A Review of Experiments and Modeling of Gas-Liquid Flow in Electrical Submersible Pumps

Abstract

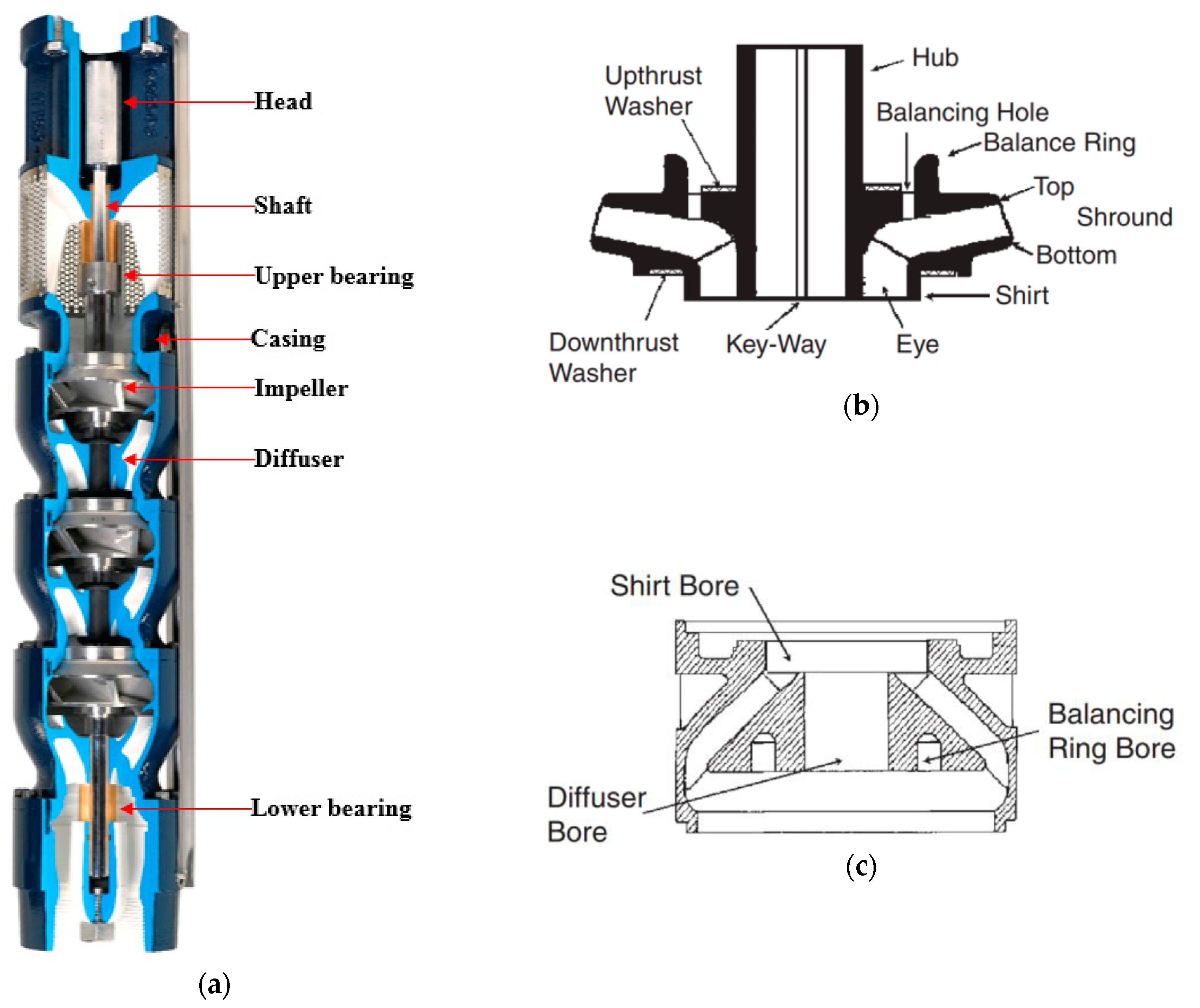

:1. Introduction

2. Boosting Pressure of Centrifugal Pump

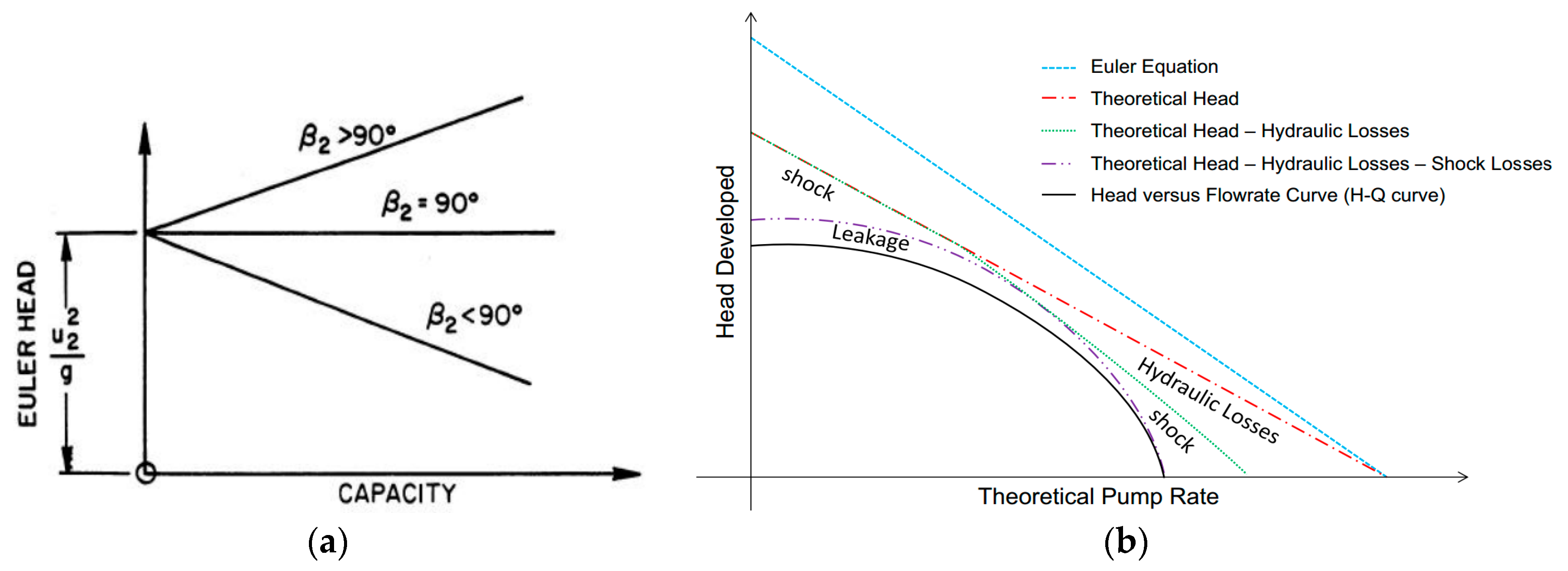

2.1. Euler Head

2.2. Head Loss Mechanisms

3. Experimental Studies

3.1. Single-Phase Tests

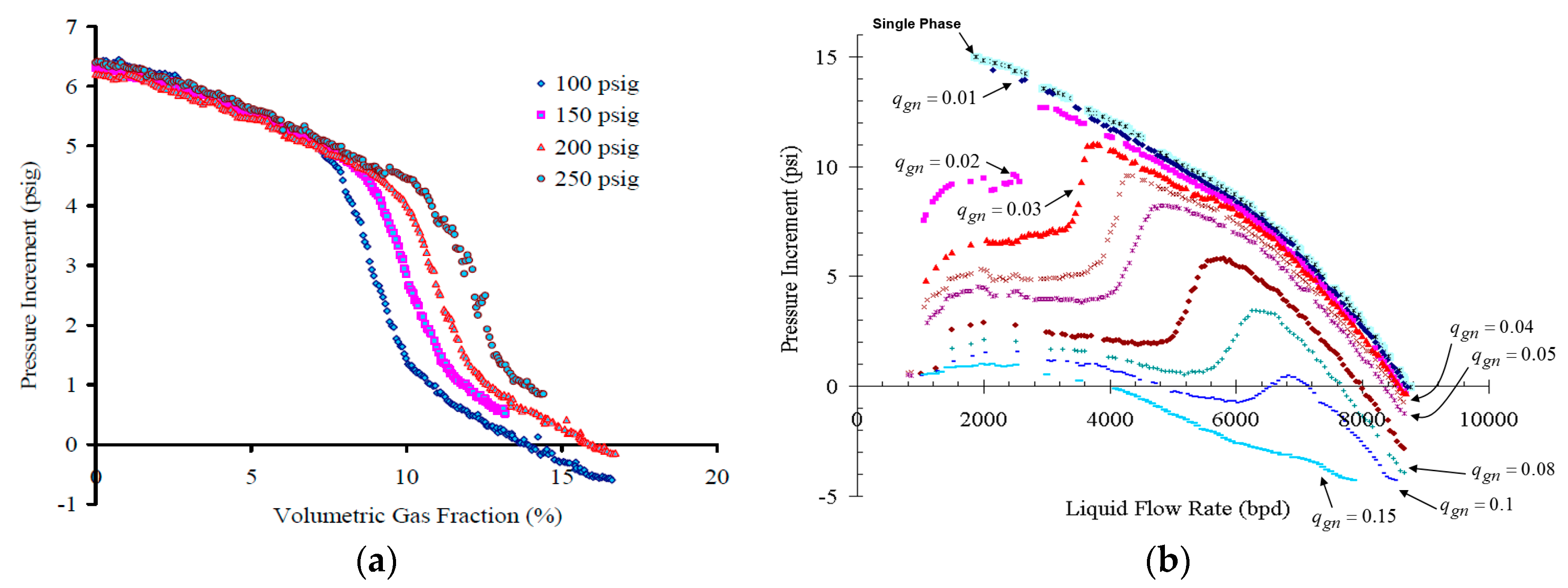

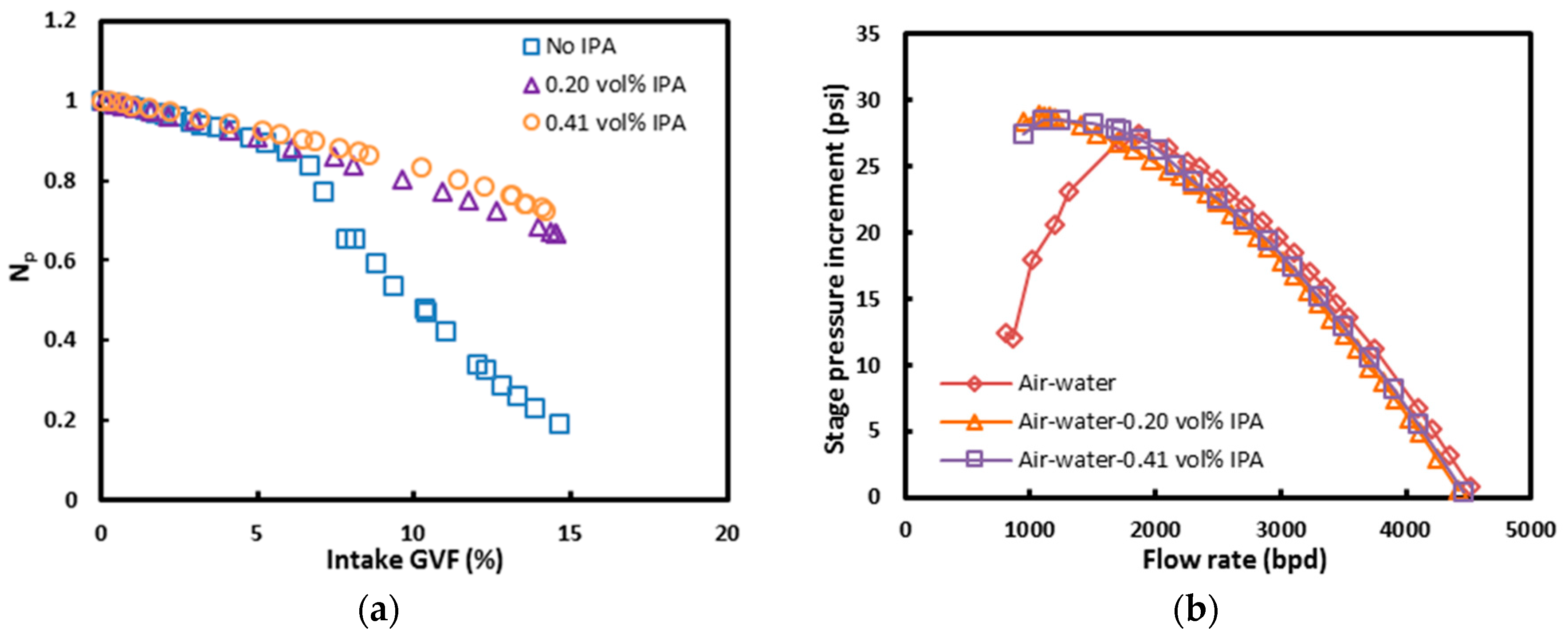

3.2. Two-Phase Tests

3.3. Flow Pattern Recognition

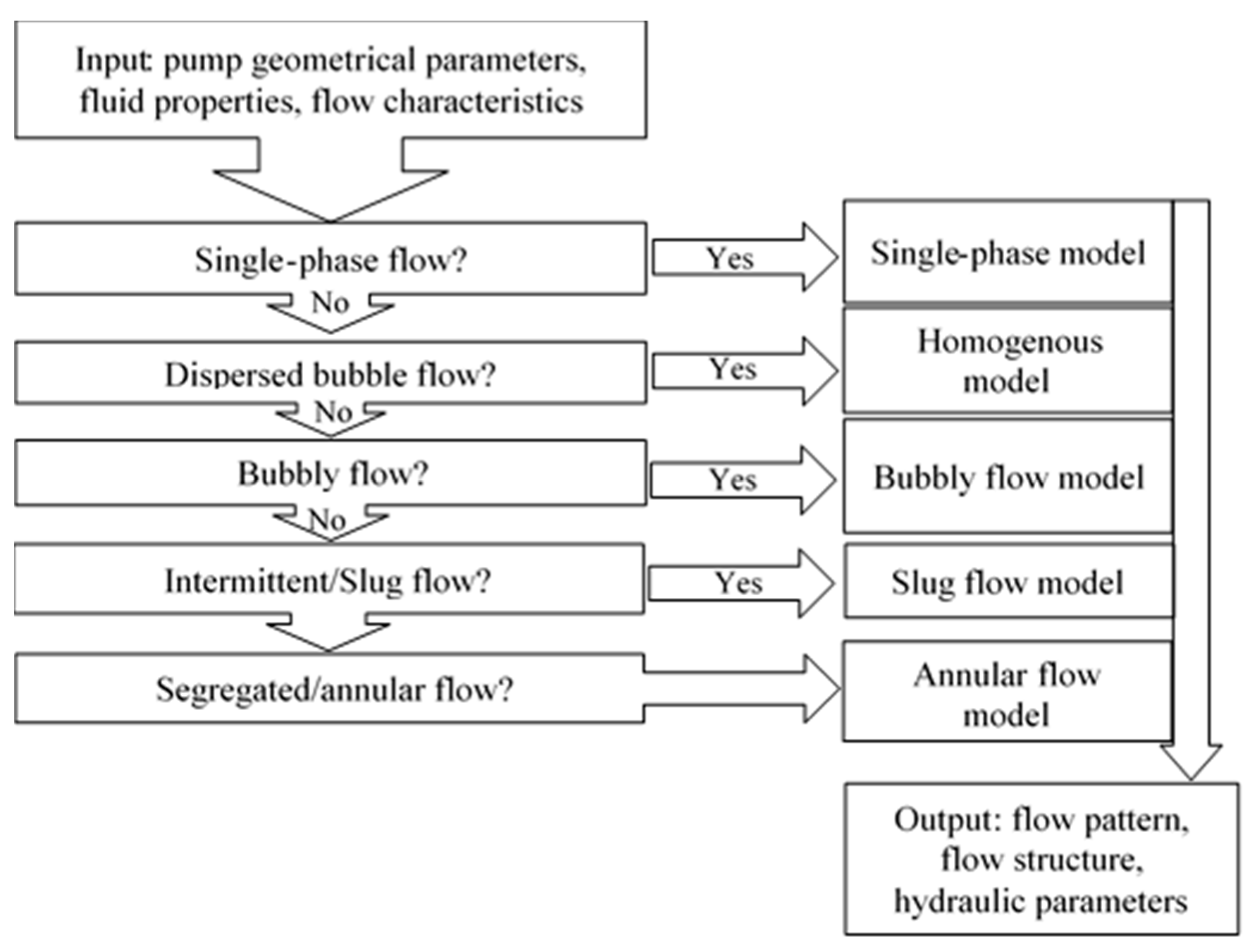

4. Modeling Approaches

4.1. Emperical Correlations

4.2. One-Dimension Two-Fluid Modeling

4.3. Three-Dimension Computational Fluid Dynamics (CFD)

4.4. Mechanistic Modeling

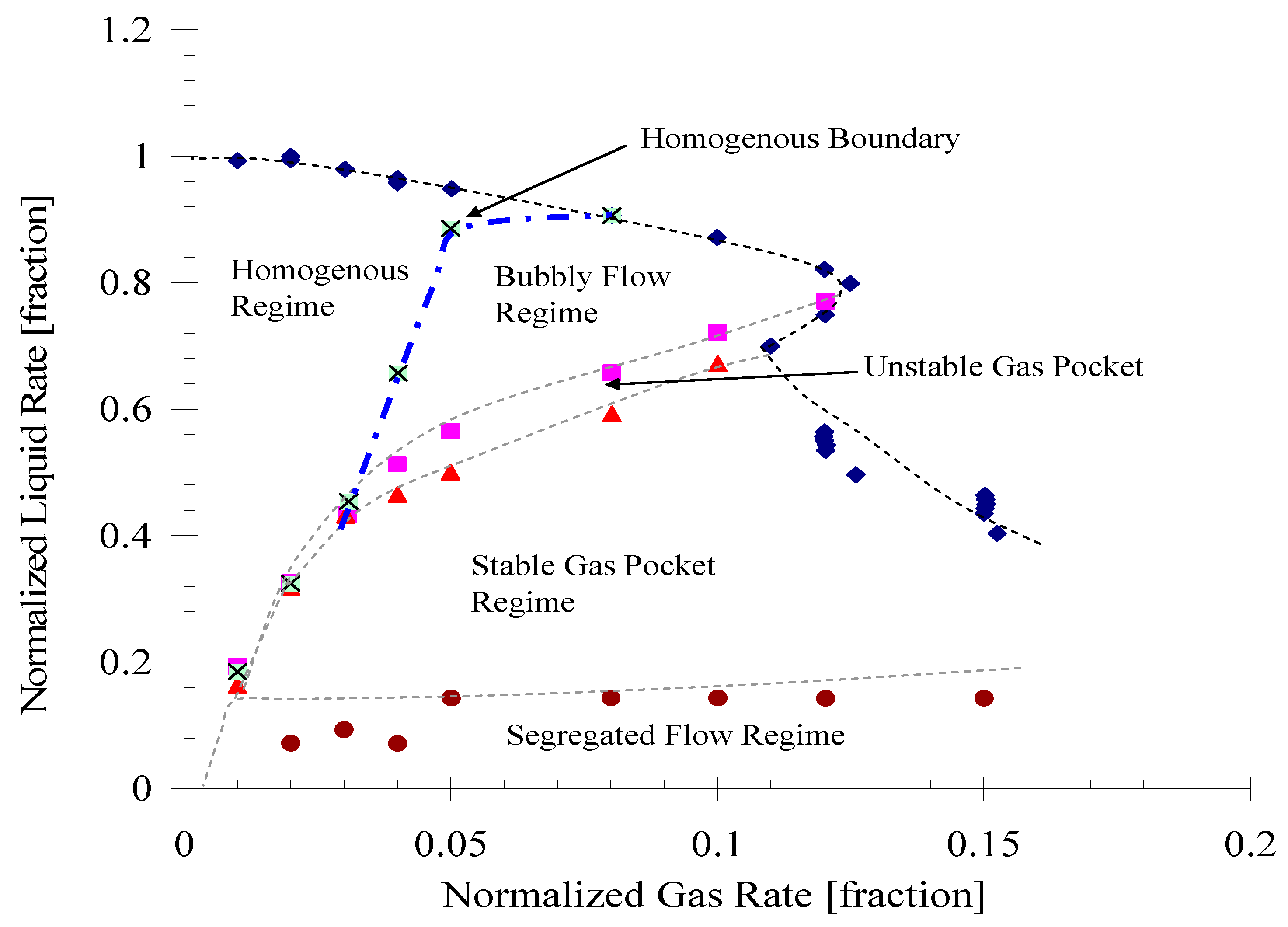

4.4.1. Flow Pattern Map and Transition Boundary

Transition from Dispersed Bubble Flow to Bubbly Flow (1st Transition Boundary)

Transition from Bubbly Flow to Intermittent Flow (2nd Transition Boundary)

Transition from Bubbly Flow to Intermittent Flow (3rd Transition Boundary)

4.4.2. Flow Model

4.4.3. Mechanistic Model Calculation

5. Closure Relationship

5.1. Bubble Size

5.2. Drag Coefficient

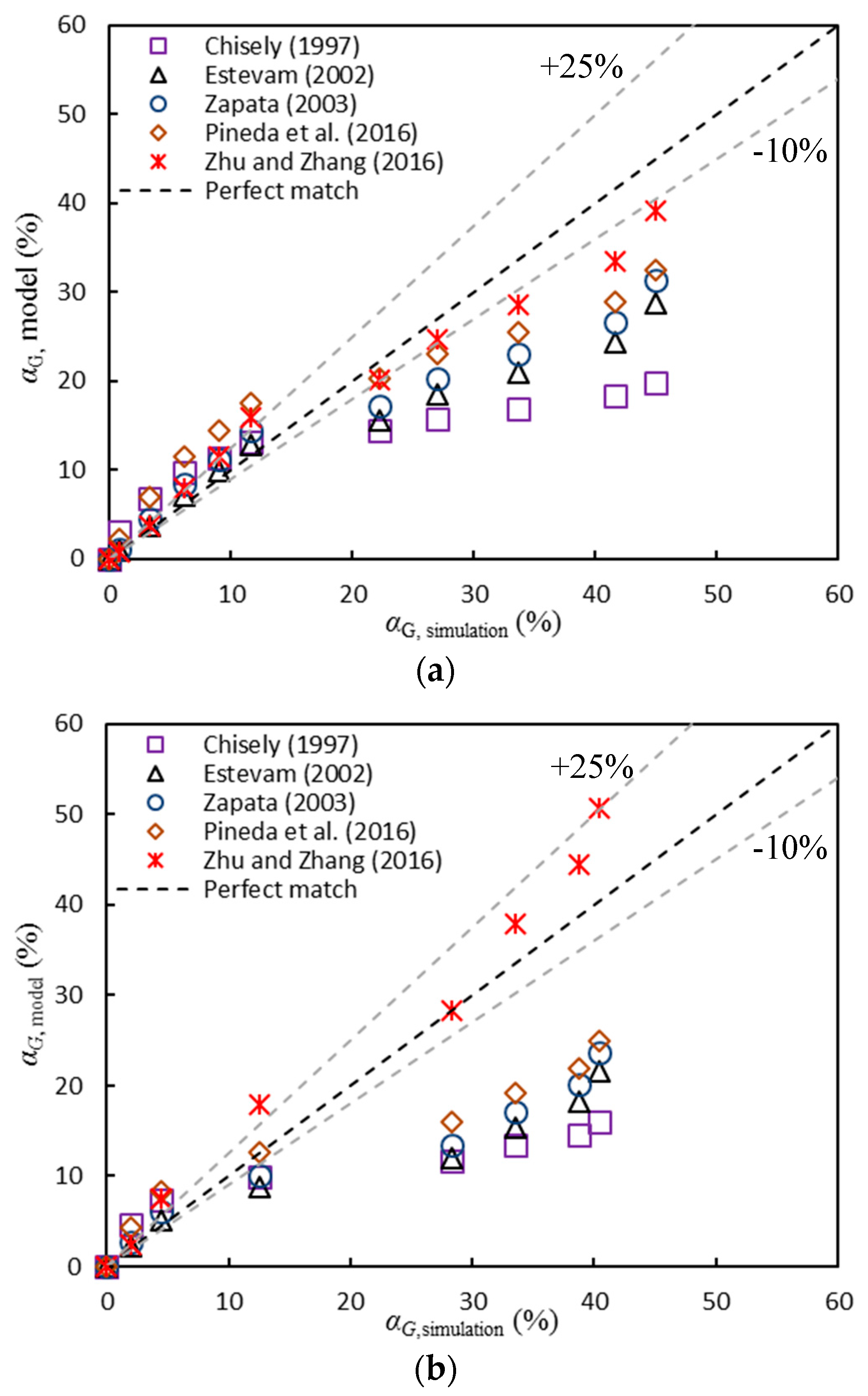

5.3. In-Situ Gas Void Fraction (αG)

6. Conclusions and Future Work

- Experimental visualization of internal two-phase flow structures in a rotating ESP is inadequate, which restricts the flow pattern assessment and the formulations of governing equations. Moreover, the measurement of in-situ gas phase is insufficient, resulting in further difficulty to characterize pump performance quantitatively. Future experimental work should take these challenges into consideration, thus providing in-depth knowledge of multiphase flow mechanisms in ESPs.

- The computational fluid dynamics techniques need to be further developed in order to capture the complex behaviors and movement of gas bubbles inside ESPs and thus better understand the interactions between the gas and liquid phases in different flow patterns.

- The mechanistic models should focus more on the physics of the two-phase flow in rotating ESPs to propose better closure relationships. From the one-dimensional two-fluid model, the simplified mass and momentum conservation equations are solvable with the help of the improved closure relationships in future, ending up with a more accurate and reliable mechanistic model to predict ESP two-phase flow performance.

Acknowledgments

Conflicts of Interest

Nomenclature

| A | area, L2, m2 |

| a | channel length, L, m |

| b | blade thickness, L, m; or channel width, L, m |

| BEP | best efficiency point |

| BHP | brake horsepower, ML2/T3, kg∙m2/s3 |

| C | absolute velocity, L/T, m/s |

| CD | drag coefficient |

| Cm | disk friction coefficient |

| Cp | diffuser loss coefficient |

| d | bubble diameter, L, m |

| D1t | diameter at tip of inlet, L, m |

| Df | diffusion factor |

| DH | hydraulic diameter, L, m |

| Di | impeller diameter, L, m |

| f | friction factor |

| fdisk | disk friction loss coefficient |

| fE | liquid entrainment factor |

| fgeo | shape factor dependent on the impeller diameters and the angle between the sidewall of the rotor and the pump shaft |

| interfacial force vector, M/(LT2), Pa | |

| gravity acceleration vector, L/(T2), m/s2 | |

| GVF | gas volumetric fraction |

| h | channel height, L, m or hydraulic head, L, m |

| H | hydraulic head, L, m or holdup |

| k | turbulent kinetic energy, L2/(T2), m2/s2 |

| kRR | friction factor |

| mass flow rate, M/T, kg/s | |

| M | momentum transfer term per unit volume, M/(L2T2), Pa/m |

| n | phase number |

| N | rotational speed, 1/L, rpm |

| p | pressure, M/(LT2), Pa |

| ΔP | stage pressure increment, M/(LT2), Pa |

| P | pressure, M/(LT2), Pa |

| q | flow rate, L3/T, m3/s |

| Q | mass flow rate, M/T, kg/s |

| r | radius, L, m |

| rH | hydraulic radius, L, m |

| Re | Reynolds number |

| s | streamline, L, m |

| Sr | Strouhal number |

| t | time, T, s |

| T | torque, (ML2)/T2, kg∙m2/s2 |

| phase velocity vector, L/T, m/s | |

| U | peripheral velocity, L/T, m/s |

| v | velocity, L/T, m/s |

| v’ | velocity fluctuation, L/T, m/s |

| V | velocity, L/T, m/s |

| Vol | volume, L3, m3 |

| W | relative velocity in ESP, L/T, m/s |

| We | Weber number |

| x | mass fraction or mole fraction |

| Y | channel height, L, m |

| Z | blade number |

| Greek Symbols | |

| α | gas void fraction, or absolute flow angle formed between the absolute velocity and its tangential component |

| β | tangential blade angle, deg |

| λG | no-slip gas void fraction (GVF) |

| μ | dynamic viscosity, M/(LT), Pa∙s |

| μt | turbulent viscosity, M/(LT), Pa∙s |

| Ω | angular speed, 1/T, rad/s |

| ω | shaft or impeller blades angular velocity, 1/T, rad/s |

| ρ | fluid density, M/L3, kg/m3 |

| σ | surface tension, M/T2, N/m or slip factor |

| stress-strain tensor, M/(LT2), Pa | |

| ε | turbulent energy dissipation rate per unit mass, L2/T3, m2/s3 |

| θ | component of the radial coordinate system |

| Subscripts | |

| 1 | inlet |

| 2 | outlet |

| 32 | Sauter mean diameter |

| B | bubble or blade |

| b_surg | bubble at pressure surging |

| c | continuous phase |

| C | gas core or critical |

| CRIT | critical |

| d | diffuser or dispersed phase or dimensionless parameter |

| D | diffuser |

| eff | effective |

| E | Euler |

| F | film |

| FI | fluid in ESP impeller |

| FD | fluid in ESP diffuser |

| G | gas phase |

| H | hydraulic parameter |

| I | interface or impeller |

| L | liquid phase |

| LF | liquid film |

| M | meridional direction or mixture |

| m | mixture |

| R | radius direction |

| sphere | sphere |

| streamline | projection on streamline |

| S | specific speed or shear or slug body |

| SG | superficial gas |

| SI | impeller channel wall |

| SL | superficial liquid |

| SR | shear in the radial direction |

| U | peripheral direction |

| vm | virtual mass |

| w | water |

| W | wall |

| Units | |

| bpd | barrel per day, 1 bpd ≈ 1.8942 × 10−6 m3/s |

| psi | pound per square inch, 1 psi ≈ 6894.76 pa |

| psia | pound per square inch for absolute pressure |

| psig | pound per square inch for gauge pressure |

References

- Zhu, J. Experiments, CFD Simulation and Modeling of ESP Performance under Gassy Conditions. Ph.D. Thesis, The University of Tulsa, Tulsa, OK, USA, 2017. [Google Scholar]

- Barrios, L.; Rojas, M.; Monteiro, G.; Sleight, N. Brazil field experience of ESP performance with viscous emulsions and high gas using multi-vane pump MVP and high power ESPs. In Proceedings of the SPE Electric Submersible Pump Symposium, The Woodlands, TX, USA, 24–28 April 2017. [Google Scholar]

- Takacs, G. Electrical Submersible Pumps Manual: Design, Operations, and Maintenance; Gulf Professional Publishing: Burlington, NY, USA, 2009. [Google Scholar]

- Oliva, G.B.; Galvão, H.L.; dos Santos, D.P.; Silva, R.E.; Maitelli, A.L.; Costa, R.O.; Maitelli, C.W. Gas effect in electrical-submersible-pump-system stage-by-stage analysis. SPE Prod. Oper. 2017, 32, 294–304. [Google Scholar] [CrossRef]

- Zhou, D.; Sachdeva, R. Simple model of electric submersible pump in gassy well. J. Pet. Sci. Eng. 2010, 70, 204–213. [Google Scholar] [CrossRef]

- Stepanoff, A.J. Centrifugal and Axial Flow Pumps: Theory, Design and Application, 2nd ed.; John Wiley & Sons: New York, NY, USA, 1957. [Google Scholar]

- Vieira, T.S.; Siqueira, J.R.; Bueno, A.D.; Morales, R.E.M.; Estevam, V. Analytical study of pressure losses and fluid viscosity effects on pump performance during monophase flow inside an ESP stage. J. Pet. Sci. Eng. 2015, 127, 245–258. [Google Scholar] [CrossRef]

- Ito, H. Friction factors for turbulent flow in curved pipes. J. Basic Eng. 1959, 81, 123–134. [Google Scholar]

- Jones, O.C. An improvement in the calculation of turbulent friction in rectangular ducts. J. Fluids Eng. 1976, 98, 173–180. [Google Scholar] [CrossRef]

- Churchill, S.W. Friction-factor equation spans all fluid-flow regimes. Chem. Eng. 1977, 84, 91–92. [Google Scholar]

- Shah, R.K. A correlation for laminar hydrodynamic entry length solutions for circular and noncircular ducts. J. Fluids Eng. 1978, 100, 177–179. [Google Scholar] [CrossRef]

- Sun, D. Modeling Gas-Liquid Head Performance of Electrical Submersible Pumps. Ph.D. Thesis, The University of Tulsa, Tulsa, OK, USA, 2003. [Google Scholar]

- Wiesner, F.J. A review of slip factors for centrifugal impellers. J. Eng. Power 1967, 89, 558–566. [Google Scholar] [CrossRef]

- Sun, D.; Prado, M.G. Single-phase model for electric submersible pump (ESP) head performance. SPE J. 2006, 11, 80–88. [Google Scholar] [CrossRef]

- Thin, K.C.; Khaing, M.M.; Aye, K.M. Design and performance analysis of centrifugal pump. World Acad. Sci. Eng. Technol. 2008, 46, 422–429. [Google Scholar]

- Ito, H.; Nanbu, K. Flow in rotating straight pipes of circular cross section. J. Basic Eng. 1971, 93, 383–394. [Google Scholar] [CrossRef]

- Bing, H.; Tan, L.; Cao, S.; Lu, L. Prediction method of impeller performance and analysis of loss mechanism for mixed-flow pump. Sci. China Technol. Sci. 2012, 55, 1988–1998. [Google Scholar] [CrossRef]

- Amaral, G. Single-Phase Flow Modeling of an ESP Operating with Viscous Fluids. Master’s Thesis, State University of Campinas, Campinas, São Paulo, Brazil, 2007. [Google Scholar]

- Gülich, J.F. Pumping highly viscous fluids with centrifugal pumps—Part 1. World Pumps 1999, 395, 30–34. [Google Scholar] [CrossRef]

- Gülich, J.F. Pumping highly viscous fluids with centrifugal pumps—Part 2. World Pumps 1999, 396, 39–42. [Google Scholar] [CrossRef]

- Tuzson, J. Centrifugal Pump Design; John Wiley & Sons: New York, NY, USA, 2000. [Google Scholar]

- Sun, D.; Prado, M.G. Modeling gas-liquid head performance of electric submersible pumps. J. Press. Vessel Technol. 2005, 127, 31–38. [Google Scholar] [CrossRef]

- Van Esch, B.P.M. Simulation of Three-Dimensional Unsteady Flow in Hydraulic Pumps. Master’s Thesis, University of Twente, Enschede, The Netherlands, 1997. [Google Scholar]

- Ladouani, A.; Nemdili, A. Influence of Reynolds number on net positive suction head of centrifugal pumps in relation to disc friction losses. Forsch. Ing. 2009, 73, 173. [Google Scholar] [CrossRef]

- Ippen, A.T. The Influence of Viscosity on Centrifugal Pump Performance; Issue 199 of Fritz Engineering Laboratory Report, ASME Paper No. A-45-57; The American Society of Mechanical Engineers: New York, NY, USA, 1945. [Google Scholar]

- Li, W.G. Experimental investigation of performance of commercial centrifugal oil pump. World Pumps 2002, 425, 26–28. [Google Scholar] [CrossRef]

- Amaral, G.; Estevam, V.; França, F.A. On the influence of viscosity on ESP performance. SPE Prod. Oper. 2009, 24, 303–310. [Google Scholar] [CrossRef]

- Solano, E.A. Viscous Effects on the Performance of Electro Submersible Pumps (ESP’s). Master’s Thesis, The University of Tulsa, Tulsa, OK, USA, 2009. [Google Scholar]

- Barrios, L.J.; Scott, S.L.; Sheth, K.K. ESP technology maturation: Subsea boosting system with high GOR and viscous fluid. In Proceedings of the SPE Annual Technical Conference and Exhibition, San Antonio, TX, USA, 8–10 October 2012. [Google Scholar]

- Banjar, H.M.; Gamboa, J.; Zhang, H.-Q. Experimental study of liquid viscosity effect on two-phase stage performance of electrical submersible pumps. In Proceedings of the SPE Annual Technical Conference and Exhibition, New Orleans, LA, USA, 30 September–2 October 2013. [Google Scholar]

- Murakami, M.; Minemura, K. Effects of entrained air on the performance of a centrifugal pump (1st report, performance and flow conditions). Bull. JSME 1974, 17, 1047–1055. [Google Scholar] [CrossRef]

- Murakami, M.; Minemura, K. Effects of entrained air on the performance of a centrifugal pump (2nd report, effects of number of blades). Bull. JSME 1974, 17, 1286–1295. [Google Scholar] [CrossRef]

- Cirilo, R. Air-Water Flow through Electric Submersible Pumps. Master’s Thesis, The University of Tulsa, Tulsa, OK, USA, 1998. [Google Scholar]

- Romero, M. An Evaluation of an Electric Submersible Pumping System for High GOR Wells. Master’s Thesis, University of Tulsa, Tulsa, OK, USA, 1999. [Google Scholar]

- Pessoa, R. Experimental Investigation of Two-Phase Flow Performance of Electrical Submersible Pump Stages. Master’s Thesis, The University of Tulsa, Tulsa, OK, USA, 2001. [Google Scholar]

- Beltur, R. Experimental Investigation of Two-Phase Flow Performance of ESP Stages. Master’s Thesis, The University of Tulsa, Tulsa, OK, USA, 2003. [Google Scholar]

- Duran, J. Pressure Effects on ESP Stages’ Air-Water Performance. Master’s Thesis, The University of Tulsa, Tulsa, OK, USA, 2003. [Google Scholar]

- Zapata, L. Rotational Speed Effects on ESP Two-Phase Performance. Master’s Thesis, The University of Tulsa, Tulsa, OK, USA, 2003. [Google Scholar]

- Barrios, L. Visualization and Modeling of Multiphase Performance inside an Electrical Submersible Pump. Ph.D. Thesis, The University of Tulsa, Tulsa, OK, USA, 2007. [Google Scholar]

- Gamboa, J. Prediction of the Transition in Two-Phase Performance of an Electrical Submersible Pump. Ph.D. Thesis, The University of Tulsa, Tulsa, OK, USA, 2008. [Google Scholar]

- Trevisan, F.E. Modeling and Visualization of Air and Viscous Liquid in Electrical Submersible Pump. Ph.D. Thesis, The University of Tulsa, Tulsa, OK, USA, 2009. [Google Scholar]

- Salehi, E. ESP Performance in Two-Phase Flow through Mapping and Surging Tests at Various Rotational Speeds and Intake Pressures. Master’s Thesis, The University of Tulsa, Tulsa, OK, USA, 2012. [Google Scholar]

- Croce Mundo, D.D. Study of Water/Oil Flow and Emulsion Formation in Electrical Submersible Pumps. Master’s Thesis, The University of Tulsa, Tulsa, OK, USA, 2014. [Google Scholar]

- Zhu, J.; Zhu, H.; Zhang, J.; Zhang, H.-Q. An experimental study of surfactant effect on gas tolerance in electrical submersible pump (ESP). In Proceedings of the ASME 2017 International Mechanical Engineering Congress and Exposition, Tampa, FL, USA, 3–9 November 2017. [Google Scholar]

- DeGennes, P.-G.; Brochard-Wyart, F.; Quere, D. Capillarity and Wetting Phenomena; Springer: New York, NY, USA, 2004. [Google Scholar]

- Hu, B.; Nienow, A.W.; Stitt, E.H.; Pacek, A.W. Bubble sizes in agitated solvent/reactant mixtures used in heterogeneous catalytic hydrogenation of 2-butyne-1,4-diol. Chem. Eng. Sci. 2006, 61, 6765–6774. [Google Scholar] [CrossRef]

- Omer, A.; Pal, R. Effects of surfactant and water concentrations on pipeline flow of emulsions. Ind. Eng. Chem. Res. 2013, 52, 9099–9105. [Google Scholar] [CrossRef]

- Van Nimwegen, A.T.; Portela, L.M.; Henkes, R.A. The effect of surfactants on vertical air/water flow for prevention of liquid loading. SPE J. 2015, 4, 488–500. [Google Scholar]

- Van Nimwegen, A.T.; Portela, L.M.; Henkes, R.A.W.M. The effect of surfactants on upward air-water pipe flow at various inclinations. Int. J. Multiph. Flow 2016, 78, 132–147. [Google Scholar] [CrossRef]

- Ajani, A.; Kelkar, M.; Sarica, C.; Pereyra, E. Effect of surfactants on liquid loading in vertical wells. Int. J. Multiph. Flow. 2016, 83, 183–201. [Google Scholar] [CrossRef]

- Ajani, A.; Kelkar, M.; Sarica, C.; Pereyra, E. Foam flow in vertical gas wells under liquid loading: Critical velocity and pressure drop prediction. Int. J. Multiph. Flow 2016, 87, 124–135. [Google Scholar] [CrossRef]

- Shoham, O. Mechanistic Modeling of Gas-Liquid Two-Phase Flow in Pipes; Society of Petroleum Engineers: Richardson, TX, USA, 2006. [Google Scholar]

- Parsi, M.; Najmi, K.; Najafifard, F.; Hassani, S.; McLaury, B.S.; Shirazi, S.A. A comprehensive review of solid particle erosion modeling for oil and gas wells and pipelines applications. J. Nat. Gas Sci. Eng. 2014, 21, 850–873. [Google Scholar] [CrossRef]

- Wu, B.; Firouzi, M.; Mitchell, T.; Rufford, T.E.; Leonardi, C.; Towler, B. A critical review of flow maps for gas-liquid flows in vertical pipes and annuli. Chem. Eng. J. 2017, 326, 350–377. [Google Scholar] [CrossRef]

- Taitel, Y.; Bornea, D.; Dukler, A.E. Modelling flow pattern transitions for steady upward gas-liquid flow in vertical tubes. AIChE J. 1980, 26, 345–354. [Google Scholar] [CrossRef]

- Minumura, K.; Murakami, M. A theoretical study on air bubble motion in a centrifugal pump impeller. J. Fluids Eng. 1980, 102, 446–455. [Google Scholar] [CrossRef]

- Patel, B.R. Investigations into the two-phase flow behavior of centrifugal pumps. In Polyphase Flow in Turbomachinery, Proceedings of the ASME Winter Annual Meeting of the American Society of Mechanical Engineering, San Francisco, CA, USA, 10–15 December 1978; The American Society of Mechanical Engineers: New York, NY, USA; pp. 79–100.

- Sekoguchi, K.; Takada, S.; Kanemori, Y. Study of air-water two-phase centrifugal pump by means of electric resistivity probe technique for void fraction measurement: 1st report, measurement of void fraction distribution in a radial flow impeller. Bull. JSME 1984, 27, 931–938. [Google Scholar] [CrossRef]

- Kim, J.H.; Duffey, R.B.; Belloni, P. On centrifugal pump head degradation in two-phase flow. In Design Methods for Two-Phase Flow in Turbomachinery; The American Society of Mechanical Engineers: New York, NY, USA, 1985. [Google Scholar]

- Sato, S.; Furukawa, A.; Takamatsu, Y. Air-water two-phase flow performance of centrifugal pump impellers with various blade angles. JSME Int. J. Ser. B Fluids Therm. Eng. 1996, 39, 223–229. [Google Scholar] [CrossRef]

- Takemura, T.; Kato, H.; Kanno, H.; Okamoto, H.; Aoki, M.; Goto, A.; Egashira, K.; Shoda, S. Development of rotordynamic multiphase pump: The first report. In Proceedings of the International Conference on Offshore Mechanics and Arctic Engineering, Vancouver, BC, Canada, 13–17 April 1997. [Google Scholar]

- Chisely, E.A. Two Phase Flow Centrifugal Pump Performance. Ph.D. Thesis, Idaho State University, Pocatello, ID, USA, 1997. [Google Scholar]

- Suryawijaya, P.; Kosyna, G. Unsteady measurement of static pressure on the impeller blade surfaces and optical observation on centrifugal pumps under varying liquid/gas two-phase flow condition. J. Comput. Appl. Mech. 2001, 6759, D9–D18. [Google Scholar]

- Estevam, V. A Phenomenological Analysis about Centrifugal Pump in Two Phase Flow Operation. Ph.D. Thesis, Universidade Estadual de Campinas, Campinas, Brazil, 2002. [Google Scholar]

- Poullikkas, A. Two phase flow performance of nuclear reactor cooling pumps. Prog. Nucl. Energy 2000, 36, 123–130. [Google Scholar] [CrossRef]

- Thum, D.; Hellmann, D.H.; Sauer, M. Influence of the patterns of liquid-gas flows on multiphase-pumping of radial centrifugal pumps. In Proceedings of the 5th North American Conference on Multiphase Technology, Banff, AB, Canada, 31 May–2 June 2006. [Google Scholar]

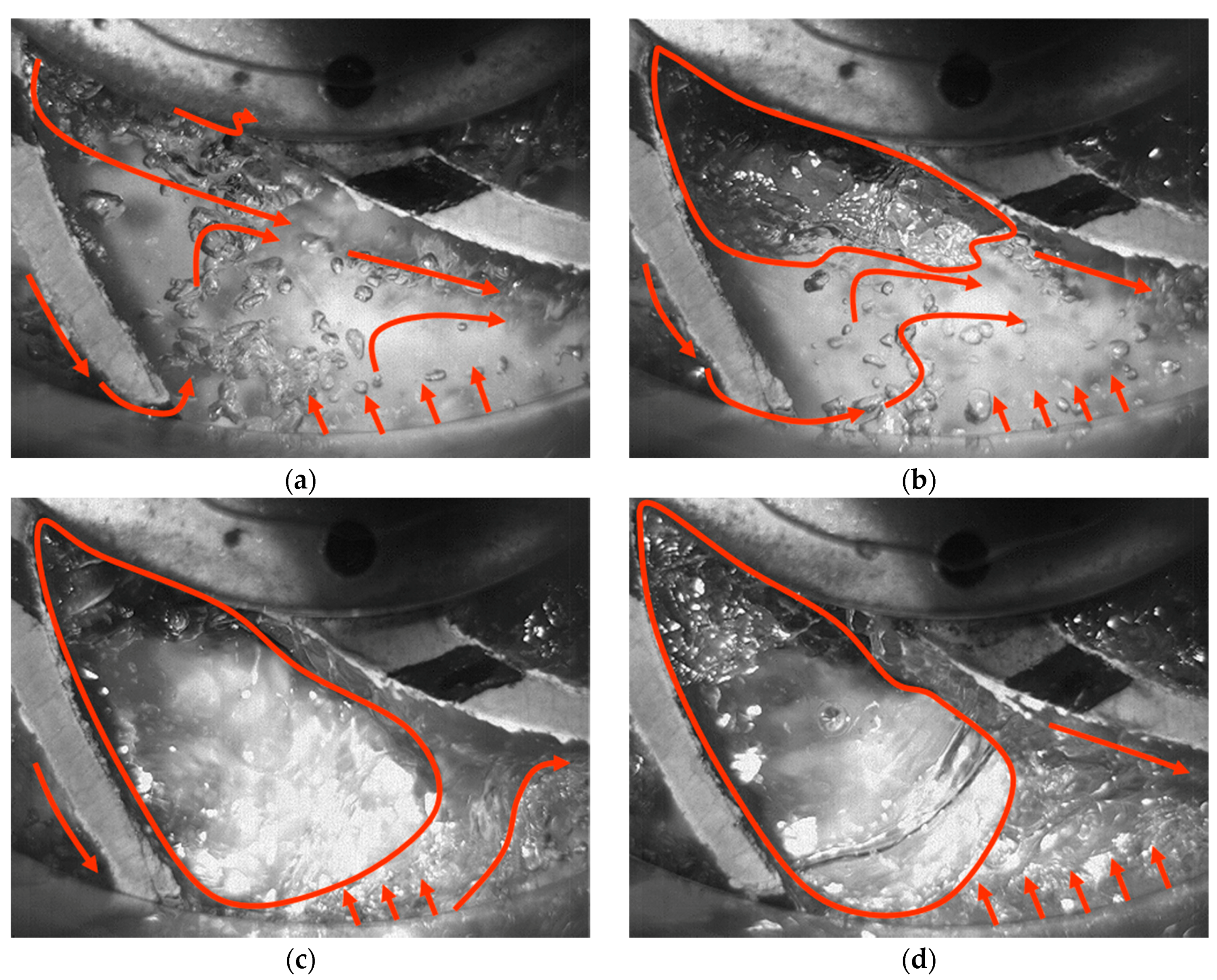

- Barrios, L.; Prado, M.G. Experimental visualization of two-phase flow inside an electrical submersible pump stage. J. Energy Resour. Technol. 2011, 133. [Google Scholar] [CrossRef]

- Schäfer, T.; Bieberle, A.; Neumann, M.; Hampel, U. Application of gamma-ray computed Tomography for the analysis of gas holdup distributions in centrifugal pumps. Flow Meas. Instrum. 2015, 46, 262–267. [Google Scholar] [CrossRef]

- Neumann, M.; Schäfer, T.; Bieberle, A.; Hampel, U. An experimental study on the gas entrainment in horizontally and vertically installed centrifugal pumps. J. Fluids Eng. 2016, 138, 091301. [Google Scholar] [CrossRef]

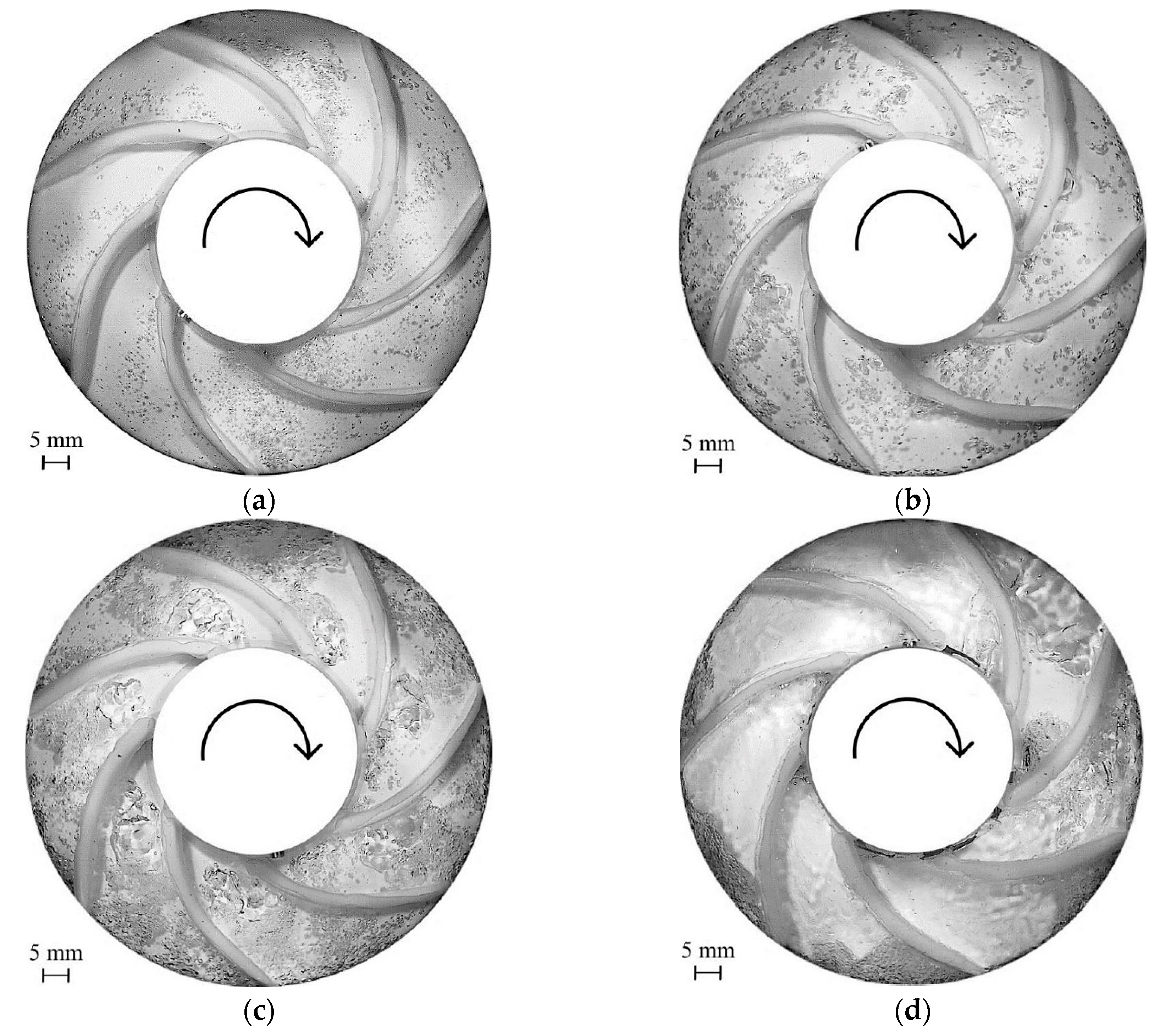

- Verde, W.M.; Biazussi, J.L.; Sassim, N.A.; Bannwart, A.C. Experimental study of gas-liquid two-phase flow patterns within centrifugal pumps impellers. Exp. Therm. Fluid Sci. 2017, 85, 37–51. [Google Scholar] [CrossRef]

- Estevam, V.; França, F.A.; Alhanati, F.J. Mapping the performance of centrifugal pumps under two-phase conditions. In Proceedings of the 17th International Congress of Mechanical Engineering, Sao Paulo, Brazil, 10–14 November 2003. [Google Scholar]

- Gamboa, J.; Prado, M. Review of electrical-submersible-pump surging correlation and models. SPE Prod. Oper. 2011, 26, 314–324. [Google Scholar] [CrossRef]

- Schäfer, T.; Neumann, M.; Bieberle, A.; Hampel, U. Experimental investigations on a common centrifugal pump operating under gas entrainment conditions. Nucl. Eng. Des. 2017, 316, 1–8. [Google Scholar] [CrossRef]

- Bieberle, A.; Schlottke, J.; Spies, A.; Schultheiss, G.; Kühnel, W.; Hampel, U. Hydrodynamics analysis in micro-channels of a viscous coupling using gamma-ray computed tomography. Flow Meas. Instrum. 2015, 45, 288–297. [Google Scholar] [CrossRef]

- Wagner, M.; Bieberle, A.; Bieberle, M.; Hampel, U. Dynamic bias error correction in gamma-ray computed tomography. Flow Meas. Instrum. 2017, 53, 141–146. [Google Scholar] [CrossRef]

- Trevisan, F.; Prado, M. Experimental investigation of the viscous effect on two-phase-flow patterns and hydraulic performance of electrical submersible pumps. J. Can. Pet. Technol. 2011, 50, 45–52. [Google Scholar] [CrossRef]

- Paternost, G.M.; Bannwart, A.C.; Estevam, V. Experimental study of a centrifugal pump handling viscous fluid and two-phase flow. SPE Prod. Oper. 2015, 30, 146–155. [Google Scholar] [CrossRef]

- Turpin, J.L.; Lea, J.F.; Bearden, J.L. Gas-liquid through centrifugal pumps-correlation of Data. In Proceedings of the Third International Pump Symposium, Houston, TX, USA, 20–22 May 1986. [Google Scholar]

- Duran, J.; Prado, M.G. ESP stages air-water two-phase performance—Modeling and experimental data. SPE 120628. Presented at the 2004 SPE ESP Workshop, Houston, TX, USA, 28–30 April 2004. [Google Scholar]

- Zakem, S. Determination of gas accumulation and two-phase slip velocity ratio in a rotating impeller. In Polyphase Flow and Transportation Technology, Proceedings of the ASME Century 2 Emerging Technology Conference, San Francisco, CA, USA, 13–15 August 1980; The American Society of Mechanical Engineers: New York, NY, USA; Volume 12, pp. 167–173.

- Furuya, O. Analytical model for prediction of two-phase (noncondensable) flow pump performance. J. Fluids Eng. 1985, 107, 139–147. [Google Scholar] [CrossRef]

- Sachdeva, R. Two-Phase Flow through Electric Submersible Pumps. Ph.D. Thesis, The University of Tulsa, Tulsa, OK, USA, 1988. [Google Scholar]

- Sachdeva, R.; Doty, D.R.; Schmidt, Z. Performance of electric submersible pumps in gassy wells. SPE Prod. Facil. 1994, 2, 55–60. [Google Scholar] [CrossRef]

- Minemura, K.; Uchiyama, T.; Shoda, S.; Kazuyuki, E. Prediction of air-water two-phase flow performance of a centrifugal pump based on one-dimensional two-fluid model. J. Fluids Eng. 1998, 120, 327–334. [Google Scholar] [CrossRef]

- Gao, C.; Gray, K.E. The development of a coupled geomechanics and reservoir simulator using a staggered grid finite difference approach. In Proceedings of the SPE Annual Technical Conference and Exhibition, San Antonio, TX, USA, 7–12 October 2017. [Google Scholar]

- Asuaje, M.; Bakir, F.; Kouidri, S.; Kenyery, F.; Rey, R. Numerical modelization of the flow in centrifugal pump: Volute influence in velocity and pressure fields. Int. J. Rotating Mach. 2005, 3, 244–255. [Google Scholar] [CrossRef]

- Maitelli, C.; Bezerra, V.; Da Mata, W. Simulation of flow in a centrifugal pump of ESP systems using computational fluid dynamics. Braz. J. Pet. Gas 2010, 4, 1–9. [Google Scholar]

- Rajendran, S.; Purushothaman, K. Analysis of a centrifugal pump impeller using ANSYS-CFX. Int. J. Eng. Res. Technol. 2012, 1, 1–6. [Google Scholar]

- Cheah, K.W.; Lee, T.S.; Winoto, S.H.; Zhao, Z.M. Numerical flow simulation in a centrifugal pump at design and off-design conditions. Int. J. Rotating Mach. 2007. [Google Scholar] [CrossRef]

- Zhu, J.; Zhang, H.-Q. Mechanistic modeling and numerical simulation of in-situ gas void fraction inside ESP impeller. J. Nat. Gas Sci. Eng. 2016, 36, 144–154. [Google Scholar] [CrossRef]

- Gonzalez, J.; Fernandez, J.; Blanco, E.; Santolaria, C. Numerical simulation of the dynamic effects due to impeller-volute interaction in a centrifugal pump. J. Fluids Eng. 2002, 124, 348–355. [Google Scholar] [CrossRef]

- Gonzalez, J.; Santolaria, C. Unsteady flow structure and global variables in a centrifugal pump. J. Fluids Eng. 2006, 128, 937–946. [Google Scholar] [CrossRef]

- Huang, S.; Mohamad, A.A.; Nandakumar, K.; Ruan, Z.Y.; Sang, D.K. Numerical simulation of unsteady flow in a multistage centrifugal pump using sliding mesh technique. Prog. Comput. Fluid Dyn. 2010, 10, 239–245. [Google Scholar] [CrossRef]

- Huang, S.; Su, X.; Guo, J.; Yue, L. Unsteady numerical simulation for gas-liquid two-phase flow in self-priming process of centrifugal pump. Energy Convers. Manag. 2014, 85, 694–700. [Google Scholar] [CrossRef]

- Shojaeefard, M.H.; Tahani, M.; Ehghaghi, M.B.; Fallahian, M.A.; Beglari, M. Numerical study of the effects of some geometric characteristics of a centrifugal pump impeller that pumps a viscous fluid. Comput. Fluids 2012, 60, 61–70. [Google Scholar] [CrossRef]

- Shojaeefard, M.H.; Boyaghchi, F.A.; Ehghaghi, M.B. Experimental study and three-dimensional numerical flow simulation in a centrifugal pump when handling viscous fluids. IUST Int. J. Eng. Sci. 2006, 17, 53–60. [Google Scholar]

- Sirino, T.; Stel, H.; Morales, R.E. Numerical study of the influence of viscosity on the performance of an electrical submersible pump. In Proceedings of the ASME 2013 Fluids Engineering Division Summer Meeting, Incline Village, NV, USA, 7–11 July 2013. [Google Scholar]

- Stel, H.; Sirino, T.; Prohmann, P.R.; Ponce, F.; Chiva, S.; Morales, R.E. CFD investigation of the effect of viscosity on a three-stage electric submersible pump. In Proceedings of the ASME 2014 4th Joint US-European Fluids Engineering Division Summer Meeting Collocated with the ASME 2014 12th International Conference on Nanochannels, Microchannels, and Minichannels, Chicago, IL, USA, 3–7 August 2014. [Google Scholar]

- Stel, H.; Sirino, T.; Ponce, F.J.; Chiva, S.; Morales, R.E.M. Numerical investigation of the flow in a multistage electric submersible pump. J. Pet. Sci. Eng. 2015, 136, 41–54. [Google Scholar] [CrossRef]

- Li, W.G. Mechanism for onset of sudden-rising head effect in centrifugal pump when handling viscous oils. J. Fluids Eng. 2014, 136. [Google Scholar] [CrossRef]

- Flores, N.G.; Goncalves, E.; Rolland, J.; Rebattet, C. Head drop of a spatial turbopump inducer. J. Fluids Eng. 2008, 130. [Google Scholar] [CrossRef]

- Jeanty, F.; De Andrade, J.; Asuaje, M.; Kenyery, F.; Vásquez, A.; Aguillón, O.; Tremante, A. Numerical simulation of cavitation phenomena in a centrifugal pump. In Proceedings of the ASME 2009 Fluids Engineering Division Summer Meeting, Vail, CO, USA, 2–6 August 2009; pp. 331–338. [Google Scholar]

- Barrios, L.; Prado, M.G.; Kenyery, F. CFD modeling inside an electrical submersible pump in two-Phase flow condition. In Proceedings of the ASME 2009 Fluids Engineering Division Summer Meeting, Vail, CO, USA, 2–6 August 2009; Volume 1, pp. 457–469. [Google Scholar]

- Zhu, J.; Zhang, H.-Q. CFD simulation of ESP performance and bubble size estimation under gassy conditions. In Proceedings of the SPE Annual Technical Conference and Exhibition, Amsterdam, The Netherlands, 29 October 2014. [Google Scholar]

- Zhu, J.; Zhang, H.-Q. Numerical study on electrical-submersible-pump two-phase performance and bubble-size modeling. SPE Prod. Oper. 2017, 32, 267–278. [Google Scholar] [CrossRef]

- Minemura, K.; Uchiyama, T. Three-dimensional calculation of air-water two-phase flow in centrifugal pump impeller based on a bubbly flow model. J. Fluids Eng. 1993, 115, 766–771. [Google Scholar] [CrossRef]

- Tremante, A.; Moreno, N.; Rey, R.; Noguera, R. Numerical turbulent simulation of the two-phase flow (liquid/gas) through a cascade of an axial pump. J. Fluids Eng. 2002, 124, 371–376. [Google Scholar] [CrossRef]

- Caridad, J.; Kenyery, F. CFD analysis of electric submersible pumps (ESP) handling two-phase mixtures. J. Energy Resour. Technol. 2004, 126, 99–104. [Google Scholar] [CrossRef]

- Caridad, J.; Asuaje, M.; Kenyery, F.; Tremante, A.; Aguillón, O. Characterization of a centrifugal pump impeller under two-phase flow conditions. J. Pet. Sci. Eng. 2008, 63, 18–22. [Google Scholar] [CrossRef]

- Qi, X.; Turnquist, N.; Ghasripoor, F. Advanced electric submersible pump design tool for geothermal applications. GRC Trans. 2012, 36, 543–548. [Google Scholar]

- Marsis, E.; Pirouzpanah, S.; Morrison, G. CFD-based design improvement for single-phase and two-phase flows inside an electrical submersible pump. In Proceedings of the ASME 2013 Fluids Engineering Division Summer Meeting, Incline Village, NV, USA, 7–11 July 2013. [Google Scholar]

- Yu, Z.; Zhu, B.; Cao, S. Interphase force analysis for air-water bubbly flow in a multiphase rotodynamic pump. Eng. Comput. 2015, 32, 2166–2180. [Google Scholar] [CrossRef]

- Yu, Z.Y.; Zhu, B.S.; Cao, S.L.; Wang, G.Y. Application of two-fluid model in the unsteady flow simulation for a multiphase rotodynamic pump. In Proceedings of the IOP Conference Series: Materials Science and Engineering, Kuala Lumpur, Malaysia, 2–4 July 2013; p. 52. [Google Scholar]

- Pineda, H.; Biazussi, J.; López, F.; Oliveira, B.; Carvalho, R.D.; Bannwart, A.C.; Ratkovich, N. Phase distribution analysis in an Electrical Submersible Pump (ESP) inlet handling water-air two-phase flow using Computational Fluid Dynamics (CFD). J. Pet. Sci. Eng. 2016, 139, 49–61. [Google Scholar] [CrossRef]

- Zhang, H.-Q.; Wang, Q.; Sarica, C.; Brill, J.P. Unified model for gas-liquid pipe flow via slug dynamics—Part 1: Model development. J. Energy Resour. Technol. 2003, 125, 266–273. [Google Scholar] [CrossRef]

- Zhang, H.-Q.; Wang, Q.; Sarica, C.; Brill, J.P. Unified model for gas-liquid pipe flow via slug dynamics—Part 2: Model validation. J. Energy Resour. Technol. 2003, 125, 274–283. [Google Scholar] [CrossRef]

- Ye, Z.; Rutter, R.; Martinez, I.; Marsis, E. CFD and FEA-Based, 3D metal printing hybrid stage prototype on electric submersible pump ESP system for high-gas wells. In Proceedings of the SPE North America Artificial Lift Conference and Exhibition. Society of Petroleum Engineers, Woodlands, TX, USA, 25–27 October 2016. [Google Scholar]

- Zhang, H.-Q.; Wang, Q.; Sarica, C.; Brill, J.P. A unified mechanistic model for slug liquid holdup and transition between slug and dispersed bubble flows. Int. J. Multiph. Flow 2003, 29, 97–107. [Google Scholar] [CrossRef]

- Zhang, H.-Q.; Wang, Q.; Sarica, C.; Brill, J.P. Unified model of heat transfer in gas-liquid pipe flow. In Proceedings of the SPE Annual Technical Conference and Exhibition, Houston, TX, USA, 26–29 September 2004. [Google Scholar]

- Zhang, H.-Q.; Sarica, C. Unified modeling of gas/oil/water pipe flow-basic approaches and preliminary validation. SPE Proj. Facil. Constr. 2006, 1, 1–7. [Google Scholar] [CrossRef]

- Padron, G.A. Effect of Surfactants on Drop Size Distributions in a Batch, Rotor-Stator Mixer. Ph.D. Thesis, University of Maryland, College Park, MD, USA, 2004. [Google Scholar]

- Zhu, J.; Guo, X.; Liang, F.; Zhang, H.-Q. Experimental study and mechanistic modeling of pressure surging in electrical submersible pump. J. Nat. Gas Sci. Eng. 2017, 45, 625–636. [Google Scholar] [CrossRef]

- Hinze, J.O. Fundamentals of the hydrodynamic mechanism of splitting in dispersion processes. AIChE J. 1955, 1, 289–295. [Google Scholar] [CrossRef]

- Levich, V. Physicochemical Hydrodynamics, 1st ed.; Prentice Hall: Upper Saddle River, NJ, USA, 1962. [Google Scholar]

- Kouba, G.E. Mechanistic models for droplet formation and breakup. In Proceedings of the ASME/JSME 2003 4th Joint Fluids Summer Engineering Conference, Honolulu, HI, USA, 6–10 July 2003; Volume 1, pp. 1607–1615. [Google Scholar]

- Schiller, L.; Naumann, A. Fundamental calculations in gravitational processing. Z. Ver. Dtsch. Ing. 1933, 77, 318–320. [Google Scholar]

- Clift, R.; Grace, J.; Weber, M. Bubbles, Drops, and Particles; Academic Press: New York, NY, USA, 1978. [Google Scholar]

- Ishii, M.; Zuber, N. Drag coefficient and relative velocity in bubbly, droplet or particulate flows. AIChE J. 1979, 25, 843–855. [Google Scholar] [CrossRef]

- Mei, R.; Klausner, J.F.; Lawrence, C.J. A note on the history force on a spherical bubble at finite Reynolds number. Phys. Fluids 1994, 6, 418–420. [Google Scholar] [CrossRef]

- Tran-Cong, S.; Gay, M.; Michaelides, E.E. Drag coefficients of irregularly shaped particles. Powder Technol. 2004, 139, 21–32. [Google Scholar] [CrossRef]

- Van Nierop, E.A.; Luther, S.; Bluemink, J.J.; Magnaudet, J.; Prosperetti, A.; Lohse, D. Drag and lift forces on bubbles in a rotating flow. J. Fluid Mech. 2007, 571, 439–454. [Google Scholar] [CrossRef]

- Legendre, D.; Magnaudet, J. The lift force on a spherical bubble in a viscous linear shear flow. J. Fluid Mech. 1998, 368, 81–126. [Google Scholar] [CrossRef]

- Rastello, M.; Marié, J.L.; Grosjean, N.; Lance, M. Drag and lift forces on interface-contaminated bubbles spinning in a rotating flow. J. Fluid Mech. 2009, 624, 159–178. [Google Scholar] [CrossRef]

- Rastello, M.; Marié, J.L.; Lance, M. Drag and lift forces on clean spherical and ellipsoidal bubbles in a solid-body rotating flow. J. Fluid Mech. 2011, 682, 434–459. [Google Scholar] [CrossRef]

| Reference | Model | Coefficient |

|---|---|---|

| Ito [8], Jones [9], Churchill [10], Shah [11], Sun [12] | ||

| Wiesner [13], Sun and Prado [14], Thin et al. [15] | b2—constant | |

| Ito and Nanbu [16], Bing et al. [17] | ||

| Zhu [1] | fFI—empirical constant |

| Reference | Model | Coefficient |

|---|---|---|

| Stepanoff [6], Amaral [18] Thin et al. [15] | kshock—empirical constant | |

| Wiesner [13] Sun and Prado [14] Thin et al. [15] | ||

| Zhu [1] | fTI—empirical constant |

| Reference | Model | Coefficient |

|---|---|---|

| Bing et al. [17] | ||

| Zhu [1] | fLK—empirical constant |

| Reference | Model | Coefficient |

|---|---|---|

| Gulich [19,20] | ||

| Sun and Prado [14], Bing et al. [17] | | |

| Tuzson [21], Thin et al. [15] | Q > QBEP Q ≤ QBEP | |

| Zhu [1] | C2E—effective outlet velocity |

| Reference | Model | Coefficient |

|---|---|---|

| Ito [8], Jones [9], Churchill [10], Shah [11], Sun [12] | ||

| Sun and Prado [14], Bing et al. [17] | ||

| Amaral [18] | | |

| Reference | Model | Coefficient |

|---|---|---|

| Sun and Prado [14] Amaral [18] | ||

| Thin et al. [15] | ||

| Van Esch [23] | cm—empirical constant | |

| Gulich [19,20] Ladouani [24] | |

| Study | Content | Pump | Fluid |

|---|---|---|---|

| Cirilo [33] | Compare two-phase flow performance of three different ESPs | GN4000 GN7000 | Air/water |

| Romero [34] | ESP gas-liquid performance with an advanced gas handler installed upstream | GN4000 | Air/water |

| Pessoa [35] | Measure stage-by-stage pump pressure increment of a multistage ESP | GC6100 | Air/water |

| Beltur [36] | Investigate pressure surging in ESP and affecting factors | GC6100 | Air/water |

| Duran [37] | Correlate experimental data of ESP two-phase performance | GC6100 | Air/water |

| Zapata [38] | Investigate pump rotational speed effect on ESP two-phase performance | GC6100 | Air/water |

| Barrios [39] | Visualize the internal flow of a 2nd stage ESP under gas/liquid flow conditions | GC6100 | Air/water |

| Gamboa [40] | Visualize ESP two-phase flow pattern using a similar pump prototype as Barrios [ 37] | GC6100 | Air/water |

| Trevisan [41] | Visualize ESP internal flow under air/viscous-liquid flow | GC6100 | Air/oil visualization |

| Banjar [30] | Investigate ESP performance with air/oil flow | DN1750 | Air/oil |

| Salehi [42] | Investigate ESP gas/liquid performance with various flow conditions | TE2700 | Air/water |

| Croce [43] | Investigate ESP performance with water/oil emulsion flow | DN1750 | Oil/water Emulsion |

| Zhu [1] | Investigate ESP gas/liquid flow performance with/without surfactant injections | TE2700 | Air/water Surfactant |

| Study | Approach | Observation |

|---|---|---|

| Murakami and Minemura [31,32,56] | Transparent casing | 1st study that associated pump perfor-mance with gas-liquid flow pattern inside an impeller |

| Patel & Runstadler [57] | Transparent casing | Small bubble flow and stationary large bubble coinciding with significant reduction of pump head |

| Sekoguchi et al. [58] | Transparent casing electric resistivity probe | The evolvement of dispersed bubble to slug flow and a large gas pocket |

| Kim et al. [59] | Transparent casing | Phase slippage leads to bubble agglomeration |

| Sato et al. [60] | Transparent casing | Bubble flow to separated flow as gas flow rate increases |

| Takemura et al. [61] | Transparent casing | Bubble accumulation coincided with large pressure gradient |

| Chisely [62] | Transparent casing | Gas filled space starts to develop at the suction pipe of the pump |

| Suryawijaya et al. [63] | Transparent casing | Bubble accumulates at pressure side of impeller blade |

| Estevam [64] | Transparent casing | 1st study of flow patterns in ESP |

| Poullikkas [65] | Transparent casing | Gas bubbles, gas pocket and blockage of pump flow |

| Thum et al. [66] | Transparent casing | Larger accumulation of bubbles is observed at pressure side than suction side, four flow patterns: bubble, plug, slug and stratified flow |

| Barrios [39,67] | Transparent casing | Bubbly flow and segregated flow are observed |

| Gamboa [40] | Transparent casing | 1st study of flow pattern map in ESP impeller |

| Schäfer et al. [68] | HireCT, non-intrusive | Measurement of gas void distribution in multiphase centrifugal pump |

| Neumann et al. [69] | HireCT, non-intrusive | Measurement of gas void distribution in multiphase centrifugal pump |

| Verde et al. [70] | Transparent casing | Flow patterns in ESP: bubble, agglomerated bubble, gas pocket, segregated flow |

| Study | Correlation | Application Range |

|---|---|---|

| Turpin et al. [78] | —empirical constant Pi < 2.8 mPa | |

| Cirilo [33] | Pi < 3.4 mPa QL < 0.02 m3/s | |

| Estevam [64] | ||

| Duran [37] | Pi < 2.4 mPa QG < 0.02 m3/s QL < 0.013 m3/s | |

| Zapata [38] | Pi < 1.4 mPa QG < 0.02 m3/s QL < 0.016 m3/s | |

| Gamboa and Prado [72] | Pi < 1.7 mPa | |

| Zhu et al. [44] |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhu, J.; Zhang, H.-Q. A Review of Experiments and Modeling of Gas-Liquid Flow in Electrical Submersible Pumps. Energies 2018, 11, 180. https://doi.org/10.3390/en11010180

Zhu J, Zhang H-Q. A Review of Experiments and Modeling of Gas-Liquid Flow in Electrical Submersible Pumps. Energies. 2018; 11(1):180. https://doi.org/10.3390/en11010180

Chicago/Turabian StyleZhu, Jianjun, and Hong-Quan Zhang. 2018. "A Review of Experiments and Modeling of Gas-Liquid Flow in Electrical Submersible Pumps" Energies 11, no. 1: 180. https://doi.org/10.3390/en11010180

APA StyleZhu, J., & Zhang, H.-Q. (2018). A Review of Experiments and Modeling of Gas-Liquid Flow in Electrical Submersible Pumps. Energies, 11(1), 180. https://doi.org/10.3390/en11010180