Experimental Research on the Injection Rate of DME and Diesel Fuel in Common Rail Injection System by Using Bosch and Zeuch Methods

Abstract

:1. Introduction

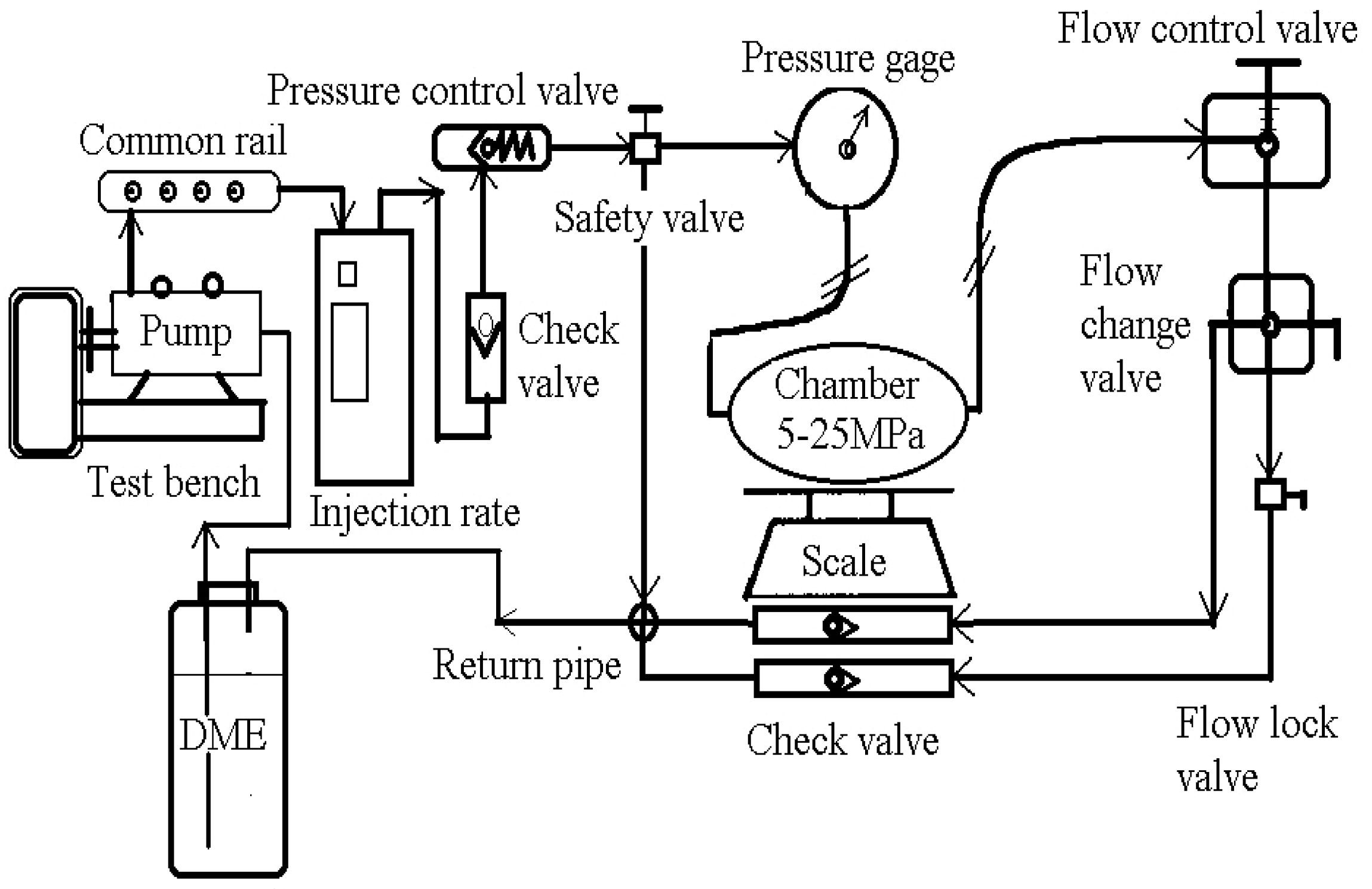

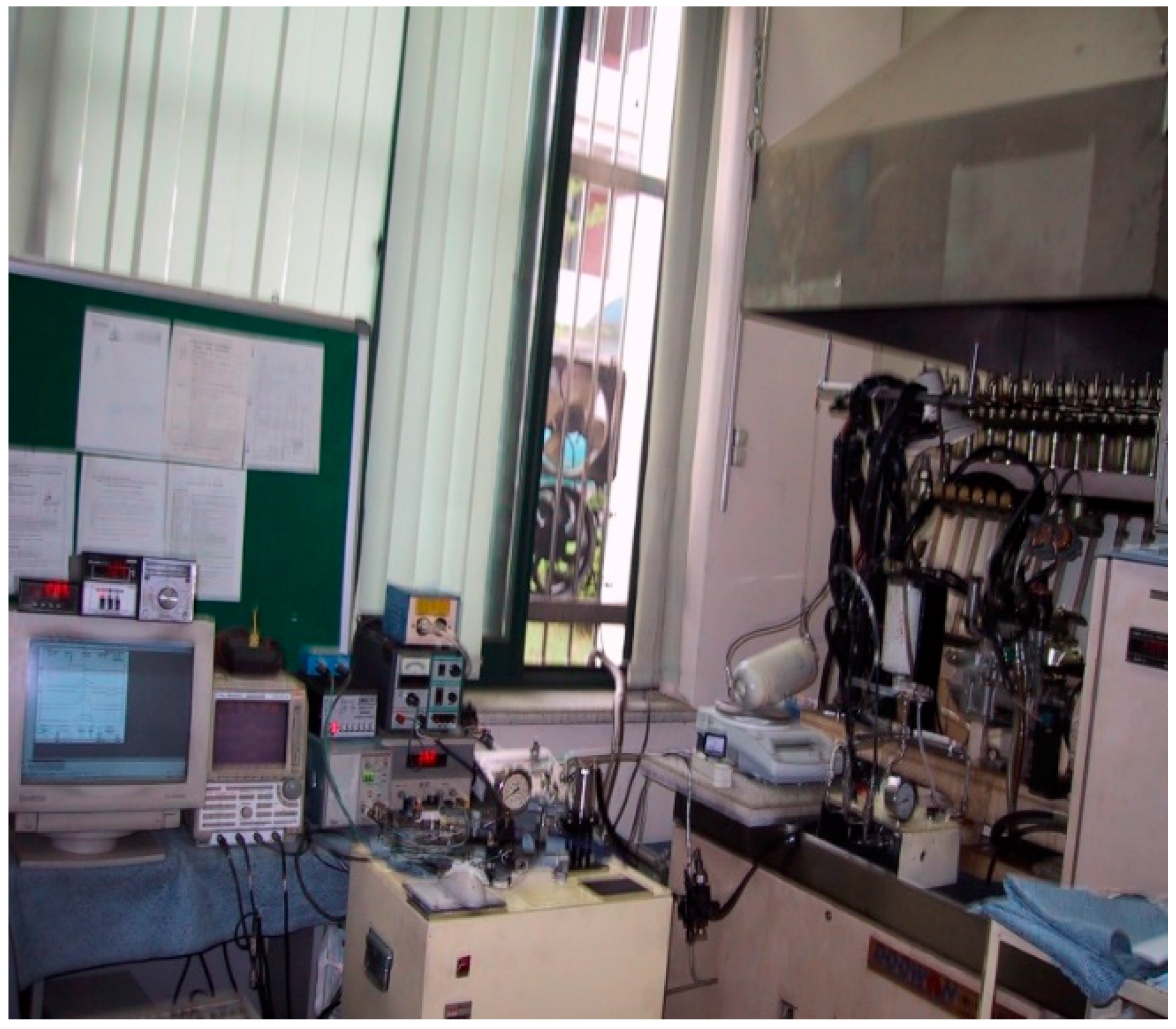

2. Experimental Apparatus and Methodology

2.1. Experimental Setup

2.2. Experimental Conditions

3. Results and Investigations

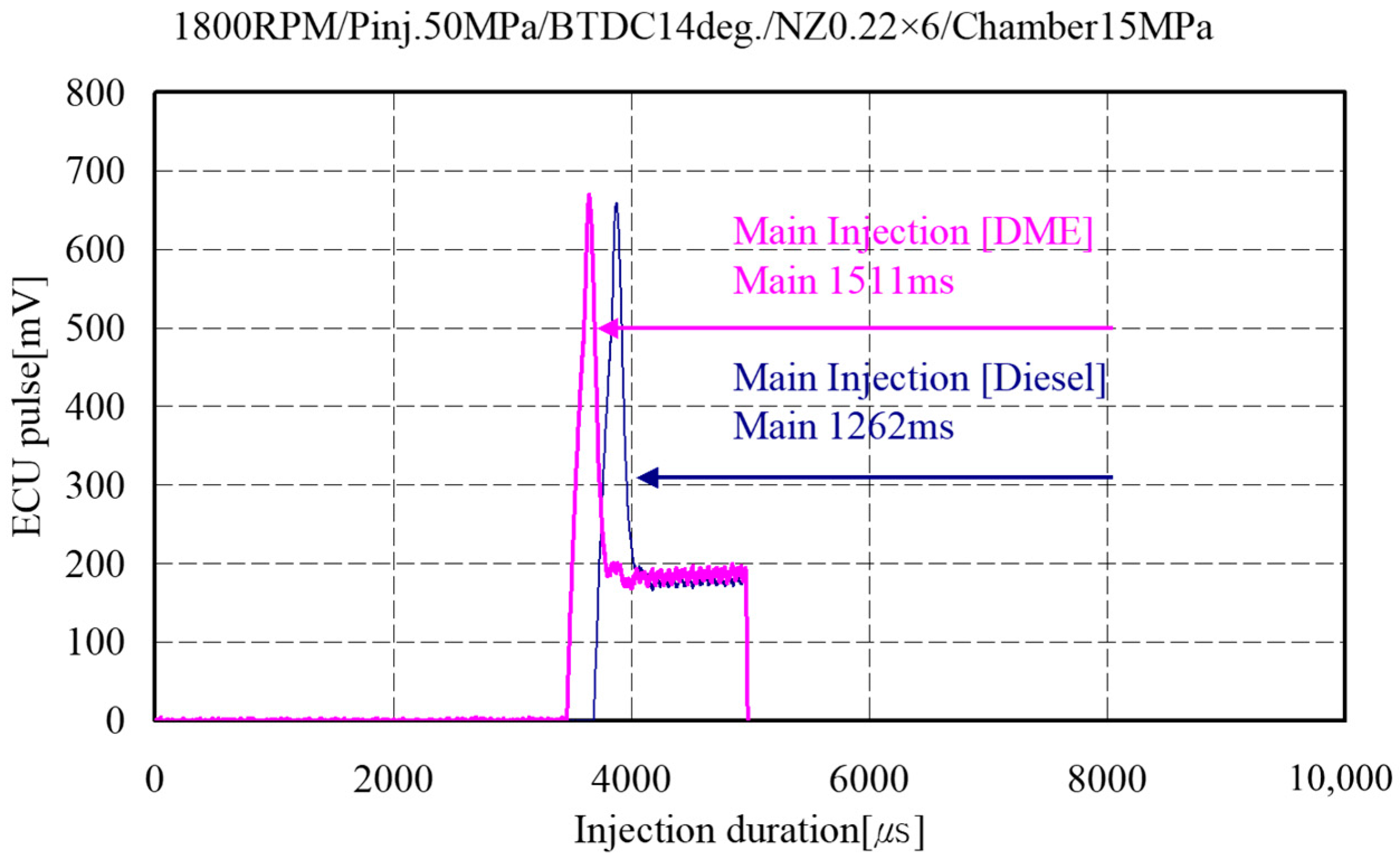

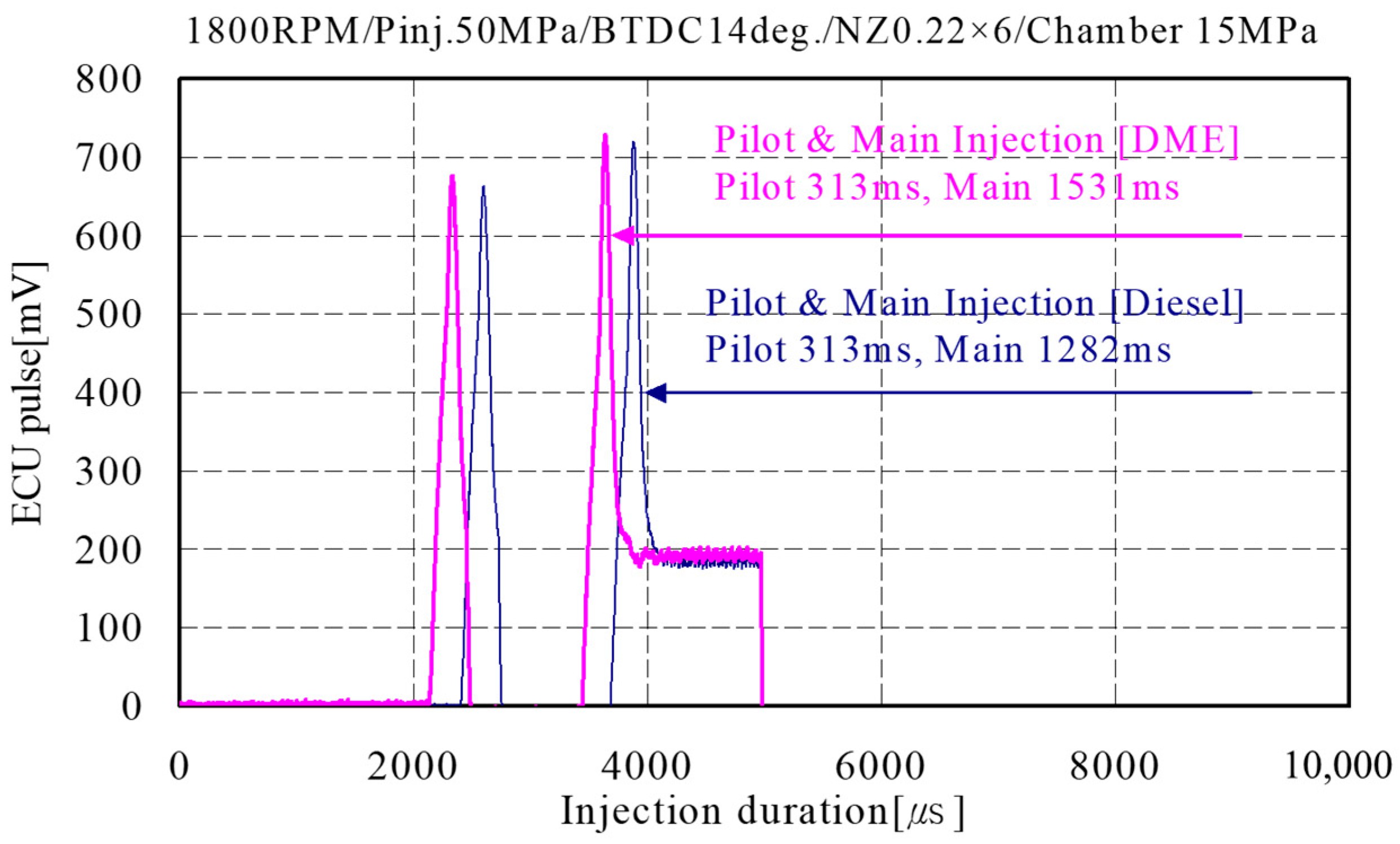

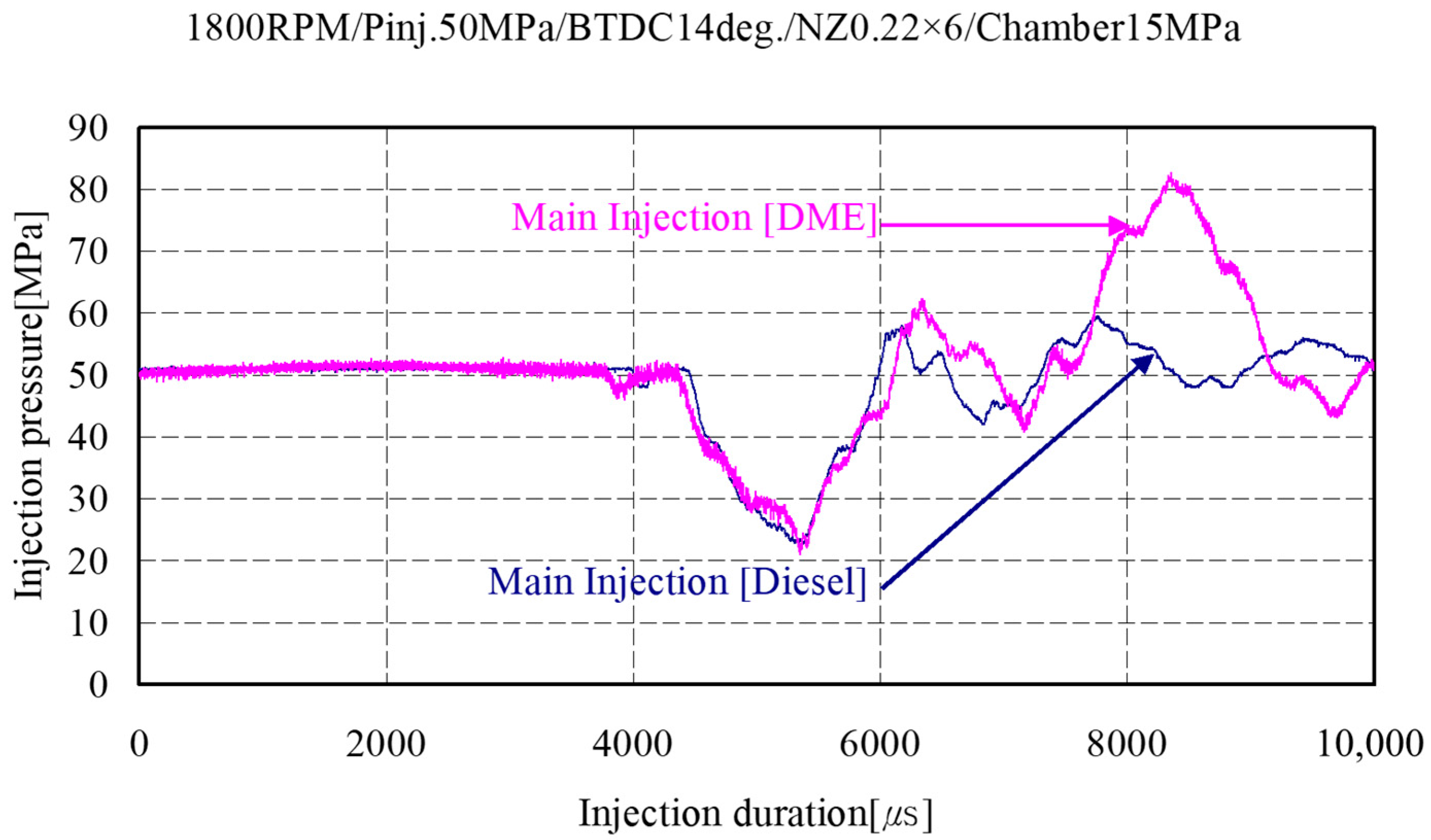

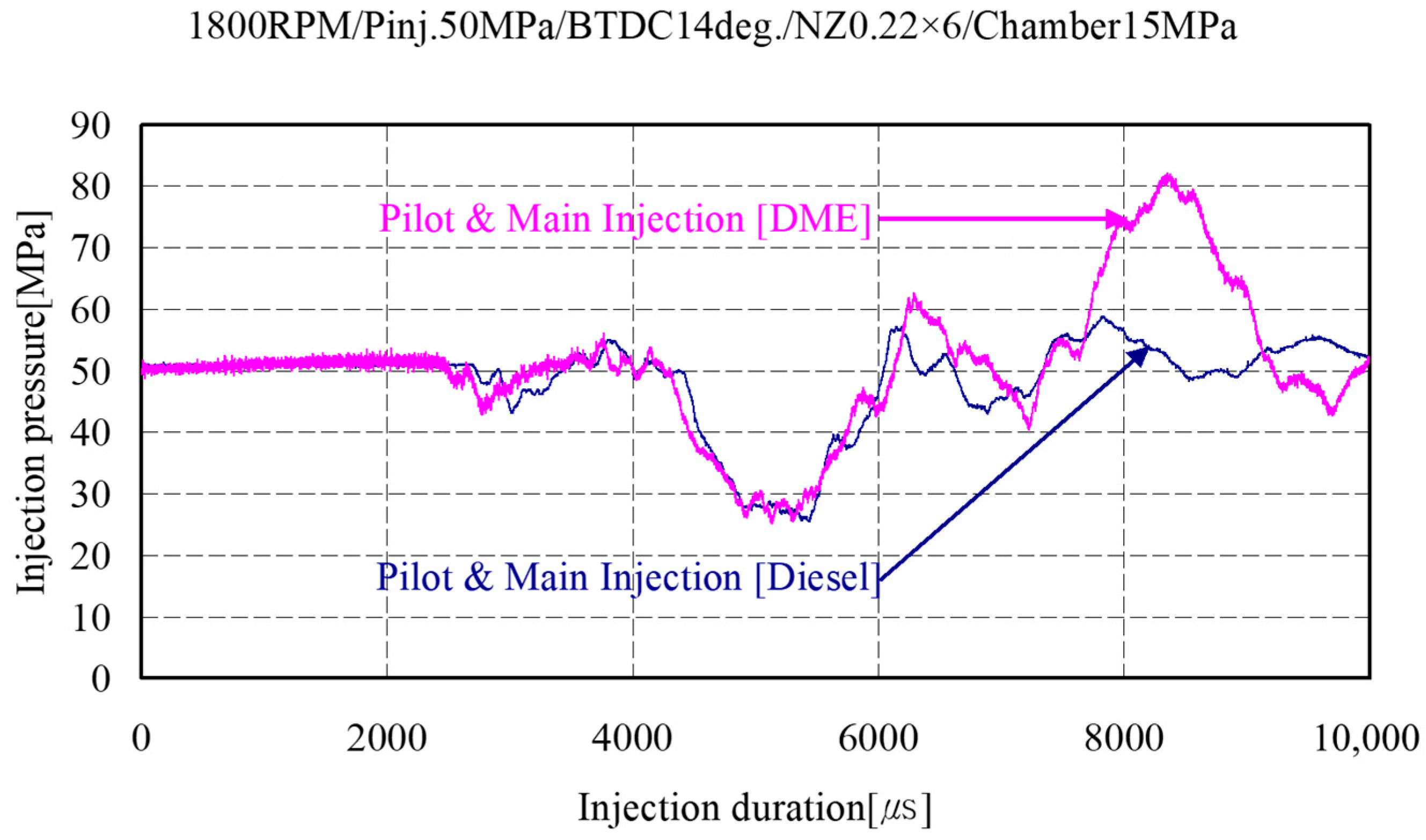

3.1. Injection Pressure in Accordance with Injection Duration

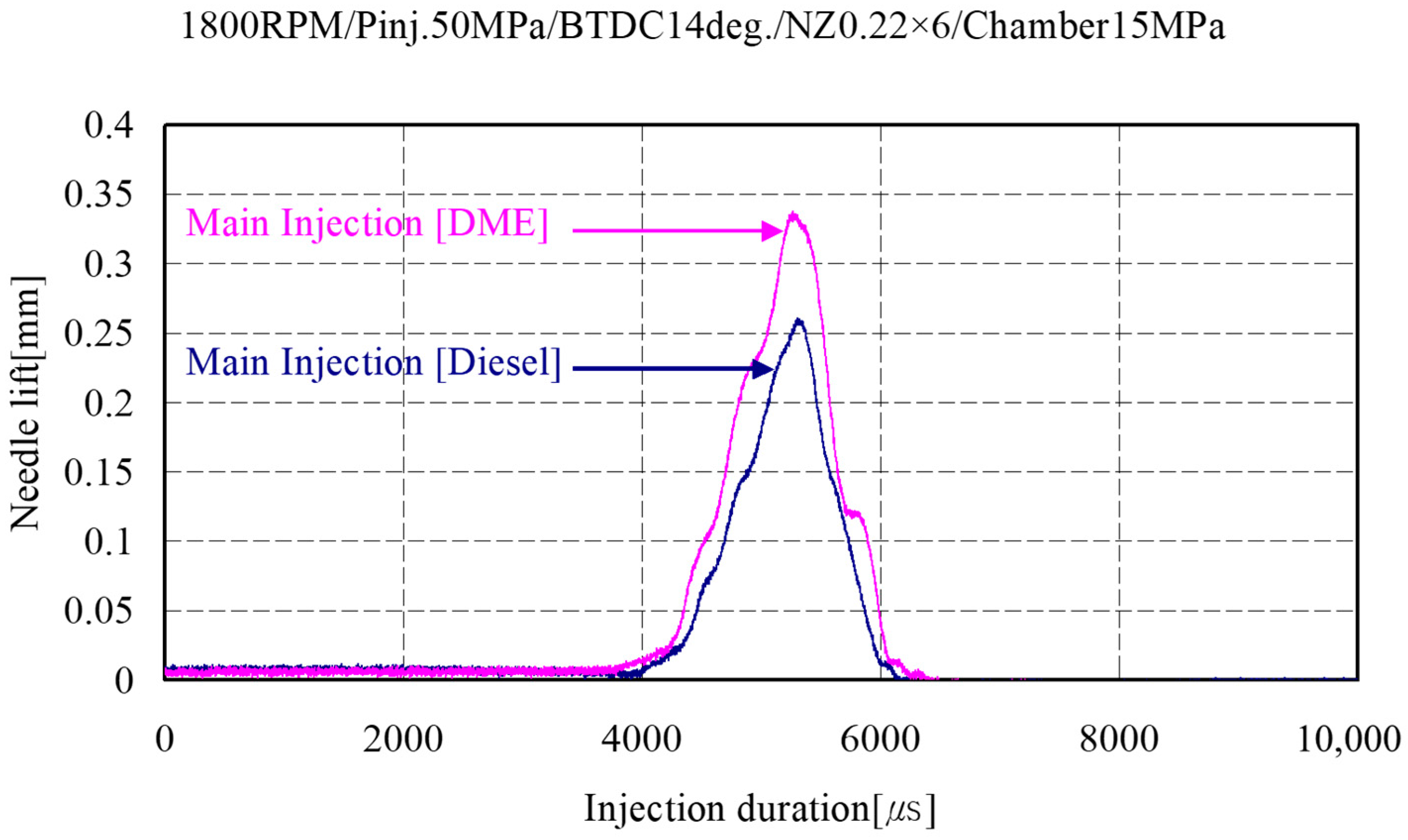

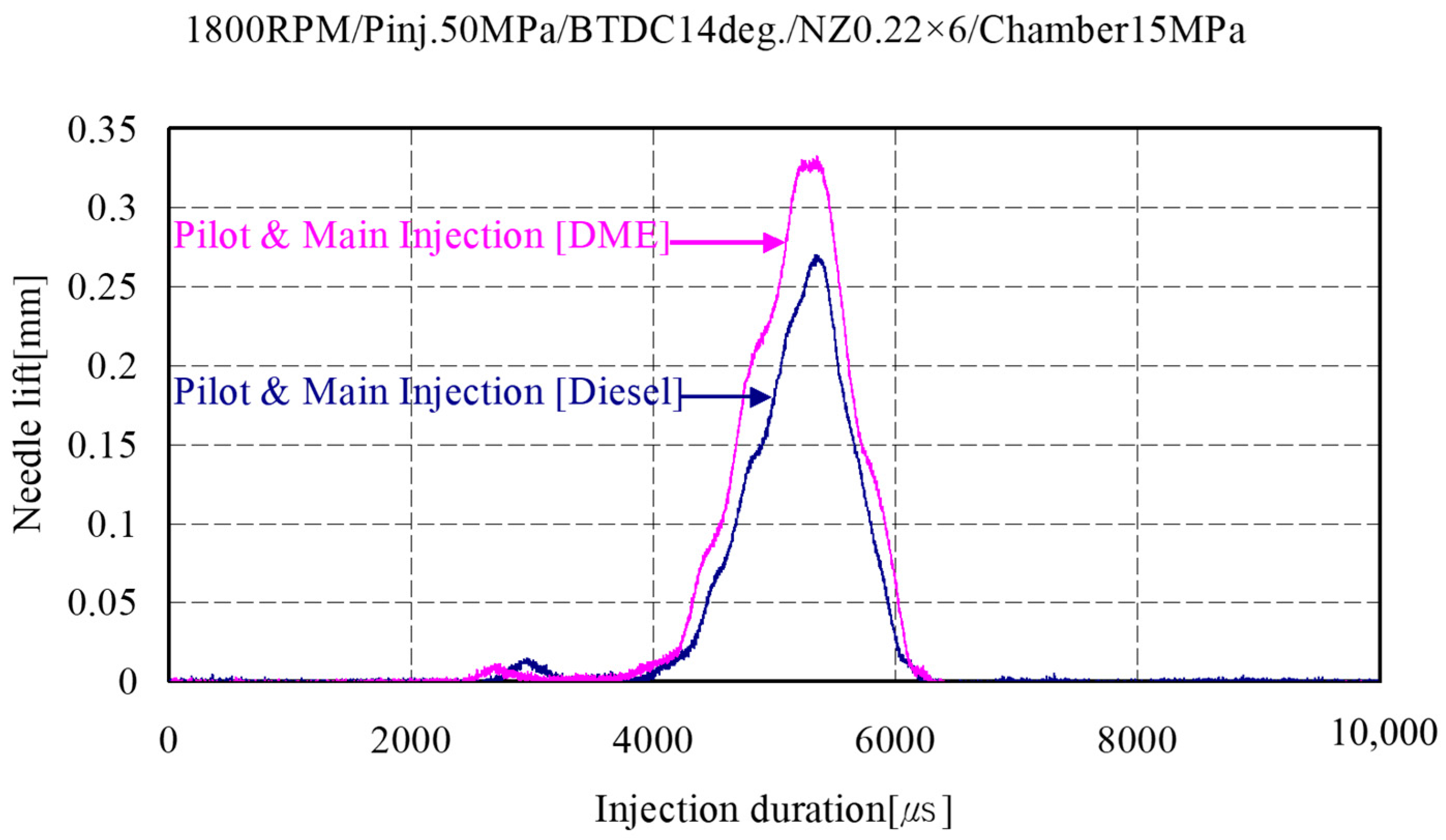

3.2. Needle Lift Variations in Accordance with Injection Timing

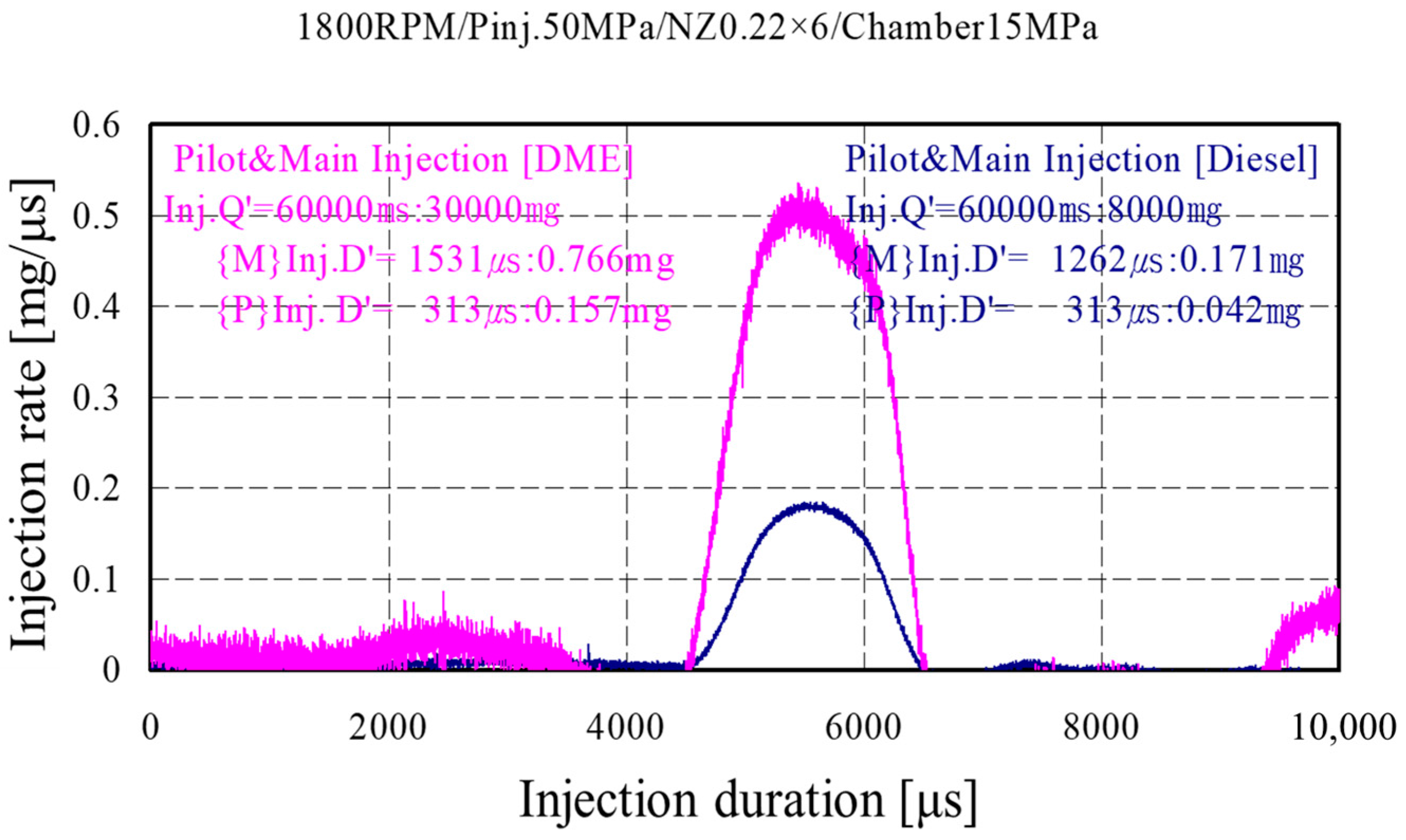

3.3. Injection Rate and Amount in Accordance with Changing Pilot and Main Injection Timing

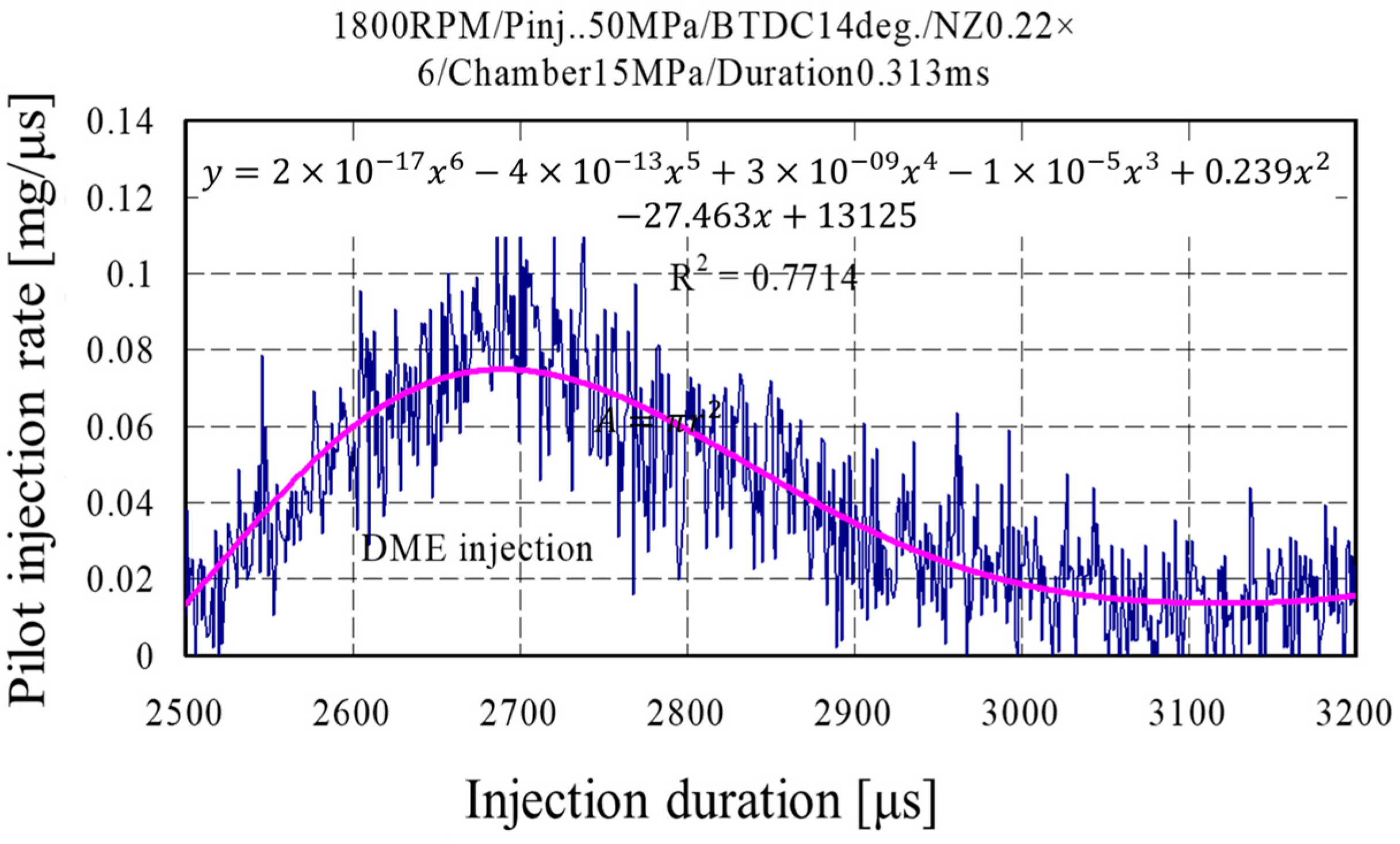

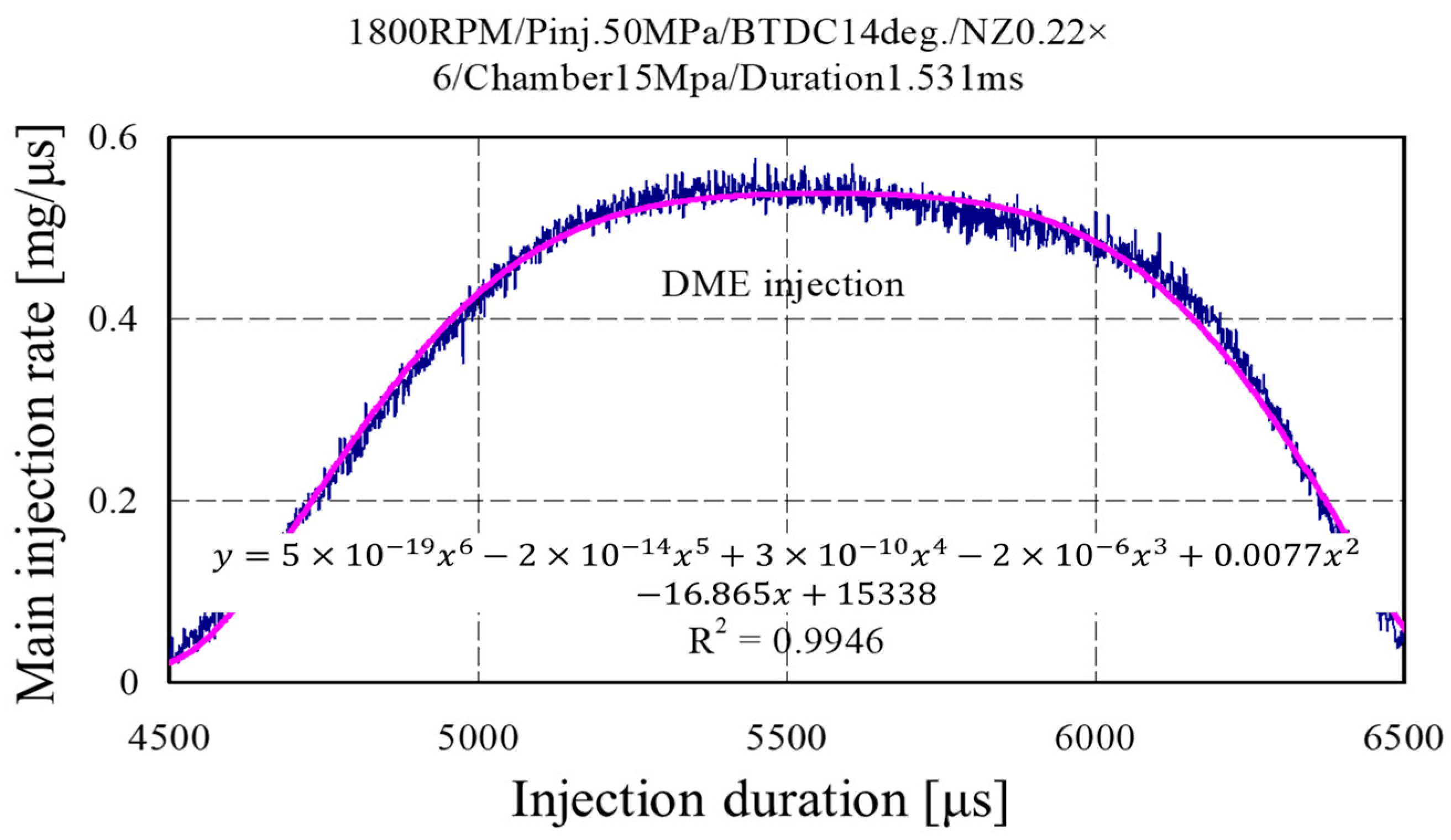

3.3.1. DME Injection Quantity by Trend Line

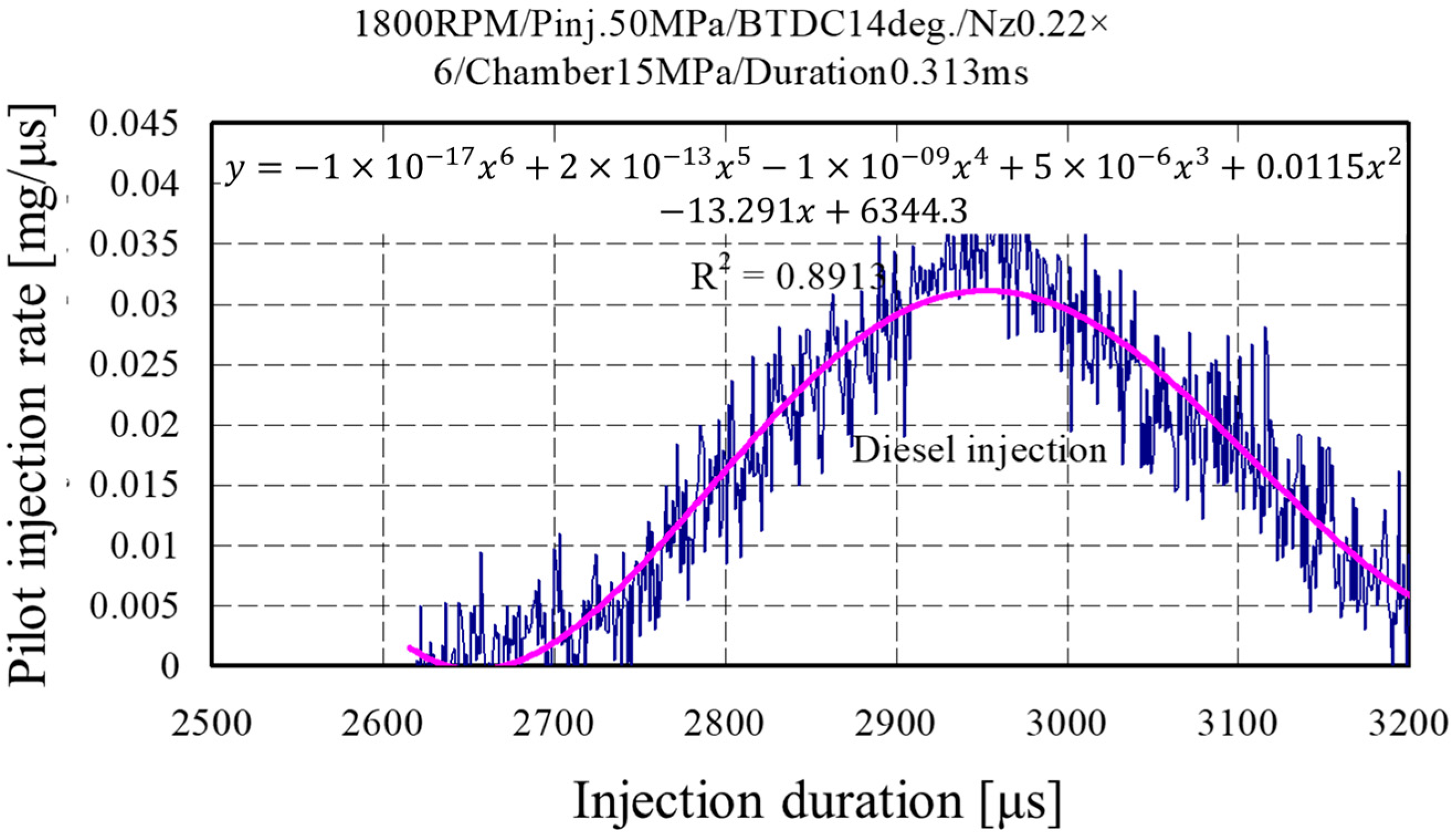

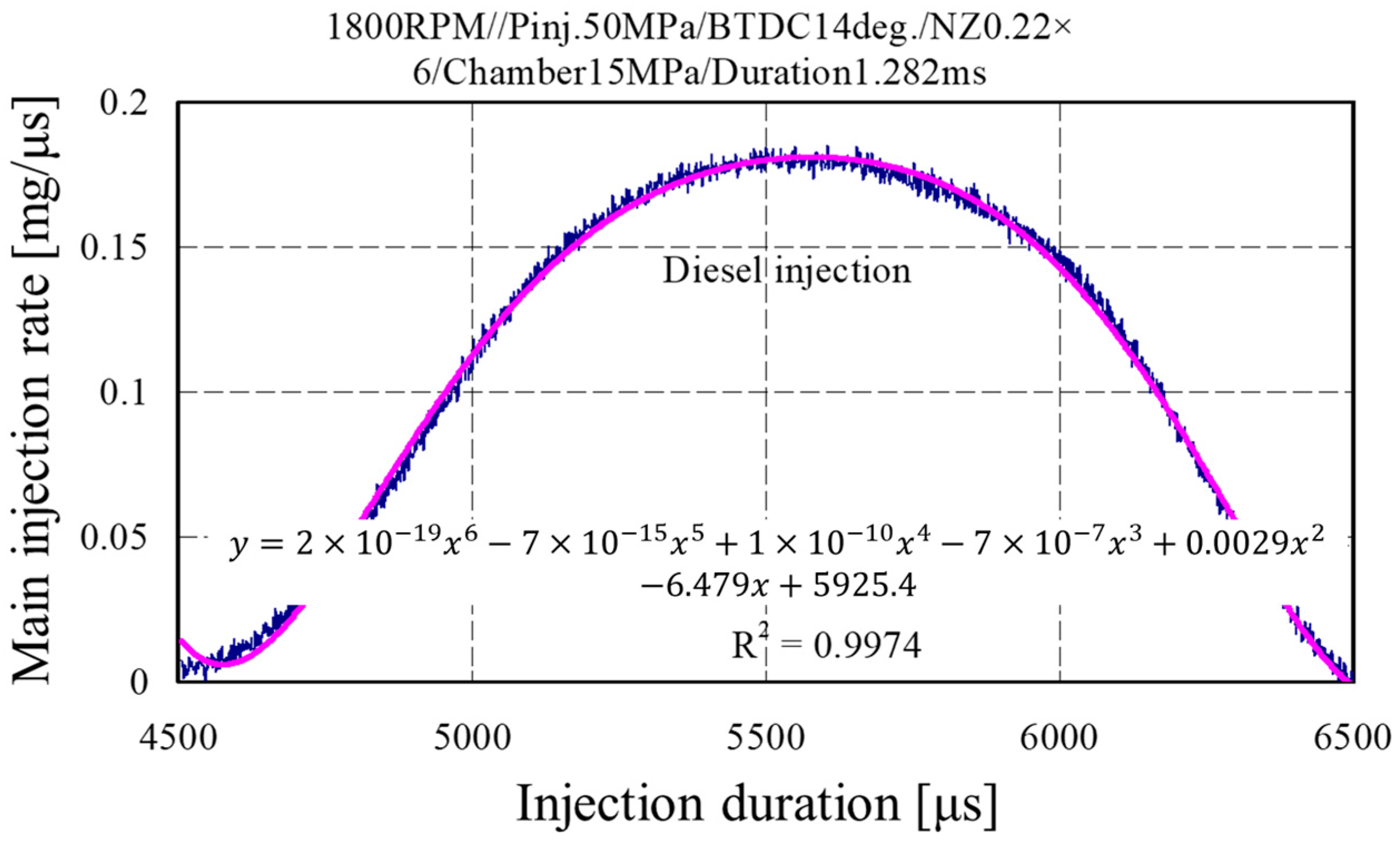

3.3.2. Diesel Injection Quantity by Trend Line

4. Conclusions

- The pressure variations in the initial injection duration (2000–6000 µs) of the main and pilot injections for diesel and DME were similar. However, after 7000 µs, the pressure of DME increased more rapidly compared to that of diesel. This finding was the result of the rapid density changes caused by the nature of compressive fluid. Therefore, the DME supply pump was expected to require a higher drive energy by approximately 20% compared to that of the diesel supply pump.

- The maximum variation during the needle lift operation was 0.25 ms for diesel and 0.35 ms for DME. Thus, that of DME was higher by 0.1 m or 29% because DME had a higher fuel consumption per unit time for fuel supply to the engine based on weight than diesel.

- The TWV pulse and the injection start time showed a difference of 1 ms in the injection rate according to the injection pressure. Unlike the mechanical supply pump that used a mechanical advancer, the common rail system was activated by the injector solenoid based on the ECU pulse. Thus, a difference between the electronic speed and the mechanical speed was observed, and the ECU program will have to consider the advancer.

- The solenoid response decreased as the needle lift operation time increased, resulting in a loss of the discharge flow. Although the injection duration and quantity were changed by the injection pressure, they were also changed by the injection duration. Thus, this characteristic must be considered when applying the common rail injection system. Furthermore, the larger the needle lift, the greater the loss of the injection quantity.

- The typical method of measuring the injection quantity per unit time of DME is to measure the injection quantity accumulated in a pressure vessel. However, one problem encountered in this method is that the chamber vessel, connecting parts, and valves can be damaged because of the chamber pressure being increased by the cumulative injection quantity.

- Based on the injection rate and quantity measurement experiment for DME in this study, we propose the Bosch–Zeuch injection rate measurement method, which combines the Bosch and Zeuch methods.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Kajitani, S.; Chen, Z.L.; Konno, M. Engine Performance and Exhaust Characteristics of Direct-Injection Diesel Engine Operated with DME; SAE 972973; SAE International: Warrendale, PA, USA, 1997. [Google Scholar]

- Fleisch, T.H.; Basu, A.; Gradassi, M.J.; Masin, J.G. Dimethyl ether: A fuel for the 21st century. Stud. Surf. Sci. Catal. 1997, 107, 117–125. [Google Scholar]

- Ikeda, T.; Ohmori, Y.; Takamura, A.; Sato, Y.; Jun, L.; Kamimoto, T. Measurement of the Rate of Multiple Fuel Injection with Diesel Fuel and DME; SAE Technical Paper 2001-01-0527; SAE International: Warrendale, PA, USA, 2001. [Google Scholar]

- Diesel EMS and Injection Engineering Department, ECD-U2 System Operation Manual (for Rir Test & Engine Test); DENSO Co.: Kariya, Japan, 1996.

- Ogawa, H.; Miyamoto, N.; Kaneko, N.; Ando, H. Combustion Control and Operating Range Expansion with Direct Injection of Reaction Suppressors in a Premixed DME HCCI Engine; SAE No. 2003-01-0746; SAE International: Warrendale, PA, USA, 2003. [Google Scholar]

- Arcoumanis, C.; Bae, C.; Crookes, R.; Kinoshita, E. The potential of di-methyl ether (DME) as an alternative fuel for compression-ignition engines: A review. Fuel 2008, 87, 1014–1030. [Google Scholar] [CrossRef]

- Ying, W.; Li, H.; Jie, Z.; Longbao, Z. Study of HCCI-DI combustion and emissions in a DME engine. Fuel 2009, 88, 2255–2261. [Google Scholar] [CrossRef]

- Kim, H.J.; Lee, K.S.; Lee, C.S. A study on the reduction of exhaust emissions through HCCI combustion by using a narrow spray angle and advanced injection timing in a DME engine. Fuel Proc. Technol. 2011, 92, 1756–1763. [Google Scholar] [CrossRef]

- Jung, D.; Iida, N. Closed-loop control of HCCI combustion for DME using external EGR and rebreathed EGR to reduce pressure-rise rate with combustion-phasing retard. Appl. Energy 2015, 138, 315–330. [Google Scholar] [CrossRef]

- Daisho, Y. Future vehicle technologies for low emission and high efficiency. In Proceedings of the 6th Symposium on Next Generation Vehicle Technology, Kwangju, Korea, 22 August 2003; pp. 15–21. [Google Scholar]

- Yoon, S.H.; Cha, J.P.; Lee, C.S. An investigation of the effects of spray angle and injection strategy on dimethyl ether (DME) combustion and exhaust emission characteristics in a common-rail diesel engine. Fuel Proc. Technol. 2010, 91, 1364–1372. [Google Scholar] [CrossRef]

- Youn, I.M.; Park, S.H.; Roh, H.G.; Lee, C.S. Investigation on the fuel spray and emission reduction characteristics for dimethyl ether (DME) fueled multi-cylinder diesel engine with common-rail injection system. Fuel Proc. Technol. 2011, 92, 1280–1287. [Google Scholar] [CrossRef]

- Lee, S.J.; Oh, S.D.; Jeong, S.J.; Lim, O.T. An investigation on the spray characteristics of DME common rail fuel injection system with variation of ambient pressure. Trans. Korean Soc. Automot. Eng. 2012, 20, 90–97. [Google Scholar] [CrossRef]

- Yu, H.; Liang, X.; Shu, G.; Wang, X.; Wang, Y.; Zhang, H. Experimental investigation on wall film distribution of dimethyl ether/diesel blended fuels formed during spray wall impingement. Energies 2016, 9, 949. [Google Scholar] [CrossRef]

- Ghurri, A.; Jae-duk, K.; Kyu-Keun, S.; Jae-Youn, J.; Gon, K.H. Qualitative and quantitative analysis of spray characteristics of diesel and biodiesel blend on common-rail injection system. J. Mech. Sci. Technol. 2011, 25, 885–893. [Google Scholar] [CrossRef]

- Park, S.H.; Lee, C.S. Combustion performance and emission reduction characteristics of automotive DME engine system. Prog. Energy Combust. Sci. 2013, 39, 147–168. [Google Scholar] [CrossRef]

- Yoon, S.H.; Han, S.C.; Lee, C.S. Effects of high EGR rate on dimethyl ether (DME) combustion and pollutant emission characteristics in a direct injection diesel engine. Energies 2013, 6, 5157–5167. [Google Scholar] [CrossRef]

- Bower, G.; Foster, D. A Comparison of the Bosch and Zuech Rate of Injection Meters; SAE Technical Paper 910724; SAE International: Warrendale, PA, USA, 1991. [Google Scholar]

- Arcoumanis, C.; Baniasad, M. Analysis of Consecutive Fuel Injection Rate Signals Obtained by the Zeuch and Bosch Methods; SAE Technical Paper 930921; SAE International: Warrendale, PA, USA, 1993. [Google Scholar]

- Postrioti, L.; Buitonia, G.; Pesceb, F.C.; Ciaravinob, Z. Zeuch method-based injection rate analysis of a common-rail system operated with advanced injection strategies. Fuel 2014, 128, 188–198. [Google Scholar] [CrossRef]

- Lee, C. An experimental study on advanced injection rate measurement of a marine engine using the Zeuch method. J. Therm. Sci. Technol. 2016, 11, JTST0026. [Google Scholar] [CrossRef]

- Ganser, M. Common Rail Injector with Injection Rate Control; SAE Technical Paper 981927; SAE International: Warrendale, PA, USA, 1998. [Google Scholar]

| Instument | Items | Specifications |

|---|---|---|

| Rate meter | Max. pressure | 100 MPa |

| Pipe length | 6000 mm | |

| Quantity meter | Chamber volume | 1500 mm3 |

| Max. pressure | 5–25 MPa |

| Division. | Unite | DME | Diesel |

|---|---|---|---|

| Liquid density | kg/m3 | 667 | 831 |

| Cetane number | >55 | 40–55 | |

| Octan number | - | - | |

| Chemical structure | (CH3)2O | - | |

| Stoich.A/F Rate | kg/kg | 9.0 | 14.6 |

| Boiling point (760 mmHg) | °C | −25 | 180/370 |

| C | wt % | 52.2 | 86 |

| H | wt % | 13 | 14 |

| O | wt % | 34.8 | 0 |

| Velocity of sound: a | m/s | 980 | 1330 |

| Kinematic viscosity (Liquid): V | cSt | <1 | 3 |

| Modulus of elasticity | N/m2 | 6.37 × 108 | 1.49 × 109 |

| Cavitation factor | K | 0.1 | 0.68 |

| Low calorific value(LCV) | MJ/kg | 28.8 | 42.7 |

| Ignition limite | λ | 0.34/ | 0.48/ |

| Vapor pressure | kPa | 530 | - |

| Mol.wt | g/mol | 46.069 | 170 |

| Autoignition temperature | °C | 235 | 250 |

| Maximum explosion pressure | Bar.m/ | 7.9 | - |

| Maximum laminar burning velocity | m/s | 0.54 | - |

| Liquid specific heat | kJ/kg·k | - | 2.2 |

| Gaseous specific heat | kJ/kg·k | 2.99 | 1.7 |

| Heat of vaporisation | kJ/kg | 467.23 | 300 |

| Items | Items | Specifications | Dimension |

|---|---|---|---|

| Supply pump | Gas booster | Bore × stroke (mm × mm) | ϕ 29 × 64 |

| Liquid pump | Bore × stroke (mm × mm) | ϕ 15 × 64 | |

| Injector | PVC | Solenoid (V) | 24 |

| Needle lift | Lift (mm) | 0.21 | |

| Injection hole | Diameter (mm) | ϕ 0.21 × 5 | |

| Common rail | Pressure (MPa) | 100 |

| Experimental Conditions | Control Specification |

|---|---|

| Pump revolution | 900 rpm |

| Pilot injection duration | 0.313 ms |

| Main inj. timing | BTDC 14° |

| Pilot inj. timing | BTDC 25° |

| Injection pressure | 50 MPa |

| Nozzle hole specification (Nozzle diameter × hole number) | ϕ 0.22 (mm) × 6 holes |

| Chamber pressure | 5–15 MPa |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, S.; Lee, C. Experimental Research on the Injection Rate of DME and Diesel Fuel in Common Rail Injection System by Using Bosch and Zeuch Methods. Energies 2018, 11, 273. https://doi.org/10.3390/en11020273

Yang S, Lee C. Experimental Research on the Injection Rate of DME and Diesel Fuel in Common Rail Injection System by Using Bosch and Zeuch Methods. Energies. 2018; 11(2):273. https://doi.org/10.3390/en11020273

Chicago/Turabian StyleYang, Seemoon, and Changhee Lee. 2018. "Experimental Research on the Injection Rate of DME and Diesel Fuel in Common Rail Injection System by Using Bosch and Zeuch Methods" Energies 11, no. 2: 273. https://doi.org/10.3390/en11020273