New Method for Shallow and Deep Trap Distribution Analysis in Oil Impregnated Insulation Paper Based on the Space Charge Detrapping

Abstract

:1. Introduction

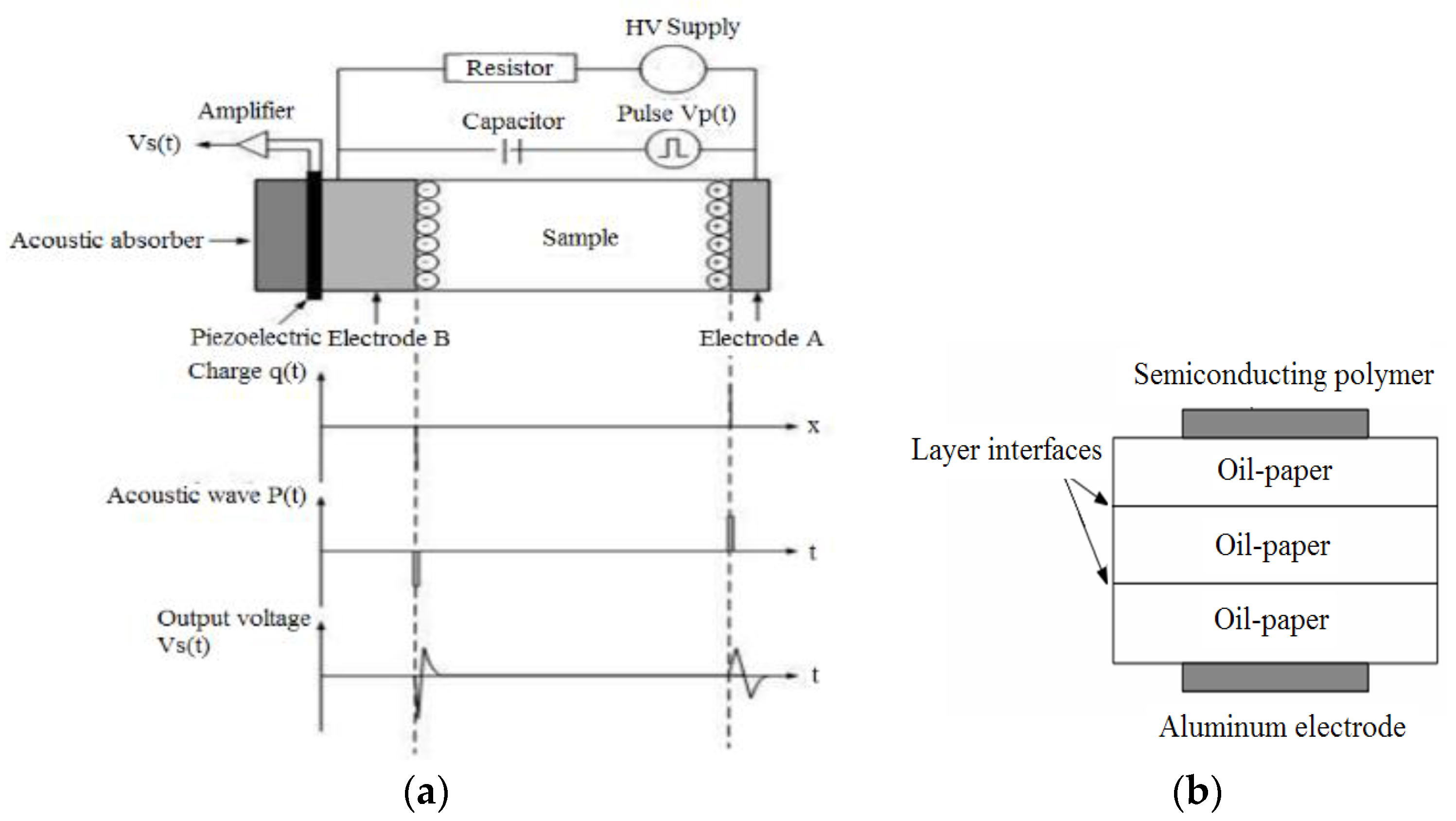

2. Experiments

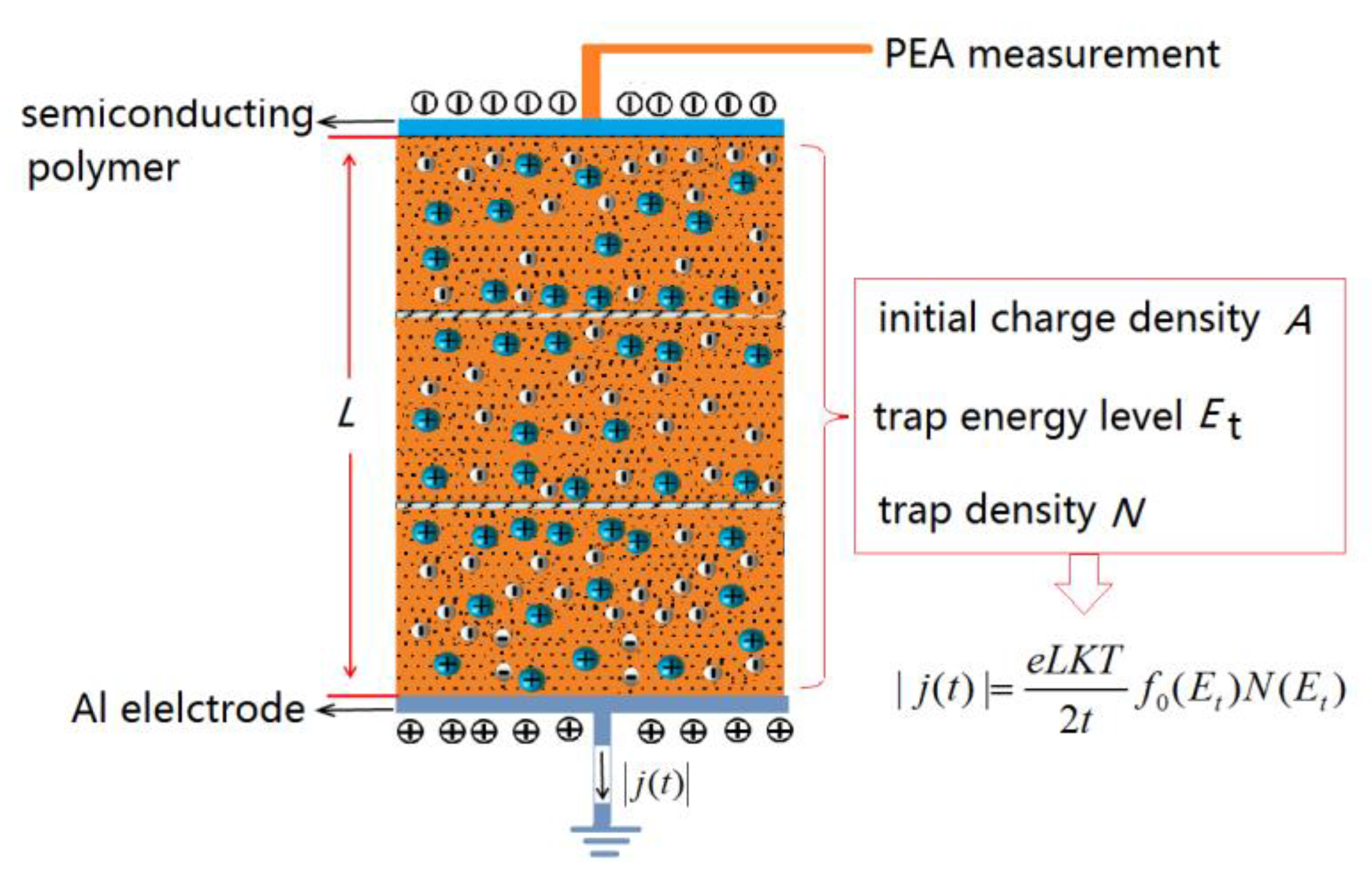

3. Experimental Results and Discussions

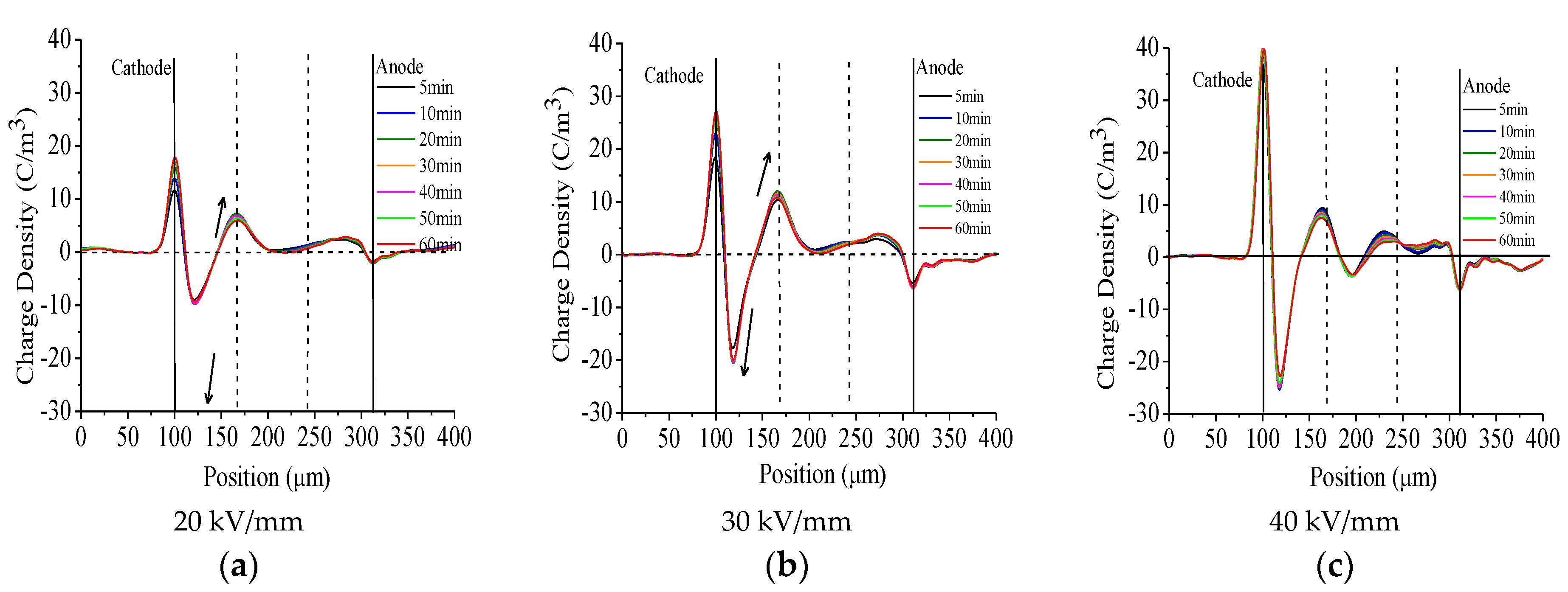

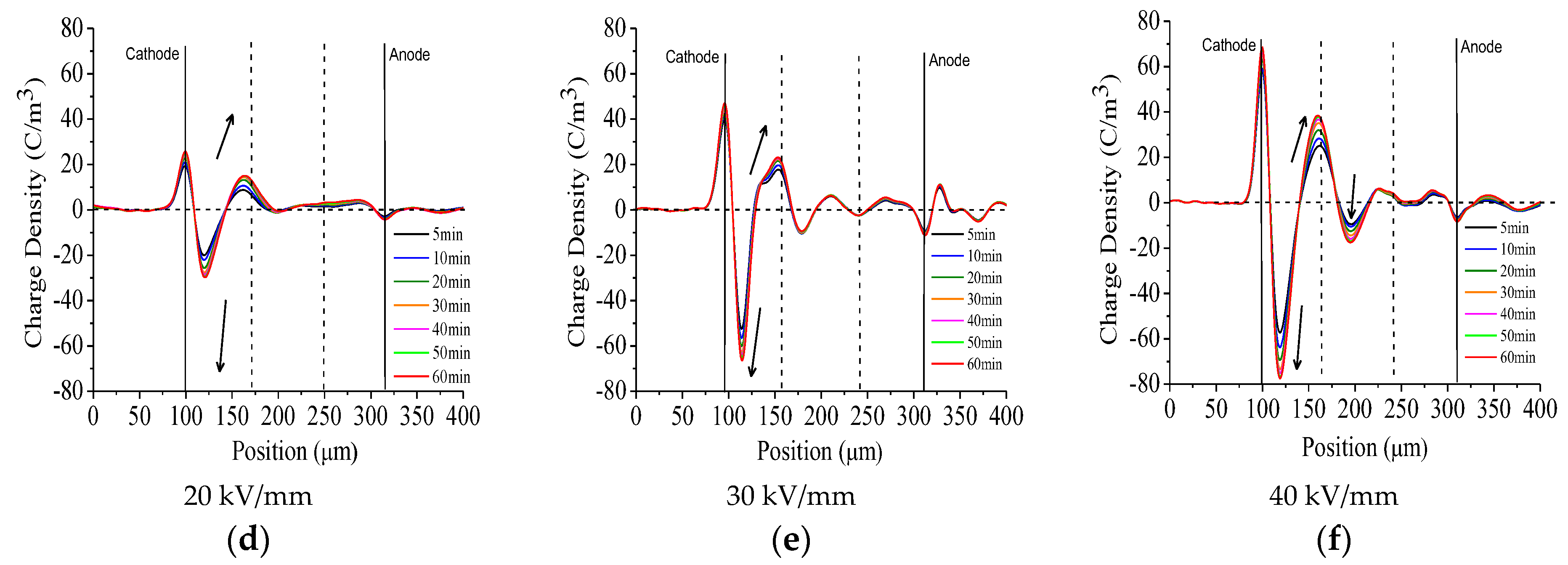

3.1. Charges Trapped in the Samples

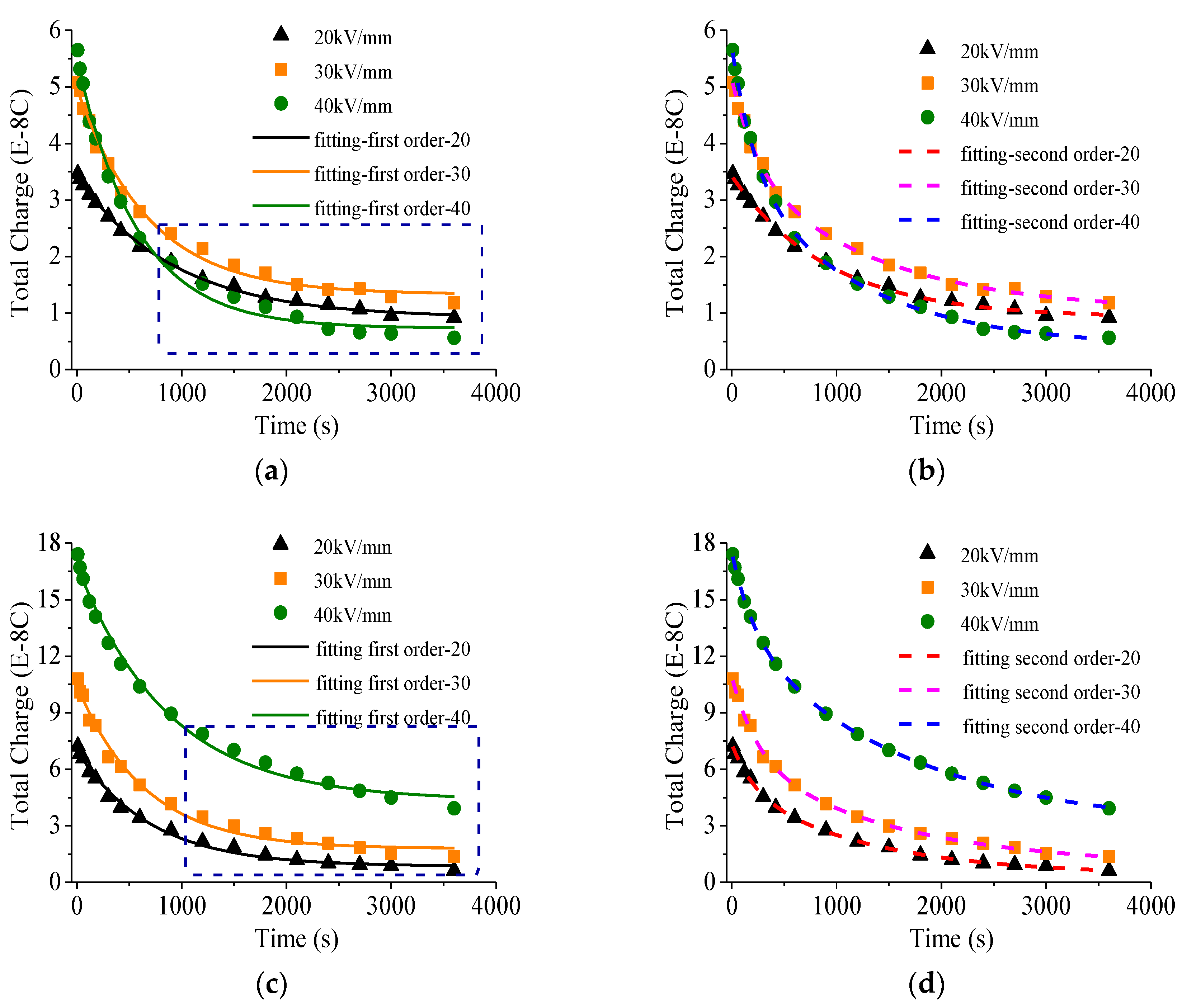

3.2. Charges Decay Process

4. Improved Method for Trap Distribution Analysis

4.1. Common Method for Trap Distribution Analysis Using Charge Detrapping Process

4.2. Improved Method for Trap Distribution Analysis Using Charge Detrapping Process

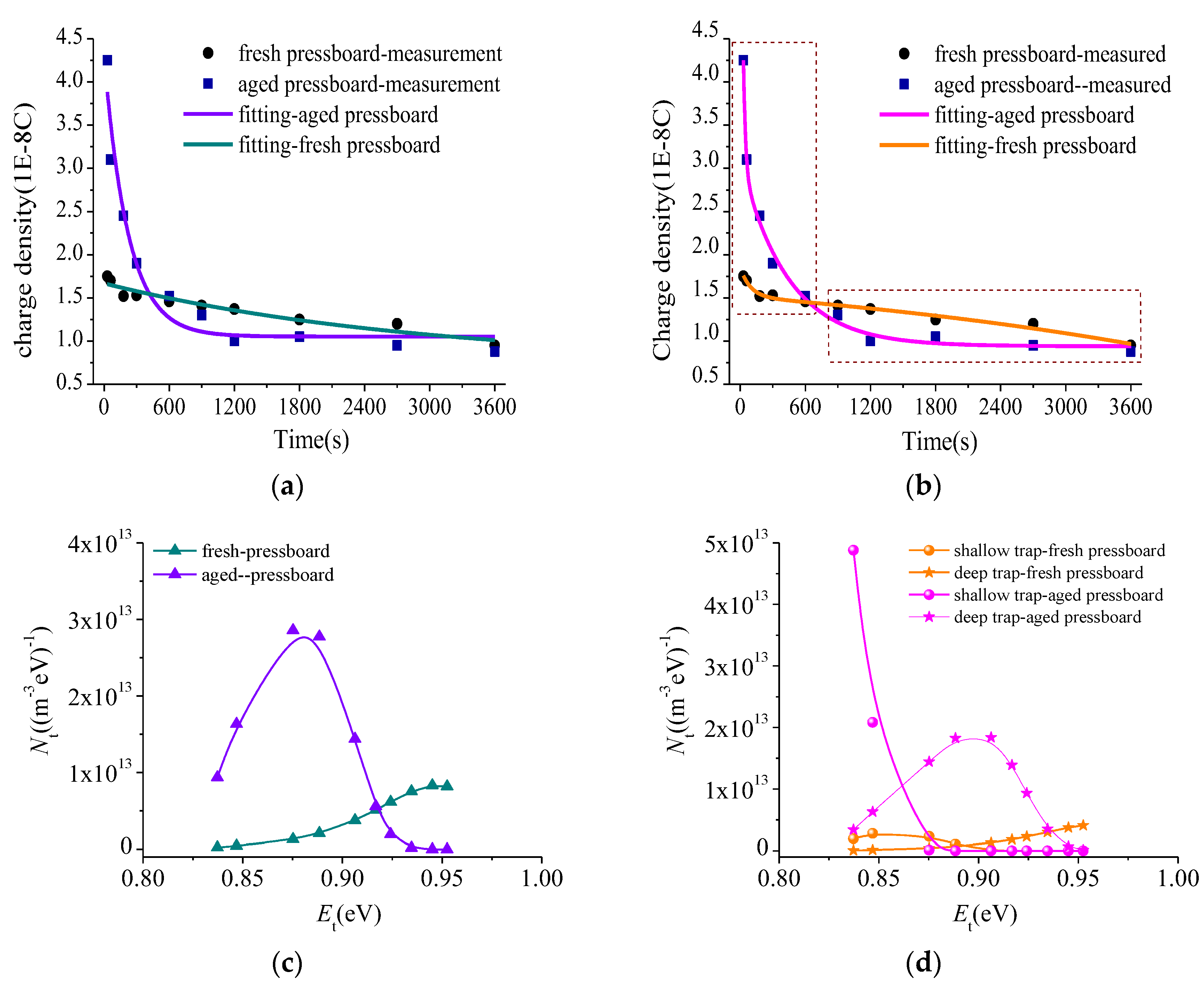

4.3. Comparison Analysis of the Charge Detrapping Process Using the Improved Method and Common Method

4.4. Comparison Analysis of the Trap Distribution Using the Improved Method and Common Method

- (1)

- (2)

- (3)

4.5. Effectiveness Verify of the Improved Method

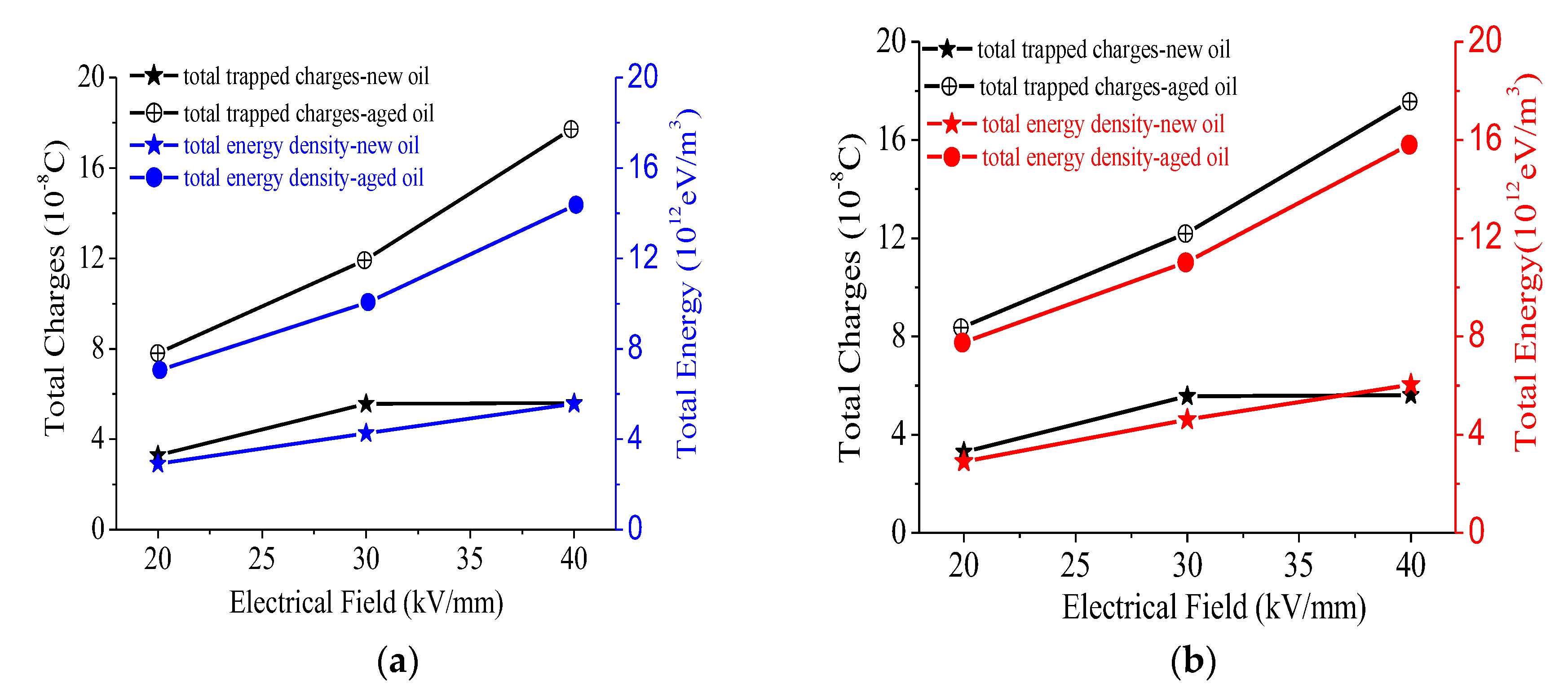

4.6. Relationship between Trapped Charges and Trap Distribution

5. Conclusions

- (1)

- The double exponential fitting analysis of charge decay includes the detrapping process of both fast charge and slow charge. Compared with the dual-level trap model and the common first order exponential fitting analysis method, the improved method is more suitable for the kinetic analysis of charge detrapping and trap distribution calculation. It could be able to obtain the energy level range and the density of shallow traps and deep traps simultaneously.

- (2)

- Using the improved trap distribution calculation method by double exponential fitting analysis of charge decay, it is not only can obtain the trap parameter changes caused by physical or chemical defects generated in material, but also can distinguish the shallow trap (physical defects) and deep trap (chemical defects). For oil impregnated insulation paper, the trap energy level and trap density representing deep traps is signal for ageing.

- (3)

- The trap density shows an increasing trend with the oil ageing, especially for the deep traps. The greater the energy that could be filled by the traps, the larger amount of charges could be trapped, especially under higher electric field strength. When one evaluating the ageing status of oil-paper insulation using trap parameters, the oil performance should not be ignored.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Tang, C.; Huang, B.; Hao, M.; Xu, Z.; Hao, J.; Chen, G. Progress of space charge research on oil-paper insulation using pulsed electroacoustic techniques. Energies 2016, 9, 53. [Google Scholar] [CrossRef]

- Du, B.X.; Zhang, J.G.; Liu, D.S. Interface charge behavior of multi-layer oil paper insulation under DC and polarity reversal voltages. IEEE Trans. Dielectr. Electr. Insul. 2015, 22, 2628–2638. [Google Scholar] [CrossRef]

- Huang, B.; Hao, M.; Hao, J.; Fu, J.; Wang, Q.; Chen, G. Space charge characteristics in oil and oil-impregnated pressboard and electric field distortion after polarity reversal. IEEE Trans. Dielectr. Electr. Insul. 2016, 23, 881–891. [Google Scholar] [CrossRef]

- Ciobanu, R.; Schreiner, C.; Pfeiffer, W.; Baraboi, B. Space charge evolution in oil-paper insulation for DC cables application. In Proceedings of the IEEE International Conference on Dielectric Liquids, Graz, Austria, 12–12 July 2002; pp. 321–324. [Google Scholar]

- Hao, J.; Chen, G.; Liao, R.; Yang, L.; Tang, C. Influence of moisture on space charge dynamics in multilayer oil-paper insulation. IEEE Trans. Dielectr. Electr. Insul. 2012, 19, 1456–1464. [Google Scholar] [CrossRef]

- Space Charge. Available online: https://en.wikipedia.org/wiki/Space_charge (accessed on 16 October 2017).

- Raju, G.G. Dielectrics in Electric Fields; Marcel Dekker Inc.: Hoboken, NJ, USA, 2003. [Google Scholar]

- Wei, Y.H.; Mu, H.B.; Deng, J.B.; Zhang, G.J. Effect of space charge on breakdown characteristics of aged oil-paper insulation under dc voltage. IEEE Trans. Dielectr. Electr. Insul. 2016, 23, 3143–3150. [Google Scholar] [CrossRef]

- Wang, S.Q.; Zhang, G.J.; Mu, H.B.; Wang, D.; Lei, M.; Suwarno, S.; Tanaka, Y.; Takada, T. Effects of paper-aged state on space charge characteristics in oil-impregnated paper insulation. IEEE Trans. Dielectr. Electr. Insul. 2013, 19, 1871–1878. [Google Scholar] [CrossRef]

- Huang, M.; Zhou, Y.; Dai, C.; Chen, W.; Lu, L.; Sha, Y. Charge transport in thermally and electrically stressed oil-impregnated paper insulation. IEEE Trans. Dielectr. Electr. Insul. 2016, 23, 266–274. [Google Scholar] [CrossRef]

- Eager, G.S.; Bader, G.; Garcia, F.G. Influence of space charges on the breakdown of oil-paper insulation. In Proceedings of the IEEE Conference on Electrical Insulation & Dielectric Phenomena, Pocono Manor, PA, USA, 18–20 September 1967; IEEE: Piscataway, NJ, USA, 2016; pp. 166–172. [Google Scholar]

- Zhou, Y.X.; Huang, M.; Chen, W.J.; Jin, F.B. Space charge behavior of oil-paper insulation thermally aged under different temperatures and moistures. J. Electr. Eng. Technol. 2015, 10, 1124–1130. [Google Scholar] [CrossRef]

- Tang, C.; Chen, G.; Fu, M.; Liao, R.J. Space charge behavior in multi-layer oil-paper insulation under different dc voltages and temperatures. IEEE Trans. Dielectr. Electr. Insul. 2010, 17, 775–784. [Google Scholar] [CrossRef]

- Zhou, Y.; Wang, Y.; Li, G.; Wang, N.; Liu, Y.; Li, B.; Li, P.; Cheng, H. Space charge phenomena in oil-paper insulation materials under high voltage direct current. J. Electrostat. 2009, 67, 417–421. [Google Scholar] [CrossRef]

- Du, B.X.; Zhang, J.G. Charge coupling behavior of double-layer oil-paper insulation under dc and pulse voltages. IEEE Trans Dielectr. Electr. Insul. 2016, 23, 1–9. [Google Scholar] [CrossRef]

- Chen, G.; Xu, Z. Charge trapping and detrapping in polymeric materials. J. Appl. Phys. 2009, 106, 123707. [Google Scholar] [CrossRef]

- Liu, N.; Zhou, C.; Chen, G.; Xu, Y.; Cao, J.; Wang, H. Model to estimate the trapping parameters of cross-linked polyethylene cable peelings of different service years and their relationships with dc breakdown strengths. High Volt. 2016, 1, 95–105. [Google Scholar] [CrossRef]

- Liu, N.; Chen, G. Changes in charge trapping/detrapping in polymeric materials and its relation with ageing. In Proceedings of the IEEE Conference on Electrical Insulation and Dielectric Phenomena, Shenzhen, China, 20–23 October 2013; pp. 800–803. [Google Scholar]

- Wei, Y.; Chen, G.; Zhang, G.J.; Liu, N.; Li, G. Trap characterization in composite of solid-liquid using dual-level trap model and TSDC method. AIP Adv. 2016, 6, 075120. [Google Scholar] [CrossRef]

- Dissado, L.A.; Fothergill, J.C. Electrical Degradation and Breakdown in Polymers; The Institution of Engineering and Technology: London, UK, 1992; Volume 9, p. 620. [Google Scholar]

- Meunier, M.; Quirke, N.; Aslanides, A. Molecular modeling of electron traps in polymer insulators: Chemical defects and impurities. J. Chem. Phys. 2001, 115, 2876–2881. [Google Scholar] [CrossRef]

- Zhang, G.J.; Shen, W.W.; Mu, H.B.; Deng, J.B. Surface trapping parameters of solid dielectrics: Novel measurement method and insulation condition characterization. In Proceedings of the International Conference on Condition Monitoring and Diagnosis, Bali, Indonesia, 23–27 September 2012; pp. 480–484. [Google Scholar]

- Yang, C.; Zhang, Y.; He, L.; Xue, Y.; Tian, F.; Jiang, X.; Lei, Q. Study on the trap distribution in polyimide thin film based on TSDC method. In Proceedings of the IEEE International Conference on the Properties and Applications of Dielectric Materials, Harbin, China, 19–23 July 2009; pp. 911–913. [Google Scholar]

- Tang, C.; Liao, R.; Chen, G.; Yang, L. Research on the feature extraction of DC space charge behavior of oil-paper insulation. Sci. China Technol. Sci. 2011, 54, 1315–1324. [Google Scholar] [CrossRef]

- Hao, M.; Zhou, Y.; Chen, G.; Wilson, G.; Jarman, P. Space charge behavior in oil gap and impregnated pressboard combined system under HVDC stresses. IEEE Trans. Dielectr. Electr. Insul. 2016, 23, 848–858. [Google Scholar] [CrossRef]

- Kostoski, D.; Dojčilović, J.; Novaković, L.; Suljovrujić, E. Effects of charge trapping in gamma irradiated and accelerated aged low-density polyethylene. Polym. Degrad. Stab. 2006, 91, 2229–2232. [Google Scholar] [CrossRef]

- Li, G.; Li, S.; Min, D.; Zhao, N.; Zhu, Y. Influence of trap depths on space charge formation and accumulation characteristics in low density polyethylene. In Proceedings of the IEEE International Conference on Solid Dielectrics, Bologna, Italy, 30 June–4 July 2013; pp. 698–701. [Google Scholar]

- Ding, H.Z.; Wang, Z.D. Kinetic analysis and modelling of the ageing process for Kraft paper aged in natural ester dielectric fluid. In Proceedings of the IEEE Conference on Electrical Insulation and Dielectric Phenomena, Kansas City, MO, USA, 15–18 October 2006; pp. 505–508. [Google Scholar]

- Institute of Electrical and Electronics Engineers. IEEE Guide for Loading Mineral Oil Immersed Transformers; Institute of Electrical and Electronics Engineers: New York, NY, USA, 1996. [Google Scholar]

- Lundgaard, L.E.; Hansen, W.; Linhjell, D.; Painter, T.J. Ageing of oil-impregnated paper in power transformers. IEEE Trans. Power Deliv. 2004, 19, 230–239. [Google Scholar] [CrossRef]

- Hao, J.; Tang, C.; Chen, G.; Liao, R. Effect of thermally aged oil on space charge dynamics in oil/paper insulation system. IEEJ Trans. Electr. Electr. Eng. 2011, 10, 1–9. [Google Scholar]

- Williams, C.K. Kinetics of trapping, detrapping, and trap generation. J. Electr. Mater. 1992, 21, 711–720. [Google Scholar] [CrossRef]

- Marsacq, D.; Hourquebie, P.; Olmedo, L.; Janah, H. Effects of physical and chemical defects of polyethylene on space charge behavior. In Proceedings of the IEEE Conference on Electrical Insulation and Dielectric Phenomena, Virginia Beach, VA, USA, 22–25 October 1995; pp. 672–675. [Google Scholar]

- Zhou, T.C.; Chen, G.; Liao, R.J.; Xu, Z. Charge trapping and detrapping in polymeric materials: Trapping parameters. J. Appl. Phys. 2011, 110, 043724. [Google Scholar] [CrossRef]

- Pukel, G.J.; Schwarz, R.; Schatzl, F.; Baumann, F.; Gerstl, A. Environmental friendly insulationg liquids-A challenge for power transformers. In Proceedings of the Cigré 2009 6th Southern Africa Regional Conference, Cape Town, South Africa, 17–21 August 2009; p. 510. [Google Scholar]

- Sanghi, R. Chemistry behind the life of a transformer. Resonance 2003, 8, 17–23. [Google Scholar] [CrossRef]

- Chen, C.Z. Insulation Oil and Its Operation Property; Industry of Mechanical Press: Beijing, China, 1975. [Google Scholar]

- Hao, M.; Zhou, Y.; Chen, G.; Wilson, G.; Jarman, P. Space charge behavior in thick oil-impregnated pressboard under HVDC stresses. IEEE Trans. Dielectr. Electr. Insul. 2015, 22, 72–80. [Google Scholar] [CrossRef]

| Common Method: First Order Exponential Fitting Analysis | Improved Method: Double Exponential Fitting Analysis |

|---|---|

| σfast and σslow: equivalent surface fast and slow charge density; Afast and Aslow: initial surface fast and slow charge density. | |

| |jfast(t)| and |jslow(t)|: the current density of the fast and slow charges. τfast and τslow is the time constant of fast charge and slow decay. | |

| , and is the trap energy level of fast and slow charges. | |

| f0() and f0() represents the original occupation rate of shallow and deep traps inside the dielectrics, both are 1/2. | |

| , and are all constant. | |

| , and are all constant. | |

| , N(): the density of trap energy level for fast charges; N(): the density of trap energy level for slow charges. |

| E(kV/mm) | Fitting Equation Q0(t) (10−8 C) | τ (s) | R2 |

|---|---|---|---|

| new oil | |||

| 20 | Q0(t) = 0.92 + 2.51 × exp(−t/922.66) | 922.66 | 0.99 |

| 30 | Q0(t) = 1.33 + 3.65 × exp(−t/683.25) | 683.25 | 0.99 |

| 40 | Q0(t) = 0.73 + 4.76 × exp(−t/577.41) | 577.41 | 0.99 |

| aged oil | |||

| 20 | Q22(t) = 0.86 + 6.15 × exp(−t/698.58) | 398.58 | 0.99 |

| 30 | Q22(t) = 1.79 + 8.68 × exp(−t/647.85) | 647.85 | 0.99 |

| 40 | Q22(t) = 4.35 + 12.48 × exp(−t/873.15) | 873.15 | 0.99 |

| E(kV/mm) | Fitting Equation Q0(t) (10−8 C) | τfast | τslow | R2 |

|---|---|---|---|---|

| new oil | ||||

| 20 | Q0(t) = 1.25 × exp(−t/922.66) + 1.25 × exp(−t/922.66) + 0.92 | 922.66 | 922.66 | 1.00 |

| 30 | Q0(t) = 1.48 × exp(−t/233.89) + 2.65 × exp(−t/1312.75) + 1.02 | 233.89 | 1312.75 | 1.00 |

| 40 | Q0(t) = 2.15 × exp(−t/214.54) + 3.19 × exp(−t/1157.06) + 0.39 | 214.54 | 1157.06 | 1.00 |

| aged oil | ||||

| 20 | Q0(t) = 2.18 × exp(−t/198.20) + 4.77 × exp(−t/1228.10) + 0.39 | 198.20 | 1228.10 | 1.00 |

| 30 | Q0(t) = 4.14 × exp(−t/214.80) + 5.94 × exp(−t/1493.10) + 0.83 | 214.80 | 1493.10 | 1.00 |

| 40 | Q0(t) = 4.10 × exp(−t/210.00) + 10.63 × exp(−t/1628.40) + 0.92 | 210.00 | 1628.40 | 1.00 |

| Common Method | Fitting Equation Q0(t) (10−8 C)) | τ (s) | R2 | |

| fresh pressboard | Q0(t) = 0.74 + 0.93 × exp(−t/2946) | 2946 | 0.91 | |

| aged pressboard | Q0(t) = 1.05 + 3.24 × exp(−t/222.2) | 222.2 | 0.95 | |

| New Method | Fitting Equation Q0(t) (10−8 C) | τfast | τslow | R2 |

| fresh pressboard | Q0(t) = 0.34 × exp(−t/93.1) − 0.47 × exp(t/4660) + 1.99 | 93.1 | 4660 | 0.98 |

| aged pressboard | Q0(t) = 6.05 × exp(−t/19.4) + 2.16 × exp(−t/437.1) + 0.94 | 19.4 | 437.1 | 0.99 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hao, J.; Zou, R.; Liao, R.; Yang, L.; Liao, Q. New Method for Shallow and Deep Trap Distribution Analysis in Oil Impregnated Insulation Paper Based on the Space Charge Detrapping. Energies 2018, 11, 271. https://doi.org/10.3390/en11020271

Hao J, Zou R, Liao R, Yang L, Liao Q. New Method for Shallow and Deep Trap Distribution Analysis in Oil Impregnated Insulation Paper Based on the Space Charge Detrapping. Energies. 2018; 11(2):271. https://doi.org/10.3390/en11020271

Chicago/Turabian StyleHao, Jian, Runhao Zou, Ruijin Liao, Lijun Yang, and Qiang Liao. 2018. "New Method for Shallow and Deep Trap Distribution Analysis in Oil Impregnated Insulation Paper Based on the Space Charge Detrapping" Energies 11, no. 2: 271. https://doi.org/10.3390/en11020271