Establishment and Analysis of Energy Consumption Model of Heavy-Haul Train on Large Long Slope

Abstract

:1. Introduction

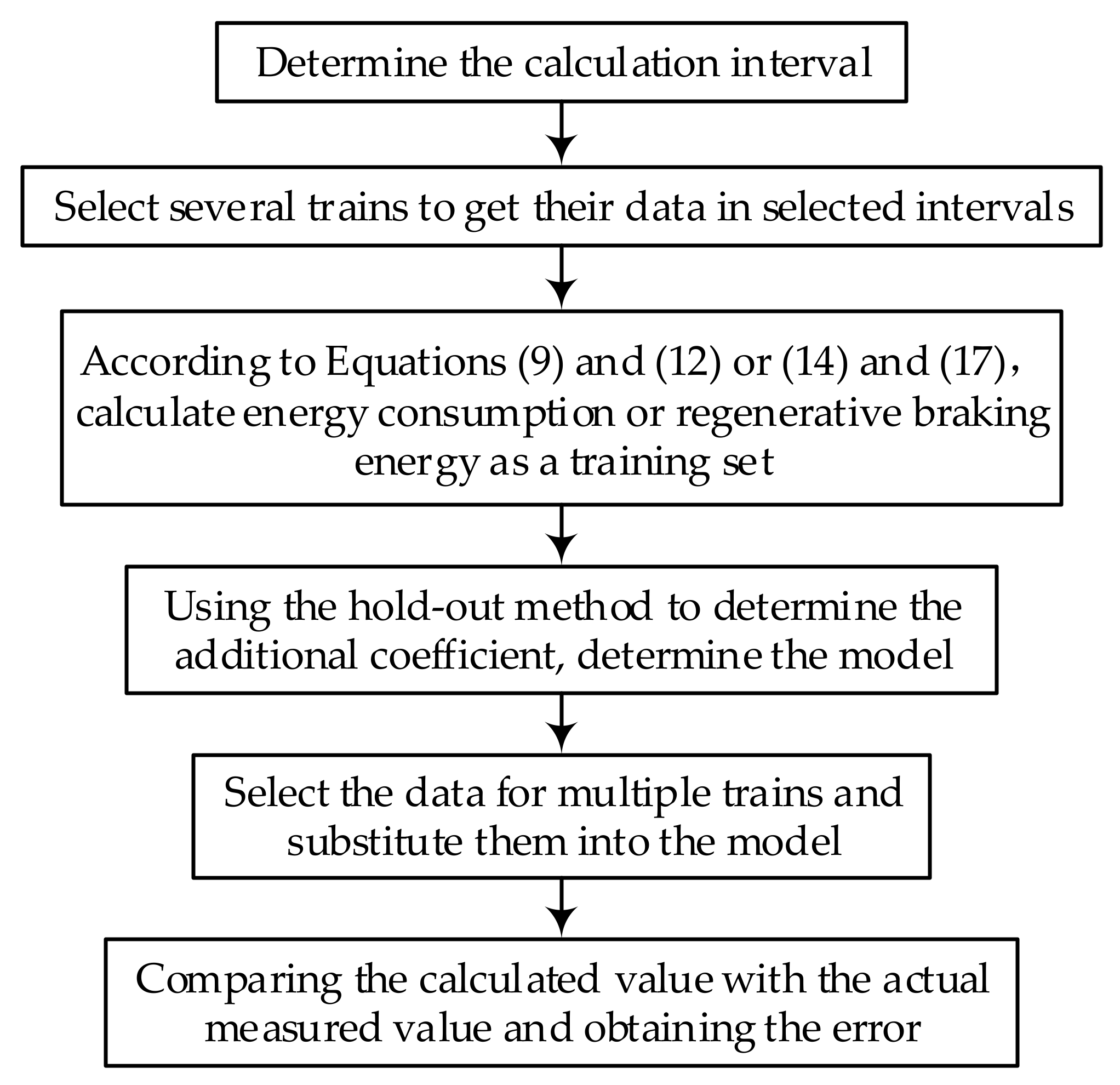

- Based on the single-particle point dynamics model and line profile reduction theory, as well as the train attributes, line condition, and speed, an energy consumption and regenerative braking energy model for the long large slope line was established. The current train diagram of the Shenshuo Railway was used as an example to verify that the percentage error of the model is generally below 10%.

- Based on verifying the basic accuracy of the energy consumption and regenerative braking model of a single train, considering the case where the regenerative braking energy of a certain train is used by the other trains, the power consumption of multiple trains in the same power supply section was deduced. Although this model is only an application of the single-vehicle model, it only theoretically considers the recovery of regenerative braking energy and does not combine the actual electrical parameters and grid factors to influence the regenerative braking energy recovery. To date, many researchers have studied the electrical parameters affecting the regenerative braking energy [19,20,21,22]; using the results of this paper and combining the conclusions of these documents, more accurate energy consumption calculations can be performed.

2. Model Formulation

2.1. Model Symbols

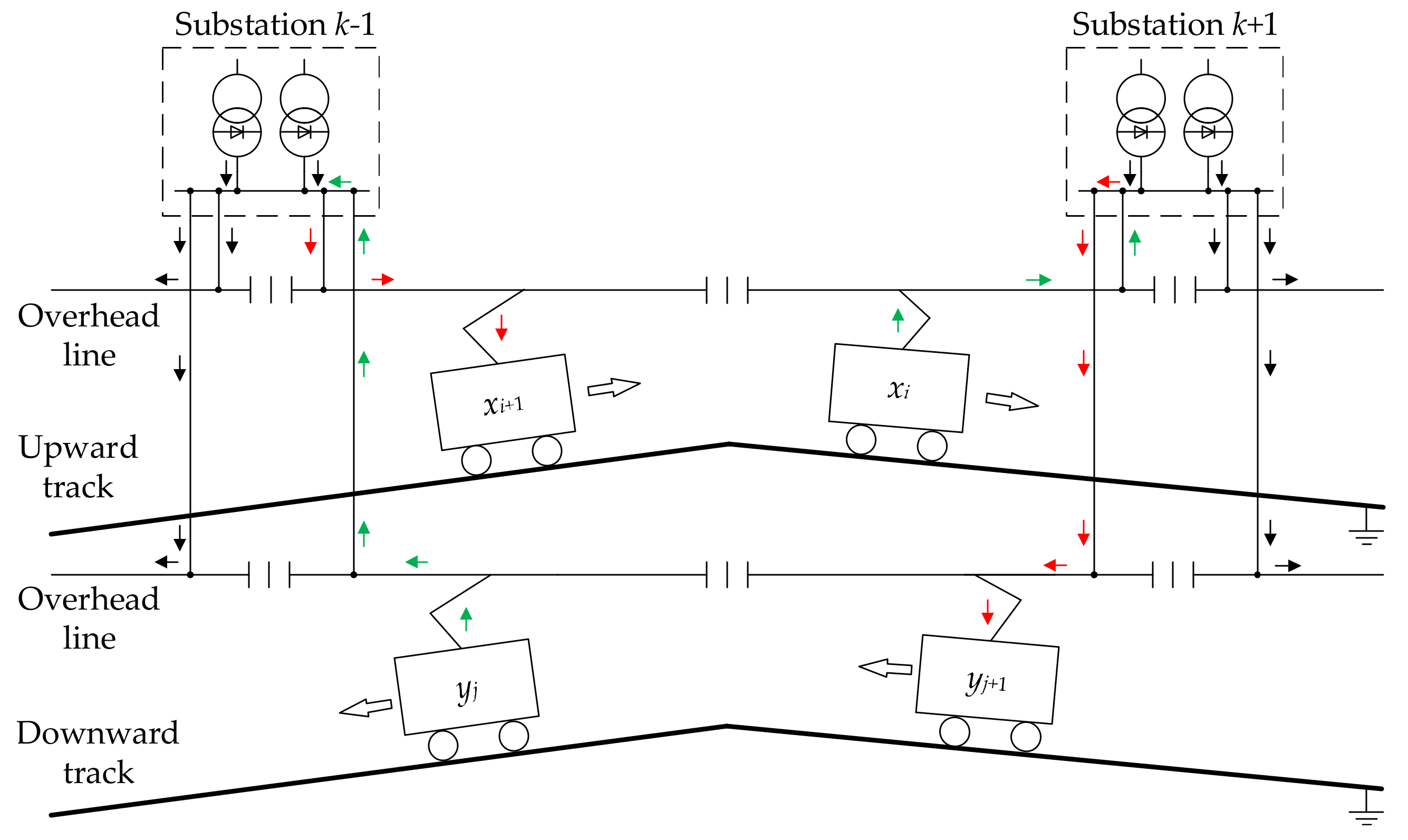

- Figure 1 represents the entire operating line, which is a linear railway network composed of n substations and 2n power supply intervals; the train runs on the double-track. The starting position of each power supply range is s0, s1, ⋯, s2n−1. The end position of the 2n-th power supply section is s2n. The power supply interval (sk, sk+1) indicates that the train is running in the upward direction, (sk+1, sk) indicates that the train is running in the downward direction, where 0 ≤ k ≤ 2n − 1.

- The sequence of the train running in the upward direction is {x1, x2, ⋯, xα}, where α is the total number of trains. The corresponding set of train quality is {Mx1, Mx2, ⋯, Mxα}, where Mxi = Pxi + Gxi, 1 ≤ i ≤ α. Pxi represents the weight of the traction locomotive for xi and Gxi represents the load of xi. The units are kilonewtons. The corresponding set of train length is {Lx1, Lx2, ⋯, Lxα}.

- The sequence of the train running in the downward direction is {y1, y2, ⋯, yβ}, where β is the total number of trains. The corresponding set of train quality is {My1, My2, ⋯, Myβ}, where Myj = Pyj + Gyj, 1 ≤ j ≤ β. Pyj represents the weight of the traction locomotive for yj and Gyj represents the load of yj. The units are kilonewtons. The corresponding set of train length is {Ly1, Ly2, ⋯, Lyα}.

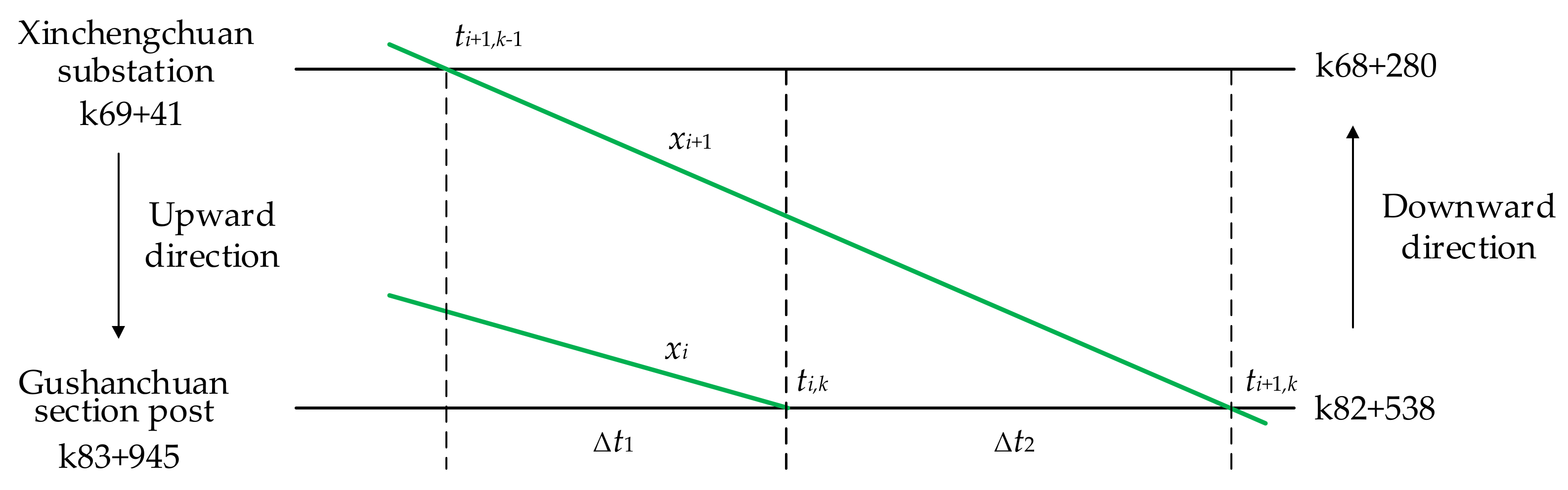

- Train xi reaches sk at ti,k and train yj reaches sk at τj,k.

- The instantaneous speed of the upward train xi is vi and the instantaneous speed at sk is vi,k; the instantaneous speed of the downward train yj is υj and the instantaneous speed at sk is υj,k.

- The acceleration of xi is ai; the acceleration of yj is aj.

- The length of the interval (sk, sk+1) is Lk. The calculation of the gradient permillage of the interval (sk, sk+1) is ihjk, and it is −ihjk in the interval (sk+1, sk). A positive number represents the uphill direction.

- The discriminant symbol function is defined as

2.2. Model Assumptions

- (1)

- The train’s running direction does not change during the running process. The train will not stop at any stop apart from the terminal station.

- (2)

- The tractive force and braking force of the train are continuous.

- (3)

- The traction mode and the braking mode of the train do not coexist within the same power supply range.

- (4)

- The impact of weather, parking, network voltage fluctuations, transmission line losses, and other factors of train energy consumption are ignored.

- (5)

- When the train generates regenerative braking energy, the consumption of vehicle auxiliary equipment is considered to be one of the factors affecting the energy conversion rate of regenerative braking [23]. If the feedback energy cannot be used in time, it will be directly fed back to the public power grid.

- (6)

- The phase separation distance is not considered.

- (7)

- Unless otherwise stated, each variable unit adopts the SI system.

2.3. Train Stress Analysis and Line Profile Reduction

2.4. Energy Consumption Model

2.5. Regenerative Braking Energy Model

2.6. Determination of Additional Coefficients η1,k and η2,k

2.7. Total Energy Consumption of Multi-Train in a Power Supply Interval

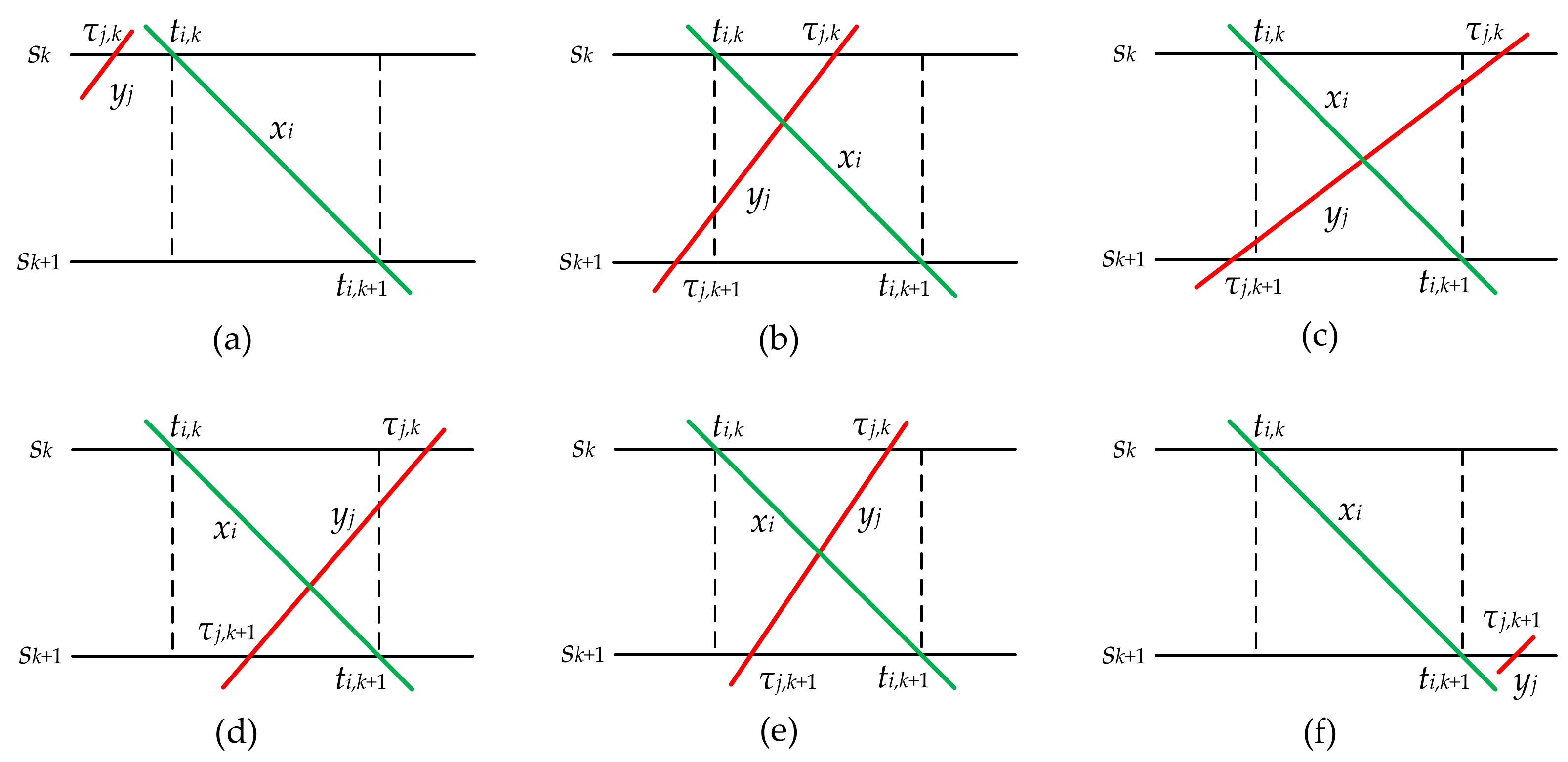

- If P > P′, the consumed power P of the traction trains is partly provided by the grid (P″); the other part comes from the feedback power P′ of the trains running in the reverse direction within the same power supply interval.

- If P ≤ P′, the traction trains do not take power from the grid, and P is entirely provided by P″. If P < P′, the regenerative braking energy cannot be fully utilized.

- The overlapping time Δt of the two types of trains running.

- The total electrical power of all braking train feedback is compared to the total consumed power of all traction trains in Δt.

2.7.1. Model with Shorter Supply Intervals

2.7.2. Model with Longer Supply Intervals

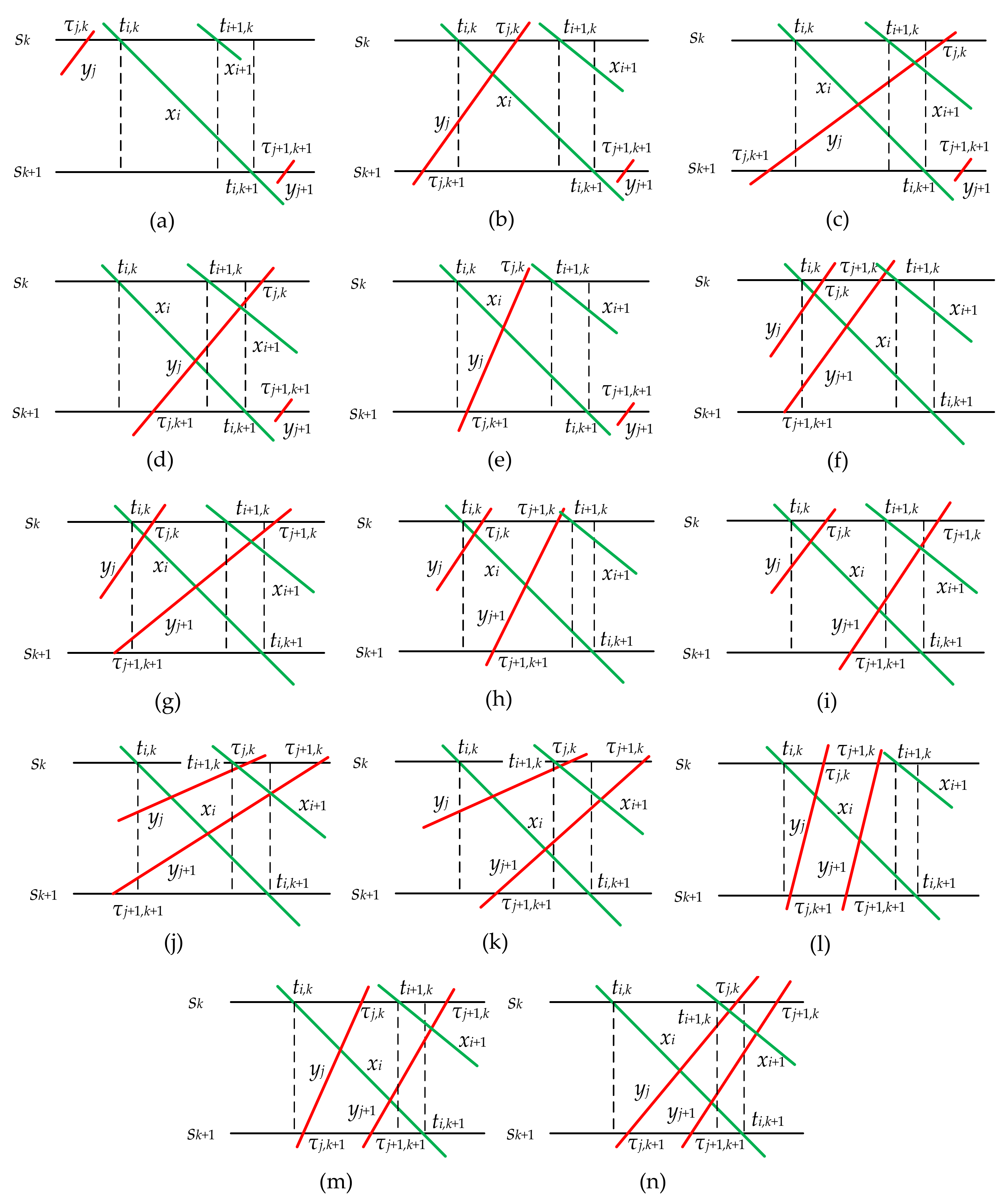

- (1)

- Train xi arrived at sk, train xi−1 left the interval (left the sk+1);

- (2)

- Train xi arrived at sk, train xi−1 did not leave the interval (left the sk+1);

- (3)

- Train xi+1 arrived at sk, train xi did not leave the interval (left the sk+1); and

- (4)

- Train xi+1 arrived at sk, train xi left the interval (left the sk+1),

- (1)

- Figure 7f,g shows trains yj and yj+1 running simultaneously in (ti,k, τj,k), and only train yj+1 consumes electricity in (τj,k, ). The total energy consumption in the interval (sk+1, sk) in (ti,k, ti+1,k) is

- (2)

- Figure 7h,i,l,m shows that only train yj consumes electricity in (, ), train yj and yj+1 simultaneously run in (, ), and only train yj+1 consumes electricity in (, ). Therefore, the total energy consumption in the interval (sk+1, sk) in (ti,k, ti+1,k) is

- (3)

- Figure 7j shows trains yj and yj+1 running simultaneously in (ti,k, ti+1,k); the total energy consumption in the interval (sk+1, sk) in (ti,k, ti+1,k) is

- (4)

- Figure 7k,n shows that only train yj consumes electricity in (, τj+1,k+1), and trains yj and yj+1 simultaneously run in (τj+1,k+1, ti+1,k). Therefore, the total energy consumption in the interval (sk+1, sk) in (ti,k, ti+1,k) is

3. Model Verification and Application

3.1. Energy Consumption and Regenerative Braking Energy Model Verification

- Train marshaling: Three HXD1 traction locomotives are followed by 108 C80 trucks.

- The load is 10,800 t and the total mass is 11,400 t.

3.2. Energy Analysis of a Single Power Supply Interval

4. Conclusions

- A model of train energy consumption and regenerative braking energy is proposed based on the single-particle point dynamic model of a train and the theory of railway longitudinal section simplification. The model takes train attributes, line status, and running speed as variables, and the expression is simpler and more convenient than that of multi-particle models. Combined with the current train operation diagram and measured data of Shenshuo Railway, the model has been verified. The results show that the error of the model is generally below 10%. Owing to the complexity of the physical system on which the model relies, and that the influencing factors and error factors are numerous and cannot be completely eliminated, the model can be considered as having good engineering application value.

- Based on the energy consumption and regenerative braking energy model of a single train, the total energy consumption of multiple trains in a single power supply interval is analyzed considering the available regenerative braking energy.

- Subsequent studies may be based on the research results of this study to establish a forecast of the total energy consumption of all trains in the whole section, and to analyze the scheme of the train operation plan that can meet the lowest total energy consumption by adjusting the train operation diagram.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Ouyang, H. Study on Control Scheme of High-Power Four-Quadrant Converter. Ph.D. Thesis, Huazhong University of Science and Technology, Wuhan, China, 2012. [Google Scholar]

- Song, K.; Georgios, K.; Li, J.; Wu, M.; Vassilios, G.A. High performance control strategy for single-phase three-level neutral-point-clamped traction four-quadrant converters. IET Power Electron. 2017, 10, 884–893. [Google Scholar]

- Gazafrudi, S.; Langerudy, A.T.; Fuchs, E.; Al-Haddad, K. Power quality issues in railway electrification: A comprehensive perspective. IEEE Trans. Ind. Electron. 2015, 62, 3081–3090. [Google Scholar] [CrossRef]

- He, L.; Xiong, J.; Zhang, P.; Zhang, K. High-performance indirect current control scheme for railway traction four-quadrant converters. IEEE Trans. Ind. Electron. 2014, 61, 6645–6654. [Google Scholar] [CrossRef]

- Steimel, A. Electric railway traction in Europe. IEEE Ind. Appl. Mag. 1996, 2, 6–17. [Google Scholar] [CrossRef]

- Suzuki, T. DC power supply system with inverting substations for traction systems using regenerative brakes. IEE Proc. B Electr. Power Appl. 1982, 129, 18–26. [Google Scholar] [CrossRef]

- Popescu, M.; Bitoleanu, A.; Suru, V.; Preda, A. System for converting the DC traction substations into active substations. In Proceedings of the 9th International Symposium on Advanced Topics in Electrical Engineering (ATEE 2015), Bucharest, Romania, 7–9 May 2015. [Google Scholar]

- Henning, P.H.; Fuchs, H.D.; Le Roux, A.D.; Mouton, H.T. A 1.5-MW seven-cell series-stacked converter as an active power filter and regeneration converter for a DC traction substation. IEEE Trans. Power Electron. 2008, 23, 2230–2236. [Google Scholar] [CrossRef]

- Manno, M.D.; Varilone, P.; Verde, P.; Santis, M.D.; Perna, C.D.; Salemme, M. User friendly smart distributed measurement system for monitoring and assessing the electrical power quality. In Proceedings of the AEIT International Annual Conference (AEIT), Naples, Italy, 14–16 October 2015; pp. 1–5. [Google Scholar]

- Tang, L.; Wu, L. Research on the Integrated Braking Energy Recovery Strategy Based on Supercapacitor Energy Storage. In Proceedings of the International Conference on Smart Grid and Electrical Automation (ICSGEA), Changsha, China, 27–28 May 2017; pp. 175–178. [Google Scholar]

- Moghbeli, H.; Hajisadeghian, H.; Asadi, M. Design and Simulation of Hybrid Electrical Energy Storage (HEES) for Esfahan Urban Railway to Store Regenerative Braking Energy. In Proceedings of the 7th Power Electronics and Drive Systems Technologies Conference (PEDSTC), Tehran, Iran, 16–18 February 2016; pp. 93–98. [Google Scholar]

- Sengor, I.; Kilickiran, H.C.; Akdemir, H.; Kekezoglu, B.; Erdinc, O.; Catalao, J.P.S. Energy management of a smart railway station considering regenerative braking and stochastic behaviour of ESS and PV generation. IEEE Trans. Sustain. Energy 2017, 1–10. [Google Scholar] [CrossRef]

- Kang, X.; Sun, J.; Meng, W. Regulations on Railway Traction Calculation (TB/T1407-201X); National Railway Administration of China: Beijing, China, 2014.

- Xue, Y.; Ma, D.; Wang, L. Calculation Method of Energy Consumption in Train Traction. China Railw. Sci. 2007, 5, 84–86. [Google Scholar]

- Li, Z.; Wei, X.; Wang, H.; Li, J. Optimizing Power for Train Operation Based on ACO. In Proceedings of the 2015 International Conference on Electrical and Information Technologies for Rail Transportation (EITRT), Zhuzhou, China, 17–19 October 2015; pp. 453–462. [Google Scholar]

- Dong, H.R.; Gao, S.; Ning, B.; Li, L. Extended fuzzy logic controller for high speed train. Neural Comp. Appl. 2013, 22, 321–328. [Google Scholar] [CrossRef]

- Zhuan, X.; Xia, X. Speed regulation with measured output feedback in the control of heavy haul trains. Automatica 2008, 44, 242–247. [Google Scholar] [CrossRef]

- Zhu, X.; Xu, Z. Dynamic Simulation of urban rail transit train based on single-particle model. J. China Railw. Soc. 2011, 33, 14–19. [Google Scholar]

- Gao, Z.; Fang, J.; Zhang, Y.; Sun, D.; Jiang, L.; Yang, X. Control Research of Supercapcitor Energy Storage System for Urban Rail Transit Network. In Proceedings of the IEEE International Conference on Information Science and Technology(ICIST), Shenzhen, China, 26–28 April 2014; pp. 181–185. [Google Scholar]

- Saleh, M.; Dutta, O.; Esa, Y.; Mohamed, A. Quantitative analysis of regenerative energy in electric rail traction systems. IEEE Trans. Ind. Appl. 2017, 1–7. [Google Scholar] [CrossRef]

- Adinolfi, A.; Lamedica, R.; Modesto, C.; Prudenzi, A. Experimental assessment of energy saving due to trains regenerative braking in an electrified subway line. IEEE Trans. Power Deliv. 1998, 13, 1536–1542. [Google Scholar] [CrossRef]

- Capasso, A.; Lamedica, R.; Penna, C. Energy regeneration in transportation systems–methodologies for power–networks simulation. IFAC Proc. 1983, 16, 119–124. [Google Scholar] [CrossRef]

- Dominguez, M.; Fernandez-Cardador, A.; Cucala, A.P.; Pecharroman, R.R. Energy Savings in Metropolitan Railway Substations through Regenerative Energy Recovery and Optimal Design of ATO Speed Profiles. IEEE Trans. Autom. Sci. Eng. 2012, 9, 496–504. [Google Scholar] [CrossRef]

- Liu, W.; Li, Q.; Tang, B. Energy saving train control for urban railway train with multi-population genetic algorithm. In Proceedings of the IFITA ‘09. International Forum on Information Technology and Applications, Chengdu, China, 15–17 May 2009; pp. 58–63. [Google Scholar]

- Zhou, Z. Machine Learning; Tsinghua University Press: Beijing, China, 2016; pp. 24–29. [Google Scholar]

- Das Gupta, S.; Pavel, L.; Tobin, K.J. An optimization model to utilize regenerative braking energy in a railway network. In Proceedings of the American Control Conference (ACC), Chicago, IL, USA, 1–3 July 2015; pp. 5919–5924. [Google Scholar]

- Yang, X.; Ning, B.; Li, X.; Tang, T. A two-objective timetable optimization model in subway systems. IEEE Trans. Intell. Transp. Syst. 2014, 15, 1913–1921. [Google Scholar] [CrossRef]

- Liu, J.; Nan, Z. Research on Energy-Saving Operation strategy for multiple trains on the urban subway line. Energies 2017, 10, 2156. [Google Scholar] [CrossRef]

| Situation | Event Relationship | Mathematical representation | Train Operation |

|---|---|---|---|

| 1 | (1) ∩ (3) | ti−1,k+1 ≤ ti,k and ti+1,k ≤ ti,k+1 | Only train xi runs in (ti,k, ti+1,k) |

| 2 | (1) ∩ (4) | ti−1,k+1 ≤ ti,k and ti+1,k ≥ ti,k+1 | Only train xi run in (ti,k, ti,k+1); no trains run in (ti,k+1, ti+1,k) |

| 3 | (2) ∩ (4) | ti−1,k+1 ≥ ti,k and ti+1,k ≤ ti,k+1 | The train xi−1 and xi run in (ti,k, ti−1,k+1); only train xi run in (ti−1,k+1, ti+1,k) |

| 4 | (2) ∩ (3) | ti−1,k+1 ≥ ti,k and ti+1,k ≥ ti,k+1 | The train xi−1 and xi run in (ti,k, ti−1,k+1); only train xi run in (ti−1,k+1, ti,k+1); no train run in (ti,k+1, ti+1,k) |

| Category | Power Supply Interval | Length (m) | The Added Ramp Thousandth (‰) |

|---|---|---|---|

| Up direction | Xinchengchuan substation to Gushanchuan section post | 14,535 | –9.38 |

| Gushanchuan section post to Fugu substation | 14,505 | –7.12 | |

| Baode section post to Qiaotou substation | 8059 | 11.72 | |

| Qiaotou substation to Wangjiazhai section post | 13,959 | 8.96 | |

| Wangjiazhai section post to Yinta substation | 12,269 | 6.87 | |

| Down direction | Yinta substation to Wangjiazhai section post | 12,800 | –6.59 |

| Wangjiazhai section post to Qiaotou substation | 14,880 | –8.13 | |

| Qiaotou substation to Baode section post | 8471 | –10.46 | |

| Fugu substation to Gushanchuan section post | 15,879 | 8.29 | |

| Gushanchuan section post to Xinchengchuan substation | 14,258 | 10.29 |

| Train Type | Power Supply Interval | η1,k | η2,k |

|---|---|---|---|

| HXD1 | Xinchengchuan substation to Gushanchuan section post | 0.77 | 0.45 |

| Gushanchuan section post to Fugu substation | 0.76 | 0.53 | |

| Baode section post to Qiaotou substation | 0.92 | 0.79 | |

| Qiaotou substation to Wangjiazhai section post | 0.91 | 0.59 | |

| Wangjiazhai section post to Yinta substation | 0.89 | 0.52 | |

| SS4B | Yinta substation to Wangjiazhai section post | 0.80 | — |

| Wangjiazhai section post to Qiaotou substation | 0.78 | — | |

| Qiaotou substation to Baode section post | 0.92 | — | |

| Fugu substation to Gushanchuan section post | 0.93 | — | |

| Gushanchuan section post to Xinchengchuan substation | 0.91 | — |

| Train Number | Xinchengchuan Substation to Gushanchuan Section Post | Gushanchuan Section Post to Fugu Substation | Baode Section Post to Qiaotou Substation | Qiaotou Substation to Wangjiazhai Section post | Wangjiazhai Section Post to Yinta Substation | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Calculated Value | Actual Value | Percent Error | Calculated Value | Actual Value | Percent Error | Calculated Value | Actual Value | Percent Error | Calculated Value | Actual Value | Percent Error | Calculated Value | Actual Value | Percent Error | |

| 18538 | −1706 | −1771 | 3.65% | −1420 | −1506 | 5.68% | 3612 | 3408 | 5.97% | 4460 | 4696 | 5.02% | 3705 | 3778 | 1.94% |

| 18126 | −1691 | −1525 | 10.87% | −1464 | −1346 | 8.75% | 3595 | 3734 | 3.73% | 4901 | 4826 | 1.56% | 3374 | 3507 | 3.80% |

| 18125 | −1692 | −1709 | 1.01% | −1446 | −1317 | 9.78% | 3681 | 3532 | 4.22% | 4476 | 4666 | 4.07% | 3701 | 3681 | 0.54% |

| 18268 | −1712 | −1718 | 0.33% | −1463 | −1619 | 9.61% | 3685 | 3568 | 3.27% | 4828 | 4661 | 3.59% | 3337 | 3469 | 3.79% |

| 18072 | −1712 | −1669 | 2.60% | −1408 | −1534 | 8.23% | 3664 | 3663 | 0.03% | 4821 | 4768 | 1.12% | 3355 | 3417 | 1.82% |

| 18106 | −1713 | −1622 | 5.62% | −1435 | −1455 | 1.35% | 3525 | 3534 | 0.26% | 4886 | 4886 | 0.01% | 3388 | 3346 | 1.27% |

| 18470 | −1791 | −1791 | 0.01% | −1387 | −1478 | 6.17% | 3504 | 3639 | 3.70% | 4611 | 4538 | 1.61% | 3605 | 3549 | 1.59% |

| 18070 | −1724 | −1832 | 5.90% | −1435 | −1432 | 0.18% | 3707 | 3662 | 1.24% | 4715 | 4840 | 2.58% | 3203 | 3349 | 4.36% |

| 18660 | −1730 | −1662 | 4.08% | −1403 | −1447 | 3.01% | 3611 | 3678 | 1.82% | 4786 | 4438 | 7.83% | 3492 | 3433 | 1.72% |

| 18436 | −1660 | −1625 | 2.16% | −1456 | −1501 | 2.97% | 3613 | 3800 | 4.92% | 4847 | 4636 | 4.55% | 3261 | 3111 | 4.82% |

| Train Number | Yinta Substation to Wangjiazhai Section Post | Wangjiazhai Section Post to Qiaotou Substation | Qiaotou Substation to Baode Section Post | Fugu Substation to Gushanchuan Section Post | Gushanchuan Section Post to Xinchengchuan Substation | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Calculated Value | Actual Value | Percent Error | Calculated Value | Actual Value | Percent Error | Calculated Value | Actual Value | Percent Error | Calculated Value | Actual Value | Percent Error | Calculated Value | Actual Value | Percent Error | |

| 18013 | −258 | −279 | 7.45% | −461 | −457 | 0.88% | −463 | −478 | 3.19% | 1450 | 1473 | 1.54% | 1538 | 1574 | 2.27% |

| 18001 | −252 | −244 | 3.43% | −442 | −410 | 7.85% | −450 | −458 | 1.77% | 1420 | 1457 | 2.52% | 1546 | 1456 | 6.18% |

| 18767 | −257 | −249 | 3.06% | −452 | −468 | 3.45% | −468 | −498 | 6.07% | 1483 | 1493 | 0.70% | 1521 | 1518 | 0.21% |

| 17051 | −315 | −312 | 0.97% | −549 | −575 | 4.50% | −552 | −587 | 5.99% | 1712 | 1589 | 7.73% | 1882 | 1834 | 2.60% |

| 16537 | −354 | −381 | 6.96% | −621 | −602 | 3.13% | −649 | −617 | 5.18% | 1980 | 1886 | 4.96% | 2050 | 1941 | 5.62% |

| 17043 | −318 | −352 | 9.76% | −578 | −633 | 8.61% | −508 | −529 | 4.05% | 1718 | 1739 | 1.19% | 1844 | 1757 | 4.92% |

| 16587 | −358 | −362 | 0.97% | −611 | −652 | 6.22% | −611 | −582 | 4.99% | 2028 | 1910 | 6.20% | 2099 | 1954 | 7.42% |

| 18031 | −266 | −261 | 1.96% | −463 | −491 | 5.71% | −465 | −433 | 7.38% | 1517 | 1673 | 9.31% | 1589 | 1731 | 8.21% |

| 18109 | −271 | −277 | 2.29% | −451 | −478 | 5.60% | −464 | −443 | 4.67% | 1454 | 1431 | 1.63% | 1571 | 1565 | 0.41% |

| 18241 | −262 | −253 | 3.59% | −465 | −472 | 1.54% | −484 | −498 | 2.84% | 1527 | 1645 | 7.20% | 1588 | 1654 | 3.99% |

| Train Number | Baode Section Post to Qiaotou Substation | Qiaotou Substation to Wangjiazhai Section Post | Wangjiazhai Section Post to Yinta Substation | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Calculated Value | Actual Value | Percent Error | Calculated Value | Actual Value | Percent Error | Calculated Value | Actual Value | Percent Error | |

| 18446 | 3699 | 3427 | 7.95% | 4852 | 4491 | 8.04% | 3361 | 3133 | 7.28% |

| 18534 | 3733 | 3841 | 2.80% | 4826 | 4444 | 8.60% | 3430 | 3255 | 5.37% |

| 18360 | 3693 | 3744 | 1.36% | 4418 | 4673 | 5.46% | 3334 | 3385 | 1.49% |

| 17012 | 3681 | 3827 | 3.81% | 4604 | 4862 | 5.32% | 3301 | 3477 | 5.07% |

| 18494 | 3799 | 4133 | 8.08% | 4571 | 4937 | 7.42% | 3433 | 3575 | 3.97% |

| 18006 | 3733 | 3517 | 6.13% | 4613 | 4793 | 3.75% | 3632 | 3952 | 8.10% |

| Train Number | Fugu Substation to Gushanchuan Section Post | Gushanchuan Section Post to Xinchengchuan Substation | ||||

|---|---|---|---|---|---|---|

| Calculated Value | Actual Value | Percent Error | Calculated Value | Actual Value | Percent Error | |

| 18439 | 1562 | 1526 | 2.37% | 1647 | 1693 | 2.74% |

| 17139 | 1647 | 1623 | 1.50% | 1543 | 1573 | 1.93% |

| 18367 | 1552 | 1603 | 3.17% | 1611 | 1591 | 1.28% |

| 18101 | 1511 | 1510 | 0.04% | 1641 | 1553 | 5.67% |

| 18757 | 1631 | 1585 | 2.88% | 1588 | 1676 | 5.24% |

| 18753 | 1635 | 1650 | 0.93% | 1633 | 1686 | 3.14% |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lu, Q.; He, B.; Wu, M.; Zhang, Z.; Luo, J.; Zhang, Y.; He, R.; Wang, K. Establishment and Analysis of Energy Consumption Model of Heavy-Haul Train on Large Long Slope. Energies 2018, 11, 965. https://doi.org/10.3390/en11040965

Lu Q, He B, Wu M, Zhang Z, Luo J, Zhang Y, He R, Wang K. Establishment and Analysis of Energy Consumption Model of Heavy-Haul Train on Large Long Slope. Energies. 2018; 11(4):965. https://doi.org/10.3390/en11040965

Chicago/Turabian StyleLu, Qiwei, Bangbang He, Mingzhe Wu, Zhichun Zhang, Jiantao Luo, Yankui Zhang, Runkai He, and Kunyu Wang. 2018. "Establishment and Analysis of Energy Consumption Model of Heavy-Haul Train on Large Long Slope" Energies 11, no. 4: 965. https://doi.org/10.3390/en11040965