Energy Consumption Optimization and User Comfort Management in Residential Buildings Using a Bat Algorithm and Fuzzy Logic

Abstract

:1. Introduction

2. Related Work

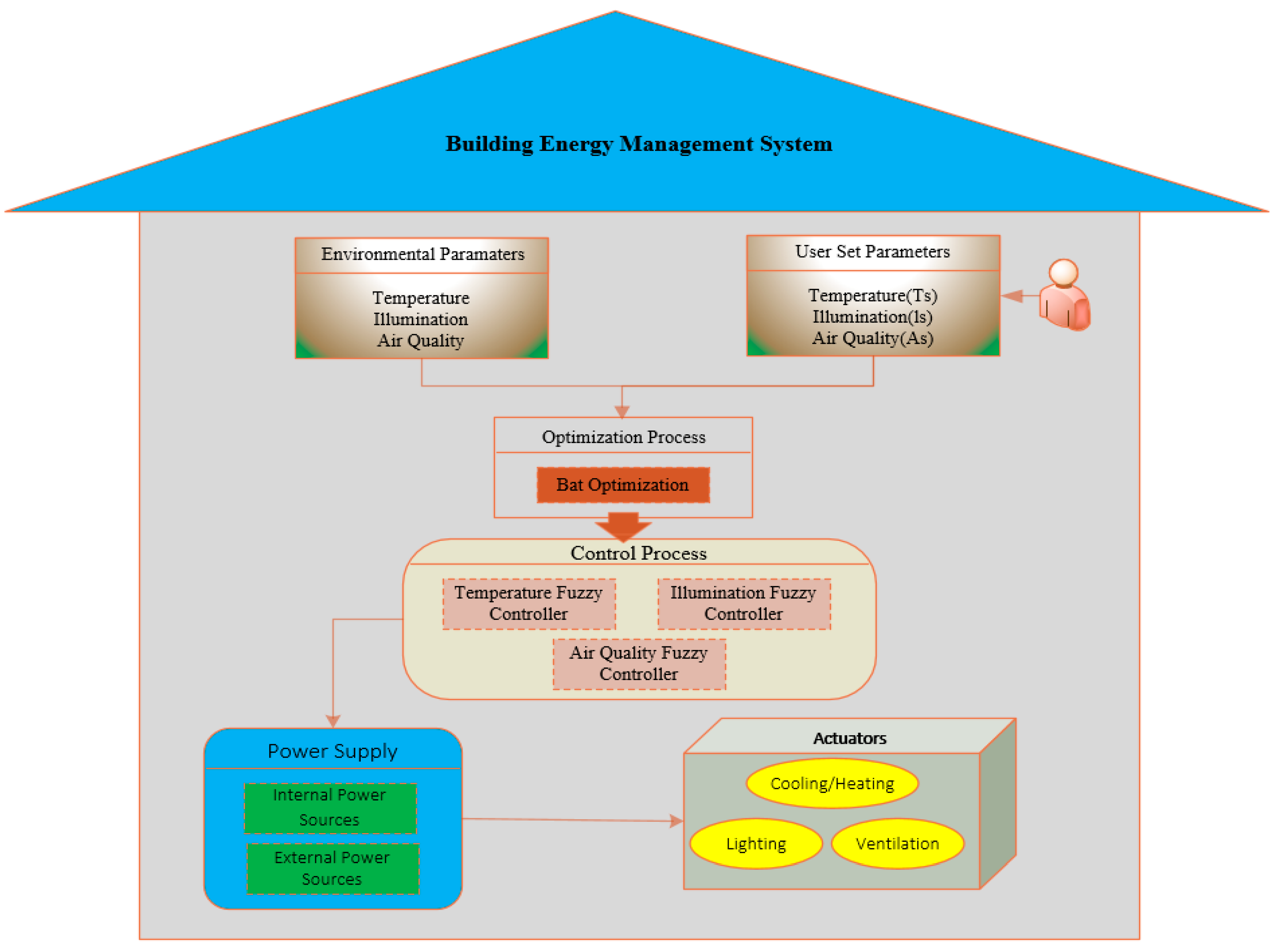

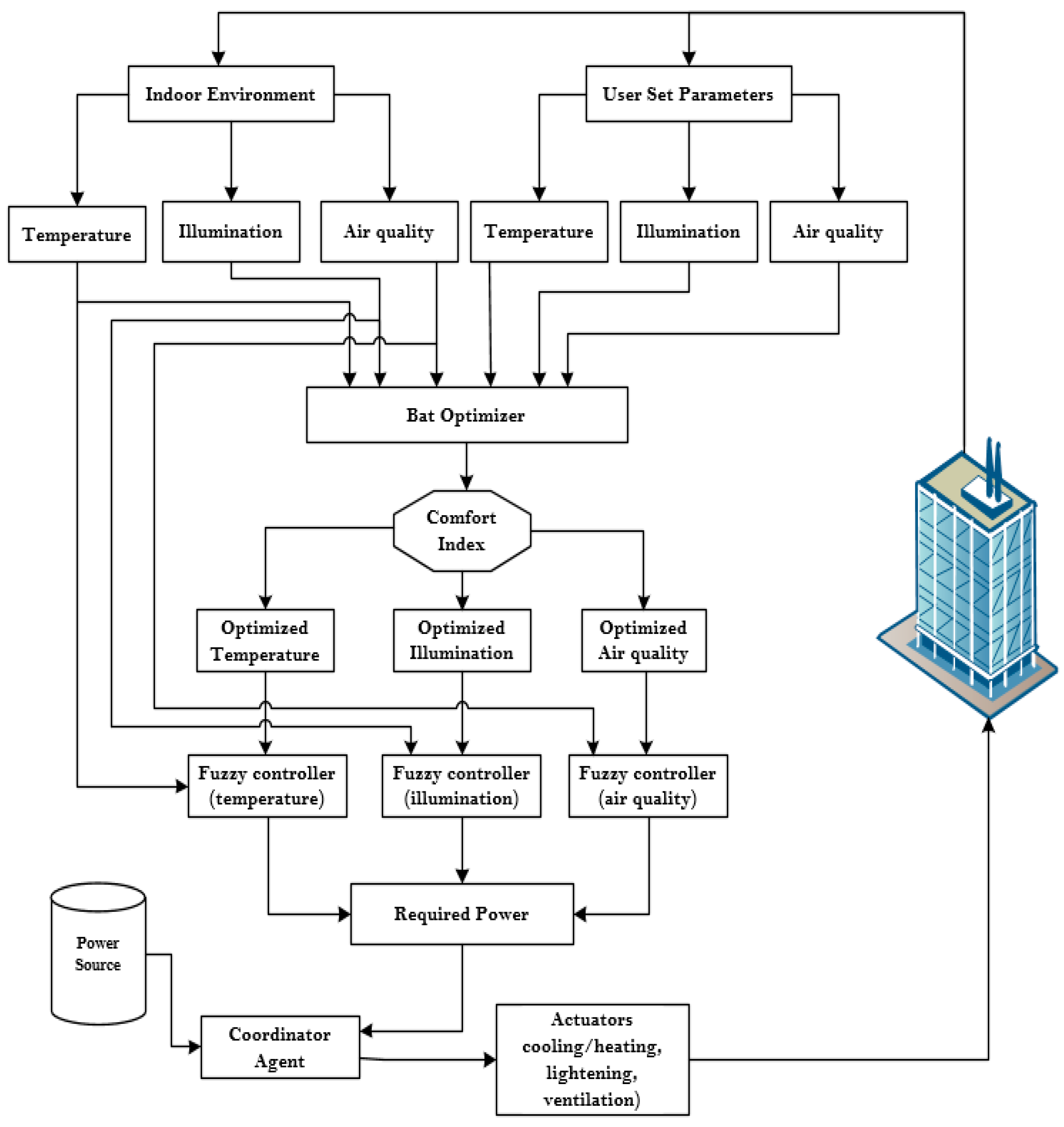

3. Proposed Methodology

3.1. Optimization Using Bat Algorithm

- (1)

- For the distance sensing all bats use echolocation and they have also the potential to distinguish the difference between background barriers and food/prey in some dreamlike way.

- (2)

- Bats fly in a random manner with velocity at position with a fixed frequency f varying wavelength ʎ and loudness to search for prey. They have the ability to regulate the wavelength of their emitted pulses automatically and adjust the rate of pulse emission r in the range [0, 1], depending on the proximity of their target.

- (3)

- While the loudness can vary in numerous ways, we undertake that the loudness ranges from a huge to a smallest constant value .

- BA implementation is simple and required less programming efforts.

- BA is flexible and has the ability to provide the solution for almost all optimization problems [31].

- The deployment of the BA algorithm has been done in numerous areas of optimization, such as classification, feature selection, scheduling, data mining, etc. [31].

- (1)

- Number of parameters (D): This indicates the size of the parameters that need to be optimized. Here in this study we have three parameters to be optimized which are temperature (T), illumination (L) and air quality (A).

- (2)

- Upper bound (UBi): UBi indicates the upper bounds of parameters i, where i = 1, 2, D and D indicates the total size of parameters of desired optimization. The upper bound for temperature (Tmax), illumination (Lmax) and air quality (Amax) are 78, 880 and 880 respectively.

- (3)

- Lower bound (LBi): LBi indicates the lower bounds of parameters i, where i = 1, 2, D and D indicates the total size of parameters that need to be optimized. Here the lower bound for temperature (Tmin), illumination (Lmin) and air quality () is 68, 720 and 700, respectively.

- (4)

- Population size: It represents the total number of solutions in search space. The population size lies from 10 to 40.

- (5)

- Number of generations: It represents the number iteration circles in the bat algorithm. The algorithm has been tried for the different number of generation to discover the ideal generation size to find the preeminent performance result.

- (6)

- Loudness (A0) and Pulse rate (r0) initialization: Both loudness and pulse rate are initially set to 0.5, where the pulse emission is represented loudness A0 is used to search for prey.

- (1)

- Adjusting the frequency: the frequency is adjusted by using the Equation (1):where ∊ (0, 1) represents the uniform distribution. In implementation, the is set 0 and to 1, hence initially the frequency is assigned randomly by each bat with uniform distribution in [, ].

- (2)

- Updating the velocity: the velocity is updated by using the Equation (2):where represents the new velocity of bat i at the time step t, and signifies the existing global top solution. The frequency of ith is used for adjusting the velocity for movement of bats to position.

- (3)

- Updating the locations/solutions: The location updating carried out by using Equation (3):where is the new position of the bat, is the current position of the bat. The new solution is generated by updating the velocity, and adjusting the frequency.

- (1)

- Best solution selection: the best solution is chosen among all current best solutions.

- (2)

- Generation of the local solution around the best solution: The selection of the best solution is carried out around the best solution using Equation (4):where is an arbitrary lie between [1, −1] and represent the average loudness of entire bats in iteration t.

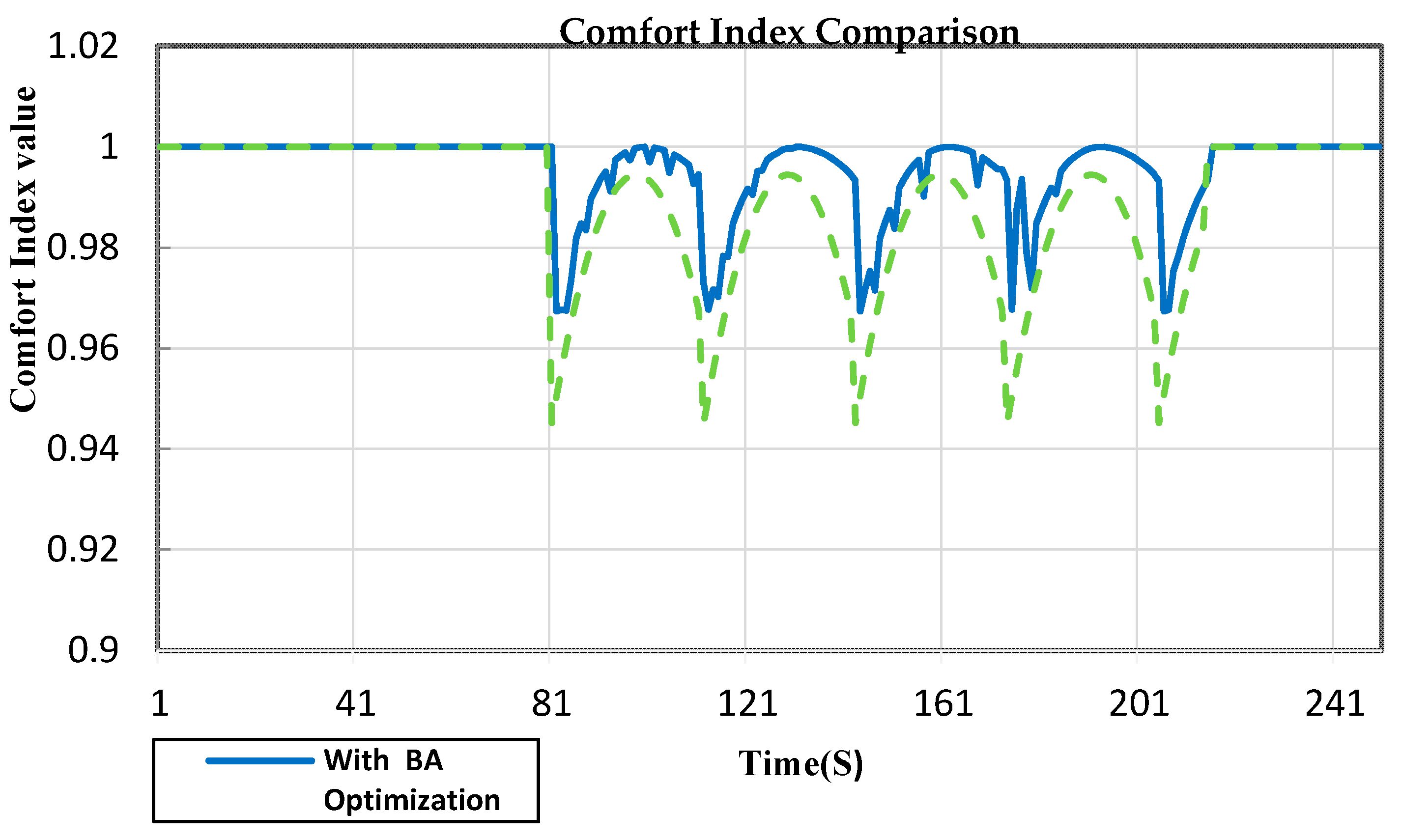

3.2. Comfort Index

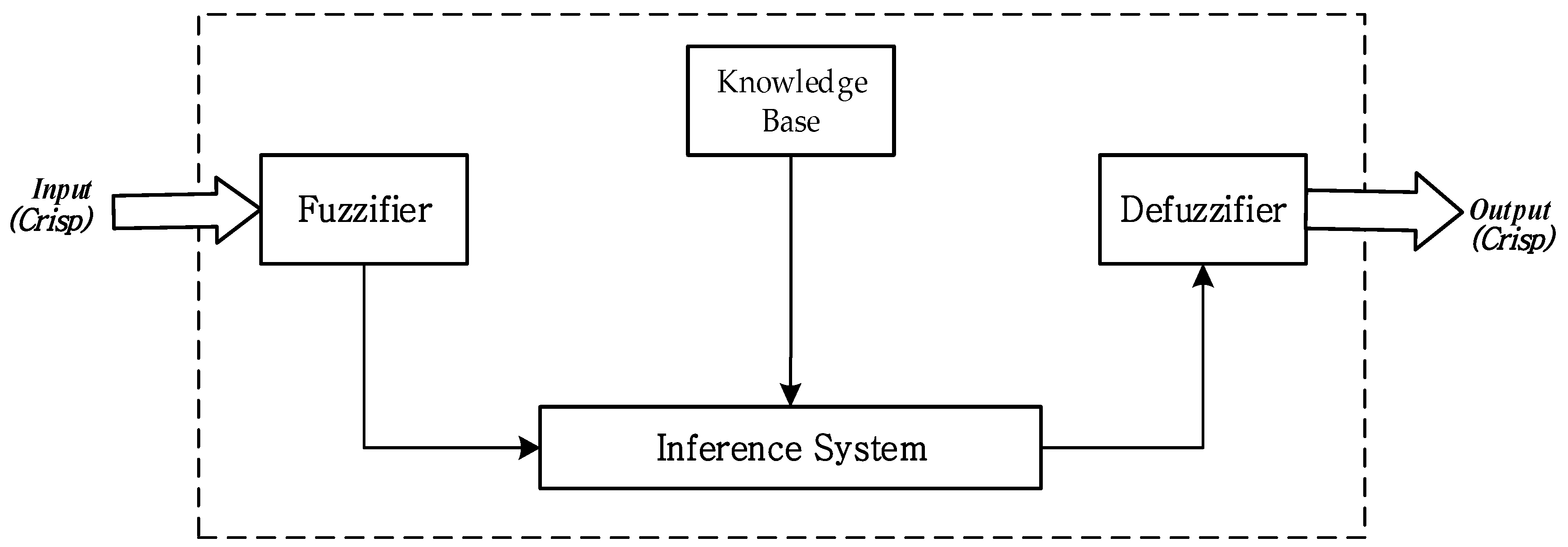

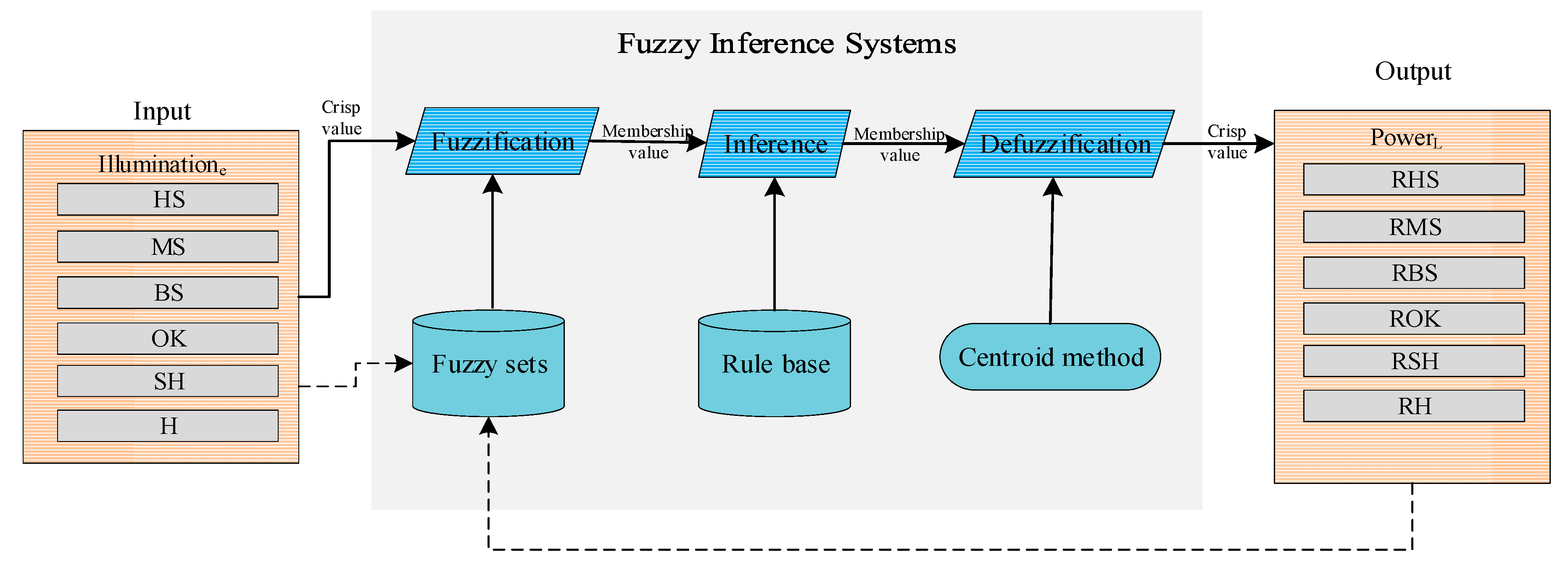

3.3. Fuzzy Controllers

3.4. Coordinator Agent

3.5. Building Actuators

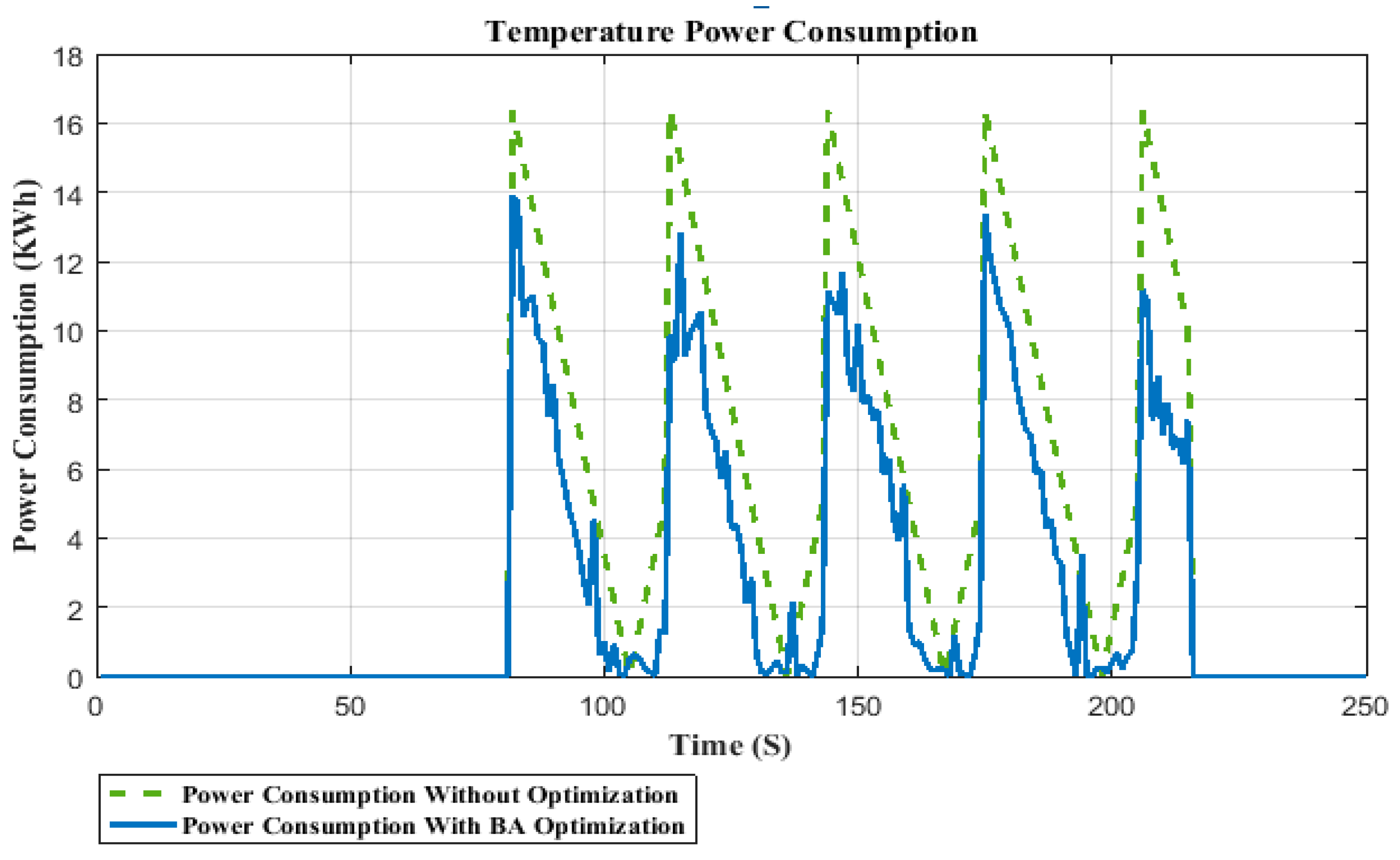

4. Experimental Results and Discussion

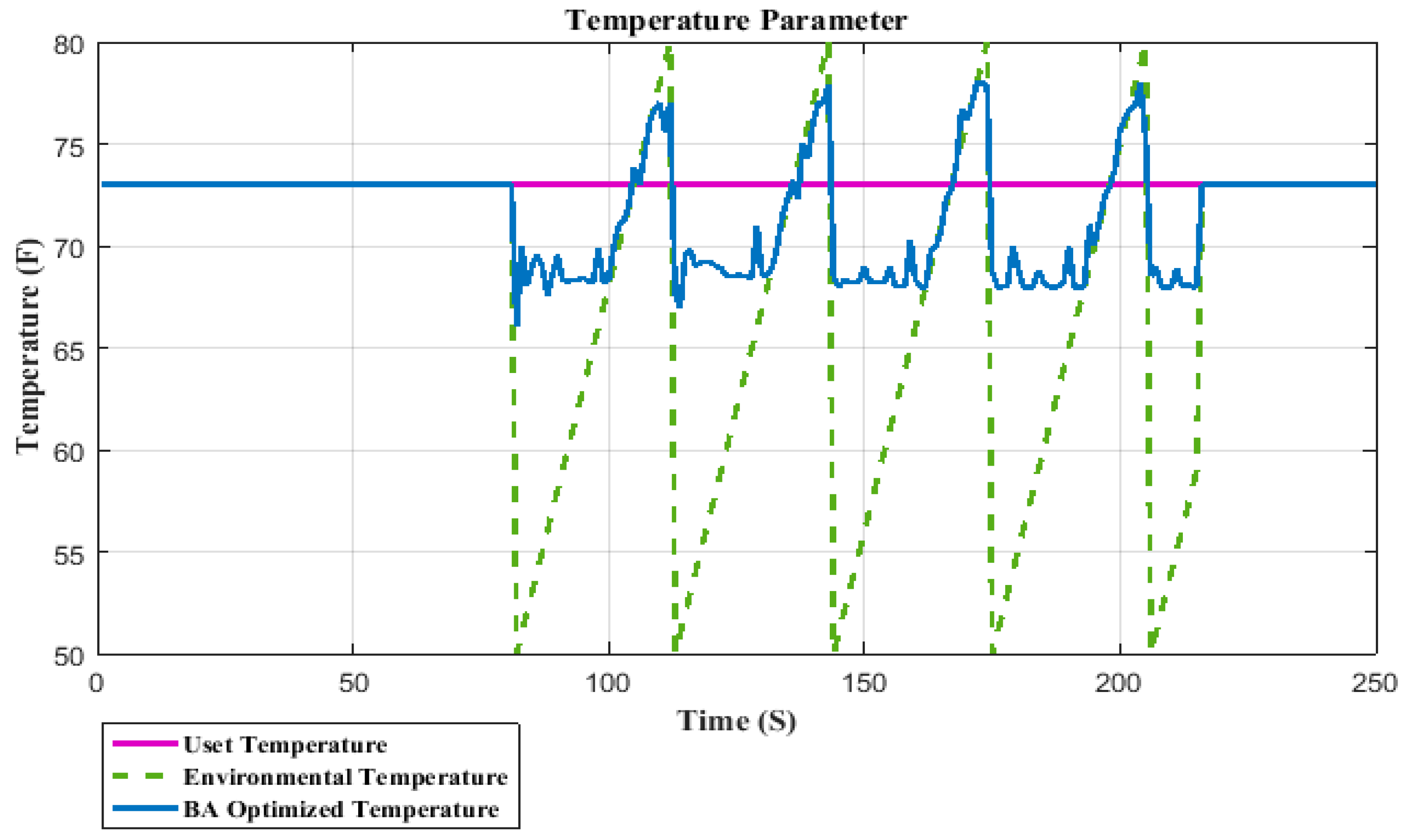

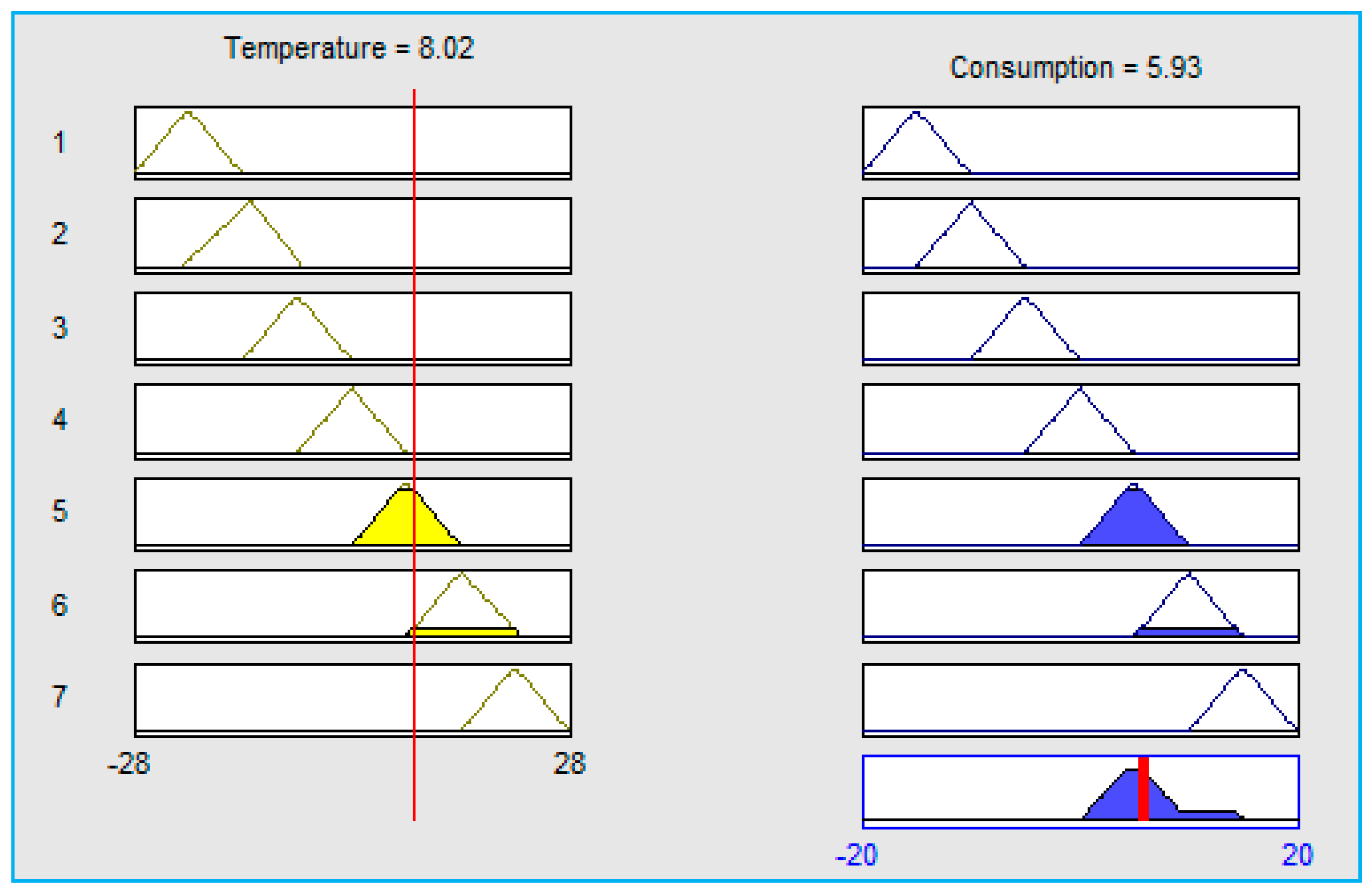

4.1. Temperature Control Process

- If ( = = NB) then RPT = RNB

- If ( = = NM) then RPT = RNM

- If ( = = NS) then RPT = RNS

- If ( = = ZE) then RPT = RZE

- If ( = = PS) then RPT = RPS

- If ( = = PM) then RPT = RPM

- If ( = = PB) then RPT = RPB

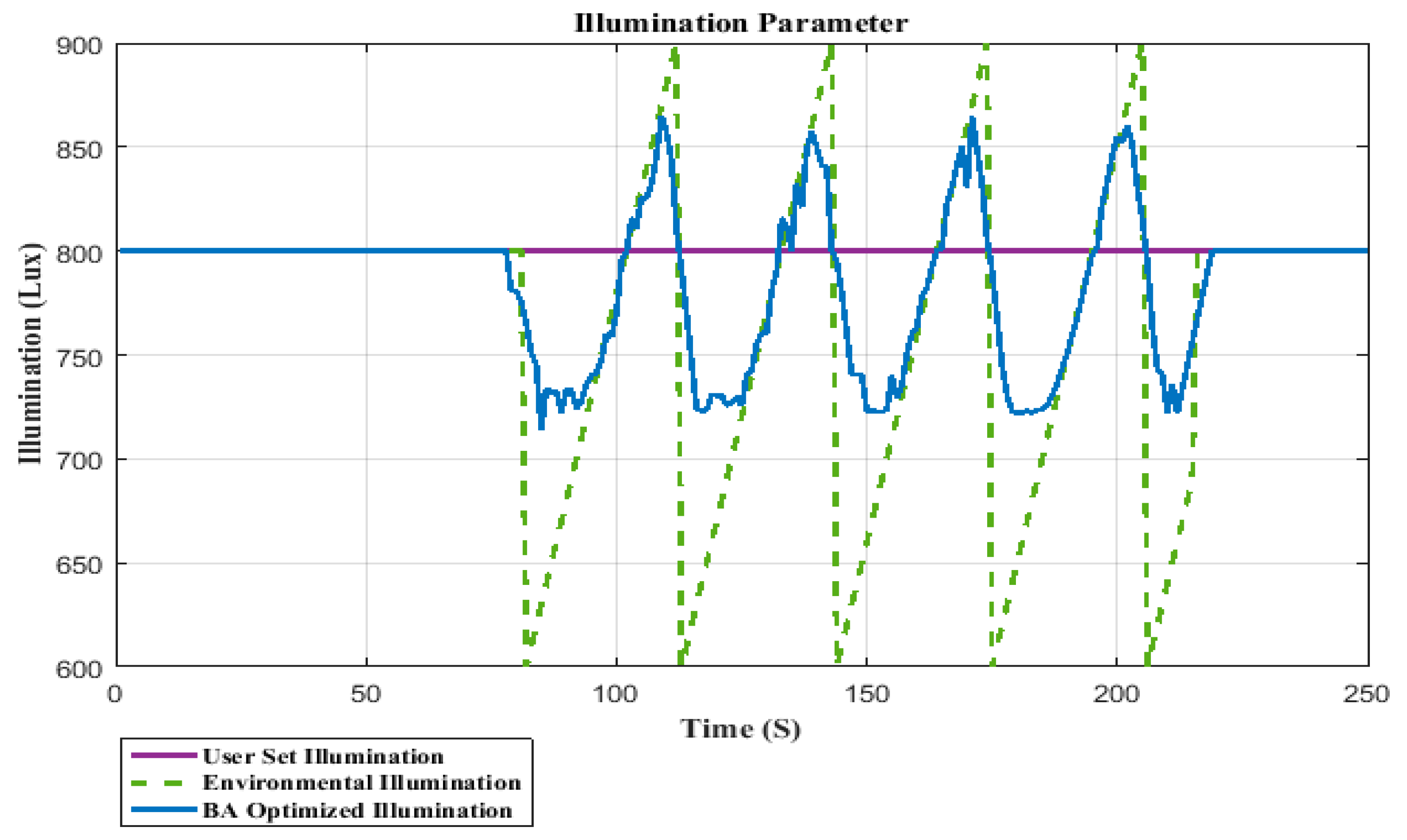

4.2. Illumination Control Process

- If ( = = HS) then RPL = RNB

- If ( = = MS) then RPL = RNM

- If ( = = BS) then RPL = RNS

- If ( = = OK) then RPL = RZE

- If ( = = SH) then RPL = RPS

- If ( = = H) then RPL = RPM

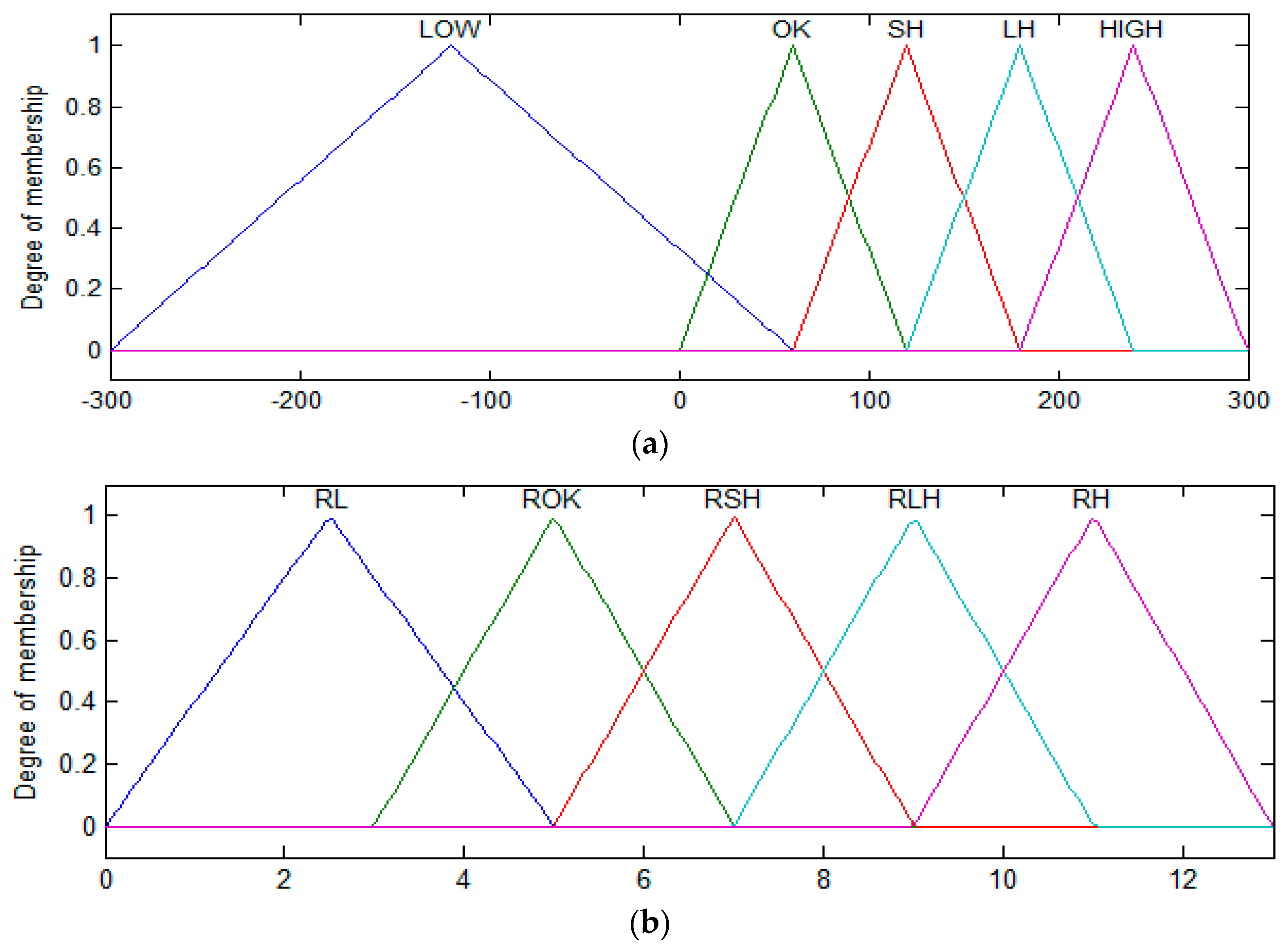

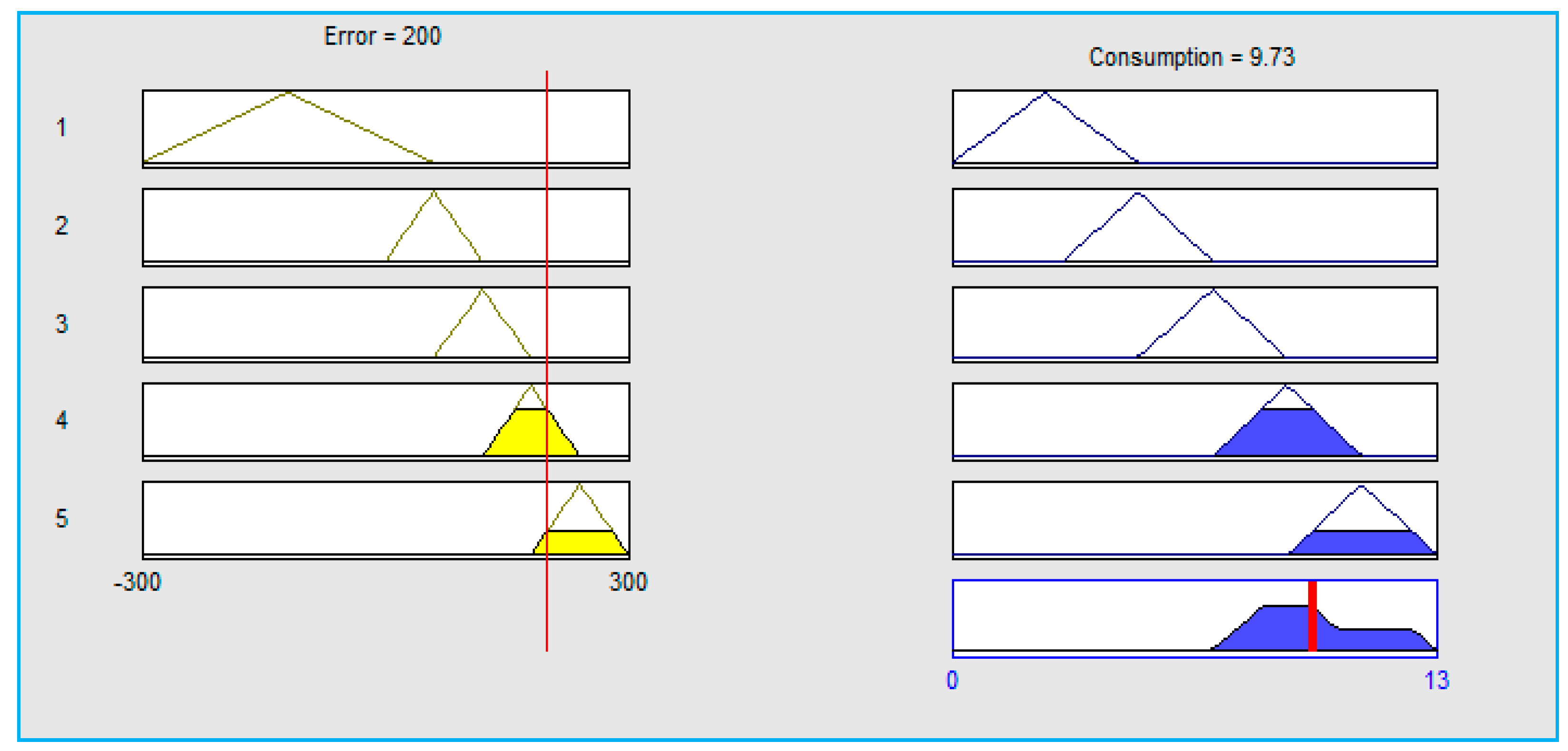

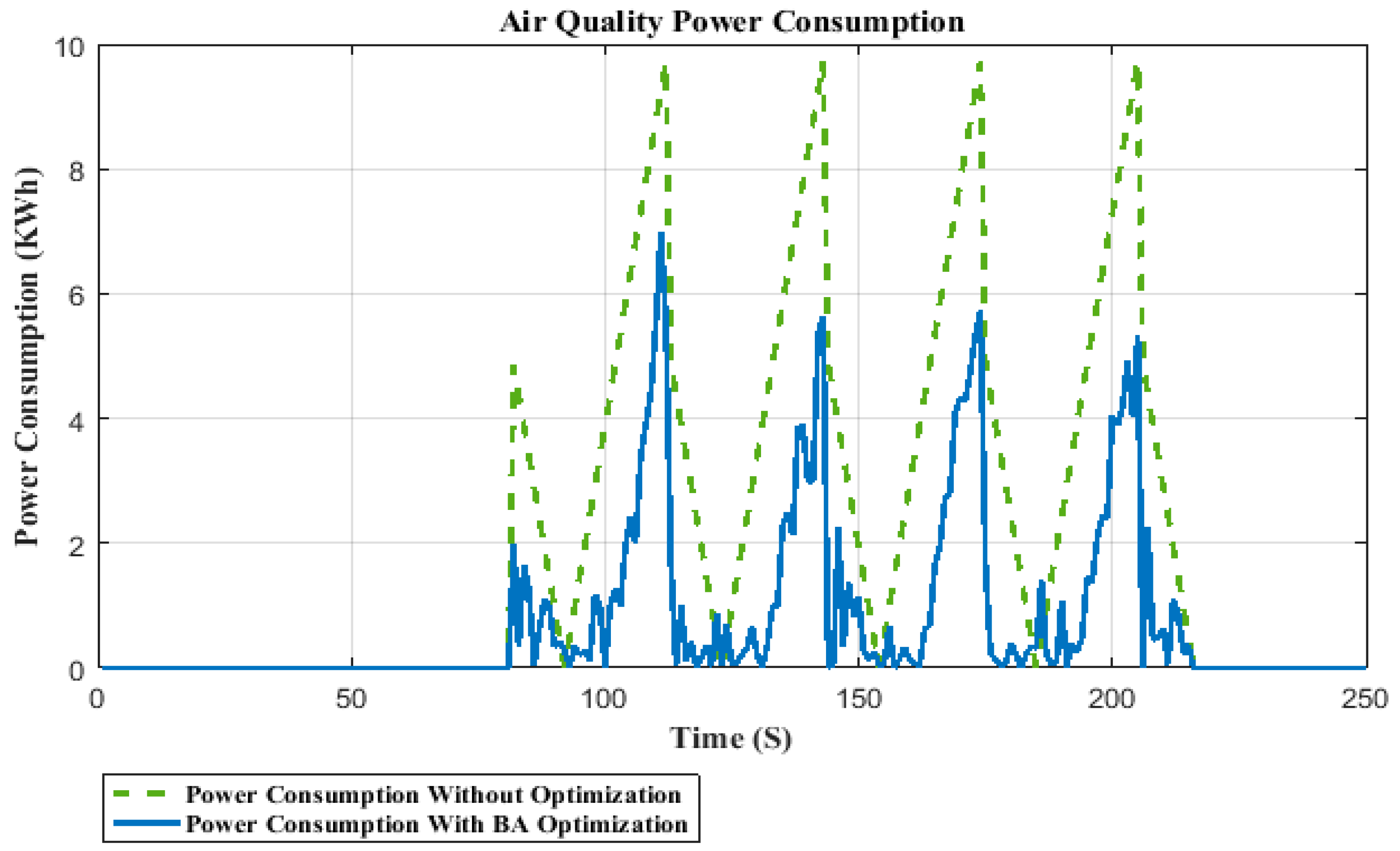

4.3. Air Quality Control Process

- If ( = = LOW) then RPV = RL

- If ( = = OK) then RPV = ROK

- If ( = = SH) then RPV = RSH

- If ( = = LH) then RPV = RLH

- If ( = = HIGH) then RPV = RH

5. Comparative Analysis of Optimization Results Bat Algorithm with Genetic Algorithm and Particle Swarm Optimization

6. Conclusions

Acknowledgment

Author Contributions

Conflicts of Interest

References

- Ali, S.; Kim, D.-H. Effective and comfortable power control model using kalman filter for building energy management. Wirel. Pers. Commun. 2013, 73, 1439–1453. [Google Scholar] [CrossRef]

- Ali, S.; Kim, D.-H. Optimized power control methodology using genetic algorithm. Wirel. Pers. Commun. 2015, 83, 493–505. [Google Scholar] [CrossRef]

- Dounis, A.I.; Caraiscos, C. Advanced control systems engineering for energy and comfort management in a building environment—A review. Renew. Sustain. Energy Rev. 2009, 13, 1246–1261. [Google Scholar] [CrossRef]

- Wang, Z.; Yang, R.; Wang, L. Multi-agent intelligent controller design for smart and sustainable buildings. In Proceedings of the 2010 4th Annual IEEE Systems Conference, San Diego, CA, USA, 5–8 April 2010; pp. 277–282. [Google Scholar]

- Emmerich, S.J.; Persily, A.K. State-of-The-Art Review of CO2 Demand Controlled Ventilation Technology and Application; Diane Publishing: Collingdale, PA, USA, 2003. [Google Scholar]

- Levermore, G.J. Building Energy Management Systems: An Application to Heating and Control; E & FN Spon: London, UK, 1992. [Google Scholar]

- Benard, C.; Guerrier, B.; Rosset-Louerat, M. Optimal building energy management. Part 2; Control. J. Sol. Energy Eng. 1992, 114. [Google Scholar] [CrossRef]

- Kolokotsa, D.; Stavrakakis, G.; Kalaitzakis, K.; Agoris, D. Genetic algorithms optimized fuzzy controller for the indoor environmental management in buildings implemented using plc and local operating networks. Eng. Appl. Artif. Intell. 2002, 15, 417–428. [Google Scholar] [CrossRef]

- Kusiak, A.; Li, M.; Zhang, Z. A data-driven approach for steam load prediction in buildings. Appl. Energy 2010, 87, 925–933. [Google Scholar] [CrossRef]

- Široký, J.; Oldewurtel, F.; Cigler, J.; Prívara, S. Experimental analysis of model predictive control for an energy efficient building heating system. Appl. Energy 2011, 88, 3079–3087. [Google Scholar] [CrossRef]

- Wang, Z.; Wang, L.; Dounis, A.I.; Yang, R. Multi-agent control system with information fusion based comfort model for smart buildings. Appl. Energy 2012, 99, 247–254. [Google Scholar] [CrossRef]

- Bluyssen, P.M.; Aries, M.; van Dommelen, P. Comfort of workers in office buildings: The European hope project. Build. Environ. 2011, 46, 280–288. [Google Scholar] [CrossRef]

- Marino, C.; Nucara, A.; Pietrafesa, M. Proposal of comfort classification indexes suitable for both single environments and whole buildings. Build. Environ. 2012, 57, 58–67. [Google Scholar] [CrossRef]

- Mohan, N.; Sivaraj, R.; Priya, R.D. A comprehensive review of bat algorithm and its applications to various optimization problems. Asian J. Res. Soc. Sci. Humanit. 2016, 6, 676–690. [Google Scholar] [CrossRef]

- Handbook, A. Fundamentals; IP Edition; American Society of Heating, Refrigeration, and Air Conditioning Engineers, Inc.: Atlanta, GA, USA, 1989. [Google Scholar]

- Wright, J.A.; Hanby, V.I. The Formulation, Characteristics and Solution of Hvac System Optimized Design Problems; Loughborough University Institutional Repository: Stratford, UK, 1987. [Google Scholar]

- Ullah, I.; Kim, D. An improved optimization function for maximizing user comfort with minimum energy consumption in smart homes. Energies 2017, 10, 1818. [Google Scholar] [CrossRef]

- Huang, W.; Lam, H. Using genetic algorithms to optimize controller parameters for hvac systems. Energy Build. 1997, 26, 277–282. [Google Scholar] [CrossRef]

- Obara, S.; Kudo, K. Multiple-purpose operational planning of fuel cell and heat pump compound system using genetic algorithm. Trans.-Soc. Heat. Air Cond. Sanit. Eng. Jpn. 2003, 91, 65–76. [Google Scholar]

- Li, H.; Nalim, R.; Haldi, P.-A. Thermal-economic optimization of a distributed multi-generation energy system—A case study of beijing. Appl. Therm. Eng. 2006, 26, 709–719. [Google Scholar] [CrossRef]

- Zhen-Ya, Z.; Hong-Mei, C.; Shu-Guang, Z. An approach to the identification of temperature in intelligent building based on feed forward neural network and genetic algorithm. In Proceedings of the 2010 3rd International Conference on Computer Science and Information Technology, Chengdu, China, 9–11 July 2010; pp. 286–290. [Google Scholar]

- Yu, T. In Modeling occupancy behavior for energy efficiency and occupants comfort management in intelligent buildings. In Proceedings of the 2010 Ninth International Conference on Machine Learning and Applications, Washington, DC, USA, 12–14 December 2010; pp. 726–731. [Google Scholar]

- Wahid, F.; Kim, D.H. Short-term energy consumption prediction in korean residential buildings using optimized multi-layer perceptron. Kuwait J. Sci. 2017, 44, 67–77. [Google Scholar]

- Wahid, F.; Ghazali, R.; Shah, A.S.; Fayaz, M. Prediction of energy consumption in the buildings using multi-layer perceptron and random forest. IJAST 2017, 101, 13–22. [Google Scholar] [CrossRef]

- Mossolly, M.; Ghali, K.; Ghaddar, N. Optimal control strategy for a multi-zone air conditioning system using a genetic algorithm. Energy 2009, 34, 58–66. [Google Scholar] [CrossRef]

- Montazeri-Gh, M.; Poursamad, A.; Ghalichi, B. Application of genetic algorithm for optimization of control strategy in parallel hybrid electric vehicles. J. Frankl. Inst. 2006, 343, 420–435. [Google Scholar] [CrossRef]

- Azadeh, A.; Tarverdian, S. Integration of genetic algorithm, computer simulation and design of experiments for forecasting electrical energy consumption. Energy Policy 2007, 35, 5229–5241. [Google Scholar] [CrossRef]

- Fong, K.F.; Hanby, V.I.; Chow, T.-T. System optimization for hvac energy management using the robust evolutionary algorithm. Appl. Therm. Eng. 2009, 29, 2327–2334. [Google Scholar] [CrossRef]

- Ling, A.P.A.; Masao, M. Selection of model in developing information security criteria on smart grid security system. In Proceedings of the 2011 IEEE Ninth International Symposium on Parallel and Distributed Processing with Applications Workshops, Busan, Korea, 26–28 May 2011; pp. 91–98. [Google Scholar]

- Yang, X.-S. A new metaheuristic bat-inspired algorithm. Nat. Inspir. Cooper. Strateg. Optim. 2010, 284, 65–74. [Google Scholar]

- Yang, X.-S.; He, X. Bat algorithm: Literature review and applications. Int. J. Bio-Inspir. Comput. 2013, 5, 141–149. [Google Scholar] [CrossRef]

- Zadeh, L.A. Fuzzy Sets, Fuzzy Sets, Fuzzy Logic, and Fuzzy Systems: Selected Papers by Lotfi A. Zadeh; World Scientific Publishing Co., Inc.: River Edge, NJ, USA, 1996; pp. 394–432. [Google Scholar]

- Mamdani, E.H.; Assilian, S. An experiment in linguistic synthesis with a fuzzy logic controller. Int. J. Man-Mach. Stud. 1975, 7, 1–13. [Google Scholar] [CrossRef]

| Algorithm | Temperature Power Consumption | Illumination Power Consumption | Air Quality Power Consumption | Total Power Consumption |

|---|---|---|---|---|

| GA | 439 | 1475.16 | 651.78 | 2566.14 |

| PSO | 521.73 | 1531.01 | 694.54 | 2747.29 |

| BA (proposed approach) | 1020.23 | 939.78 | 536.97 | 2496.98 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fayaz, M.; Kim, D. Energy Consumption Optimization and User Comfort Management in Residential Buildings Using a Bat Algorithm and Fuzzy Logic. Energies 2018, 11, 161. https://doi.org/10.3390/en11010161

Fayaz M, Kim D. Energy Consumption Optimization and User Comfort Management in Residential Buildings Using a Bat Algorithm and Fuzzy Logic. Energies. 2018; 11(1):161. https://doi.org/10.3390/en11010161

Chicago/Turabian StyleFayaz, Muhammad, and DoHyeun Kim. 2018. "Energy Consumption Optimization and User Comfort Management in Residential Buildings Using a Bat Algorithm and Fuzzy Logic" Energies 11, no. 1: 161. https://doi.org/10.3390/en11010161

APA StyleFayaz, M., & Kim, D. (2018). Energy Consumption Optimization and User Comfort Management in Residential Buildings Using a Bat Algorithm and Fuzzy Logic. Energies, 11(1), 161. https://doi.org/10.3390/en11010161