1. Introduction

Ultra-low magnetic fields have important applications in the fields of particle physics, aerospace, magnetometry, geomagnetic navigation, and weak magnetism biology [

1,

2,

3,

4]. High performance magnetically shielded rooms (MSRs) are constructed to obtain ultra-low magnetic fields, which often adopt the combination of passive magnetic shielding and active magnetic shielding. The passive magnetic shield has been extensively used for high frequency ranges. To shield static and very low frequency magnetic fields, active compensation coils are widely used because of low costs when compared with the passive magnetic shield [

5,

6]. There are two main objectives for this combination in MSRs. One is to shield high frequency magnetic fields and the geomagnetic field. The combination reduces costs and improves the shielding performance. The other one is to obtain the desired uniform magnetic field inside the shield thanks to a dedicated coil. The magnetic shield, which is made of ferromagnetic material, causes a substantial reduction in the uniform volume of the coil, which needs to be considered when designing the coil [

7,

8,

9,

10,

11].

The design of a coil inside a magnetic shield is generally limited to one of the following scenarios according to the shape of the shield. (1) The analytical model of the circular coil that is used inside a cylindrical magnetic shield is established for the coil design, whose premise is the cylindrical magnetic shield considered as an infinitely long shield [

8,

9,

10]. Two pairs of solenoid coils that were designed for electric dipole moment (EDM) experiments at Tokyo Institute of Technology were used inside a cylindrical magnetic shield with a length to diameter ratio 1.7 [

10]. A radial coil is proposed that produces highly uniform magnetic fields inside a cylindrical ferromagnetic shield [

11]. (2) The currently best magnetically shielded rooms are the BMSR-II at Physikalisch Technische Bundesanstalt (PTB) in Berlin, using the square coils inside a cubic magnetic shield without a systematic design method [

12].

Large magnetically shielded rooms cannot adopt cylindrical magnetic shield because of the limitation of manufacturer technology. The famous high performance MSRs such as the BMSR and BMSR-II of PTB, MSR of Athinoula A. Martinos Center in America, MSR of Technische Universität München in Germany, are all cubic magnetically shielded rooms [

13,

14]. In order to make full use of the space, the coils are placed so that they almost touch the inner surface of the shield, one has to take into account the coupling effect of the coil and the shield. For the design of the coil, it is necessary to establish an analytic model of coils inside the cubic shield to calculate the magnetic field. The analytical model of coils inside the cubic shield is different from that inside the cylindrical shield since the shield cannot be equivalent to an infinitely long shield. At present, there is no paper to propose a method of designing a coil inside a cubic shield.

The homogeneous volume of conventional coils is degraded when the coils used in a magnetic shield. This paper provides a novel design method of the coil used in a cubic magnetic shield with a large homogeneous volume. Firstly, the analytical model is established and verified by finite elements analysis. Secondly, a new design method of the coil used inside the cubic magnetic shield is put forward based on the analytical model in this paper. Finally, the performance of a coil system that is developed according to the new method is evaluated. It demonstrates the accuracy of the analytical model and the validity of the design method. The coil can be used for providing a large homogeneous volume for experiment in the MSRs. It can also be used for Earth field compensation and active shielding in high performance MSRs.

2. Influence of the Magnetic Shield

Coil systems are used to generate magnetic fields for physics and biology experiments, sensors calibration, and so on. Some conventional square coil designs are the square Helmholtz and Merritt coils. The square Helmholtz coil consists of two identical square coils that are placed symmetrically along a common axis. Two coils are separated by a distance of 0.5445 times the length of the coil. Each coil carries an equal electrical current flowing in the same direction. The Merritt coil consists of four identical square coils placed symmetrically along a common axis. The two outer coils have ∼2.361197 times the current to the inner coils. Inner coils are separated by ∼0.256212 times their length, whilst the outer coils are separated by ∼1.010984 times their length.

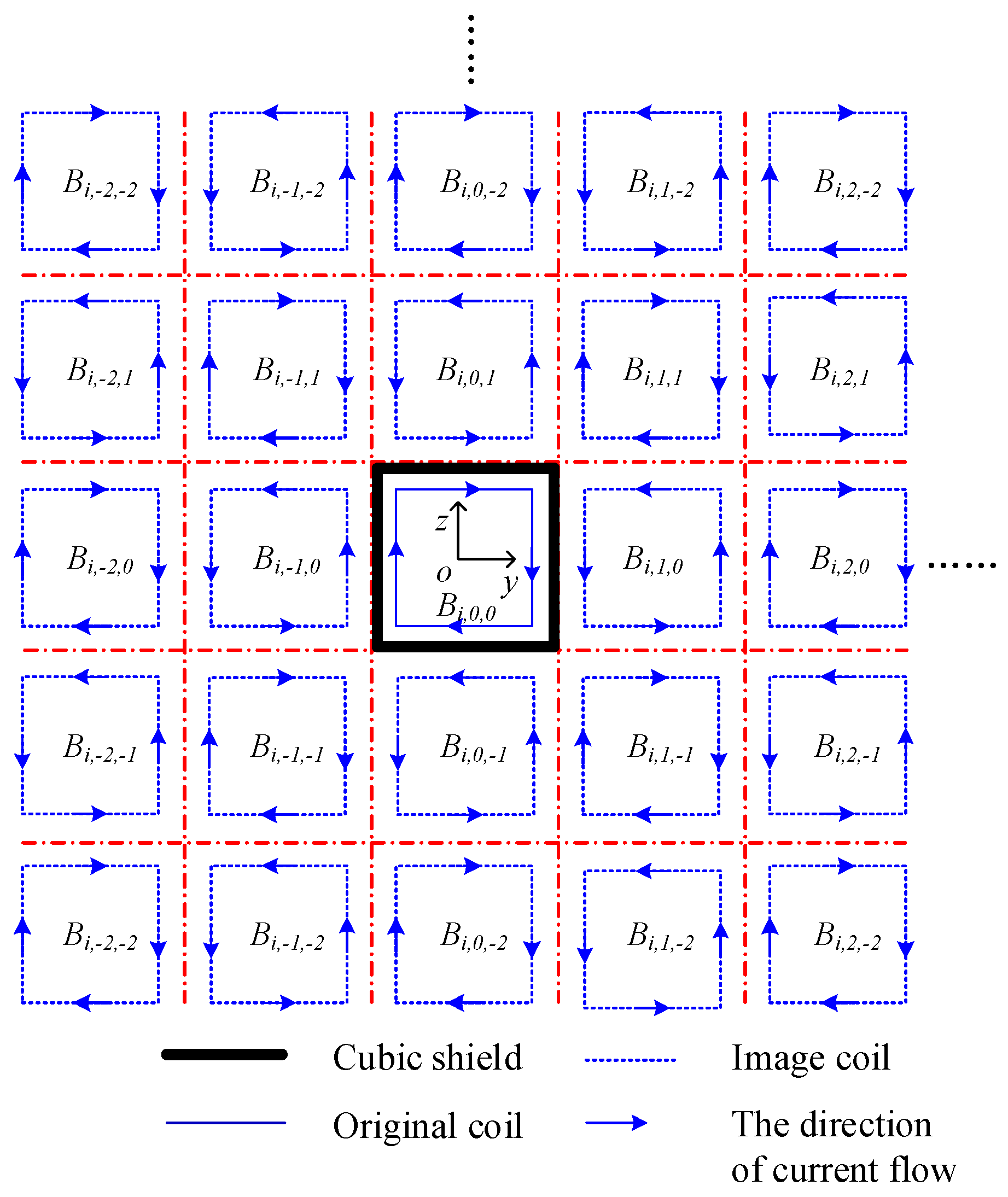

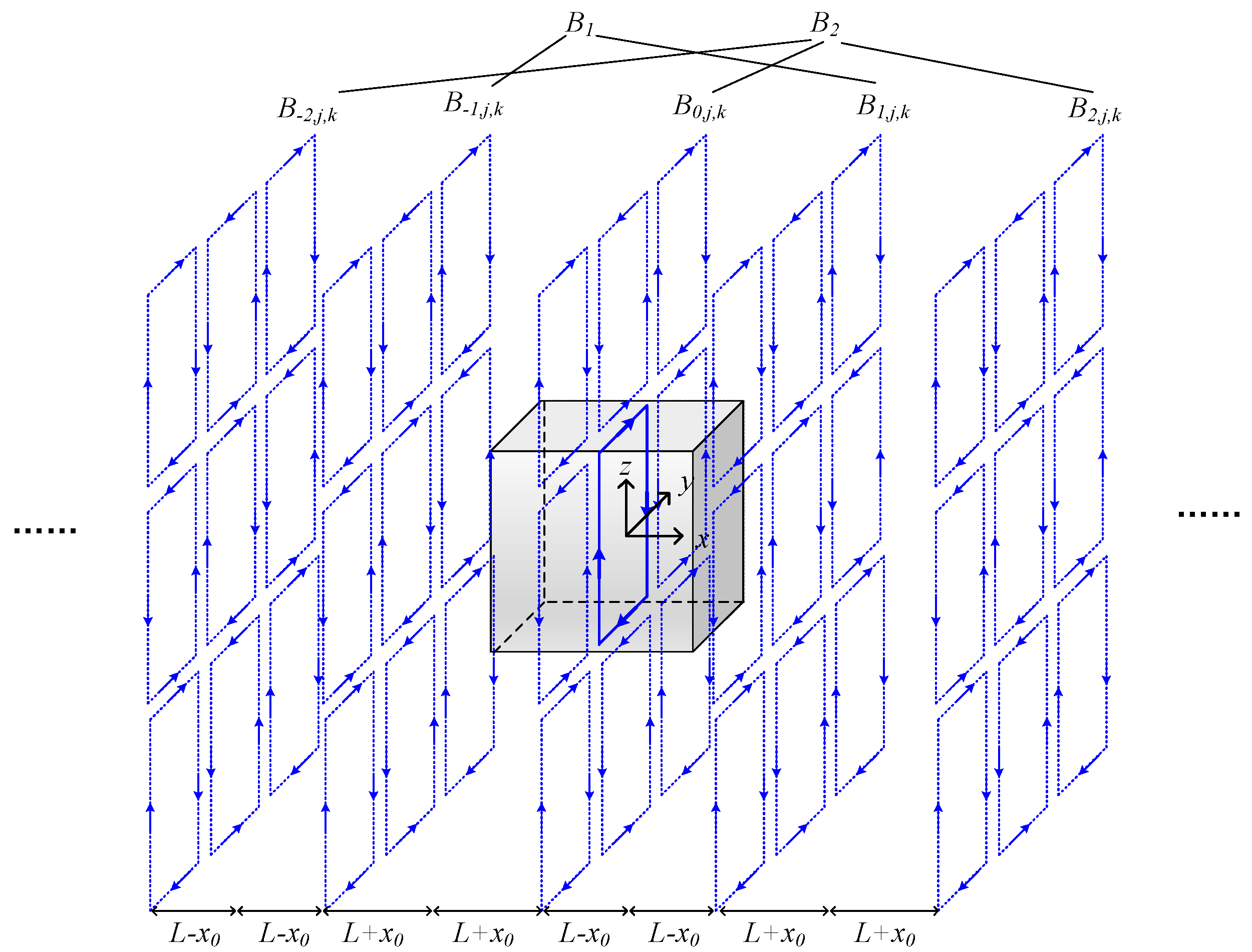

The magnetic field uniformity of the coil system used inside the magnetic shield is degraded by the magnetic shield. The magnetic shield imposes a ferromagnetic boundary condition that leads to a kind of mirror effect concerning the current loops [

15]. It enhances the ability of the coil to generate large magnetic fields. In order to explore the effect of magnetic shield on the uniform volume that is generated by the coil, a one-axial Merritt coil is placed inside a cubic shield with 1.85 m side length [

16,

17]. The thickness of the shield layer is 1 cm and the relative permeability is 50,000. The axis of the coil is the

x-axis. The center of the coil coincides with the center of the shield. Key parameters of Merritt coil are shown in

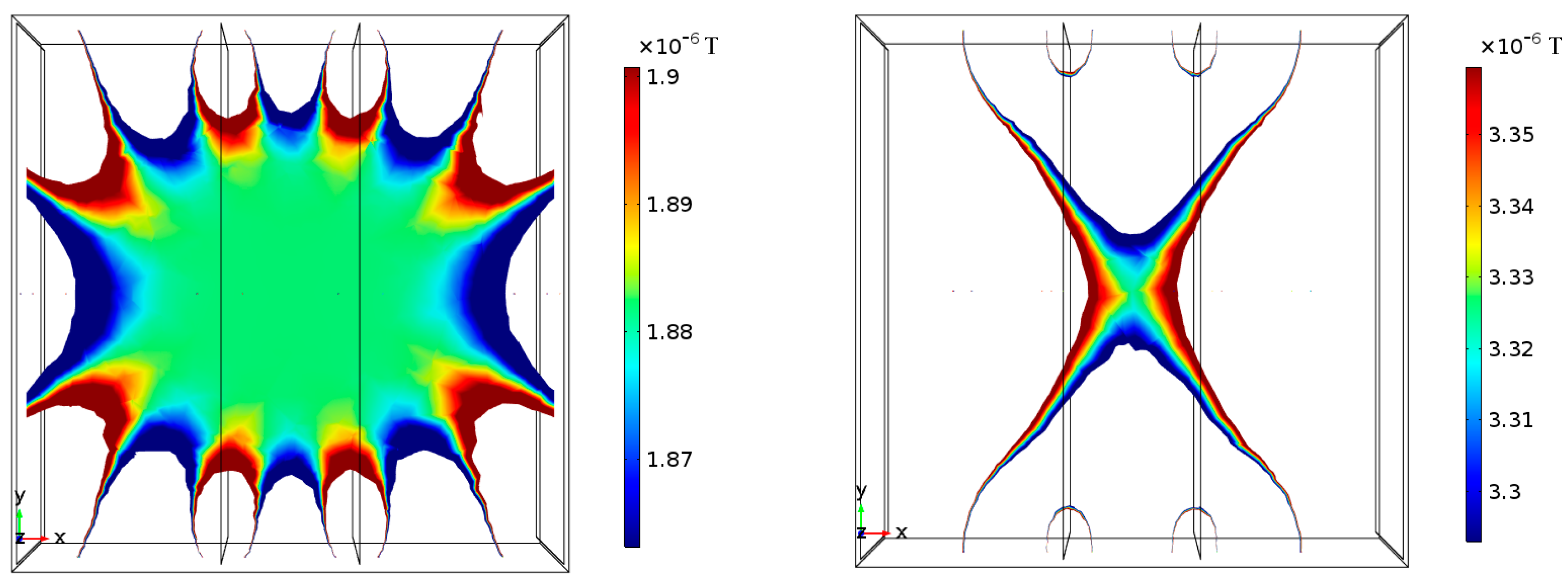

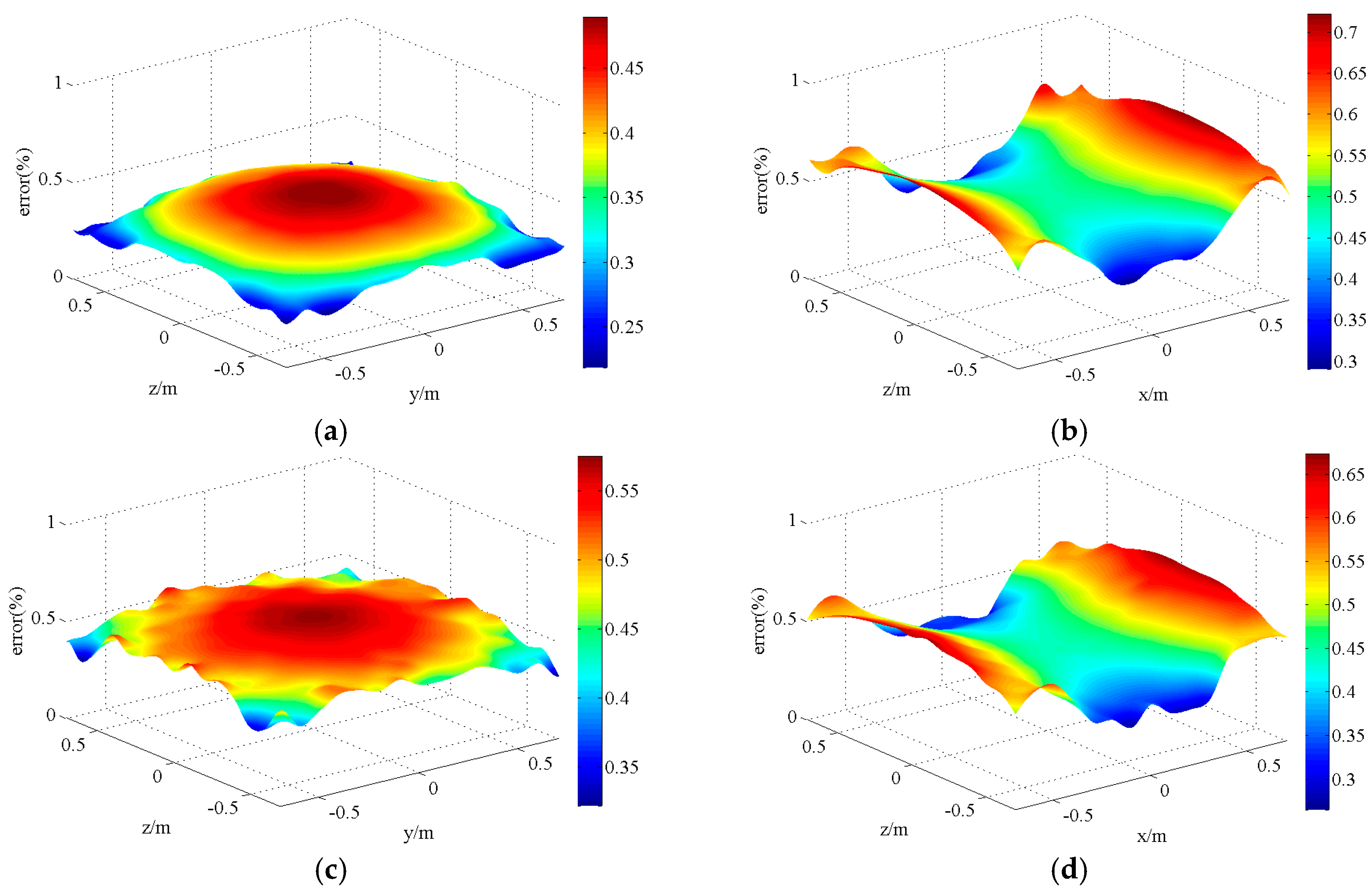

Table 1. The magnetic flux density that is generated by Merritt coil inside the cubic shield are simulated in COMSOL (COMSOL Multiphysics, Stockholm, Sweden), and compared with the flux density generated by Merritt coil without any shield, as shown in

Figure 1.

Bc is the flux density at the center,

B(

x,

y,

z) is the flux density at (

x,

y,

z) point, the practical deviation rate of flux density between (

x,

y,

z) and the center point is defined as Equation (1), which is a conventional index in practice [

18].

It can be seen that the magnetic field uniformity generated by Merritt coil inside the cubic shield is very significantly degraded. Conventional coil systems, such as Merritt coil, Braunbeck coil, and square Helmholtz coil cannot be used directly in the cubic shield and a new coil needs to be designed to guarantee optimal performance inside the shield.

4. Coil Design

Tri-axial coil systems widely used in MSR are a combination of well-designed one-axial coils. Therefore, the design of a coil will refer to the mono axial coil. There are two main criteria of a coil, the flux density deviation rate, and its corresponding uniform volume. Take the excitation of the

x-axis coil for example:

Bc is the magnetic flux density at the center which only has

x component. The change in the magnetic flux density away from center is normalized relative to

Bc. For a perfect field uniformity within the volume of the coil system,

and

, this definition is equivalent to the definition of the flux density that is uniformity presented in Equation (8), the total deviation rate Δ

BT is defined as Equation (9) [

20,

21]. For a given magnetic field deviation, the larger the uniform volume of the coil system, the better for the application. However, a slender uniform area has a low utilization in most cases. So, we define uniform volume

Vm, which is the maximum cubic volume that the uniform area can accommodate in a certain deviation.

The more coils per axis, the higher uniformity and larger uniform region achievable. However, since the alignment of many coils is difficult, large coil systems mostly use four coils for one axis [

22]. So, we adopt the design of a four-coil system for one axis. The new coil consists of four identical square coils, which is similar to Merritt coil.

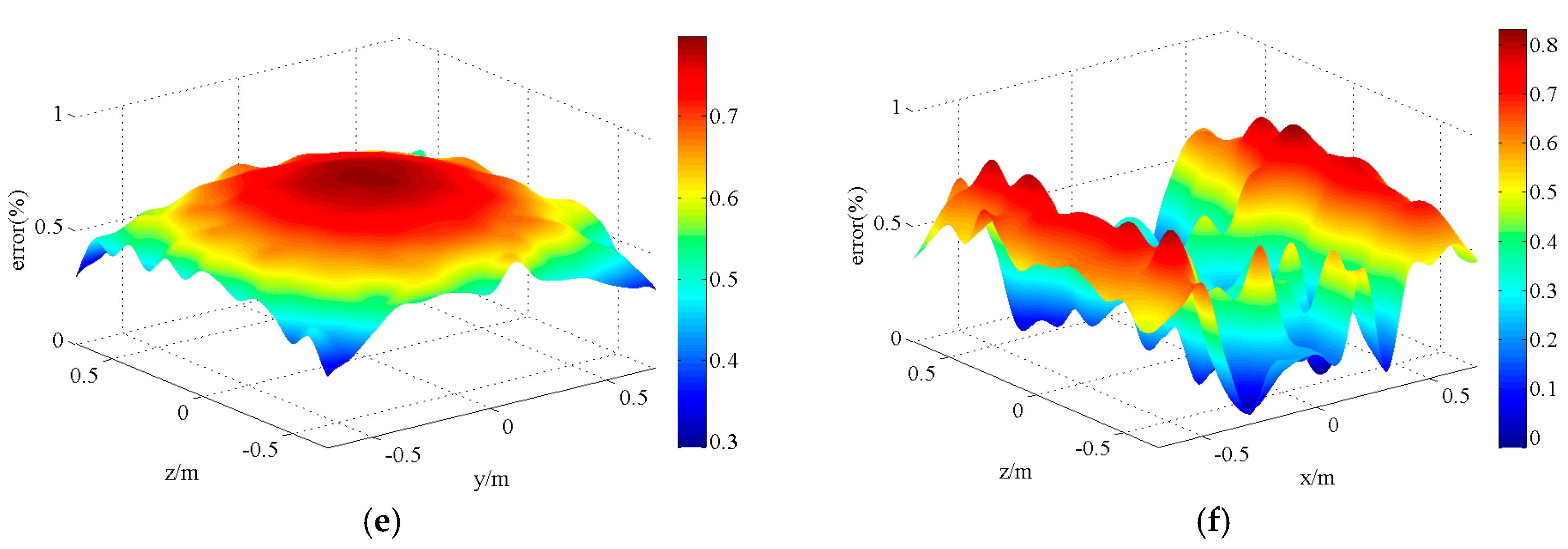

Setting the length of coils as l and the current value of the two inner coils as I2, and when considering that the four coils have the same number of turns, the coil system can be described thanks to three variables: the spacing between the two outer coils 2a, the spacing between the two inner coils 2b, and the current of the two outer coils I1.

The optimization of the coil used inside the cubic magnetic shield consists in finding the optimal value of the three variables so that the coil has the largest uniform area

Vm in for a given deviation. The common deviation rate is 1% in application, we set a slightly higher theoretical target of 0.85% when considering the performance of practical coils will be worse. So, we focused on the uniform volume of 0.85% deviation rate. A cubic computational volume

V is defined inside the coil whose center coincides with the center of the coil, which is the green volume in

Figure 6. We discretize the volume

V and divide it into

n ×

n ×

n grid points. If Δ

BT of all the points in the volume is less than 0.85%,

U equals one which means the total deviation rate of the region is less than 0.85%.

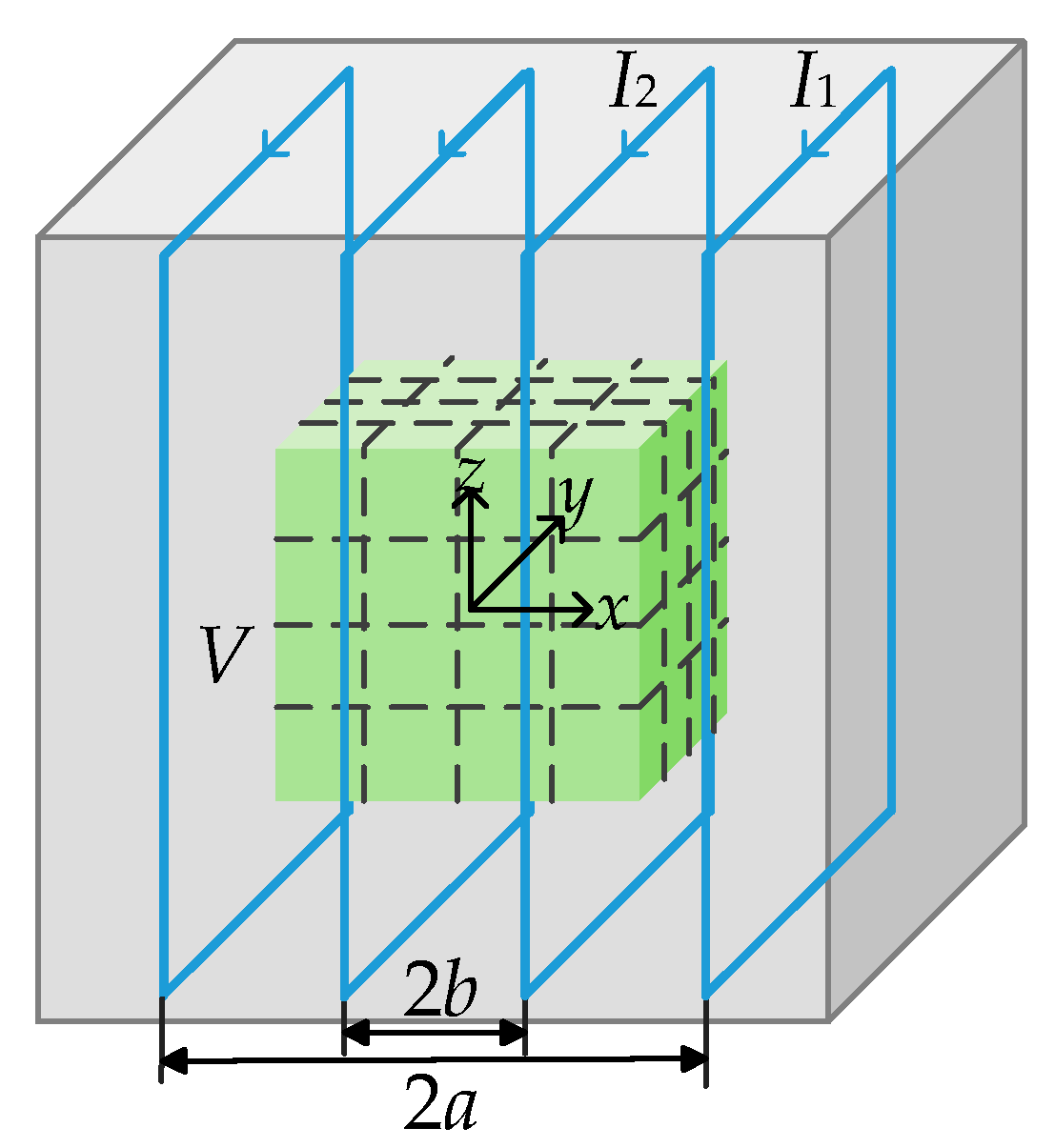

The flow chart of the coil design method is shown in

Figure 7. Firstly, the values of parameters

V,

l,

I2, and the ranges of three variables 2

b, 2

a,

I1 are chosen. Parameters of several sets of the coil are then generated according to the ranges of variables. Calculate

U of the volume

V, if more than one set of coils meet the condition that

U equal to 1, expand the volume

V, and repeat the above calculation until only one set of the coil meet the condition.

Practically, the side length of the magnetically shielded room is 1.85 m. Because of the space constraint, the largest side length of the coil that can be assembled in the room is 1.55 m. The values of parameters and the range of variables are given in

Table 2.

With the small cubic computational volume,

U takes the maximum value 1 for several, parameters corresponding to different coil designs are obtained. The volume is then progressively extended outwards, until only one coil design satisfies the homogeneity criterion. The uniform volume

Vm of the new coil is 0.8 × 0.8 × 0.8 m. Key parameters of the coil have been tabulated in

Table 3.

In order to compare the effectiveness of different coils, the ratios of the uniform volume to the total volume bounded by the coil (referred to as the normalized usable volume) are shown in

Figure 8 for classical structures (Square Helmholtz and Merritt coils) and our proposed design.

Figure 8 shows that the Merritt coil and the new coil have larger normalized usable volumes than the square Helmholtz coil. It can be explained by the fact that they consist of more coils per axis resulting in an increased ability to produce a uniform volume. Both the Merritt coil and the new coil consist of four identical coils per axis. But, the new coil that is used in the shield provides a larger normalized usable volume than the Merritt coil. The reason is that the design method enhances the ability of the new coil to produce a large homogeneous volume. Besides, the design narrows distance between the outer two coils, thus the total volume of the coil is reduced. It also increases the normalized usable volume of the new coil. In the desired total deviation rate 0.85%, the normalized usable volume increases by 70% for the new coil relatively to the Merritt coil.

5. Experiment

The aim of the experiment is to measure the magnetic field uniformity of 0.8 × 0.8 × 0.8 m size generated by the new coil system inside a magnetically shielded room to verify our model predictions. The MSR in Harbin Institute of Technology is a cubic magnetic shield with the 1.85 m side length. The MSR consists of one permalloy layer of 2 mm thickness.

The key to the development of the coil system is the selection of materials of the frame and the coil, and the calculation of the wire diameter. Since magnetic materials might distort the magnetic field, the frame and fastenings are made of non-magnetic aluminum alloy, bolts, and nuts are made of nylon. Cables are attached to the frame to make square coils. A prototype of the new coil system is illustrated in

Figure 9. The cables consist of five 1 mm

2 section wires.

The coil performance test system consists of a constant current source, a magnetic field sensor, and a sensor stand. We use a three-axis magnetic field sensor Mag-03 of Bartington Company for measuring. The sensor is fixed on the stand that is also made of aluminum alloy and is movable and height adjustable. The sensor is moved to the center of the coil to measure the flux density firstly. Given the coil system and the MSR symmetry, flux density was measured within a volume of 0.4(−0.4 m x 0 m) × 0.4(−0.4 m y 0 m) × 0.4(0 m z 0.4 m) instead of the whole volume of the coil for the sake of experimental efficiency. Magnetic flux density is measured at grid points located every 10 cm along the x, y and z directions.

6. Results

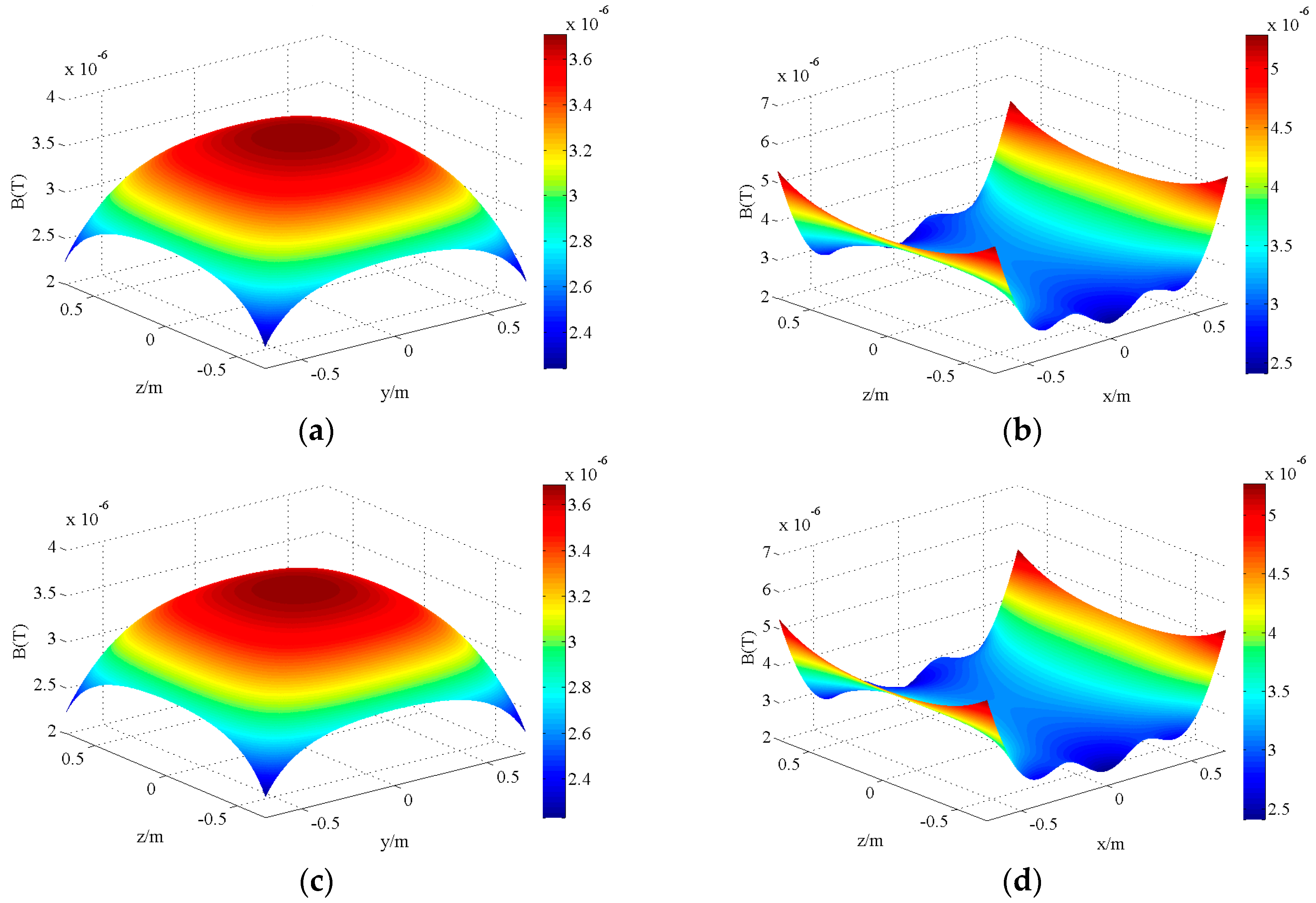

The FEM, analytical, and experimental results at the center of the coil are compared in

Table 4. It can be seen from the table that there is no

y,

z component of the magnetic flux density of the center point in theory. However, the experimental value have

y,

z component since we cannot make sure that the

x,

y, and

z axes of the coil system coincide strictly with the

x,

y, and

z axes of the sensor. In the uniform volume,

x component of the flux density is large, and the

y and

z components are almost zero in theory. Due to the large

x component of the flux density, the slight deviation of the sensor’s coordinate axes result in a large error in measuring the

y and

z components of the flux density. So, we just focus on the

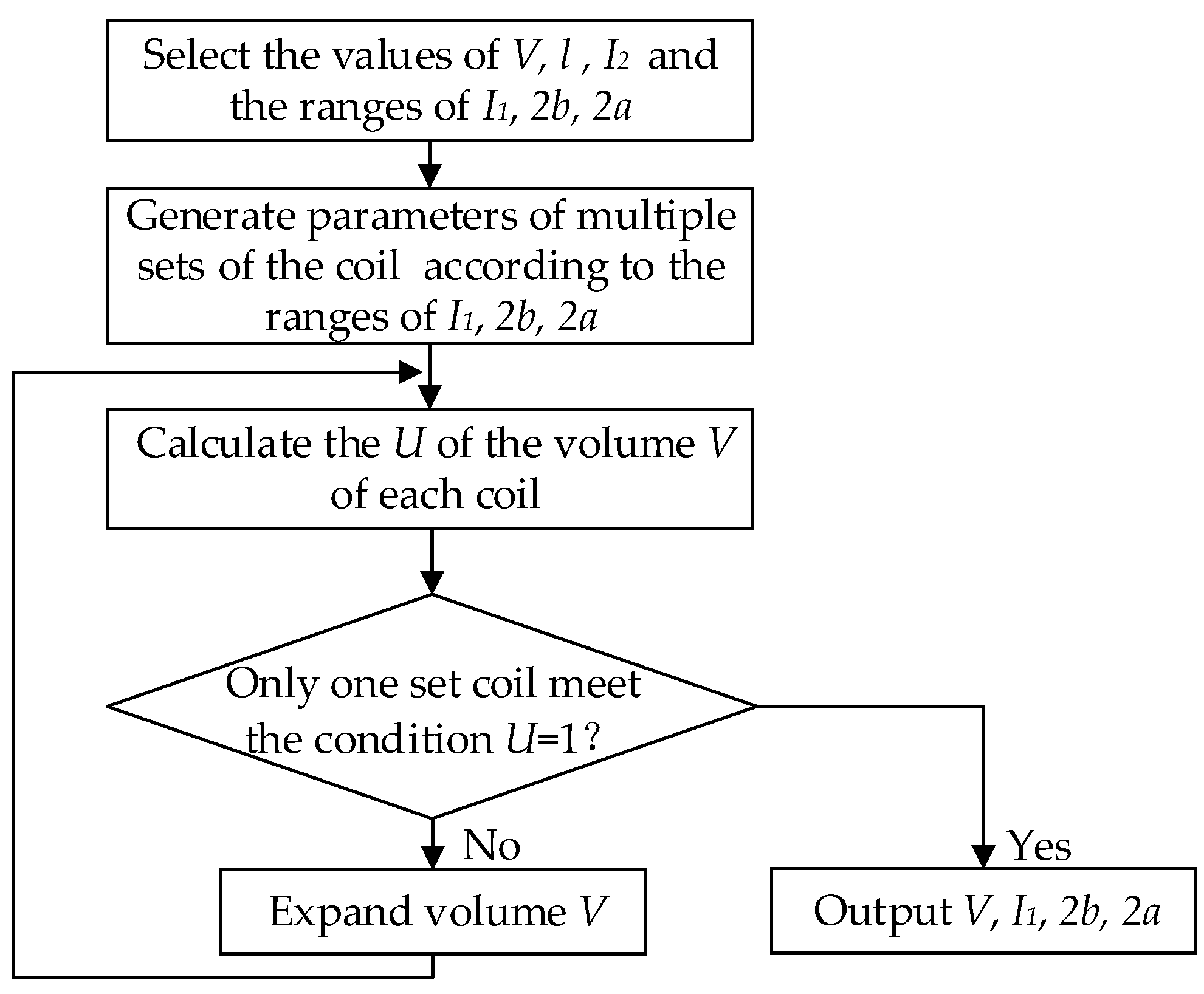

x component of the flux density and flux density amplitude. Values of the measuring points are fitted and the relative errors between the analytical and experimental results are calculated, as shown in

Figure 10 and

Figure 11. There are small relative errors of below 0.566% between the analytical and experimental

x component of the flux density and 0.570% between the analytical and experimental flux density amplitude.

There are some reasons for relative errors. (1) The MSR is an ideal cubic layer in the analytical model. The actual MSR is made of pieces of permalloy plate. The room has a door and a number of holes for ventilation. (2) The coils deformation and alignment mismatch can cause the errors. Since there may be a little deviation between the axes of the coil and axes of the sensor, we use practical deviation rate Δ

Bpr as the index that only contains the amplitude of flux density. The practical deviation rates of the measuring points are calculated and fitted, as shown in

Figure 12. The maximum value of the practical deviation rates of the measuring points is 0.920%, which is in good agreement with the theoretical value 0.804%.