Effect of Densification Conditions on Specific Energy Requirements and Physical Properties of Compacts Made from Hop Cone

Abstract

:1. Introduction

2. Materials and Methods

2.1. Hop Cones Characterization

2.2. Hydraulic Compacts Press

2.3. Compacts Production and Specific Compression Energy Calculation

2.4. Compacts Durability

2.5. Statistical Analysis

3. Results and Discussion

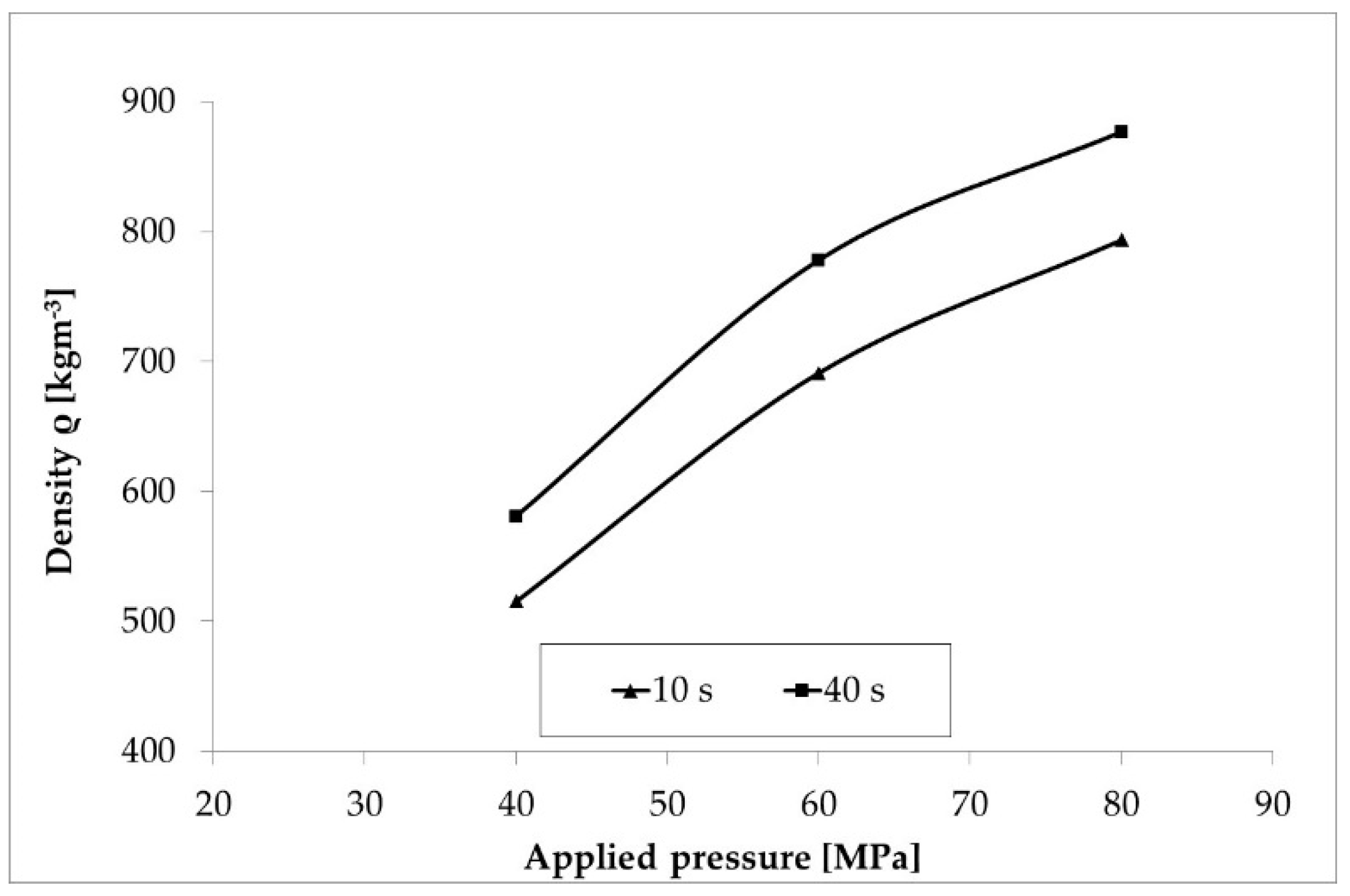

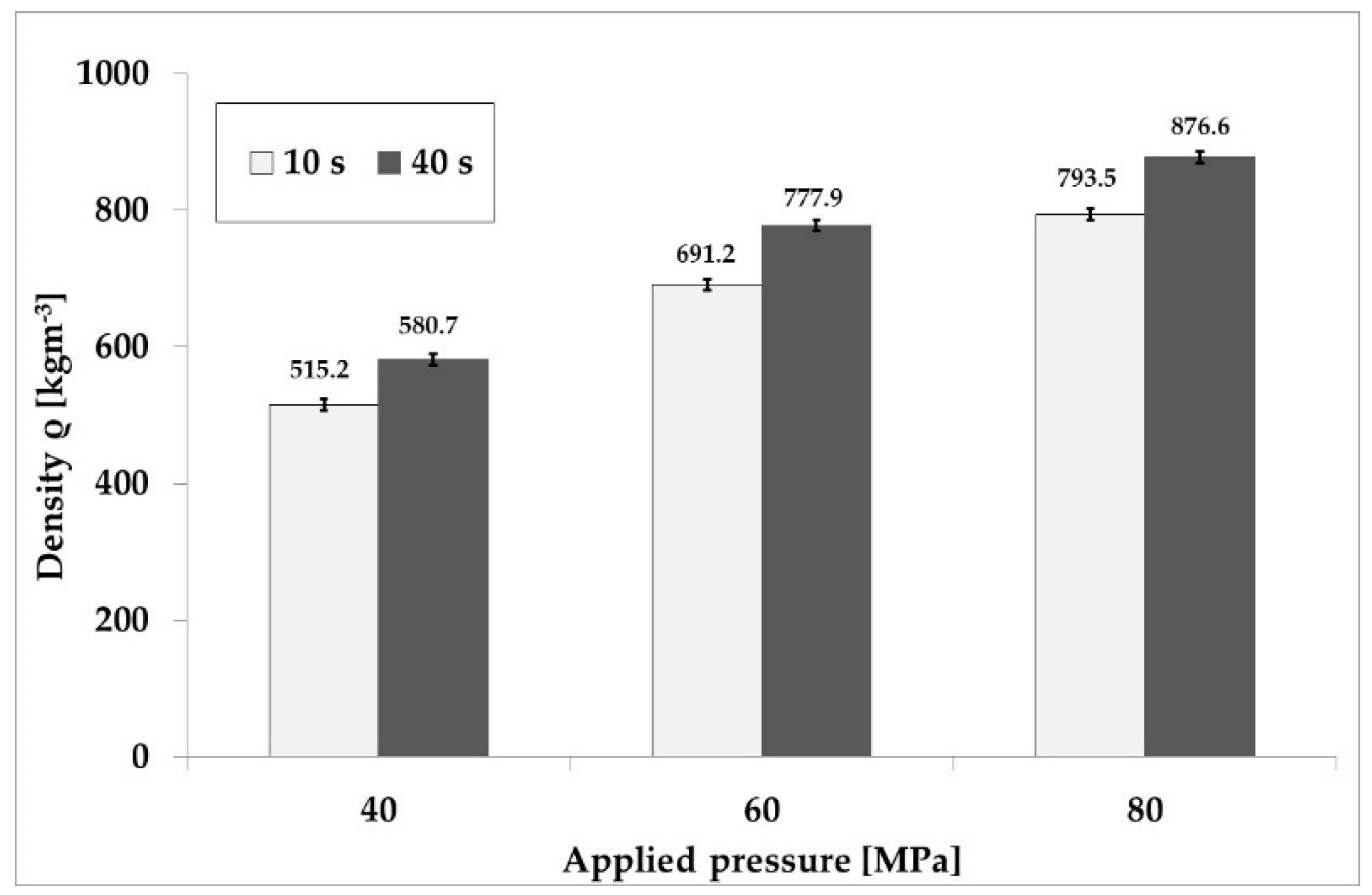

3.1. Compacts Density

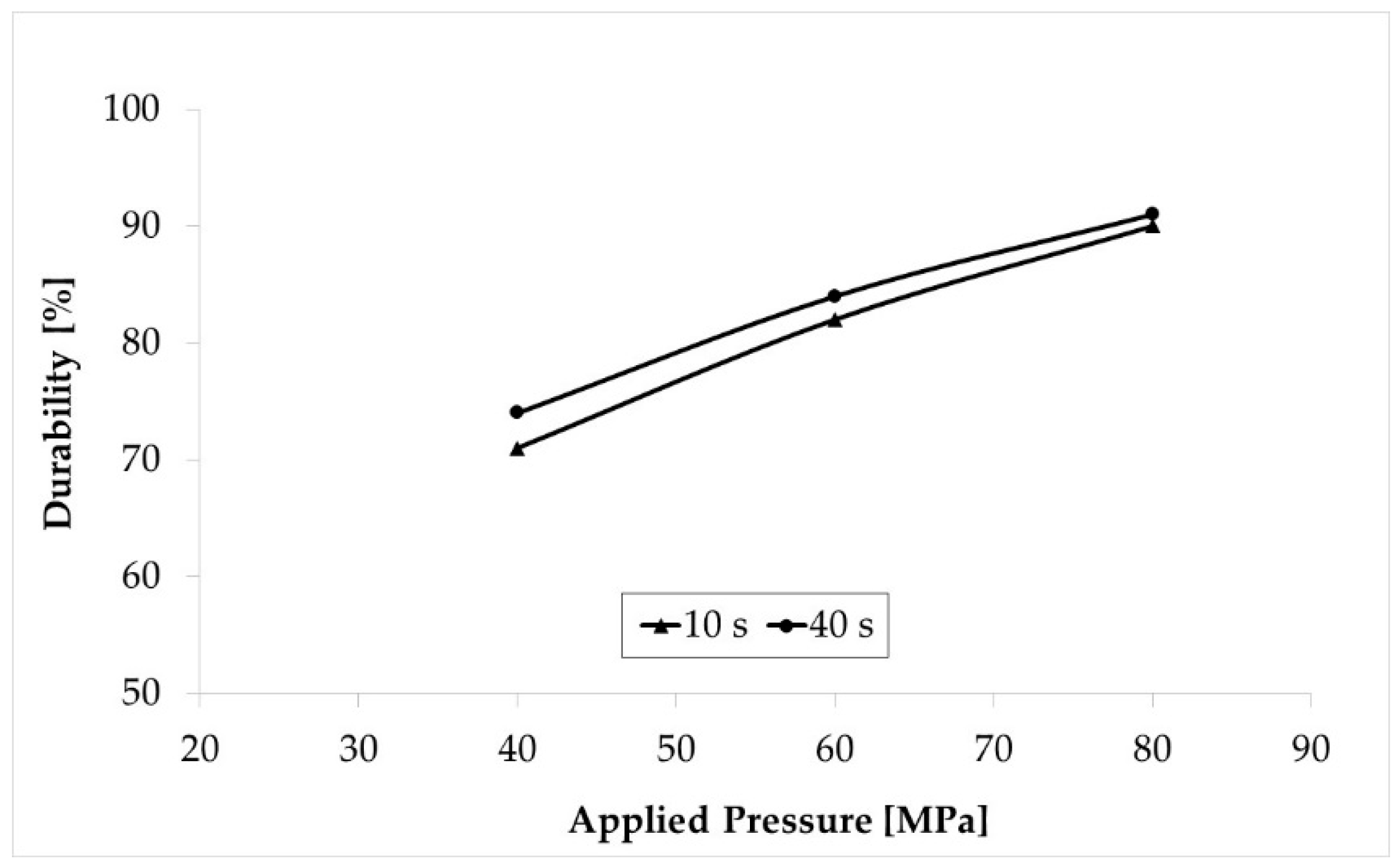

3.2. Compacts Durability

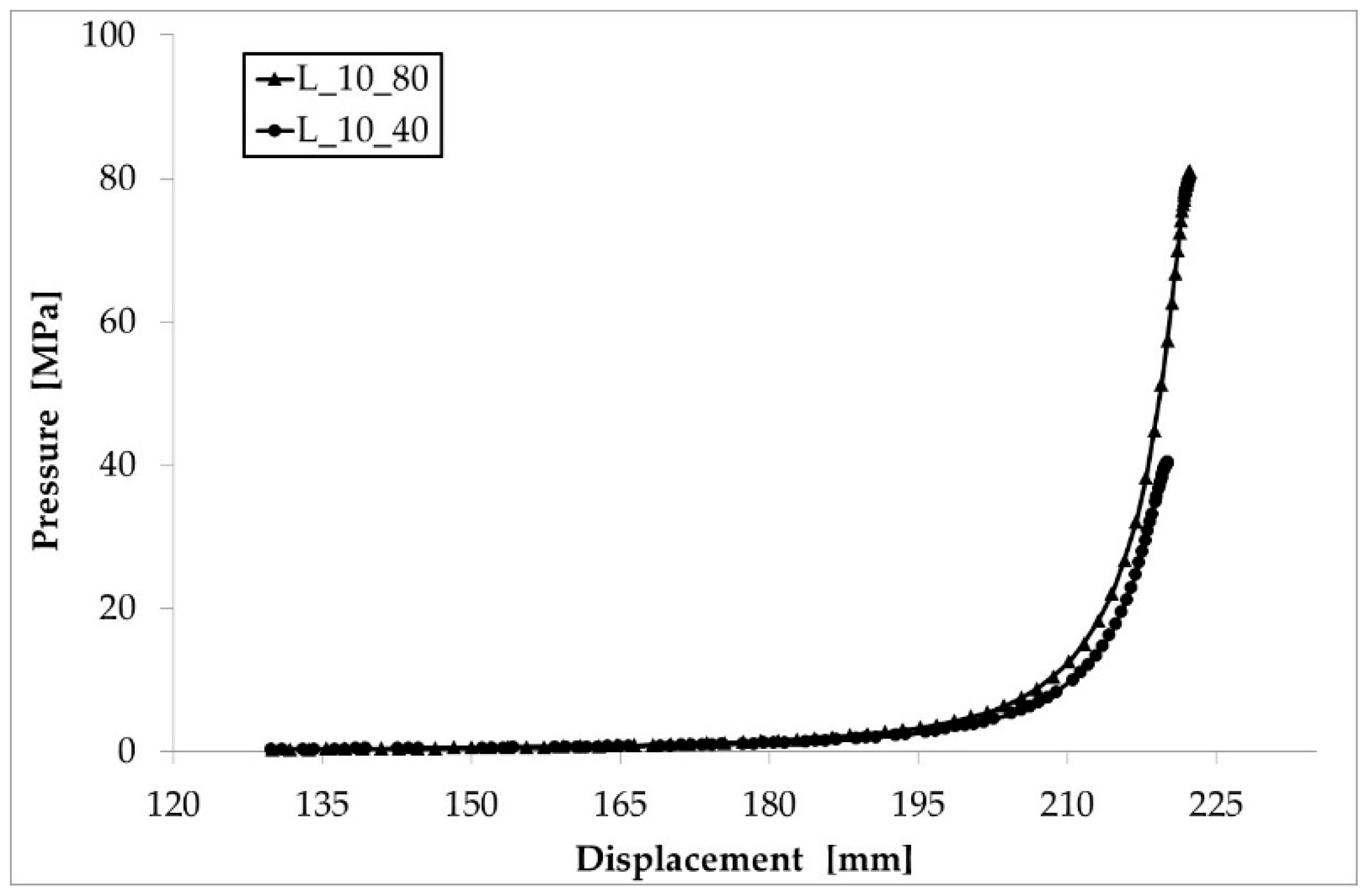

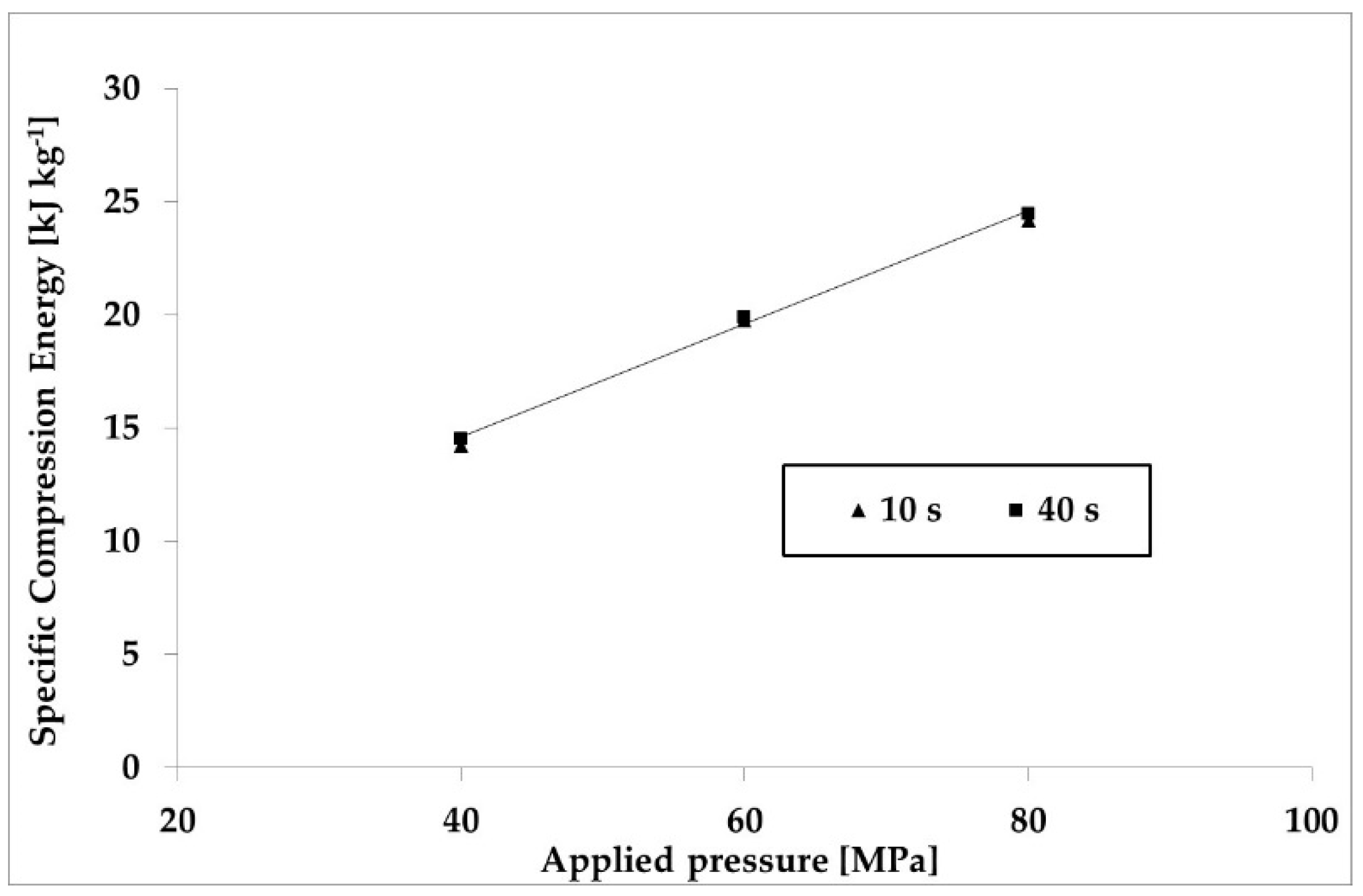

3.3. Specific Compression Energy—SCE

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Maietti, A.; Brighenti, V.; Bonetti, G.; Tedeschi, P.; Principe, P.F.; Benvenuti, S.; Brandolini, V.; Pellati, F. Metabolite profiling of flavonols and in vitro antioxidant activity of young shoots of wild Humulus lupulus L. (hop). J. Pharm. Biomed. Anal. 2017, 142, 28–34. [Google Scholar] [CrossRef] [PubMed]

- Food and Agriculture Organization of the United Nations—FAOSTAT. Available online: http://faostat.fao.org (accessed on 15 June 2018).

- European Commission: Agriculture. 2017. Hops. Available online: https://ec.europa.eu/agriculture/hops_en (accessed on 20 December 2017).

- Sakamoto, K.; Konings, W.N. Beer spoilage bacteria and hop resistance. Int. J. Food Microbiol. 2003, 89, 105–124. [Google Scholar] [CrossRef]

- Schnaitter, M.; Wimmer, A.; Kollmannsberger, H.; Gastl, M.; Becker, T. Influence of hop harvest date of the ‘Mandarina Bavaria’ hop variety on the sensory evaluation of dry-hopped top-fermented beer. J. Inst. Brew. 2016, 122, 661–669. [Google Scholar] [CrossRef]

- Kopp, P.A. Hoptopia: A World of Agriculture and Beer in Oregon’s Willamette Valley; University of California Press: Oakland, CA, USA, 2016; 306p, ISBN 978-0-520-27748-9. [Google Scholar]

- Krofta, K.; Mikyska, A.; Haskova, D. Changes in antioxidative properties of hops in the course of drying, milling, palletization and storage. Kvasny Prumysl 2007, 53, 266–272. [Google Scholar] [CrossRef]

- Kumhala, F.; Blahovec, J. Bulk properties of densified hop cones related to storage and throughput measurements. Biosyst. Eng. 2014, 126, 123–128. [Google Scholar] [CrossRef]

- Obernberger, I.; Thek, G. Physical characterization and chemical composition of densified biomass fuels with regard to their combustion behavior. Biomass Bioenergy 2004, 27, 653–669. [Google Scholar] [CrossRef]

- Adapa, P.; Tabil, L.; Schoenau, G. Compaction characteristics of barley, canola, oat and wheat straw. Biosyst. Eng. 2009, 204, 335–344. [Google Scholar] [CrossRef]

- Pampuro, N.; Facello, A.; Cavallo, E. Pressure and specific energy requirements for densification of compost derived from swine solid fraction. Span. J. Agric. Res. 2013, 11, 678–684. [Google Scholar] [CrossRef]

- Cavallo, E.; Pampuro, N. Effects of compressing pressure on briquettes made from woody biomass. Chem. Eng. Trans. 2017, 58, 517–522. [Google Scholar]

- Kaliyan, N.; Vance Morey, R. Factors affecting strength and durability of densified biomass products. Biomass Bioenergy 2009, 33, 337–359. [Google Scholar] [CrossRef]

- Mikyska, A.; Krofta, K.; Haskova, D.; Culik, J.; Cejka, P. Impact of hop pellets storage on beer quality. Kvasny Prumysl 2012, 58, 148–154. [Google Scholar] [CrossRef]

- Lisowski, A.; Dabrowska-Salin, M.; Ostrowska-Ligeza, E.; Nawrocka, A.; Stasiak, M.; Swietochowski, A.; Klonowski, J.; Sypula, M.; Lisowska, B. Effects of the biomass moisture content and pelleting temperature on the pressure-induced agglomeration process. Biomass Bioenergy 2017, 107, 376–383. [Google Scholar] [CrossRef]

- Battacharya, S.C.; Sett, S.; Shrestha, R.M. State of the art for biomass densification. Energy Source 1989, 11, 161–182. [Google Scholar] [CrossRef]

- Tumuluru, J.S.; Wright, C.T.; Hess, J.R.; Kenney, K.L. A review of biomass densification systems to develop uniform feedstock commodities for bioenergy application. Biofuels Bioprod. Biorefin. 2011, 5, 683–707. [Google Scholar] [CrossRef] [Green Version]

- Tabil, L.G.; Sokhansanj, S. Process conditions affecting the physical quality of alfalfa pellets. Appl. Eng. Agric. 1996, 12, 345–350. [Google Scholar] [CrossRef]

- Pampuro, N.; Bagagiolo, G.; Priarone, P.C.; Cavallo, E. Effects of pelletizing pressure and the addition of woody bulking agents on the physical and mechanical properties of pellets made from composted pig solid fraction. Powder Technol. 2017, 311, 112–119. [Google Scholar] [CrossRef]

- Carone, M.T.; Pantaleo, A.; Pellerano, A. Influence of process parameters and biomass characteristics on the durability of pellets from the pruning residues of Olea europea L. Biomass Bioenergy 2011, 35, 402–410. [Google Scholar] [CrossRef]

- American Society of Agricultural and Biological Engineers (ASABE). ASAE S358.2—Moisture Measurement—Forages. In American Society of Agricultural and Biological Engineers Standards; ASABE: St. Joseph, MI, USA, 2006; p. 608. [Google Scholar]

- American Society of Agricultural and Biological Engineers (ASABE). ASAE S269.4—Cubes, pellets and crumbles—Definitions and methods for determining density, durability and moisture content. In American Society of Agricultural and Biological Engineers Standards; ASABE: St. Joseph, MI, USA, 2007; pp. 624–626. [Google Scholar]

- Pampuro, N.; Preti, C.; Cavallo, E. Recycling pig slurry solid fraction as a sound absorber. Sustainability 2018, 10, 277. [Google Scholar] [CrossRef]

- Thoreson, C.P.; Webster, K.E.; Darr, M.J.; Kapler, E.J. Investigation of process variables in the densification of corn stover briquettes. Energies 2014, 7, 4019–4032. [Google Scholar] [CrossRef]

- Li, Y.; Liu, H. High-pressure densification of wood residues to form an upgraded fuel. Biomass Bioenergy 2000, 19, 177–186. [Google Scholar] [CrossRef]

- Adapa, P.K.; Schoenau, G.J.; Tabil, L.G.; Sokhansanj, S.; Singh, A. Compression of fractionated sun-cured and dehydrated alfalfa chops into cubes—Specific energy models. Bioresour. Technol. 2007, 98, 38–45. [Google Scholar] [CrossRef] [PubMed]

- Mani, S.; Tabil, L.G.; Sokhansanj, S. Specific energy requirement for compacting corn stover. Bioresour. Technol. 2006, 97, 1420–1426. [Google Scholar] [CrossRef] [PubMed]

- Ruiz Celma, A.; Cuadros, F.; Lopez-Rodriguez, F. Characterization of pellets from industrial tomato residues. Food Bioprod. Process. 2012, 90, 700–706. [Google Scholar] [CrossRef]

- Kaliyan, N.; Vance Morey, R. Densification characteristics of corn cobs. Fuel Process. Technol. 2010, 91, 559–565. [Google Scholar] [CrossRef]

- Demibras, A. Physical properties of briquettes from waste paper and wheat straw mixtures. Energy Convers. Manag. 1999, 40, 437–445. [Google Scholar]

- Theerarattananoon, K.; Xu, F.; Wilson, J.; Ballard, R.; Mckinney, L.; Staggenborg, S.; Vadlani, P.; Pei, Z.J.; Wang, D. Physical properties of pellets made from sorghum stalk, corn stover, wheat straw, and big bluestem. Ind. Crops Prod. 2011, 33, 325–332. [Google Scholar] [CrossRef]

- Colley, Z.; Fasina, O.O.; Bransby, D.; Lee, Y.Y. Moisture effect on the physical characteristics of switchgrass pellets. Trans. ASAE 2006, 49, 1845–1851. [Google Scholar] [CrossRef]

- Karunanithy, C.; Wang, Y.; Muthukumarappan, K.; Pugalendhi, S. Physiochemical Characterization of briquettes made from different feedstocks. Biotechnol. Res. Int. 2012, 2012, 1–12. [Google Scholar] [CrossRef] [PubMed]

- Kaliyan, N.; Vance Morey, R. Densification characteristics of corn stover and switchgrass. Trans. ASABE 2009, 52, 907–920. [Google Scholar] [CrossRef]

- Mani, S.; Tabil, L.G.; Sokhansanj, S. Evaluation of compaction equations applied to four biomass species. Can. Biosyst. Eng. 2004, 46, 351–361. [Google Scholar]

- Santamarta, L.C.; Ramirez, A.D.; Godwin, R.J.; White, D.R.; Chaney, K.; Humphries, A.C. Energy use and carbon dioxide emissions associated with the compression of oilseed rape straw. In Proceedings of the International Conference of Agricultural Engineering-CIGR-AgEng 2012: Agriculture and Engineering for a Healthier Life, Valencia, Spain, 8–12 July 2012. [Google Scholar]

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pampuro, N.; Busato, P.; Cavallo, E. Effect of Densification Conditions on Specific Energy Requirements and Physical Properties of Compacts Made from Hop Cone. Energies 2018, 11, 2389. https://doi.org/10.3390/en11092389

Pampuro N, Busato P, Cavallo E. Effect of Densification Conditions on Specific Energy Requirements and Physical Properties of Compacts Made from Hop Cone. Energies. 2018; 11(9):2389. https://doi.org/10.3390/en11092389

Chicago/Turabian StylePampuro, Niccolò, Patrizia Busato, and Eugenio Cavallo. 2018. "Effect of Densification Conditions on Specific Energy Requirements and Physical Properties of Compacts Made from Hop Cone" Energies 11, no. 9: 2389. https://doi.org/10.3390/en11092389