Design and Validation of Ultra-Fast Charging Infrastructures Based on Supercapacitors for Urban Public Transportation Applications

Abstract

:1. Introduction

- Overnight charging method. In this case, the electric buses are equipped with a huge energy storage system in order to satisfy the bus routes during the day. The large storage system (i.e., for a 12 m bus there are about 350 kWh of lithium batteries) must be recharged during the night (in about 6 h).

- Route charging method. In this method, the buses are charging in the bus-station during each break at the end of the routes. The charging time takes only 10–15 min. Compared to the previous method, the energy storage system is significantly reduced (i.e., for a 12 m bus there are about 40–60 kWh of lithium batteries), whereas the charging infrastructure is more stressed than the overnight charger due to the higher power requests. Thus, in this case, the advantage is the smaller energy storage system onboard the buses, leading to less costs.

- Flash charging method. In this case, the electric bus recharges at bus stops in just a few seconds. In fact, the charging time takes only 20–30 s (when the passengers are getting on the bus). Then, each time the buses come to the final stop throughout the day, it quickly recharges. The energy storage system on board the bus is smaller than in previous cases (i.e., for a 12 m bus there are about 1–2 kWh of lithium batteries). Since the charge/discharge are carried out at high power, the energy storage system is composed of supercapacitors instead of batteries. Consequently, the supercapacitors are used to realize charging infrastructure. Using this method, the costs are drastically reduced due to the smaller energy storage system on board the bus compared to the previous methods.

2. The Pantograph Equipped Vehicle

- Maximum operating voltage: 1000 V;

- Continuous charging current: 150 A (6 h);

- Maximum charging current: 1000 A (15 min);

- Service life: 100,000 cycles.

3. Charging Architecture

- (1)

- The charging time at every bus-stop must be less than the pick-up and drop-off times of the passengers. The acceptable charging time is fixed at 30 s;

- (2)

- The charging station supercapacitors must be rapidly charged. A maximum charging time is set at 3 min;

- (3)

- The charging station must charge the electric bus even if the bus storage system has a different voltage from the designed value. The bus energy consumption is not constant during its route, depending on traffic and passenger load. Consequently, the charging station must be able to charge the bus independently of the state of the charge of the onboard supercapacitors;

- (4)

- A ground storage is required to reduce the peak power demanded of the power grid.

4. Results

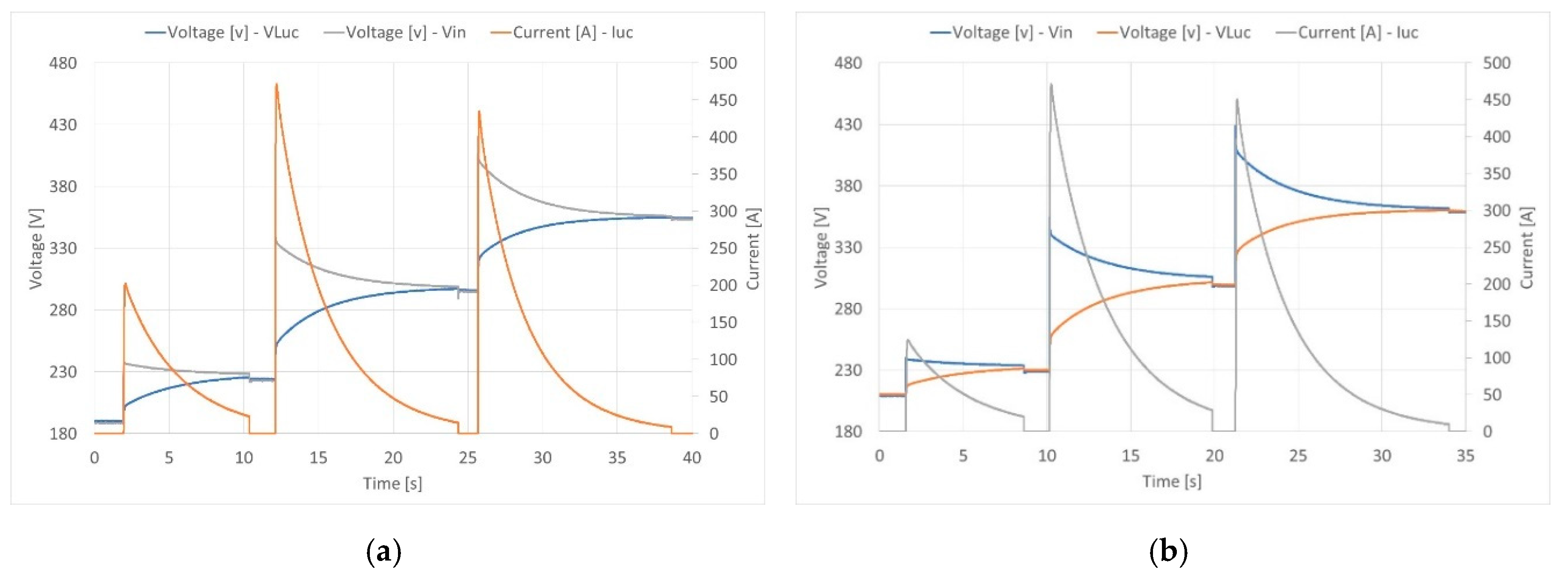

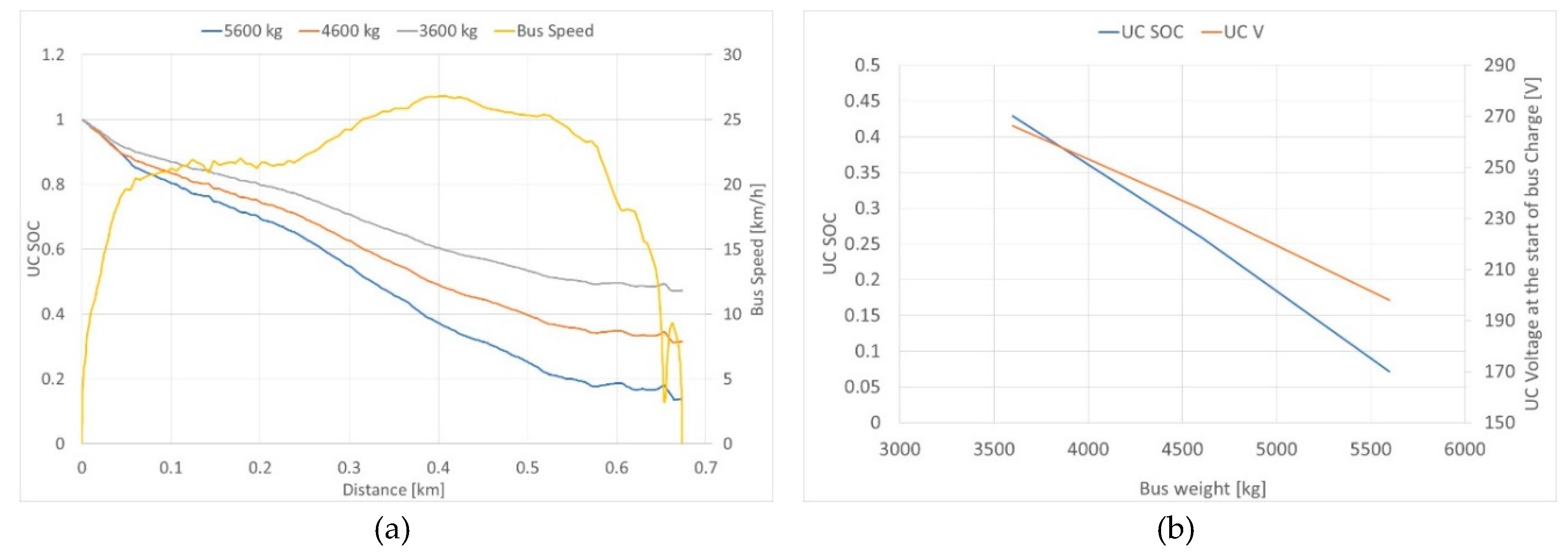

- Verifying that the charging process is completed within a prefixed time: At this stage the charging process is non-automatized, so from one step to the following one there could be a delay that could be easily removed in the future. The end of each step and the start of the following one is set to when the current falls below a threshold value of 20 A.

- Verifying that the ground supercapacitors are fully recharged in a fixed period of time in order to be ready to charge the next bus.

- Verifying that the maximum current and voltage do not exceed the nominal ones: every supercapacitor module has a nominal voltage of 125 V, but only half of this value is used. Hence, the maximum charge voltage is 375 V, while the minimum voltage is 187.5 V

- Verifying that the charging station is able to charge the bus even if the bus storage has a supercapacitor voltage different from the minimum allowed. The bus energy consumption is not constant during the route, depending on traffic, path, and pay-load. Accordingly, the charging station must be able to charge the onboard energy storage even if it is not completely discharged.

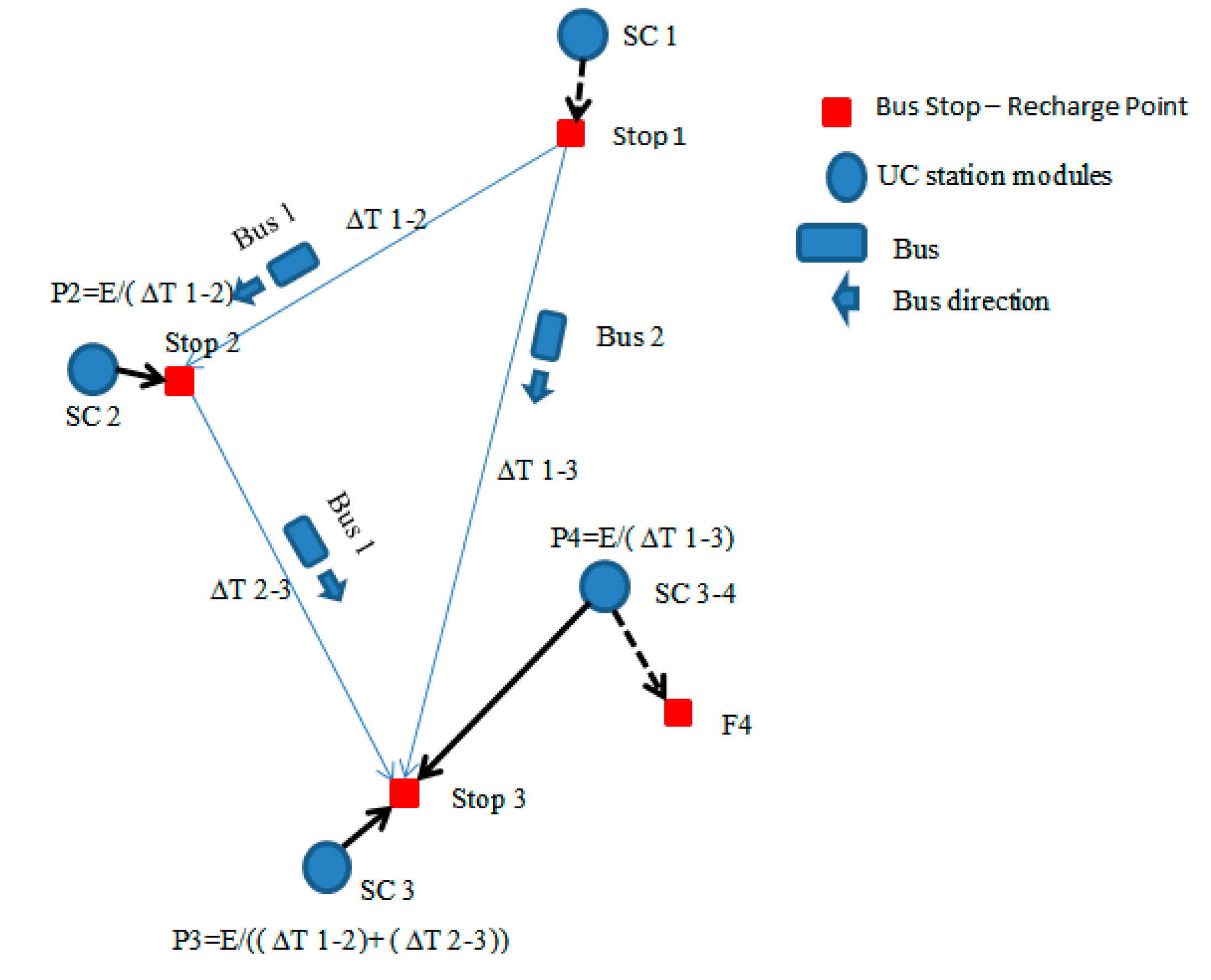

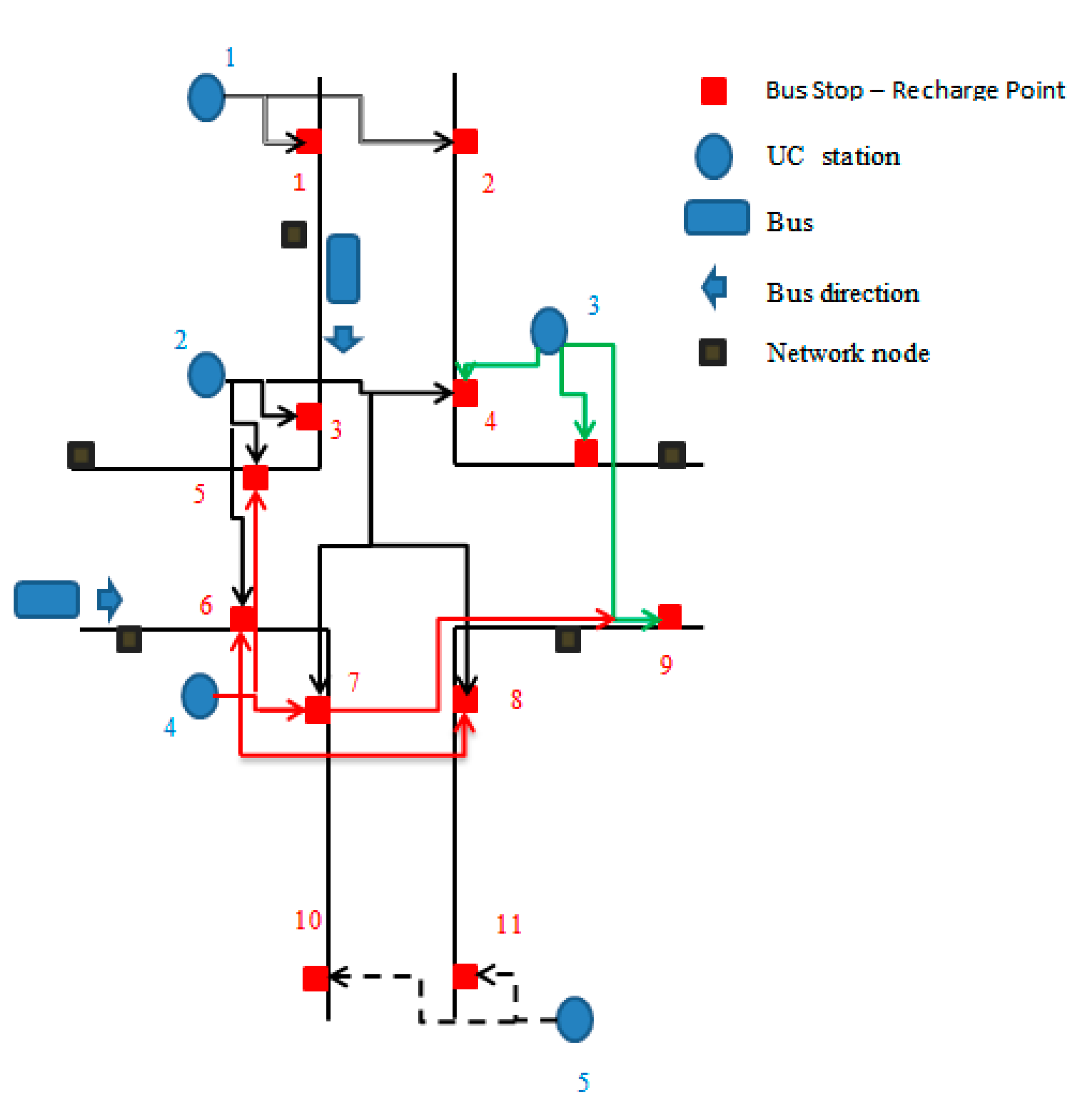

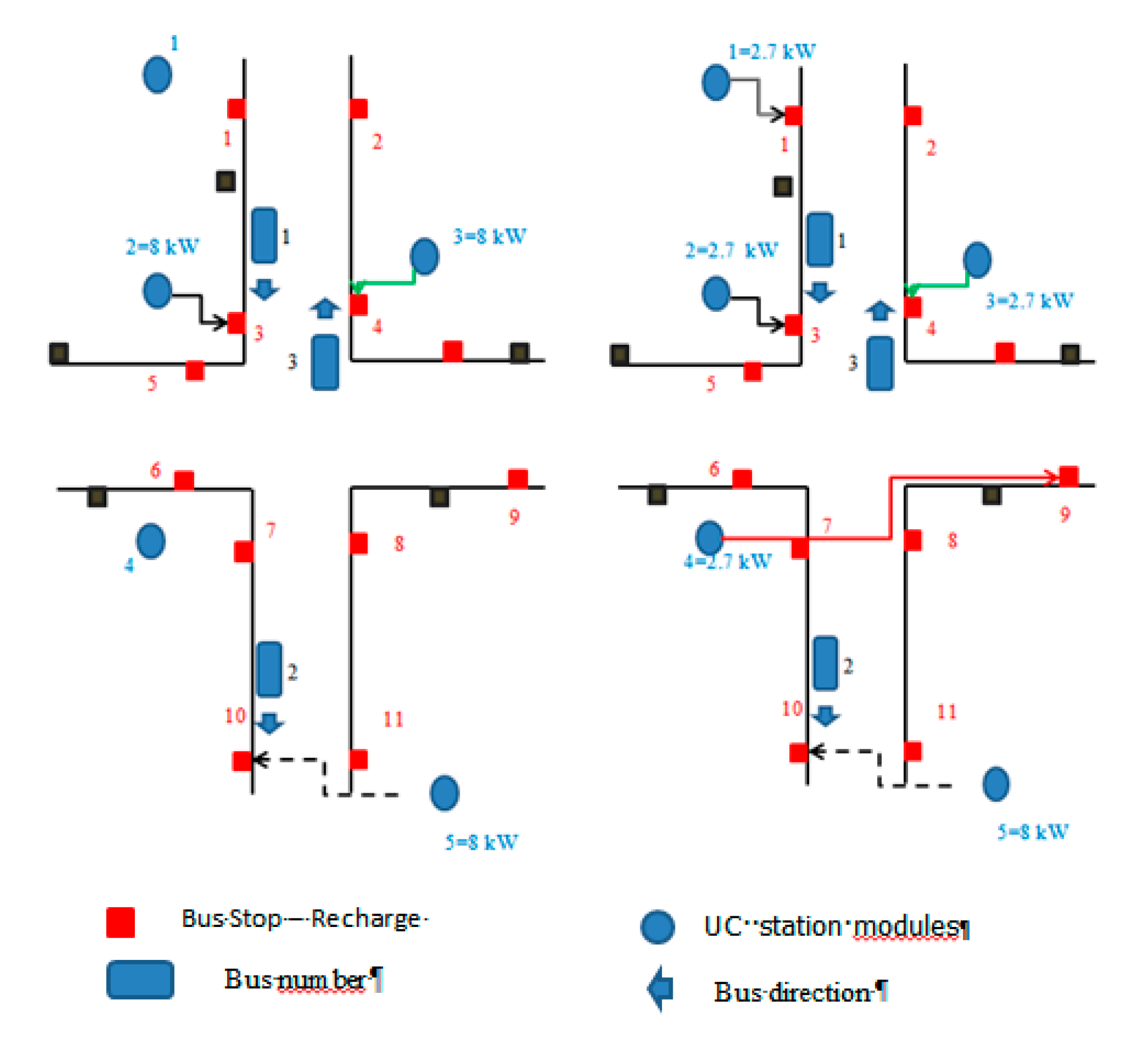

5. Structure of a Charging Network and its Management

- the distance between the different bus stops;

- the frequency of passing buses;

- the presence of transformation stations near the stops.

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Su, C.; Yu, J.; Chin, H.; Kuo, C. Evaluation of power-quality field measurements of an electric bus charging station using remote monitoring systems. In Proceedings of the 2016 10th International Conference on Compatibility, Power Electronics and Power Engineering (CPE-POWERENG), Bydgoszcz, Poland, 29 June–1 July 2016; pp. 58–63. [Google Scholar]

- Varghese, A.S.; Thomas, P.; Varghese, S. An efficient voltage control strategy for fast charging of plug-in electric vehicle. In Proceedings of the 2017 Innovations in Power and Advanced Computing Technologies (i-PACT), Vellore, India, 21–22 April 2017; pp. 1–4. [Google Scholar]

- Yu, H.; Cheli, F.; Castelli-Dezza, F. Optimal Design and Control of 4-IWD Electric Vehicles Based on a 14-DOF Vehicle Model. IEEE Trans. Veh. Technol. 2018, 67, 10457–10469. [Google Scholar] [CrossRef] [Green Version]

- You, P.; Yang, Z.; Zhang, Y.; Low, S.H.; Sun, Y. Optimal Charging Schedule for a Battery Switching Station Serving Electric Buses. IEEE Trans. Power Syst. 2016, 31, 3473–3483. [Google Scholar] [CrossRef]

- Nademi, H.; Zadeh, M.; Undeland, T. Interfacing an Electric Vehicle to the Grid with Modular Conversion Unit: A Case Study of a Charging Station and its Control Framework. In Proceedings of the IECON 2018—44th Annual Conference of the IEEE Industrial Electronics Society, Washington, DC, USA, 21–23 October 2018; pp. 5171–5176. [Google Scholar]

- Ríos, M.A.; Muñoz, L.E.; Zambrano, S.; Albarracín, A. Load profile for a bus rapid transit flash station of full-electric buses. In Proceedings of the IEEE PES Innovative Smart Grid Technologies, Europe, Istanbul, Turkey, 12–15 October 2014; pp. 1–6. [Google Scholar]

- Vepsäläinen, J.; Baldi, F.; Lajunen, A.; Kivekäs, K.; Tammi, K. Cost-Benefit Analysis of Electric Bus Fleet with Various Operation Intervals. In Proceedings of the 2018 21st International Conference on Intelligent Transportation Systems (ITSC), Maui, HI, USA, 4–7 November 2018; pp. 1522–1527. [Google Scholar]

- Rahbari-Asr, N.; Chow, M. Cooperative Distributed Demand Management for Community Charging of PHEV/PEVs Based on KKT Conditions and Consensus Networks. IEEE Trans. Ind. Inform. 2014, 10, 1907–1916. [Google Scholar] [CrossRef]

- Zhai, N.S.; Yao, Y.Y.; Zhang, D.I.; Xu, D.G. Design and Optimization for a Supercapacitor Application System. In Proceedings of the 2006 International Conference on Power System Technology, Chongqing, China, 22–26 October 2006; pp. 1–4. [Google Scholar]

- Conti, V.; Orchi, S.; Valentini, M.P. Upgrading del sistema di supporto alle decisioni relativo all’elettrificazione di singole linee di trasporto pubblico locale. Rome, Italy, RdS/PAR2016/226. Available online: http://www.enea.it/it/Ricerca_sviluppo/documenti/ricerca-di-sistema-elettrico/adp-mise-enea-2015-2017/accumulo-di-energia/rds_par2015-193.pdf (accessed on 20 May 2019).

- Rossi, E.; Villante, C. A hybrid city car. IEEE Veh. Technol. Mag. 2011, 6, 24–37. [Google Scholar] [CrossRef]

- Conte, M.; Genovese, A.; Ortenzi, F.; Vellucci, F. Hybrid battery-supercapacitor storage for an electric forklift: A life-cycle cost assessment. J. Appl. Electrochem. 2014, 44, 523–532. [Google Scholar] [CrossRef]

- Ortenzi, F.; Pede, G.; Rossi, E. Lithium-Ion/Supercapacitors Storage System Powered Microcar: Development and Testing. Energy Procedia 2015, 81, 422–429. [Google Scholar] [CrossRef] [Green Version]

- Ortenzi, F.; Orchi, S.; Pede, G. Technical and economical evaluation of hybrid flash-charging stations for electric public transport. In Proceedings of the 2017 IEEE International Conference on Industrial Technology (ICIT), Toronto, ON, Canada, 22–25 March 2017; pp. 549–554. [Google Scholar]

- Ortenzi, F.; Orchi, S.; Pede, G. Technical and Economical Evaluation of Hybrid Fast-Charging Stations for Electric Public Transport. In Proceedings of the Evs30—Electric Vehicle Symposium & Exhibition, Stuttgart, Germany, 9–11 October 2017. [Google Scholar]

- Ortenzi, F.; Pede, M.P.G.; Lidozzi, A.; di Benedetto, M. Ultra-fast charging infrastructure for vehicle on-board ultracapacitors in urban public transportation applications. In Proceedings of the EVS31—The 31st International Electric Vehicles Symposium & Exhibition & International Electric Vehicle Technology Conference 2018, Kobe, Japan, 30 September–3 October 2018. [Google Scholar]

- di Rienzo, R.; Baronti, F.; Vellucci, F.; Cignini, F.; Ortenzi, F.; Pede, G.; Roncella, R.; Saletti, R. Experimental Analysis of an Electric Minibus with Small Battery and Fast Charge Policy. In Proceedings of the ESARS-ITEC 2016, Toulouse, France, 2–4 November 2016. [Google Scholar]

- Alessandrini, A.; Cignini, F.; Ortenzi, F.; Pede, G.; Stam, D. Advantages of retrofitting old electric buses and minibuses. Energy Procedia 2017, 126, 995–1002. [Google Scholar] [CrossRef]

- Alessandrini, A.; Barbieri, R.; Berzi, L.; Cignini, F.; Genovese, A.; Locorotondo, E.; Ortenzi, F.; Pierini, M.; Pugi, L. Design of a Hybrid Storage for Road Public Transportation Systems. In Advances in Italian Mechanism Science. IFToMM ITALY 2018; Mechanisms and Machine Science; Carbone, G., Gasparetto, A., Eds.; Springer: Cham, Switzerland, 2019; Volume 68. [Google Scholar]

| Parameter | Stock Version | Flash Charge Version |

|---|---|---|

| Length | 5.3 m | |

| Passengers | 28 | |

| Max Speed | 33 km/h | |

| Electric Motor | 235 Nm@950 Rpm 24.8 kW@1035 Rpm | |

| Auxiliaries consumption | ~0.9 kW | |

| Weight (kg) | 4285 (Tare)–6045 (Gross) | 3500 (Tare)–6045 (Gross) |

| Storage | Lead Acid 72V/585 Ah (42.1 kWh) | Lead Acid: 72V/120 Ah (8.6 kWh) Supercapacitors: 375V 63F (410 Wh) |

| L = 5.4 mH |

| Resistance = 0.155 Ω |

| Maximum Current = 500 A |

| Ku = 0.5 |

| IRMS = 187 A |

| Number Step | Recharge Time [s] | Max Current [A] | Vcbus Final [V] | ΔEuc Bus [kWh] |

|---|---|---|---|---|

| 1 | 24 | 1152 | 343.7 | 43.58 |

| 3 | 40 | 513 | 370.7 | 53.69 |

| Time (min) | 0 | 3 | 6 | 9 | 12 | 15 |

|---|---|---|---|---|---|---|

| Bus 1 | N | 1 | N | 3 | N | 9 |

| Bus 2 | N | 6 | 7 | 10 | N | N |

| Bus 3 | N | 11 | N | 4 | 2 | N |

| Bus 4 | N | N | 11 | N | N | 9 |

| Time (min) | C1 (kW) | C1F | C2 (kW) | C2F | C3 (kW) | C3F | C4 (kW) | C4F | C5 (kW) | C5F |

|---|---|---|---|---|---|---|---|---|---|---|

| 0 | 8 | 1 | 8 | 6 | 0 | 0 | 0 | 0 | 8 | 11 |

| 3 | 0 | 0 | 0 | 0 | 0 | 0 | 8 | 7 | 8 | 11 |

| 6 | 0 | 0 | 8 | 3 | 8 | 4 | 0 | 0 | 8 | 10 |

| 9 | 8 | 2 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| 12 | 0 | 0 | 0 | 0 | 8 | 9 | 8 | 9 | 0 | 0 |

| 15 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| Time (min) | C1 (kW) | C1F | C2 (kW) | C2F | C3 (kW) | C3F | C4 (kW) | C4F | C5 (kW) | C5F |

|---|---|---|---|---|---|---|---|---|---|---|

| 0 | 8 | 1 | 2.7 | 3 | 2.7 | 4 | 8 | 6 | 8 | 11 |

| 3 | 2.7 | 2 | 2.7 | 3 | 2.7 | 4 | 8 | 7 | 8 | 11 |

| 6 | 2.7 | 2 | 2.7 | 3 | 2.7 | 4 | 2.7 | 9 | 8 | 10 |

| 9 | 2.7 | 2 | 0 | 0 | 4 | 9 | 2.7 | 9 | 0 | 0 |

| 12 | 0 | 0 | 0 | 0 | 4 | 9 | 2.7 | 9 | 0 | 0 |

| 15 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ortenzi, F.; Pasquali, M.; Prosini, P.P.; Lidozzi, A.; Di Benedetto, M. Design and Validation of Ultra-Fast Charging Infrastructures Based on Supercapacitors for Urban Public Transportation Applications. Energies 2019, 12, 2348. https://doi.org/10.3390/en12122348

Ortenzi F, Pasquali M, Prosini PP, Lidozzi A, Di Benedetto M. Design and Validation of Ultra-Fast Charging Infrastructures Based on Supercapacitors for Urban Public Transportation Applications. Energies. 2019; 12(12):2348. https://doi.org/10.3390/en12122348

Chicago/Turabian StyleOrtenzi, Fernando, Manlio Pasquali, Pier Paolo Prosini, Alessandro Lidozzi, and Marco Di Benedetto. 2019. "Design and Validation of Ultra-Fast Charging Infrastructures Based on Supercapacitors for Urban Public Transportation Applications" Energies 12, no. 12: 2348. https://doi.org/10.3390/en12122348