Adaptive Luminaire with Variable Luminous Intensity Distribution

Abstract

:1. Introduction

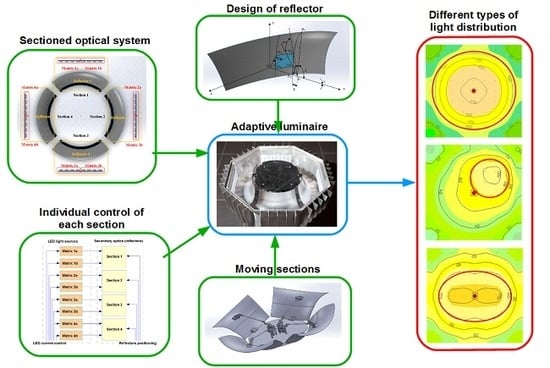

2. Luminaire Design Assumptions

- Adjustment of the luminous flux of light sources,

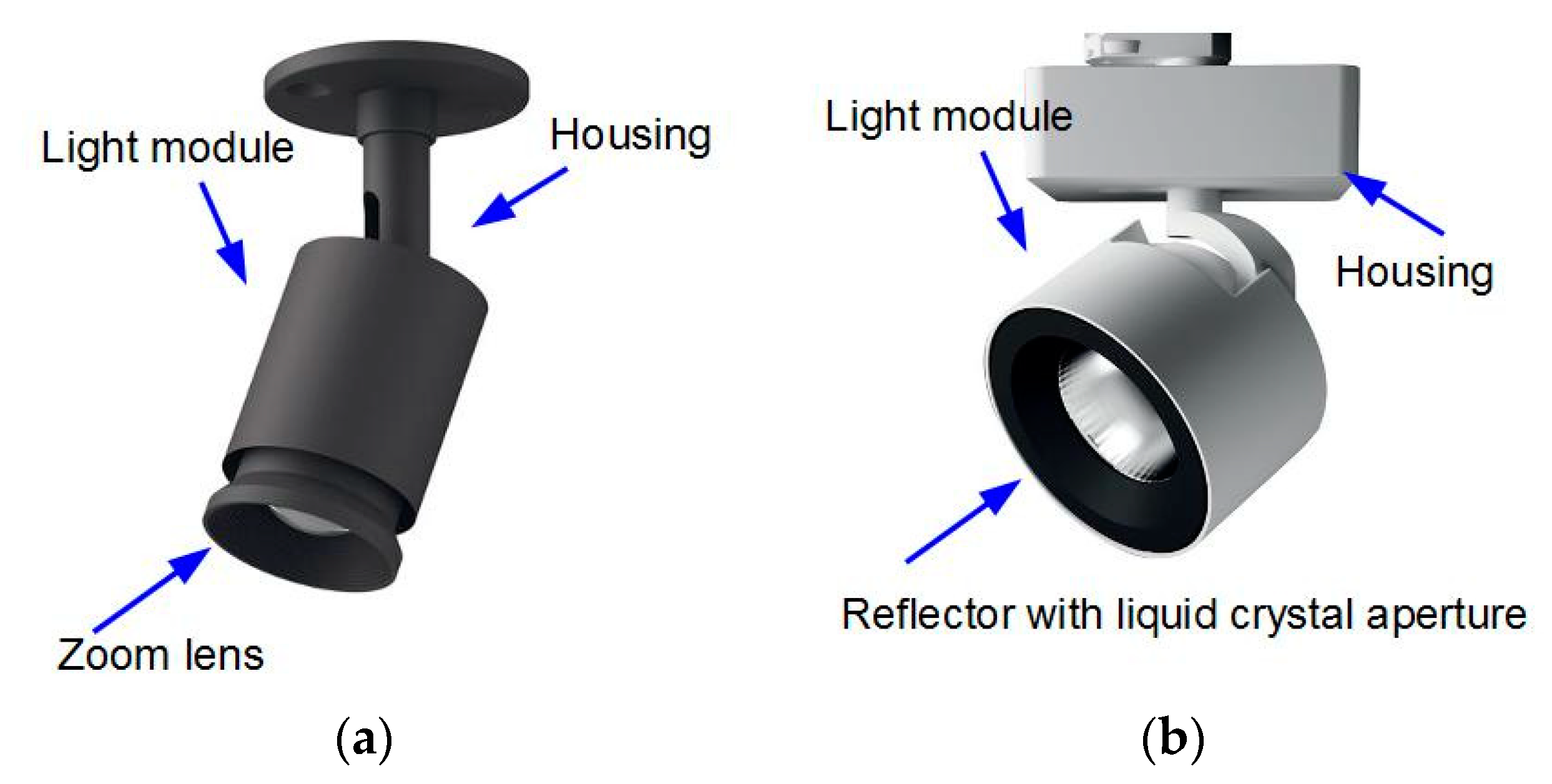

- Changing the luminous intensity distribution by positioning the elements of the optical system relative to the light source, without the necessity to replace them with elements with different geometry,

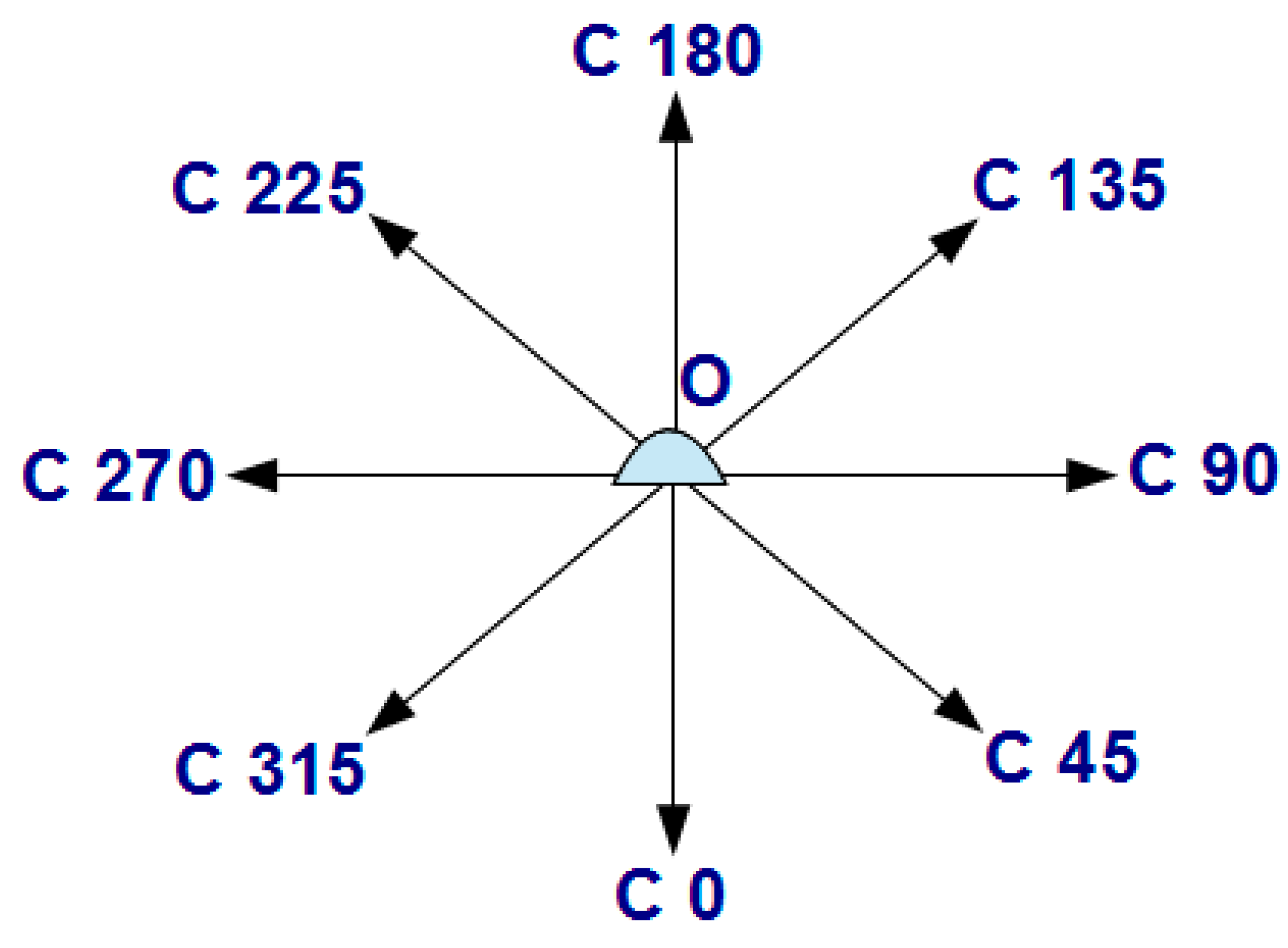

- Adjustment of luminous intensity distribution uniformly in all directions determined by the C half plane (Figure 4), with the rotational symmetry of the luminous intensity distribution maintained,

- Possibility of obtaining bi-axial luminous intensity distribution,

- Possibility of obtaining asymmetrical, diagonal distribution and directing it in one of eight main directions,

- The light-optical system consisting of independently controlled sections that enable the orientation of the light distribution in all directions,

- Ensuring adequate thermal conditions for the operation of LED sources in order to maintain high luminous efficacy.

3. Computer Modeling of the Light-Optical System of an Adaptive Luminaire

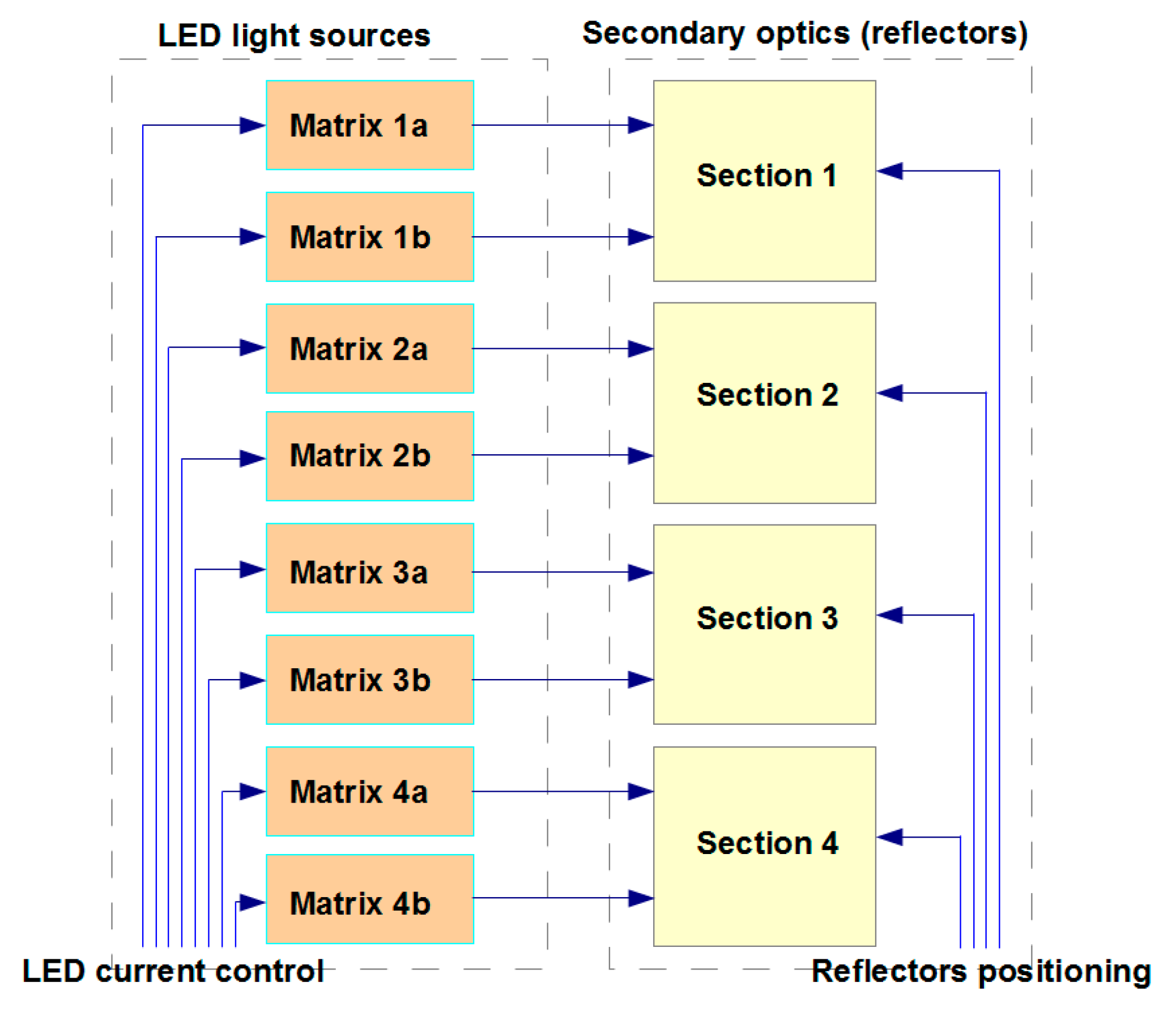

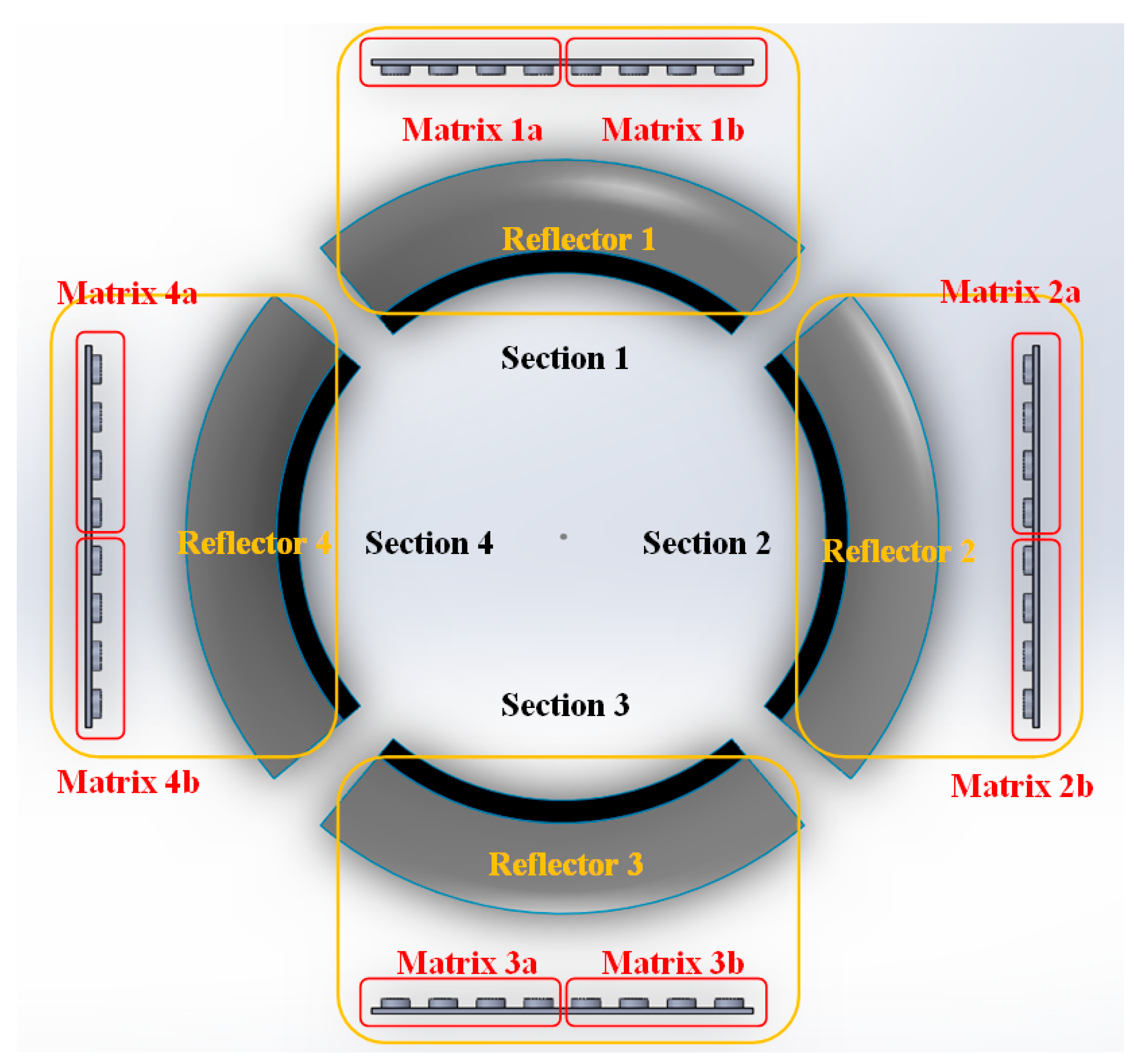

3.1. The Concept of the Optical System

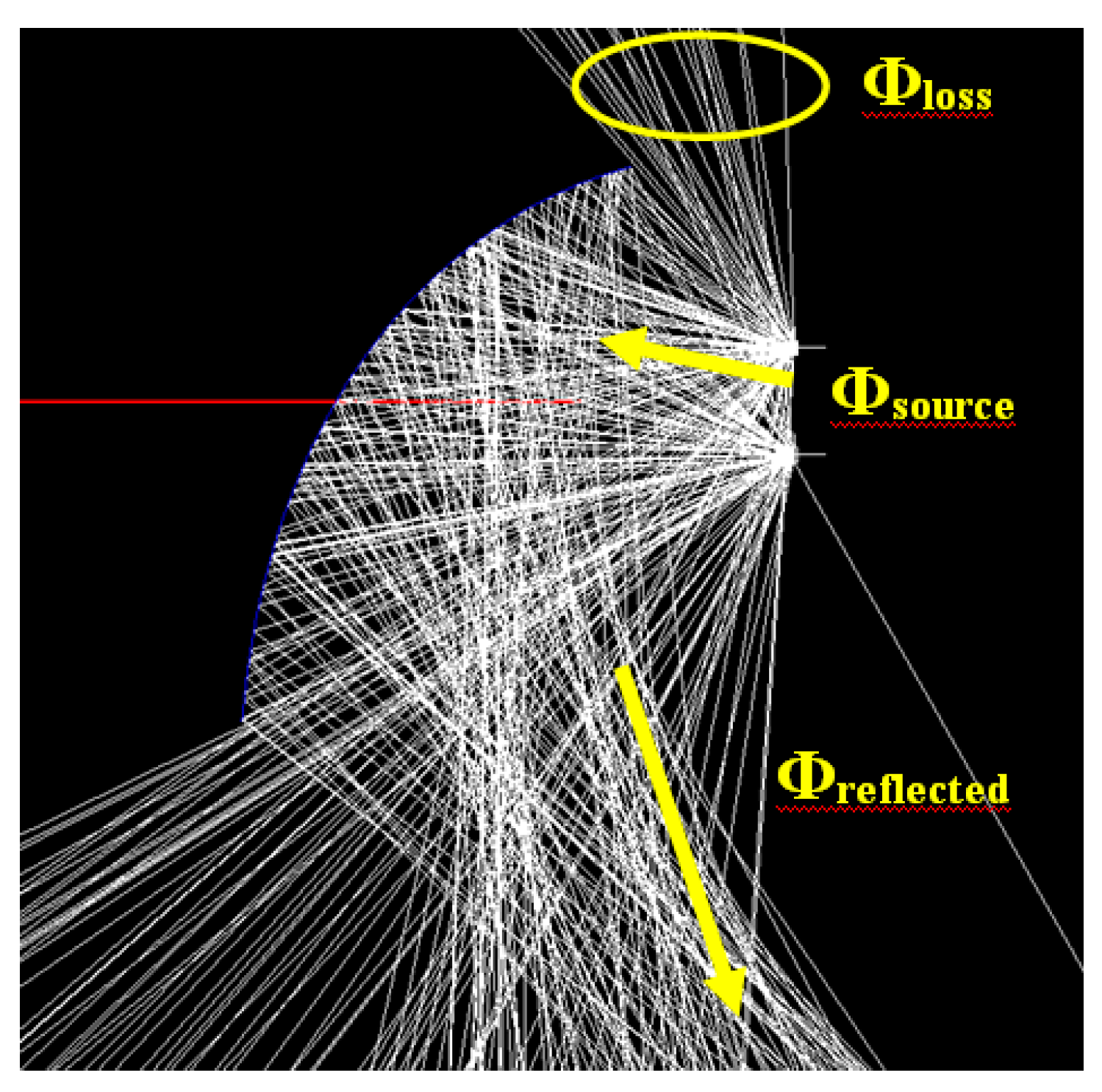

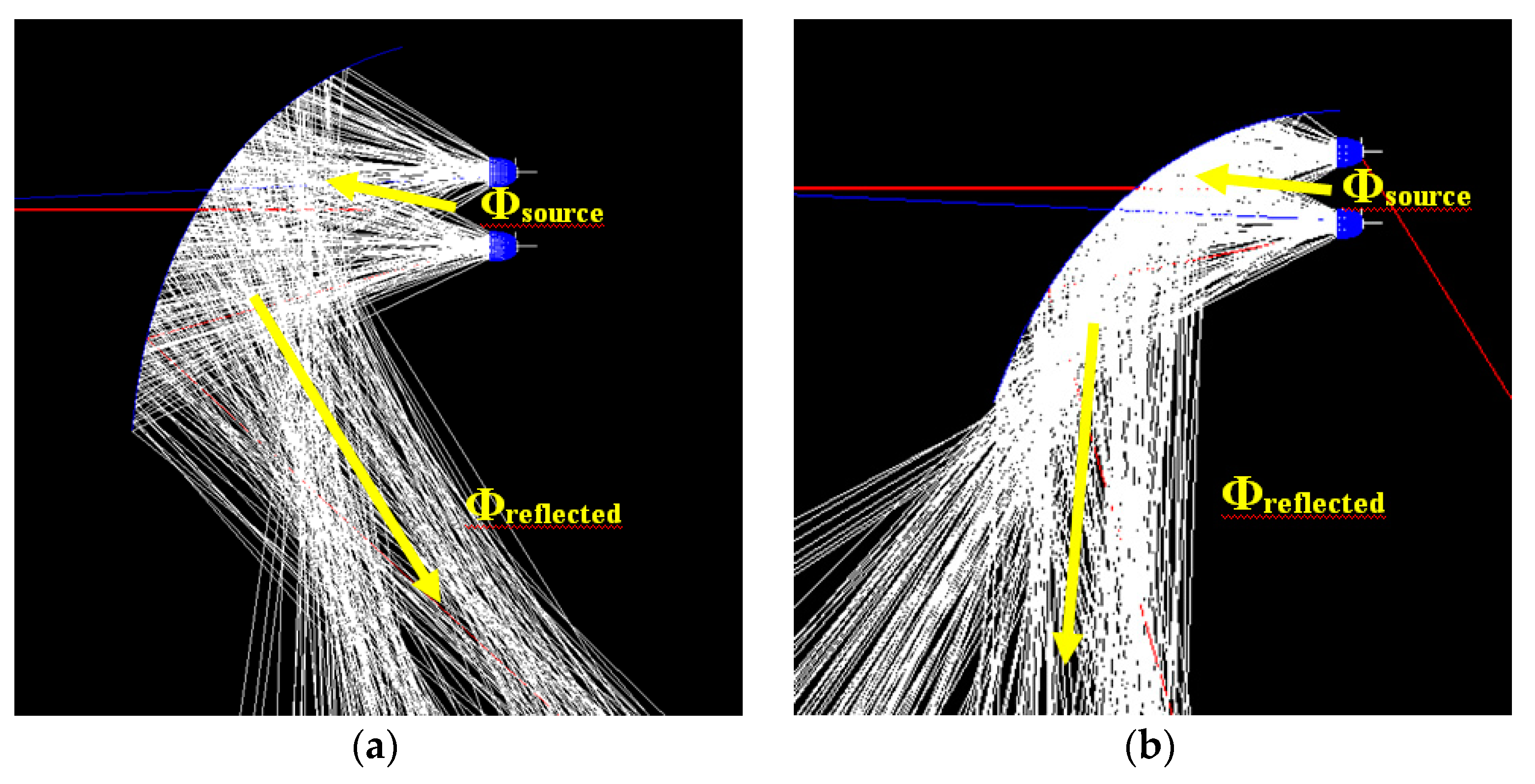

3.2. Modeling the Surface of Reflector

3.3. Analysis of Optically Active Reflector Surface

4. Testing the Performance of Optical System

4.1. Constructing a Luminaire Prototype

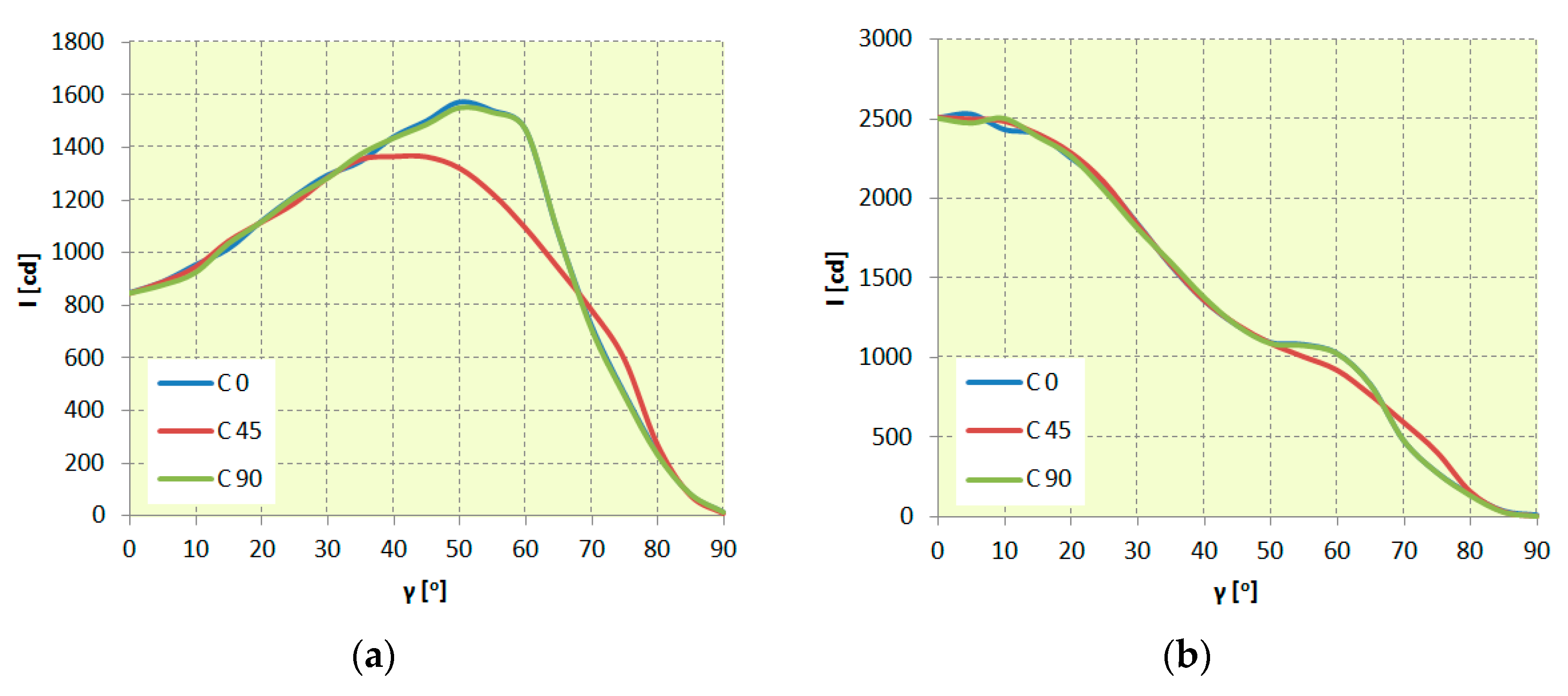

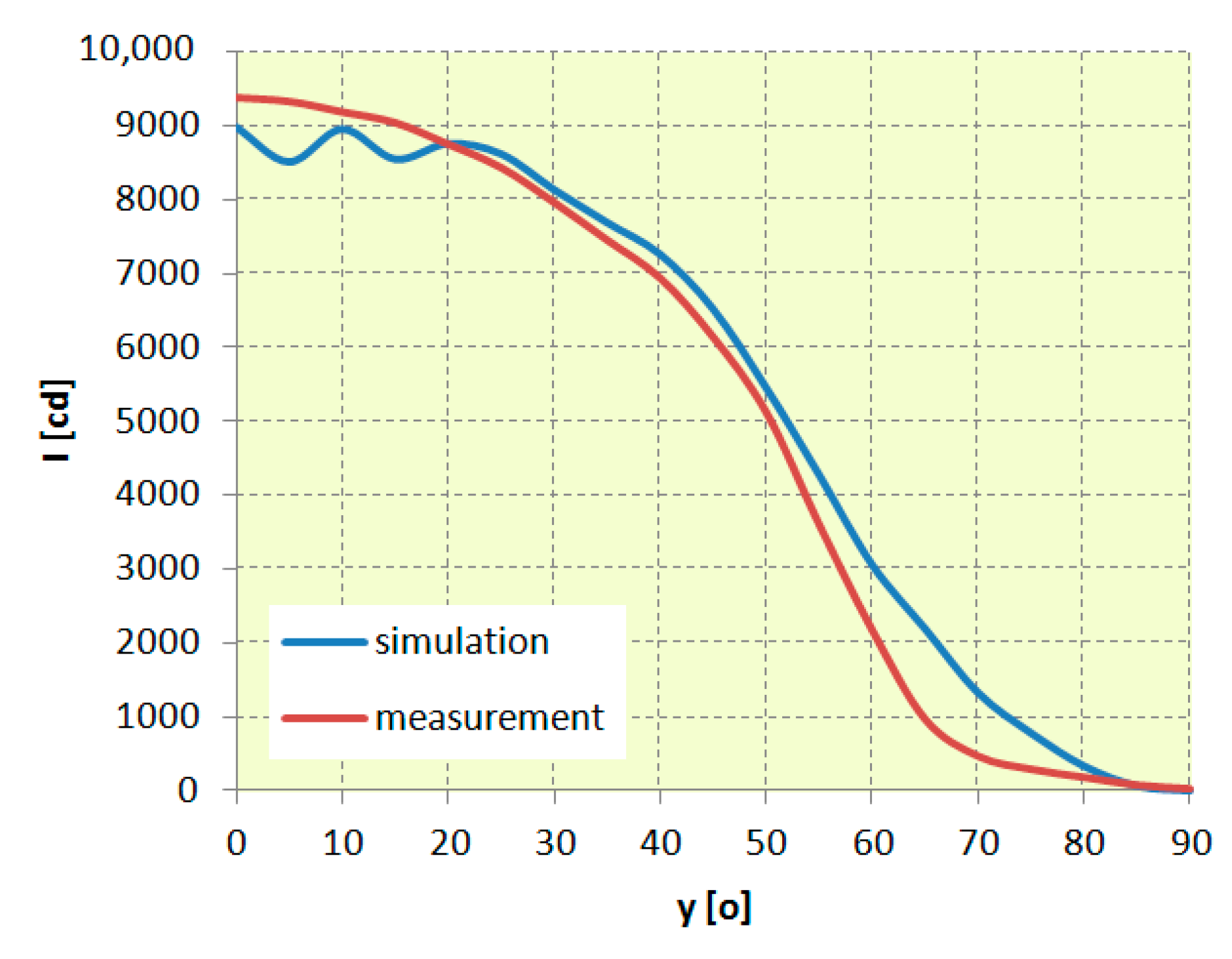

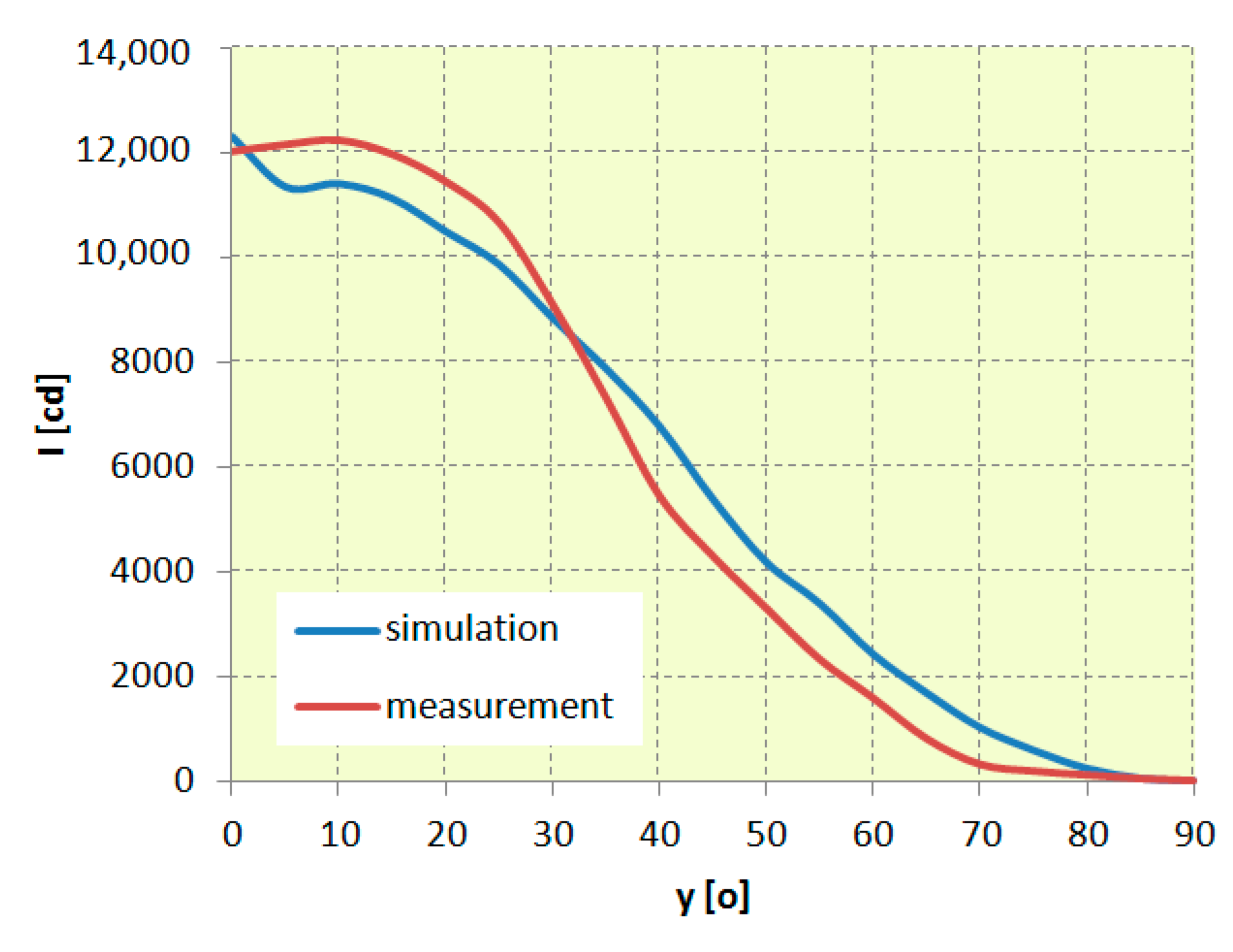

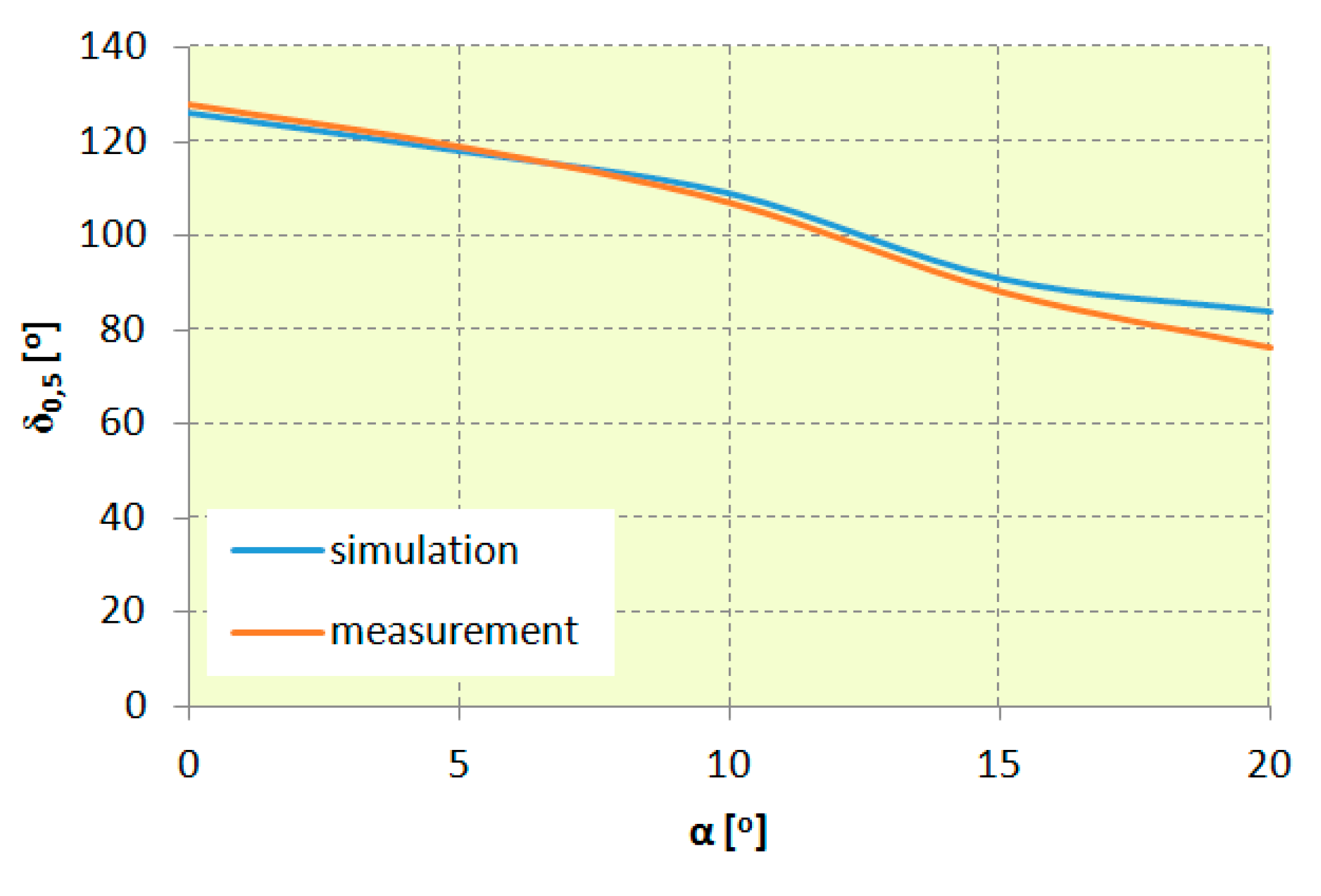

4.2. Determining Luminous Intensity Distribution

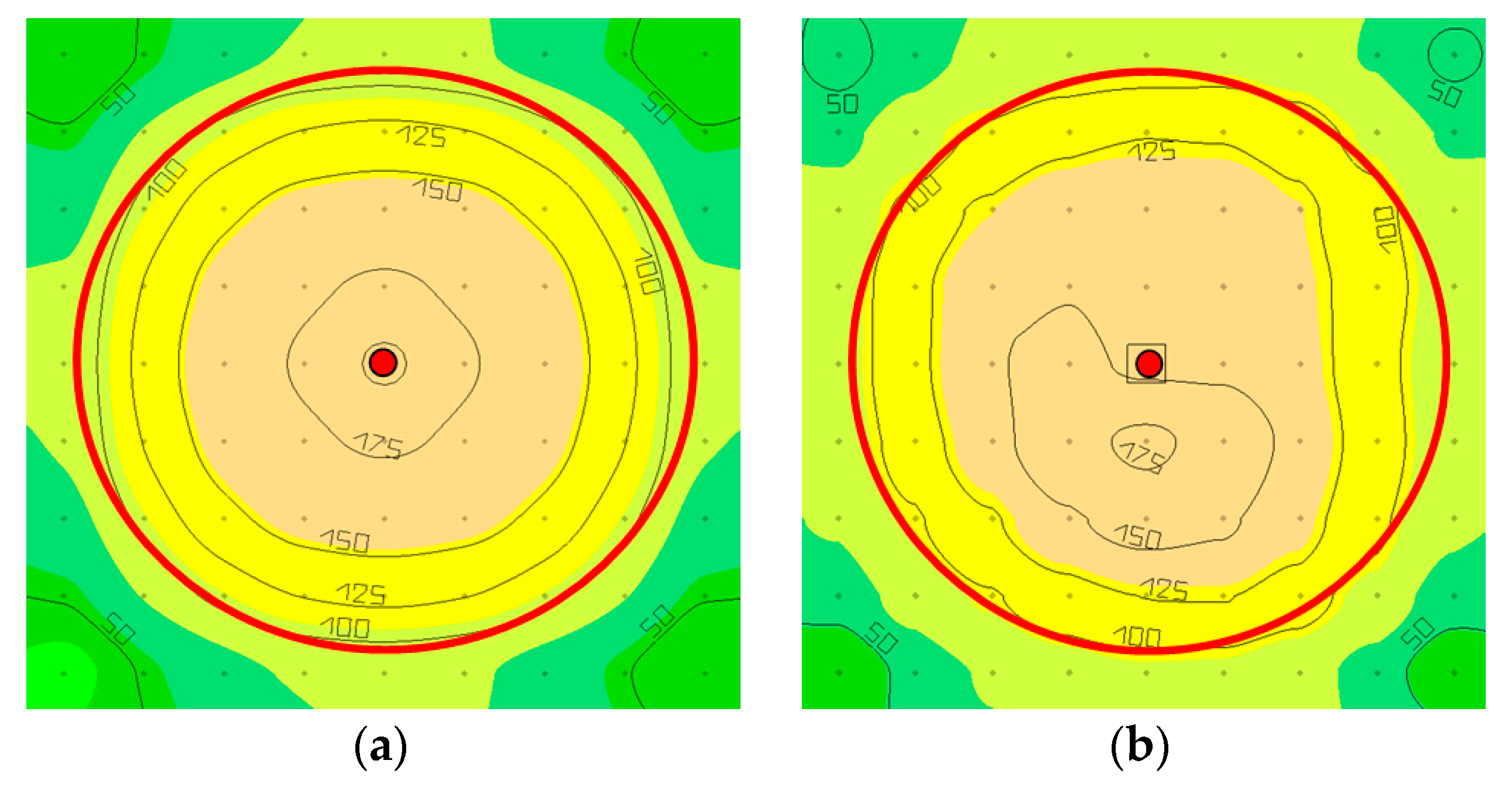

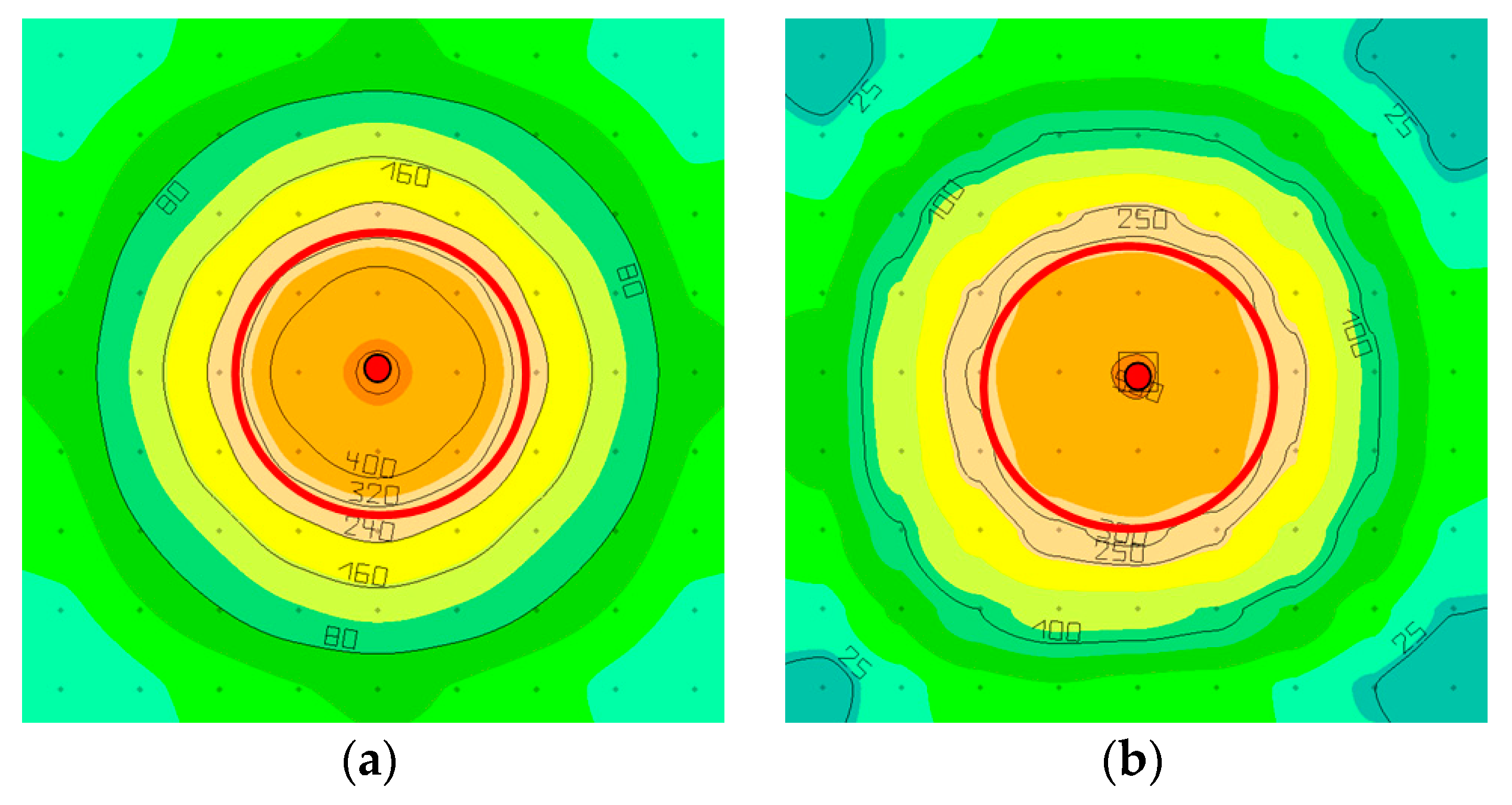

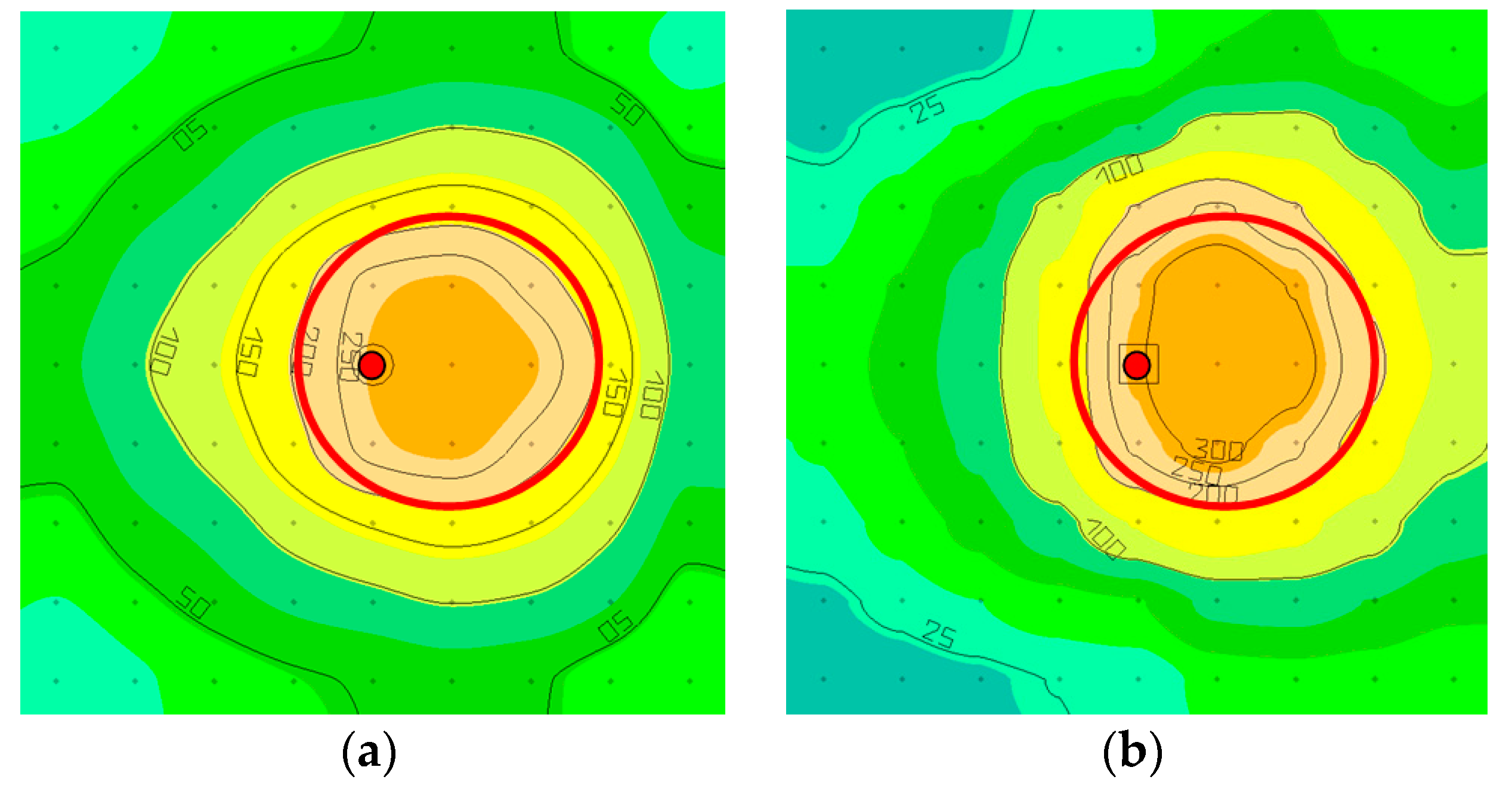

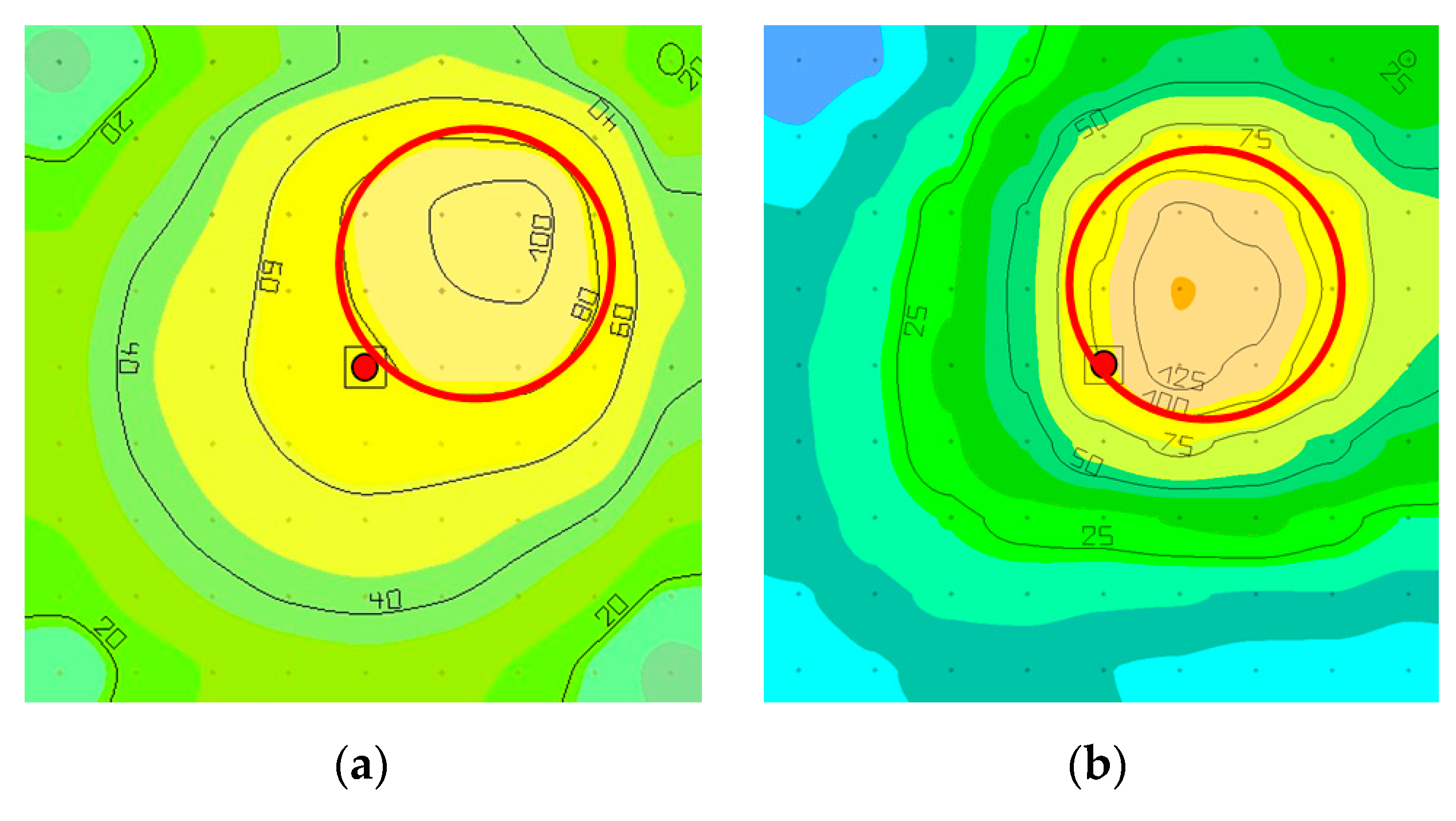

4.3. Determining Illuminance on the Plane

4.4. Analysis of Optical Efficiency

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Khanh, T.; Bodrogi, P.; Vinh, Q.; Winkler, H. LED Lighting. Technology and Perception; Wiley-VCH Verlag GmbH: Darmstadt, Germany, 2015. [Google Scholar]

- Różowicz, A.; Leśko, M.; Wachta, H. Evaluation of the zonal luminous flux distribution of LED sources. In Proceedings of the 2016 13th Selected Issues of Electrical Engineering and Electronics (WZEE), Rzeszow, Poland, 4–8 May 2016; pp. 1–6. [Google Scholar]

- Barbosa, J.L.F.; Simon, D.; Calixto, W.P. Design Optimization of a High Power LED Matrix Luminaire. Energies 2017, 10, 639. [Google Scholar] [CrossRef] [Green Version]

- Barbosa, J.L.F.; Calixto, W.P.; Simon, D. High power LED luminaire design optimization. In Proceedings of the IEEE 16th International Conference on Environment and Electrical Engineering, Florence, Italy, 7–10 June 2016; pp. 1–6. [Google Scholar]

- Rozowicz, A.; Lesko, M.; Wachta, H. The technical possibilities of losses reduction in the LED optical systems. In Proceedings of the 2016 IEEE Lighting Conference of the Visegrad Countries (Lumen V4), Karpacz, Poland, 13–16 September 2016; pp. 1–5. [Google Scholar]

- Vu, N.H.; Tuan Pham, T.; Shin, S. LED Uniform Illumination Using Double Linear Fresnel Lenses for Energy Saving. Energies 2017, 10, 2091. [Google Scholar] [CrossRef] [Green Version]

- Light and Lighting—Lighting of Work Places—Part 1: Indoor Work Places; EN 16464-1: 2012; PKN: Warszawa, Poland, 2012; Polish Version.

- CIE. Review of Lighting Quality Measures for Interior Lighting with LED Lighting Systems; Technical Report 205:2013; CIE: Vienna, Austria, 2013. [Google Scholar]

- Guideline for the Application of General Illumination (“White”) Light-Emitting Diode (LED) Technologies; IES G-2-10; Illuminating Engineering Society: New York, NY, USA, 2010.

- Liu, M.; Rong, B.; Salemink, H.W. Evaluation of LED application in general lighting. Opt. Eng. 2007, 46, 074002. [Google Scholar]

- Gueorgiev, V.; Rizov, P. Lighting in High Temperature Industrial Enviroment. In Proceedings of the 2018 Seventh Balkan Conference on Lighting (BalkanLight), Varna, Bulgaria, 20–22 September 2018; pp. 1–3. [Google Scholar]

- Barroso, A.; Dupuis, P.; Alonso, C.; Jammes, B.; Seguier, L.; Zissis, G. A characterization framework to optimize LED luminaire’s luminous efficacy. In Proceedings of the 2015 IEEE Industry Applications Society Annual Meeting, Addison, TX, USA, 18–22 October 2015; pp. 905–913. [Google Scholar]

- Baran, K.; Wachta, H.; Leśko, M.; Różowicz, A. Research on thermal resistance Rthj-c of high power semiconductor light sources. In Proceedings of the 15th Conference on Computational Technologies in Engineering, Mikolajki, Poland, 16–19 October 2018; AIP Conference Proceedings 2078. p. 020047. [Google Scholar]

- Baran, K.; Wachta, H.; Leśko, M.; Różowicz, A. Thermal Modeling and Simulation of High Power LED Module. In Proceedings of the 15th Conference on Computational Technologies in Engineering, Mikolajki, Poland, 16–19 October 2018; AIP Conference Proceedings 2078. p. 020048. [Google Scholar]

- Lasance, C.; Poppe, A. Thermal Management for LED Applications; Springer Science, Business Media: New York, NY, USA, 2014. [Google Scholar]

- Mathews, E.; Guclu, S.S.; Liu, Q.; Ozcelebi, T.; Lukkien, J.J. The Internet of Lights: An Open Reference Architecture and Implementation for Intelligent Solid State Lighting Systems. Energies 2017, 10, 1187. [Google Scholar] [CrossRef] [Green Version]

- Vu, N.H.; Shin, S. Flat Optical Fiber Daylighting System with Lateral Displacement Sun-Tracking Mechanism for Indoor Lighting. Energies 2017, 10, 1679. [Google Scholar] [CrossRef] [Green Version]

- Scientific Committee on Health, Environmental and Emerging Risks (SCHEER). Opinion on Potential risks to human health of Light Emitting Diodes (LEDs); SCHEER: Bruxelles, Belgium, 2018. [Google Scholar]

- Behar-Cohen, F.; Martinsons, C.; Viénot, F.; Zissis, G.; Barlier-Salsi, A.; Cesarini, J.P.; Enouf, O.; Garcia, M.; Picaud, S.; Attiah, D. Light-emitting diodes (LED) for domestic lighting: Any risks for the eye? Prog. Retin. Eye Res. 2011, 30, 239–257. [Google Scholar] [CrossRef] [PubMed]

- Leccese, F.; Salvadori, G.; Casini, M.; Bertozzi, M. Analysis and Measurements of Artificial Optical Radiation (AOR) Emitted by Lighting Sources Found in Offices. Sustainability 2014, 6, 5941–5954. [Google Scholar] [CrossRef] [Green Version]

- Photobiological Safety of Lamps and Lamp Systems; IEC/EN 62471: 2006; IEC: Geneva, Switzerland, 2006.

- Photobiological Safety of Lamps and Lamp Systems. Part 2: Guidance on Manufacturing Requirements Relating to Non-Laser Optical Radiation Safety; IEC/TR 62471-2:2009; IEC: Geneva, Switzerland, 2009.

- Application of IEC 62471 for the Assessment of Blue Light Hazard to Light Sources and Luminaires; IEC/TR 62778:2014; IEC: Geneva, Switzerland, 2014.

- SOLLS Products. Available online: http://solls.pl/katalog/produkty/ (accessed on 12 November 2019).

- ES-System Industry Flower. Available online: https://www.essystem.pl/produkty/s/59;industry-flower-maxi (accessed on 12 November 2019).

- Targetti Otto. Available online: http://www.targetti.com/en/indoor-lighting/projectors/otto_base (accessed on 16 December 2019).

- Targetti Zeno Medium DBS. Available online: http://www.targetti.com/en/indoor-lighting/projectors/zeno/?0=Reflector||168||DBS (accessed on 16 December 2019).

- Leśko, M.; Różowicz, A.; Baran, K.; Wachta, H. A luminaire with variable light distribution. E3S Web Conf. 2018, 49, 00066. [Google Scholar] [CrossRef] [Green Version]

- Leśko, M.; Baran, K.; Wachta, H.; Różowicz, A. A Concept of an Adaptive Luminaire with Variable Luminous Intensity Distribution. In Proceedings of the 2018 VII Lighting Conference of the Visegrad Countries (Lumen V4), Trebic, Czech Republic, 18–20 September 2018; pp. 1–4. [Google Scholar]

- Durmus, D.; Davis, W. Optimising light source spectrum for object reflectance. Opt. Express 2015, 23, A456–A464. [Google Scholar] [CrossRef] [PubMed]

- Vázquez, D.; Alvarez, A.; Canabal, H.; Garcia, A.; Mayorga, S.; Muro, C.; Galan, T. Point to point multispectral light projection applied to cultural heritage. In Proceedings of the SPIE 10379, Nonimaging Optics: Efficient Design for Illumination and Solar Concentration XIV, San Diego, CA, USA, 7 September 2017; p. 103790K. [Google Scholar]

- Elmer, W.B. The Optical Design of Reflectors; John Wiley &Sons: New York, NY, USA, 1980. [Google Scholar]

- Zalewski, S. A proposed method for the calculation of light emitting diode road lighting. Light. Res. Technol. 2012, 44, 186–196. [Google Scholar] [CrossRef]

- Januszewski, B.; Bieniasz, J. Geometryczne Podstawy Grafiki Inżynierskiej; Oficyna Wydawnicza Politechniki Rzeszowskiej: Rzeszów, Poland, 2000. (In Polish) [Google Scholar]

- Nicyporowicz, E. Krzywe płaskie. Wybrane Zagadnienia z Geometrii Analitycznej i Różniczkowej; PWN: Warszawa, Poland, 1991. (In Polish) [Google Scholar]

- Alanod. Available online: https://alanod-westlake.com/products/ (accessed on 12 November 2019).

- Almeco Group. Available online: https://almecogroup.com/en/pages/377-reflecting-surfaces-for-lighting (accessed on 12 November 2019).

- ACA Corp. Available online: https://acacorp.com/lighting/ (accessed on 12 November 2019).

- CREE LED Components. Available online: https://www.cree.com/led-components/products/xlamp-leds-discrete/xlamp-xp-g3 (accessed on 12 November 2019).

- LEDIL. Available online: https://www.ledil.com/product-card/?product=C14607_HB-2X2-M (accessed on 12 November 2019).

- LTI Optics Photopia Design Software. Available online: http://www.ltioptics.com/en/photopia-general-2017.html (accessed on 12 November 2019).

- Rozowicz, S.; Delag, M. Approval of Special Warning Lights for the Power-Driven Vehicles in Free Market. In Proceedings of the 2018 Conference: Conference on Electrotechnology–Processes, Models, Control and Computer Science (EPMCCS), Cedzyna, Poland, 12–14 November 2018. [Google Scholar]

- DIALux evo. Available online: https://www.dial.de/en/dialux-desktop/ (accessed on 12 November 2019).

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Leśko, M.; Różowicz, A.; Wachta, H.; Różowicz, S. Adaptive Luminaire with Variable Luminous Intensity Distribution. Energies 2020, 13, 721. https://doi.org/10.3390/en13030721

Leśko M, Różowicz A, Wachta H, Różowicz S. Adaptive Luminaire with Variable Luminous Intensity Distribution. Energies. 2020; 13(3):721. https://doi.org/10.3390/en13030721

Chicago/Turabian StyleLeśko, Marcin, Antoni Różowicz, Henryk Wachta, and Sebastian Różowicz. 2020. "Adaptive Luminaire with Variable Luminous Intensity Distribution" Energies 13, no. 3: 721. https://doi.org/10.3390/en13030721