An Assessment of the Sustainability of Lignocellulosic Bioethanol Production from Wastes in Iceland

Abstract

:1. Introduction

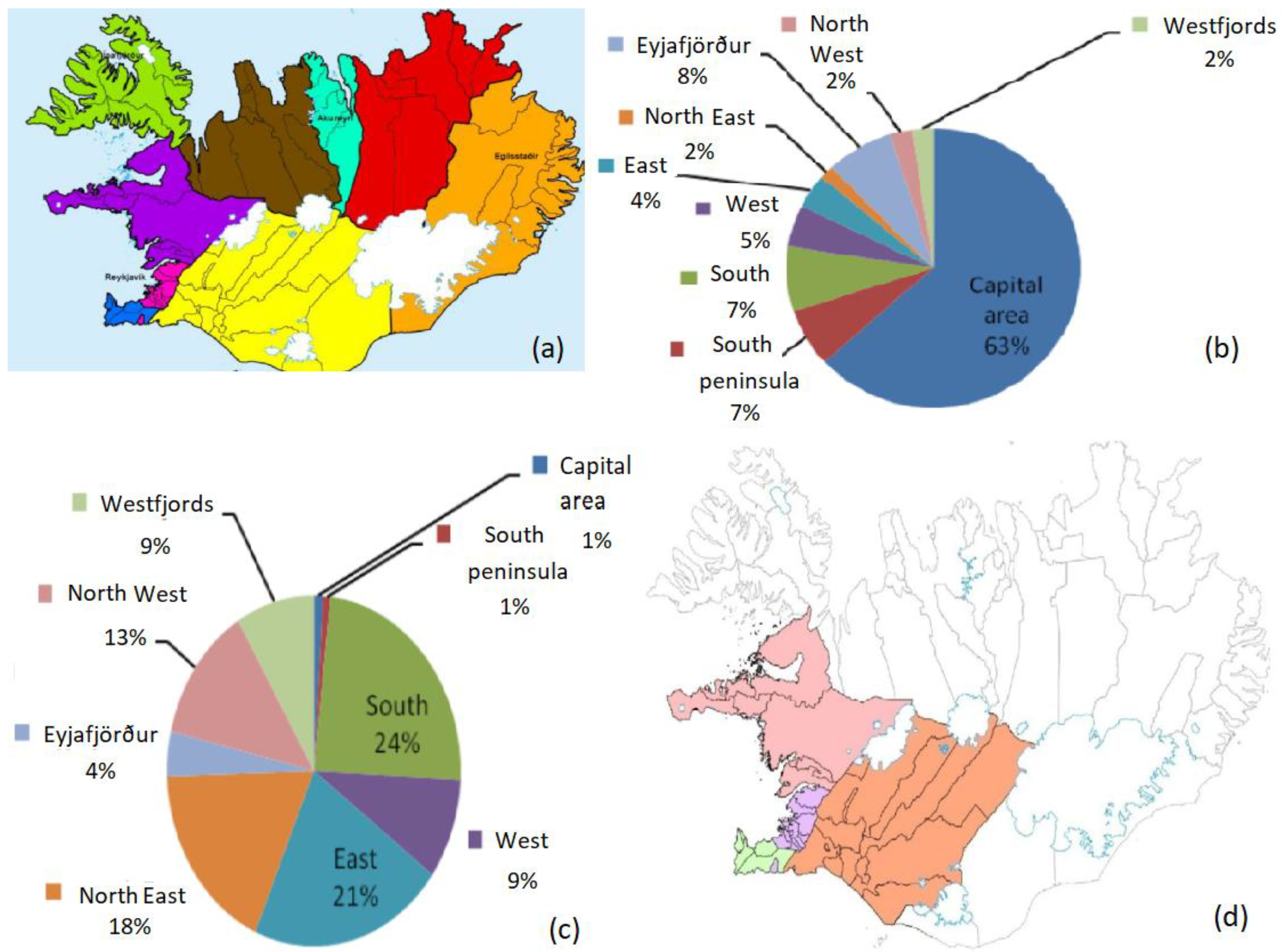

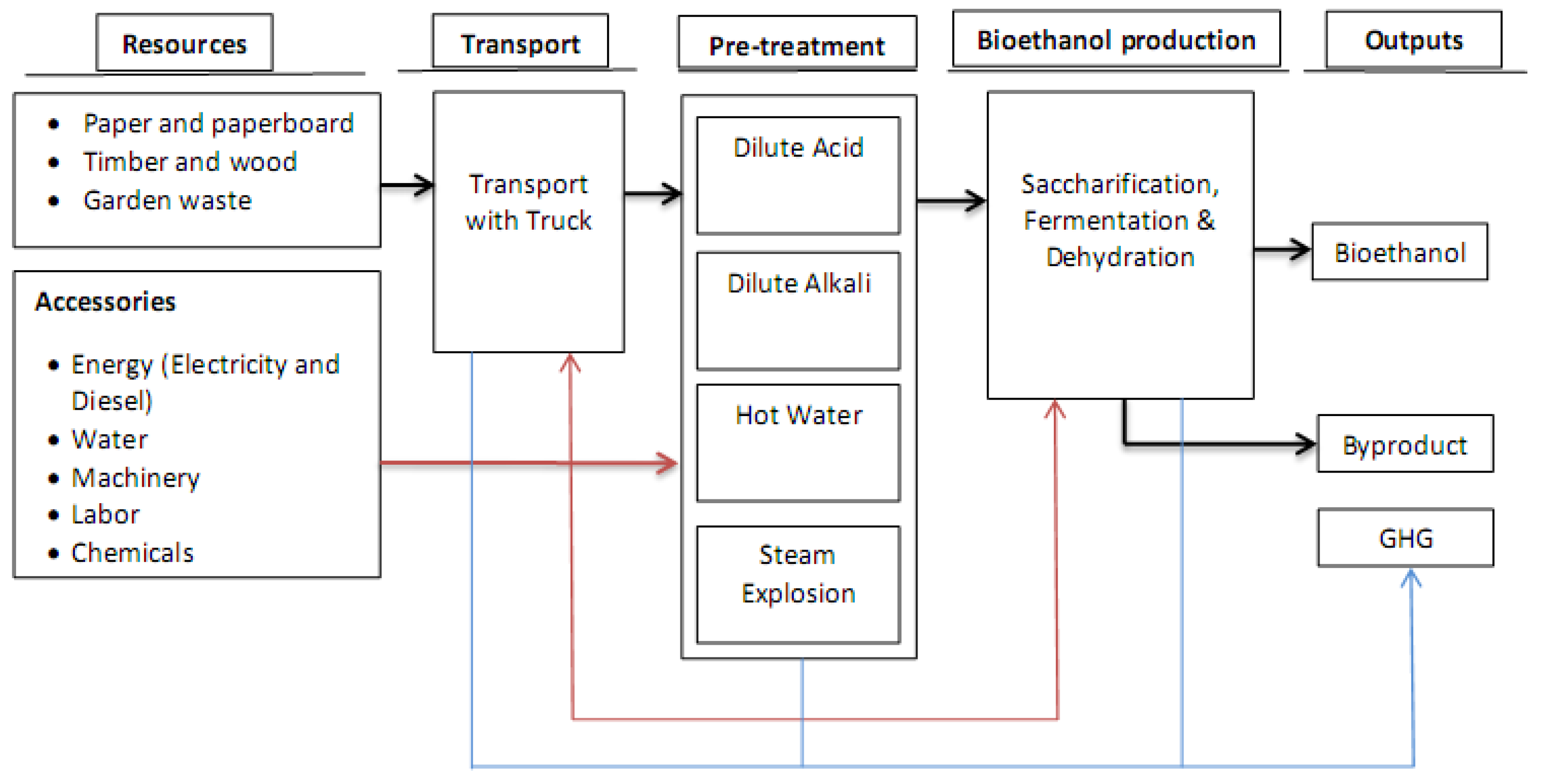

2. System Description

2.1. Resource Level

2.2. Transport Level

2.3. Pretreatment Level

2.4. Bioethanol Production Level

3. Model Description and Data

3.1. Bioethanol Production Level

3.2. Pretreatment Level

3.3. Transport Level

3.4. Resource Level

3.5. Total Material and Machinery Consumption

3.6. Potential of Bioethanol Production

3.7. Modeling of Sustainability Indicators

3.7.1. Economic Indicators

3.7.2. Energy Indicators

3.7.3. Environmental Indicators

4. Results and Discussion

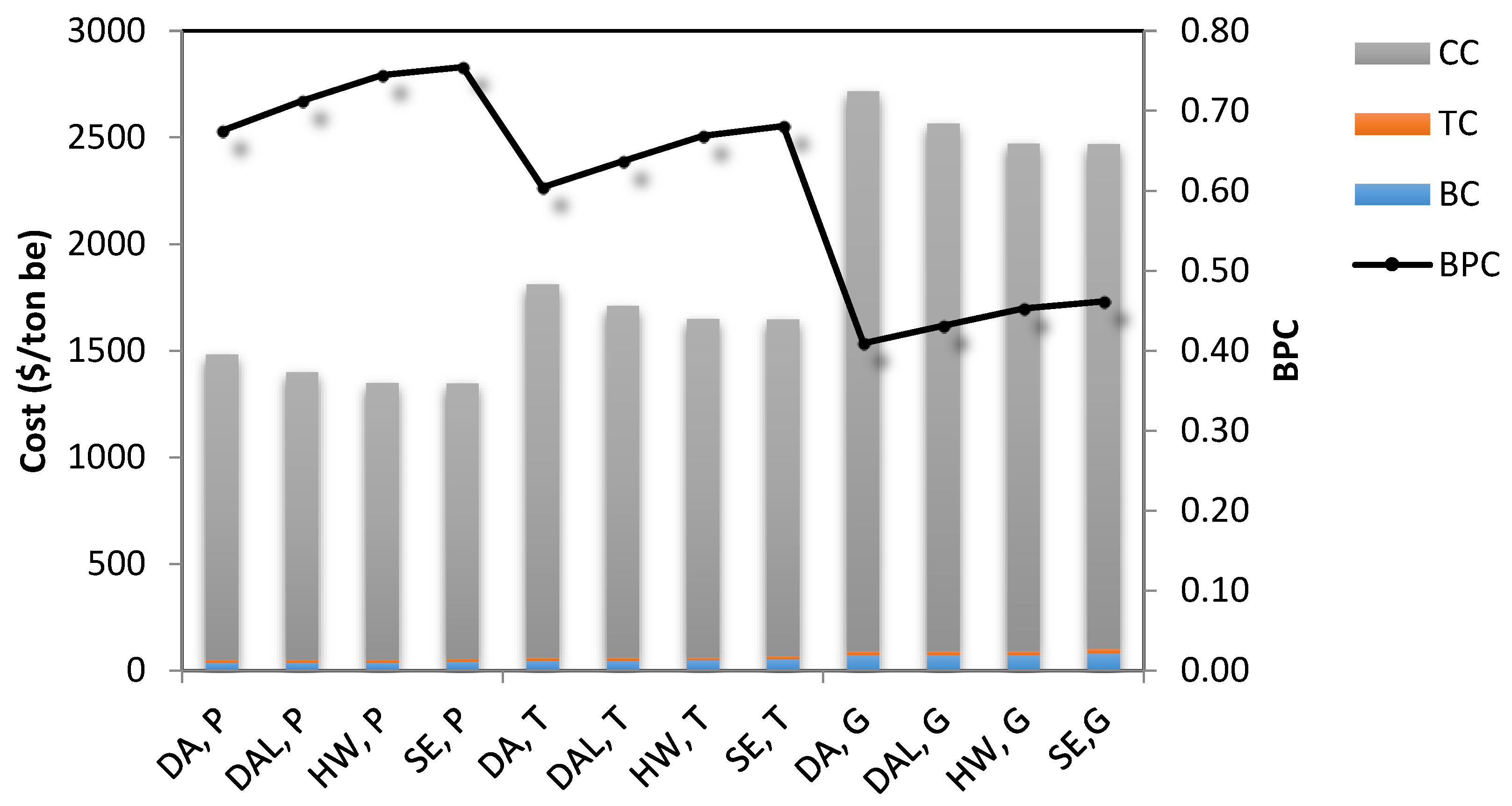

4.1. Economic Assessment

4.2. Energy Assessment

4.3. Environmental Assessment

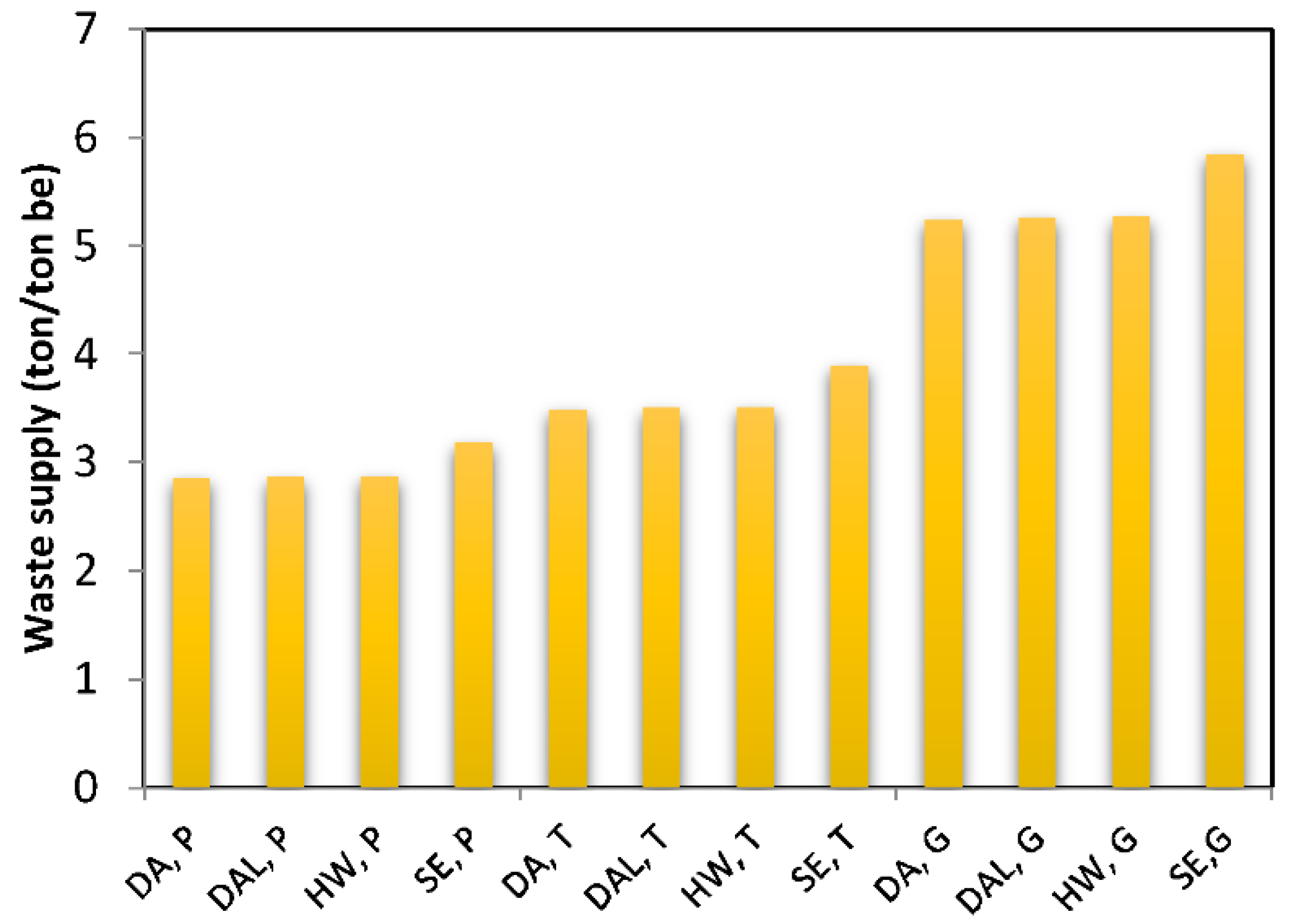

4.4. Potential of Bioethanol Production

4.5. Comparison of Alternatives

5. Conclusions

- (1)

- Among the MOWs, paper and paperboard rank highest in most assessments. The steam explosion option is the most beneficial production technology from an economic, energy and environmental perspective; thus, it would be the most promising technique for producing bioethenal from the studied wastes.

- (2)

- The dilute acid method also ranks highly, technically; however, this it is not a desirable option due to its low energy performance, high production costs and high greenhouse gasses emission.

- (3)

- In addition to steam explosion, more economic and environmentally oriented policies should favor hot water technology, as no chemicals are required for treatment and the hydrolysis yield is similar to that of other pretreatment methods.

- (4)

- The dilute alkali technique for deriving bioethanol from paper also ranks highly for most of the indicators, except for environmental, due to its high GHG emissions and moderate water consumption.

- (5)

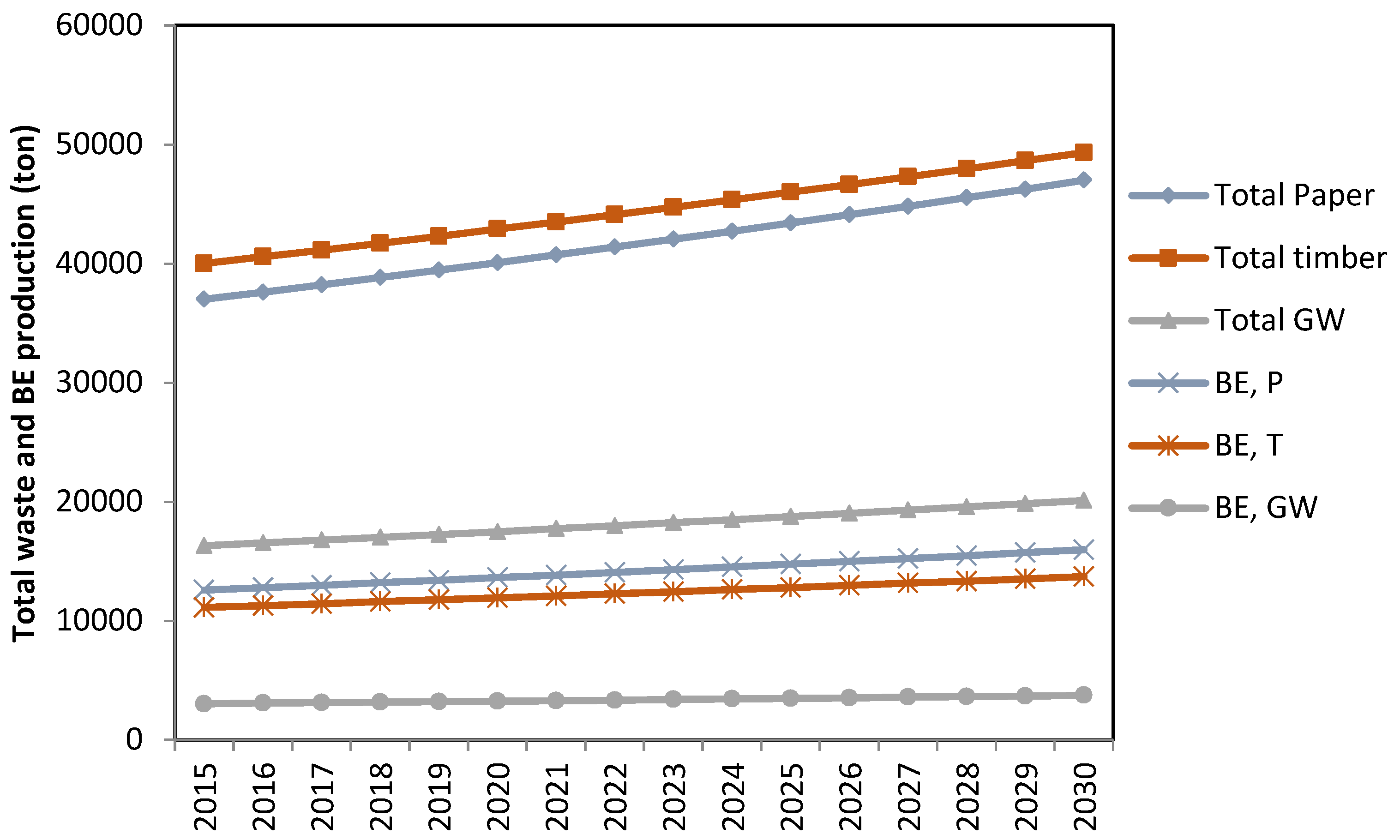

- Finally, estimates of the potential of different wastes and bioethanol production types in 2015 and 2030 were calculated. The total amount of paper, timber and garden wastes in Iceland in 2015 can be estimated as approximately 37, 40 and 16 thousand tons, respectively, which could increase to about 47, 49 and 20 thousand tons by 2030. Thus, the average potential of bioethanol production in 2015 was approximately 12.5, 11 and 3 thousand tons from paper, timber and garden wastes, which may likewise increase to about 15.9, 13.7 and 3.7 thousand tons in 2030.

Author Contributions

Conflicts of Interest

References

- Rajaeifar, M.A.; Akram, A.; Ghobadian, B.; Rafiee, S.; Heijungs, R.; Tabatabaei, M. Environmental impact assessment of olive pomace oil biodiesel production and consumption: A comparative lifecycle assessment. Energy 2016, 106, 87–102. [Google Scholar] [CrossRef]

- Jahirul, M.I.; Rasul, M.G.; Chowdhury, A.A.; Ashwath, N. Biofuels production through biomass pyrolysis—A technological review. Energies 2012, 5, 4952–5001. [Google Scholar] [CrossRef]

- Talebnia, F.; Karakashev, D.; Angelidaki, I. Production of bioethanol from wheat straw: An overview on pretreatment, hydrolysis and fermentation. Bioresour.Technol. 2010, 101, 4744–4753. [Google Scholar] [CrossRef] [PubMed]

- Hirschnitz-Garbers, M.; Gosens, J. Producing bio-ethanol from residues and wastes. A technology with enormous potential in need of further research and development. Policy Brief 2015. Available online: http://ec.europa.eu/environment/integration/green_semester/pdf/Recreate_PB_2015_SEI.PDF (accessed on 2 December 2017).

- Michailos, S.; Parker, D.; Webb, C. Design, sustainability analysis and multiobjective optimisation of ethanol production via syngas fermentation. Waste Biomass Valoriz. 2017, 1–12. [Google Scholar] [CrossRef]

- Liguori, R.; Soccol, C.R.; Porto de Souza Vandenberghe, L.; Woiciechowski, A.L.; Faraco, V. Second generation ethanol production from brewers’ spent grain. Energies 2015, 8, 2575–2586. [Google Scholar] [CrossRef]

- Miezah, K.; Obiri-Danso, K.; Kádár, Z.; Heiske, S.; Fei-Baffoe, B.; Mensah, M.; Meyer, A.S. Municipal solid waste management in a low income economy through biogas and bioethanol production. Waste Biomass Valoriz. 2017, 8, 115–127. [Google Scholar] [CrossRef]

- Sundberg, M.; Guðmundsson, J.; Guðmundsson, M. Biofuel Production in Iceland: Survey of Potential Raw Materials and Yields to 2030; MANNVIT Engineering: Kópavogur, Iceland, 15 October 2010. Available online: http://www.lifeldsneyti.is/resources/Files/Lifeldsneyti/Lifeldsneyti-Arsskyrsla-2010/Fylgiskjal_1_Mannvit.pdf (accessed on 2 December 2017).

- Hálfdánarson, H.E. Ethanol Production from Timothy (Phleum pratense L.). Master’ Thesis, Agricultural University of Iceland, Hvanneyri, Island, June 2015. [Google Scholar]

- Snæbjörnsson, A.; Hjartardóttir, D.; Blöndal, E.; Pétursson, J.; Eggertsson, Ó.; Halldórsson, O. Skýrsla Nefndar um Landnotkun-Athugun á Notkun og Varðveislu Ræktanlegs Lands; Ministry of Fisheries and Agriculture: Reykjavık, Iceland, 2010.

- Dell, R.; Unnthorsson, R.; Wei, C.; Foley, W. Waste geothermal hot water for enhanced outdoor agricultural production. In Proceedings of the ASME 2013 Power Conference, Boston, MA, USA, 29 July–1 August 2013; American Society of Mechanical Engineers: New York, NY, USA, 2013; p. V002T009A013. [Google Scholar] [CrossRef]

- Lin, J.; Babbitt, C.W.; Trabold, T.A. Life cycle assessment integrated with thermodynamic analysis of bio-fuel options for solid oxide fuel cells. Bioresour. Technol. 2013, 128, 495–504. [Google Scholar] [CrossRef] [PubMed]

- Strategic Planning for the Management of Wastes 2009–2020; Mannvit Engineering: Reykjavik, Iceland, 2015.

- Íslenska Gámafélagið. Available online: http://www.gamur.is/ (accessed on 2 December 2017).

- Ng, S.Y.; Ong, S.Y.; Ng, Y.Y.; Liew, A.H.; Ng, D.K.; Chemmangattuvalappil, N.G. Optimal design and synthesis of sustainable integrated biorefinery for pharmaceutical products from palm-based biomass. Process Integr. Optim. Sustain. 2017, 1, 135–151. [Google Scholar] [CrossRef]

- Holmgren, K. Waste incineration in swedish municipal energy systems. WIT Trans. Ecol. Environ. 2006, 92. [Google Scholar] [CrossRef]

- Halldorsson, T.I.; Auðunsson, G.A.; Guicharnaud, R.; Dýrmundsson, Ó.R.; Hansson, S.Ö.; Hreinsson, K. Contamination of livestock due to the operation of a small waste incinerator: A case incident in skutulsfjörður, iceland, in 2010. Acta Vet. Scand. 2012, 54, S4. [Google Scholar] [CrossRef]

- Niðurstöður úr Mælingum á Díoxínum í jarðvegi; Umhverfisstofnun: Reykjavık, Iceland, 2011. Available online: https://www.ust.is/einstaklingar/frettir/frett/2011/07/06/Nidurstodur-ur-maelingum-a-dioxinum-i-jardvegi/ (accessed on 2 December 2017).

- Gunnarsson, A. Maintenance of the Steam Turbines at Hellisheiði Power Plant. Master’ Thesis, University of Iceland, Reykjavik, Iceland, May 2013. [Google Scholar]

- Rajaeifar, A.M.; Ghobadian, B.; Davoud Heidari, M.; Fayyazi, E. Energy consumption and greenhouse gas emissions of biodiesel production from rapeseed in iran. J. Renew. Sustain. Energy 2013, 5, 063134. [Google Scholar] [CrossRef]

- Mousavi-Avval, S.H.; Rafiee, S.; Jafari, A.; Mohammadi, A. Energy flow modeling and sensitivity analysis of inputs for canola production in iran. J. Clean. Prod. 2011, 19, 1464–1470. [Google Scholar] [CrossRef]

- Mood, S.H.; Golfeshan, A.H.; Tabatabaei, M.; Jouzani, G.S.; Najafi, G.H.; Gholami, M.; Ardjmand, M. Lignocellulosic biomass to bioethanol, a comprehensive review with a focus on pretreatment. Renew. Sustain. Energy Rev. 2013, 27, 77–93. [Google Scholar] [CrossRef]

- Taherzadeh, M.J.; Karimi, K. Pretreatment of lignocellulosic wastes to improve ethanol and biogas production: A review. Int. J. Mol. Sci. 2008, 9, 1621–1651. [Google Scholar] [CrossRef] [PubMed]

- Kumar, D.; Murthy, G.S. Impact of pretreatment and downstream processing technologies on economics and energy in cellulosic ethanol production. Biotechnol. Biofuels 2011, 4, 27. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Talebnia, F.; Bafrani, M.P.; Lundin, M.; Taherzadeh, M. Optimization study of citrus wastes saccharification by dilute acid hydrolysis. BioResources 2007, 3, 108–122. [Google Scholar]

- Behera, S.; Arora, R.; Nandhagopal, N.; Kumar, S. Importance of chemical pretreatment for bioconversion of lignocellulosic biomass. Renew. Sustain. Energy Rev. 2014, 36, 91–106. [Google Scholar] [CrossRef]

- Agbor, V.B.; Cicek, N.; Sparling, R.; Berlin, A.; Levin, D.B. Biomass pretreatment: Fundamentals toward application. Biotechnol. Adv. 2011, 29, 675–685. [Google Scholar] [CrossRef] [PubMed]

- Sritrakul, N.; Nitisinprasert, S.; Keawsompong, S. Evaluation of dilute acid pretreatment for bioethanol fermentation from sugarcane bagasse pith. Agric. Natl. Resour. 2018. [Google Scholar] [CrossRef]

- McIntosh, S.; Vancov, T. Enhanced enzyme saccharification of sorghum bicolor straw using dilute alkali pretreatment. Bioresour. Technol. 2010, 101, 6718–6727. [Google Scholar] [CrossRef] [PubMed]

- Hu, G.; Heitmann, J.A.; Rojas, O.J. Feedstock pretreatment strategies for producing ethanol from wood, bark, and forest residues. BioResources 2008, 3, 270–294. [Google Scholar]

- Viola, E.; Zimbardi, F.; Cardinale, M.; Cardinale, G.; Braccio, G.; Gambacorta, E. Processing cereal straws by steam explosion in a pilot plant to enhance digestibility in ruminants. Bioresour. Technol. 2008, 99, 681–689. [Google Scholar] [CrossRef] [PubMed]

- Wang, L.; Littlewood, J.; Murphy, R.J. Environmental sustainability of bioethanol production from wheat straw in the uk. Renew. Sustain. Energy Rev. 2013, 28, 715–725. [Google Scholar] [CrossRef]

- Safarian, S.; Khodaparast, P.; Kateb, M. Modeling and technical-economic optimization of electricity supply network by three photovoltaic systems. J. Sol. Energy Eng. 2014, 136, 024501. [Google Scholar] [CrossRef]

- Safarian, S.; Saboohi, Y.; Kateb, M. Evaluation of energy recovery and potential of hydrogen production in iranian natural gas transmission network. Energy Policy 2013, 61, 65–77. [Google Scholar] [CrossRef]

- Safarian, S.; Sattari, S.; Hamidzadeh, Z. Sustainability assessment of biodiesel supply chain from various biomasses and conversion technologies. Biophys. Econ. Resour. Qual. (BERQ) 2018, 3, 6. [Google Scholar] [CrossRef]

- Azadeh, A.; Arani, H.V.; Dashti, H. A stochastic programming approach towards optimization of biofuel supply chain. Energy 2014, 76, 513–525. [Google Scholar] [CrossRef]

- You, F.; Tao, L.; Graziano, D.J.; Snyder, S.W. Optimal design of sustainable cellulosic biofuel supply chains: Multiobjective optimization coupled with life cycle assessment and input–output analysis. AIChE J. 2012, 58, 1157–1180. [Google Scholar] [CrossRef]

- Sheinbaum-Pardo, C.; Ruiz-Mendoza, B.J.; Rodríguez-Padilla, V. Mexican energy policy and sustainability indicators. Energy Policy 2012, 46, 278–283. [Google Scholar] [CrossRef]

- Tsai, W.-T. Energy sustainability from analysis of sustainable development indicators: A case study in taiwan. Renew. Sustain. Energy Rev. 2010, 14, 2131–2138. [Google Scholar] [CrossRef]

- Angelis-Dimakis, A.; Arampatzis, G.; Assimacopoulos, D. Monitoring the sustainability of the greek energy system. Energy Sustain. Dev. 2012, 16, 51–56. [Google Scholar] [CrossRef]

- How, B.S.; Lam, H.L. Pca method for debottlenecking of sustainability performance in integrated biomass supply chain. Process Integr. Optim. Sustain. 2018, 1–22. [Google Scholar] [CrossRef]

- Atlantsolía ehf. Available online: https://www.atlantsolia.is/stodvaverd/ (accessed on 2 December 2017).

- Veitur ohf. Available online: https://www.veitur.is/verdskrar/vatnsveita (accessed on 2 December 2017).

- Foreign Big Company in Crash with Electricity Prices. Available online: https://kjarninn.is/skodun/erlent-storfyrirtaeki-i-feluleik-med-raforkuverd/ (accessed on 2 December 2017).

- Mousavi-Avval, S.H.; Rafiee, S.; Jafari, A.; Mohammadi, A. Optimization of energy consumption for soybean production using data envelopment analysis (dea) approach. Appl. Energy 2011, 88, 3765–3772. [Google Scholar] [CrossRef]

- Klein, S.J.; Whalley, S. Comparing the sustainability of us electricity options through multi-criteria decision analysis. Energy Policy 2015, 79, 127–149. [Google Scholar] [CrossRef]

- Rajaeifar, M.A.; Ghobadian, B.; Safa, M.; Heidari, M.D. Energy life-cycle assessment and co2 emissions analysis of soybean-based biodiesel: A case study. J. Clean. Prod. 2014, 66, 233–241. [Google Scholar] [CrossRef]

- Hamelinck, C.N.; Van Hooijdonk, G.; Faaij, A.P. Ethanol from lignocellulosic biomass: Techno-economic performance in short-, middle-and long-term. Biomass Bioenergy 2005, 28, 384–410. [Google Scholar] [CrossRef]

- Shahzadi, T.; Mehmood, S.; Irshad, M.; Anwar, Z.; Afroz, A.; Zeeshan, N.; Rashid, U.; Sughra, K. Advances in lignocellulosic biotechnology: A brief review on lignocellulosic biomass and cellulases. Adv. Biosci. Biotechnol. 2014, 5, 246–251. [Google Scholar] [CrossRef]

- Kumar, S.; Shukla, S. A review on recent gasification methods for biomethane gas production. Int. J. Energy Eng. 2016, 6, 32–43. [Google Scholar]

| Participating Areas | Operator Company | No Municipalities | Waste Quantity (1000 tons) |

|---|---|---|---|

| Western Iceland | Sorpurðun Vesturlands | 10 | 29 |

| Suðurnes | Kalka | 5 | 22 |

| Capital area | Sorpa | 8 | 272 |

| Southern Iceland | Sorpstöð Suðurlands | 11 | 33 |

| Chemicals | Units | Dilute Acid | Dilute Alkali | Hot Water | Steam Explosion |

|---|---|---|---|---|---|

| Water | m3/tonb | 1.422 | 1.44 | 1.387 | 0.934 |

| Sulphuric acid | kg/tonb | 49.04 | 11.40 | 0.00 | 0.00 |

| Ca hydroxide | kg/tonb | 23.88 | 0.00 | 0.00 | 0.00 |

| DAP | kg/tonb | 0.316 | 0.32 | 0.32 | 0.32 |

| Cellulase | kg/tonb | 62.40 | 72.00 | 72.00 | 68.00 |

| Yeast | kg/tonb | 0.79 | 0.79 | 0.79 | 0.79 |

| Sodium hydroxide | kg/tonb | 0.00 | 0.40 | 0.00 | 0.00 |

| Electricity | kwh/tonb | 133.44 | 123.50 | 123.28 | 124.00 |

| Steam | MJ/tonb | 4870.80 | 4731.60 | 4936.80 | 3102.00 |

| Items | Unit | Quantity |

|---|---|---|

| Waste cost | $/kg | 0.014 |

| Chemicals cost | ||

| a. Sulphuric acid | $/kg | 0.035 |

| b. Ca hydroxide | $/kg | 0.1 |

| c. DAP | $/kg | 0.21 |

| d. Cellulase | $/kg | 0.52 |

| e. Yeast | $/kg | 2.3 |

| f. Sodium hydroxide | $/kg | 0.45 |

| Water cost (usage fee) | $/m3 | 0.32 |

| Energy cost | ||

| a. Electricity | $/kwh | 0.03 |

| b. Truck diesel | $/L | 1.08 |

| Capital cost of bioethanol production by using: | ||

| a. Dilute acid | $/tonb | 457.52 |

| b. Dilute alkali | $/tonb | 410.93 |

| c. Hot water | $/tonb | 407.78 |

| d. Steam explosion | $/tonb | 363.45 |

| Product price | ||

| Bioethanol | $/kg | 0.85 |

| Lignin | $/kg | 0.25 |

| Input | Unit | Energy Coefficient (MJ/unit) |

|---|---|---|

| Diesel fuel | L | 47.80 |

| Electricity | kWh | 11.93 |

| Chemicals and machinery in bioethanol production | tonb | 37.5 |

| Bioethanol | kg | 29.3 |

| Lignin | kg | 21.13 |

| Systems | BPC | EUE | GHG Emission | Water Consumption | Production Yield |

|---|---|---|---|---|---|

| SE,P | 1 | 1 | 1 | 1 | 4 |

| HW,P | 2 | 4 | 2 | 3 | 3 |

| DAL,P | 3 | 2 | 9 | 5 | 2 |

| DA,P | 5 | 5 | 5 | 4 | 1 |

| SE,T | 4 | 3 | 3 | 2 | 8 |

| HW,T | 6 | 7 | 4 | 6 | 7 |

| DAL,T | 7 | 6 | 10 | 8 | 6 |

| DA,T | 8 | 8 | 8 | 7 | 5 |

| SE,G | 9 | 9 | 6 | 9 | 12 |

| HW,G | 10 | 11 | 7 | 10 | 11 |

| DAL,G | 11 | 10 | 12 | 12 | 10 |

| DA,G | 12 | 12 | 11 | 11 | 9 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Safarian, S.; Unnthorsson, R. An Assessment of the Sustainability of Lignocellulosic Bioethanol Production from Wastes in Iceland. Energies 2018, 11, 1493. https://doi.org/10.3390/en11061493

Safarian S, Unnthorsson R. An Assessment of the Sustainability of Lignocellulosic Bioethanol Production from Wastes in Iceland. Energies. 2018; 11(6):1493. https://doi.org/10.3390/en11061493

Chicago/Turabian StyleSafarian, Sahar, and Runar Unnthorsson. 2018. "An Assessment of the Sustainability of Lignocellulosic Bioethanol Production from Wastes in Iceland" Energies 11, no. 6: 1493. https://doi.org/10.3390/en11061493