Key Technologies and Application Test of an Innovative Noncoal Pillar Mining Approach: A Case Study

Abstract

:1. Introduction

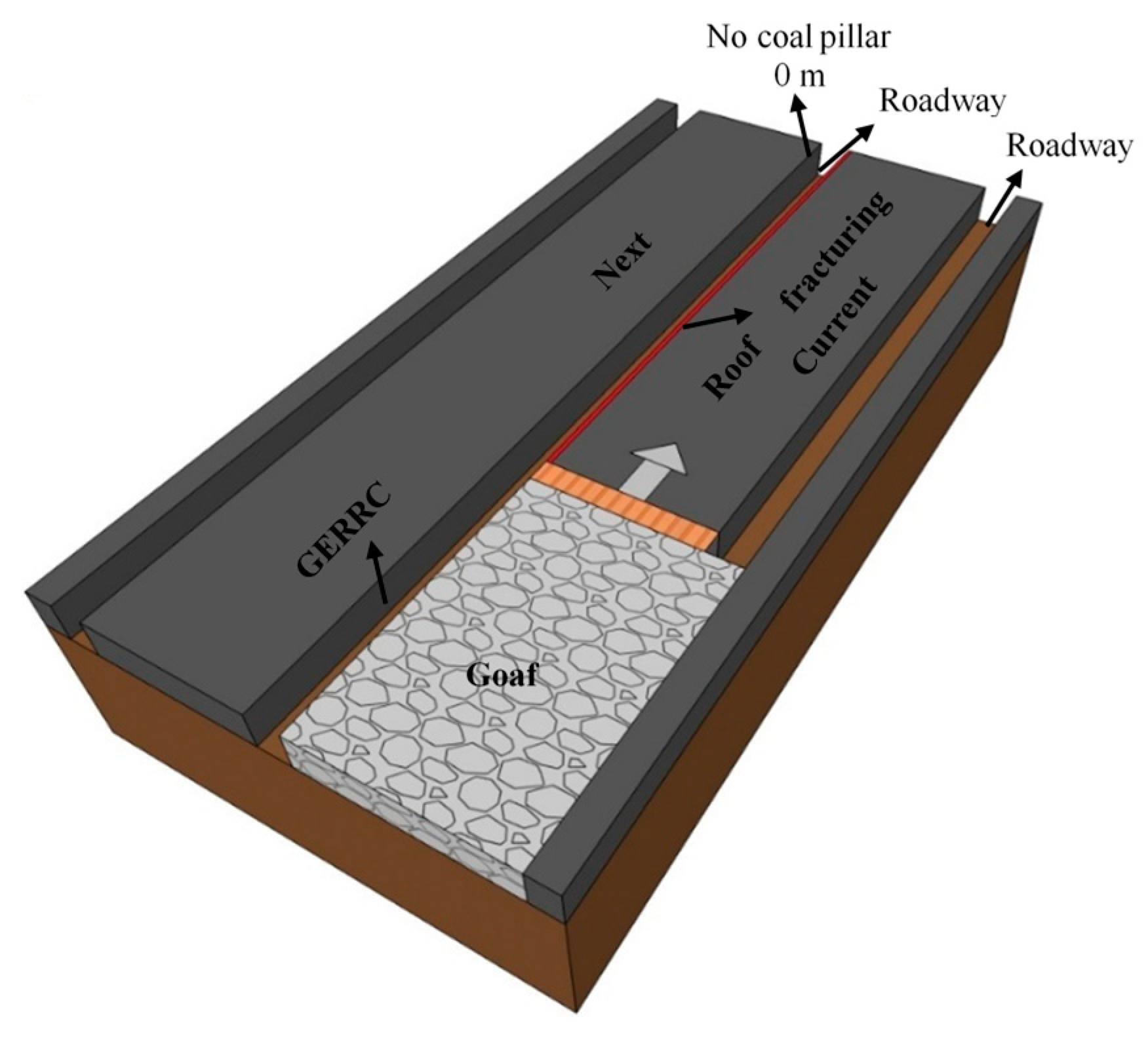

2. Gob-Side Entry Retaining by Roof Cutting (GERRC) Technology

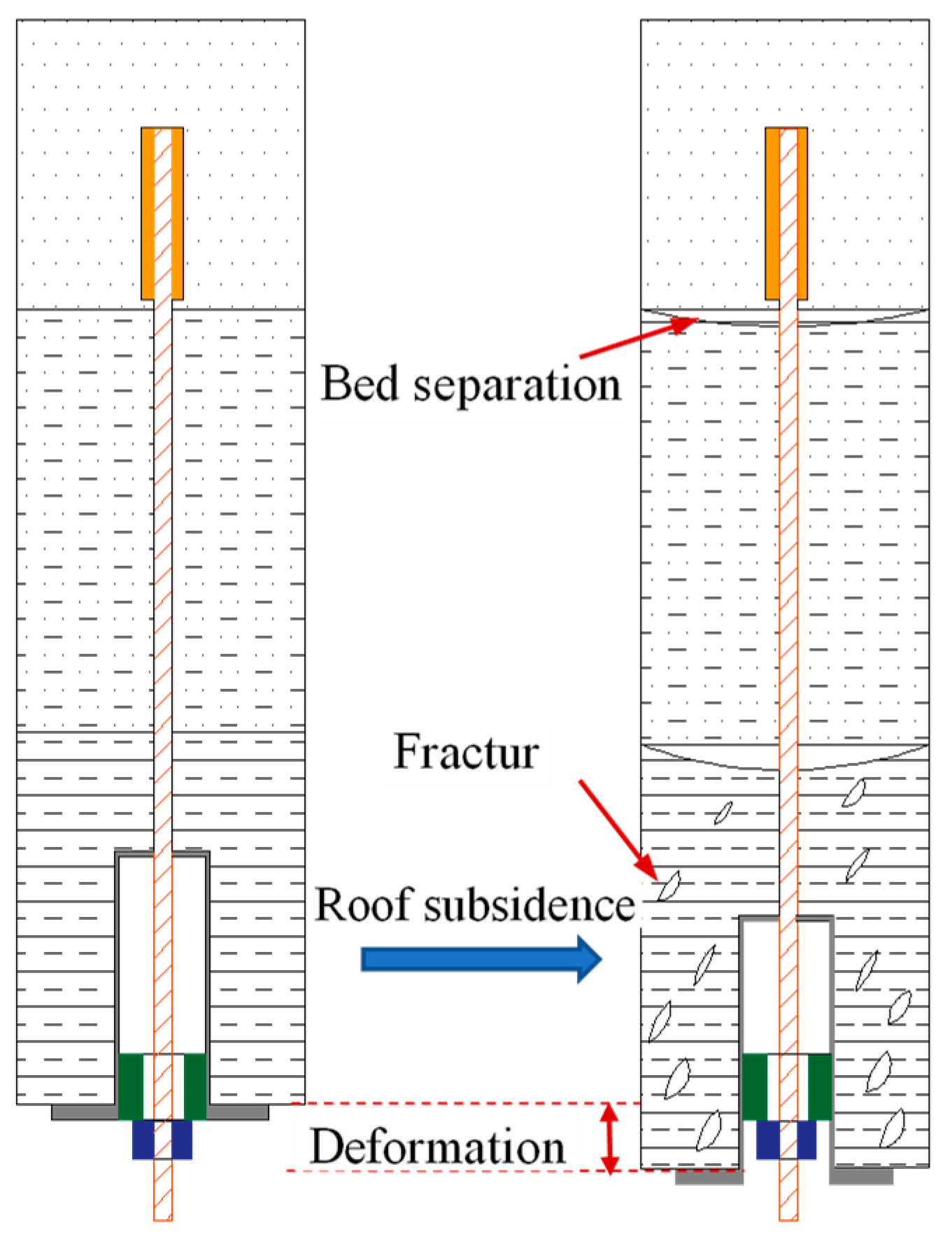

2.1. Principle of GERRC

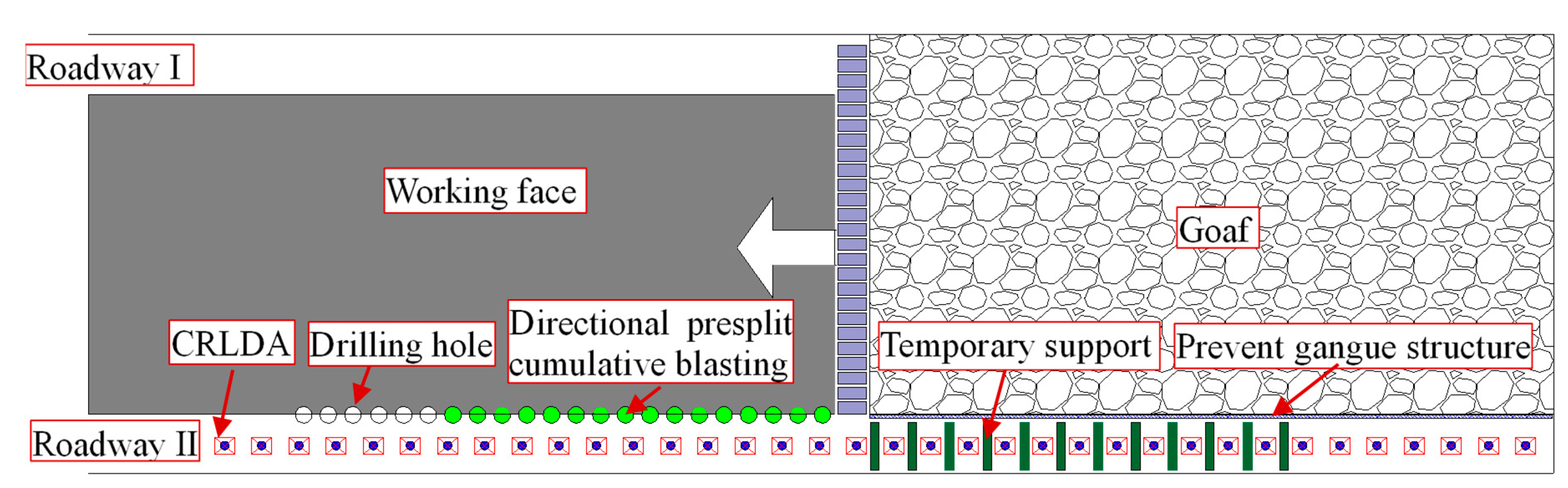

2.2. Process of GERRC

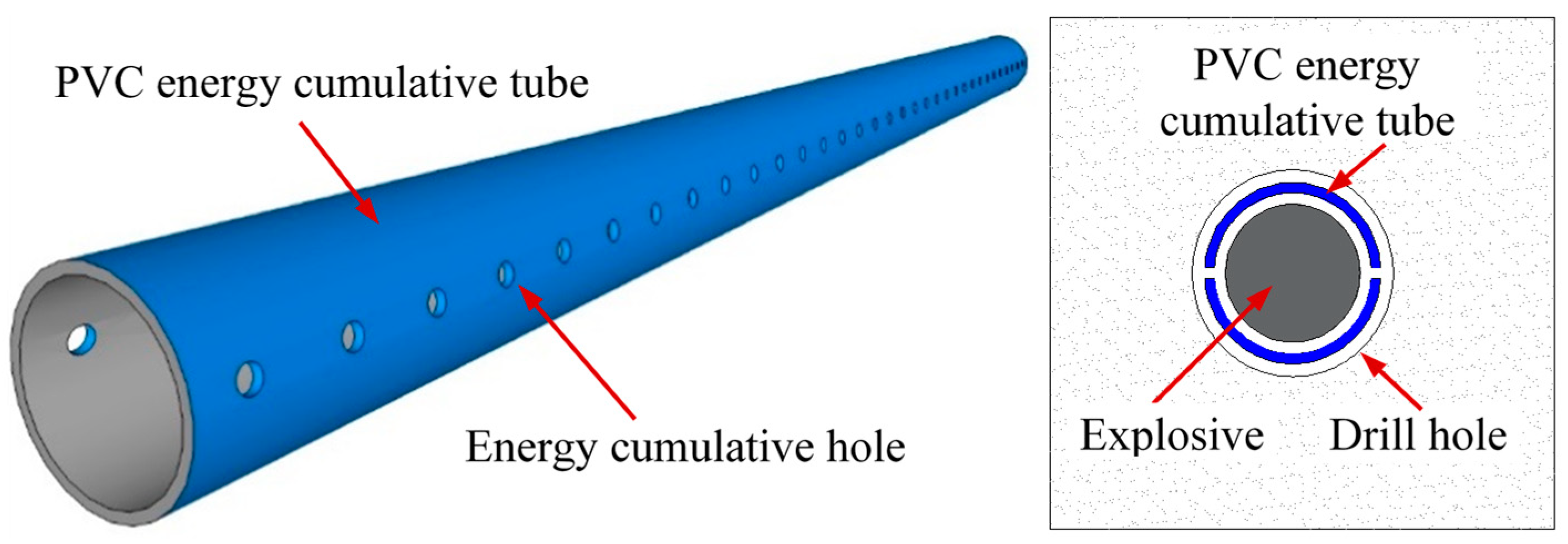

2.3. Key Technologies of GERRC

3. Materials and Research Methods

3.1. Theoretical Analysis on the Mechanical Mechanism of GERRC

3.2. Laboratory Experiment on the CRLDA Support Technology

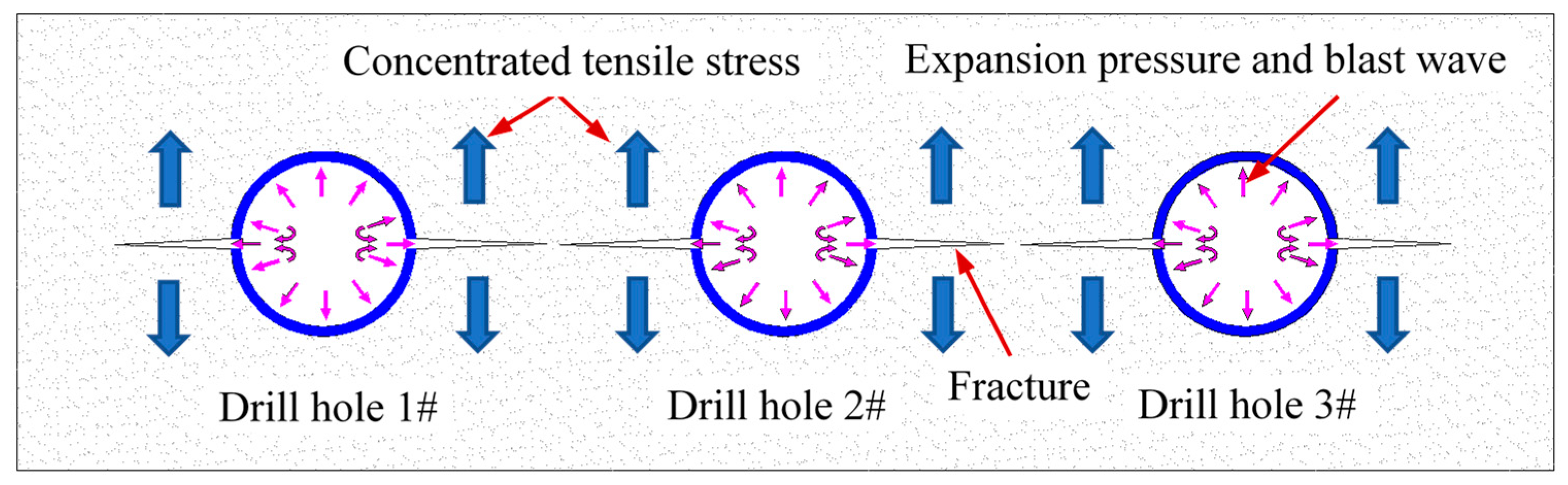

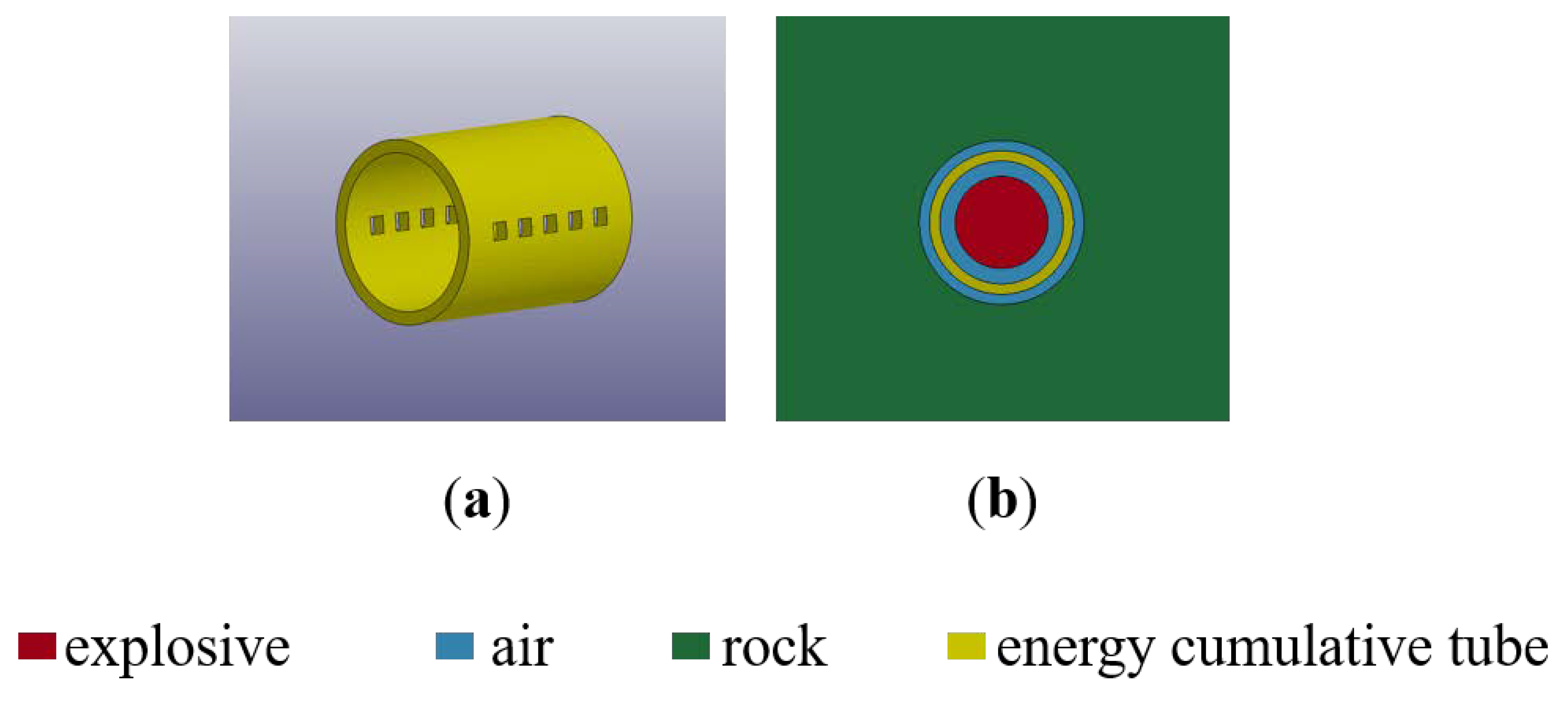

3.3. Numerical Simulation on the Directional Presplit Cumulative Blasting Technology

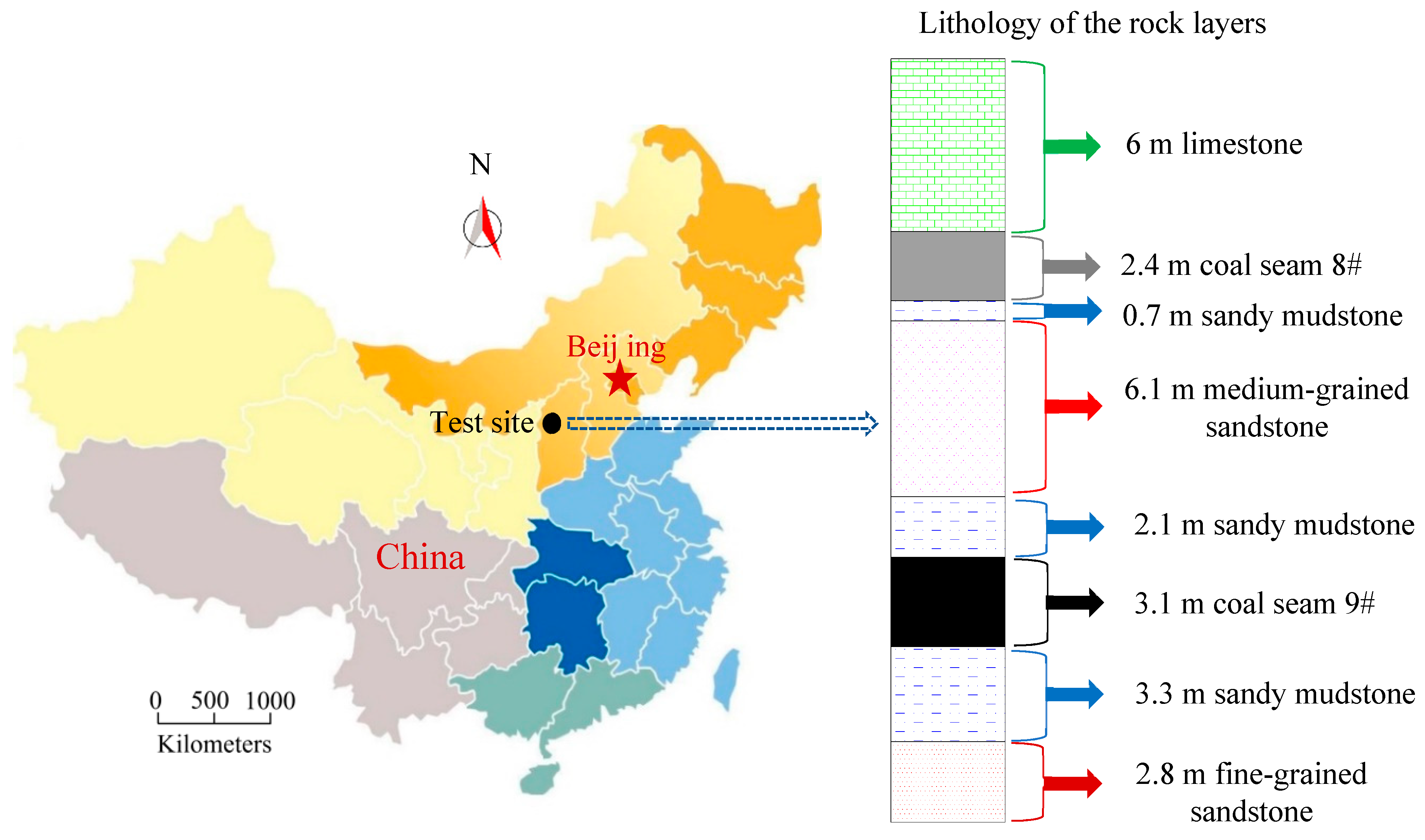

3.4. Field Experiment

4. Field Application Test

4.1. Test Conditions

4.2. Design of CRLDA Support

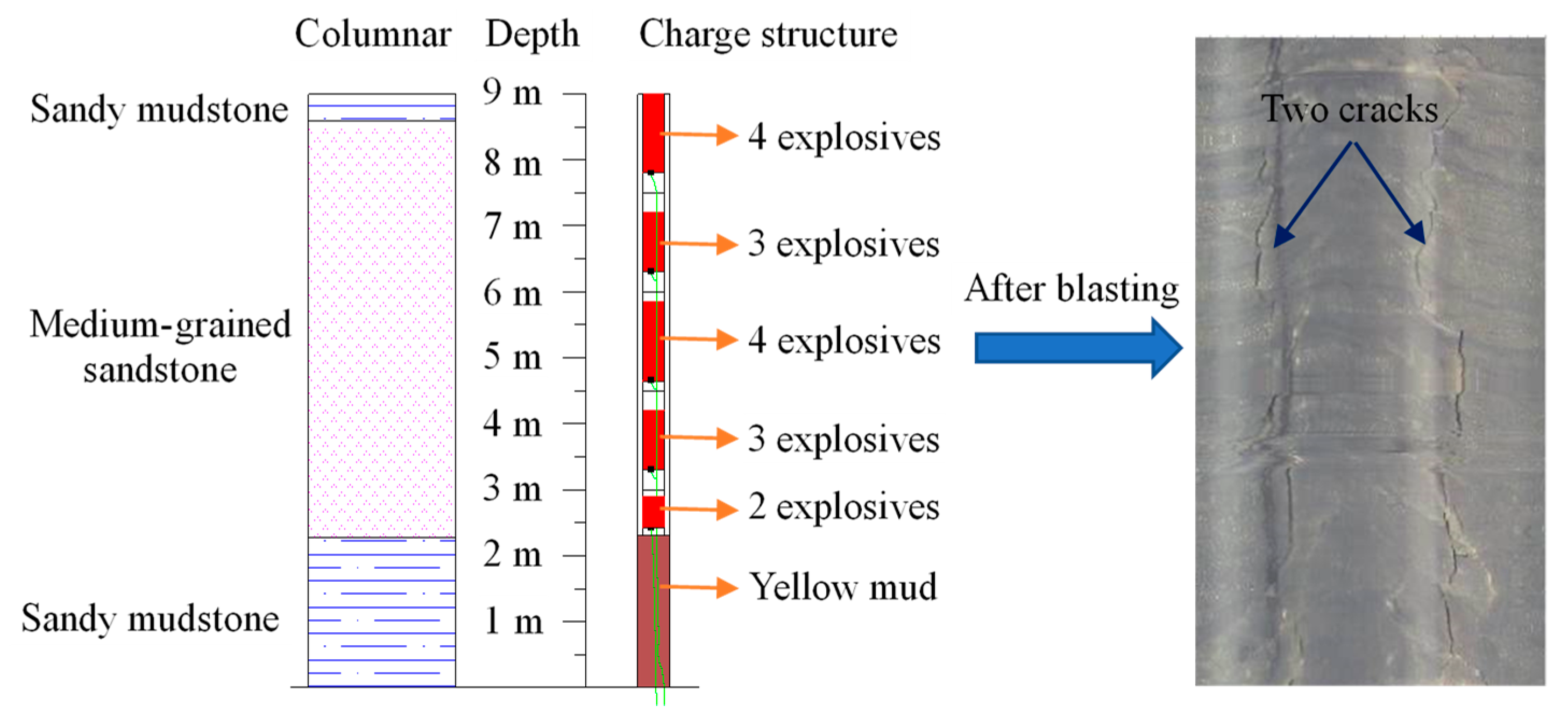

4.3. Design of Directional Presplit Cumulative Blasting

4.4. Design of the Surrounding Rock Control in GERRC

5. Research Results

5.1. Mechanical Mechanism of GERRC Technology

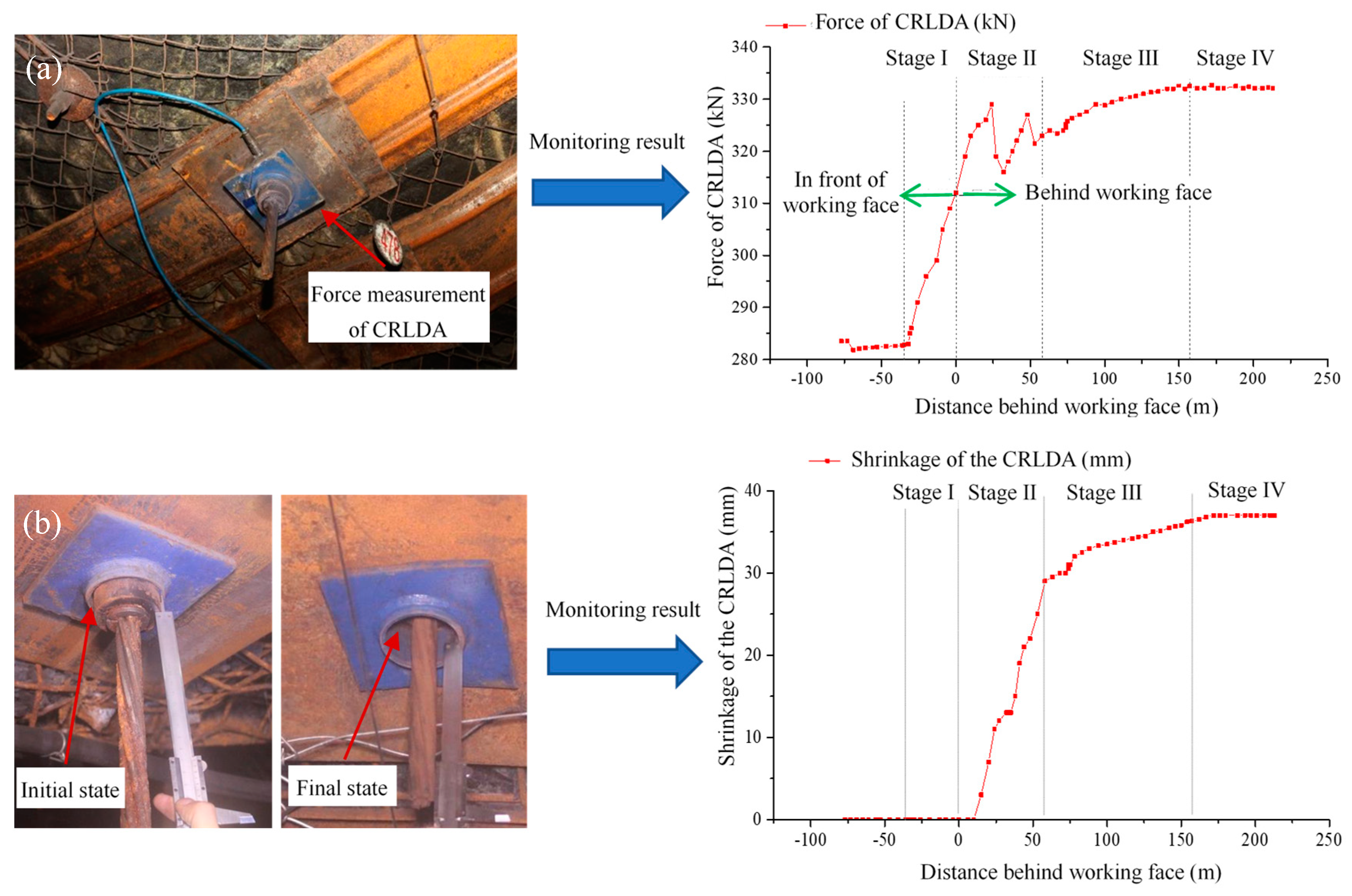

5.2. Mechanical Properties and Application Effects of CRLDA

5.2.1. Mechanical Properties of CRLDA

5.2.2. Support Effects of CRLDA in the Field Experiment

5.3. Effects of Directional Presplit Cumulative Blasting Technology

5.3.1. Analysis of Numerical Simulation Results

5.3.2. Application Effects in the Field Experiment

5.4. Effects of the Surrounding Rock Control in the Field Experiment

6. Discussion

7. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Qian, M.; Miao, X.; He, F. Analysis of key block in the structure of voussoir beam in longwall mining. J. China Coal Soc. 1994, 31, 191A. [Google Scholar]

- Zheng, X.; Yao, Z.; Zhang, N. Stress distribution of coal pillar with gob-side entry driving in the process of excavation & mining. J. Min. Saf. Eng. 2012, 29, 459–465. [Google Scholar]

- Zhang, Z.; Bai, J.; Chen, Y.; Yan, S. An innovative approach for gob-side entry retaining in highly gassy fully-mechanized longwall top-coal caving. Int. J. Rock Mech. Min. Sci. 2015, 80, 1–11. [Google Scholar] [CrossRef]

- Basarir, H.; Oge, I.; Aydin, O. Prediction of the stresses around main and tail gates during top coal caving by 3D numerical analysis. Int. J. Rock Mech. Min. Sci. 2015, 76, 88–97. [Google Scholar] [CrossRef]

- Yang, H.; Cao, S.; Wang, S.; Fan, Y.; Wang, S.; Chen, X. Adaptation assessment of gob-side entry retaining based on geological factors. Eng. Geol. 2016, 209, 143–151. [Google Scholar] [CrossRef]

- Guy, R.; Kent, M.; Russell, F. An assessment of coal pillar system stability criteria based on a mechanistic evaluation of the interaction between coal pillars and the overburden. Int. J. Min. Sci. Technol. 2017, 27, 9–15. [Google Scholar]

- Tesarik, D.R.; Seymour, J.B.; Yanske, T.R. Long-term stability of a backfilled room-and-pillar test section at the Buick Mine, Missouri, USA. Int. J. Rock Mech. Min. Sci. 2009, 46, 1182–1196. [Google Scholar] [CrossRef]

- He, M.; Zhu, G.; Guo, Z. Longwall mining “cutting cantilever beam theory” and 110 mining method in China—The third mining science innovation. J. Rock Mech. Geot. Eng. 2015, 7, 483–492. [Google Scholar] [CrossRef]

- Zhang, G.; He, M.; Yu, X.; Huang, Z. Research on the technique of no-pillar mining with gob-side entry formed by advanced roof caving in the protective seam in Baijiao coal mine. J. Min. Saf. Eng. 2011, 28, 511–516. [Google Scholar]

- Zhang, G.; Xu, Y.; Ge, P. Research on cut gob-side entry retaining in thin coal seam of Tangshan ditch. Chin. J. Rock Mech. Eng. 2016, 35, 1397–1406. [Google Scholar]

- Sun, X.; Xin, L.; Liang, G.; Dong, W.; Jiang, Y. Key parameters of gob-side entry retaining formed by roof cut and pressure releasing in thin coal seams. Chin. J. Rock Mech. Eng. 2014, 33, 1449–1456. [Google Scholar]

- He, M.; Gao, Y.; Yang, J.; Gong, W. An Innovative approach for gob-side entry retaining in thick coal seam longwall mining. Energies 2017, 10, 1785. [Google Scholar] [CrossRef]

- Gao, Y.; Liu, D.; Zhang, X.; He, M. Analysis and optimization of entry stability in underground longwall mining. Sustainability 2017, 9, 2079. [Google Scholar] [CrossRef]

- Wang, Y.; Gao, Y.; Wang, E.; He, M.; Yang, J. Roof deformation characteristics and preventive techniques using a novel non-pillar mining method of gob-side entry retaining by roof cutting. Energies 2018, 11, 627. [Google Scholar] [CrossRef]

- He, M.; Wang, J.; Sun, X.; Yang, X. Mechanics characteristics and applications of prevention and control rock bursts of the negative poisson’s ratio effect anchor. J. China Coal Soc. 2014, 39, 214–221. [Google Scholar]

- He, M.; Gong, W.; Wang, J.; Qi, P.; Tao, Z.; Du, S.; Peng, Y. Development of a novel energy-absorbing bolt with extraordinarily large elongation and constant resistance. Int. J. Rock Mech. Min. Sci. 2014, 67, 29–42. [Google Scholar] [CrossRef]

- He, M.; Li, C.; Gong, W.; Sousa, L.R.; Li, S. Dynamic tests for a constant-resistance-large-deformation bolt using a modified SHTB system. Tunn. Undergr. Space Tech. 2017, 64, 103–116. [Google Scholar] [CrossRef]

- Zhang, G.; Wang, E.; Xu, L. Mechanical characteristics of high constant resistance and large deformation anchor rope in coal mines. Chin. J. Rock Mech. Eng. 2016, 35, 2033–2043. [Google Scholar]

- Chen, J.; Zhang, J.; Li, X. Study of presplitting blasting parameters and its application based on rock blasting-induced damage theory. Rock Soil Mech. 2016, 37, 1441–1450. [Google Scholar]

- Gao, Y.; He, M.; Yang, J.; Ma, X. Experimental study of caving and distribution of gangues influenced by roof fracturing in pillarless mining with gob-side entry retaining. J. China Univ. Min. Technol. 2018, 47, 21–31. [Google Scholar]

- Konicek, P.; Soucek, K.; Stas, L.; Singh, R. Long-hole destress blasting for rockburst control during deep underground coal mining. Int. J. Rock Mech. Min. Sci. 2013, 61, 141–153. [Google Scholar] [CrossRef]

- Yilmaz, O.; Unlu, T. Three dimensional numerical rock damage analysis under blasting load. Tunn. Undergr. Space Tech. 2013, 38, 266–278. [Google Scholar] [CrossRef]

- Yang, G.; Yang, R.; Tong, J. Research and application of cut blasting with slotted charge. J. China Coal Soc. 2012, 37, 385–388. [Google Scholar]

- He, M.; Cao, W.; Shan, R.; Wang, S. New blasting technology-bilateral cumulative tensile explosion. Chin. J. Rock Mech. Eng. 2003, 22, 2047–2051. [Google Scholar]

- Xie, L.; Lu, W.; Zhang, Q.; Jiang, Q.; Wang, G.; Zhao, J. Damage evolution mechanisms of rock in deep tunnels induced by cut blasting. Tunn. Undergr. Space Tech. 2016, 58, 257–270. [Google Scholar] [CrossRef]

- Zhu, Z.; Mohanty, B.; Xie, H. Numerical investigation of blasting-induced crack initiation and propagation in rocks. Int. J. Rock Mech. Min. Sci. 2007, 44, 412–424. [Google Scholar] [CrossRef]

- Bendezu, M.; Romanel, C.; Roehl, D. Finite element analysis of blast-induced fracture propagation in hard rocks. Comput. Struct. 2017, 182, 1–13. [Google Scholar] [CrossRef]

- Xie, L.; Lu, W.; Zhang, Q.; Jiang, Q.; Chen, M.; Zhao, J. Analysis of damage mechanisms and optimization of cut blasting design under high in-situ stresses. Tunn. Undergr. Space Tech. 2017, 66, 19–33. [Google Scholar] [CrossRef]

- Li, X.; Huang, J.; Luo, Y.; Chen, P. A study of smooth wall blasting fracture mechanisms using the timing sequence control method. Int. J. Rock Mech. Min. Sci. 2017, 92, 1–8. [Google Scholar] [CrossRef]

- He, M.; Gao, Y.; Yang, J.; Guo, Z.; Wang, E.; Wang, Y. An energy-gathered roof cutting technique in no-pillar mining and its impact on stress variation in surrounding rocks. Chin. J. Rock Mech. Eng. 2017, 36, 1314–1325. [Google Scholar]

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ma, Z.; Wang, J.; He, M.; Gao, Y.; Hu, J.; Wang, Q. Key Technologies and Application Test of an Innovative Noncoal Pillar Mining Approach: A Case Study. Energies 2018, 11, 2853. https://doi.org/10.3390/en11102853

Ma Z, Wang J, He M, Gao Y, Hu J, Wang Q. Key Technologies and Application Test of an Innovative Noncoal Pillar Mining Approach: A Case Study. Energies. 2018; 11(10):2853. https://doi.org/10.3390/en11102853

Chicago/Turabian StyleMa, Zimin, Jiong Wang, Manchao He, Yubing Gao, Jinzhu Hu, and Qiong Wang. 2018. "Key Technologies and Application Test of an Innovative Noncoal Pillar Mining Approach: A Case Study" Energies 11, no. 10: 2853. https://doi.org/10.3390/en11102853