A New Method of Selecting the Airlift Pump Optimum Efficiency at Low Submergence Ratios with the Use of Image Analysis

Abstract

:1. Introduction

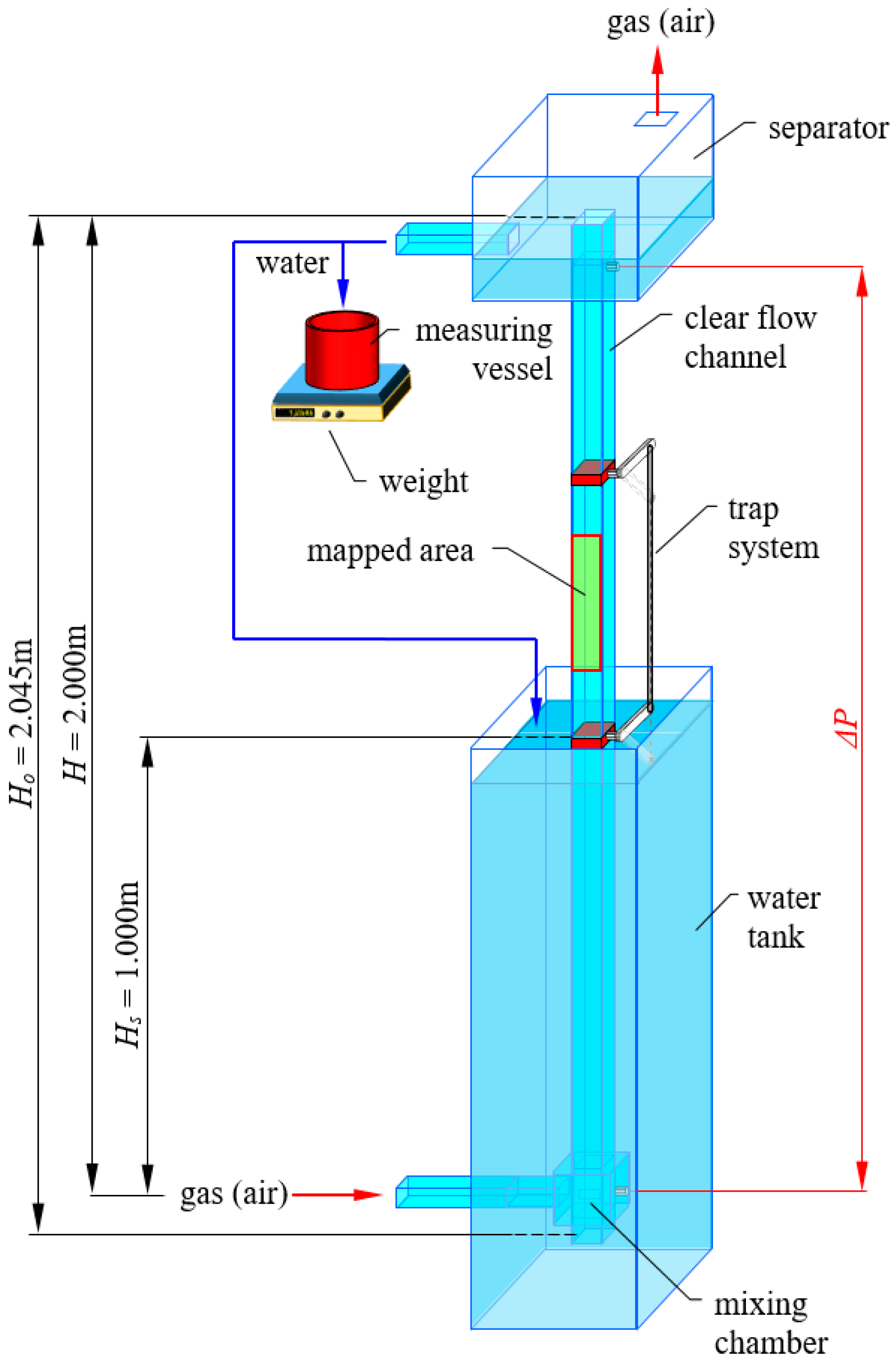

2. Measurement Setup

- (1)

- feeding the gas phase through the perforated nozzle (eight holes with the diameter of 2 mm with a symmetrical distribution on two walls in the channel);

- (2)

- feeding the gas phase through the slot nozzle (two slots with the dimensions of 2 × 20 mm);

- (3)

- feeding the gas phase through the ceramic porous element (two porous bodies with the 45% porosity, particle size 300–500 µm and dimensions of 30 × 20 mm).

3. Methods

4. Results and Discussion

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

Nomenclature

| λ | coefficient of resistance dependent on the Reynolds number (Re) and the relative roughness of the pipe, - |

| ε | submergence ratio, - |

| η | airlift pump overall efficiency, - |

| ηs | compressor efficiency, - |

| ρL | liquid density, kg/m3 |

| ρ2P | two phase mixture density, kg/m3 |

| ρG | gas density, kg/m3 |

| σ | liquid phase surface tension, N/m |

| C0 | liquid slug velocity profile coefficient (C0 = 1.2 for high Re, C0 = 2.0 for low Re) |

| D | riser pipe diameter, m |

| energy flux resulting from the liquid phase, W | |

| energy flux resulting from the gas phase, W | |

| normalized energy flux (liquid phase), - | |

| normalized energy flux (gas phase), - | |

| g | gravitational acceleration, m/s |

| ΦG | Lockhart-Martinelli equation multiplier for gas phase, - |

| ФGtt | L-M multiplier for the gas phase, where the liquid phase is turbulent and the gas phase is also turbulent, - |

| ФGtv | L-M multiplier for the gas phase where the liquid phase is turbulent but the gas phase is laminar (viscous), - |

| ФGvt | L-M multiplier for the gas phase where the liquid phase is laminar (viscous) but the gas phase is turbulent, - |

| ФGvv | L-M multiplier for the gas phase where the liquid phase is laminar (viscous) and the gas phase also laminar (viscous), - |

| ΦL | L-M multiplier for liquid phase, - |

| ФLtt | L-M multiplier for the liquid phase where the liquid phase is turbulent and the gas phase is also turbulent, - |

| ФLtv | L-M multiplier for the liquid phase where the liquid phase is turbulent but the gas phase is laminar (viscous), - |

| ФLvt | L-M multiplier for the liquid phase where the liquid phase is laminar (viscous) but the gas phase flowing alone in the channel is turbulent, - |

| ФLvv | L-M multiplier for the liquid phase where the liquid phase is laminar (viscous) and the gas phase is also laminar (viscous), - |

| H | total lift, m |

| Hl | pump lift height, m |

| Ho | overall height of the pump, m |

| Hs | immersion depth, m |

| i | respective phase (i.e., gas or liquid) as subscript |

| RG | Void friction, - |

| ∆P | total pressure drop related to gas flux considering two-phase flow, |

| ΔP2F,H | pressure drop caused by a change in hydrostatic energy, |

| ΔP2F,T | pressure drop caused by friction, |

| QG | volume of gas, m3/h |

| Q’L | dimensionless liquid flow coefficient, - |

| QL | volume of liquid, m3/h |

| Q’L | dimensionless gas flow coefficient, - |

| W’Ts | dimensionless coefficient of plug movement in stationary liquid, - |

| WG | gas velocity, m/s |

| WGO | superficial velocity of gas phase, m/s |

| WLO | superficial velocity of liquid phase, m/s |

References

- Hanafizadeh, P.; Ghorbani, B. Review study on airlift pumping systems. Multiph. Sci. Technol. 2012, 24, 323–362. [Google Scholar] [CrossRef]

- Kumar, E.A.; Kumar, K.R.V.; Ramayya, A.V. Augmentation of airlift pump performance with tapered upriser pipe. An experimental study. J. Mech. Eng. Div. 2003, 84, 114–119. [Google Scholar]

- Yoo, K.H.; Masser, M.P.; Hawcroft, B.A. An in-pond raceway system incorporating removal of fish waste. Aquac. Eng. 1994, 14, 175–187. [Google Scholar] [CrossRef]

- Loyless, J.C.; Malone, R.C. Evaluation of air-lift pump capabilities for water delivery, aeration, and degasification for application to recirculating aquaculture systems. Aquac. Eng. 1988, 18, 117–133. [Google Scholar] [CrossRef]

- Ahmed, W.H.; Aman, A.M.; Badr, H.M.; Al-Qutub, A.M. Air injection methods: The key to better performance of airlift pump. Exp. Therm. Fluids Sci. 2016, 70, 354–365. [Google Scholar] [CrossRef]

- Qiang, Y.; Fan, W.; Xiao, C.; Pan, Y.; Chen, Y. Effects of operating parameters and injection method on the performance of an artificial upwelling by using airlift pump. Appl. Ocean Res. 2018, 78, 212–222. [Google Scholar] [CrossRef]

- Deendarlianto; Supraba, I.; Majid, A.I.; Pradecta, M.R.; Indarto; Widyaparaga, A. Experimental investigation on the flow behavior during the solid particles lifting in a micro-bubble generator type airlift pump system. Case Stud. Therm. Eng. 2019, 13, 100386. [Google Scholar] [CrossRef]

- Kassab, S.Z.; Kandil, H.A.; Warda, H.A.; Ahmed, W.H. Experimental and analytical investigations of airlift pumps operating in three-phase flow. Chem. Eng. J. 2007, 131, 273–281. [Google Scholar] [CrossRef]

- Fujimoto, H.; Nagadani, T.; Takuda, H. Performance characteristics of a gas-liquid-solid airlift pump. Int. J. Multiph. Flow 2005, 31, 1116–1133. [Google Scholar] [CrossRef]

- Masiukiewicz, M.; Anweiler, S. Two-phase flow phenomena assessment in minichannels for compact heat exchangers using image analysis methods. Energy Convers. Manag. 2015, 104, 44–54. [Google Scholar] [CrossRef]

- Qi, D.; Zou, H.; Ding, Y.; Luo, W.; Yang, J. Engineering Simulation Tests on Multiphase Flow in Middle-and High-Yield Slanted Well Bores. Energies 2018, 11, 2591. [Google Scholar] [CrossRef]

- Samaras, V.C.; Margaris, D.P. Two-phase flow regime maps for air-lift pump vertical upward gas-liquid flow. Int. J. Multiph. Flow 2005, 31, 757–766. [Google Scholar] [CrossRef]

- Apazidis, N. Influence of buble expansion and relative velocity on the performance and stability of an airlift pump. Int. J. Multiph. Flow 1985, 11, 459–475. [Google Scholar] [CrossRef]

- Wasilewski, M. Analysis of the effects of temperature and the share of solid and gas phases on the process of separation in a cyclone suspension preheater. Sep. Purif. Technol. 2016, 168, 114–123. [Google Scholar] [CrossRef]

- Pietrzak, M.; Placzek, M.; Witczak, S. Comparison of pressure drop correlations for two-phase flow in small diameter channels. Przem. Chem. 2017, 96, 592–597. [Google Scholar]

- Ganat, T.A.; Hrairi, M. Gas–Liquid Two-Phase Upward Flow through a Vertical Pipe: Influence of Pressure Drop on the Measurement of Fluid Flow Rate. Energies 2018, 11, 2937. [Google Scholar] [CrossRef]

- Pietrzak, M.; Witczak, S. Flow patterns and void fractions of phases during gas–liquid two-phase and gas–liquid–liquid three-phase flow in U-bends. Int. J. Heat Fluid Flow 2013, 44, 700–710. [Google Scholar] [CrossRef]

- Sikora, M. Flow structures during refrigerants condensation. J. Mech. Energy Eng. 2017, 1, 101–106. [Google Scholar]

- Anweiler, S. Development of videogrammetry as a tool for gas-particle fluidization research. J. Environ. Manag. 2017, 203, 942–949. [Google Scholar] [CrossRef]

- Anweiler, S.; Ulbrich, R. Flow pattern for different fluidization apparatuses. Inzynieria Chemiczna i Procesowa 2004, 25, 577–582. [Google Scholar]

- Ligus, G.; Wasilewski, M. Impact of stirrer rotational speed on liquid circulation in a rectangular vessel—A study applying DPIV. E3S Web Conf. 2018, 44, 00096. [Google Scholar] [CrossRef]

- Wang, Z.; Kang, Y.; Wang, X.; Wu, S.; Li, X. Investigation of the hydrodynamics of slug flow in airlift pumps. Chin. J. Chem. Eng. 2018, 26, 2391–2402. [Google Scholar] [CrossRef]

- Kim, S.H.; Sohn, C.H.; Hwang, J.Y. Effect of tube diameter and submergence ratio on bubble pattern and performance of airlift pump. Int. J. Multiph. Flow 2014, 58, 195–204. [Google Scholar] [CrossRef]

- Oueslati, A.; Megriche, A. The effect of liquid temperature on the performance of an airlift pump. Enrgy Procedia 2017, 119, 693–701. [Google Scholar] [CrossRef]

- Abed, K.A. Operational criteria of performance of airlift pump. J. Inst. Eng. 2003, 84, 92–94. [Google Scholar]

- Deckwer, W.D. Bubble Column Reactors; John Wiley and Sons: New York, NY, USA, 1991. [Google Scholar]

- Mishima, K.; Hibiki, T. Some characteristics of air-water two-phase flow in small diameter vertical tubes. Int. J. Multiph. Flow 1996, 22, 703–712. [Google Scholar] [CrossRef]

- Kassab, S.; Kandil, H.A.; Warda, H.A.; Ahmed, W.H. Air-lift pump characteristics under two-phase flow conditions. Int. J. Heat Fluid Flow 2009, 30, 88–98. [Google Scholar] [CrossRef]

- Hanafizadeh, P.; Ghanbarzadeh, S.; Saidi, M.H. Visual technique for detection of gas-liquid two-phase flow regime in the airlift pump. J. Pet. Sci. Eng. 2011, 75, 327–335. [Google Scholar] [CrossRef]

- Borsuk, G.; Pochwala, S.; Wydrych, J. Numerical methods in processes of design and operation in pneumatic conveying systems. In Engineering Mechanics Book Series: Engineering Mechanics; Zolotarev, I., Radolf, V., Eds.; Institute of Thermomechanics, Academy of Sciences of the Czech Republic: Prague, Czech Republic, 2016; pp. 83–86. [Google Scholar]

- Wasilewski, M.; Duda, J. Multicriteria optimisation of first-stage cyclones in the clinker burning system by means of numerical modelling and experimental research. Powder Technol. 2016, 289, 143–158. [Google Scholar] [CrossRef]

- De Cachard, F.; Delhaje, J.M. A slug-churn flow model for small-diameter airlift pumps. Int. J. Multiph. Flow 1996, 22, 627–649. [Google Scholar] [CrossRef]

- Tighzert, H.; Brahimi, M.; Kechround, N.; Benabbas, F. Effect of submergence ratio on the liquid phase velocity, efficiency and void fraction in air-lift pump. J. Pet. Sci. Eng. 2013, 110, 155–161. [Google Scholar] [CrossRef]

- Tramba, A.; Topalidou, A.; Kastrinakis, E.G.; Nychas, S.G. Visual study of an airlift pump operating at low submergance ration. Can. J. Chem. Eng. 1995, 73, 755–764. [Google Scholar] [CrossRef]

- Lubbesmeyer, D.; Leoni, B. Fluid-velocity measurements and flow pattern identification by noise-analysis of light-beam signals. Int. J. Multiph. Flow 1983, 9, 665–679. [Google Scholar] [CrossRef]

- Lubbesmeyer, D. Possibilities of flow-pattern identification by noise techniques. Prog. Nucl. Energy 1982, 9, 13–21. [Google Scholar] [CrossRef]

- Zuber, N.; Findlay, J.A. Average volumetric concentration in two-phase flow systems. J. Heat Transf. 1965, 87, 453–468. [Google Scholar] [CrossRef]

- Masiukiewicz, M.; Anweiler, S. Two-phase flow structure assessment based on dynamic image analysis. Flow Meas. Instrum. 2019, 65, 195–202. [Google Scholar] [CrossRef]

- Reinemann, D.J.; Parlange, J.Y.; Timmons, M.B. Theory of small-diameter airlift pump. Int. J. Multiph. Flow 1990, 16, 113–122. [Google Scholar] [CrossRef]

- Lockhart, R.W.; Martinelli, R.C. Proposed Correlation of data for isothermal two-phase flow. Chem. Eng. Prog. 1949, 45, 39–48. [Google Scholar]

- Masiukiewicz, M.; Zając, D.; Ulbrich, R. Image analysis applied to pattern recognition of two-phase flow in two-dimensional bed. Inzynieria Chemiczna i Procesowa 2001, 22, 917–922. [Google Scholar]

- Ulbrich, R.; Krótkiewicz, M.; Szmolke, N.; Anweiler, S.; Masiukiewicz, M.; Zajac, D. Recognition of two-phase flow patterns with the use of dynamic image analysis. Proc. Inst. Mech. Eng. Part E J. Process Mech. Eng. 2002, 216, 227–233. [Google Scholar] [CrossRef]

| Measurement Device | Description |

|---|---|

| Rotameter ROS-10 | Measuring range: 0.11–1.1 m3/h Standard accuracy class 2.5 according to PN-85/M-42371 Absolute error: 0.0275 |

| Rotameter ROS-16 | Measurement range: 0.5–5.0 m3/h Standard accuracy class 2.5 according to PN-85/M-42371 Absolute error: 0.125 |

| Rotameter RDN-25 | Measurement range: 3.0–30.0 m3/h Standard accuracy class 2.5 according to PN-85/M-42371 Absolute error: 0.75 |

| Scale Radwag WPT5 | Measuring range: 0.5–3000 g Accuracy: 0.5 g |

| PELTRON PXWD 0.2 Differential pressure transducer | Measuring range: 0–20 kPa Standard accuracy class 0.25 according to PN-85/M-42371 Absolute error: 50 Pa |

| Timer | Accuracy: 0.01 s |

| Porous Gas Distributor | Perforated Gas Distributor | Slot Gas Distributor | |

|---|---|---|---|

| Bubble flow |  |  |  |

| Slug flow |  |  |  |

| Churn flow |  |  |  |

| Wispy-annular flow |  |  |  |

| Type of Gas Distributor | Impact on Two-Phase Flow Mixture | Impact on Pressure Drop | Impact on Void Friction |

|---|---|---|---|

| Porous | The high intensity of the heterogeneous flow High stability of liquid transport A small number of local circulations and vortices in the liquid phase | High values of pressure drops Greatest validity of a Lockhart-Martinelli model Exceeding the error limit in the small and medium gas flux range | Greatest validity of a Reinemann model Exceeding the error limit in the small and medium gas flux range |

| Perforated | Medium intensity of the heterogeneous flow Medium stability of liquid transport A small number of local circulations and vortices in the liquid phase for bubble structures, significant for other structures | Medium values of pressure drops Medium validity of a Lockhart-Martinelli model Exceeding the error limit in the small and medium gas flux range | Medium validity of a Reinemann model Exceeding the error limit in the small and medium gas flux range |

| Slot | Low intensity of the heterogeneous flow Low stability of liquid transport A significant number of local circulations and vortices in the liquid phase | Low values of pressure drops Medium validity of a Lockhart-Martinelli model Exceeding the error limit in the small and medium gas flux range | Medium validity of a Reinemann model Exceeding the error limit in the high gas flux range |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ligus, G.; Zając, D.; Masiukiewicz, M.; Anweiler, S. A New Method of Selecting the Airlift Pump Optimum Efficiency at Low Submergence Ratios with the Use of Image Analysis. Energies 2019, 12, 735. https://doi.org/10.3390/en12040735

Ligus G, Zając D, Masiukiewicz M, Anweiler S. A New Method of Selecting the Airlift Pump Optimum Efficiency at Low Submergence Ratios with the Use of Image Analysis. Energies. 2019; 12(4):735. https://doi.org/10.3390/en12040735

Chicago/Turabian StyleLigus, Grzegorz, Daniel Zając, Maciej Masiukiewicz, and Stanisław Anweiler. 2019. "A New Method of Selecting the Airlift Pump Optimum Efficiency at Low Submergence Ratios with the Use of Image Analysis" Energies 12, no. 4: 735. https://doi.org/10.3390/en12040735