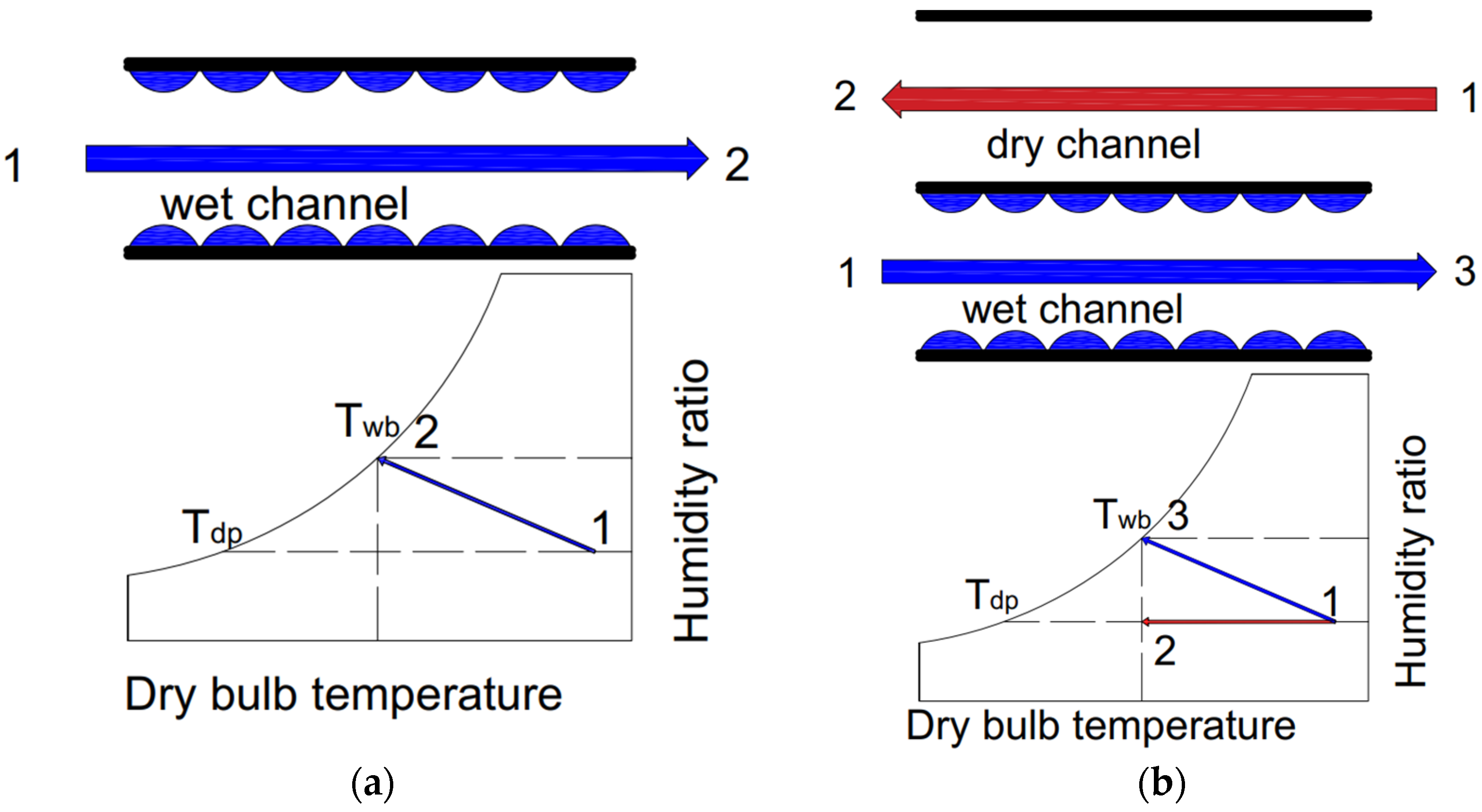

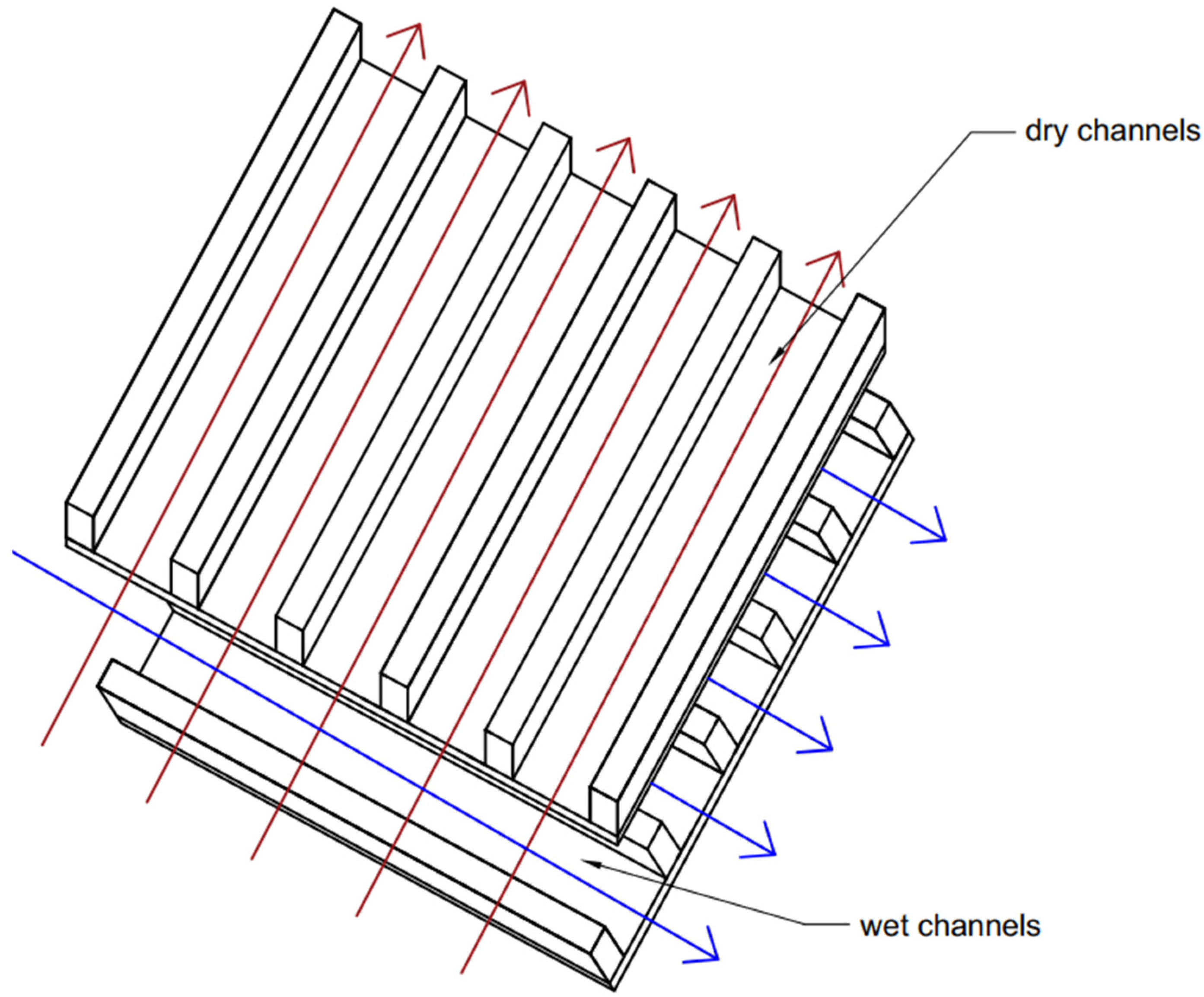

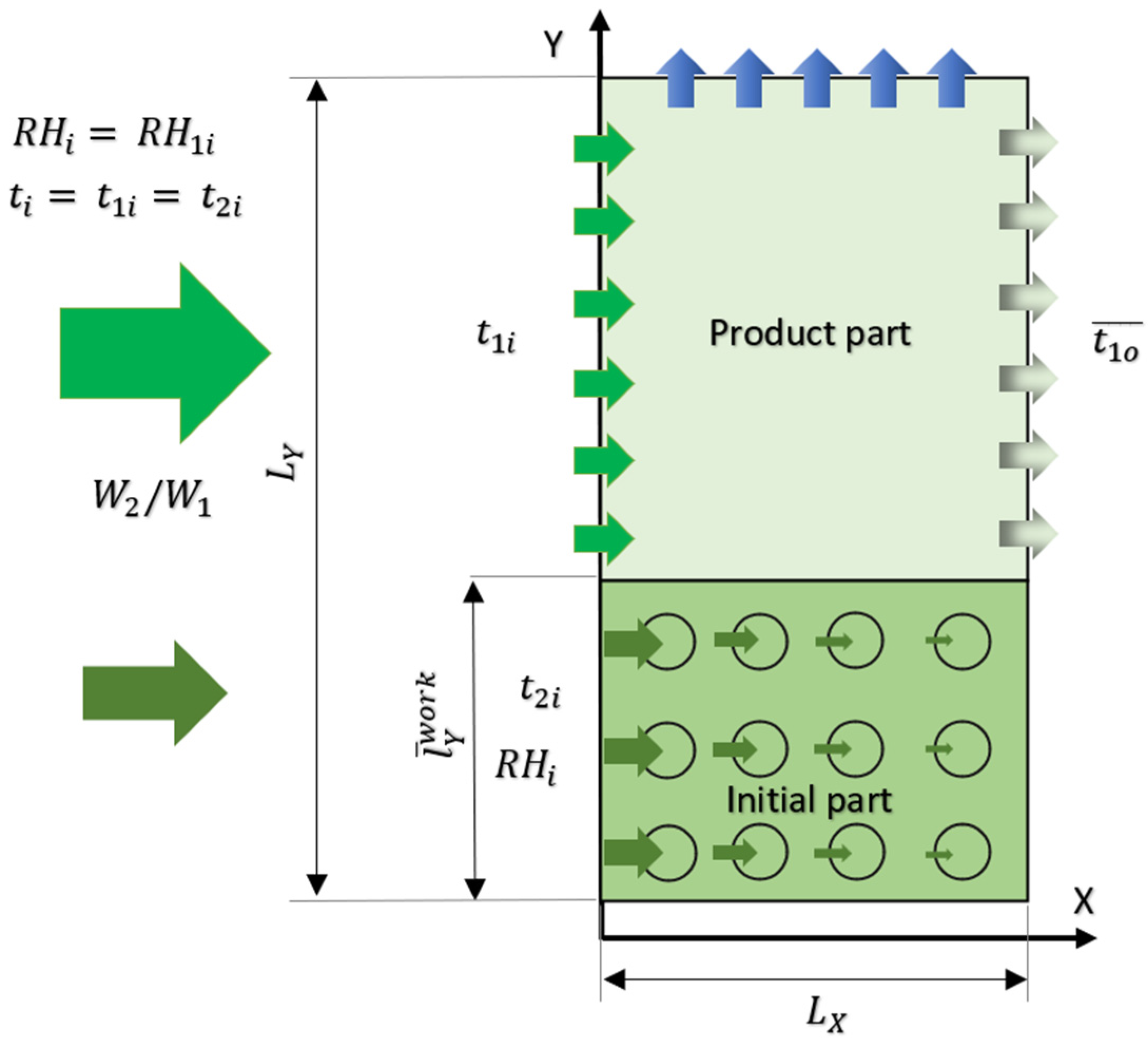

2. M-Cycle Principle of Operation

- Dew-point thermal effectiveness—the ratio of the difference between the primary flow inlet and outlet temperatures to the difference between the primary flow inlet and outlet dew-point temperatures [25]:

- Theoretical coefficient of performance (COP)—calculated as the ratio between cooling capacity and the fan energy consumption [26]:

3. M-Cycle HVAC Systems

- Arab Gulf cities (numerical studies of the dew-point indirect evaporative cooler (DPIEC)) [35].

- Riyad, South Arabia (numerical studies of the DPIEC [36].

- Martos, Spain (experimental studies of the solar desiccant cooling system) [37].

- Beijing, China (numerical studies of a DPIEC with a heat and mass exchanger) [38].

- North Italy (numerical and partial experimental studies of the DPIEC) [39].

- Bushehr, Iran (numerical studies of the solar desiccant cooling system) [40].

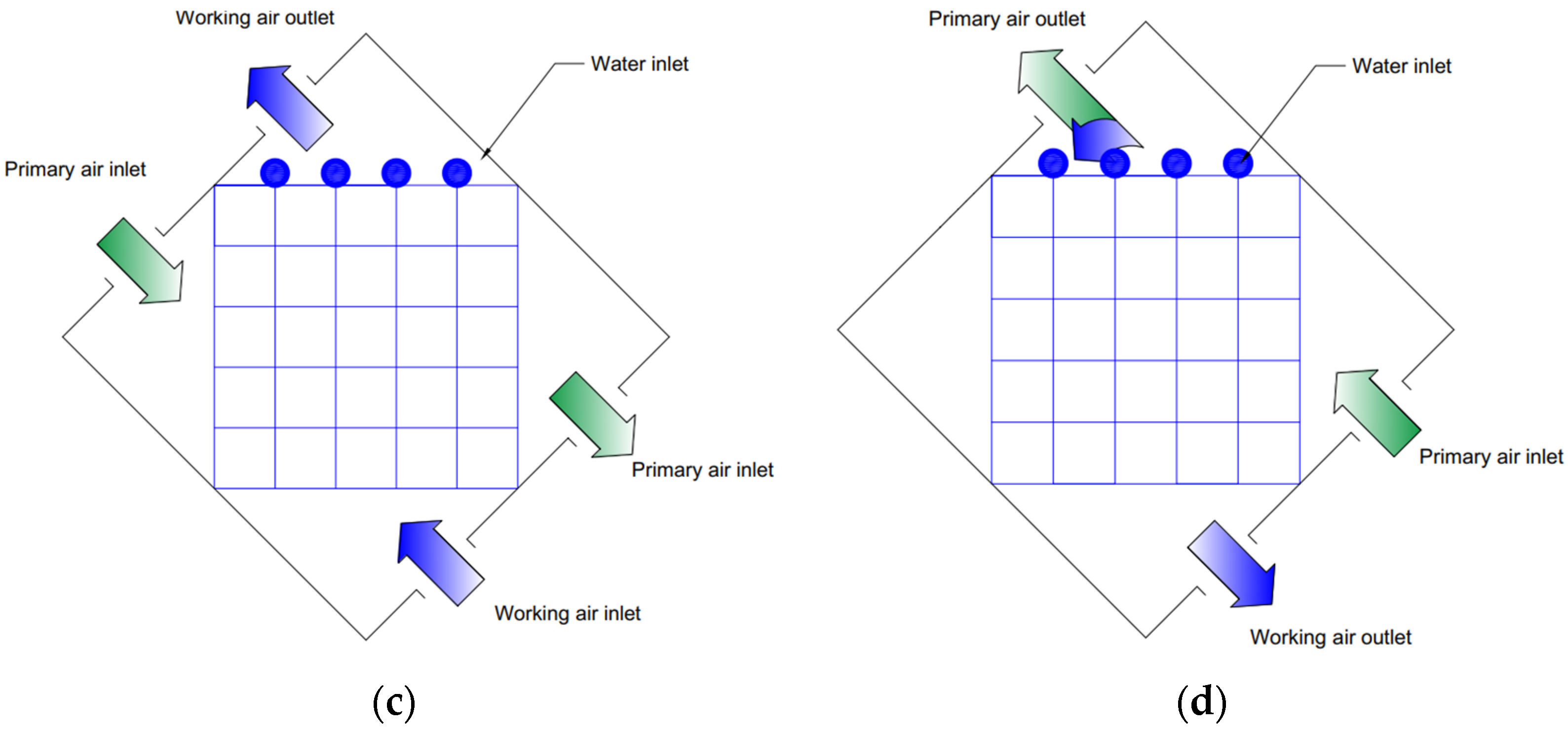

3.1. Maisotsenko Air Conditioning (MAC)

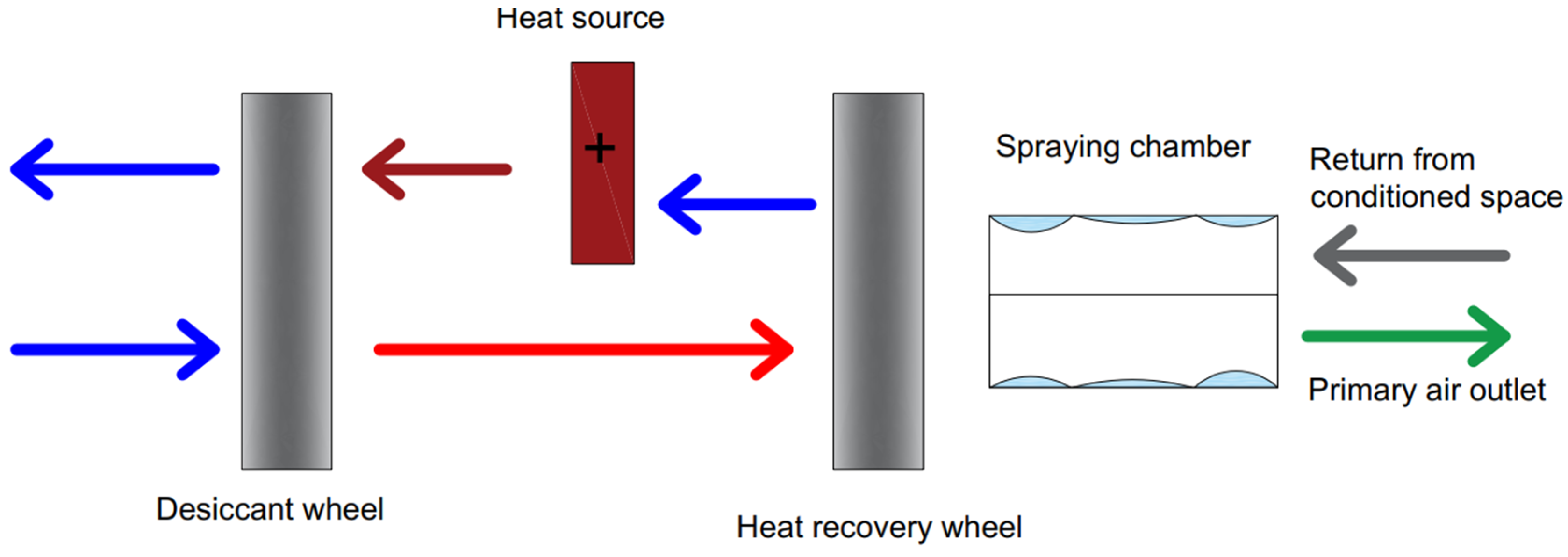

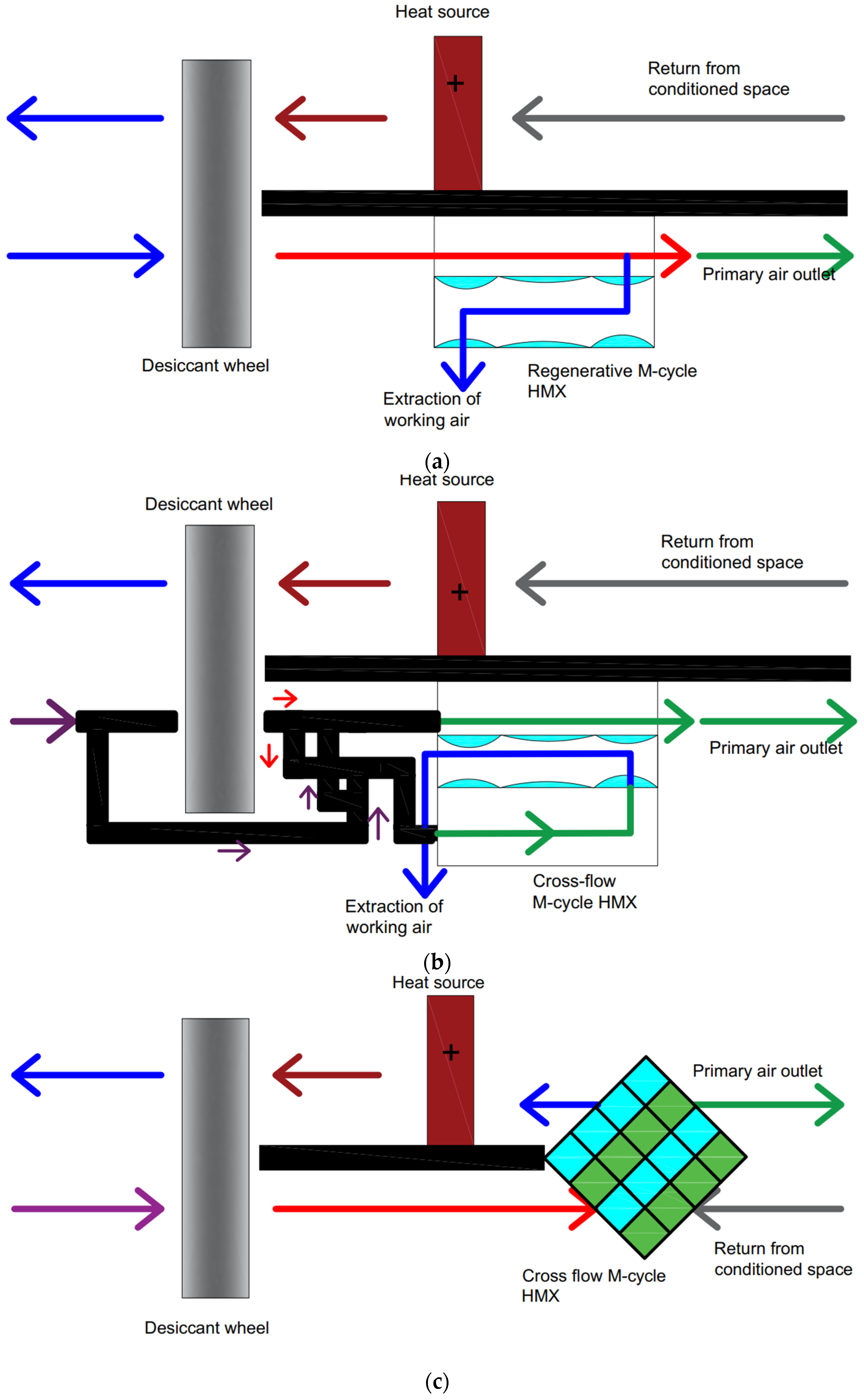

3.2. Desiccant M-Cycle Air Conditioning (D-MAC)

3.3. Hybrid M-Cycle Air Conditioning (H-MAC)

4. M-Cycle Cooling

4.1. M-Cooling Tower (MCT)

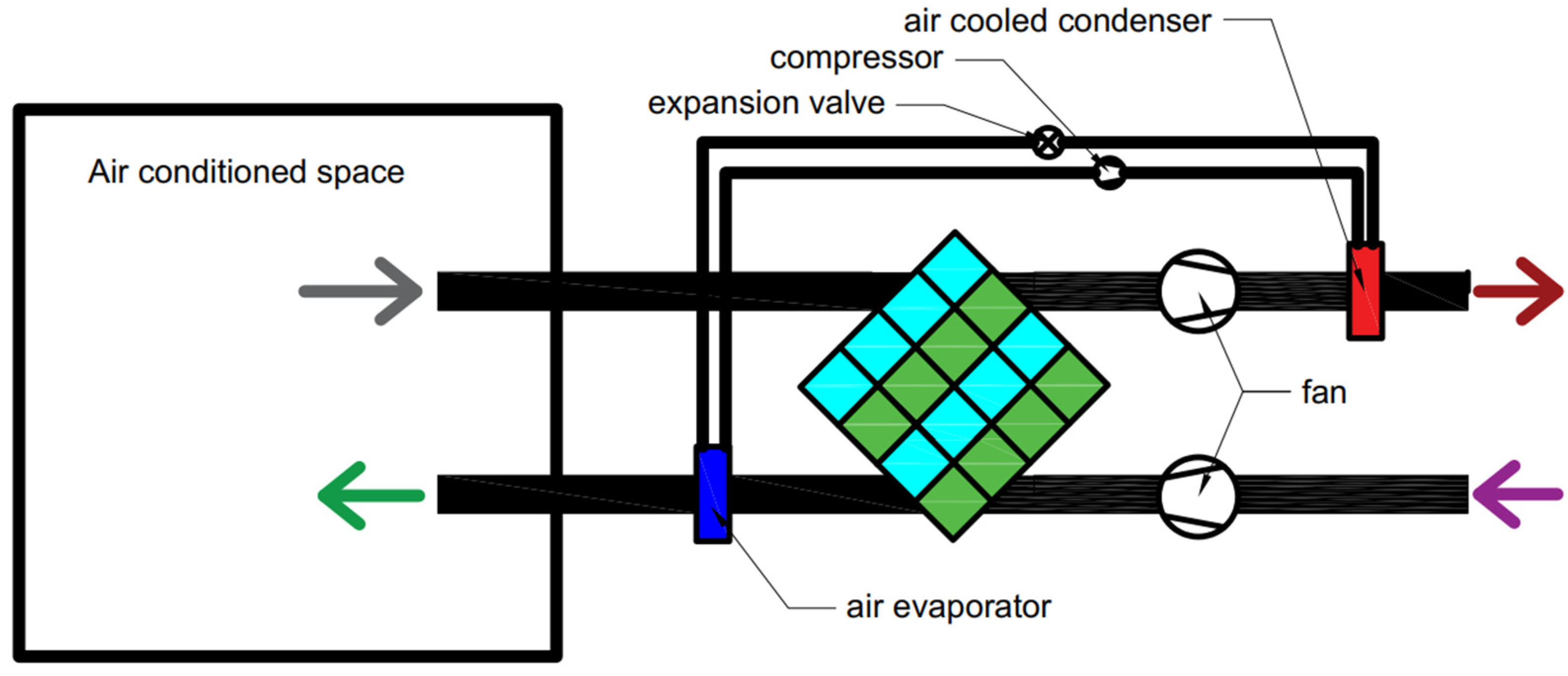

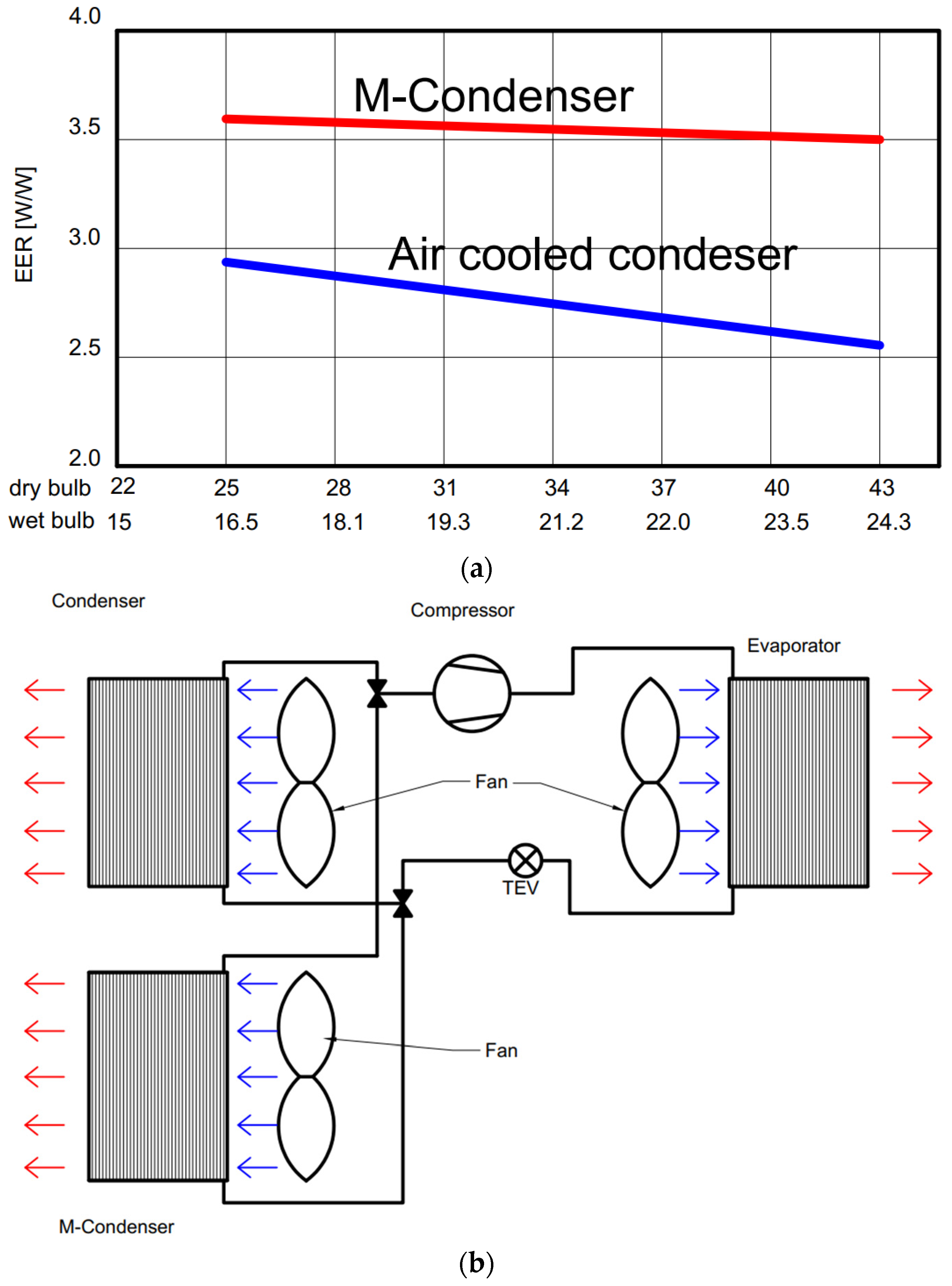

4.2. M-Condenser

5. Discussion

6. Challenges and Drawbacks

- Improvement of water and air distribution inside channels.

- Developing of new materials dedicated for IEC for greater heat and mass transfer, less pressures drops and better applicability.

- Looking for novel solutions and connect with IEC to increase efficiency of systems. For example, applying novel bare tube plastic heat exchanger (BTHX) to D-MAC. The asymmetry tube geometry shows better heat transfer performance [70].

- Conducting further studies and research on increasing the thermal COP.

- Simplification of the system. The evaporative cooling systems are more complicated and occupy more space than conventional HVAC machines.

- Optimize construction costs, keeping the cooling efficiency at high level.

7. Conclusions

- The standalone MAC can provide thermal comfort for inhabitants when air humidity is not very high.

- For more humid regions, some modifications and design variations are discussed to achieve proper air-conditioning cooling load.

- D-MAC enables a significant energy saving in humid regions.

- Unlike standard cooling towers, the M-cooling tower has greater COP.

- The M-condenser could enhance dissipation of the heat load of the system compared to evaporative condensers.

- Application of the Maisotsenko cycle for power generation plants improves thermodynamic efficiency of the cycle with NOx reduction.

- Experimental studies on several M-cycle application, (HVAC, cooling, power plants, desalination, etc.) are still limited.

- The interest in M-cycle solutions should be stimulated in future to obtain new applications.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Nomenclature

| AC | Air conditioning |

| BTHX | Bare tube plastic heat exchanger |

| cp | Specific heat capacity (J/(kgK)) |

| CO2 | Carbon dioxide as refrigerant |

| COP | Coefficient of performance |

| DEC | Direct evaporative cooler |

| DPEC | Dew point evaporative cooler |

| DPIEC | Dew-point indirect evaporative cooler |

| D-MAC | Desiccant M-cycle air conditioning |

| EER | Energy efficient ratio |

| G | Mass flow of moist air (kg/s) |

| GWP | Global warming potential |

| h | Height (m) |

| HMX | Heat and mass exchanger |

| HVAC | Heating, ventilation and air conditioning |

| H-MAC | Hybrid M-cycle air conditioning |

| IEC | Indirect evaporative cooler |

| Lx | Cooler length stream-wise (m) |

| Ly | Channel width (m) |

| MAC | Maisotsenko air conditioning |

| MCT | M-cooling tower |

| M-HAT | Maisotsenko air turbine cycle |

| M-SAB | Maisotsenko sub-atmospheric Brayton cycle |

| M-ABC | Maisotsenko air bottoming cycle |

| N | theoretical fan power (W) |

| NDCT | Natural draft cooling tower |

| NH3 | Ammonia as refrigerant |

| ODP | Ozone depletion potential |

| Q | Cooling capacity (W) |

| R290 | Propane as refrigerant |

| R718 | Water as refrigerant |

| RH | Relative humidity (%) |

| T | Temperature (°C) |

| TEV | Thermo expansion valve |

| VHMX | HMX structure volume (m3) |

| W | Heat capacity rate of the fluid (W/K) |

| ∆p | Pressure drop (Pa) |

| Special characters | |

| δ | Thickness (m) |

| ε | Effectiveness (-) |

| Subscripts | |

| 1 | Inlet parameters of primary flow or secondary |

| 2 | Outlet of primary |

| 3 | Outlet of secondary |

| db | Dry-bulb temperature |

| dp | Dew-point temperature |

| wb | Wet-bulb temperature |

| IN | Inlet |

| OUT | Outlet |

| plt | Channel plate |

| product | Reference to product air stream |

| work | Reference to working air stream |

References

- Energy Market Agency S.A, Statistics Poland, Enterprises Department. Consumption of Fuels and Energy Carriers in 2019; Energy Market Agency: Warsaw, Poland, 2020.

- De Angelis, A.; Chinese, D.; Saro, O. Free-cooling potential in shopping mall buildings with plants equipped by dry-coolers boosted with evaporative pads. Int. J. Heat Technol. 2017, 35, 853–863. [Google Scholar] [CrossRef]

- Fan, Y.; Luo, L.; Souyri, B. Review of solar sorption refrigeration technologies: Development and applications. Renew. Sustain. Energy Rev. 2007, 11, 1758–1775. [Google Scholar] [CrossRef]

- IEA. The Future of Cooling. Available online: https://www.iea.org/reports/the-future-of-cooling (accessed on 19 April 2021).

- BITZER Kuehlmaschinenbau GmbH. Refrigerant Report 20; A-501-20 EN. Available online: https://www.bitzer.de/gb/en/ (accessed on 19 April 2021).

- Yanga, Z.; Feng, B.; Ma, H.; Zhang, L.; Duan, C.; Liu, B.; Zhang, Y.; Chen, S.; Yang, Z. Analysis of lower GWP and flammable alternative refrigerants. Int. J. Refrig. 2021, 126, 12–22. [Google Scholar] [CrossRef]

- Artusoa, P.; Marinetti, S.; Minetto, S.; Del Col, D.; Rossetti, A. Modelling the performance of a new cooling unit for refrigerated transport using carbon dioxide as the refrigerant. Int. J. Refrig. 2020, 115, 158–171. [Google Scholar] [CrossRef]

- Longo, G.; Mancin, S.; Righetti, G.; Zilio, C. Hydrocarbon refrigerants HC290 (Propane) and HC1270 (Propylene) low GWP long-term substitutes for HFC404A: A comparative analysis in vaporisation inside a small-diameter horizontal smooth tube. Appl. Therm. Eng. 2017, 124, 707–715. [Google Scholar] [CrossRef]

- Bruno, F. On-site experimental testing of a novel dew point evaporative cooler. Energy Build. 2011, 43, 3475–3483. [Google Scholar] [CrossRef]

- Saman, W. Developments in evaporative and desiccant cooling systems and their potential application in Australia. In Proceedings of the Fifth Australian Heat and Mass Transfer Conference, Brisbane, Australia, 6–9 December 1993. [Google Scholar]

- Mahmood, M.; Sultan, M.; Miyazaki, T.; Koyama, S.; Maisotsenko, V. Overview of the Maisotsenko cycle—A way towards dew point evaporative cooling. Renew. Sustain. Energy Rev. 2016, 66, 537–555. [Google Scholar] [CrossRef]

- Ashrae Climatic Design Conditions 2009/2013/2017. Available online: http://ashrae-meteo.info/v2.0/ (accessed on 19 April 2021).

- Meteonorm Database, Meteotest AG Fabrikstrasse 14, 3012 Bern, Schweiz. Available online: https://meteonorm.com/ (accessed on 19 April 2021).

- Free Online Interactive Psychrometric Chart Flycarpet. Available online: http://www.flycarpet.net/en/PsyOnline (accessed on 20 April 2021).

- Coolerado Corporation. Available online: http://www.coolerado.com/ (accessed on 19 April 2021).

- U.S. Department of Energy. Coolerado Cooler Helps to Save Cooling Energy and Dollars. 2007. Available online: https://www.nrel.gov/docs/fy07osti/40041.pdf (accessed on 1 January 2022).

- Pandelidis, D.; Cichoń, A.; Drąg, M.; Worek, W.; Cetin, S. Water desalination through the dewpoint evaporative system. Energy Convers. Manag. 2021, 229, 113757. [Google Scholar] [CrossRef]

- Buyadgie, D.; Buyadgie, O.; Drakhnia, O.; Brodetsky, P.; Maisotsenko, V. Solar low-pressure turbo-ejector Maisotsenko cycle-based power system for electricity, heating, cooling and distillation. Int. J. Low-Carbon Technol. 2015, 10, 157–164. [Google Scholar] [CrossRef] [Green Version]

- Jenkins, P.; Cerza, M.; Saaid, M. Analysis of using the M-cycle regenerative humidification process on a gas turbine. J. Energy Power Eng. 2014, 8, 1824–1837. [Google Scholar]

- Saghafifar, M.; Gadalla, M. Innovative inlet air cooling technology for gas turbine power plants using integrated solid desiccant and Maisotsenko cooler. Energy 2015, 87, 663–677. [Google Scholar] [CrossRef]

- Saghafifar, M.; Gadalla, M. Analysis of Maisotsenko open gas turbine power cycle with a detailed air saturator model. Appl. Energy 2015, 149, 338–353. [Google Scholar] [CrossRef]

- Rogdakis, E.; Tertipis, D. Maisotsenko cycle: Technology overview and energy-saving potential in cooling systems. Energy Emiss. Control. Technol. 2015, 3, 15–22. [Google Scholar]

- Anisimov, S.; Pandelidis, D.; Danielewicz, J. Numerical study and optimisation of the combined indirect evaporative air cooler for air-conditioning systems. Energy 2015, 80, 452–464. [Google Scholar] [CrossRef]

- Anisimov, S.; Pandelidis, D.; Jedlikowski, A.; Polushkin, V. Performance investigation of a M (Maisotsenko)-cycle cross-flow heat exchanger used for indirect evaporative cooling. Energy 2014, 76, 593–606. [Google Scholar] [CrossRef]

- Duan, Z.; Zhan, C.; Zhang, X.; Mustafa, M.; Zhao, X.; Alimohammadisagvand, B.; Hasan, A. Indirect evaporative cooling: Past, present and future potentials. Renew. Sustain. Energy Rev. 2012, 16, 6823–6850. [Google Scholar] [CrossRef]

- Pandelidis, D.; Anisimov, S. Application of a statistical design for analysing basic performance characteristics of the cross-flow Maisotsenko cycle heat exchanger. Int. J. Heat Mass Transf. 2016, 95, 45–61. [Google Scholar] [CrossRef]

- Pandelidis, D.; Anisimov, S. Numerical study and optimisation of the cross-flow Maisotsenko cycle indirect evaporative air cooler. Int. J. Heat Mass Transf. 2016, 103, 1029–1041. [Google Scholar] [CrossRef]

- Wakil Shahzad, M.; Burhan, M.; Ang, L.; Choon Ng, K. Energy-water-environment nexus underpinning future desalination sustainability. Desalination 2017, 413, 52–64. [Google Scholar] [CrossRef]

- Tariq, R.; Sheikh, N.A.; Xamán, J.; Bassam, A. An innovative air saturator for humidification-dehumidification desalination application. Appl. Energy 2018, 228, 789–807. [Google Scholar] [CrossRef]

- Köppen Pidwinry, M. Climate classification system. Encycl. Earth 2011, 11, 1633–1644. [Google Scholar]

- Gillan, L.; Maisotsenko, V. Maisotsenko Open Cycle Used for Gas Turbine Power Generation. In Proceedings of the ASME Turbo Expo 2003, Collocated with the 2003 International Joint Power Generation Conference, Atlanta, GA, USA, 16–19 June 2003; Volume 3, pp. 75–84. [Google Scholar]

- Zhu, G.; Chow, T.-T.; Chun, L. Performance analysis of biogas-fueled maisotsenko combustion turbine cycle. Appl. Therm. Eng. 2021, 195, 117247. [Google Scholar] [CrossRef]

- Carrier, W.H. Apparatus for Treating Air. U.S. Patent US,808,897A, 16 September 1904. [Google Scholar]

- Pacak, A.; Worek, W. Review of Dew Point Evaporative Cooling Technology for Air Conditioning Applications. Appl. Sci. 2021, 11, 934. [Google Scholar] [CrossRef]

- Baakeem, S.; Orfi, J.; Mohamad, A.; Bawazeer, S. The possibility of using a novel dew point air cooling system (M-Cycle) for A/C application in Arab Gulf Countries. Build. Environ. 2019, 148, 185–197. [Google Scholar] [CrossRef]

- Sohani, A.; Sayyaadi, H.; Mohammadhosseini, N. Comparative study of the conventional types of heat and mass exchangers to achieve the best design of dew point evaporative coolers at diverse climatic conditions. Energy Convers. Manag. 2018, 158, 327–345. [Google Scholar] [CrossRef]

- Comino, F.; González, J.C.; Navas-Martos, F.J.; De Adana, M.R. Experimental energy performance assessment of a solar desiccant cooling system in Southern Europe climates. Appl. Therm. Eng. 2020, 165, 114579. [Google Scholar] [CrossRef]

- Badiei, A.; Akhlaghi, Y.G.; Zhao, X.; Li, J.; Yi, F.; Wang, Z. Can whole building energy models outperform numerical models, when forecasting performance of indirect evaporative cooling systems? Energy Convers. Manag. 2020, 213, 112886. [Google Scholar] [CrossRef]

- Zanchini, E.; Naldi, C. Energy saving obtainable by applying a commercially available M-cycle evaporative cooling system to the air conditioning of an office building in North Italy. Energy 2019, 179, 975–988. [Google Scholar] [CrossRef]

- Delfani, S.; Karami, M. Transient simulation of solar desiccant/M-Cycle cooling systems in three different climatic conditions. J. Build. Eng. 2020, 29, 101–152. [Google Scholar] [CrossRef]

- Pandelidis, D.; Anisimov, S. Mathematical Modelling of the M-Cycle Heat and Mass Exchanger Used in Air Conditioning Systems. Ph.D. Thesis, Wrocław University of Science and Technology, Wrocław, Poland, 2016. [Google Scholar]

- Cuce, P.M.; Riffat, S. A state of the art review of evaporative cooling systems for building applications. Renew. Sustain. Energy Rev. 2016, 54, 1240–1249. [Google Scholar] [CrossRef]

- Khandelwal, A.; Talukdar, P.; Jain, S. Energy savings in a building using regenerative evaporative cooling. Energy Build. 2011, 43, 581–591. [Google Scholar] [CrossRef]

- Costelloe, B.; Finn, D. Indirect evaporative cooling potentiall in air-water systems in temperate climates. Energy Build. 2003, 35, 573–591. [Google Scholar] [CrossRef] [Green Version]

- Heidarinejad, G.; Bozorgmehr, M.; Delfani, S.; Esmaeelian, J. Experimental investigation of two-stage indirect/direct evaporative cooling system in various climatic conditions. Build. Environ. 2009, 44, 2073. [Google Scholar] [CrossRef]

- Lin, J.; Wang, R.Z.; Kumja, M.; Bui, T.D.; Chua, K.J. Modelling and experimental investigation of the cross-flow dew point evaporative cooler with and without dehumidification. Appl. Therm. Eng. 2017, 121, 1–13. [Google Scholar] [CrossRef]

- Ali, M.; Ahmad, W.; Sheikh, N.A.; Ali, H.; Kousar, R.; Rashid, T. Performance enhancement of a cross flow dew point indirect evaporative cooler with circular finned channel geometry. J. Build. Eng. 2021, 35, 101980. [Google Scholar] [CrossRef]

- Khalid, O.; Ali, M.; Sheikh, N.A.; Ali, H.M.; Shehryar, M. Experimental analysis of an improved Maisotsenko cycle design under low velocity conditions. Appl. Therm. Eng. 2016, 95, 288–295. [Google Scholar] [CrossRef]

- Pandelidis, D.; Anisimov, S.; Worek, W. Performance study of the Maisotsenko Cycle heat exchangers in different air-conditioning applications. Int. J. Heat Mass Transf. 2015, 81, 207–221. [Google Scholar] [CrossRef]

- Lin, J.; Wang, R.; Ja, M.K.; Bui, D.T.; Chua, K. Multivariate scaling and dimensional analysis of the counter-flow dew point evaporative cooler. Energy Convers. Manag. 2017, 150, 172–187. [Google Scholar] [CrossRef]

- Lin, J.; Bui, D.T.; Wang, R.; Chua, K.J. The counter-flow dew point evaporative cooler: Analyzing its transient and steady-state behaviour. Appl. Therm. Eng. 2018, 143, 34–47. [Google Scholar] [CrossRef]

- Pakari, A.; Ghani, S. Comparison of 1D and 3D heat and mass transfer models of a counter flow dew point evaporative cooling system: Numerical and experimental study. Int. J. Refrig. 2019, 99, 114–125. [Google Scholar] [CrossRef]

- Moshari, S.; Heidarinejad, G. Analytical estimation of pressure drop in indirect evaporative coolers for power reduction. Energy Build. 2017, 150, 149–162. [Google Scholar] [CrossRef]

- Wan, Y.; Lin, J.; Jon, K.; Ren, C. Similarity analysis and comparative study on the performance of counter-flow dew point evaporative coolers with experimental validation. Energy Convers. Manag. 2018, 169, 97–110. [Google Scholar] [CrossRef]

- Pandelidis, D.; Anisimov, S.; Worek, W.; Drag, P. Numerical analysis of a desiccant system with cross-flow Maisotsenko cycle heat and mass exchanger. Energy Build. 2016, 123, 136–150. [Google Scholar] [CrossRef]

- She, X.; Yin, Y.; Zhang, X. Suggested solution concentration for an energy-efficient refrigeration system combined with condensation heat-driven liquid desiccant cycle. Renew. Energy 2015, 83, 553–564. [Google Scholar] [CrossRef]

- Chen, C.; Hsu, C.; Chen, C.; Chen, S. Silica gel polymer composite desiccants for air conditioning systems. Energy Build. 2015, 101, 122–132. [Google Scholar] [CrossRef]

- Pandelidis, D.; Anisimov, S.; Worek, W.; Drag, P. Comparison of desiccant air conditioning systems with different indirect evaporative air coolers. Energy Convers. Manag. 2016, 117, 375–392. [Google Scholar] [CrossRef]

- Kozubal, E.; Slayzak, S. Coolerado 5 Ton RTU Performance: Western Cooling Challenge Results; NREL: Golden, CO, USA, 2010.

- Cui, X.; Chua, K.J.; Islam, M.R. Performance evaluation of an indirect pre-cooling evaporative heat exchanger operating in hot and humid climate. Energy Convers. Manag. 2015, 102, 140–150. [Google Scholar] [CrossRef]

- Pandelidis, D.; Drag, M.; Drag, P.; Worek, W.; Cetin, S. Comparative analysis between traditional and M-Cycle based cooling tower. Int. J. Heat Mass Transf. 2020, 159, 120–124. [Google Scholar] [CrossRef]

- Anisimov, A.; Kozlov, P.; Glanville, M.; Khinkis, V.; Maisotsenko, V.; Shi, J. Advanced cooling tower concept for commercial and industrial applications. In Proceedings of the ASME 2014 Power Conference, Baltimore, ML, USA, 28–31 July 2014. [Google Scholar]

- Karp, I.; Isakov, B. Prospects of the Maisotsenko thermodynamic cycle application in Ukraine. Int. J. Energy Clean Environ. 2011, 12, 141–157. [Google Scholar]

- Gillan, L.; Gillan, A.; Kozlov, A.; Kalensky, D. An advanced evaporative condenser through the Maisotsenko cycle. Int. J. Energy Clean Environ. 2011, 12, 251–258. [Google Scholar] [CrossRef]

- De Antonellis, S.; Cignatta, L.; Facchini, C.; Liberati, P. Effect of heat exchanger plates geometry on performance of an indirect evaporative cooling system. Appl. Therm. Eng. 2020, 173, 115200. [Google Scholar] [CrossRef]

- Xu, P.; Ma, X.; Zhao, X.; Fancey, K. Experimental investigation of a super performance dew point air cooler. Appl. Energy 2017, 203, 761–777. [Google Scholar] [CrossRef]

- Al-Zubaydi, A.Y.T.; Hong, G. Experimental study of a novel water-spraying configuration in indirect evaporative cooling. Appl. Therm. Eng. 2019, 151, 283–293. [Google Scholar] [CrossRef]

- Jafarian, H.; Sayyaadi, H.; Torabi, F. Modeling and optimisation of dew-point evaporative coolers based on a developed GMDH-type neural network. Energy Convers. Manag. 2017, 143, 49–65. [Google Scholar] [CrossRef]

- Golizadeh Akhlaghi, Y.; Aslansefat, K.; Zhao, X.; Sadati, S.; Badiei, A.; Xiao, X.; Shittu, S.; Fan, Y.; Ma, X. Hourly performance forecast of a dew point cooler using explainable Artificial Intelligence and evolutionary optimisations by 2050. Appl. Energy 2021, 281, 116062. [Google Scholar] [CrossRef]

- Amer, M.; Chen, M.R.; Sajjad, U.; Ali, H.M.; Abbas, N.; Lu, M.C.; Wang, C.C. Experiments for suitability of plastic heat exchangers for dehumidification applications. Appl. Therm. Eng. 2019, 158, 113827. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Taler, J.; Jagieła, B.; Jaremkiewicz, M. Overview of the M-Cycle Technology for Air Conditioning and Cooling Applications. Energies 2022, 15, 1814. https://doi.org/10.3390/en15051814

Taler J, Jagieła B, Jaremkiewicz M. Overview of the M-Cycle Technology for Air Conditioning and Cooling Applications. Energies. 2022; 15(5):1814. https://doi.org/10.3390/en15051814

Chicago/Turabian StyleTaler, Jan, Bartosz Jagieła, and Magdalena Jaremkiewicz. 2022. "Overview of the M-Cycle Technology for Air Conditioning and Cooling Applications" Energies 15, no. 5: 1814. https://doi.org/10.3390/en15051814