Multi-Ejector Concept: A Comprehensive Review on its Latest Technological Developments

Abstract

:1. Introduction

- The government subsidies has led “CO2 only” heat pump units for domestic hot water (DHW) purposes to become standard in Japan;

- Transcritical R744 solutions are gaining ever-growing attraction in industrial refrigeration applications featuring large cooling loads [4].

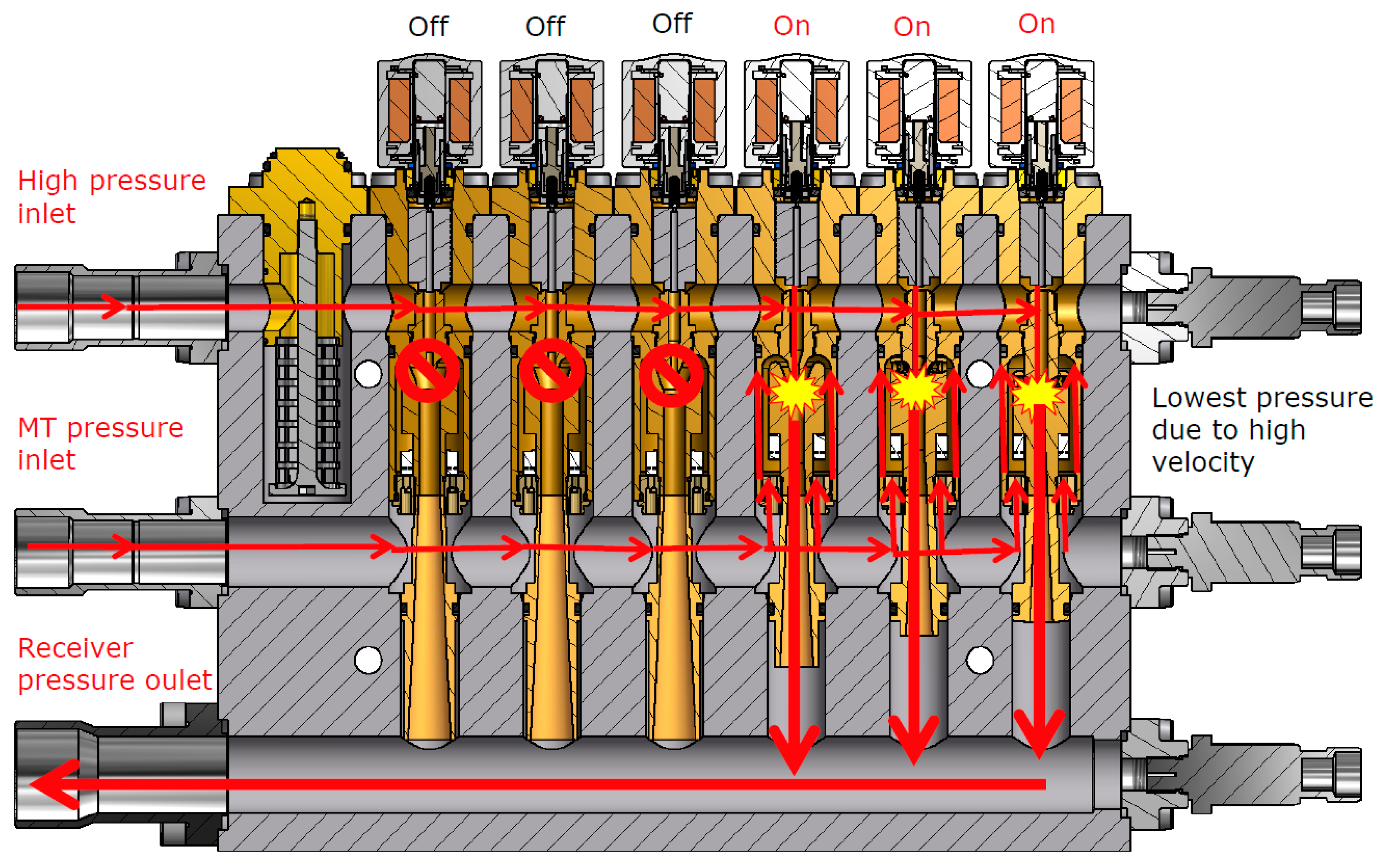

2. Multi-Ejector Concept

3. Supermarket Applications

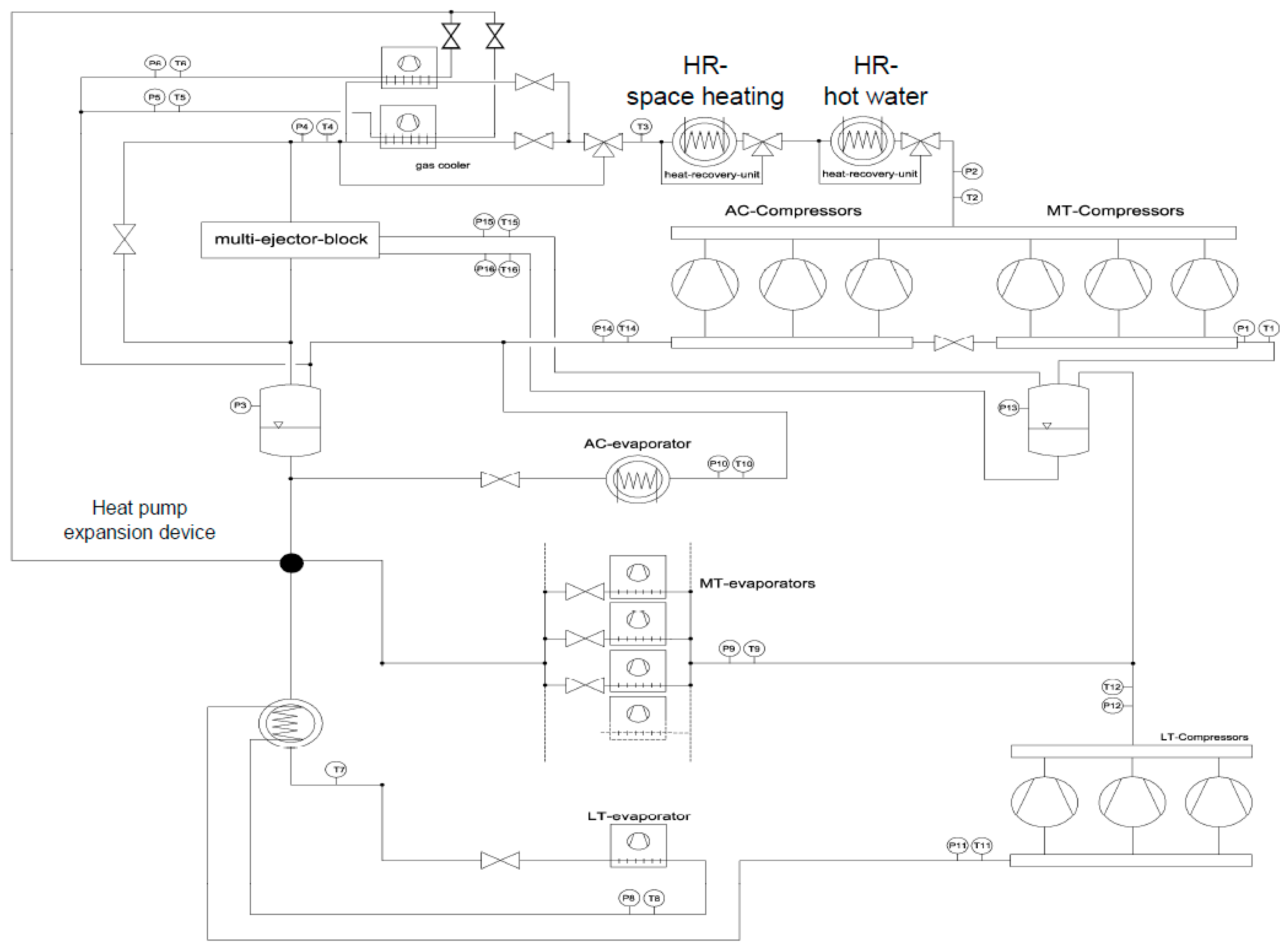

3.1. Evolution of System Layout

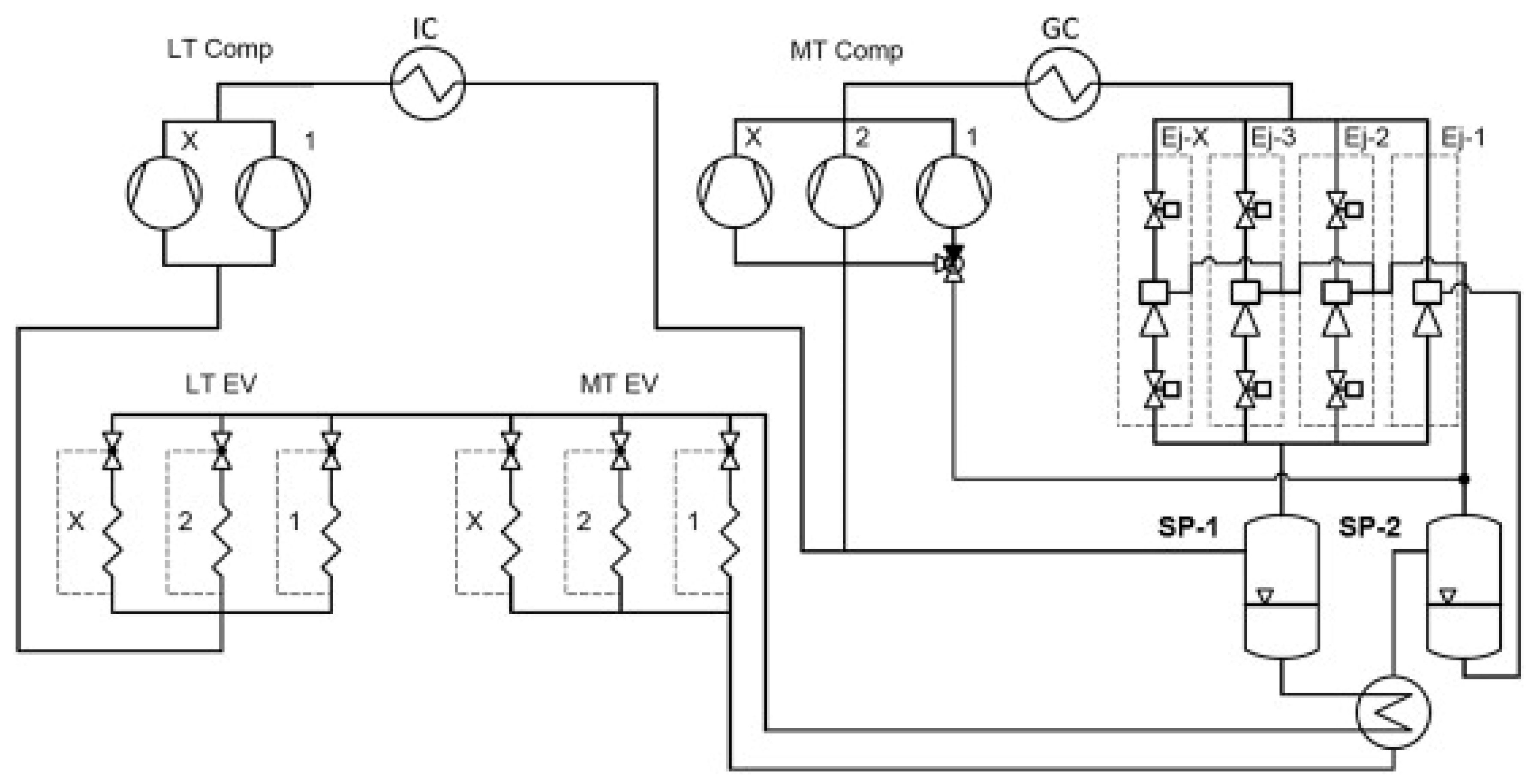

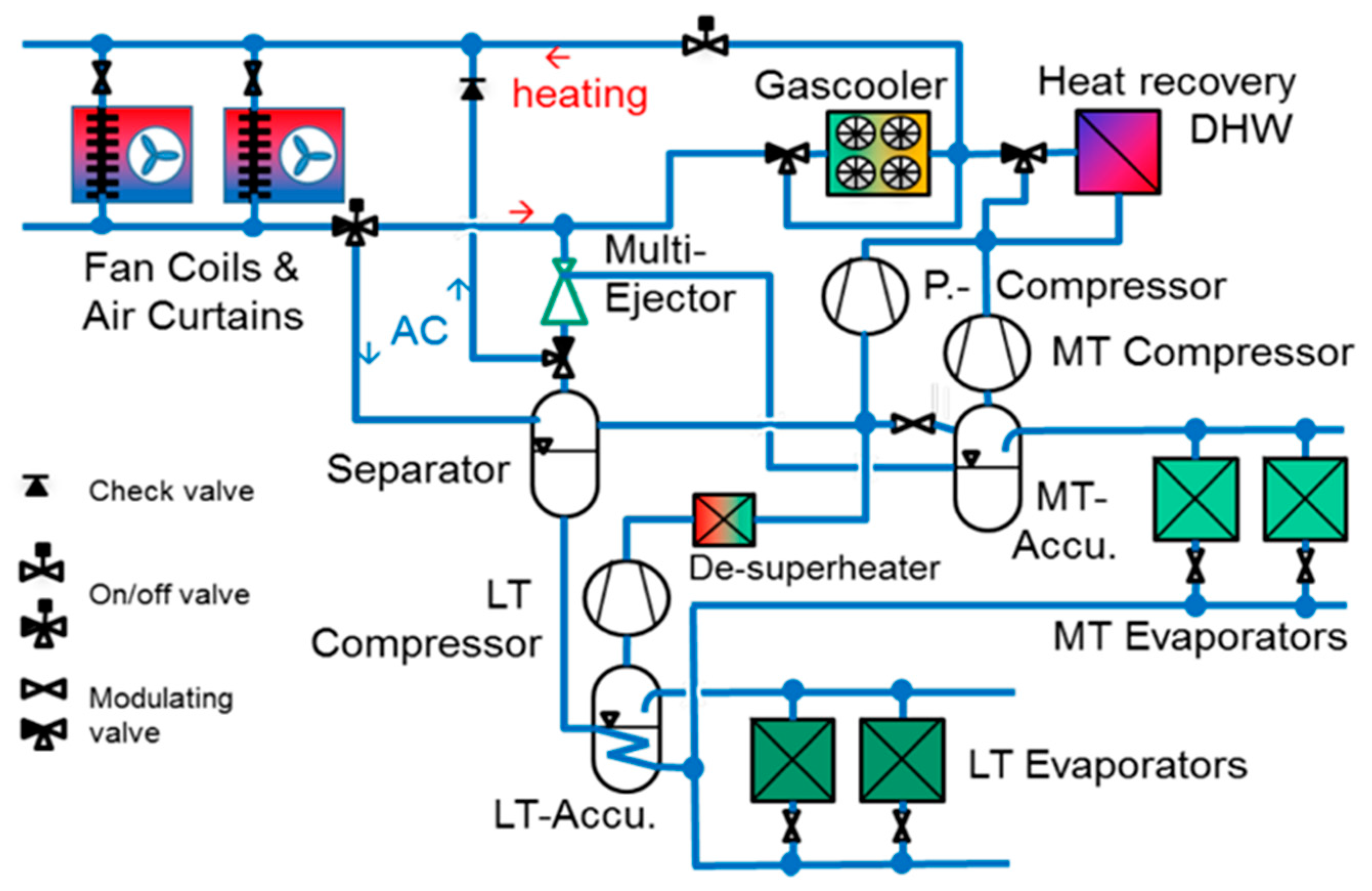

3.2. Evolution of Multi-Ejector Equipped System Layout

3.3. Multi-Ejector Based Solutions without Integration with Air Conditioning Unit

3.3.1. Technological Aspects

- Significantly decreasing the compressor discharge temperature. This is shown in Figure 12, in which curve refers to the typical operating conditions of an overfed evaporator, whereas curve b and c are related to two conventional running modes of dry-expansion evaporators. Therefore, these results highlight considerable benefits to the lifetime of the lubricant, components on the discharge line and de-superheater for heat recovery;

- Improved protection against liquid in the compressor suction manifolds thanks to both the adopted active methods with the purpose of limiting the liquid level and the MP liquid receiver;

- A reduction in total installed swept volume in relation to a single compression system;

- An enhanced overall energy efficiency at outdoor temperatures up to between 40 °C and 42 °C.

3.3.2. Theoretical Assessments/Statements

- The r1234ze(E)/R744 indirect arrangement with MT and LT flooded evaporators and the r134a/R744 cascade solution present some modest energy savings;

- The other evaluated systems (i.e., R1234ze(E)/R744 indirect arrangement with MT flooded evaporators, R290/R744 indirect arrangement with and without LT flooded evaporators, R450A/R744 cascade solution and R513A/R744 cascade system) are not suitable candidates.

3.3.3. Laboratory and Field Experimental Assessments

Laboratory Experimental Assessments

Field Experimental Assessments

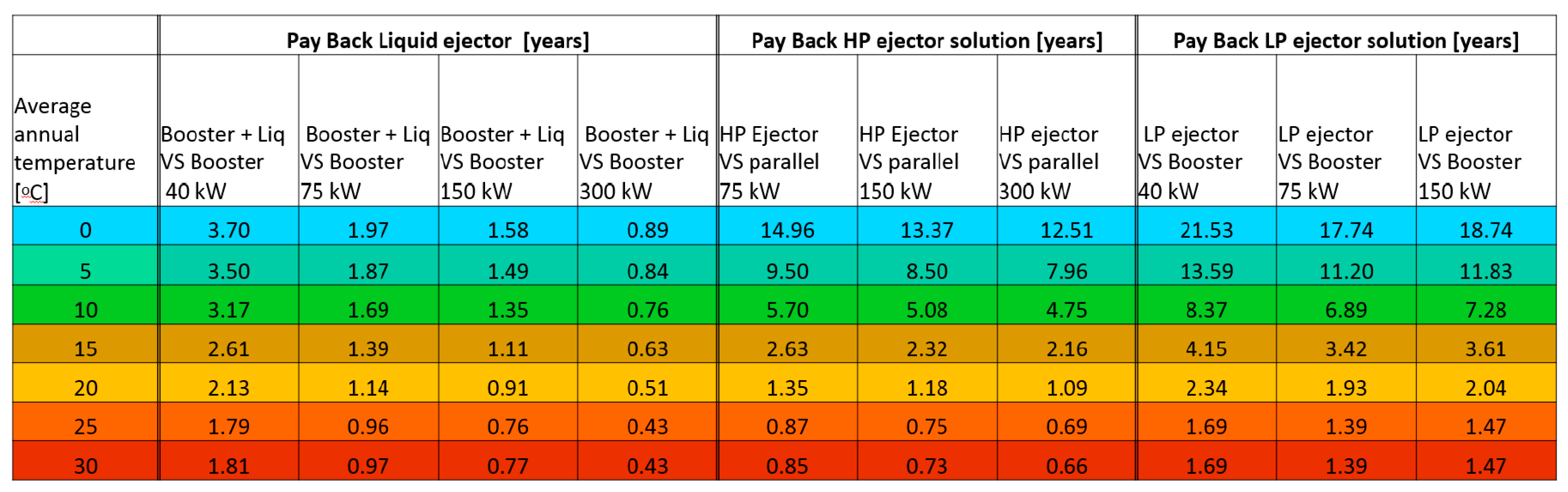

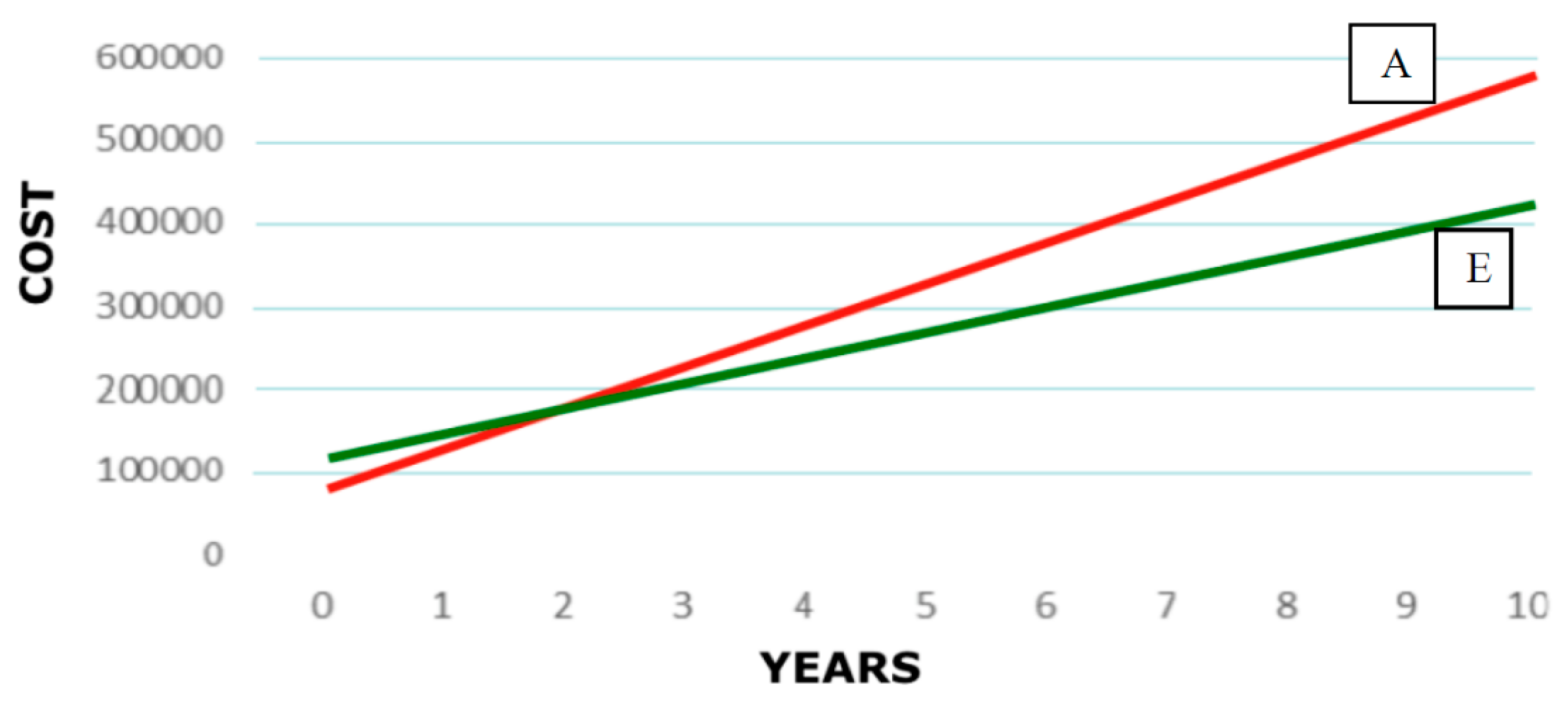

3.3.4. Economic Assessments

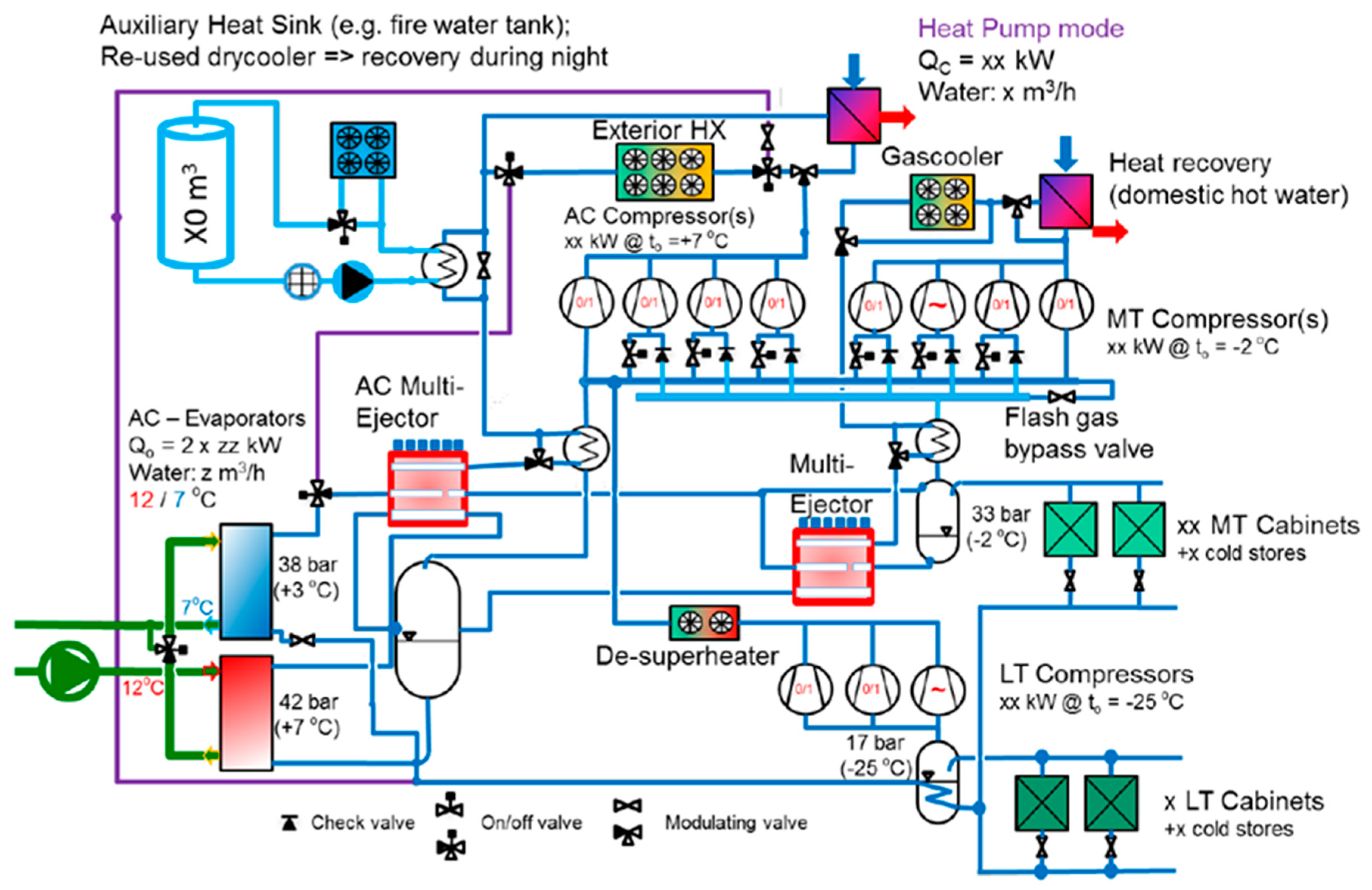

3.4. Multi-Ejector Based Solutions with Integration with Air Conditioning Unit

3.4.1. Technological Aspects

3.4.2. Theoretical Assessments/Statements

- The multi-ejector enhanced parallel compression unit with two multi-ejector blocks (one for MT load and one for AC demand) and AC evaporator located downstream of the liquid receiver is a suitable solution as high AC pressures are required;

- The multi-ejector enhanced parallel compression system with MT multi-ejector module and AC evaporator located upstream of the liquid receiver is an adequate solution as low AC pressures are necessary;

- The optimum discharge pressure is strongly related to the outdoor temperature, MT, AC evaporator position and AC evaporating pressure in transcritical operating conditions.

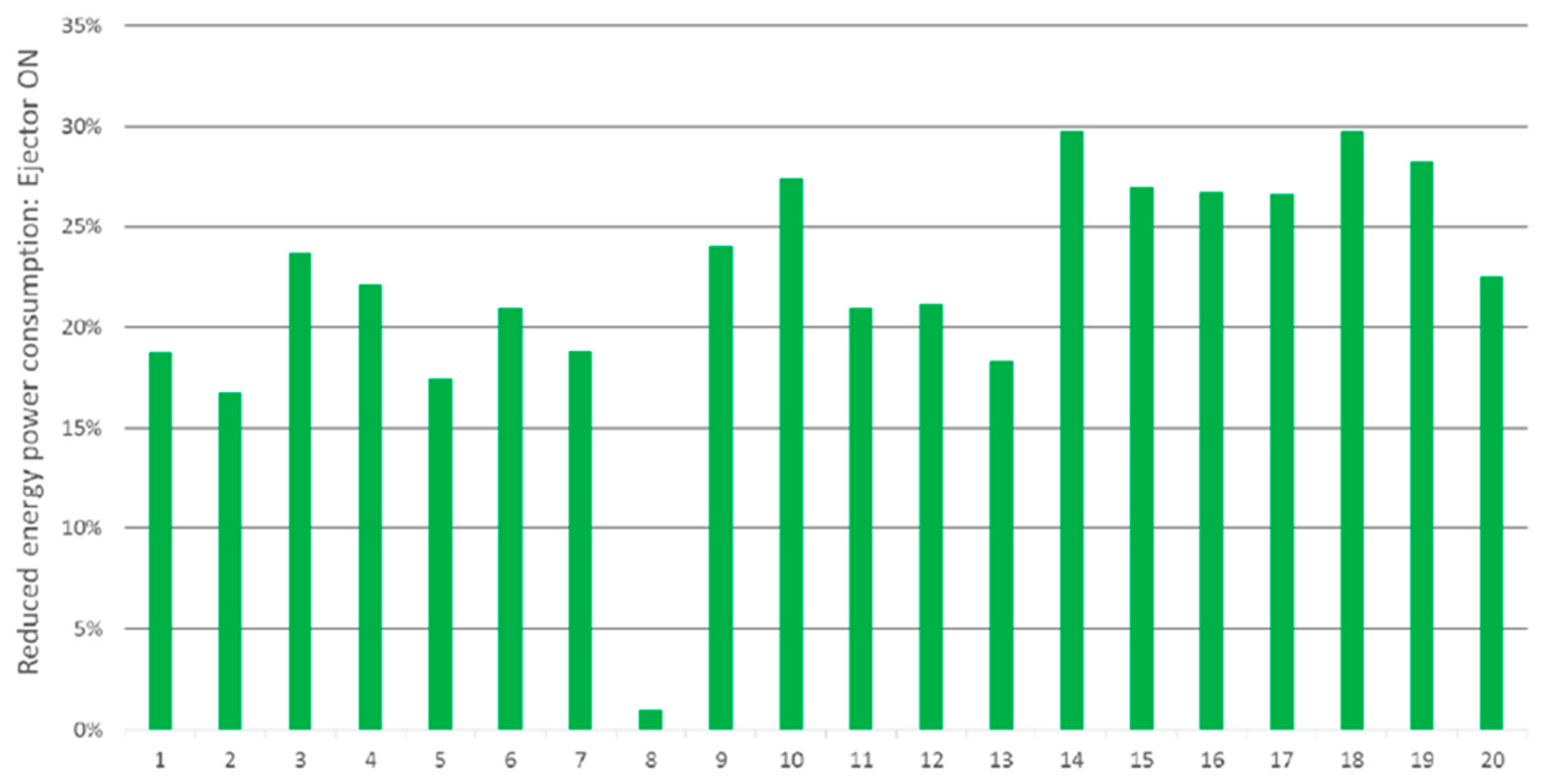

- A multi-ejector based solution integrated with the AC unit (solution similar to that in Figure 6) consumes from 19.3% to 26.9% less electricity;

- The investigated r1234ze(E)-based indirect arrangements (i.e., With and without integration with the AC equipment) offer energy savings between 4.7% and 6.4%;

- The r134a/R744 cascade system separately operating with a r1234ze(E) chiller can reduce the energy consumption from 1.9% to 4.7%;

- The other assessed solutions (i.e., R1234ze(E)-, R290-, R450A- and R513A-based systems) are not appropriate candidates.

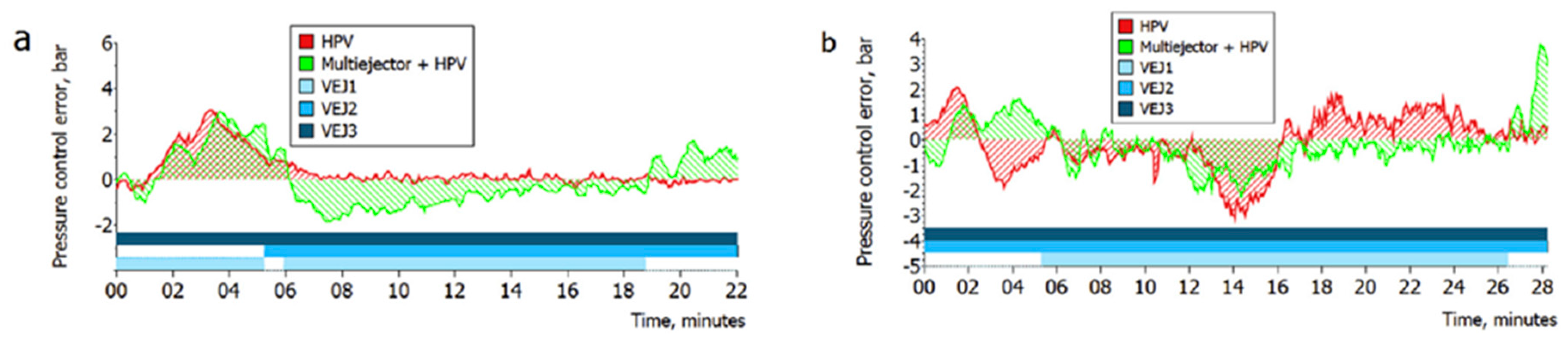

3.4.3. Field Experimental Assessments

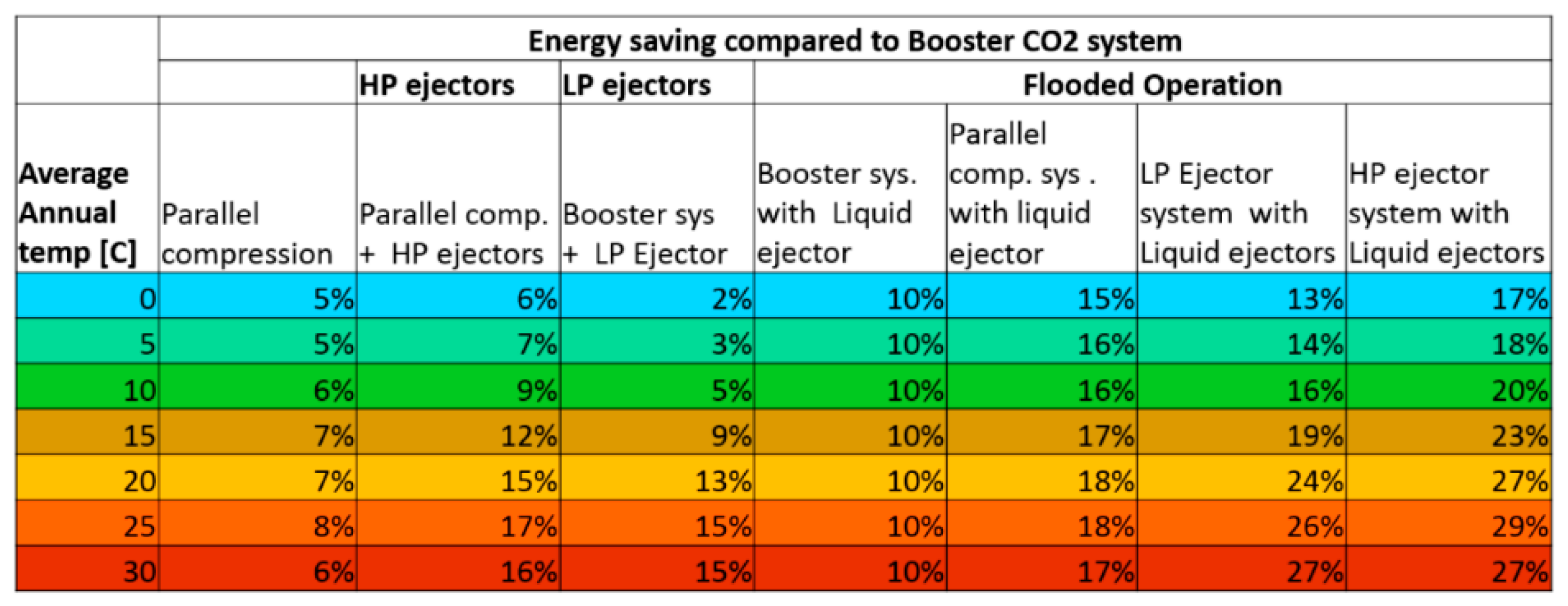

3.5. High Ambient Temperature Countries

4. Other Applications

4.1. Theoretical Assessemnts

4.2. Laboratory Experimental Assessments

5. Conclusions and Future Work

- (1)

- The persevering non-technological barriers, amongst which the lack of awareness of available technologies at decision making level and the lack of trained installers and service technicians [78];

- (2)

- The limited amount of available field measurements and economic evaluations, especially with respect to the latest proposed solutions (i.e., Units relying on two multi-ejector blocks and/or implementing direct heating and cooling fan coils and air curtains). The availability of such information would help to build confidence in these solutions and thus lead to finally open the doors to their market penetration in warm climates as well.

Author Contributions

Funding

Conflicts of Interest

Nomenclature

| Symbols, abbreviations and subscripts/superscripts | |

| AC | Air conditioning |

| COP | Coefficient of Performance (-) |

| DHW | Domestic hot water |

| GWP | Global Warming Potential () |

| h | Enthalpy per unit of mass (kJ·kg−1) |

| HCFC | Hydrochlorofluorocarbon |

| HFC | Hydrofluorocarbon |

| HP | High pressure (bar) |

| HVP | High pressure electronic expansion valve |

| HX | Heat exchanger |

| IHX | Internal heat exchanger |

| IP | Intermediate pressure (bar) |

| LP | Low pressure (bar) |

| LT | Low temperature (°C) |

| Mass flow rate (kg·s−1) | |

| MP | Medium pressure (bar) |

| MT | Medium temperature (°C) |

| ODP | Ozone Depletion Potential |

| p | Pressure (bar) |

| Heat transfer rate (kW) | |

| RC&H | Refrigeration, cooling & heating |

| s | Entropy per unit of mass (kJ·kg−1·K−1) |

| t | Temperature (°C) |

| TEWI | Total Equivalent Warming Impact () |

| Power (kW) | |

| Greek symbols | |

| η | Efficiency [-] |

| Suction pressure ratio [-] | |

| Mass entrainment ratio [-] | |

References

- European Commission. Regulation (EU) No 517/2014 of the European Parliament and of the Council of 16th April 2014 on Fluorinated Greenhouse Gases and Repealing Regulation (EC) No 842/2006; EU: Brussels, Belgium, 2014.

- International Institute of Refrigeration. Newsletter No. 73; International Institute of Refrigeration: Paris, France, 2018. [Google Scholar]

- UNEP. Report of the Twenty-Eighth Meeting of the Parties to the Montreal Protocol on Substances that Deplete the Ozone Layer; UNEP: Kigali, Rwanda, 2016. [Google Scholar]

- Ciconkov, R. Refrigerants: There is still no vision for sustainable solutions. Int. J. Refrig. 2018, 86, 441–448. [Google Scholar] [CrossRef]

- Ge, Y.T.; Tassou, S.A. Thermodynamic analysis of transcritical CO2 booster refrigeration systems in supermarket. Energy Convers. Manag. 2011, 52, 1868–1875. [Google Scholar] [CrossRef]

- Hafner, A. 2020 perspectives CO2 refrigeration and heat pump systems. In Proceedings of the 6th IIR Ammonia and CO2 Refrigeration Technologies Conference, Ohrid, Macedonia, 16–18 April 2015. [Google Scholar]

- De Oña, A.; Gkizelis, A.; Skačanová, K.; Boccabella, E. Global market and policy trends for CO2 and ammonia as natural refrigerants. In Proceedings of the 7th IIR Ammonia and CO2 Refrigeration Technologies Conference, Ohrid, Macedonia, 11–13 May 2017. [Google Scholar]

- Gullo, P.; Hafner, A.; Banasiak, K. Transcritical R744 refrigeration systems for supermarket applications: Current status and future perspectives. Int. J. Refrig. 2018, 93, 269–310. [Google Scholar] [CrossRef]

- Hafner, A.; Poppi, S.; Nekså, P.; Minetto, S.; Eikevik, T.M. Development of commercial refrigeration systems with heat recovery for supermarket building. In Proceedings of the 10th IIR Gustav Lorentzen Conference on Natural Refrigerants, Delft, The Netherlands, 25–27 June 2012. [Google Scholar]

- Hafner, A.; Försterling, S.; Banasiak, K. Multi-ejector concept for R-744 supermarket refrigeration. Int. J. Refrig. 2014, 43, 1–13. [Google Scholar] [CrossRef]

- Cavallini, A.; Zilio, C. Carbon dioxide as a natural refrigerant. Int. J. Low-Carbon Technol. 2007, 2, 225–249. [Google Scholar] [CrossRef] [Green Version]

- Elbel, S.; Lawrence, N. Review of recent developments in advanced ejector technology. Int. J. Refrig. 2016, 62, 1–18. [Google Scholar] [CrossRef]

- Banasiak, K.; Hafner, A.; Haddal, O.; Eikevik, T. Test facility for a multiejector R744 refrigeration system. In Proceedings of the 11th IIR Gustav Lorentzen Conference on Natural Refrigerants, Hangzhou, China, 31 August–2 September 2014. [Google Scholar]

- Elbel, S.; Hrnjak, P. Experimental validation of a prototype ejector design to reduce throttling losses encountered in transcritical R744 system operate. Int. J. Refrig. 2008, 31, 411–422. [Google Scholar] [CrossRef]

- Banasiak, K.; Hafner, A.; Kriezi, E.E.; Madsen, K.B.; Birkelund, M.; Fredslund, K.; Olsson, R. Development and performance mapping of a multi-ejector expansion work recovery pack for R744 vapour compression units. Int. J. Refrig. 2015, 57, 265–276. [Google Scholar] [CrossRef]

- Sever, M. Transcritical CO2 refrigeration systems in all climates. In Proceedings of the ATMOsphere Japan 2018, Tokyo, Japan, 13 February 2018. [Google Scholar]

- Girotto, S. Improved transcritical CO2 refrigeration systems for warm climates. In Proceedings of the 7th IIR Ammonia and CO2 Refrigeration Technologies Conference, Ohrid, Macedonia, 11–13 May 2017. [Google Scholar]

- Marimon, M.A.; Aria, J.; Lundqvist, P.; Bruno, J.C.; Coronas, A. Integration of trigeneration in an indirect cascade refrigeration system in supermarkets. Energy Build. 2011, 43, 1427–1434. [Google Scholar] [CrossRef]

- Karampour, M.; Sawalha, S.; Arias, J. Eco-Friendly Supermket—An Overview, Public Report 2 for SuperSmart Project (Project Number: 696076). 2016. Available online: http://www.supersmart-supermarket.info/downloads/ (accessed on 12 December 2018).

- Nekså, P.; Hafner, A.; Bredesen, A.; Eikevik, T.M. CO2 as working fluid—Technological development on the road to sustainable refrigeration. In Proceedings of the 12th IIR Gustav Lorentzen Natural Working Fluids Conference, Edinburgh, UK, 21–24 August 2016. [Google Scholar]

- Hafner, A.; Banasiak, K.; Fredslund, K.; Girotto, S.; Smolka, J. R744 ejector system case: Italian supermarket, Spiazzo. In Proceedings of the 12th IIR Gustav Lorentzen Natural Working Fluids Conference, Edinburgh, UK, 21–24 August 2016. [Google Scholar]

- Sawalha, S. Investigation of heat recovery in CO2 trans-critical solution for supermarket refrigeration. Int. J. Refrig. 2013, 36, 145–156. [Google Scholar] [CrossRef]

- Ge, Y.T.; Tassou, S.A. Performance evaluation and optimal design of supermarket refrigeration systems with supermarket model “SuperSim”. Part II: Model applications. Int. J. Refrig. 2011, 34, 540–549. [Google Scholar] [CrossRef] [Green Version]

- Ommen, T.; Elmegaard, B. Numerical model for thermoeconomic diagnosis in commercial transcritical/subcritical booster refrigeration systems. Energy Convers. Manag. 2012, 60, 161–169. [Google Scholar] [CrossRef]

- Sawalha, S.; Piscopiello, S.; Karampour, M.; Tamilarasan, M.L.; Rogstam, J. Field Measurements of Supermarket Refrigeration Systems. Part II: Analysis of HFC refrigeration systems and comparison to CO2 trans-critical. Appl. Therm. Eng. 2017, 111, 170–182. [Google Scholar] [CrossRef]

- Karampour, M.; Sawalha, S. Energy efficiency evaluation of integrated CO2 trans-critical system in supermarkets: A field measurements and modelling analysis. Int. J. Refrig 2017, 82, 470–486. [Google Scholar] [CrossRef]

- Purohit, N.; Gullo, P.; Dasgupta, M.S. Comparative assessment of low-GWP based refrigerating plants operating in hot climates. Energy Procedia 2017, 109, 138–145. [Google Scholar] [CrossRef]

- Gullo, P.; Elmegaard, B.; Cortella, G. Advanced exergy analysis of a R744 booster refrigeration system with parallel compression. Energy 2016, 107, 562–571. [Google Scholar] [CrossRef] [Green Version]

- Gullo, P.; Elmegaard, B.; Cortella, G. Energy and environmental performance assessment of R744 booster supermarket refrigeration systems operating in warm climates. Int. J. Refrig. 2016, 64, 61–79. [Google Scholar] [CrossRef] [Green Version]

- Minetto, S.; Brignoli, R.; Zilio, C.; Marinetti, S. Experimental analysis of a new method of overfeeding multiple evaporators in refrigeration systems. Int. J. Refrig. 2014, 38, 1–9. [Google Scholar] [CrossRef]

- Gullo, P.; Cortella, G.; Minetto, S.; Polzot, A. Overfed evaporators and parallel compression in commercial R744 booster refrigeration systems—An assessment of energy benefits. In Proceedings of the 12th IIR Gustav Lorentzen Natural Working Fluids Conference, Edinburgh, UK, 21–24 August 2016. [Google Scholar]

- Polzot, A.; D’Agaro, P.; Gullo, P.; Cortella, G. Modelling commercial refrigeration systems coupled with water storage to improve energy efficiency and perform heat recovery. Int. J. Refrig. 2016, 69, 313–323. [Google Scholar] [CrossRef]

- Polzot, A.; Gullo, P.; D’Agaro, P.; Cortella, G. Performance evaluation of a R744 booster system for supermarket refrigeration, heating and DHW. In Proceedings of the 12th IIR Gustav Lorentzen Natural Working Fluids Conference, Edinburgh, UK, 21–24 August 2016. [Google Scholar]

- Ge, Y.T.; Tassou, S.A. Control optimizations for heat recovery from CO2 refrigeration systems in supermarket. Energy Convers. Manag. 2014, 78, 245–252. [Google Scholar] [CrossRef]

- Reinholdt, L.; Madsen, C. Heat recovery on CO2 systems in supermarkets. In Proceedings of the 9th IIR Gustav Lorentzen Conference on Natural Refrigerants, Sydney, Australia, 12–14 April 2010. [Google Scholar]

- Minetto, S.; Girotto, S.; Rossetti, A.; Marinetti, S. Experience with ejector work recovery and auxiliary compressors in CO2 refrigeration systems. Technological aspects and application perspectives. In Proceedings of the 6th IIR Ammonia and CO2 Refrigeration Technologies Conference, Ohrid, Macedonia, 16–18 April 2015. [Google Scholar]

- Schönenberger, J. Experience with R744 refrigerating systems and implemented multi ejectors and liquid overfeed. In Proceedings of the 12th IIR Gustav Lorentzen Natural Working Fluids Conference, Edinburgh, UK, 21–24 August 2016. [Google Scholar]

- Hafner, A.; Banasiak, K. Full scale supermarket laboratory R744 ejector supported and AC integrated parallel compression unit. In Proceedings of the 12th IIR Gustav Lorentzen Natural Working Fluids Conference, Edinburgh, UK, 21–24 August 2016. [Google Scholar]

- Hafner, A.; Fredslund, K.; Banasiak, K. Next generation R744 refrigeration technology for supermarkets. In Proceedings of the 24th IIR International Congress of Refrigeration, Yokohama, Japan, 16–22 August 2015. [Google Scholar]

- Hafner, A. Integrated CO2 system refrigeration, air conditioning and sanitary hot water. In Proceedings of the 7th IIR Ammonia and CO2 Refrigeration Technologies Conference, Ohrid, Macedonia, 11–13 May 2017. [Google Scholar]

- Girotto, S. Direct space heating and cooling with CO2 refrigerant—A new solution for commercial buildings. In Proceedings of the ATMOsphere Europe 2016, Barcelona, Spain, 19–20 April 2016. [Google Scholar]

- Schönenberger, J.; Hafner, A.; Banasiak, K.; Girotto, S. Experience with ejectors implemented in a R744 booster system operating in a supermarket. In Proceedings of the 11th IIR Gustav Lorentzen Conference on Natural Refrigerants, Hangzhou, China, 31 August–2 September 2014. [Google Scholar]

- Hafner, A.; Schönenberger, J.; Banasiak, K.; Girotto, S. R744 ejector supported parallel vapour compression system. In Proceedings of the 3rd IIR International Conference on Sustainability and Cold Chain, London, UK, 23–25 June 2014. [Google Scholar]

- Minetto, S.; Girotto, S.; Salvatore, M.; Rossetti, A.; Marinetti, S. Recent installations of CO2 supermarket refrigeration system for warm climates: Data from field. In Proceedings of the 3rd IIR International Conference on Sustainability and Cold Chain, London, UK, 23–25 June 2014. [Google Scholar]

- Javerschek, O.; Reichle, M.; Karbiner, J. Influence of ejectors on the selection of compressors in carbon dioxide booster systems. In Proceedings of the 9th International Conference on Compressors and Coolants, Bratislava, Slovakia, 6–8 September 2017. [Google Scholar]

- Bodys, J.; Palacz, M.; Haida, M.; Smolka, J.; Nowak, A.J.; Banasiak, K.; Hafner, A. Full-scale multi-ejector module for a carbon dioxide supermarket refrigeration system: Numerical study of performance evaluation. Energy Convers. Manag. 2017, 138, 312–326. [Google Scholar] [CrossRef]

- Pisano, G. The use of ejectors technology: How to boost efficiency in warm climates—A real example from Italy. In Proceedings of the 13th IIR Gustav Lorentzen Conference on Natural Refrigerants, Valencia, Spain, 18–20 June 2018. [Google Scholar]

- Gullo, P.; Hafner, A.; Cortella, G. Multi-ejector R744 booster refrigerating plant and air conditioning system integration—A theoretical evaluation of energy benefits for supermarket applications. Int. J. Refrig. 2017, 75, 164–176. [Google Scholar] [CrossRef]

- Gullo, P.; Tsamos, K.; Hafner, A.; Ge, Y.; Tassou, S. State-of-the-art technologies for R744 refrigeration systems—A theoretical assessment of energy advantages for European food retail industry. Energy Procedia 2017, 123, 46–53. [Google Scholar] [CrossRef]

- European Commission. ANNEXES to the REPORT FROM THE COMMISSION Assessing the 2022 Requirement to Avoid Highly Global Warming Hydrofluorocarbons in Some Commercial Refrigeration Systems; C(2017) 5230 Final ANNEXES 1 to 2; European Commission: Brussels, Belgium, 2017.

- Gullo, P.; Hafner, A. Comparative assessment of supermarket refrigeration systems using ultra low-GWP refrigerants—Case study of selected American cities. In Proceedings of the 30th International Conference on Efficiency, Cost, Optimisation, Simulation and Environmental Impact of Energy Systems, San Diego, CA, USA, 2–6 July 2017. [Google Scholar]

- Gullo, P.; Tsamos, K.M.; Hafner, A.; Banasiak, K.; Ge, Y.T.; Tassou, S.A. Crossing CO2 equator with the aid of multi-ejector concept: A comprehensive energy and environmental comparative study. Energy 2018, 164, 236–263. [Google Scholar] [CrossRef]

- Madsen, K.B.; Kriezi, E.K. Financial aspects of ejector solutions in supermarket and smaller industrial systems. In Proceedings of the 13th IIR Gustav Lorentzen Conference on Natural Refrigerants, Valencia, Spain, 18–20 June 2018. [Google Scholar]

- Gullo, P.; Hafner, A.; Banasiak, K. Thermodynamic Performance Investigation of Commercial R744 Booster Refrigeration Plants Based on Advanced Exergy Analysis. Energies 2019, 12, 354. [Google Scholar] [CrossRef]

- Fredslund, K.; Kriezi, E.E.; Madsen, K.B.; Birkelund, M.; Olsson, R. CO2 installations with a multi ejector for supermarkets, case studies from various locations. In Proceedings of the 12th IIR Gustav Lorentzen Natural Working Fluids Conference, Edinburgh, UK, 21–24 August 2016. [Google Scholar]

- Haida, M.; Banasiak, K.; Smolka, J.; Hafner, A.; Eikevik, T.M. Experimental analysis of the R744 vapour compression rack equipped with the multi-ejector expansion work recovery module. Int. J. Refrig. 2016, 64, 93–107. [Google Scholar] [CrossRef] [Green Version]

- Pardiñas, A.A.; Hafner, A.; Banasiak, K. Integrated R744 ejector supported parallel compression racks for supermarkets. Experimental results. In Proceedings of the 13th IIR Gustav Lorentzen Conference on Natural Refrigerants, Valencia, Spain, 18–20 June 2018. [Google Scholar]

- Hafner, A.; Hemmingsen, A.K. R744 refrigeration technologies for supermarkets in warm climates. In Proceedings of the 24th IIR International Congress of Refrigeration, Yokohama, Japan, 16–22 August 2015. [Google Scholar]

- Kriezi, E.E.; Fredslund, K.; Birkelund, M.; Banasiak, K.; Hafner, A. R744 multi ejector development. In Proceedings of the 12th IIR Gustav Lorentzen Natural Working Fluids Conference, Edinburgh, UK, 21–24 August 2016. [Google Scholar]

- Kriezi, E.E.; Larsen, L.F.S.; Piscopiello, S.; Madsen, K.B. System efficiency and energy savings with parallel compression and ejectors under flooded conditions. In Proceedings of the 13th IIR Gustav Lorentzen Conference on Natural Refrigerants, Valencia, Spain, 18–20 June 2018. [Google Scholar]

- Pardiñas, A.A.; Hafner, A.; Banasiak, K.; Kvalsik, K.H.; Larsen, L. Strategy for the control of two groups of ejectors operating in parallel in integrated R744 refrigeration systems. In Proceedings of the 13th IIR Gustav Lorentzen Conference on Natural Refrigerants, Valencia, Spain, 18–20 June 2018. [Google Scholar]

- Pardiñas, A.A.; Hafner, A.; Banasiak, K. Novel integrated CO2 vapour compression racks for supermarkets. Thermodynamic analysis of possible system configurations and influence of operational conditions. Appl. Therm. Eng. 2018, 131, 1008–1025. [Google Scholar] [CrossRef]

- Isaac, M.; van Vuuren, D.P. Modeling global residential sector energy demand for heating and air conditioning in the context of climate change. Energy Policy 2009, 37, 507–521. [Google Scholar] [CrossRef]

- Middle East’s First CO2 Supermarket Opens in Jordan. Available online: http://r744.com/articles/8148/ middle_east_first_co2_supermarket_opens_in_jordan?utm_source=mailchimp&utm_medium=email&utm_campaign=Bi-weekly%20Newsletter (accessed on 12 December 2018).

- Kvalsvik, K.H.; Banasiak, K.; Hafner, A. Integrated CO2 refrigeration and AC unit for hot climates. In Proceedings of the 7th IIR Ammonia and CO2 Refrigeration Technologies Conference, Ohrid, Macedonia, 11–13 May 2017. [Google Scholar]

- Singh, S.; Amshith, R.; Prakash, M.M.; Banasiak, K.; Hafner, A.; Nekså, P. Analysis of R744 refrigeration system with liquid ejectors. In Proceedings of the 13th IIR Gustav Lorentzen Conference on Natural Refrigerants, Valencia, Spain, 18–20 June 2018. [Google Scholar]

- Singh, S.; Banasiak, K.; Hafner, A.; Maiya, P.; Nekså, P. Performance evaluation of CO2 ejector system with parallel compressor for supermarket application. In Proceedings of the 17th International Refrigeration and Air Conditioning Conference at Purdue, West Lafayette, IN, USA, 9–12 July 2018. [Google Scholar]

- Blust, S.; Singh, S.; Hafner, A.; Banasiak, K.; Nekså, P. Environment-friendly refrigeration packs for Indian supermarkets: Experimental investigation of energy performance of a multiejector-driven R744 integrated compressor rack. In Proceedings of the 13th IIR Gustav Lorentzen Conference on Natural Refrigerants, Valencia, Spain, 18–20 June 2018. [Google Scholar]

- Singh, S.; Hafner, A.; Banasiak, K.; Maiya, P.; Nekså, P. Experimental evaluation of multi-ejector based CO2 cooling system for supermarkets in tropical zones. In Proceedings of the 17th International Refrigeration and Air Conditioning Conference at Purdue, West Lafayette, IN, USA, 9–12 July 2018. [Google Scholar]

- Nekså, P.; Rekstad, H.; Zakeri, G.; Schiefloe, P.A. CO2-heat pump water heater: Characteristics, system design and experimental results. Int. J. Refrig. 1998, 21, 172–179. [Google Scholar] [CrossRef]

- Nekså, P. CO2 heat pump systems. Int. J. Refrig. 2002, 25, 421–427. [Google Scholar] [CrossRef]

- Cecchinato, L.; Chiarello, M.; Corradi, M. Design and experimental analysis of a carbon dioxide transcritical chiller for commercial refrigeration. Appl. Energy 2010, 87, 2095–2101. [Google Scholar] [CrossRef]

- Minetto, S.; Cecchinato, L.; Brignoli, R.; Marinetti, S.; Rossetti, A. Water-side reversible CO2 heat pump for residential application. Int. J. Refrig. 2016, 63, 237–250. [Google Scholar] [CrossRef]

- Schoenenberger, J.; Fraga, G.R. Experience with industrial refrigerating systems for southern climate. In Proceedings of the 13th IIR Gustav Lorentzen Conference on Natural Refrigerants, Valencia, Spain, 18–20 June 2018. [Google Scholar]

- Boccardi, G.; Botticella, F.; Lillo, G.; Mastrullo, R.; Mauro, A.W.; Trinchieri, R. Thermodynamic Analysis of a Multi-Ejector, CO2, Air-To-Water Heat Pump System. Energy Procedia 2016, 101, 846–853. [Google Scholar] [CrossRef]

- Boccardi, G.; Botticella, F.; Lillo, G.; Mastrullo, R.; Mauro, A.W.; Trinchieri, R. Experimental investigation on the performance of a transcritical CO2 heat pump with multi-ejector expansion system. Int. J. Refrig. 2017, 82, 389–400. [Google Scholar] [CrossRef]

- Singh, S.; Amshith, R.; Prakash, M.M.; Banasiak, K.; Hafner, A.; Nekså, P. Performance Investigation of a Multi-ejector R744 Heat Pump. In Proceedings of the 13th IIR Gustav Lorentzen Conference on Natural Refrigerants, Valencia, Spain, 18–20 June 2018. [Google Scholar]

- Minetto, S.; Marinetti, S.; Saglia, P.; Masson, N.; Rossetti, A. Non-technological barriers to the diffusion of energy-efficient HVAC&R solutions in the food retail sector. Int. J. Refrig. 2018, 86, 422–434. [Google Scholar] [CrossRef]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gullo, P.; Hafner, A.; Banasiak, K.; Minetto, S.; Kriezi, E.E. Multi-Ejector Concept: A Comprehensive Review on its Latest Technological Developments. Energies 2019, 12, 406. https://doi.org/10.3390/en12030406

Gullo P, Hafner A, Banasiak K, Minetto S, Kriezi EE. Multi-Ejector Concept: A Comprehensive Review on its Latest Technological Developments. Energies. 2019; 12(3):406. https://doi.org/10.3390/en12030406

Chicago/Turabian StyleGullo, Paride, Armin Hafner, Krzysztof Banasiak, Silvia Minetto, and Ekaterini E. Kriezi. 2019. "Multi-Ejector Concept: A Comprehensive Review on its Latest Technological Developments" Energies 12, no. 3: 406. https://doi.org/10.3390/en12030406