Derivation and Application of a New Transmission Loss Formula for Power System Economic Dispatch

Abstract

:1. Introduction

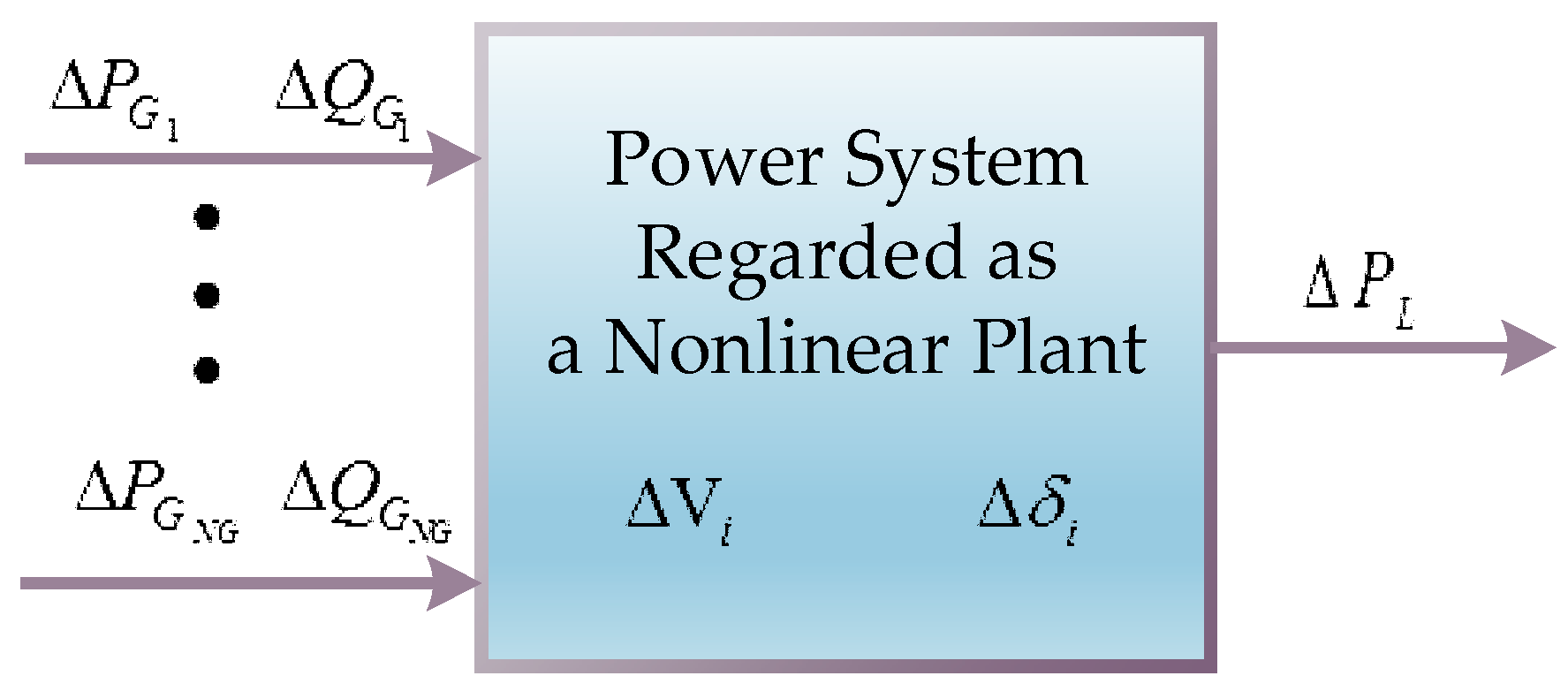

2. Problem Description

- (1)

- The power factor at each generator bus remains constant, i.e., is fixed.

- (2)

- The voltage angle at each voltage-controlled bus voltage-controlled bus (PV) bus(voltage-controlled bus) remains constant.

- (3)

- The voltage magnitude at each PV bus remains constant.

- (4)

- The ratio of the load current to the total load current remains constant.

3. Derivation of New Loss Formulas and Its Application to Economic Dispatch

3.1. Derivation of New Loss Formula

3.2. TL Formula Considering Real Power Output

3.3. TL Formula Considering Real and Reactive Power Outputs

3.4. Economic Dispatch Based on New Loss Formula

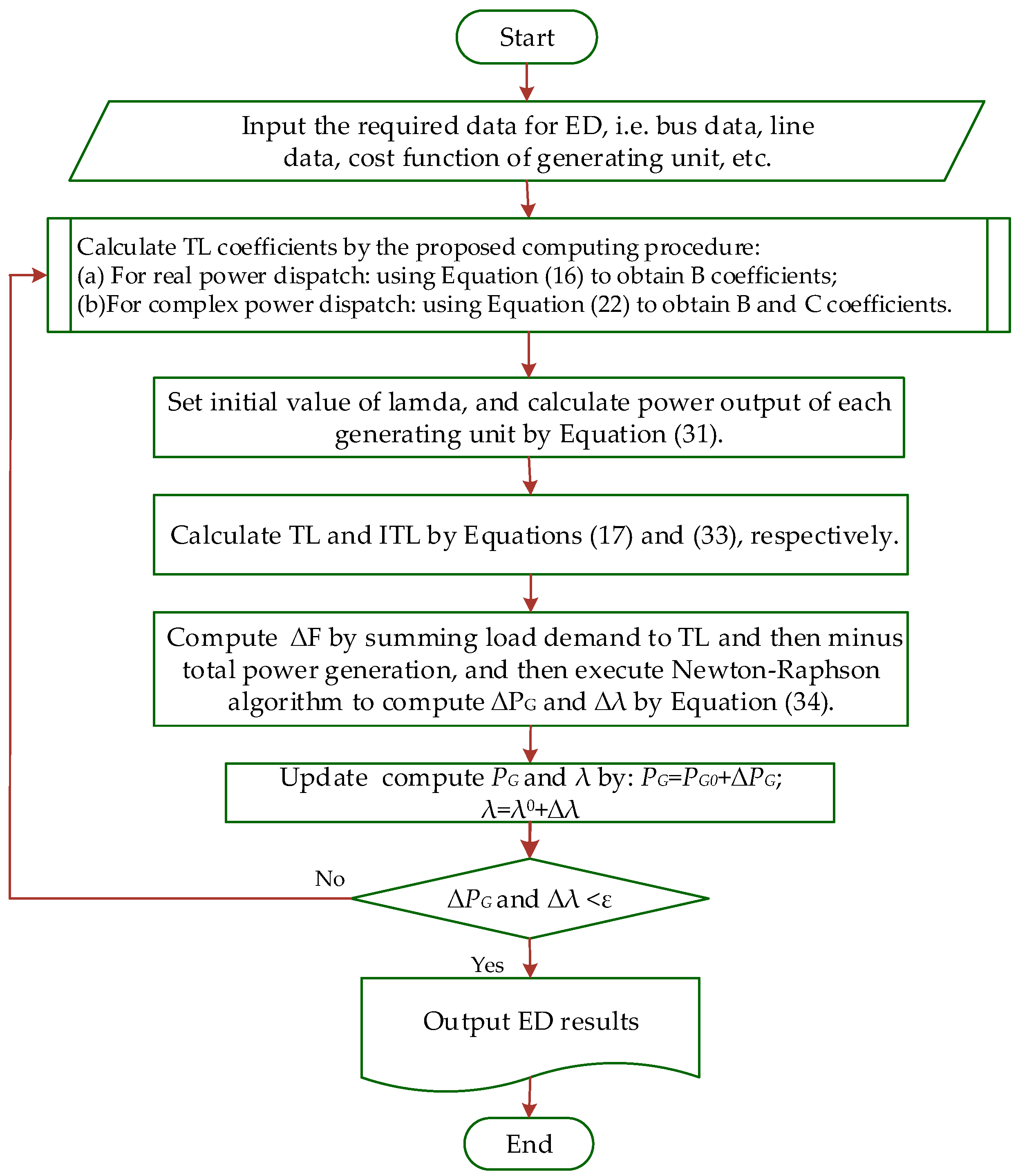

- Step 1:

- Input the required data for ED, i.e., bus data, line data, and cost function of the generating unit.

- Step 2:

- Calculate TL coefficients by the proposed computing procedure: (a) using Equation (16) to obtain the B coefficients; and (b) using Equation (22) to obtain the B and C coefficients.

- Step 3:

- Set initial value of lambda, and calculate power output of each generating unit by Equation (31).

- Step 4:

- Calculate TL and ITL by Equations (17) and (33), respectively.

- Step 5:

- Compute by summing load demand to TL, then subtracting total power generation, and finally executing the Newton–Raphson algorithm to compute ΔPG and by Equation (34).

- Step 6:

- Update and by and .

- Step 7:

- Check for convergence by examining whether ΔPG and are smaller than the tolerance ; if convergence exists, then terminate the iterative process and go to Step 8. Otherwise, go to Step 4 to continue the iterative process until convergence.

- Step 8:

- Print out the ED results.

4. Discussion of the Simulation Results

4.1. Numerical Results of the New Loss Coefficients

4.2. Simulation Results of ED by New Loss Coefficients

4.2.1. IEEE 14-Bus System

4.2.2. IEEE 30-Bus System

4.3. Discussions

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Ma, K.; Wang, C.; Yang, J.; Yang, Q.; Yuan, Y. Economic Dispatch with Demand Response in Smart Grid: Bargaining Model and Solutions. Energies 2017, 10, 1193. [Google Scholar] [CrossRef]

- Xie, J.; Cao, C. Non-Convex Economic Dispatch of a Virtual Power Plant via a Distributed Randomized Gradient-Free Algorithm. Energies 2017, 10, 1051. [Google Scholar] [CrossRef]

- Hu, Y.; Li, Y.; Xu, M.; Zhou, L.; Cui, M. A Chance-Constrained Economic Dispatch Model in Wind-Thermal-Energy Storage System. Energies 2017, 10, 326. [Google Scholar] [CrossRef]

- Jang, Y.-S.; Kim, M.-K. A Dynamic Economic Dispatch Model for Uncertain Power Demands in an Interconnected Microgrid. Energies 2017, 10, 300. [Google Scholar] [CrossRef]

- Huang, W.-T.; Yao, K.-C.; Wu, C.-C.; Chang, Y.-R.; Lee, Y.-D.; Ho, Y.-H. A Three-Stage Optimal Approach for Power System Economic Dispatch Considering Microgrids. Energies 2016, 9, 976. [Google Scholar] [CrossRef]

- Wood, A.J.; Wollenberg, B.F.; Sheblé, G.B. Power Generation, Operation and Control, 3rd ed.; Wiley: New York, NY, USA, 2013; pp. 410–430. [Google Scholar]

- Charker, D.C.; Jacobs, W.E.; Ferguson, R.W.; Harder, E.L. Loss Evaluation Part I—Loss Associated with Sale Power-In-Phase Method. Trans. Am. Inst. Electr. Eng. 1954, 73, 709–716. [Google Scholar]

- Kirchmayer, L.K.; Happ, H.H.; Stagg, G.W.; Hohenstein, J.F. Direct Calculation of Transmission Loss Formula-I. Trans. Am. Inst. Electr. Eng. 1960, 79, 962–967. [Google Scholar] [CrossRef]

- George, E.E. A New Method of Making Transmission-Loss Formula by Means of Eigenvalues and Modal Matrices. Trans. Am. Inst. Electr. Eng. 1960, 79, 287–296. [Google Scholar] [CrossRef]

- Happ, H.H.; Hohenstein, J.F.; Kirchmayer, L.K.; Stagg, G.W. Direct Calculation of Transmission Loss Formula-II. Trans. Am. Inst. Electr. Eng. 1964, 83, 702–707. [Google Scholar] [CrossRef]

- Scott Meyer, W.; Albertson, V.D. Improved Loss Formula Computation by Optimally Ordered Elimination Techniques. IEEE Trans. Power Appar. Syst. 1967, PAS-90, 62–69. [Google Scholar] [CrossRef]

- Zhan, J.P.; Wu, Q.H.; Guo, C.X.; Zhou, X.X. Fast λ-Iteration Method for Economic Dispatch with Prohibited Operating Zones. IEEE Trans. Power Syst. 2014, 29, 990–991. [Google Scholar] [CrossRef]

- Bayon, L.; Grau, J.M.; Ruiz, M.M.; Suarez, P.M. The Exact Solution of the Environmental/Economic Dispatch Problem. IEEE Trans. Power Syst. 2012, 27, 723–731. [Google Scholar] [CrossRef]

- Zadeh, A.K.; Nor, K.M.; Zeynal, H. Multi-Thread Security Constraint Economic Dispatch with Exact Loss Formulation. In Proceedings of the 2010 IEEE International Conference on Power and Energy, Kuala Lumpur, Malaysia, 29 November–1 December 2010; pp. 864–869. [Google Scholar]

- Jiang, A.; Ertem, S. Polynomial Loss Models for Economic Dispatch and Error Estimation. IEEE Trans. Power Appar. Syst. 1995, 10, 1546–1552. [Google Scholar] [CrossRef]

- Chowdhury, B.H. A review of recent advances in Economic Dispatch. IEEE Trans. Power Syst. 1990, 5, 1248–1259. [Google Scholar] [CrossRef]

- Ciornei, I.; Kyriakides, E. A GA-API Solution for the Economic Dispatch of Generation in Power System Operation. IEEE Trans. Power Syst. 2012, 23, 1825–1835. [Google Scholar] [CrossRef]

- Kuo, C.C. A Novel Coding Scheme for Practical Economic Dispatch by Modified Particle Swam Approach. IEEE Trans. Power Syst. 2008, 29, 990–991. [Google Scholar]

- Qu, B.; Qiao, B.; Zhu, Y.; Liang, J.; Wang, L. Dynamic Power Dispatch Considering Electric Vehicles and Wind Power Using Decomposition Based Multi-Objective Evolutionary Algorithm. Energies 2017, 10, 1991. [Google Scholar] [CrossRef]

- Lim, S.Y.; Montakhab, M.; Nouri, H. Economic Dispatch of Power System Using Particle Swarm Optimization with Constriction Factor. Int. J. Innov. Energy Syst. Power 2009, 4, 29–34. [Google Scholar]

- Chaturvedi, K.T.; Pandit, M.; Srivastava, L. Self-Organizing Hierarchical Particle Swarm Optimization for Nonconvex Economic Dispatch. IEEE Trans. Power Syst. 2008, 23, 1079–1087. [Google Scholar] [CrossRef]

- Niu, Q.; Zhou, Z.; Zhang, H.-Y.; Deng, J. An Improved Quantum-Behaved Particle Swarm Optimization Method for Economic Dispatch Problems with Multiple Fuel Options and Valve-Points Effects. Energies 2012, 5, 3655–3673. [Google Scholar] [CrossRef]

- Chen, C.I. Simulated annealing-based optimal wind-thermal coordination scheduling. IET Gener. Transm. Distrib. 2007, 1, 447–455. [Google Scholar] [CrossRef]

- Lin, W.-M.; Tu, C.-S.; Tsai, M.-T. Energy Management Strategy for Microgrids by Using Enhanced Bee Colony Optimization. Energies 2016, 9, 5. [Google Scholar] [CrossRef]

- Lin, W.-M.; Cheng, F.S.; Tsay, M.T. An improved tabu search for economic dispatch with multiple minima. IEEE Trans. Power Syst. 2002, 17, 108–112. [Google Scholar] [CrossRef]

- Latif, A.; Palensky, P. Economic Dispatch Using Modified Bat Algorithm. Algorithms 2014, 7, 328–338. [Google Scholar] [CrossRef]

- Ding, T.; Bo, R.; Li, F.; Sun, H. A Bi-Level Branch and Bound Method for Economic Dispatch with Disjoint Prohibited Zones Considering Network Losses. IEEE Trans. Power Syst. 2015, 30, 2841–2885. [Google Scholar] [CrossRef]

- Stevenson, W.D. Elements of Power System Analysis; McGraw-Hill: New York, NY, USA, 1962. [Google Scholar]

- Cataliotti, A.; Cosentino, V.; Di Cara, D.; Tinè, G. LV Measurement Device Placement for Load Flow Analysis in MV Smart Grids. IEEE Trans. Instrum. Meas. 2016, 65, 999–1006. [Google Scholar] [CrossRef]

- Bhonsle, J.; Junghare, A. Optimal placing of PMUs in a constrained grid: An approach. Turk. J. Electr. Eng. Comput. Sci. 2016, 24, 4508–4516. [Google Scholar] [CrossRef]

- Ali, S.; Wu, K.; Weston, K.; Marinakis, D. A Machine Learning Approach to Meter Placement for Power Quality Estimation in Smart Grid. IEEE Trans. Smart Grid 2016, 7, 1552–1561. [Google Scholar] [CrossRef]

- Power Systems Test Case Archive. Available online: http://www.ee.washington.edu/research/pstca/ (accessed on 26 December 2017).

- Taipower Website. Available online: http://www.taipower.com.tw/content/new_info/new_info_in.aspx?LinkID=30 (accessed on 27 December 2017).

- Walters, D.C.; Sheble, G.B. Genetic Algorithm Solution of Economic Dispatch with Valve Point Loading. IEEE Trans. Power Syst. 1993, 8, 1325–1332. [Google Scholar] [CrossRef]

| IEEE 14-Bus System | |||

|---|---|---|---|

| B Coefficients | Value | C Coefficients | Value |

| B1 | 0.002545293 | C1 | 0.013908593 |

| B2 | −0.032753049 | C2 | −0.047553930 |

| B3 | −0.054144950 | C3 | −0.014210789 |

| B11 | 0.008313448 | C11 | 0.057777864 |

| B12 | 0.002088989 | C12 | −0.225351026 |

| B13 | −0.005324837 | C13 | −0.057871841 |

| B22 | 0.009819698 | C22 | −0.246029254 |

| B23 | 0.001901216 | C23 | −0.326517907 |

| B33 | 0.027155199 | C33 | 0.098653719 |

| IEEE 30-Bus System | |||

|---|---|---|---|

| B Coefficients | Value | C Coefficients | Value |

| B1 | 0.015751021 | C1 | 0.007147022 |

| B2 | 0.004147944 | C2 | −0.101595336 |

| B3 | −0.016343019 | C3 | −0.230603855 |

| B4 | −0.004154358 | C4 | −0.285013950 |

| B5 | −0.007096220 | C5 | −0.322118026 |

| B6 | 0.008479213 | C6 | −0.345166406 |

| B11 | 0.026652970 | C11 | −0.343221969 |

| B12 | 0.032812831 | C12 | 0.103648253 |

| B13 | 0.007563165 | C13 | −0.139702650 |

| B14 | 0.017715676 | C14 | −0.120076524 |

| B15 | 0.003144289 | C15 | −0.164410470 |

| B16 | 0.020161422 | C16 | −0.069327226 |

| B22 | 0.054859151 | C22 | 0.164111869 |

| B23 | 0.028419732 | C23 | −0.097968419 |

| B24 | 0.036122309 | C24 | −0.072616973 |

| B25 | 0.021161791 | C25 | −0.11868853 |

| B26 | 0.037326855 | C26 | −0.011605329 |

| B33 | 0.035596536 | C33 | −0.263471716 |

| B34 | 0.016784607 | C34 | −0.353249701 |

| B35 | 0.001870497 | C35 | −0.402305931 |

| B36 | 0.016779734 | C36 | −0.301730208 |

| B44 | 0.049620059 | C44 | −0.211006479 |

| B45 | 0.023143156 | C45 | −0.329357571 |

| B46 | 0.034976567 | C46 | −0.221578735 |

| B55 | 0.013354820 | C55 | 0.100097924 |

| B56 | 0.014568420 | C56 | −0.195383733 |

| B66 | 0.054766327 | C66 | 0.315360202 |

| Bus No. | TPF-ED | TBC-ED | NLC-ED | ||

|---|---|---|---|---|---|

| Output (pu) | Output (pu) | Error (%) | Output (pu) | Error (%) | |

| 1 | 1.6045 | 1.7199 | 7.192 | 1.6044 | 0.006 |

| 2 | 0.6880 | 0.6602 | 4.041 | 0.6881 | 0.015 |

| 6 | 0.3957 | 0.3080 | 22.163 | 0.3957 | 0.000 |

| Cost | 1137.7 | 1136.4 | 0.114 | 1137.7 | 0.000 |

| TL | 0.0982 | 0.0981 | 0.102 | 0.0982 | 0.000 |

| λ | 405.4473 | 416.9914 | 2.847 | 405.4473 | 0.000 |

| Bus No. | TPF-ED | TBC-ED | NLC-ED | ||

|---|---|---|---|---|---|

| Output (pu) | Output (pu) | Error (%) | Output (pu) | Error (%) | |

| 1 | 1.7748 | 1.9019 | 7.161 | 1.7858 | 0.620 |

| 2 | 0.8817 | 0.8553 | 2.994 | 0.8639 | 2.019 |

| 6 | 0.5874 | 0.4725 | 19.561 | 0.5629 | 4.171 |

| Cost | 1375.4 | 1367.6 | 0.567 | 1361.3 | 1.025 |

| TL | 0.1359 | 0.1218 | 10.375 | 0.1046 | 23.032 |

| λ | 422.481 | 435.194 | 3.009 | 423.580 | 0.260 |

| Bus No. | TPF-ED | TBC-ED | NLC-ED | ||

|---|---|---|---|---|---|

| Output (pu) | Output (pu) | Error (%) | Output (pu) | Error (%) | |

| 1 | 1.4358 | 1.540281 | 7.277 | 1.4248 | 0.766 |

| 2 | 0.49774 | 0.469045 | 5.765 | 0.513 | 3.066 |

| 6 | 0.20684 | 0.144235 | 30.267 | 0.2282 | 10.327 |

| Cost | 913.5225 | 917.7751 | 0.466 | 914.42 | 0.098 |

| TL | 0.0683 | 0.0816 | 19.473 | 0.0690 | 1.025 |

| λ | 388.5756 | 399.028 | 2.690 | 387.4829 | 0.281 |

| Bus No.% | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| PD | 0 | 0 | 5 | 6 | 8 | 0 | 7 | 0 | 12 | 10 | 11 | 6 | 7 | 9 |

| QD | 0 | 0 | 15 | 6 | 8 | 0 | 7 | 0 | 12 | 30 | 11 | 6 | 7 | 29 |

| Bus No. | TPF-ED | TBC-ED | NLC-ED | ||

|---|---|---|---|---|---|

| Output (pu) | Output (pu) | Error (%) | Output (pu) | Error (%) | |

| 1 | 1.6567 | 1.7747 | 7.123 | 1.6591 | 0.145 |

| 2 | 0.7466 | 0.7188 | 3.724 | 0.7412 | 0.723 |

| 6 | 0.4545 | 0.3576 | 21.320 | 0.4463 | 1.804 |

| Cost | 1209.2 | 1204.9 | 0.356 | 1204.2 | 0.413 |

| TL | 0.1112 | 0.1046 | 5.935 | 0.0999 | 10.162 |

| λ | 410.671 | 422.500 | 2.880 | 410.909 | 0.058 |

| Scenario | TPF-ED | TBC-ED | NLC-ED | ||

|---|---|---|---|---|---|

| Computing Time (X) | Computing Time (Y) | X/Y | Computing Time (Z) | X/Z | |

| base case system demand condition | 0.188 (s) | 0.035 (s) | 5.371 | 0.025 (s) | 7.520 |

| conforming system demand increased by 20% condition | 0.188 (s) | 0.026 (s) | 7.231 | 0.028 (s) | 6.714 |

| conforming system demand decreased by 20% condition | 0.156 (s) | 0.028 (s) | 5.571 | 0.023 (s) | 6.783 |

| nonconforming system demand change condition | 0.187 (s) | 0.025 (s) | 7.408 | 0.028 (s) | 6.679 |

| Bus No. | TPF-ED | TBC-ED | NLC-ED | ||

|---|---|---|---|---|---|

| Output (pu) | Output (pu) | Error% | Output (pu) | Error% | |

| 1 | 0.5127 | 0.582 | 13.517 | 0.5127 | 0.000 |

| 2 | 0.3551 | 0.354 | 0.310 | 0.3551 | 0.000 |

| 5 | 0.7052 | 0.658 | 6.693 | 0.7052 | 0.000 |

| 8 | 0.3591 | 0.341 | 5.040 | 0.3591 | 0.000 |

| 11 | 0.4430 | 0.414 | 6.546 | 0.4430 | 0.000 |

| 13 | 0.4870 | 0.513 | 5.339 | 0.4871 | 0.021 |

| Cost | 1325.1 | 1324.6 | 0.038 | 1325.1 | 0.000 |

| TL | 0.0281 | 0.028 | 0.356 | 0.0281 | 0.000 |

| λ | 381.015 | 386.556 | 1.454 | 381.014 | 0.000 |

| Bus No. | TPF-ED | TBC-ED | NLC-ED | ||

|---|---|---|---|---|---|

| Output (pu) | Output (pu) | Error% | Output (pu) | Error% | |

| 1 | 0.6009 | 0.675 | 12.332 | 0.6458 | 7.472 |

| 2 | 0.4352 | 0.425 | 2.344 | 0.3885 | 10.731 |

| 5 | 0.8243 | 0.774 | 6.102 | 0.8276 | 0.400 |

| 8 | 0.4661 | 0.449 | 3.669 | 0.4324 | 7.230 |

| 11 | 0.5409 | 0.514 | 4.973 | 0.5902 | 9.114 |

| 13 | 0.5731 | 0.598 | 4.345 | 0.5553 | 3.106 |

| Cost | 1551.7 | 1549.5 | 0.142 | 1551.8 | 0.006 |

| TL | 0.0397 | 0.036 | 9.320 | 0.0391 | 1.511 |

| λ | 388.074 | 394.024 | 1.533 | 391.666 | 0.926 |

| Bus No. | TPF-ED | TBC-ED | NLC-ED | ||

|---|---|---|---|---|---|

| Output (pu) | Output (pu) | Error% | Output (pu) | Error% | |

| 1 | 0.4244 | 0.4885 | 15.104 | 0.3846 | 9.378 |

| 2 | 0.2752 | 0.283 | 2.834 | 0.3183 | 15.661 |

| 5 | 0.5876 | 0.543 | 7.590 | 0.5871 | 0.085 |

| 8 | 0.2529 | 0.233 | 7.869 | 0.2847 | 12.574 |

| 11 | 0.3453 | 0.315 | 8.775 | 0.3029 | 12.279 |

| 13 | 0.4010 | 0.427 | 6.484 | 0.4185 | 4.364 |

| Cost | 1104.5 | 1105.48 | 0.089 | 1108.4 | 0.353 |

| TL | 0.0192 | 0.0228 | 18.750 | 0.0287 | 49.479 |

| λ | 373.952 | 379.07 | 1.369 | 370.764 | 0.853 |

| Bus No% | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | 15 |

| PD | 0 | 0 | 15 | 25 | 0 | 18 | 6 | 0 | 5 | 24 | 0 | 28 | 0 | 0 | 5 |

| QD | 0 | 0 | 10 | 30 | 0 | 8 | 25 | 0 | 20 | 14 | 0 | 18 | 0 | 6 | 27 |

| Bus No% | 16 | 17 | 18 | 19 | 20 | 21 | 22 | 23 | 24 | 25 | 26 | 27 | 28 | 29 | 30 |

| PD | 30 | 15 | 6 | 30 | 11 | 7 | 15 | 12 | 0 | 16 | 11 | 30 | 14 | 25 | 0 |

| QD | 30 | 12 | 5 | 7 | 6 | 23 | 6 | 25 | 16 | 6 | 22 | 28 | 24 | 5 | 0 |

| Bus No. | TPF-ED | TBC-ED | NLC-ED | ||

|---|---|---|---|---|---|

| Output (pu) | Output (pu) | Error% | Output (pu) | Error% | |

| 1 | 0.5393 | 0.6097 | 13.054 | 0.5517 | 2.299 |

| 2 | 0.3777 | 0.3755 | 0.582 | 0.3654 | 3.257 |

| 5 | 0.7291 | 0.6922 | 5.061 | 0.7411 | 1.646 |

| 8 | 0.3929 | 0.3730 | 5.065 | 0.3810 | 3.029 |

| 11 | 0.4767 | 0.4440 | 6.860 | 0.4860 | 1.951 |

| 13 | 0.5191 | 0.5383 | 3.699 | 0.5074 | 2.254 |

| Cost | 1392.1 | 1390.87 | 0.088 | 1391.4 | 0.050 |

| TL | 0.0323 | 0.03042 | 5.820 | 0.0302 | 6.502 |

| λ | 383.145 | 3.887 | 1.450 | 384.137 | 0.259 |

| Scenario | TPF-ED | TBC-ED | NLC-ED | ||

|---|---|---|---|---|---|

| Computing Time (X) | Computing Time (Y) | X/Y | Computing Time (Z) | X/Z | |

| base case system demand condition | 0.312 (s) | 0.0243 (s) | 12.840 | 0.0158 (s) | 19.747 |

| conforming system demand increased by 20% condition | 0.313 (s) | 0.029 (s) | 10.793 | 0.019 (s) | 16.474 |

| conforming system demand decreased by 20% condition | 0.343 (s) | 0.0318 (s) | 10.790 | 0.017 (s) | 20.176 |

| nonconforming system demand change condition | 0.343 (s) | 0.0252 (s) | 13.611 | 0.02 (s) | 17.150 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Huang, W.-T.; Yao, K.-C.; Chen, M.-K.; Wang, F.-Y.; Zhu, C.-H.; Chang, Y.-R.; Lee, Y.-D.; Ho, Y.-H. Derivation and Application of a New Transmission Loss Formula for Power System Economic Dispatch. Energies 2018, 11, 417. https://doi.org/10.3390/en11020417

Huang W-T, Yao K-C, Chen M-K, Wang F-Y, Zhu C-H, Chang Y-R, Lee Y-D, Ho Y-H. Derivation and Application of a New Transmission Loss Formula for Power System Economic Dispatch. Energies. 2018; 11(2):417. https://doi.org/10.3390/en11020417

Chicago/Turabian StyleHuang, Wei-Tzer, Kai-Chao Yao, Ming-Ku Chen, Feng-Ying Wang, Cang-Hui Zhu, Yung-Ruei Chang, Yih-Der Lee, and Yuan-Hsiang Ho. 2018. "Derivation and Application of a New Transmission Loss Formula for Power System Economic Dispatch" Energies 11, no. 2: 417. https://doi.org/10.3390/en11020417