Solving Non-Smooth Optimal Power Flow Problems Using a Developed Grey Wolf Optimizer

Abstract

:1. Introduction

2. Optimal Power Flow Formulation

2.1. Objective Functions

2.1.1. Quadratic Fuel Cost

2.1.2. Quadratic Cost with Valve-Point Effect and Prohibited Zones

2.1.3. Piecewise Quadratic Cost Functions

2.2. Operating Constraints

2.2.1. Equality Operating Constraints

2.2.2. Inequality Operating Constrains

3. Developed Grey Wolf Optimizer

3.1. Grey Wolf Optimizer

- Encircling prey.

- Hunting the prey.

- Attacking the prey.

3.1.1. Encircling Prey

3.1.2. Hunting the Prey

3.1.3. Attacking the Prey

3.2. Developed Grey Wolf Optimizer

- : the best position (alpha wolf position).

- b: is a constant value for defining the logarithmic spiral shape.

- : is a random number [−1, 1].

- (1)

- Initialize maximum number of iterations () and search agents (N).

- (2)

- Read the input system data.

- (3)

- Initialize grey wolf population as:where, , and are the minimum and maximum limits of control variables which are predefined values. rand is a random number in range [0, 1].

- (4)

- Calculate the objective function for all grey wolf population using Newton Raphson load flow method.

- (5)

- Determine , , (first, second, and third best search agent).

- (6)

- Update the location of each search agent according Equations (24)–(31) and calculate the objective function using Newton Raphson load flow for the updated agents.

- (7)

- Update the values of a [2:0], A and C according Equations (22) and (23).

- (8)

- Update the adaptive operator, according to Equation (34)

- (9)

- IF < rand, update the position of search agent based on random mutation according to Equation (32)ELSE IF K > rand, update the position of search agent locally in spiral path using Equation (33)ENDIF Fitness () < Fitness ()ELSE, ENDwhere, Fitness is the objective function of the position vector n while Fitness () is the objective function of the updated position vector j.

- (10)

- Repeat steps from (4) to (9) until the iteration number equals to its maximum value.

- (11)

- Find the best vector () which include the system control variables and its related fitness function.

4. Simulation Results

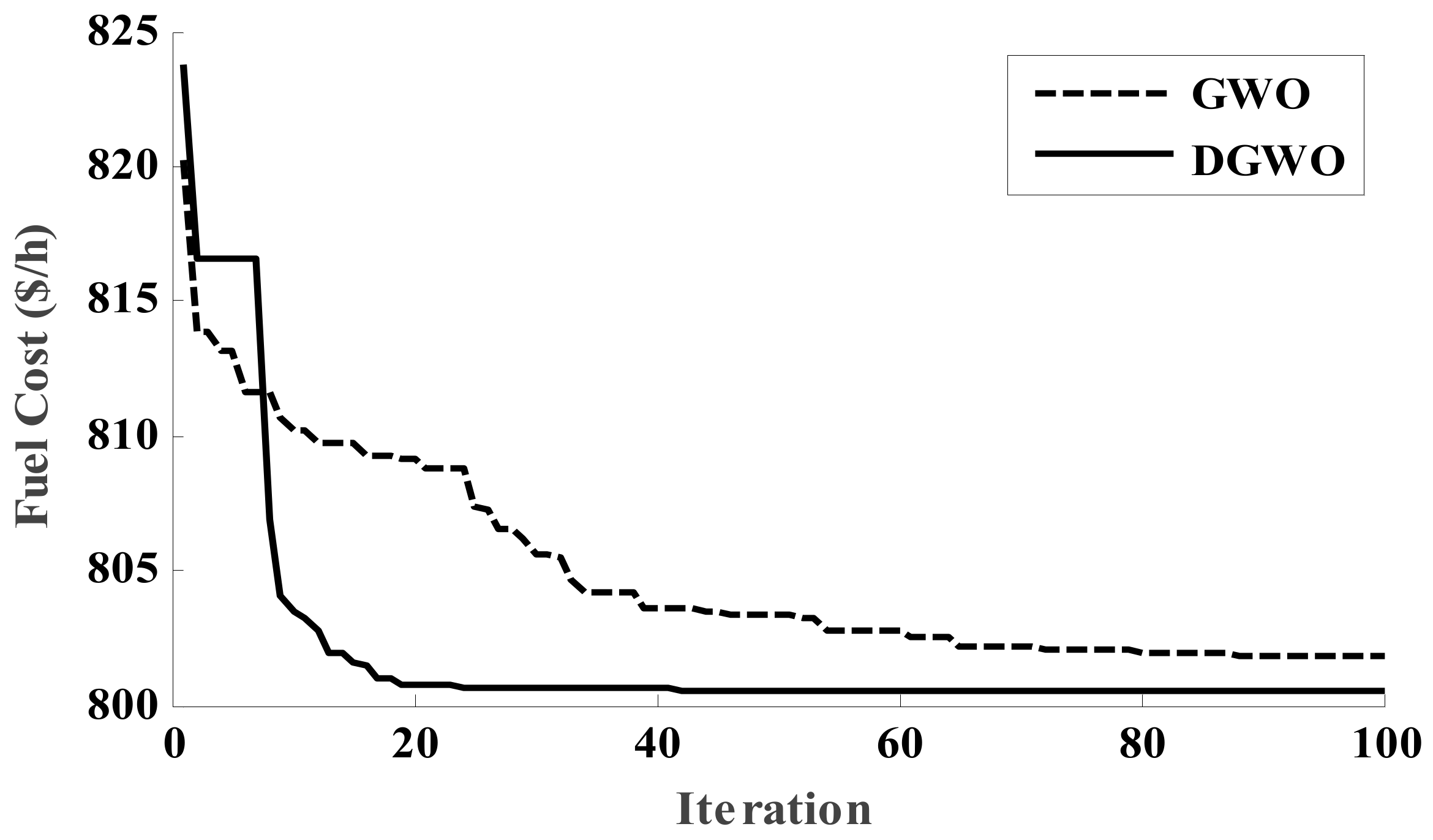

4.1. Case1: OPF Solution without Considering the Valve Point Effects

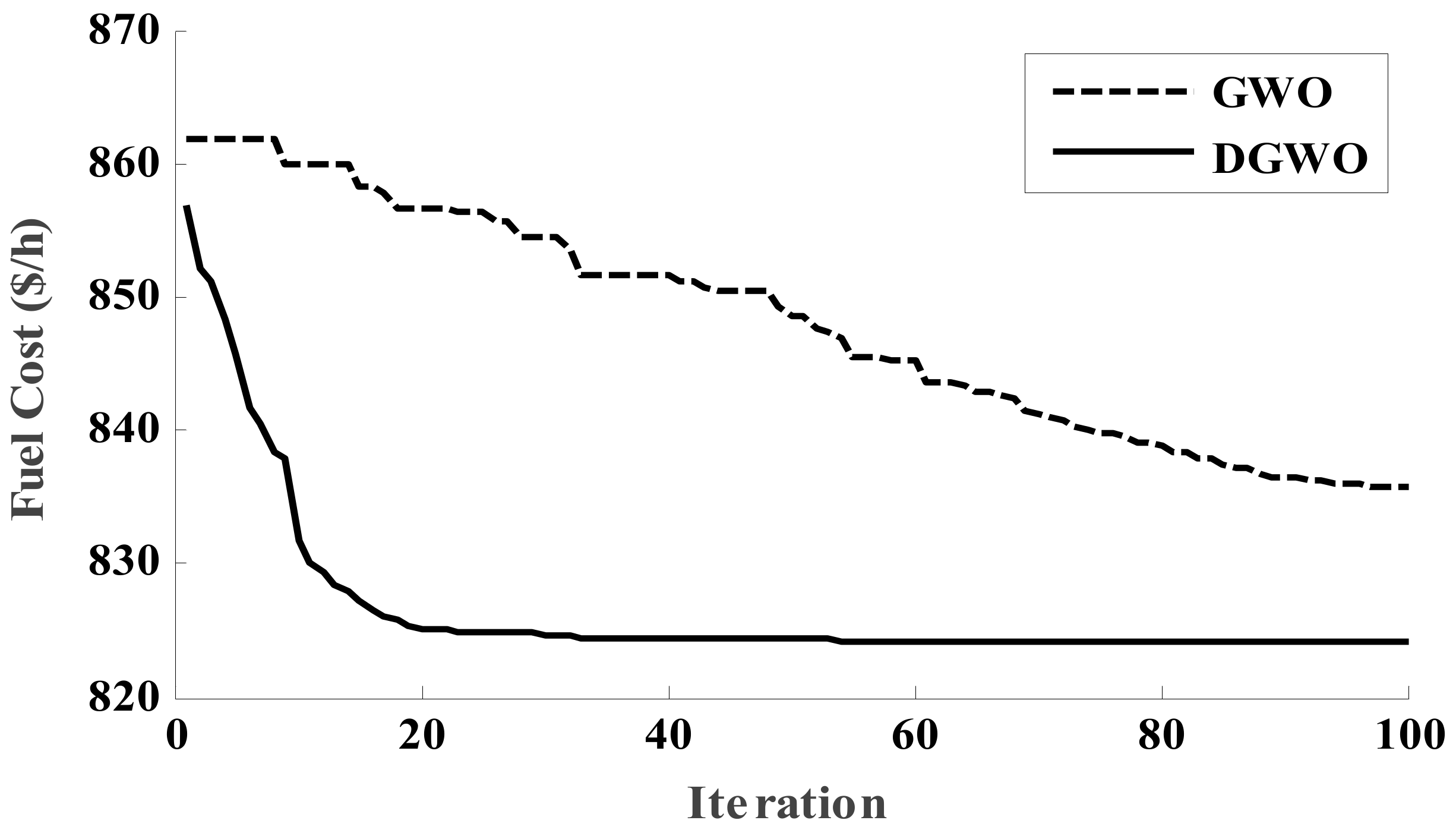

4.2. Case 2: OPF Solution Considering the Valve Point Effects

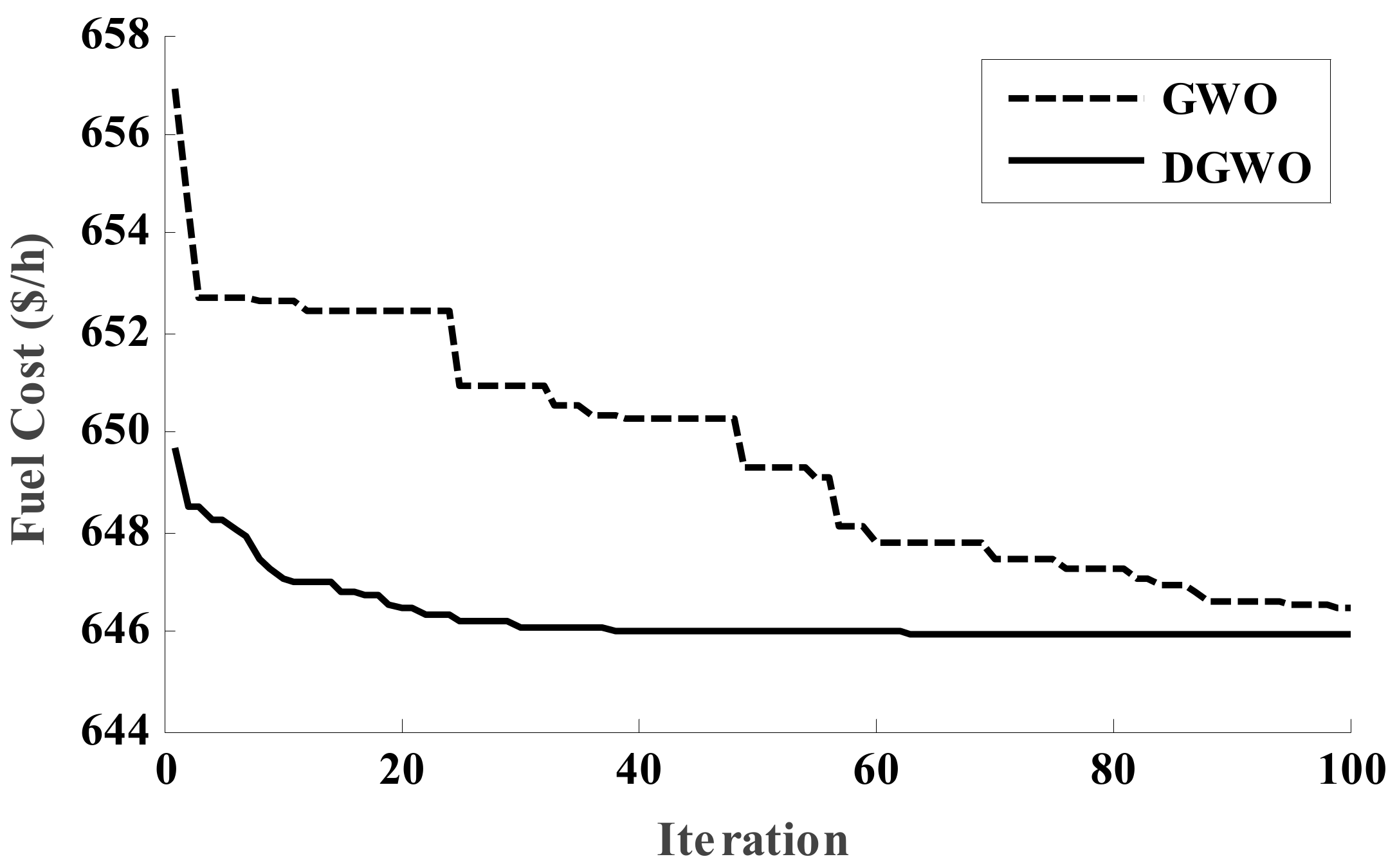

4.3. Case 3: OPF Solution Considering Piecewise Quadratic Fuel Cost Function

5. Conclusions

- -

- The proposed technique has successfully performed to find the optimal settings of the control variables of test system.

- -

- Different objective functions (quadratic fuel cost minimization, piecewise quadratic cost minimization, and quadratic fuel cost minimization considering the valve point effect) have been achieved using the proposed algorithm.

- -

- The superiority of DGWO compared with the conventional GWO and other well-known optimization techniques has been proved.

- -

- DGWO has a fast and stable convergence characteristic compared with the conventional GWO.

Author Contributions

Funding

Conflicts of Interest

Nomenclature

| ABC | Artificial bee colony algorithm |

| BSA | Backtracking search algorithm |

| DGWO | Developed grey wolf optimizer |

| GA | Genetic algorithm |

| GWO | Grey wolf optimizer |

| LP | Linear programming |

| MSA | Moth swarm algorithm |

| OPF | Optimal power flow |

| QP | Quadratic programming |

| TS | Tabu search |

| MFO | Moth-flame algorithm |

| ITS | Improved Tabu Search |

| Random vectors | |

| x | The state variables vector |

| The lower and upper boundary of control variables | |

| QG | The reactive power output of generators |

| t | The current iteration |

| The maximum number of iterations | |

| , | The active and reactive load demand at bus i |

| Phase difference of voltages | |

| VL | The voltage of load bus |

| VG | The voltage of generation bus |

| NPQ | Number of load buses |

| di, ei | The fuel cost coefficients of the ith generator unit with valve-point effects |

| NTL | Number of transmission lines |

| R | Random number |

| Random value | |

| Transmission line conductance | |

| Transmission line susceptance | |

| The prey position vector | |

| k | Adaptive operator |

| b | Constant value |

| Penalty factors | |

| First, second, and third best search agents | |

| max, min | Superscript refers to maximum and minimum values |

| BBO | Biogeography-based optimization |

| DE | Differential evolution |

| EP | Evolutionary programming |

| GSA | Gravitational search algorithm |

| MDE | Modified differentia evolution |

| NLP | Nonlinear programming |

| PSO | Particle swarm optimization |

| SFLA | Shuffle frog leaping algorithm |

| SOS | Symbiotic organisms search |

| TLBO | Teaching–learning-based optimization |

| IP | Interior point |

| F | The objective function |

| gi, hj | The equality and inequality constraints |

| u | The control variables vector |

| m, p | Number of equality and inequality constraints |

| QC | The injected reactive power of shunt compensator |

| PG1 | The generated power of slack bus |

| PG | The output active power of generator |

| SL | The apparent power flow in transmission line |

| T | Tap setting of transformer |

| NG | Number of generators |

| NC | Number of shunt compensator |

| NT | Number of transformers |

| NPV | Number of generators PV buses |

| ai, bi, ci | The cost coefficients of ith generator. |

| NPV | Number of generation buses |

| I | Current |

| V | Magnitude of node voltage |

| R, X, Z | Resistance, reactance, impedance |

| P, Q, S | Active, reactive, apparent powers |

| The location of the present solution | |

| A random number | |

| New generated vector | |

| Alpha, beta, delta, omega fittest solutions | |

| Random vectors |

References

- Lee, K.; Park, Y.; Ortiz, J. A united approach to optimal real and reactive power dispatch. IEEE Trans. Power Appar. Syst. 1985, PER-5, 1147–1153. [Google Scholar] [CrossRef]

- Zhu, J. Optimization of Power System Operation; John Wiley & Sons: Hoboken, NJ, USA, 2015; Volume 47. [Google Scholar]

- Dommel, H.W.; Tinney, W.F. Optimal power flow solutions. IEEE Trans. Power Appar. Syst. 1968, PAS-87, 1866–1876. [Google Scholar] [CrossRef]

- Mota-Palomino, R.; Quintana, V. Sparse reactive power scheduling by a penalty function-linear programming technique. IEEE Trans. Power Syst. 1986, 1, 31–39. [Google Scholar] [CrossRef]

- Burchett, R.; Happ, H.; Vierath, D. Quadratically convergent optimal power flow. IEEE Trans. Power Appar. Syst. 1984, PAS-103, 3267–3275. [Google Scholar] [CrossRef]

- Santos, A.J.; da Costa, G. Optimal-power-flow solution by Newton’s method applied to an augmented Lagrangian function. IEE Proc. Gener. Transm. Distrib. 1995, 142, 33–36. [Google Scholar] [CrossRef]

- Yan, X.; Quintana, V.H. Improving an interior-point-based OPF by dynamic adjustments of step sizes and tolerances. IEEE Trans. Power Syst. 1999, 14, 709–717. [Google Scholar]

- Chung, T.; Li, Y. A hybrid GA approach for OPF with consideration of FACTS devices. IEEE Power Eng. Rev. 2000, 20, 54–57. [Google Scholar] [CrossRef]

- Paranjothi, S.; Anburaja, K. Optimal power flow using refined genetic algorithm. Electr. Power Compon. Syst. 2002, 30, 1055–1063. [Google Scholar] [CrossRef]

- Ebeed, M.; Kamel, S.; Youssef, H. Optimal setting of STATCOM based on voltage stability improvement and power loss minimization using Moth-Flame algorithm. In Proceedings of the 2016 Eighteenth International Middle East Power Systems Conference (MEPCON), Cairo, Egypt, 27–29 December 2016; pp. 815–820. [Google Scholar]

- Varadarajan, M.; Swarup, K.S. Solving multi-objective optimal power flow using differential evolution. IET Gener. Transm. Distrib. 2008, 2, 720–730. [Google Scholar] [CrossRef]

- Abou El Ela, A.A.; Abido, M.; Spea, S. Optimal power flow using differential evolution algorithm. Electr. Power Syst. Res. 2010, 80, 878–885. [Google Scholar] [CrossRef]

- Abido, M. Optimal power flow using particle swarm optimization. Int. J. Electr. Power Energy Syst. 2002, 24, 563–571. [Google Scholar] [CrossRef]

- Mohamed, A.-A.A.; Mohamed, Y.S.; El-Gaafary, A.A.; Hemeida, A.M. Optimal power flow using moth swarm algorithm. Electr. Power Syst. Res. 2017, 142, 190–206. [Google Scholar] [CrossRef]

- Ongsakul, W.; Tantimaporn, T. Optimal power flow by improved evolutionary programming. Electr. Power Compon. Syst. 2006, 34, 79–95. [Google Scholar] [CrossRef]

- Yuryevich, J.; Wong, K.P. Evolutionary programming based optimal power flow algorithm. IEEE Trans. Power Syst. 1999, 14, 1245–1250. [Google Scholar] [CrossRef]

- Adaryani, M.R.; Karami, A. Artificial bee colony algorithm for solving multi-objective optimal power flow problem. Int. J. Electr. Power Energy Syst. 2013, 53, 219–230. [Google Scholar] [CrossRef]

- Duman, S.; Güvenç, U.; Sönmez, Y.; Yörükeren, N. Optimal power flow using gravitational search algorithm. Energy Convers. Manag. 2012, 59, 86–95. [Google Scholar] [CrossRef]

- Bhattacharya, A.; Chattopadhyay, P. Application of biogeography-based optimisation to solve different optimal power flow problems. IET Gener. Transm. Distrib. 2011, 5, 70–80. [Google Scholar] [CrossRef]

- Niknam, T.; Narimani, M.R.; Azizipanah-Abarghooee, R. A new hybrid algorithm for optimal power flow considering prohibited zones and valve point effect. Energy Convers. Manag. 2012, 58, 197–206. [Google Scholar] [CrossRef]

- Shaheen, A.M.; El-Sehiemy, R.A.; Farrag, S.M. Solving multi-objective optimal power flow problem via forced initialised differential evolution algorithm. IET Gener. Transm. Distrib. 2016, 10, 1634–1647. [Google Scholar] [CrossRef]

- Abido, M. Optimal power flow using tabu search algorithm. Electr. Power Compon. Syst. 2002, 30, 469–483. [Google Scholar] [CrossRef]

- Sayah, S.; Zehar, K. Modified differential evolution algorithm for optimal power flow with non-smooth cost functions. Energy Convers. Manag. 2008, 49, 3036–3042. [Google Scholar] [CrossRef]

- Duman, S. Symbiotic organisms search algorithm for optimal power flow problem based on valve-point effect and prohibited zones. Neural Comput. Appl. 2017, 28, 3571–3585. [Google Scholar] [CrossRef]

- Kılıç, U. Backtracking search algorithm-based optimal power flow with valve point effect and prohibited zones. Electr. Eng. 2015, 97, 101–110. [Google Scholar] [CrossRef]

- Ghasemi, M.; Ghavidel, S.; Gitizadeh, M.; Akbari, E. An improved teaching–learning-based optimization algorithm using Lévy mutation strategy for non-smooth optimal power flow. Int. J. Electr. Power Energy Syst. 2015, 65, 375–384. [Google Scholar] [CrossRef]

- Mohammadi, A.; Mehrtash, M.; Kargarian, A. Diagonal quadratic approximation for decentralized collaborative TSO+ DSO optimal power flow. IEEE Trans. Smart Grid 2018. [Google Scholar] [CrossRef]

- Naderi, E.; Azizivahed, A.; Narimani, H.; Fathi, M.; Narimani, M.R. A comprehensive study of practical economic dispatch problems by a new hybrid evolutionary algorithm. Appl. Soft Comput. 2017, 61, 1186–1206. [Google Scholar] [CrossRef]

- Mirjalili, S.; Mirjalili, S.M.; Lewis, A. Grey wolf optimizer. Adv. Eng. Softw. 2014, 69, 46–61. [Google Scholar] [CrossRef]

- Azizivahed, A.; Narimani, H.; Fathi, M.; Naderi, E.; Safarpour, H.R.; Narimani, M.R. Multi-objective dynamic distribution feeder reconfiguration in automated distribution systems. Energy 2018, 147, 896–914. [Google Scholar] [CrossRef]

- IEEE 30-Bus Test System Data. Available online: https://www.ee.washington.edu/research/pstca/pf57/pg_tca30bus.hm (accessed on 26 June 2018).

| Bus No. | Cost Coefficients | Prohibited Zones | |||||

|---|---|---|---|---|---|---|---|

| a | b | c | |||||

| 1 | 250 | 50 | −20 | 0 | 2.0 | 0.00375 | (55–66), (80–120) |

| 2 | 80 | 20 | −20 | 0 | 1.75 | 0.0175 | (21–24), (45–55) |

| 5 | 50 | 15 | −15 | 0 | 1.0 | 0.0625 | (30–36) |

| 8 | 35 | 10 | −15 | 0 | 3.25 | 0.00834 | (25–30) |

| 11 | 30 | 10 | −10 | 0 | 3.00 | 0.025 | (25–28) |

| 13 | 40 | 12 | −15 | 0 | 3.00 | 0.025 | (24–30) |

| Variables | Limit | Case 1 | Case 2 | Case 3 | ||||

|---|---|---|---|---|---|---|---|---|

| Min. | Max. | GWO | DGWO | GWO | DGWO | GWO | DGWO | |

| P1 (MW) | 50 | 250 | 171.094 | 176.949 | 212.633 | 219.801 | 140.00 | 140.00 |

| P2 (MW) | 20 | 80 | 48.615 | 48.519 | 25.684 | 28.358 | 54.992 | 55.000 |

| P5 (MW) | 15 | 50 | 21.123 | 21.326 | 17.612 | 15.047 | 34.930 | 24.105 |

| P8 (MW) | 10 | 35 | 22.068 | 21.571 | 14.185 | 10.000 | 25.008 | 35.000 |

| P11 (MW) | 10 | 30 | 15.479 | 12.026 | 10.651 | 10.000 | 16.934 | 18.239 |

| P13 (MW) | 12 | 40 | 13.665 | 12.001 | 13.751 | 12.000 | 18.223 | 17.664 |

| V1 (p.u) | 0.95 | 1.1 | 1.080 | 1.083 | 1.087 | 1.090 | 1.077 | 1.073 |

| V2 (p.u) | 0.95 | 1.1 | 1.062 | 1.063 | 1.062 | 1.065 | 1.064 | 1.060 |

| V5 (p.u) | 0.95 | 1.1 | 1.030 | 1.031 | 1.023 | 1.032 | 1.035 | 1.032 |

| V8 (p.u) | 0.95 | 1.1 | 1.036 | 1.035 | 1.035 | 1.035 | 1.044 | 1.040 |

| V11 (p.u) | 0.95 | 1.1 | 1.080 | 1.060 | 1.051 | 1.099 | 1.062 | 1.049 |

| V13 (p.u) | 0.95 | 1.1 | 1.054 | 1.050 | 1.060 | 1.037 | 1.036 | 1.060 |

| T11 | 0.90 | 1.1 | 0.982 | 0.977 | 1.0128 | 0.948 | 1.023 | 0.994 |

| T12 | 0.90 | 1.1 | 1.026 | 1.013 | 0.908 | 1.025 | 1.008 | 0.978 |

| T15 | 0.90 | 1.1 | 0.989 | 0.934 | 0.986 | 0.970 | 1.019 | 0.971 |

| T36 | 0.90 | 1.1 | 0.981 | 0.975 | 0.976 | 0.981 | 0.959 | 0.975 |

| Q10 (MVar) | 0.00 | 5.00 | 2.144 | 1.695 | 3.170 | 3.277 | 0.986 | 1.251 |

| Q12 (MVar) | 0.00 | 5.00 | 2.929 | 3.394 | 2.143 | 2.367 | 3.996 | 3.157 |

| Q15 (MVar) | 0.00 | 5.00 | 1.400 | 4.777 | 1.959 | 1.228 | 2.978 | 2.433 |

| Q17 (MVar) | 0.00 | 5.00 | 3.526 | 4.153 | 1.126 | 4.660 | 2.148 | 4.831 |

| Q20 (MVar) | 0.00 | 5.00 | 2.954 | 3.738 | 2.369 | 3.585 | 4.139 | 4.462 |

| Q21 (MVar) | 0.00 | 5.00 | 3.588 | 4.941 | 2.016 | 3.603 | 2.878 | 4.653 |

| Q23 (MVar) | 0.00 | 5.00 | 2.974 | 3.567 | 1.532 | 3.560 | 3.603 | 3.043 |

| Q24 (MVar) | 0.00 | 5.00 | 3.688 | 4.996 | 1.675 | 4.603 | 1.377 | 4.467 |

| Q29 (MVar) | 0.00 | 5.00 | 3.259 | 2.200 | 2.378 | 3.232 | 3.628 | 2.439 |

| PLoss(MW) | NA | NA | 8.6428 | 8.9921 | 11.1151 | 11.805 | 6.6860 | 6.6079 |

| VD (p.u) | NA | NA | 0.7285 | 0.8784 | 0.7055 | 0.8589 | 0.6170 | 0.8825 |

| Lmax (p.u) | NA | NA | 0.1299 | 0.1279 | 0.1328 | 0.1281 | 0.1307 | 0.1280 |

| Fuelcost ($/h) | NA | NA | 801.259 | 800.433 | 830.028 | 824.132 | 646.426 | 645.913 |

| Computational time (s) | NA | NA | 53.6 | 37.8 | 41.70 | 41.5 | 52.4 | 47.2 |

| Algorithm | Best Cost | Average Cost | Worst Cost |

|---|---|---|---|

| DGWO | 800.433 | 800.4674 | 800.4989 |

| GWO | 801.259 | 802.663 | 804.898 |

| MSA [14] | 800.5099 | NA | NA |

| SOS [24] | 801.5733 | 801.7251 | 801.8821 |

| ABC [17] | 800.6600 | 800.8715 | 801.8674 |

| TS [22] | 802.290 | NA | NA |

| MDE [23] | 802.376 | 802.382 | 802.404 |

| IEP [15] | 802.465 | 802.521 | 802.581 |

| TS [15] | 802.502 | 802.632 | 802.746 |

| EP [16] | 802.62 | 803.51 | 805.61 |

| TS/SA [15] | 802.788 | 803.032 | 803.291 |

| EP [15] | 802.907 | 803.232 | 803.474 |

| ITS [15] | 804.556 | 805.812 | 806.856 |

| GA [9] | 805.937 | NA | NA |

| Algorithm | Best Cost | Average Cost | Worst Cost |

|---|---|---|---|

| DGWO | 824.132 | 824.295 | 824.663 |

| GWO | 830.028 | 844.639 | 852.388 |

| SOS [24] | 825.2985 | 825.4039 | 825.5275 |

| BSA [25] | 825.23 | 827.69 | 830.15 |

| SFLA-SA [20] | 825.6921 | NA | NA |

| SFLA [20] | 825.9906 | NA | NA |

| PSO [20] | 826.5897 | NA | NA |

| SA [20] | 827.8262 | NA | NA |

| Bus No. | Output Power Limit (MW) | Cost Coefficients | |||

|---|---|---|---|---|---|

| Min. | Max. | a | b | c | |

| 1 | 50 | 140 | 55.0 | 0.70 | 0.0050 |

| 140 | 200 | 82.5 | 1.05 | 0.0075 | |

| 2 | 20 | 55 | 40.0 | 0.30 | 0.0100 |

| 55 | 80 | 80.0 | 0.60 | 0.0200 | |

| Algorithm | Best Cost | Average Cost | Worst Cost |

|---|---|---|---|

| DGWO | 645.9132 | 645.993 | 646.095 |

| GWO | 646.426 | 647.432 | 648.681 |

| GSA [18] | 646.8480 | 646.8962 | 646.9381 |

| Lévy LTLBO [26] | 647.4315 | 647.4725 | 647.8638 |

| PSO [13] | 647.69 | 647.73 | 647.87 |

| BBO [19] | 647.7437 | 647.7645 | 647.7928 |

| TLBO [26] | 647.8125 | 647.8335 | 647.8415 |

| MDE [23] | 647.846 | 648.356 | 650.664 |

| ABC [17] | 649.0855 | 654.0784 | 659.7708 |

| EP [16] | 650.206 | 654.501 | 657.120 |

| TS [15] | 651.246 | 654.087 | 658.911 |

| TS/SA [15] | 654.378 | 658.234 | 662.616 |

| ITS [15] | 654.874 | 664.473 | 675.035 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Abdo, M.; Kamel, S.; Ebeed, M.; Yu, J.; Jurado, F. Solving Non-Smooth Optimal Power Flow Problems Using a Developed Grey Wolf Optimizer. Energies 2018, 11, 1692. https://doi.org/10.3390/en11071692

Abdo M, Kamel S, Ebeed M, Yu J, Jurado F. Solving Non-Smooth Optimal Power Flow Problems Using a Developed Grey Wolf Optimizer. Energies. 2018; 11(7):1692. https://doi.org/10.3390/en11071692

Chicago/Turabian StyleAbdo, Mostafa, Salah Kamel, Mohamed Ebeed, Juan Yu, and Francisco Jurado. 2018. "Solving Non-Smooth Optimal Power Flow Problems Using a Developed Grey Wolf Optimizer" Energies 11, no. 7: 1692. https://doi.org/10.3390/en11071692

APA StyleAbdo, M., Kamel, S., Ebeed, M., Yu, J., & Jurado, F. (2018). Solving Non-Smooth Optimal Power Flow Problems Using a Developed Grey Wolf Optimizer. Energies, 11(7), 1692. https://doi.org/10.3390/en11071692