Numerical Calculation Method of Model Predictive Control for Integrated Vehicle Thermal Management Based on Underhood Coupling Thermal Transmission

Abstract

:1. Introduction

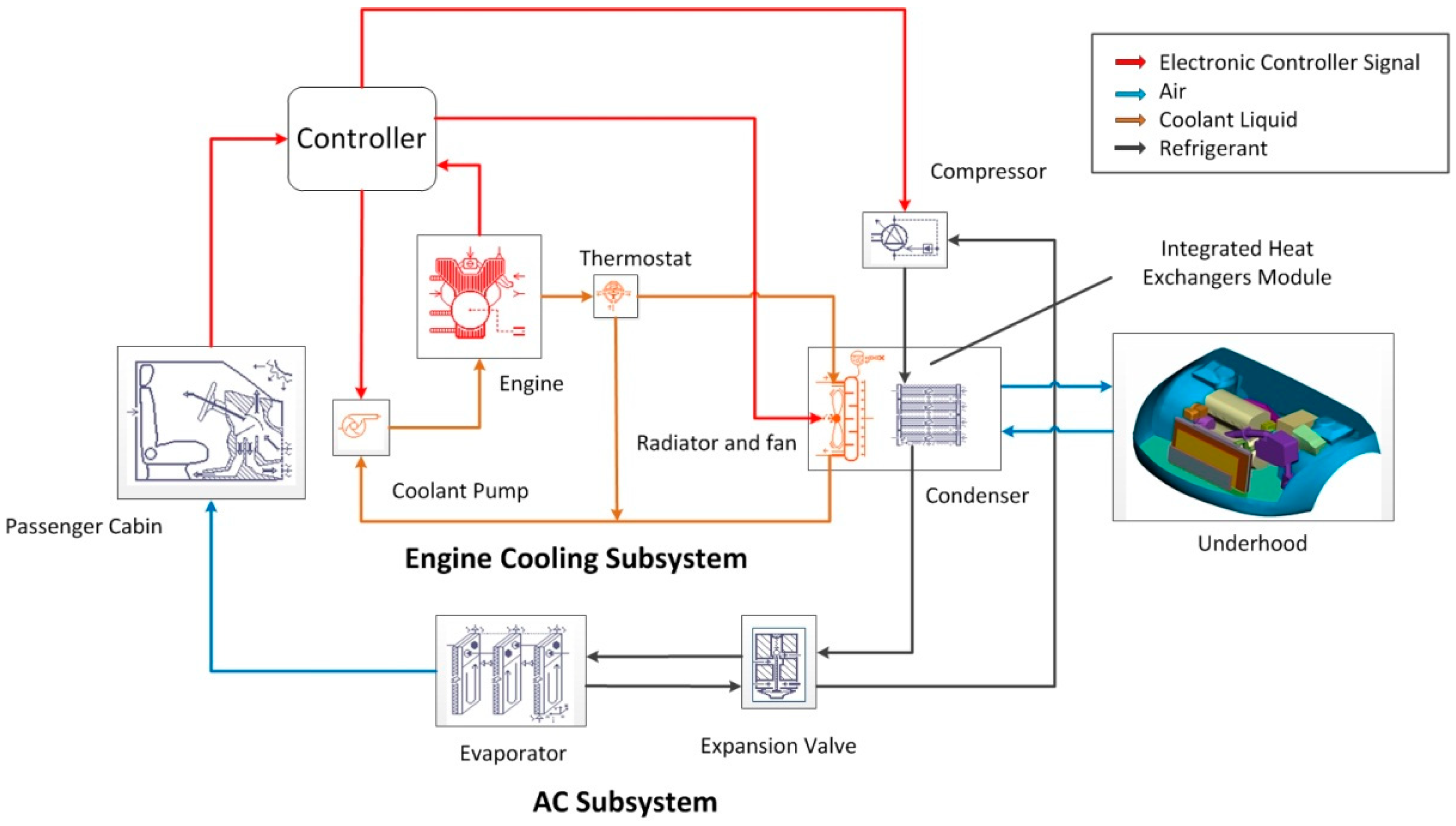

- The technical scheme of the motor driven pump, intelligent fan, electronic thermostat, and electronic control unit (ECU) controller is adopted to replace the mechanical pump and graded speed fan. Converting the passive control mode into the active control mode improves the engine efficiency, emission, and attachment energy consumption and enhances the comprehensive performance of the cooling system [3].

- The air conditioning, oil cooling, and turbo charging intercooling systems are extended into the integrated thermal management system [4]. The mechanism of the complex multiple thermodynamic systems coupling transmission can be studied by applying the computer simulation approach and the wind tunnel test analysis. In addition, the single system verification design can be transformed into a multi-system integration optimization design [5].

1.1. Trend towards Electronic Thermal Management

1.2. Underhood Multi-Thermodynamic System Coupling Thermal Transmission

1.3. Research Content

- (1)

- How to select the reasonable control scheme and control strategy of engine cooling system to improve the temperature control stability of components and the system dynamic responsiveness [30].

- (2)

- How to optimize the structural arrangement in underhood to restrain the harmful thermal interaction of multiple heat exchangers and improve the radiator thermal efficiency [31].

- (3)

- How to evaluate the engine cooling performance effectively to strengthen the matching degree between components and increase the energy efficiency of thermal management system [32].

- Step 1:

- The mechanism mathematical model of engine cooling process was established to provide system state prediction for NMPC controller, and the simulation results were compared with system bench test to verify the reliability of the prediction model.

- Step 2:

- By means of CFD numerical calculation, the complex underhood aerodynamic coupling thermal transmission process was analyzed. Then a multi-system thermal transmission characterization method based on coupling factor was provided to be the coupling thermal boundary condition for the model predictive control process.

- Step 3:

- The NMPC controller of an integrated thermal management system was designed. With determining the controlled parameters, objective function optimization equation and system constraints, the cooperative control of the pump and fan can be realized in the engine cooling process.

- Step 4:

- The temperature control stability and system energy consumption were chosen to be evaluation indices. The thermal control performance comparison and analysis between control schemes of NMPC and PID were carried out. On the above basis, control strategy optimization scheme and underhood thermal transmission structure optimization scheme had been outlined to improve system energy efficiency.

2. Engine Cooling Mechanism Model

2.1. Engine Internal Thermal Transmission Model

2.2. External Cooling Circulation Model

2.3. System Energy Consumption Model

2.4. Model Validation

- (1)

- At the engine starting stage, the thermostat was closed and some coolant remains idle in the radiator cycle but not in the bypass cycle. As a result, the coolant mass determined by the simulation calculation was higher than the actual test value, thereby resulting in a reduced heating rate.

- (2)

- The radiator heat transfer rate of simulation model was calculated based on steady radiator data without considering the actual heat transfer inertia. In addition, temperature response velocity was infinity. This hypothesis is more suitable for the condition of a relatively stable coolant temperature, which resulted in the forward movement of the thermostat opening time.

3. Coupling Thermal Transmission Model of the Underhood Structure

3.1. Underhood CFD Simulation

- Due to fan rotation motion, the standard turbulence equation covered the influencing factors of vorticity in the air rotation domain. Therefore, a more reasonable RNG turbulence transport equation was adopted to improve the accuracy of the flow calculation. In addition, the second order windward discrete scheme was selected to enhance the precision of the simulation results.

- Different grid forms were used to discretize the underhood geometry model. Heat exchangers and other important observation components were divided by the high-quality structural mesh. The complex structures—such as the shell, engine, and fan—adopted a more flexible unstructured grid. In addition, local encryption was carried out on the acute angle boundary and the area with a high extension ratio to guarantee the integrity of the geometric features. Considering the boundary effect of air flow, the wall boundary layer mesh were refined in the following regions, the fan blades, air rotation domain, flow scanning surfaces of radiator, condenser, and engine.

- Based on the test results, the total number of grids was more than 1.5 million. And when the number of iteration steps was exceeded 800, the global calculation precision residuals of CFD model can be controlled within 10−3, and the residuals of the important observation parameters were less than 10−5. Such observation parameters can be temperature, pressure, turbulent dissipation rate, and convection heat transfer coefficient. This simulation also took consideration of grid independence, computational stability, and simulation time. After mesh trials, the model mesh size was finally defined to be 2.5–6.5 mm, the grid number is 1.7 million with a mesh quality of 0.5–0.85. Furthermore, the iterative step number is 900 in the steady simulations.

3.2. Coupling Thermal Transmission Equation

- The thermal transmission interaction of the heat exchangers is only considered and the heat convection of engine block and external environment heat transfer rate are ignored.

- The physical parameters of air were regarded as constant such as the density, specific heat, and thermal conductivity. Therefore, the temperature field in the engine compartment may not affect the air flow and thus may not change the convection heat transfer coefficient of the heat exchanger.

- Assuming an acceptable response speed of the aerodynamic heat transfer, the system dynamic process can be replaced by multiple steady state conditions.

4. Integrated Thermal Management NMPC Control Design

4.1. NMPC Controller Design

4.2. Predictive Model Equation

4.3. Objective Functions and System Constraints

5. NMPC Thermal Management System Performance Evaluation and Optimization

5.1. Performance Comparison of Control Schemes for Integrated Thermal Management System

5.2. NMPC Controller Optimization Design

5.3. Underhood Thermal Transmission Structure Optimization

6. Conclusions

- (1)

- As compared to the traditional engine cooling mode (PID scheme), the NMPC thermal management scheme clearly exhibits better temperature control effects and lower system energy consumption.

- (2)

- The system energy efficiency could be improved by reasonable coordination of air side and liquid side thermal transfer capacity based on engine thermal load.

- (3)

- The influence of coupling thermal transmission should be considered in system control process and it is of great significance for energy consumption reduction to enhance the aerodynamic thermal transmission in underhood.

Author Contributions

Funding

Conflicts of Interest

Nomenclature

| Abbreviation | |

| ECU | Electronic Control Unit |

| IVTM | Integrated Vehicle Thermal Management |

| NEDC | New European Driving Cycle |

| NMPC | Nonlinear Model Predictive Control |

| Symbols | |

| Radiator heat transfer coefficient on the air side () | |

| Radiator heat transfer coefficient on the coolant side () | |

| Coolant to engine block heat transfer coefficient () | |

| Wall to coolant heat transfer coefficient () | |

| Radiator heat transfer area on the air side () | |

| Radiator heat transfer area on the coolant side () | |

| Heat transfer area between coolant and engine block () | |

| Heat transfer area between liner and coolant () | |

| Tube wall heat transfer area () | |

| Thermostat flow area () | |

| Coolant specific heat capacity () | |

| Engine block specific heat capacity () | |

| Liner specific heat capacity () | |

| Thermostat flow coefficient () | |

| Radiator energy efficiency () | |

| Engine revs per cycle () | |

| Air equivalent mass flow ( | |

| Coolant equivalent mass flow ( | |

| Heat emission coefficient () | |

| Pump hydraulic head () | |

| Thermostat relative lift (%) | |

| Coolant mass flow through by-pass circulation ( | |

| Coolant mass flow through the engine ( | |

| Mass of coolant in the engine () | |

| Mass of coolant in the radiator () | |

| Engine block mass () | |

| Liner mass () | |

| Coolant mass flow through the radiator ( | |

| Fan speed () | |

| Pump speed () | |

| Engine flow resistance () | |

| Fan energy consumption () | |

| Effective fan power () | |

| Fan pressure increase () | |

| Pump energy consumption () | |

| Effective pump power () | |

| Radiator flow resistance () | |

| Thermostat throttle resistance in by-pass circulation () | |

| Thermostat throttle resistance in radiator circulation () | |

| Total system energy consumption (W) | |

| Engine block to air heat transfer rate () | |

| Gas combustion exothermic rate () | |

| Coolant to engine block heat transfer rate () | |

| Heat transfer rate due to friction () | |

| Gas to cylinder heat transfer rate () | |

| Coolant to air heat transfer rate in the radiator () | |

| Liner to coolant heat transfer rate () | |

| Determination coefficient () | |

| Radiator intake temperature (°C)) | |

| Coolant temperature at engine inlet () | |

| Coolant temperature at engine outlet (°C) | |

| Coolant reference target temperature (°C)) | |

| Coolant temperature at radiator outlet | |

| Engine block temperature (°C)) | |

| Environment temperature (°C)) | |

| Mean cylinder temperature () | |

| Cylinder reference target temperature (°C)) | |

| Engine displacement () | |

| Vehicle speed () | |

| Fan volume flow () | |

| Pump displacement () | |

| Engine angular speed () | |

| Coolant density () | |

| Tube wall heat conductivity coefficient () | |

| Tube wall thickness () |

References

- Melzer, F.; Hesse, U.; Rocklage, G.; Schmitt, M. Thermomanagement; SAE International: Detroit, MI, USA, 1999. [Google Scholar]

- Wang, Y.; Gao, Q.; Zhang, T.; Wang, G.; Jiang, Z.; Li, Y. Advances in integrated vehicle thermal management and numerical simulation. Energies 2017, 10, 1636. [Google Scholar] [CrossRef]

- Salah, M.H.; Mitchell, T.H.; Wagner, J.R.; Dawson, D.M. Nonlinear-control strategy for advanced vehicle thermal-management systems. IEEE Trans. Veh. Technol. 2008, 57, 127–137. [Google Scholar] [CrossRef]

- Traussnig, A.; Petutschnig, H.; Ennemoser, A.; Stolz, M.; Tizianel, M. Vehicle thermal Management Simulation Method Integrated in the Development Process from Scratch to Prototype; SAE International: Detroit, MI, USA, 2014. [Google Scholar]

- Song, X.; Myers, J.; Sarnia, S. Integrated low temperature cooling system development in turbo charged vehicle application. SAE Int. J. Passeng. Cars Mech. Syst. 2014, 7, 163–173. [Google Scholar] [CrossRef]

- Wagner, J.R.; Ghone, M.C.; Dawson, D.W.; Marotta, E.E. Coolant Flow Control Strategies for Automotive Thermal Management Systems; SAE International: Detroit, MI, USA, 2002. [Google Scholar]

- Butt, S.S.; Prabe, R.; Aschemann, H. Robust nonlinear control of an innovative engine cooling system. IFAC PapersOnLine 2015, 48, 235–240. [Google Scholar] [CrossRef]

- Wang, T.; Wagner, J. Advanced automotive thermal management—Nonlinear radiator fan matrix control. Control Eng. Pract. 2015, 41, 113–123. [Google Scholar] [CrossRef]

- Khaled, M.; Harambat, F.; Hage, H.E.; Peerhossaini, H. Spatial optimization of an underhood cooling module—Towards an innovative control approach. Appl. Energy 2011, 88, 3841–3849. [Google Scholar] [CrossRef]

- Khaled, M.; Mangi, F.; Hage, H.E.; Harambat, F.; Peerhossaini, H. Fan air flow analysis and heat transfer enhancement of vehicle underhood cooling system—Towards a new control approach for fuel consumption reduction. Appl. Energy 2012, 91, 439–450. [Google Scholar] [CrossRef]

- Zhou, B.; Lan, X.D.; Xu, X.H.; Liang, X.G. Numerical model and control strategies for the advanced thermal management system of diesel engine. Appl. Therm. Eng. 2015, 82, 368–379. [Google Scholar] [CrossRef]

- Huang, M.; Nakada, H.; Butts, K.; Kolmanovsky, I. Nonlinear model predictive control of a diesel engine air path: A comparison of constraint handling and computational strategies. IFAC PapersOnLine 2015, 48, 372–379. [Google Scholar] [CrossRef]

- Sowman, J.; Laila, D.S.; Cruden, A.J.; Fussey, P. Nonlinear model predictive control for cold start selective catalytic reduction. IFAC PapersOnLine 2015, 48, 471–476. [Google Scholar] [CrossRef]

- Vermillion, C.; Sun, J.; Butts, K. In Model Predictive Control Allocation—Design and Experimental Results on a Thermal Management System. In Proceedings of the Conference on American Control Conference, St. Louis, MO, USA, 10–12 June 2009; pp. 1365–1370. [Google Scholar]

- Vermillion, C.; Sun, J.; Butts, K. Predictive Control allocation for a thermal management system based on an inner loop reference model—Design, analysis, and experimental results. IEEE Trans. Control Syst. Technol. 2011, 19, 772–781. [Google Scholar] [CrossRef]

- Vermillion, C.; Sun, J.; Butts, K. Modeling, control design, and experimental validation of an overactuated thermal management system for engine dynamometer applications. IEEE Trans. Control Syst. Technol. 2009, 17, 540–551. [Google Scholar] [CrossRef]

- Khodabakhshian, M.; Feng, L.; Börjesson, S.; Lindgärde, O.; Wikander, J.; Khodabakhshian, M.; Feng, L.; Börjesson, S.; Lindgärde, O.; Wikander, J. Reducing auxiliary energy consumption of heavy trucks by onboard prediction and real-time optimization. Appl. Energy 2017, 188, 652–671. [Google Scholar] [CrossRef]

- Sanz, J.L.; Eguilaz, M.M.; Alvarez-Florez, J.; Ruiz-Mansilla, R.; Lux, G.; Kalmus, J.; Graber, M.; Ocampo-Martinez, C. Nonlinear model predictive control for thermal management in plug-in hybrid electric vehicles. IEEE Trans. Veh. Technol. 2016, 66, 3632–3644. [Google Scholar]

- Minovski, B.B.; Lofdahl, L. Study of Software Integration for Transient Simulation of Future Cooling System for heavy Truck Application; SAE International: Detroit, MI, USA, 2014. [Google Scholar]

- Minovski, B. Study of Software System Integration for Transient Simulation of Future Cooling System for Heavy Truck Applications. Bachelor’s Thesis, Chalmers University of Technology, Gothengurg, Sweden, 2013. [Google Scholar]

- Eller, J.; Reister, H.; Binner, T.; Widdecke, N.; Wiedemann, J. A New Approach to Predicting Component Temperature Collectives for Vehicle Thermal Management; SAE International: Detroit, MI, USA, 2017. [Google Scholar]

- Costa, E.A. CFD Approach on Underhood Thermal Management of Passenger Cars and Trucks; SAE International: São Paulo, Brasil, 2003. [Google Scholar]

- Juan, T. Investigation and Assessment of Factors Affecting the Underhood Cooling Air Flow Using CFD; SAE International: Rosemont, IL, USA, 2008. [Google Scholar]

- Zhang, Q.; Xu, L.; Li, J.; Ouyang, M. Performance prediction of proton exchange membrane fuel cell engine thermal management system using 1D and 3D integrating numerical simulation. Int. J. Hydrogen Energy 2018, 43, 1736–1748. [Google Scholar] [CrossRef]

- Moffat, J. Coupling of 1-D and 3-D CFD Models to Predict Transient Hydraulics in an Engine Cooling Circuit; SAE International: Detroit, MI, USA, 2002. [Google Scholar]

- Bayraktar, I. Computational simulation methods for vehicle thermal management. Appl. Therm. Eng. 2012, 36, 325–329. [Google Scholar] [CrossRef]

- Mao, S.; Feng, Z.; Michaelides, E.E. Off-highway heavy-duty truck under-hood thermal analysis. Appl. Therm. Eng. 2010, 30, 1726–1733. [Google Scholar] [CrossRef]

- Wang, G.; Gao, Q.; Zhang, T.; Wang, Y. A simulation approach of under-hood thermal management. Adv. Eng. Softw. 2016, 100, 43–52. [Google Scholar] [CrossRef]

- Lu, P.; Gao, Q.; Wang, Y. The simulation methods based on 1D/3D collaborative computing for the vehicle integrated thermal management. Appl. Therm. Eng. 2016, 104, 42–53. [Google Scholar] [CrossRef]

- Karnik, A.Y.; Fuxman, A.; Bonkoski, P.; Jankovic, M.; Pekar, J. Vehicle powertrain thermal management system using model predictive control. SAE Int. J. Mater. Manuf. 2016, 9, 525–533. [Google Scholar] [CrossRef]

- Lee, H.S.; Cho, C.W.; Seo, J.H.; Lee, M.Y. Cooling performance characteristics of the stack thermal management system for fuel cell electric vehicles under actual driving conditions. Energies 2016, 9, 320. [Google Scholar] [CrossRef]

- Di Battista, D.; Cipollone, R. Improving engine oil warm up through waste heat recovery. Energies 2018, 11, 10. [Google Scholar] [CrossRef]

- Caresana, F.; Bilancia, M.; Bartolini, C.M. Numerical method for assessing the potential of smart engine thermal management: Application to a medium-upper segment passenger car. Appl. Therm. Eng. 2011, 31, 3559–3568. [Google Scholar] [CrossRef] [Green Version]

- Zhang, J.; Xu, Z.; Lin, J.; Lin, Z.; Wang, J.; Xu, T. Thermal characteristics investigation of the internal combustion engine cooling-combustion system using thermal boundary dynamic coupling method and experimental verification. Energies 2018, 11, 2127. [Google Scholar] [CrossRef]

- Pang, L.; Li, S.; Liu, M.; Rong, A.; Li, A.; Meng, F. Influence of the design parameters of a fuel thermal management system on its thermal endurance. Energies 2018, 11, 1677. [Google Scholar] [CrossRef]

- Chastain, J.H.; Wagner, J.R. Advanced Thermal Management for Internal Combustion Engines—Valve Design, Component Testing and Block Redesign; SAE International: Detroit, MI, USA, 2006. [Google Scholar]

- Guo, L. Pumps and Fans; Water Resources and Electric Power Press Publishing: Chongqing, China, 1986. [Google Scholar]

- Saha, R.; Madurai Kumar, M.; Hwang, L.K.; Wang, X.; Zhang, F.; Zhang, X.; Yagui, L.; Sun, W.; Wang, Y.; Cheng, W.; et al. Analysis and Design Validation of Medium Duty Truck Cooling System; SAE International: Detroit, MI, USA, 2016. [Google Scholar]

- Minovski, B.B.; Lofdahl, L.; Gullberg, P. A 1D Method for Transient Simulations of Cooling Systems with Non-Uniform Temperature and Flow Boundaries Extracted from a 3D CFD Solution; SAE International: Detroit, MI, USA, 2015. [Google Scholar]

- Chang, Y.J.; Hsu, K.C.; Lin, Y.T.; Wang, C.C. A generalized friction correlation for louver fin geometry. Int. J. Heat Mass Transf. 2000, 43, 2237–2243. [Google Scholar] [CrossRef]

- Khaled, M.; Ramadan, M.; El-Hage, H.; Elmarakbi, A.; Harambat, F.; Peerhossaini, H. Review of underhood aerothermal management: Towards vehicle simplified models. Appl. Therm. Eng. 2014, 73, 842–858. [Google Scholar] [CrossRef]

- Kim, H.J.; Kim, C.J. A numerical analysis for the cooling module related to automobile air-conditioning system. Appl. Therm. Eng. 2008, 28, 1896–1905. [Google Scholar] [CrossRef]

- Kumar, V.; Shendge, S.A.; Baskar, S. Underhood Thermal Simulation of a Small Passenger Vehicle with Rear Engine Compartment to Evaluate and Enhance Radiator Performance; SAE International: Detroit, MI, USA, 2010. [Google Scholar]

- Lu, Y.H.; Sun, P.; Chen, C. Model Predictive Control for Engine Thermal Management with Electronic Fan. In Proceedings of the International Symposium on Electric Vehicles, Stockholm, Sweden, 26–29 July 2017; pp. 26–29. [Google Scholar]

- Setlur, P.; Wagner, J.R.; Dawson, D.M.; Marotta, E. An Advanced Engine Thermal Management System: Nonlinear Control and Test. IEEE/ASME Trans. Mechatron. 2005, 10, 210–220. [Google Scholar] [CrossRef]

- Page, R.W.; Hnatczuk, W.J.; Kozierowski, J. Thermal Management for the 21st Century—Improved Thermal Control & Fuel Economy in an Army Medium Tactical Vehicle; SAE International: Toronto, ON, Canada, 2005. [Google Scholar]

- Yan, Q. Analysis of Under-Hood Aerodynamic Cooling Process Coupling Air Conditioning System. Bachelor’s Thesis, Jilin University, Changchun, China, 2012. [Google Scholar]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lu, P.; Gao, Q.; Lv, L.; Xue, X.; Wang, Y. Numerical Calculation Method of Model Predictive Control for Integrated Vehicle Thermal Management Based on Underhood Coupling Thermal Transmission. Energies 2019, 12, 259. https://doi.org/10.3390/en12020259

Lu P, Gao Q, Lv L, Xue X, Wang Y. Numerical Calculation Method of Model Predictive Control for Integrated Vehicle Thermal Management Based on Underhood Coupling Thermal Transmission. Energies. 2019; 12(2):259. https://doi.org/10.3390/en12020259

Chicago/Turabian StyleLu, Pengyu, Qing Gao, Liang Lv, Xiaoye Xue, and Yan Wang. 2019. "Numerical Calculation Method of Model Predictive Control for Integrated Vehicle Thermal Management Based on Underhood Coupling Thermal Transmission" Energies 12, no. 2: 259. https://doi.org/10.3390/en12020259