A Feasibility Study on Power Generation from Solar Thermal Wind Tower: Inclusive Impact Assessment Concerning Environmental and Economic Costs

Abstract

:1. Introduction

2. Methodology

2.1. STWT Design Principles and Output Power

2.1.1. Physical Model of STWT

2.1.2. Parameters

2.2. Environmental Impact: Life-Cycle Assessment

2.2.1. Materials and Weight Distribution

2.2.2. Carbon Footprint

2.3. Economic Aspect: Levelized Electricity Cost

2.3.1. Investment Cost

2.3.2. Levelized Electricity Cost

2.3.3. Parameters

2.4. Inclusive Impact: Triple I and Ecological Footprint

2.4.1. Ecological Footprint

2.4.2. Inclusive Impact Assessment Index (Triple I-light)

3. Results and Discussion

3.1. Calculations of Output Power and System Efficiency

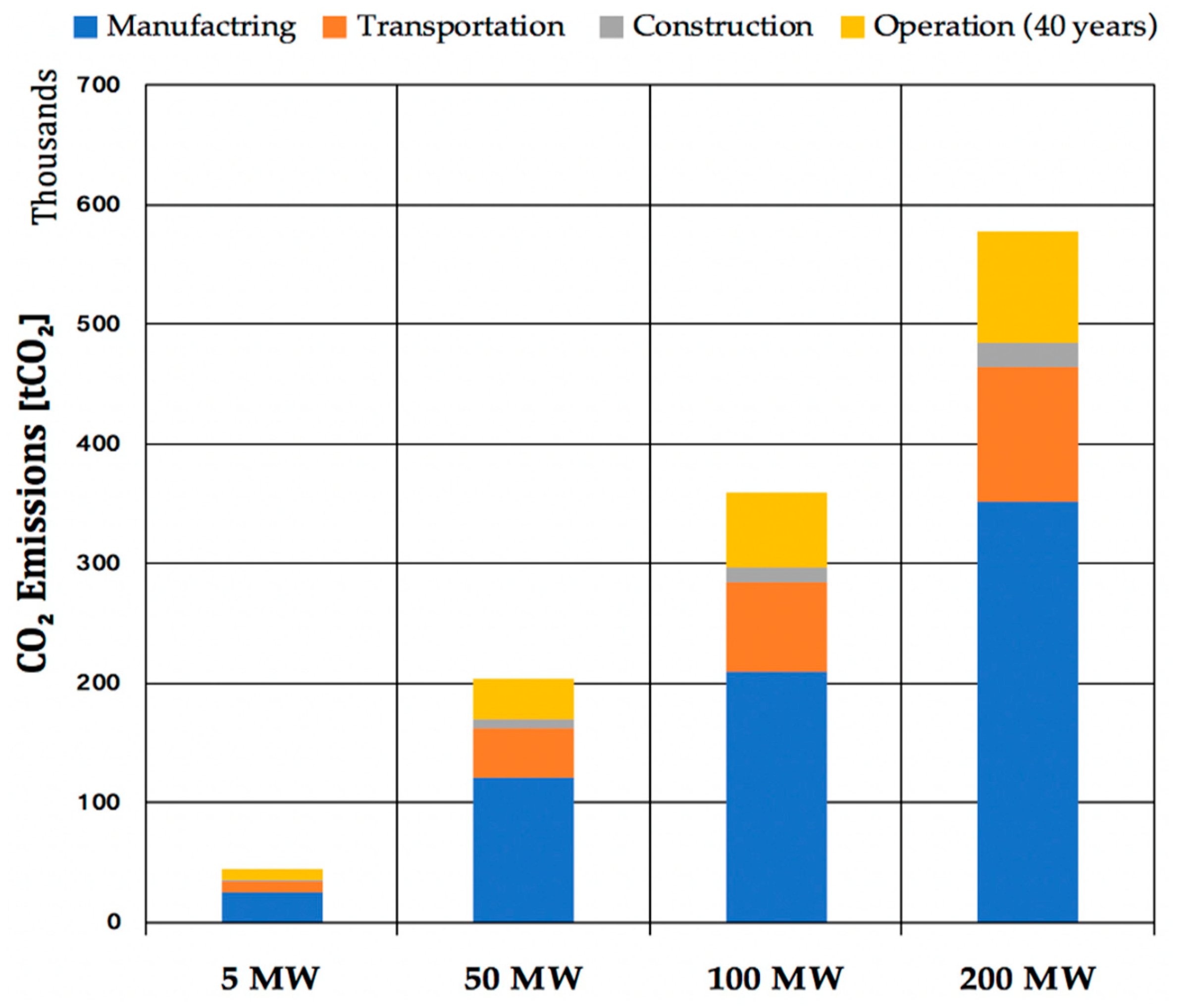

3.2. Carbon Footprint

3.3. Levelized Electricity Cost

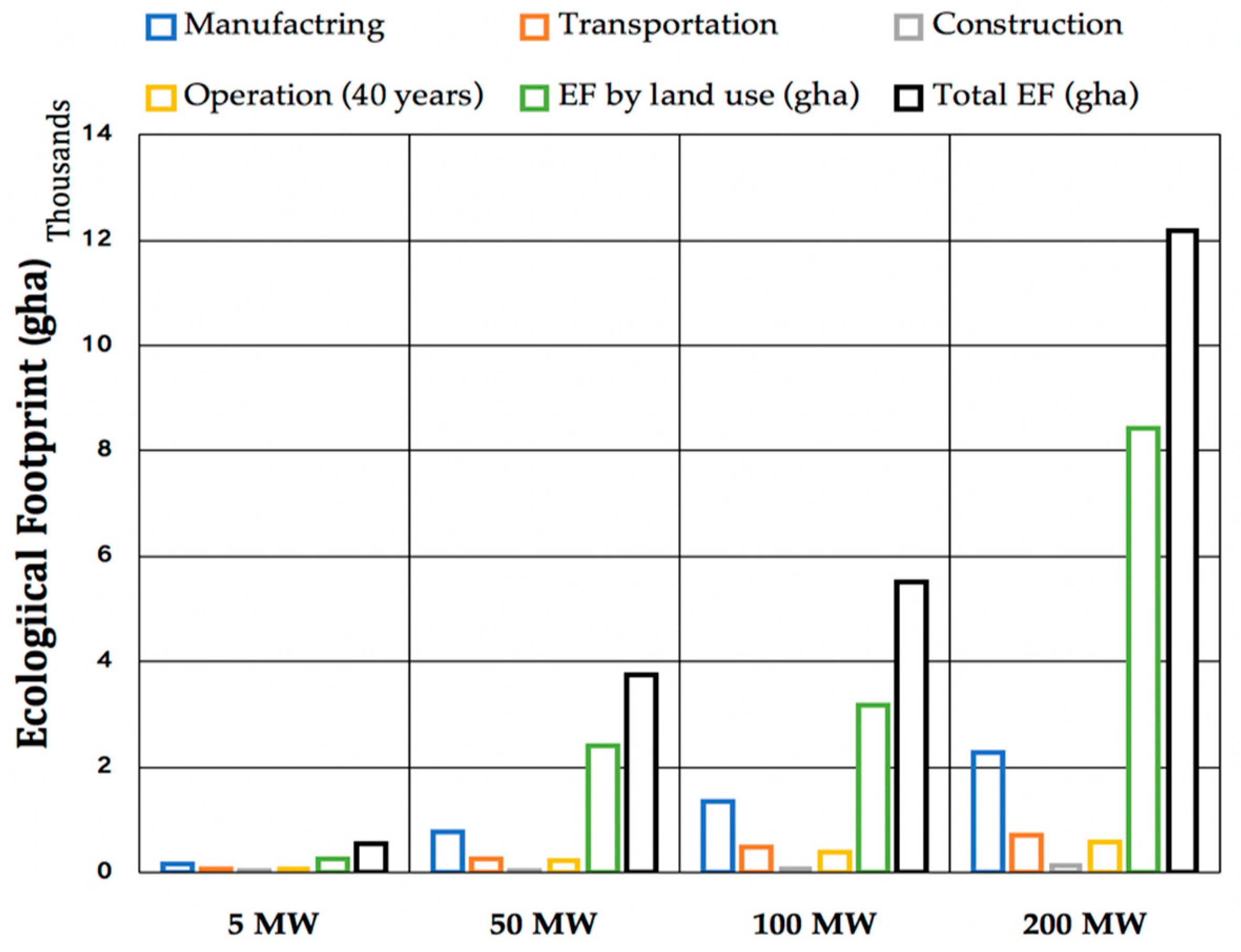

3.4. Ecological Footprint and Triple I Indexes

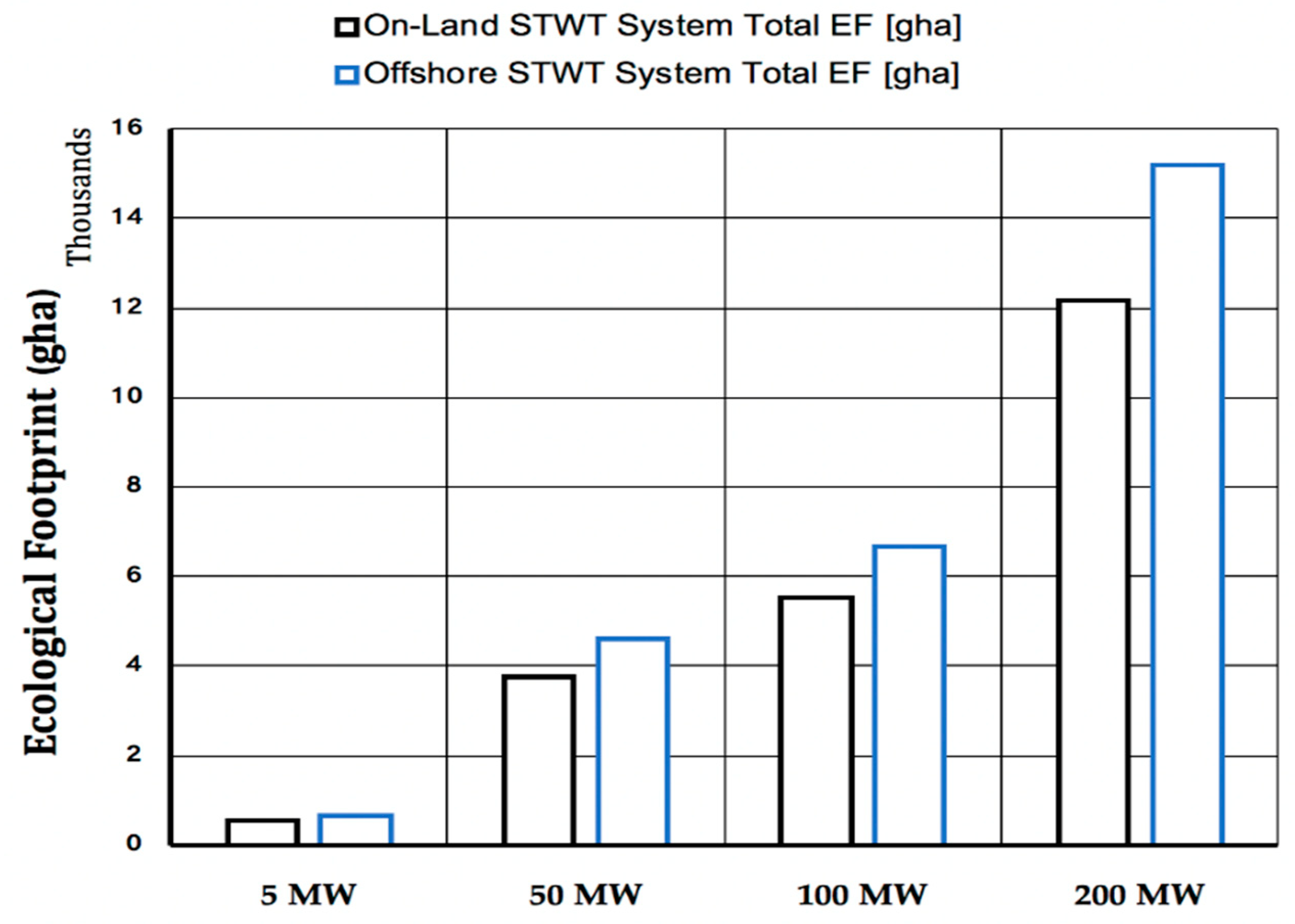

3.4.1. Total EF in the Life Cycle of the STWT System

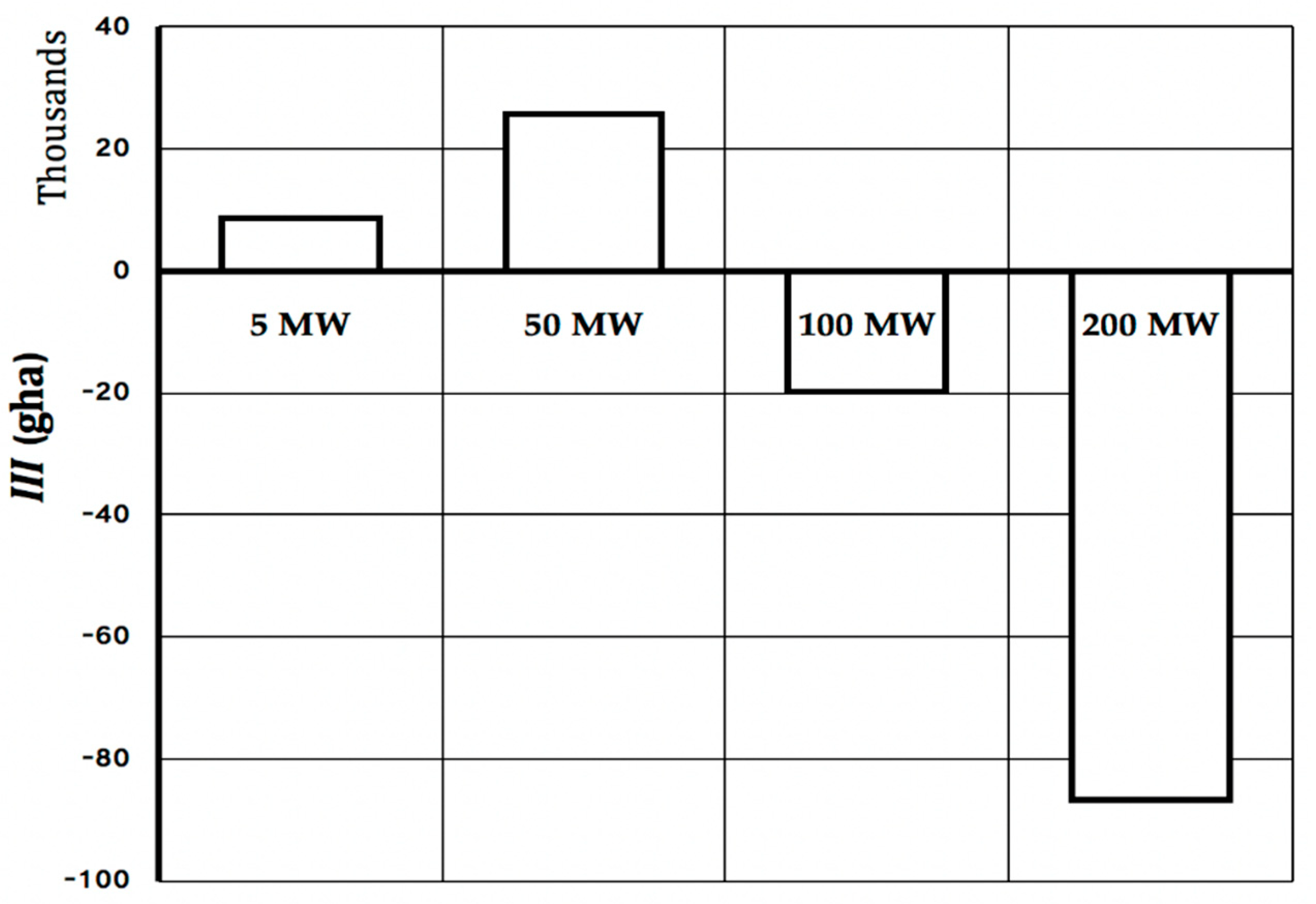

3.4.2. Triple I Index

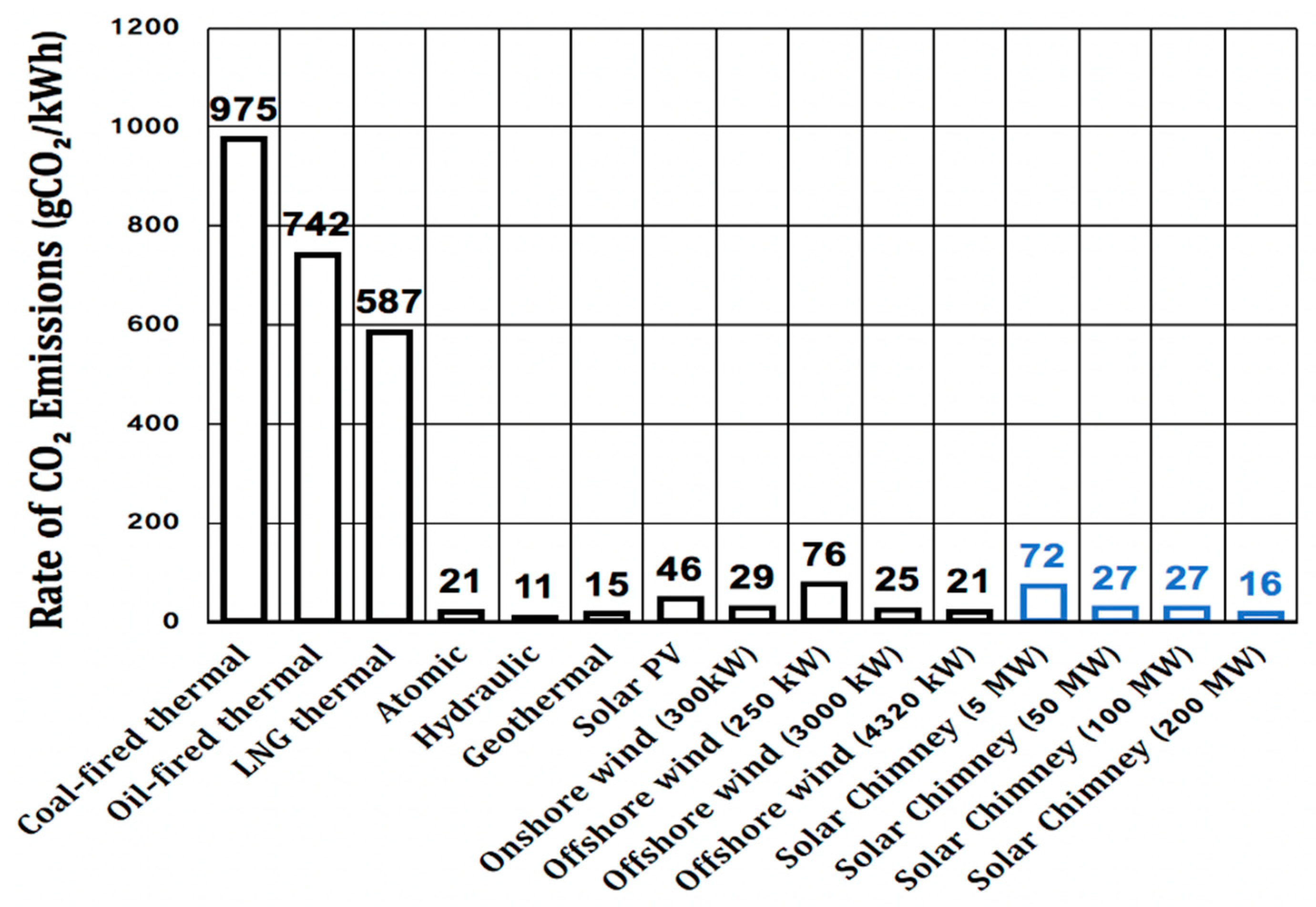

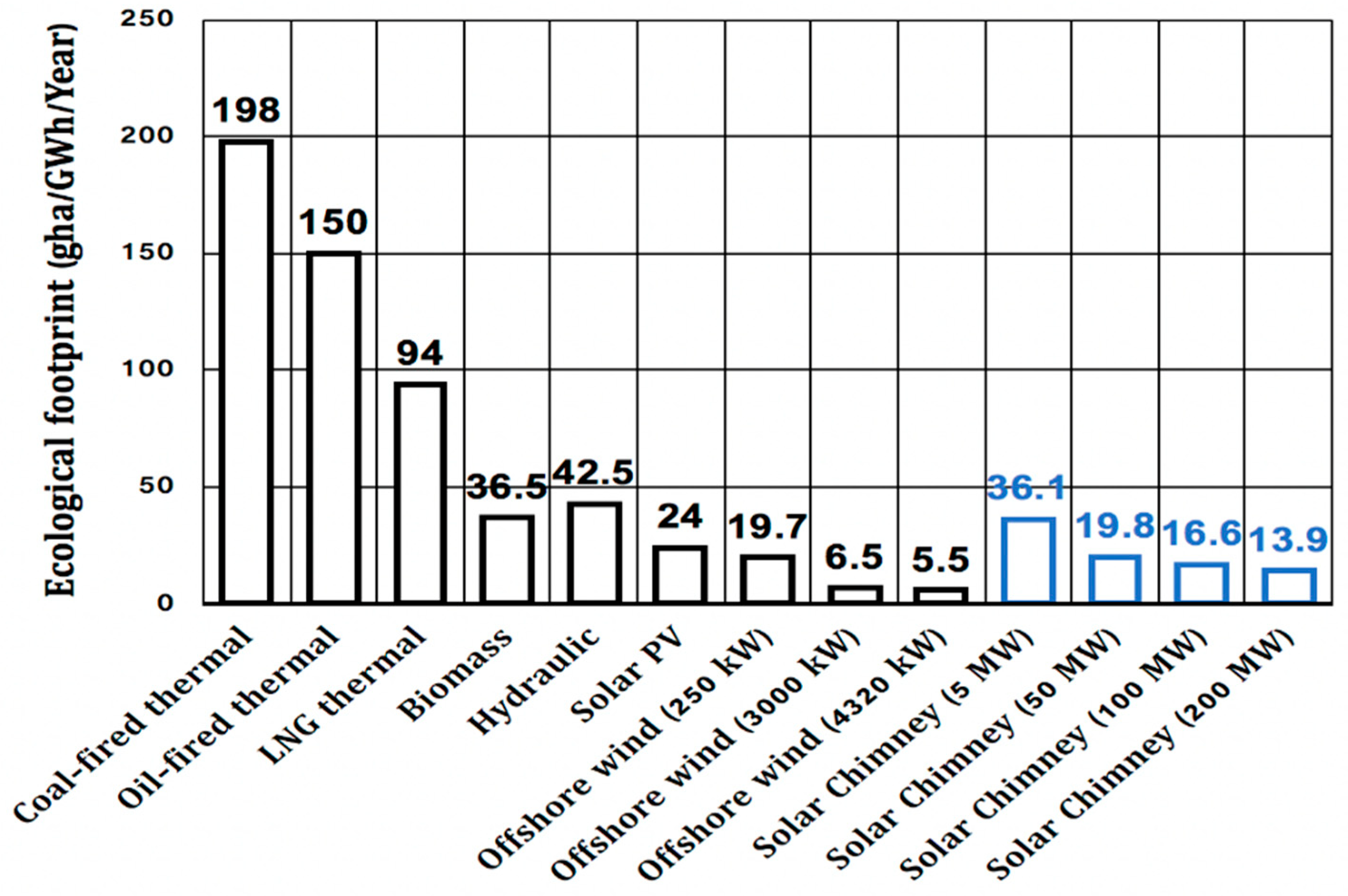

3.5. Comparison with Other Kinds of Power Generation Plants

4. Potential of Offshore STWT Technology

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Abbreviations

| Area of collector | |

| Annual energy production | |

| Benefit | |

| Cost | |

| Total capital cost | |

| Collector cost | |

| Tower cost | |

| Turbine cost | |

| Specific capital cost for material and construction | |

| Annual operation and maintenance cost | |

| Specific heat capacity of air at constant pressure | |

| Diameter of collector | |

| Diameter of tower | |

| Embodied carbon | |

| Ecological footprint | |

| Gross domestic product | |

| Gravity | |

| Height of tower | |

| Height of collector inlet | |

| Solar radiation | |

| Inclusive impact index – light | |

| Levelized electricity cost | |

| Mass flow rate of air | |

| Number of years (lifetime) | |

| Total power | |

| Electrical power output | |

| Cost percentage for the collector per unit area. | |

| Cost percentage for every one-meter height of collector inlet. | |

| Cost percentage for the turbines. | |

| Cost percentage for operation and maintenance | |

| Useful heat gain to the air flow | |

| Inputted solar energy | |

| Capital recovery factor | |

| Reinforced concrete | |

| Annual interest rate | |

| Solar thermal wind tower | |

| Ambient air temperature | |

| Maximum airflow speed | |

| Total pressure difference of air | |

| Temperature rise | |

| Efficiency of the collector | |

| Efficiency of the tower | |

| Efficiency of the turbines | |

| Density of the ambient air | |

| Density of air inside the tower |

Appendix A

| Component | Material | Percentage | |

|---|---|---|---|

| Turbines | Blade | Steel | 14% |

| Epoxy | 29% | ||

| Fibrous glass | 57% | ||

| Nacelle | Steel | 93% | |

| Stainless steel | 1% | ||

| Cast steel | 7% | ||

| Grease | 0% | ||

| Generator | Steel | 66% | |

| Silicon Steel plate | 8% | ||

| Aluminum | 3% | ||

| Copper | 6% | ||

| Heat-hardening resin | 12% | ||

| Grease | 6% | ||

| Material | (kgCO2/kg) | Material | (kgCO2/kg) |

|---|---|---|---|

| Steel | 1.366 | Fibrous Glass | 2.138 |

| Stainless steel | 2.744 | Insulator | 2.911 |

| Cast steel | 3.718 | Grease | 0.255 |

| Silicon steel plate | 1.366 | Heat-hardening resin | 5.035 |

| Aluminum | 5.442 | Concrete | 0.114 |

| Copper | 2.508 | Cement | 0.808 |

| Epoxy | 6.886 | Stone material | 0.008 |

References

- Richter, C.; Lincot, D.; Gueymard, C.A. Solar Updraft Towers. In Solar Energy; Meyers, R.A., Ed.; Springer: New York, NY, USA, 2012; pp. 658–687. [Google Scholar]

- Schlaich, J.; Bergermann, R.; Schiel, W.; Weinrebe, G. Design of Commercial Solar Updraft Tower Systems: Utilization of Solar Induced Convective Flows for Power Generation. J. Sol. Energy Eng. 2005, 127, 117–124. [Google Scholar] [CrossRef]

- Ming, T. Solar Chimney Power Plant Generating Technology; Elsevier: Amsterdam, The Netherlands, 2016; pp. 1–69. [Google Scholar]

- Al-Kayiem, H.H.; Aja, O.C. Historic and recent progress in solar chimney power plant enhancing technologies. Renew. Sustain. Energy Rev. 2016, 58, 1269–1292. [Google Scholar] [CrossRef]

- Mullett, L.B. The solar chimney—Overall efficiency, design and performance. Int. J. Ambient Energy 2011, 8, 35–40. [Google Scholar] [CrossRef]

- EnviroMission Company, Australia. Available online: www.enviromission.com.au (accessed on 30 September 2018).

- Krätzi Wilfried, B.; Harte, R.; Montag, U. From large natural draft cooling tower shells to chimneys of solar upwind power plants, Giga-Shells for Energy Generation: Natural Draft Cooling Towers and Solar Updraft Chimneys. In Proceedings of the 6th International Symposium on Cooling Towers, Cologne, Germany, 20–23 June 2012. [Google Scholar]

- Purnell, P. The carbon footprint of reinforced concrete. Adv. Cem. Res. 2013, 25, 362–368. [Google Scholar] [CrossRef] [Green Version]

- Vestergaard Nielsen, C. Carbon Footprint of Concrete Buildings seen in the Life Cycle Perspective. In Proceedings of the NRMCA 2008 Concrete Technology Forum, Denver, CO, USA, 20–22 May 2008. [Google Scholar]

- Documentation for Greenhouse Gas Emission and Energy Factors Used in the Waste Reduction Model, U.S. Environmental Protection Agency. Available online: www.epa.gov/warm (accessed on 30 September 2018).

- Murai, M.; Aono, T. Inclusive Environmental Assessment for Offshore Wind Power Stations. In Proceedings of the Nineteenth International Offshore and Polar Engineering Conference, Osaka, Japan, 21–26 June 2009; ISBN 978-1-880653-53-1. [Google Scholar]

- Takahashi, T.; Sato, T. Inclusive environmental impact assessment indices with consideration of public acceptance: Application to power generation technologies in Japan. Appl. Energy 2015, 144, 64–72. [Google Scholar] [CrossRef]

- Okoye, C.O.; Solyalı, O.; Taylan, O. A new economic feasibility approach for solar chimney power plant design. Energy Convers. Manag. 2016, 126, 1013–1027. [Google Scholar] [CrossRef]

- Harte, R.; Graffmann, R. Optimization of Solar Updraft Chimneys by Nonlinear Response Analysis. Appl. Mech. Mater. 2013, 283, 25–34. [Google Scholar] [CrossRef]

- BuildRight Toolbox, Australia. Available online: https://emedia.rmit.edu.au/dlsweb/Toolbox/buildright/ (accessed on 30 September 2018).

- Ir. Stephen Leung, Arup Materials Technology, Technical seminar on Carbon Dioxide (CO2) Emissions of Concrete, SCCT 2009, Hong Kong. 2009. Available online: http://www.hkengineer.org.hk/program/home/idamain.php?cat=ida&volid=112&dept=mat (accessed on 30 September 2018).

- Boyle, G. Renewable Energy: Power for a Sustainable Future, 3rd ed.; Oxford University Press: Oxford, UK, 2012. [Google Scholar]

- Wackerbagel, M.; Rees, W. Our Ecological Footprint, Godo-Shuppan; New Society: Gabriola Island, BC, Cananda, 2004. [Google Scholar]

- Living Planet Report 2016. Available online: http://wwf.panda.org (accessed on 30 September 2018).

- MacDonald, M. Costs of Low-Carbon Generation Technologies, Committee on Climate Change. 2011. Available online: https://www.mottmac.com (accessed on 30 September 2018).

- Crossland, C.; Baird, D.; Ducrotoy, J.-P.; Lindeboom, H.; W.Buddemeier, R.; Dennison, W.; Maxwell, B.; Smith, S.; Swaney, D. The Coastal Zone—A Domain of Global Interactions. In Coastal Fluxes in the Anthropocene: The Land-Ocean Interactions in the Coastal Zone Project of the International Geosphere-Biosphere Programme; Springer: Berlin, Germany, 2005; pp. 1–37. [Google Scholar] [CrossRef]

- Zuo, L.; Zheng, Y.; Li, Z.; Sha, Y. Solar chimneys integrated with sea water desalination. Desalination 2011, 276, 207–213. [Google Scholar] [CrossRef]

- Niroomand, N.; Amidpour, M. New combination of solar chimney for power generation and seawater desalination. Desalin. Water Treat. 2013, 51, 7401–7411. [Google Scholar] [CrossRef] [Green Version]

- Diendorfer, C.; Haider, M.; Lauermann, M. Performance Analysis of Offshore Solar Power Plants. Energy Procedia 2014, 49, 2462–2471. [Google Scholar] [CrossRef]

- The World Economic Forum. Available online: https://www.weforum.org (accessed on 30 September 2018).

| Component | Weight (ton) | ||||

|---|---|---|---|---|---|

| 5 MW | 50 MW | 100 MW | 200 MW | ||

| Tower | 52,685.23 | 195,558.13 | 425,076.72 | 463,545.20 | |

| Collector | 12,664.55 | 113,980.91 | 149,867.16 | 397,160.14 | |

| Turbines | Blade | 201.60 | 201.60 | 201.60 | 201.6 |

| Nacelle | 331.20 | 331.20 | 331.20 | 331.2 | |

| Generator | 737.60 | 737.60 | 737.60 | 737.6 | |

| Total | 66,620.18 | 310,809.44 | 576,214.28 | 861,975.75 | |

| Component | CO2 Emissions (tCO2) | ||||

|---|---|---|---|---|---|

| 5 MW | 50 MW | 100 MW | 200 MW | ||

| Tower | 15,805.57 | 58,667.44 | 127,523.02 | 139,063.56 | |

| Collector | 6712.21 | 60,409.88 | 79,429.60 | 210,494.88 | |

| Turbines | Total | 2601.58 | 2601.58 | 2601.58 | 2601.580 |

| Blade | 684.94 | 684.94 | 684.94 | 684.940 | |

| Nacelle | 506.89 | 506.89 | 506.89 | 506.893 | |

| Generator | 1409.75 | 1409.75 | 1409.75 | 1409.746 | |

| Total | 25,119.36 | 121,678.90 | 209,554.19 | 352,160.02 | |

| Transportation System | Railway | Ship | Truck/Lorry |

|---|---|---|---|

| CO2 emissions (kg/(kg·km)) | ≈30 | 10–100 | 75–220 |

| Process | CO2 Emissions (tCO2) | |||

|---|---|---|---|---|

| 5 MW | 50 MW | 100 MW | 200 MW | |

| Transportation Stage | 8660.62 | 40,405.23 | 74,907.86 | 112,056.85 |

| Construction Stage | 1507.16 | 7300.73 | 12,573.25 | 21,129.60 |

| Operation and Maintenance | 9009.76 | 34,405.45 | 62,007.55 | 91,726.74 |

| Capacity | 5 MW | 50 MW | 100 MW | 200 MW |

|---|---|---|---|---|

| Tower Height (m) | 550 | 750 | 1000 | 1000 |

| Tower Diameter (m) | 45 | 90 | 110 | 120 |

| Collector Diameter (m) | 1250 | 3750 | 4300 | 7000 |

| Collector Area (km2) | 1.22 | 11.04 | 14.52 | 38.48 |

| Electricity Output (GWh/Year) | 15 | 189 | 331 | 878 |

| No. of typical households | 2813 | 34,524 | 60,526 | 160,398 |

| Overall system efficiency (%) | 0.815 | 1.111 | 1.482 | 1.482 |

| Capacity | 5 MW | 50 MW | 100 MW | 200 MW |

|---|---|---|---|---|

| Chimney cost [M€] | 5.4 | 20.0 | 43.4 | 47.3 |

| Collector cost [M€] | 36.3 | 326.9 | 429.9 | 1139.1 |

| Turbines cost [M€] | 4.2 | 34.7 | 47.3 | 118.6 |

| Total capital cost [M€] | 45.9 | 381.6 | 520.6 | 1305.1 |

| O&M cost [M€/year] | 0.2 | 1.9 | 2.6 | 6.5 |

| AEP [kWh] | 1.54 × 107 | 1.89 × 108 | 3.31 × 108 | 8.78 × 108 |

| LEC [€/kWh] | 0.2128 | 0.1443 | 0.1123 | 0.1062 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Elsayed, I.; Nishi, Y. A Feasibility Study on Power Generation from Solar Thermal Wind Tower: Inclusive Impact Assessment Concerning Environmental and Economic Costs. Energies 2018, 11, 3181. https://doi.org/10.3390/en11113181

Elsayed I, Nishi Y. A Feasibility Study on Power Generation from Solar Thermal Wind Tower: Inclusive Impact Assessment Concerning Environmental and Economic Costs. Energies. 2018; 11(11):3181. https://doi.org/10.3390/en11113181

Chicago/Turabian StyleElsayed, Islam, and Yoshiki Nishi. 2018. "A Feasibility Study on Power Generation from Solar Thermal Wind Tower: Inclusive Impact Assessment Concerning Environmental and Economic Costs" Energies 11, no. 11: 3181. https://doi.org/10.3390/en11113181