An Improved Droop Control Strategy for Low-Voltage Microgrids Based on Distributed Secondary Power Optimization Control

Abstract

:1. Introduction

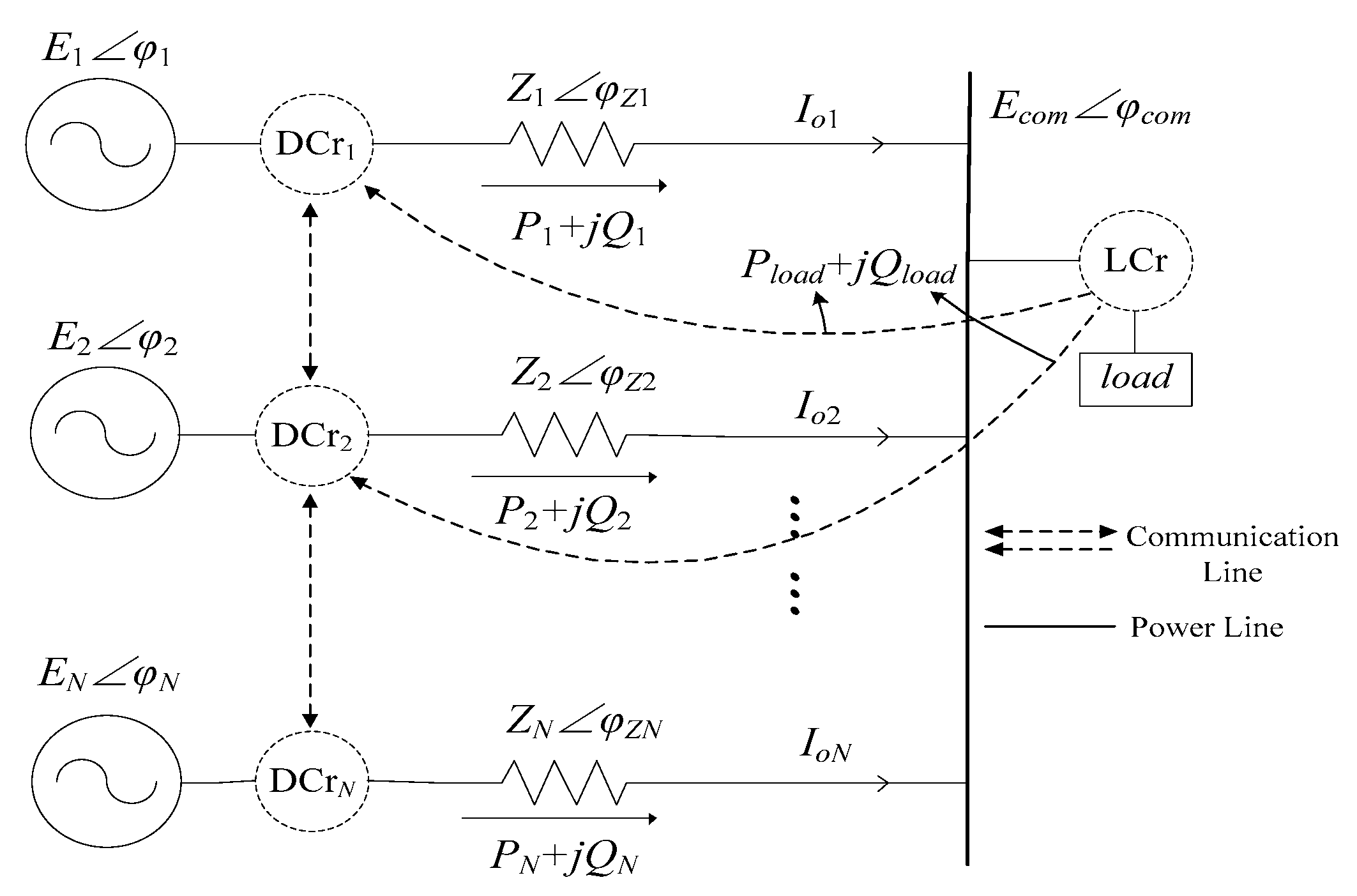

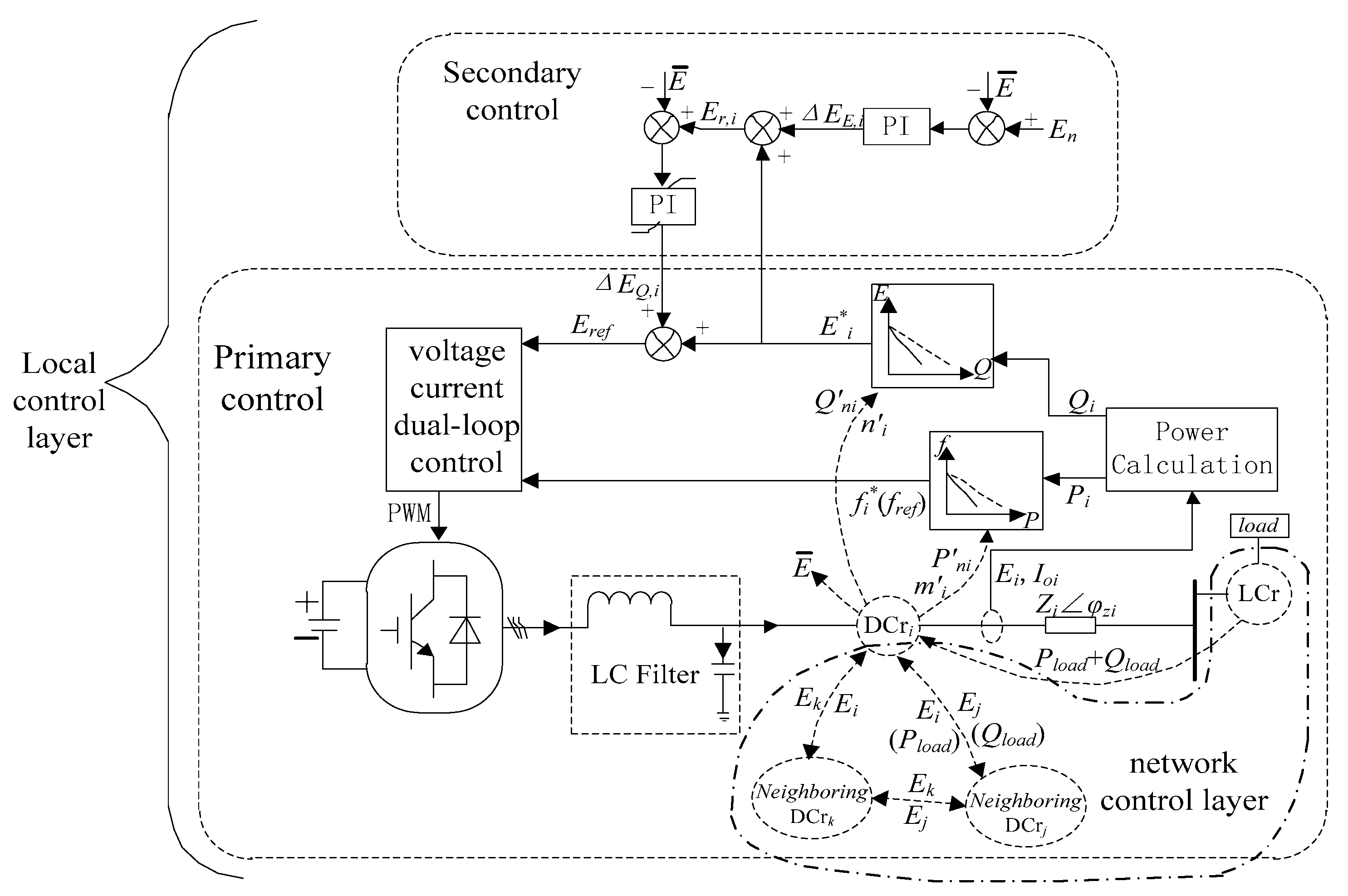

2. Conventional Droop Control and Reactive Power Sharing Analysis

3. Improved Droop Control Strategy

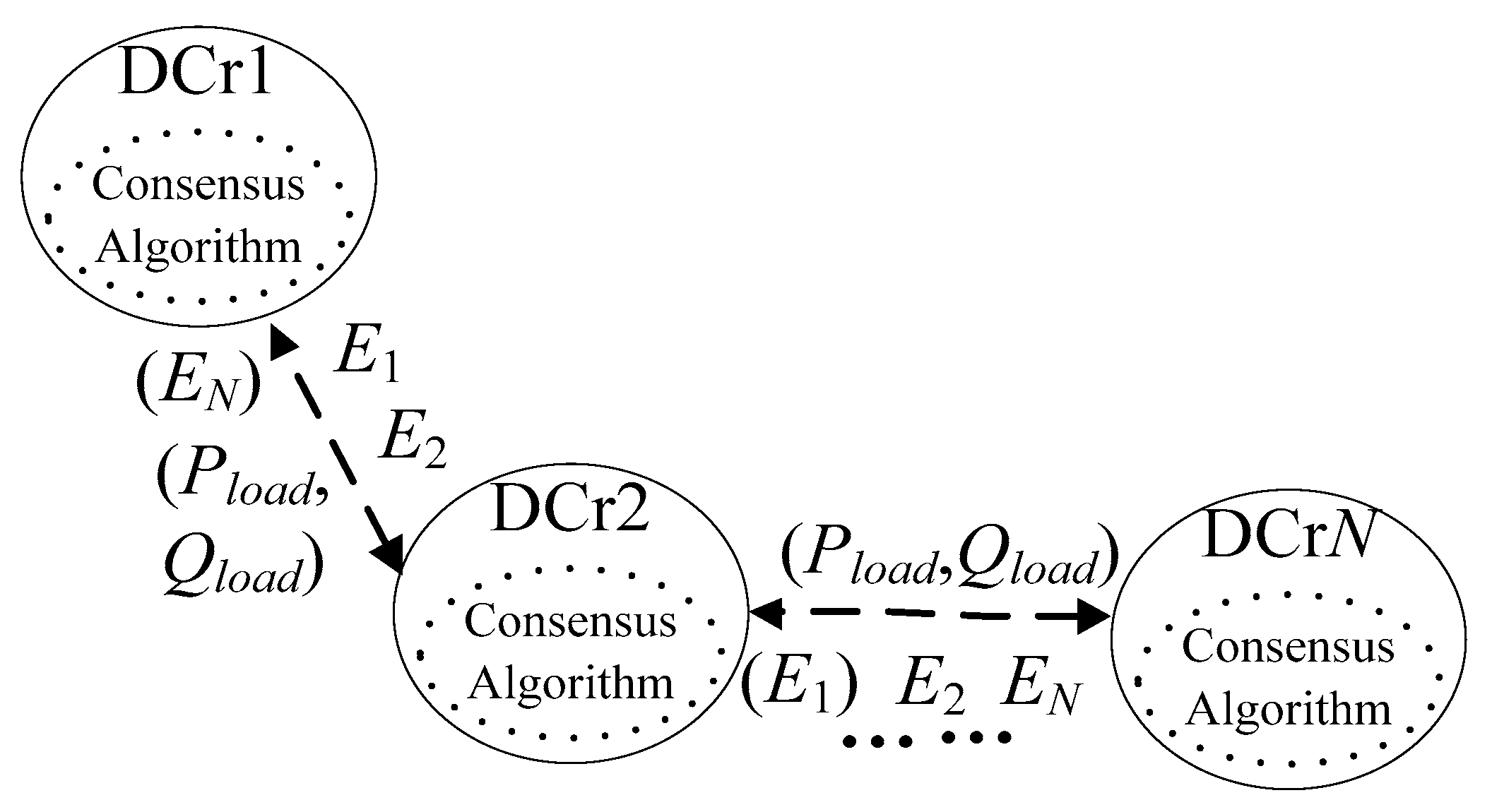

4. Distributed Secondary Power Optimization Control Based on a Consensus Algorithm

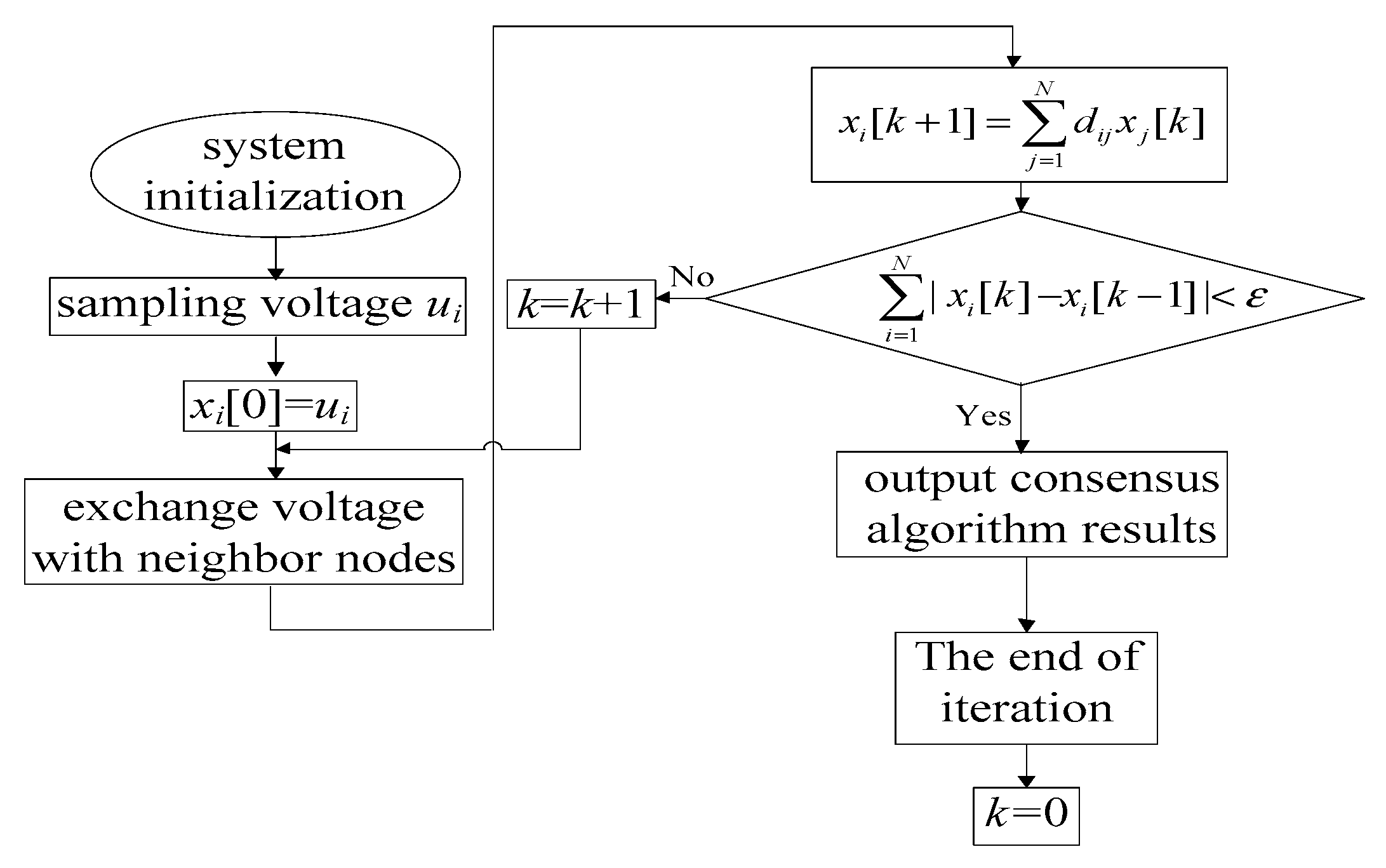

4.1. Discrete Consensus Algorithm

4.2. Distributed Secondary Power Optimization Control Based on a Discrete Consensus Algorithm

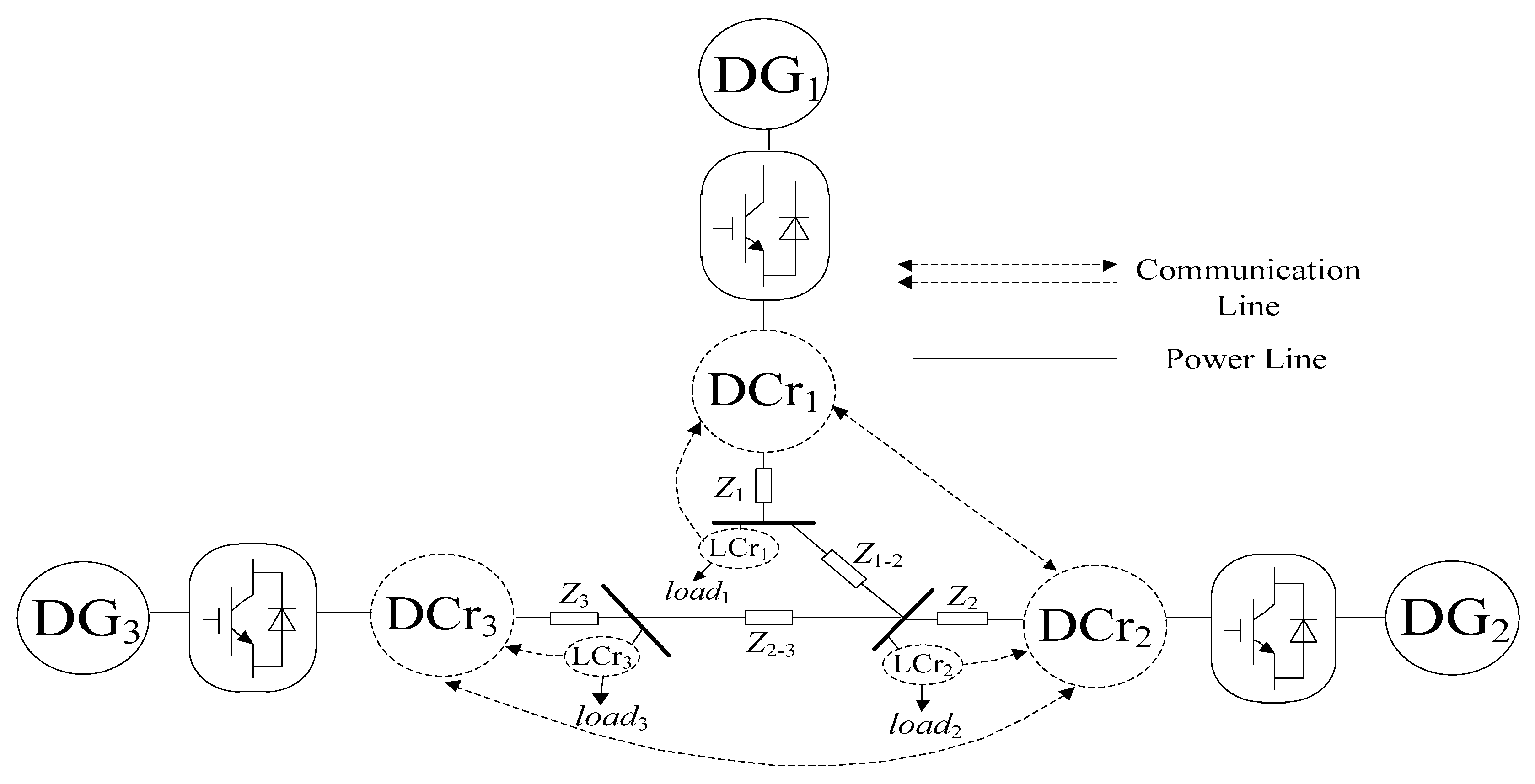

5. Simulation Results

5.1. Case A: Disturbance Analysis

- Stage 1 (0–1 s):

- The conventional droop control shown in Equation (3) is used to control the 3 DGs in Figure 6. Load 1 and Load 2 are connected to the system at t = 0 s.

- Stage 2 (1–2 s):

- The improved droop control shown in Equation (8) is used to control the 3 DGs at t = 1 s.

- Stage 3 (2–3 s):

- The secondary power optimization control is added to the improved Q-E droop control to optimize reactive power and regulate voltage amplitude at t = 2 s.

- Stage 4 (3–4 s):

- Load 3 is connected to the system at t = 3 s.

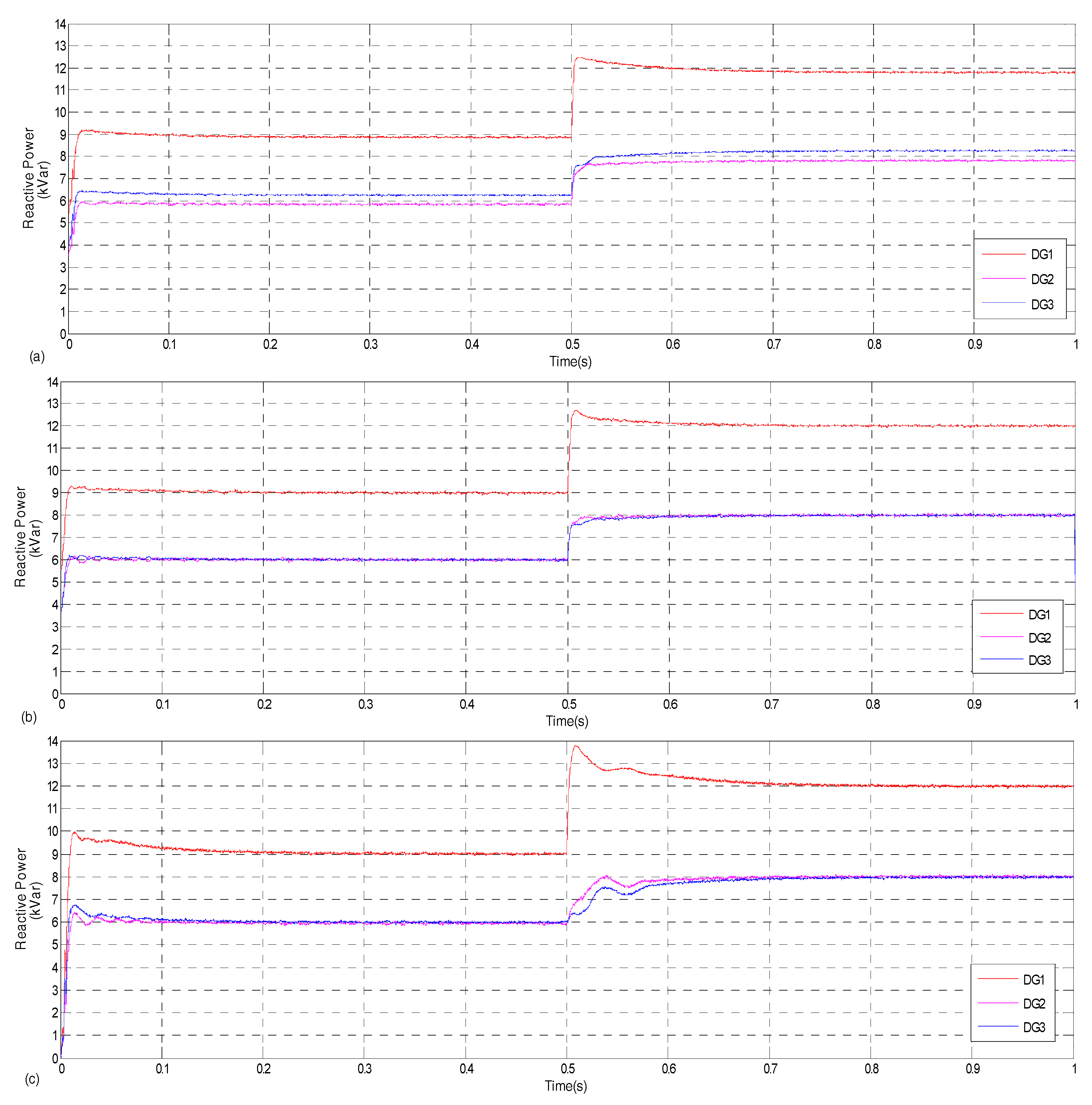

5.2. Case B: Variations of Line Impedance

5.3. Case C: Influence of Different Convergence Accuracies

5.4. Case D: Influence of Communication Delay

6. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Wang, H.; Huang, J. Joint Investment and Operation of Microgrid. IEEE Trans. Smart Grid 2017, 8, 833–845. [Google Scholar] [CrossRef]

- Golsorkhi, M.S.; Lu, D.D.C. A control method for inverter-based islanded microgrids based on V-I droop characteristics. IEEE Trans. Power Deliv. 2015, 30, 1196–1204. [Google Scholar] [CrossRef]

- Ahn, C.; Peng, H. Decentralized and real-time power dispatch control for an islanded microgrid supported by distributed power sources. Energies 2013, 6, 6439–6454. [Google Scholar] [CrossRef]

- Katiraei, F.; Iravani, M.R.; Lehn, P.W. Microgrid autonomous operation during and subsequent to islanding process. IEEE Trans. Power Deliv. 2005, 20, 248–257. [Google Scholar] [CrossRef]

- Yu, Z.; Ai, Q.; He, X.; Piao, L. Adaptive droop control for microgrids based on the synergetic control of multi-agent systems. Energies 2016, 9, 1057. [Google Scholar] [CrossRef]

- Guerrero, J.M.; Vasquez, J.C.; Matas, J.; Vicuna, L.G.D.; Castilla, M. Hierarchical control of droop-controlled AC and DC microgrids—A General Approach Toward Standardization. IEEE Trans. Ind. Electron. 2011, 58, 158–172. [Google Scholar] [CrossRef]

- Bidram, A.; Davoudi, A. Hierarchical structure of microgrids control system. IEEE Trans. Smart Grid 2012, 3, 1963–1976. [Google Scholar] [CrossRef]

- Parhizi, S.; Lotfi, H.; Khodaei, A.; Bahramirad, S. State of the art in research on microgrids: A review. IEEE Access 2015, 3, 890–925. [Google Scholar] [CrossRef]

- Lu, X.; Guerrero, J.M.; Sun, K.; Vasquez, J.C.; Teodorescu, R.; Huang, L. Hierarchical control of parallel AC-DC converter interfaces for hybrid microgrids. IEEE Trans. Smart Grid 2014, 5, 683–692. [Google Scholar] [CrossRef]

- Patterson, M.; Macia, N.F.; Kannan, A.M. Hybrid microgrid model based on solar photovoltaic battery fuel cell system for intermittent load applications. IEEE Trans. Energy Convers. 2015, 30, 359–366. [Google Scholar] [CrossRef]

- Dragicevic, T.; Guerrero, J.M.; Vasquez, J.C.; Škrlec, D. Supervisory control of an adaptive-droop regulated dc Microgrid with battery management capability. IEEE Trans. Ind. Electron. 2014, 29, 695–706. [Google Scholar] [CrossRef]

- Egwebe, A.M.; Fazeli, M.; Igic, P.; Holland, P.M. Implementation and stability study of dynamic droop in islanded microgrids. IEEE Trans. Energy Convers. 2016, 31, 821–832. [Google Scholar] [CrossRef]

- Guo, F.; Wen, C.; Mao, J.; Song, Y. Distributed secondary voltage and frequency restoration control of droop-controlled inverter-based microgrids. IEEE Trans. Ind. Electron. 2015, 62, 4355–4364. [Google Scholar] [CrossRef]

- Guerrero, J.M.; Matas, J.; de Vicuña, L.G. Decentralized control for parallel operation of distributed generation inverters using resistive output impedance. IEEE Trans. Ind. Electron. 2007, 54, 994–1004. [Google Scholar] [CrossRef]

- Gu, W.; Liu, W.; Wu, Z.; Zhao, B.; Chen, W. Cooperative control to enhance the frequency stability of islanded microgrids with DFIG-SMES. Energies 2013, 6, 3951–3971. [Google Scholar] [CrossRef]

- Tuladhar, A.; Jin, H.; Unger, T.; Mauch, K. Control of parallel inverters in distributed AC power systems with consideration of line impedance effect. IEEE Trans. Ind. Appl. 2000, 36, 131–138. [Google Scholar] [CrossRef]

- Li, Y.; Kao, C.-N. An accurate power control strategy for power-electronics-interfaced distributed generation units operating in a low-voltage multibus microgrid. IEEE Trans. Power Electron. 2009, 24, 2977–2988. [Google Scholar]

- Guerrero, J.M.; Vicuna, L.G.D.; Matas, J.; Castilla, M.; Miret, J. Out impedance design of parallel-connected UPS inverters with wireless load-sharing control. IEEE Trans. Ind. Electron. 2005, 52, 1126–1135. [Google Scholar] [CrossRef]

- He, J.; Li, Y. Analysis, design, and implementation of virtual impedance for power electronics interfaced distributed generation. IEEE Trans. Ind. Appl. 2011, 47, 2525–2538. [Google Scholar] [CrossRef]

- Zhu, Y.; Zhuo, F.; Wang, F.; Liu, B.; Gou, R.; Zhao, Y. A virtual impedance optimization method for reactive power sharing in networked microgrid. IEEE Trans. Power Electron. 2016, 31, 2890–2904. [Google Scholar] [CrossRef]

- Majumder, R.; Ledwich, G.; Ghosh, A. Droop control of converter-interfaced microsources in rural distributed generation. IEEE Trans. Power Deliv. 2010, 25, 2768–2778. [Google Scholar] [CrossRef] [Green Version]

- Hajizadeh, A.; Golkar, M.A. Intelligent power management strategy of hybrid distributed generation system. Int. J. Electr. Power Energy Syst. 2007, 29, 783–795. [Google Scholar] [CrossRef]

- Wang, C.; Yang, X.; Wu, Z.; Che, Y.; Guo, L.; Zhang, S.; Liu, Y. A Highly integrated and reconfigurable microgrid testbed with hybrid distributed energy sources. IEEE Trans. Smart Grid 2016, 7, 451–459. [Google Scholar] [CrossRef]

- Yao, W.; Chen, M.; Matas, J.; Guerrero, J.M.; Qian, Z. Design and analysis of the droop control method for parallel inverters considering the impact of the complex impedance on the power sharing. IEEE Trans. Ind. Electron. 2011, 58, 576–588. [Google Scholar] [CrossRef]

- Ahn, S.J.; Nam, S.R.; Choi, J.H.; Moon, S.I. Power scheduling of distributed generators for economic and stable operation of a microgrid. IEEE Trans. Smart Grid 2013, 4, 398–405. [Google Scholar] [CrossRef]

- Shafiee, Q.; Guerrero, J.M.; Vasquez, J.C. Distributed secondary control for islanded microgrids—A novel approach. IEEE Trans. Power Electron. 2014, 29, 1018–1030. [Google Scholar] [CrossRef]

- Nasirian, V.; Davoudi, A.; Lewis, F.L.; Guerrero, J.M. Distributed adaptive droop control for DC distribution systems. IEEE Trans. Energy Convers. 2014, 29, 944–956. [Google Scholar] [CrossRef]

- Zhong, Q. Robust droop controller for accurate proportional load sharing among inverters operated in parallel. IEEE Trans. Ind. Electron. 2013, 60, 1281–1290. [Google Scholar] [CrossRef]

- Wu, D.; Dragicevic, T.; Vasquez, J.C.; Guerrero, J.M. Secondary coordinated control of islanded microgrids based on consensus algorithms. In Proceedings of the Energy Conversion Congress and Exposition (ECCE), Pittsburgh, PA, USA, 14–18 September 2014; pp. 4290–4297. [Google Scholar]

- Vandoorn, T.L.; Kooning, J.D.M.D.; Vyver, J.V.D.; Vandevelde, L. Three-Phase Primary Control for Unbalance Sharing between Distributed Generation Units in a Microgrid. Energies 2013, 6, 6586–6607. [Google Scholar] [CrossRef] [Green Version]

- Mohamed, Y.; El-Saadany, E.F. Adaptive decentralized droop controller to preserve power sharing stability of paralleled inverters in distributed generation microgrids. IEEE Trans. Power Electron. 2008, 23, 2806–2816. [Google Scholar] [CrossRef]

- Savaghebi, M.; Jalilian, A.; Vasquez, J.C.; Guerrero, J.M. Secondary Control Scheme for Voltage Unbalance Compensation in an Islanded Droop-Controlled Microgrid. IEEE Trans. Smart Grid 2012, 3, 797–807. [Google Scholar] [CrossRef]

- Hou, X.; Sun, Y.; Yuan, W.; Zhong, C. Conventional P-ω/Q-V droop control in highly resistive line of low-voltage converter-based AC microgrid. Energies 2016, 9, 943. [Google Scholar] [CrossRef]

- Hatano, Y.; Mesbahi, M. Agreement over random networks. IEEE Trans. Autom. Control 2005, 50, 1867–1872. [Google Scholar] [CrossRef]

- Pogaku, N.; Prodanovic, M.; Green, T.C. Modeling, Analysis and Testing of Autonomous Operation of an Inverter-Based Microgrid. IEEE Trans. Power Electron. 2007, 22, 613–625. [Google Scholar] [CrossRef]

- Khoo, S.; Xie, L.; Man, Z. Robust Finite-Time Consensus Tracking Algorithm for Multirobot Systems. IEEE/ASME Trans. Mechatron. 2009, 14, 219–228. [Google Scholar] [CrossRef]

- Xu, Y.; Liu, W. Novel multiagent based load restoration algorithm for microgrids. IEEE Trans. Smart Grid 2011, 2, 152–161. [Google Scholar] [CrossRef]

- Zhang, Z.; Chow, M.Y. Convergence analysis of the incremental cost consensus algorithm under different communication network topologies in a smart grid. IEEE Trans. Power Syst. 2012, 27, 1761–1768. [Google Scholar] [CrossRef]

| DG | P-f Droop Gain mi,0 (Hz/kW) | Q-E Droop Gain ni,0 (V/kVar) | Rated Active Power Pni,0 (kW) | Rated Reactive Power Qni,0 (kVar) | Load | Values | Line Impedance | Values |

|---|---|---|---|---|---|---|---|---|

| DG1 | 0.0556 | 1.4286 | 9 | 10.5 | Load1/KVA | 9 + j10 | Z1/Ω | 0.2 + j0.031 |

| DG2 | 0.0833 | 2.1429 | 6 | 7 | Load2/KVA | 8.5 + j11 | Z2/Ω | 0.3 + j0.063 |

| Z3/Ω | 0.2 + j0.031 | |||||||

| DG3 | 0.0833 | 2.1429 | 6 | 7 | Load3/KVA | 7 + j7 | Z1-2/Ω | 0.4 + j0.063 |

| Z2-3/Ω | 0.5 + j0.094 |

| Groups | Z1/Ω | Z2/Ω | Z3/Ω | Z1-2/Ω | Z2-3/Ω |

|---|---|---|---|---|---|

| Group 1 | 0.2 + j0.031 | 0.4 + j0.063 | 0.3 + j0.063 | 0.5 + j0.063 | 0.4 + j0.063 |

| Group 2 | 0.2 + j0.031 | 0.4 + j0.063 | 0.3 + j0.031 | 0.5 + j0.063 | 0.4 + j0.063 |

| Group 3 | 0.3 + j0.063 | 0.3 + j0.063 | 0.2 + j0.031 | 0.6 + j0.094 | 0.5 + j0.063 |

| Group 4 | 0.2 + j0.031 | 0.3 + j0.063 | 0.2 + j0.031 | 0.4 + j0.063 | 0.5 + j0.094 |

| Groups | Parameters | DG1 | DG2 | DG3 |

|---|---|---|---|---|

| Group 1 | Reactive Power/kVar | 8.86 | 5.61 | 6.37 |

| Voltage/V | 313.1 | 314 | 313.2 | |

| eQ/% | 4.741 | |||

| Average Voltage Deviation/V | 2.433 | |||

| Group 2 | Reactive Power/kVar | 8.99 | 5.98 | 5.99 |

| Voltage/V | 310.5 | 311.2 | 311.3 | |

| eQ/% | 0.204 | |||

| Average Voltage Deviation/V | 0 | |||

| Group 3 | Reactive Power/kVar | 8.98 | 5.99 | 5.99 |

| Voltage/V | 311.7 | 311.1 | 310.3 | |

| eQ/% | 0.185 | |||

| Average Voltage Deviation/V | 0.033 | |||

| Group 4 | Reactive Power/kVar | 8.99 | 5.98 | 6.00 |

| Voltage/V | 310.7 | 311.4 | 310.9 | |

| eQ/% | 0.148 | |||

| Average Voltage Deviation/V | 0 | |||

| ε | Ei/V | eE/× 10−3 | ||

|---|---|---|---|---|

| DCr1 | DCr2 | DCr3 | ||

| 0.1 | 311.0752 | 311.1621 | 311.1132 | 0.0970 |

| 0.01 | 310.9923 | 311.0126 | 310.9857 | 0.0337 |

| 0.001 | 310.9931 | 310.9951 | 310.9937 | 0.0024 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, D.; Zhao, B.; Wu, Z.; Zhang, X.; Zhang, L. An Improved Droop Control Strategy for Low-Voltage Microgrids Based on Distributed Secondary Power Optimization Control. Energies 2017, 10, 1347. https://doi.org/10.3390/en10091347

Li D, Zhao B, Wu Z, Zhang X, Zhang L. An Improved Droop Control Strategy for Low-Voltage Microgrids Based on Distributed Secondary Power Optimization Control. Energies. 2017; 10(9):1347. https://doi.org/10.3390/en10091347

Chicago/Turabian StyleLi, Demin, Bo Zhao, Zaijun Wu, Xuesong Zhang, and Leiqi Zhang. 2017. "An Improved Droop Control Strategy for Low-Voltage Microgrids Based on Distributed Secondary Power Optimization Control" Energies 10, no. 9: 1347. https://doi.org/10.3390/en10091347