Thermal Comfort, Energy and Cost Impacts of PMV Control Considering Individual Metabolic Rate Variations in Residential Building

Abstract

:1. Introduction

1.1. Background

1.2. Literature Review

1.3. Metabolic Rate

2. Method

2.1. Simulation Software

2.2. Predicted Mean Vote (PMV) Assessment During Simulation

2.3. Schedule

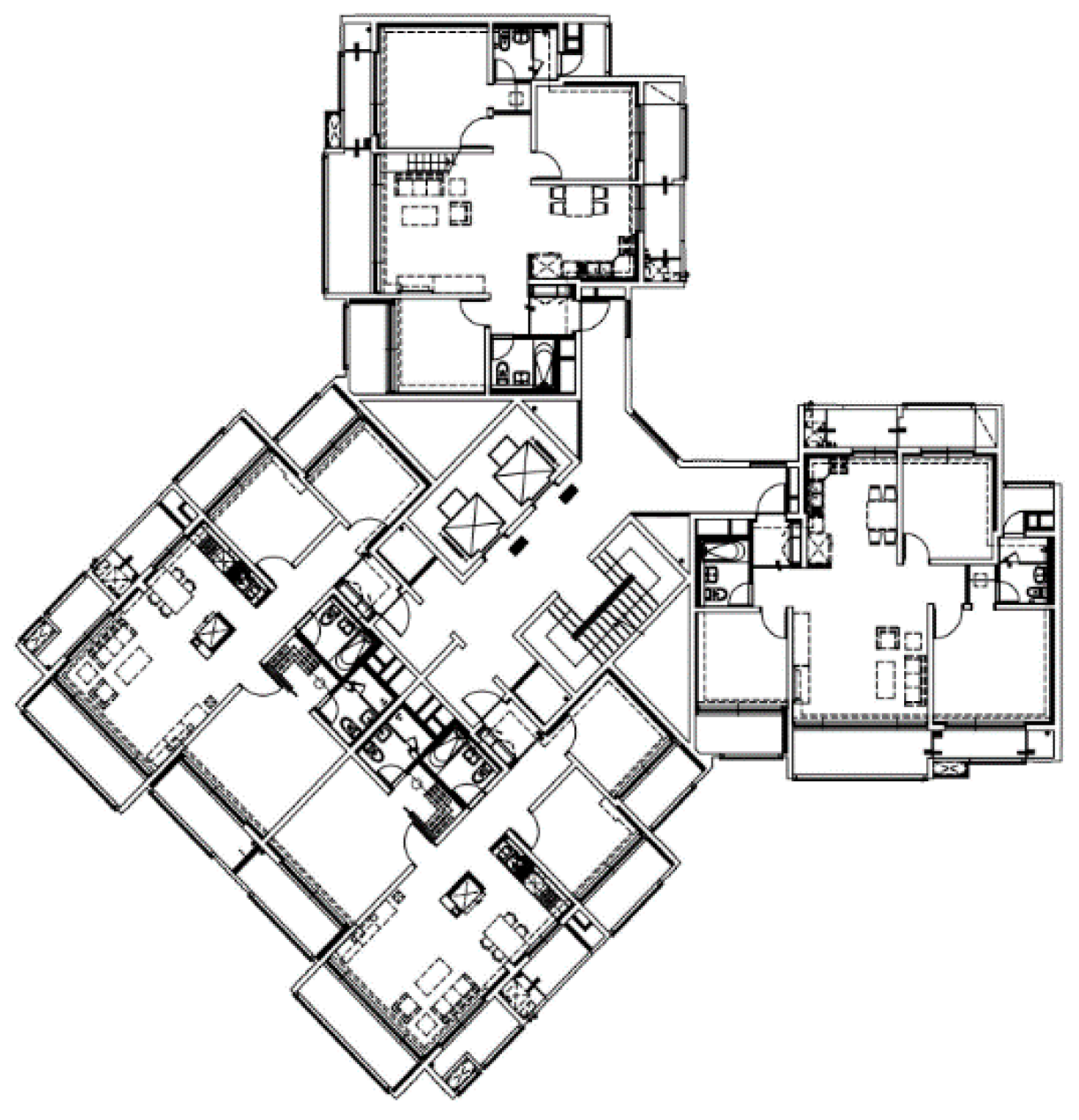

2.4. Description of the Simulated Apartment Building

2.5. Simulation Condition

2.6. Simulation Case

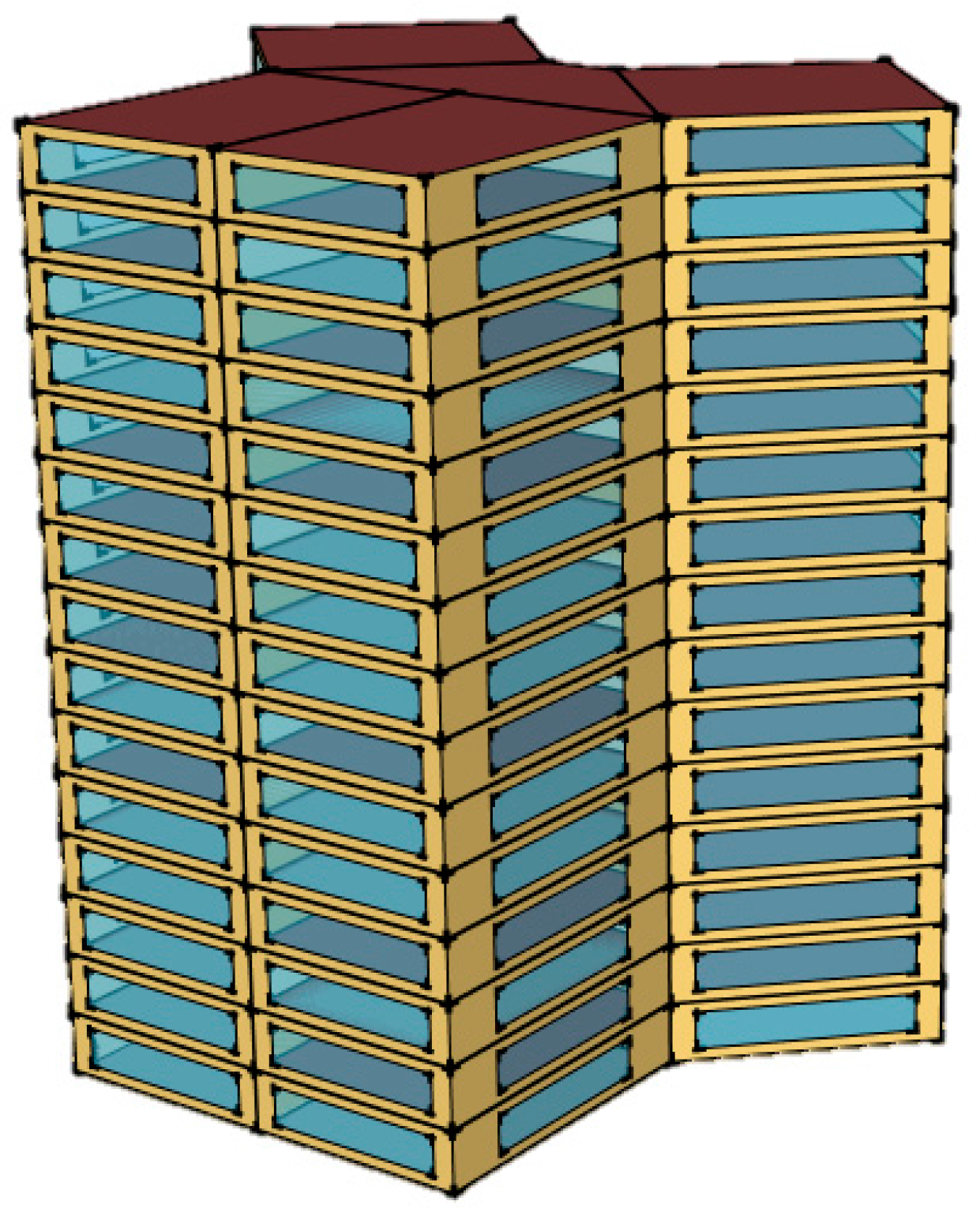

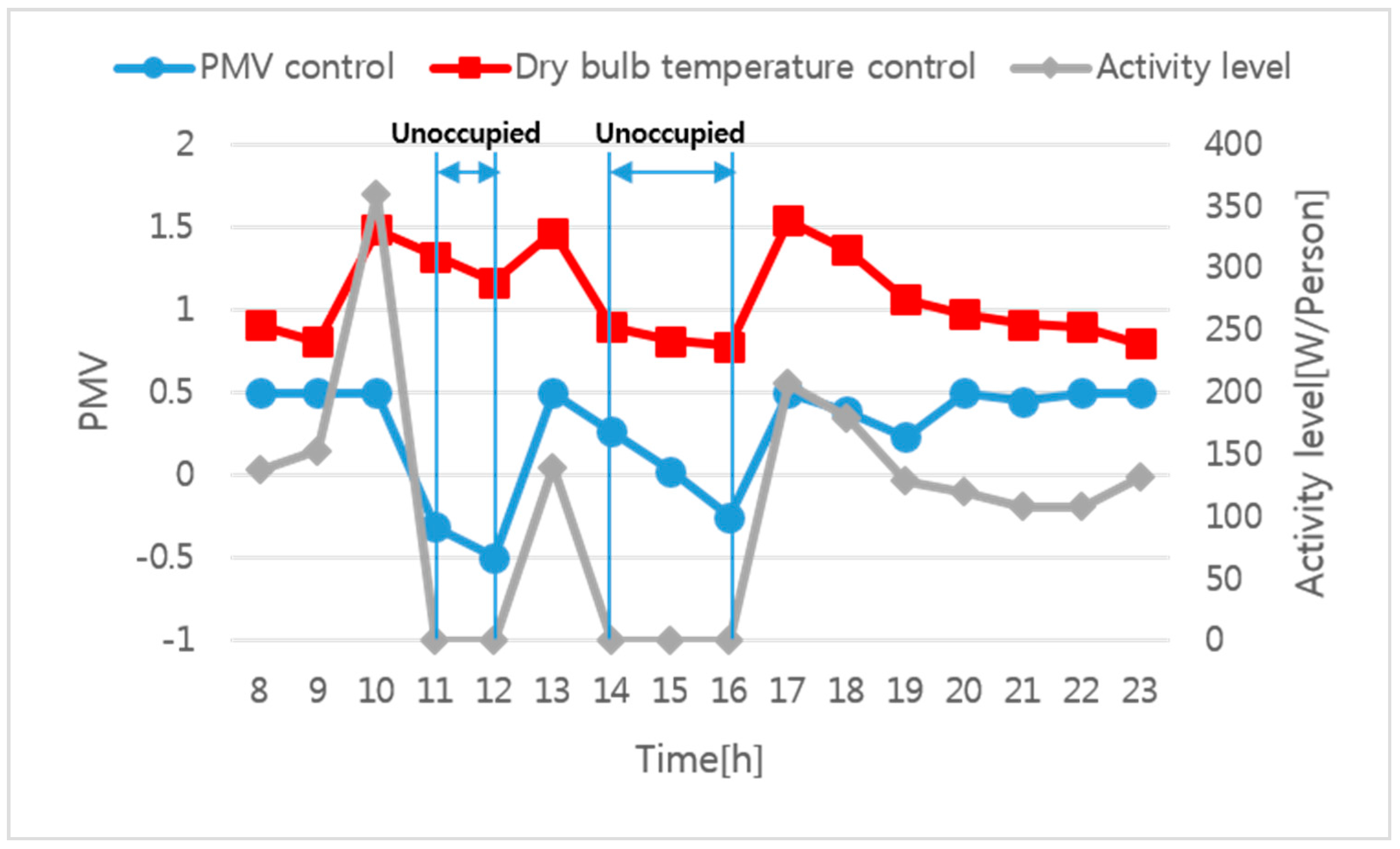

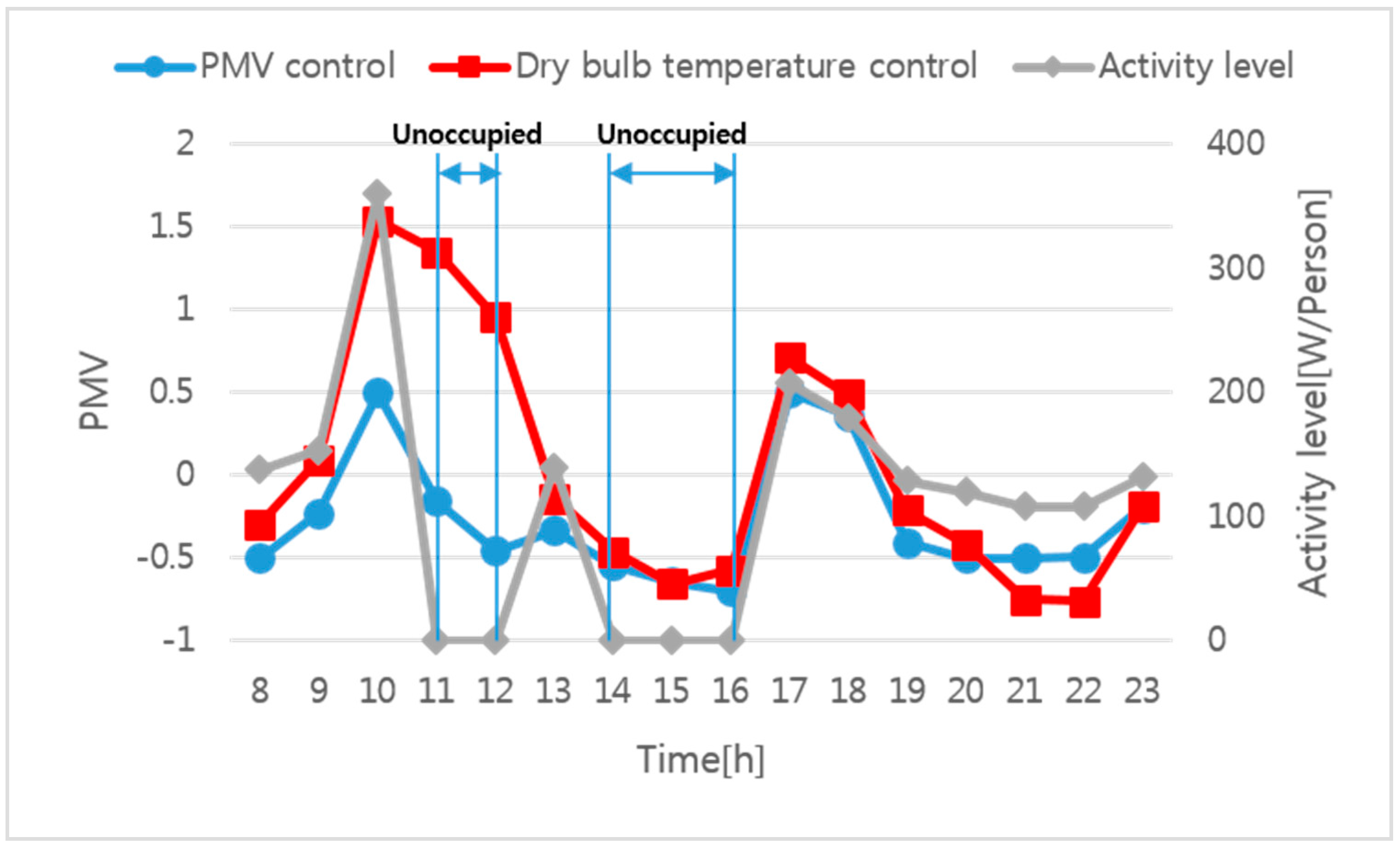

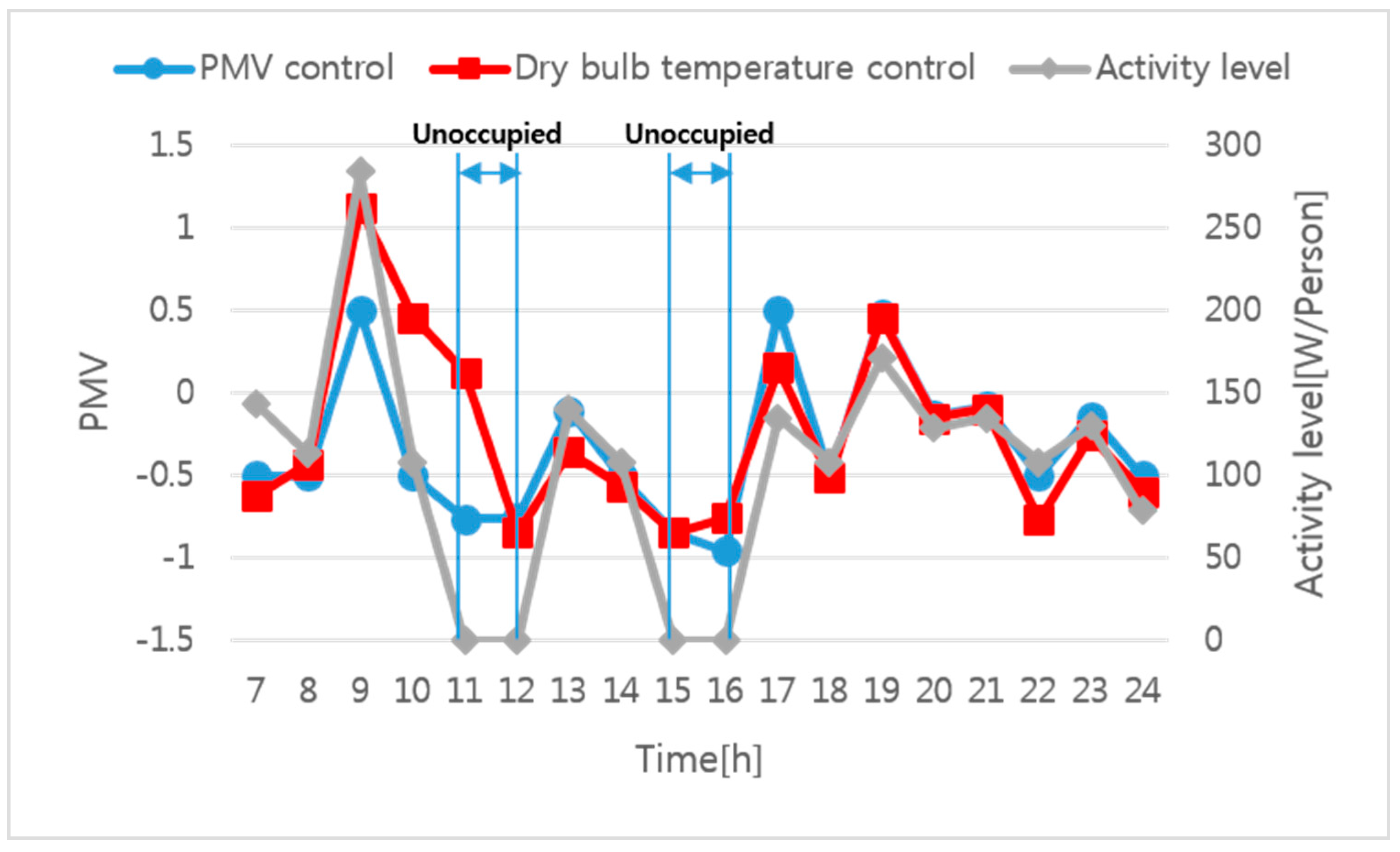

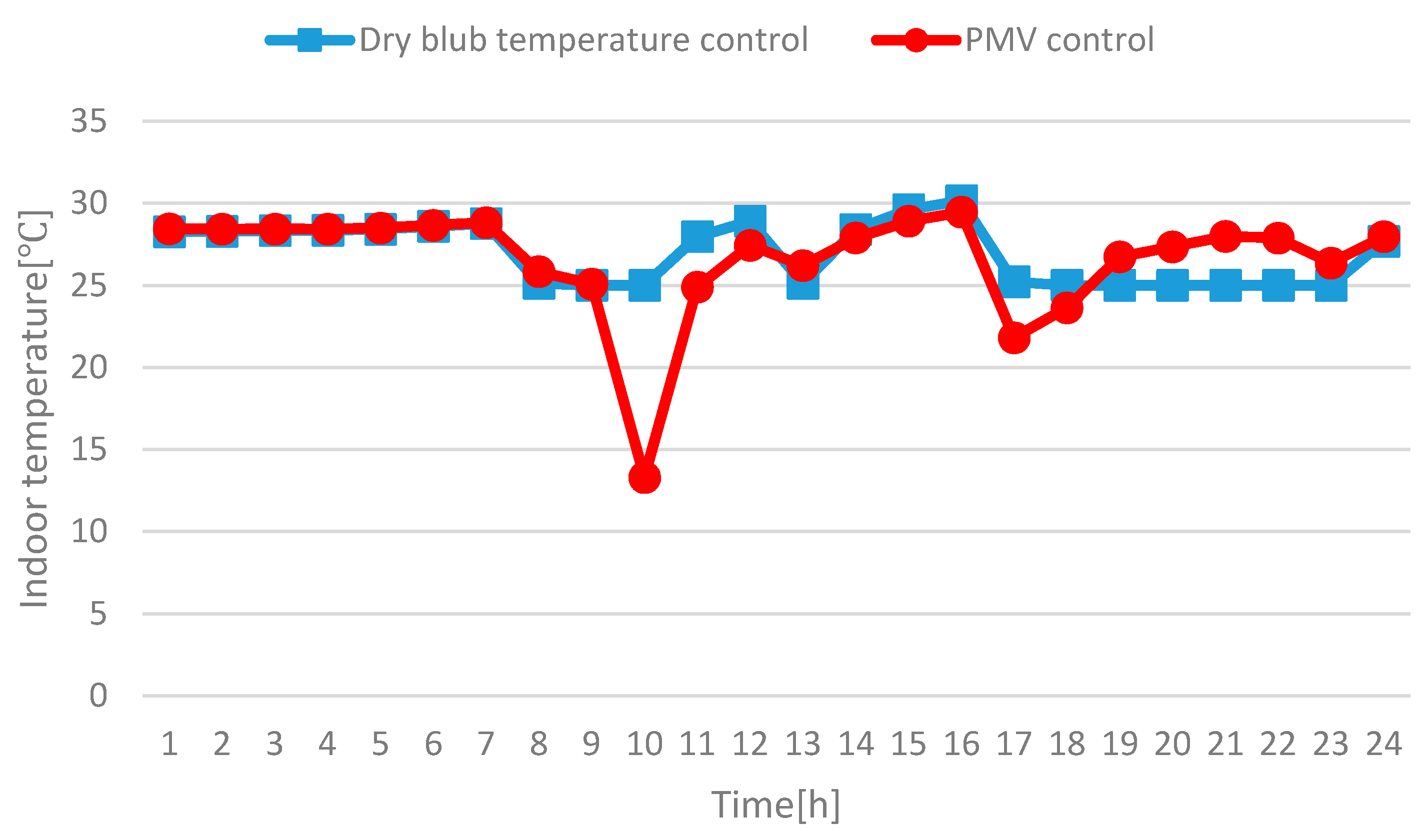

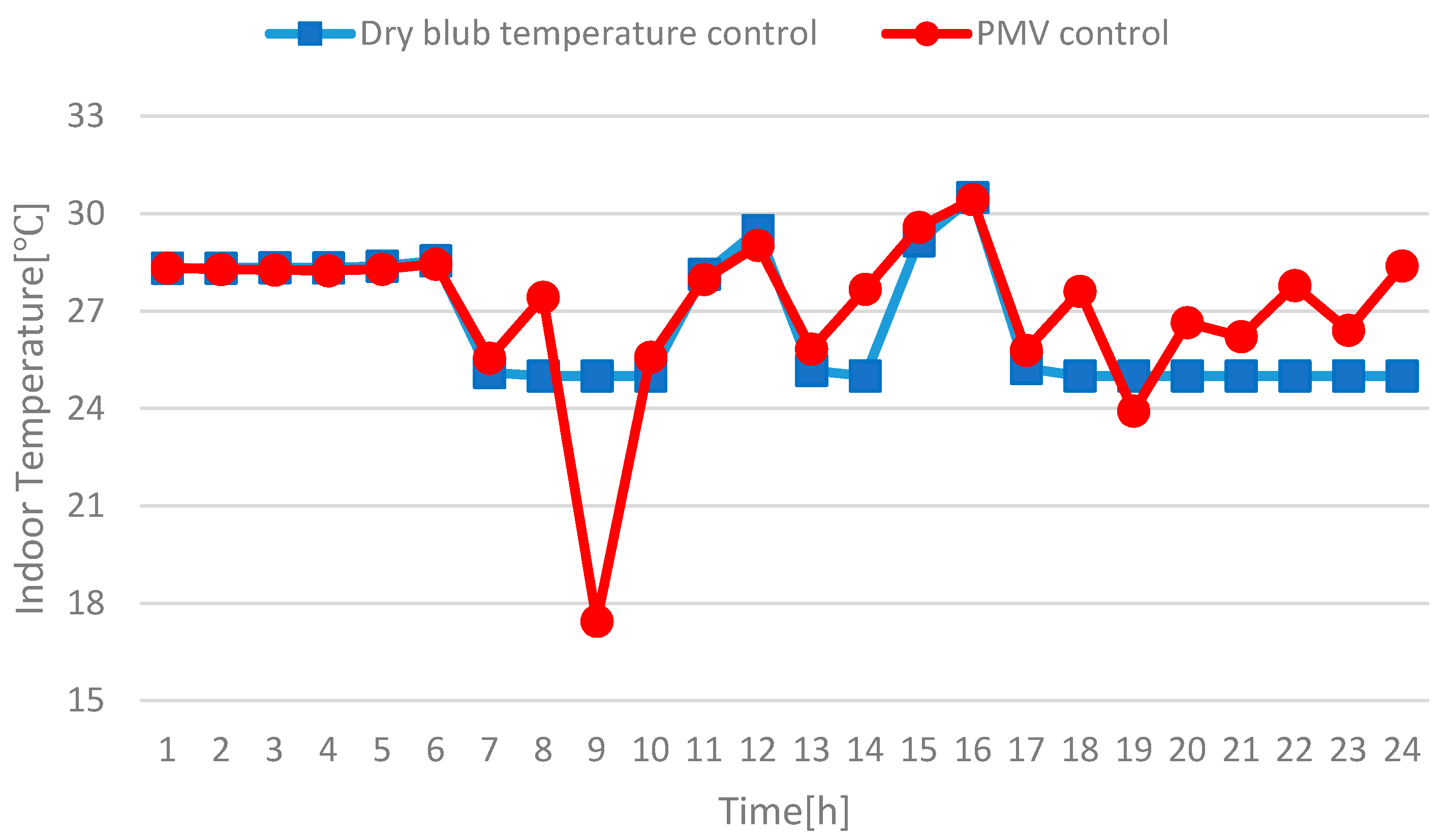

2.7. Weekday, Holiday Schedule

3. Result and Discussion

3.1. PMV

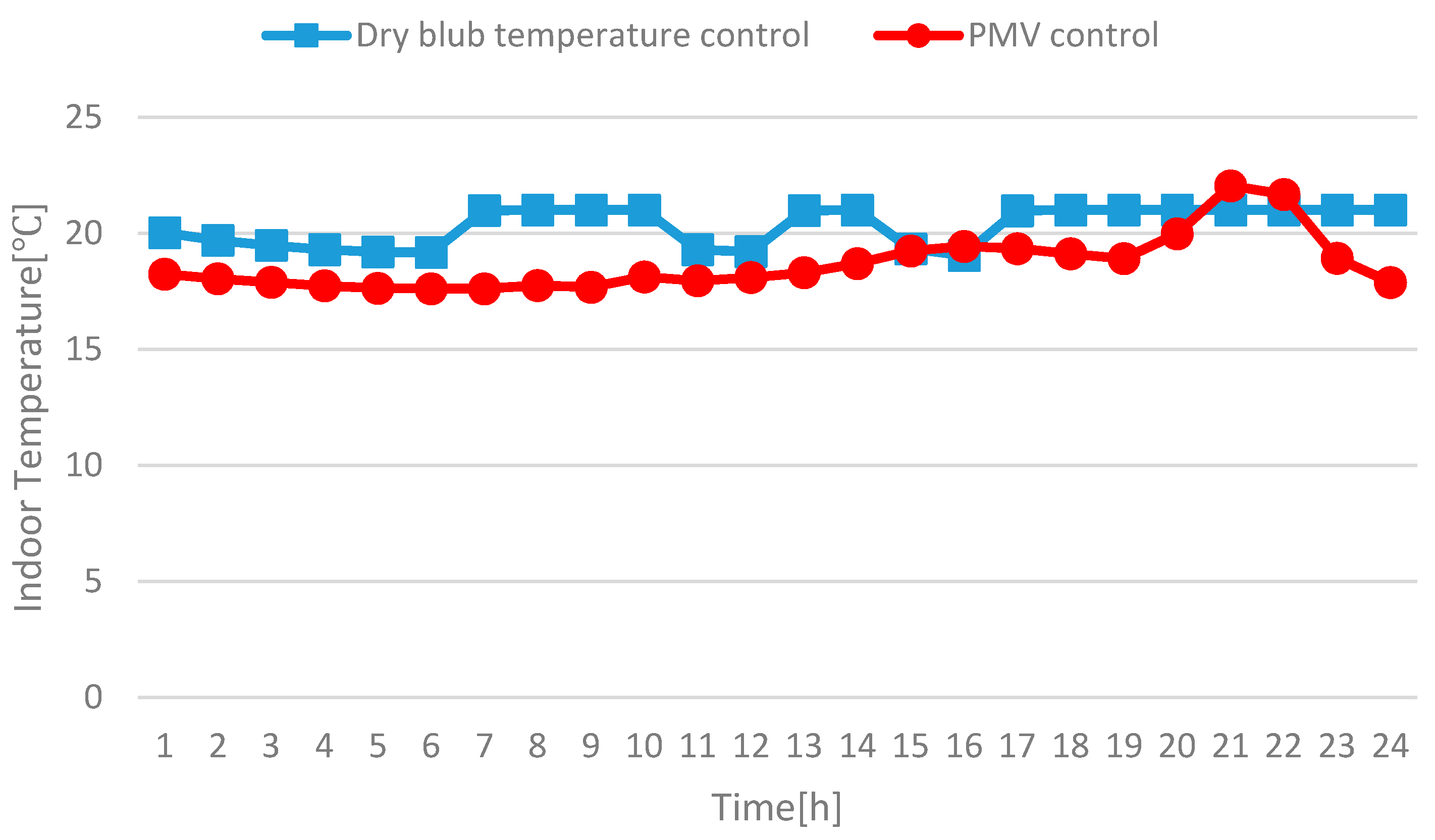

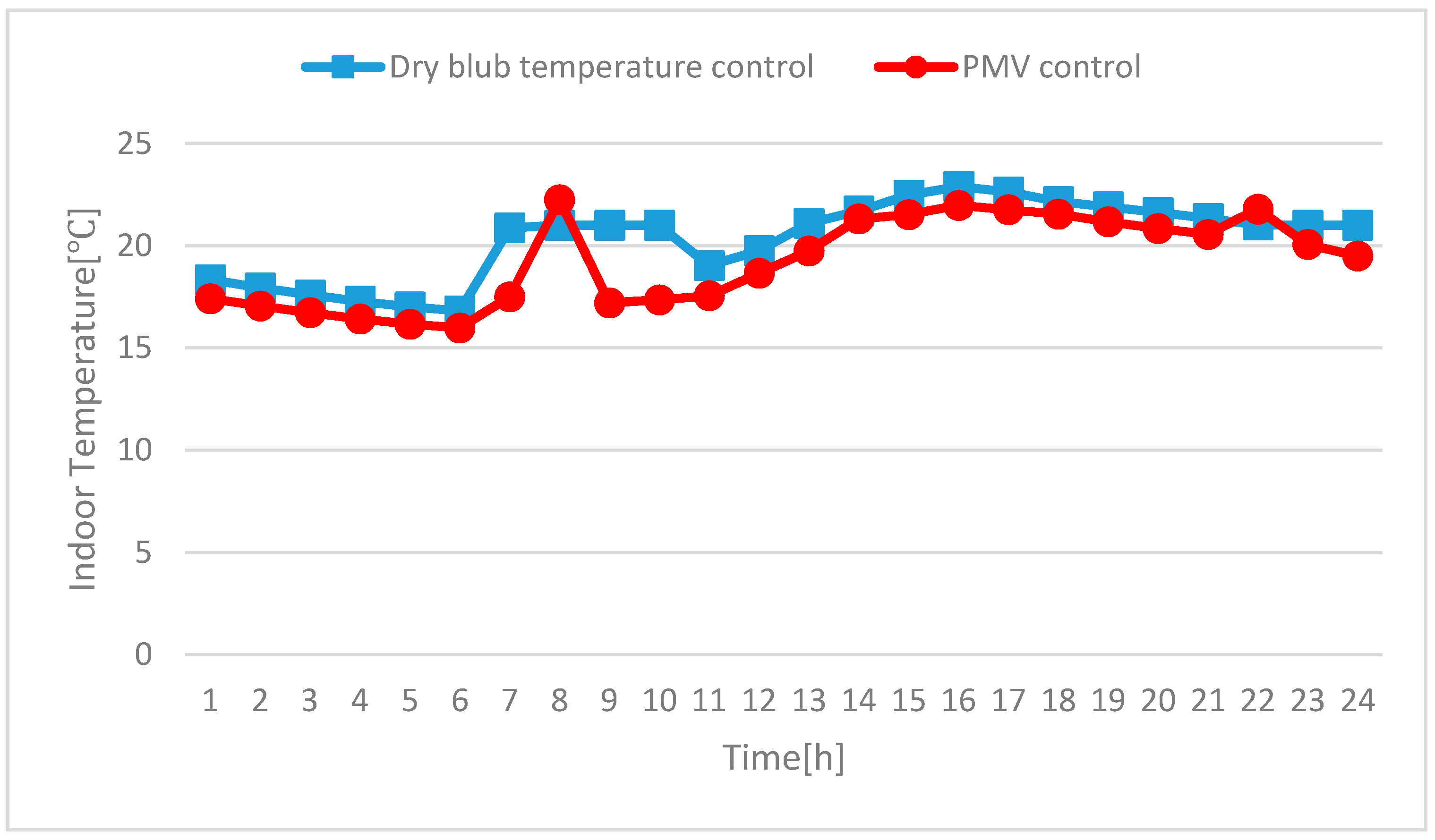

3.2. Indoor Temperature

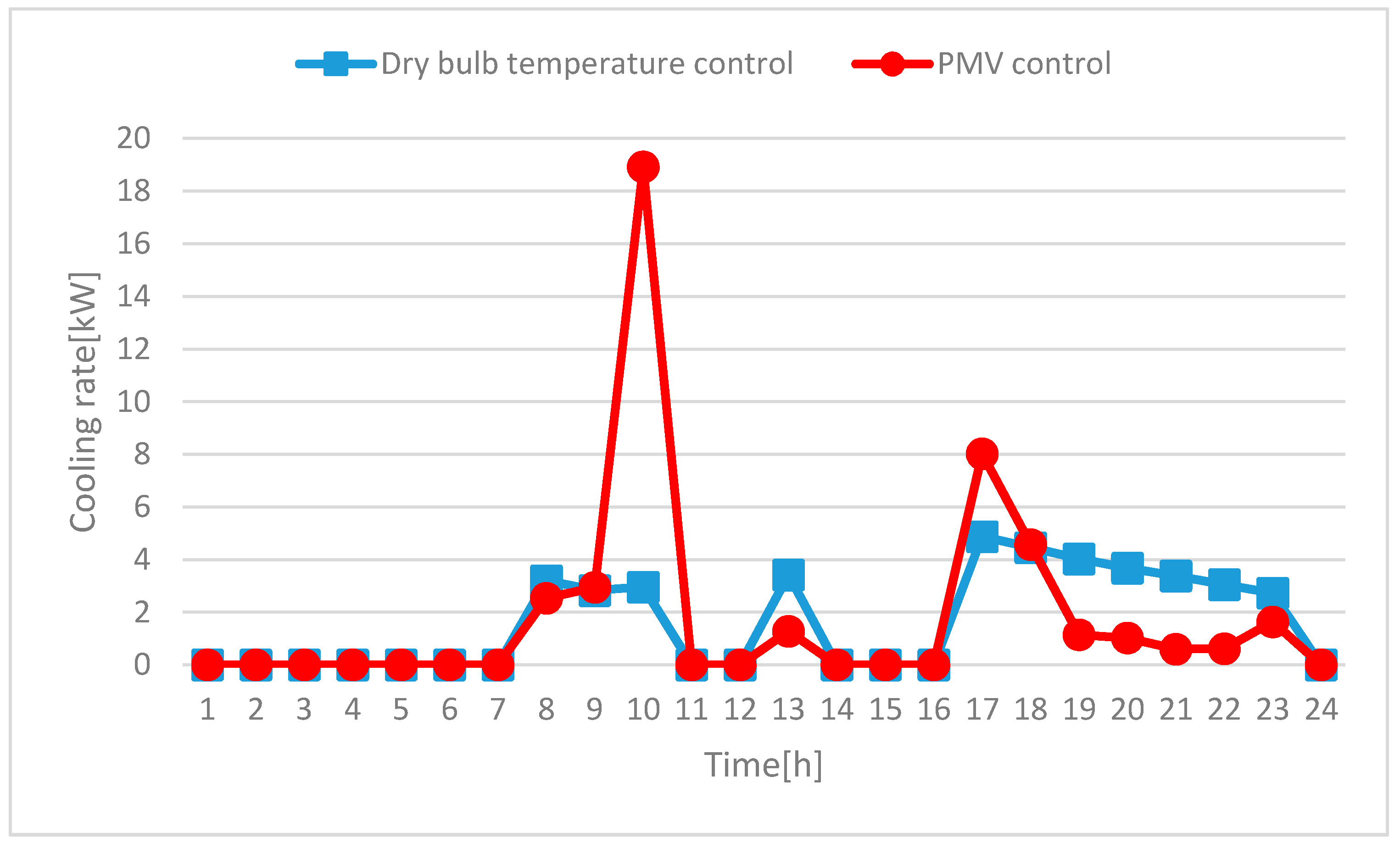

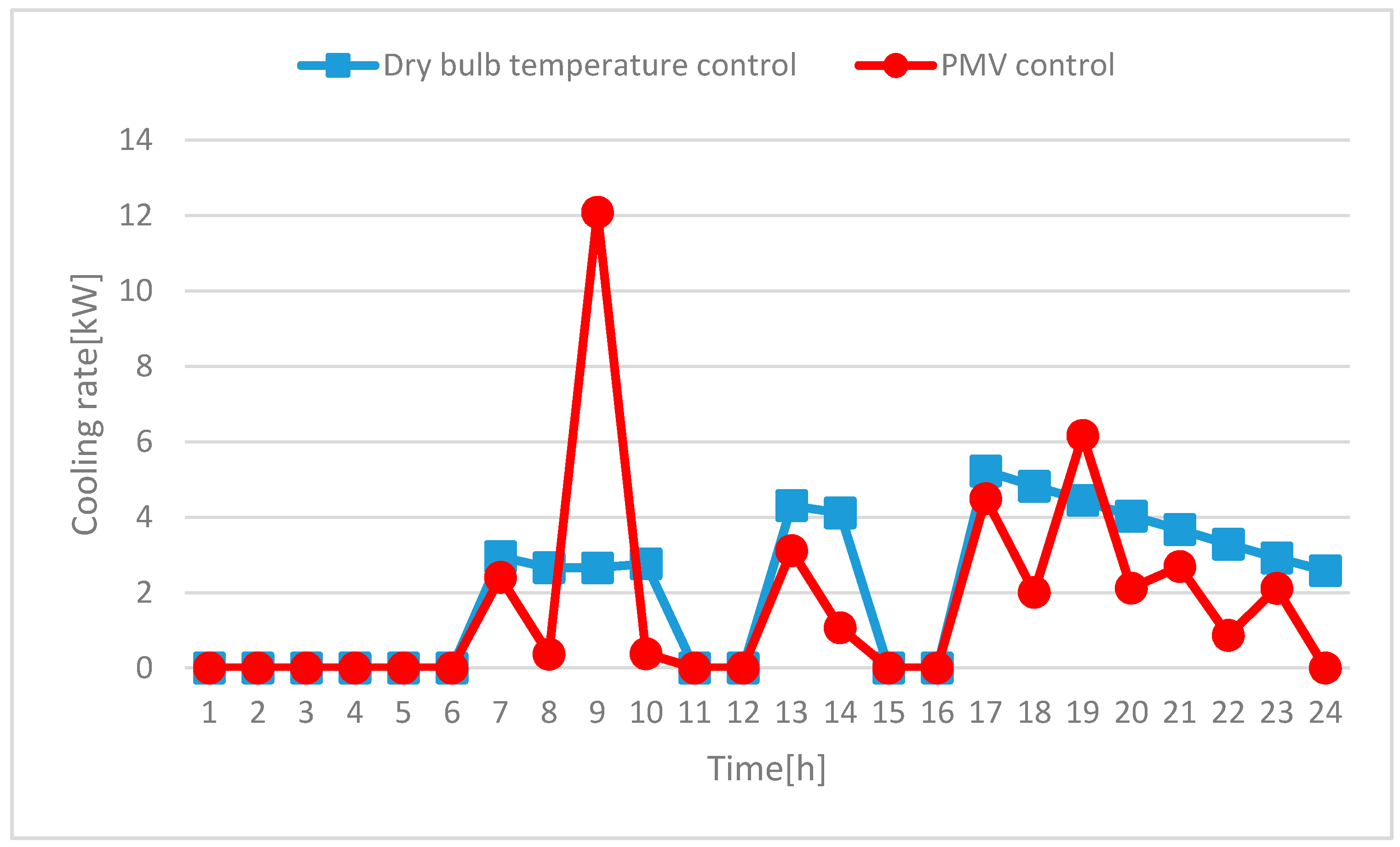

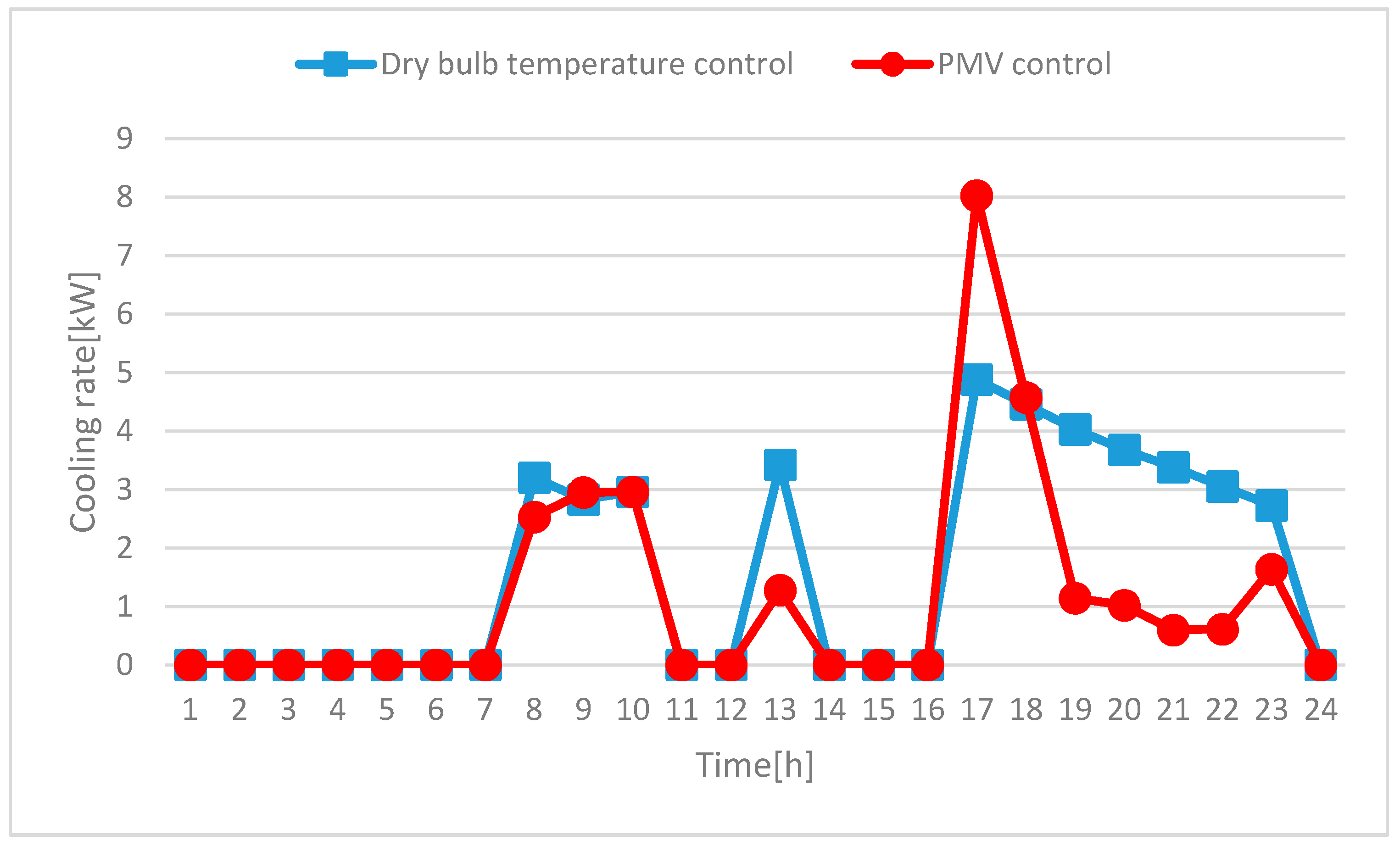

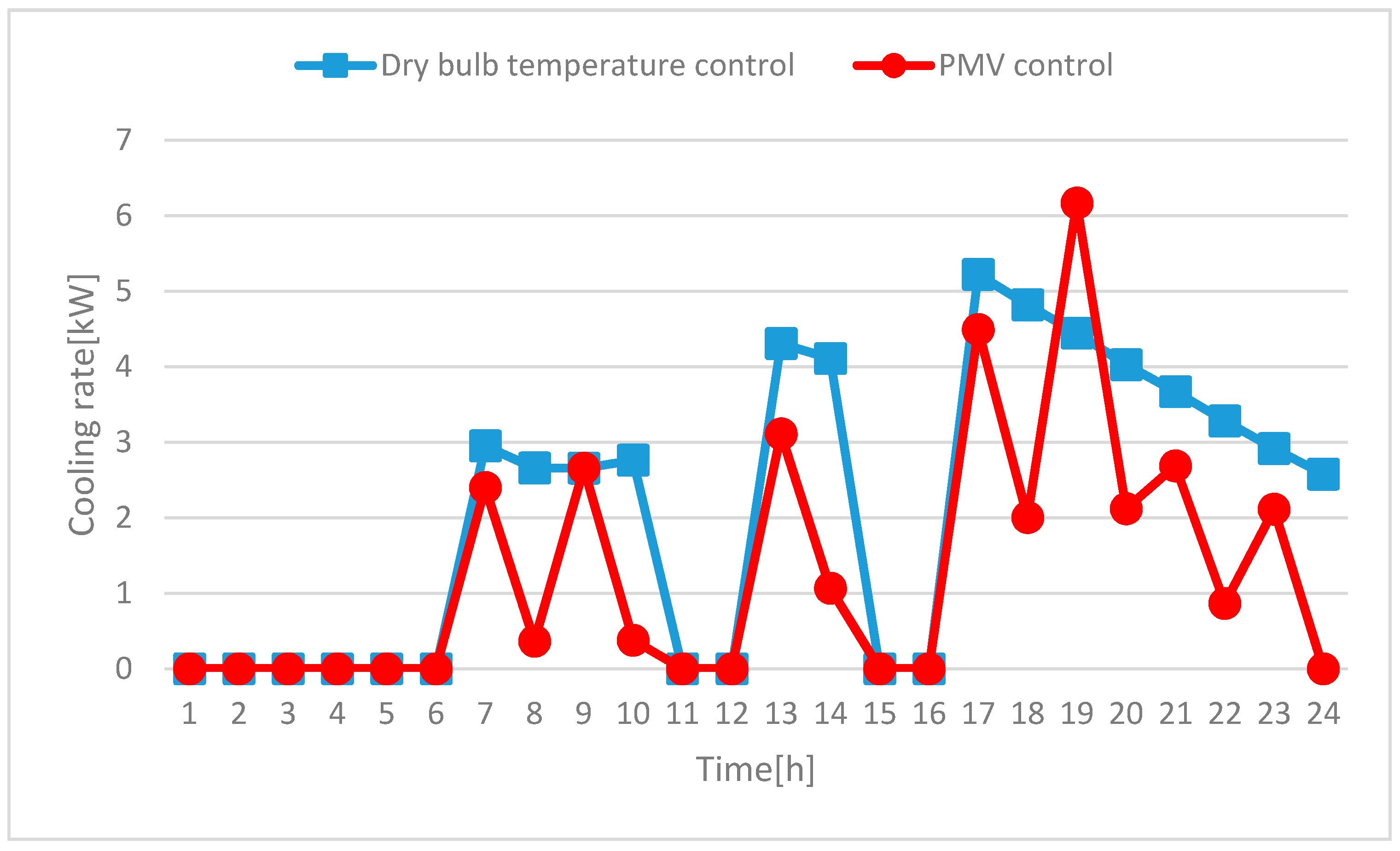

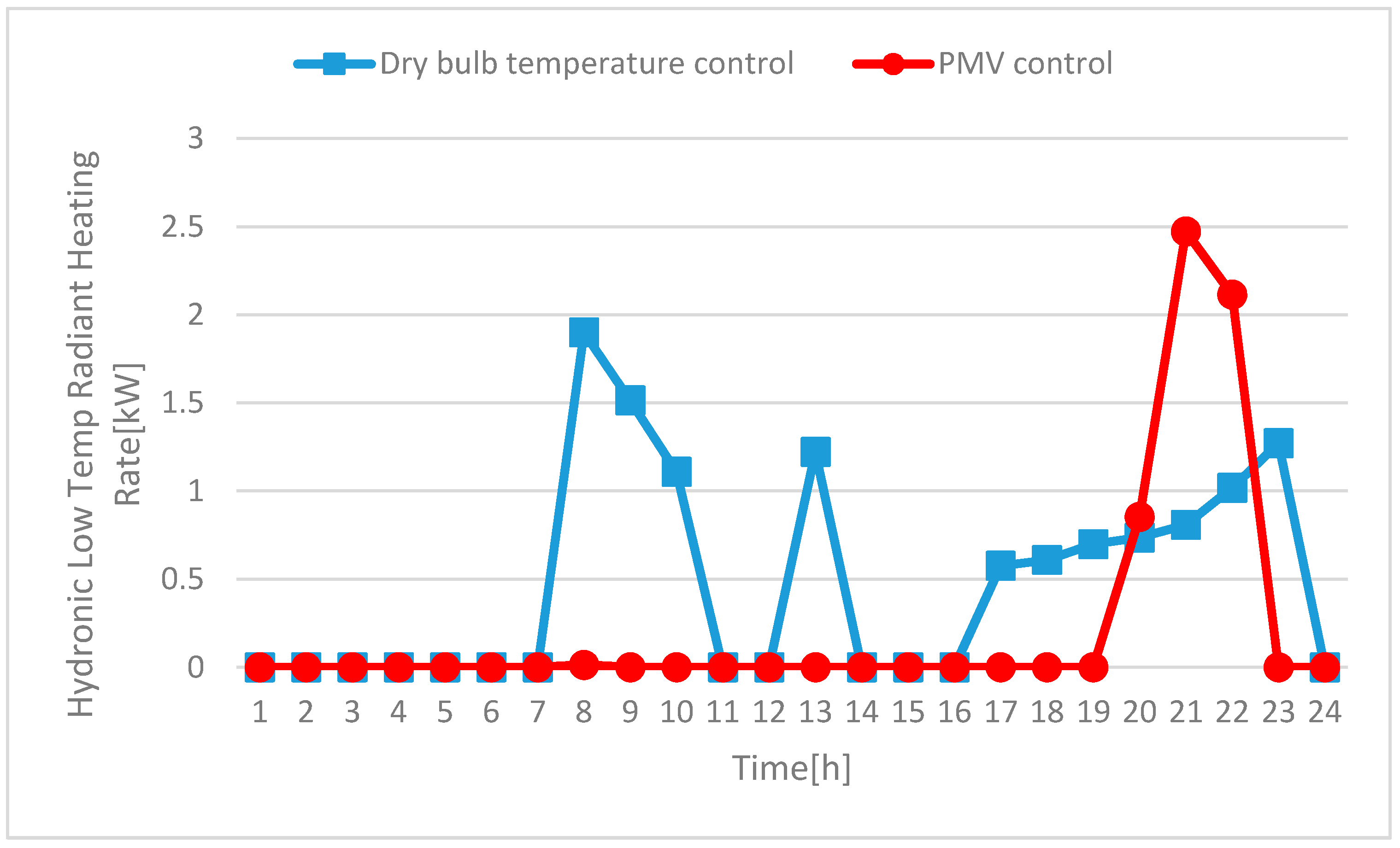

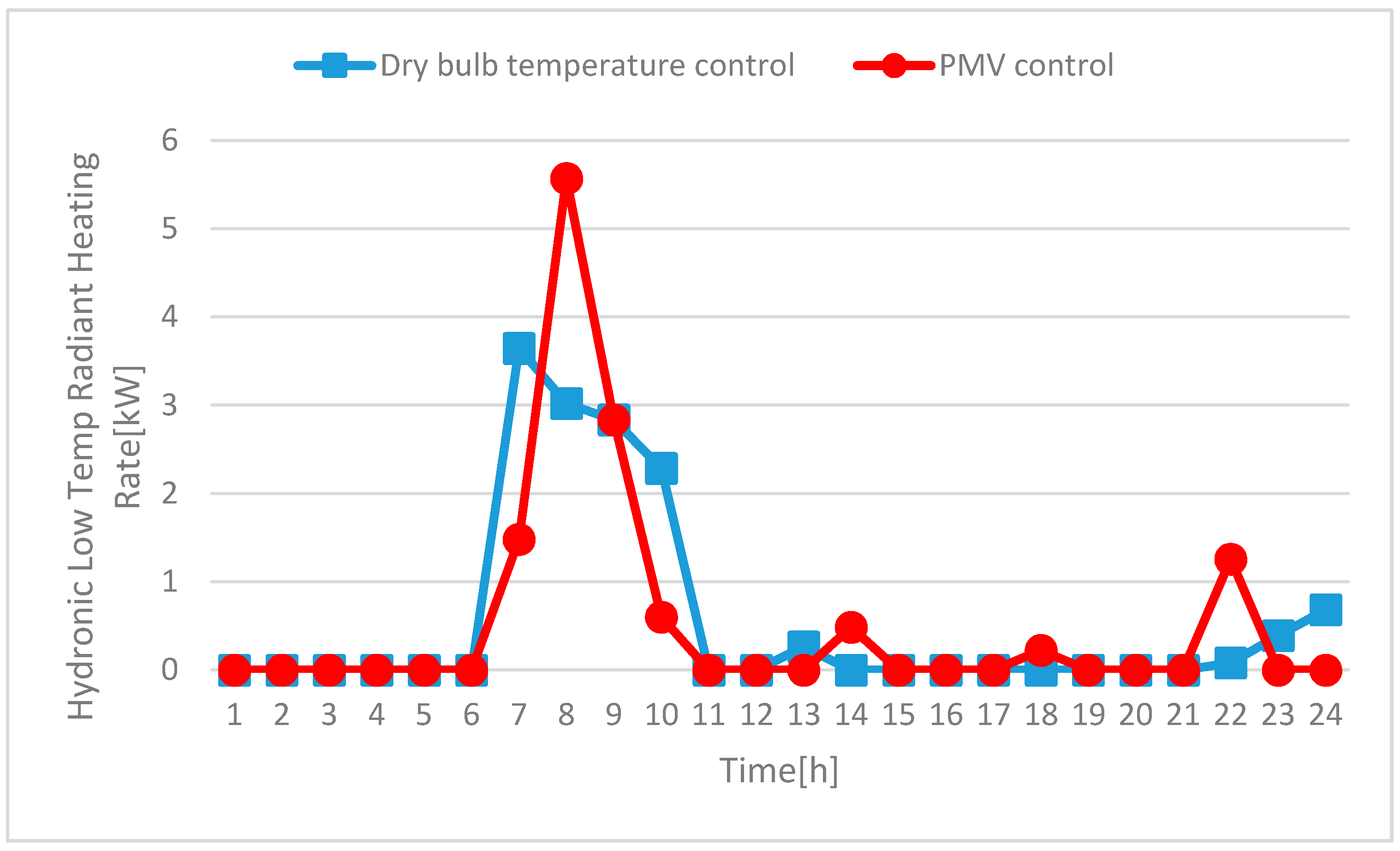

3.3. Hourly Cooling and Heating Rate

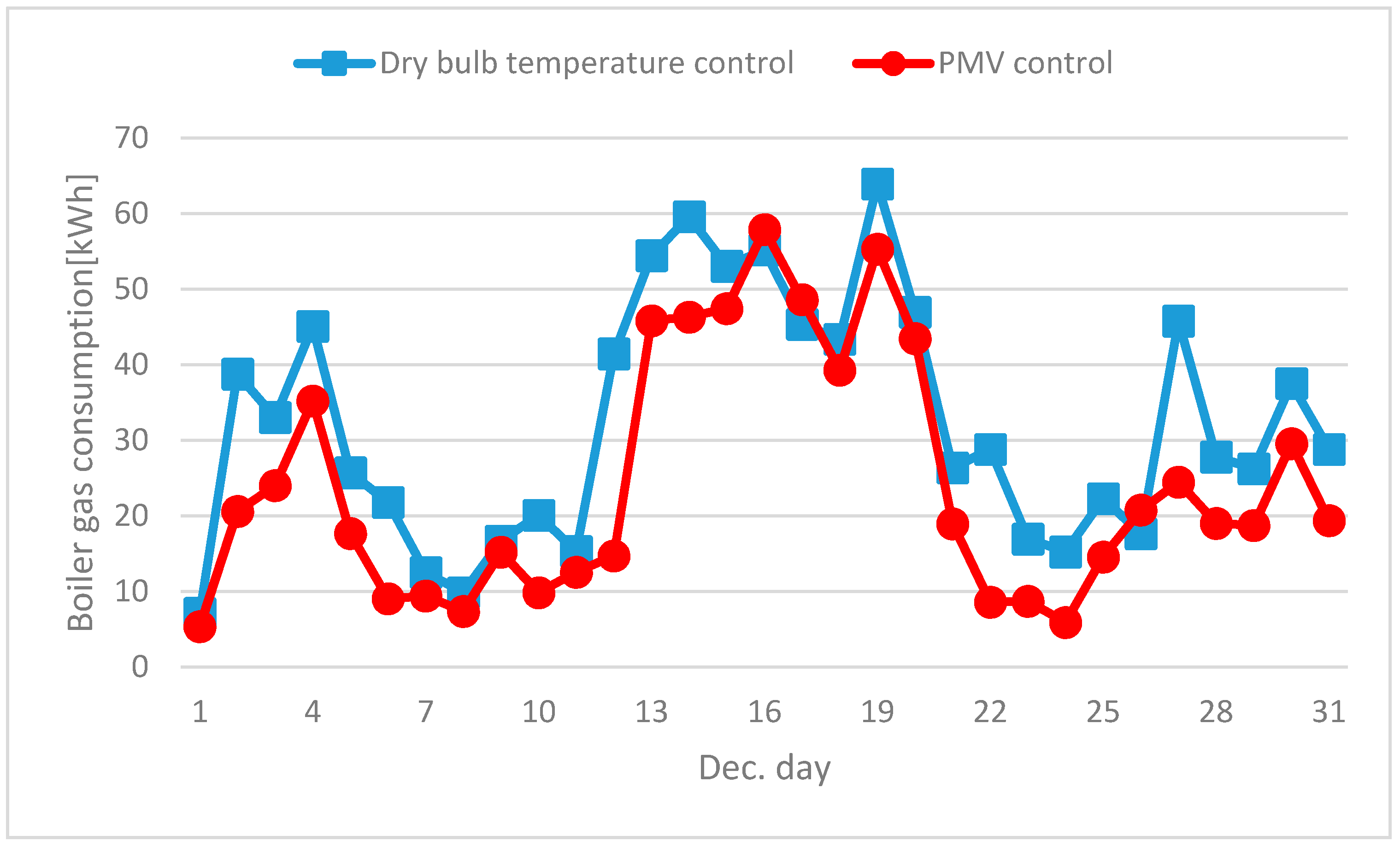

3.4. Daily Energy Consumption

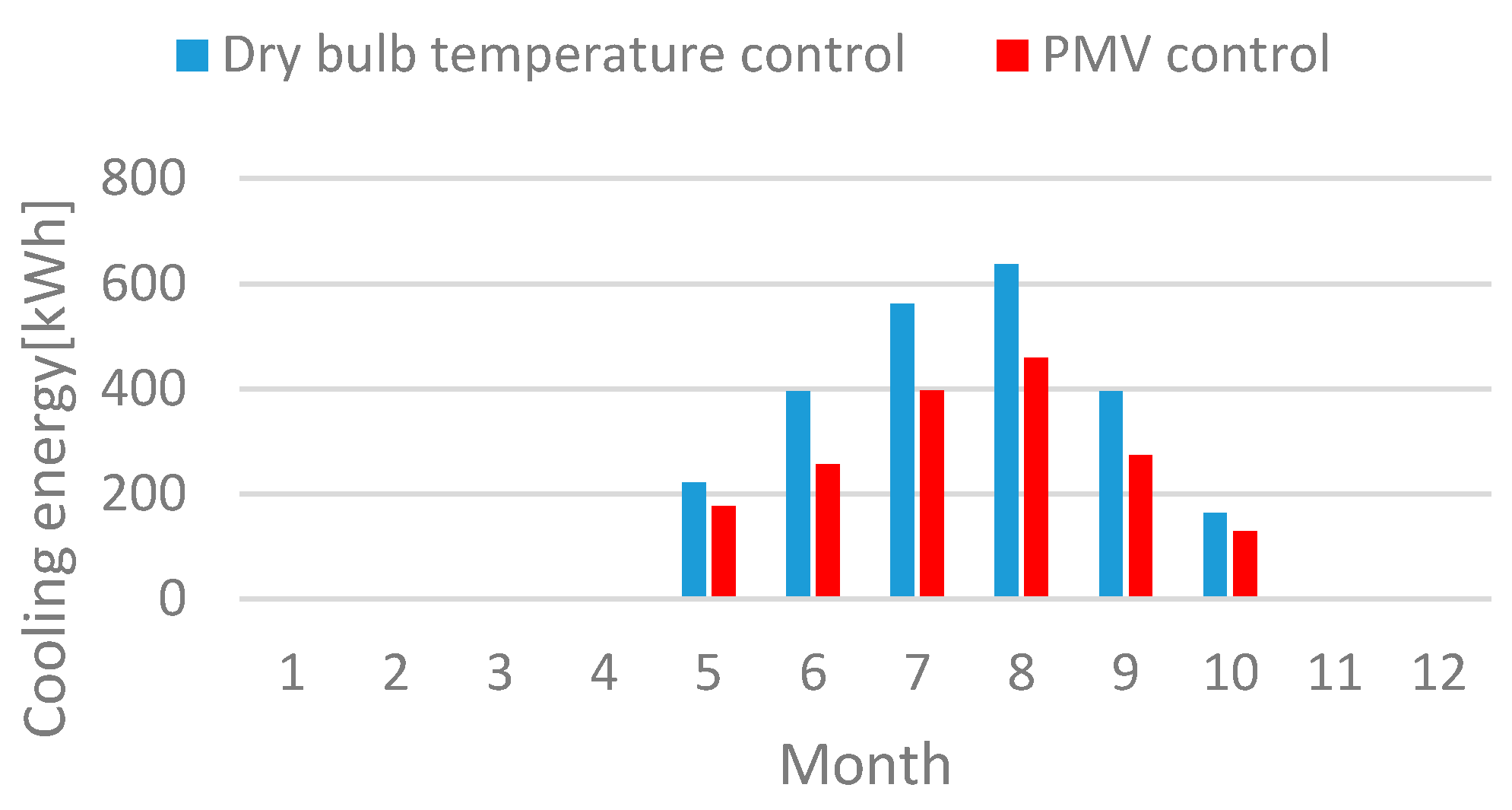

3.5. Monthly and Annual Heating and Cooling Energy Consumption

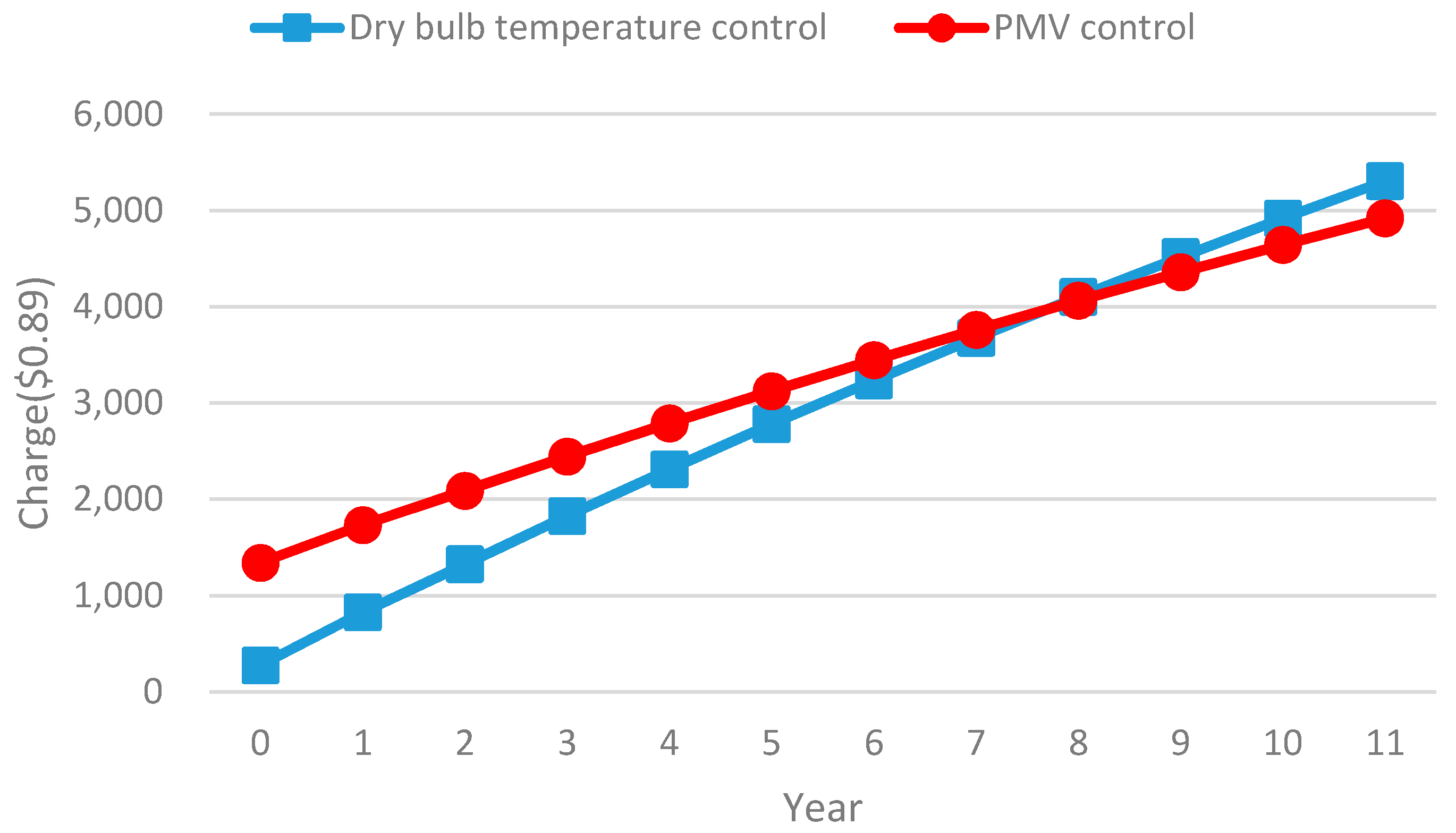

3.6. Economic Analysis

4. Conclusions

Author Contributions

Acknowledgments

Conflicts of Interest

References

- Kim, Y.S.; Chang, S.J. Development of indoor CO2 level associated building PMV prediction model using artificial neural network. Archit. Inst. Korea 2017, 37, 612–615. [Google Scholar]

- Korea Institute of S&T Evaluation and Planning 2015, 29. Available online: http://www.kistep.re.kr/c3/sub6.jsp (accessed on 26 December 2015).

- Kim, S.H.; Yun, S.J.; Chung, K.S. A study on the application of simulation-based simplified PMV regression model for indoor thermal comfort control. J. Energy Eng. 2015, 24, 69–77. [Google Scholar] [CrossRef]

- Jang, H.I.; Suh, S.J. Analysis of indoor thermal environment and energy consumption in office building controlled by PMV. Korean Sol. Energy Soc. 2013, 33, 15–22. [Google Scholar] [CrossRef]

- AREN 3050 Environmental Systems for Building I. Prediction Thermal Comfort. Available online: http://ceae.colorado.edu/~brandem/aren3050/ (accessed on 20 October 2005).

- Federation of European Heating, Ventilation and Air-conditioning Association. Indoor Environment and Productivity in Office Environment-Summary of the Key Contents of REHVA Guidebook No. 6; REHVA: Brussels, Belgium, 2014. [Google Scholar]

- d’Ambrosio Alfano, F.R.; Olesen, B.W.; Palella, B.I.; Riccio, G. Thermal comfort: Design and assessment for energy saving. Energy Build. 2014, 81, 326–336. [Google Scholar] [CrossRef]

- Fanger, P.O. Thermal Comfort; Danish Technical Press: Copenhagen, Denmark, 1970. [Google Scholar]

- ASHRAE (American Society of Heating, Refrigerating and Air-Conditioning Engineers). Thermal Environmental Conditions for Human Occupancy; ASRHAE Standard 55: Atlanta, GA, USA, 2017. [Google Scholar]

- ISO (International Organization for Standardization). Moderate Thermal Environments—Determination of the PMV and PPD Indices and Specification of the Conditions for Thermal Comfort; ISO 7730; ISO: Geneva, Switzerland, 2005. [Google Scholar]

- ISO. Ergonomics of the Thermal Environment—Determination of Metabolic Rate; ISO 8996:2004; ISO: Geneva, Switzerland, 2004. [Google Scholar]

- ISO. Ergonomics of the Thermal Environment—Estimation of Thermal Insulation and Water Vapour Resistance of a Clothing Ensemble; ISO 9920:2007; ISO: Geneva, Switzerland, 2007. [Google Scholar]

- Malchaire, J.; Ambrosio Alfano, F.R.; Palella, B.I. Evaluation of the metabolic rate based on the recording of the heart rate. Ind. Health 2017, 55, 219–232. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ambrosio Alfano, F.B.; Olesen, B.W.; Palella, B.I. Povl ole fanger’s impact ten years later. Energy Build. 2017, 152, 243–249. [Google Scholar] [CrossRef]

- Ambrosio Alfano, F.B.; Palella, B.I.; Riccio, G. Notes on the calculation of the PMV index by means of apps. Energy Procedia 2016, 101, 249–256. [Google Scholar] [CrossRef]

- Leger, J.; Rousse, D.R.; Le Borgne, K.; Lassuec, S. Comparing electric heating systems at equal thermal comfort: An experimental investigation. Build. Environ. 2018, 128, 161–169. [Google Scholar] [CrossRef]

- Jette, M.; Sidney, K.; Blumchen, G. Metabolic Equivalents (METS) in Exercise Testing, Exercise Prescription and Evaluation of Functional Capacity; Department of Kinanthropology, School of Human Kinetics, University of Ottawa: Ottawa, ON, Canada, 1990; Volume 13, pp. 555–565. [Google Scholar]

- The U.S. Department of Energy. EnergyPlus Engineering Reference: The Reference to EnergyPlus Calculations; The U.S. Department of Energy: Washington, DC, USA, 2011. [Google Scholar]

- The U.S. Department of Energy. EnergyPlus Input Output Reference: The Encyclopedic Reference to EnergyPlus Input and Output; The U.S. Department of Energy: Washington, DC, USA, 2010. [Google Scholar]

- ISO. Energy Performance of Buildings—Schedule and Condition of Building, Zone and Space Usage for Energy Calculation, Part 2 Residential Buildings, Annex A; ISO 18523-2; ISO: Geneva, Switzerland, 2018. [Google Scholar]

- Korea Energy Agency. Available online: http://www.kogas.or.kr/portal.contents.do?key=2024 (accessed on 1 January 2016).

- Korea Electric Power Corporation. 2016. Available online: http://cyber.kepco.co.kr/ckepco (accessed on 1 December 2016).

| +3 | Hot |

| +2 | Warm |

| +1 | Slightly warm |

| 0 | Neutral |

| −1 | Slightly cool |

| −2 | Cool |

| −3 | Cold |

| Activity | Activity Level (W/Person) | Metabolic Rate Per Person (Met) |

|---|---|---|

| Sleeping | 72 | 0.7 |

| Reclining | 81 | 0.8 |

| Seated, quiet | 108 | 1 |

| Standing, relaxed | 126 | 1.2 |

| Reading, seated | 99 | 1 |

| Writing | 108 | 1 |

| Typing | 117 | 1.1 |

| Filling, seated | 126 | 1.2 |

| Filling, standing | 144 | 1.4 |

| Cooking | 171 to 207 | 1.6 to 2.0 |

| House cleaning | 207 to 360 | 2.0 to 3.4 |

| Time | Metabolic Rate | System (ON/OFF) | Activity Level |

|---|---|---|---|

| (W/Person) | |||

| 1:00 | 0.7 | OFF | 72 |

| 2:00 | 0.7 | OFF | 72 |

| 3:00 | 0.7 | OFF | 72 |

| 4:00 | 0.7 | OFF | 72 |

| 5:00 | 0.7 | OFF | 72 |

| 6:00 | 0.7 | OFF | 72 |

| 7:00 | 1.4 | ON | 144 |

| 8:00 | 1.05 | ON | 113 |

| 9:00 | 2.7 | ON | 284 |

| 10:00 | 1 | ON | 108 |

| 11:00 | 0 | OFF | 0 |

| 12:00 | 0 | OFF | 0 |

| 13:00 | 1.35 | ON | 140 |

| 14:00 | 1 | ON | 108 |

| 15:00 | 0 | OFF | 0 |

| 16:00 | 0 | OFF | 0 |

| 17:00 | 1.3 | ON | 135 |

| 18:00 | 1 | ON | 108 |

| 19:00 | 1.6 | ON | 171 |

| 20:00 | 1.225 | ON | 129 |

| 21:00 | 1.3 | ON | 135 |

| 22:00 | 1 | ON | 108 |

| 23:00 | 1.25 | ON | 130 |

| 0:00 | 0.775 | ON | 79 |

| Time | Metabolic Rate | System (ON/OFF) | Activity Level |

|---|---|---|---|

| (W/Person) | |||

| 1:00 | 0.7 | OFF | 72 |

| 2:00 | 0.7 | OFF | 72 |

| 3:00 | 0.7 | OFF | 72 |

| 4:00 | 0.7 | OFF | 72 |

| 5:00 | 0.7 | OFF | 72 |

| 6:00 | 0.7 | OFF | 72 |

| 7:00 | 0.7 | OFF | 72 |

| 8:00 | 1.325 | ON | 138 |

| 9:00 | 1.5 | ON | 153 |

| 10:00 | 3.4 | ON | 360 |

| 11:00 | 0 | OFF | 0 |

| 12:00 | 0 | OFF | 0 |

| 13:00 | 1.35 | ON | 140 |

| 14:00 | 0 | OFF | 0 |

| 15:00 | 0 | OFF | 0 |

| 16:00 | 0 | OFF | 0 |

| 17:00 | 2 | ON | 207 |

| 18:00 | 1.7 | ON | 180 |

| 19:00 | 1.225 | ON | 129 |

| 20:00 | 1.125 | ON | 120 |

| 21:00 | 1 | ON | 108 |

| 22:00 | 1 | ON | 108 |

| 23:00 | 1.25 | ON | 132 |

| 0:00 | 0.7 | OFF | 72 |

| People | |

| Number of People Calculation Method | Area/Person |

| Zone Floor Area per Person | 32 m2/Person |

| Fraction Radiant | 0.3 |

| Light | |

| Design Level Calculation Method | Watts/Area |

| Watts per Zone Floor Area | 3.88 W/m2 |

| Return Air Fraction | 0 |

| Fraction Radiant | 0.2 |

| Fraction Visible | 0.2 |

| Equipment | |

| Design Level Calculation Method | Watts/Area |

| Watts per Zone Floor Area | 5.38 W/m2 |

| Construction | |

|---|---|

| Exterior Floor | I02 50 mm insulation board |

| M15 200 mm heavyweight concrete | |

| Exterior Wall | M01 100 mm brick |

| M15 200 mm heavyweight concrete | |

| I02 50 mm insulation board | |

| F04 Wall airspace resistance | |

| G01a 19 mm gypsum board | |

| Interior Wall | G01a 19 mm gypsum board |

| F04 Wall airspace resistance | |

| G01a 19 mm gypsum board | |

| Exterior Roof | M11 100 mm lightweight concrete |

| F05 Ceiling airspace resistance | |

| F16 Acoustic tile | |

| Interior Ceiling | Finish flooring |

| INS-Expanded EXT polystyrene R12 2 In | |

| Concrete-dried sand and gravel 4 | |

| Exterior Window | Clear 3 mm |

| Air 13 mm | |

| Clear 3 mm | |

| Interior Window | Clear 3 mm |

| Exterior Door | F08 Metal surface |

| I01 25 mm insulation board | |

| Interior Door | G05 25 mm wood |

| Category | Primary Energy Conversion Factor |

|---|---|

| Gas(fuel) | 1.1 |

| Electricity | 2.75 |

| District heating | 0.728 |

| District cooling | 0.937 |

| Dry Bulb Temperature Control | PMV Control | ||

|---|---|---|---|

| Type | Price (KRW) | Type | Price (KRW) |

| Temperature controller | 55,000 ($50.95) | Temperature & humidity sensor | 2000 ($1.85) |

| Airflow sensor | 70,000 ($64.84) | ||

| MRT | 45,000 ($41.69) | ||

| Camera | 6000 ($5.56) | ||

| Board | 90,000 ($83.37) | ||

| Temperature controller | 55,000 ($50.95) | ||

| Base Rate (KRW) | Energy Charge (KRW/kWh) | ||

|---|---|---|---|

| 1–200 kWh | 730 ($0.68) | 1–200 kWh | 78.3 ($0.07) |

| 201–400 kWh | 1260 ($1.17) | 201–400 kWh | 147.3 ($0.14) |

| 400 kWh~ | 6060 ($5.61) | 400 kWh~ | 215.6 ($0.2) |

| Year | Dry Bulb Temperature Control Present Value (KRW 1000) | PMV Control Present Value (KRW 1000) |

|---|---|---|

| 1 | 825.68 ($767.30) | 1731.84 ($1609.52) |

| 2 | 1325.07 ($1231.48) | 2087.18 ($1939.76) |

| 3 | 1825.52 ($1696.74) | 2443.27 ($2270.71) |

| 4 | 2310.27 ($2147.29) | 2788.19 ($2591.26) |

| 5 | 2779.80 ($2583.46) | 3122.29 ($2901.76) |

| 6 | 3234.60 ($3006.13) | 3445.90 ($3202.52) |

| 7 | 3675.12 ($3415.54) | 3759.36 ($3493.83) |

| 8 | 4101.82 ($3812.1) | 4062.98 ($3776.01) |

| 9 | 4515.13 ($4196.22) | 4357.07 ($4049.32) |

| 10 | 4915.46 ($4568.28) | 4641.93 ($4313.66) |

| 11 | 5303.24 ($4928.66) | 4917.85 ($4570.07) |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hong, S.H.; Lee, J.M.; Moon, J.W.; Lee, K.H. Thermal Comfort, Energy and Cost Impacts of PMV Control Considering Individual Metabolic Rate Variations in Residential Building. Energies 2018, 11, 1767. https://doi.org/10.3390/en11071767

Hong SH, Lee JM, Moon JW, Lee KH. Thermal Comfort, Energy and Cost Impacts of PMV Control Considering Individual Metabolic Rate Variations in Residential Building. Energies. 2018; 11(7):1767. https://doi.org/10.3390/en11071767

Chicago/Turabian StyleHong, Sung Hyup, Jong Man Lee, Jin Woo Moon, and Kwang Ho Lee. 2018. "Thermal Comfort, Energy and Cost Impacts of PMV Control Considering Individual Metabolic Rate Variations in Residential Building" Energies 11, no. 7: 1767. https://doi.org/10.3390/en11071767