Exergy Replacement Cost of Fossil Fuels: Closing the Carbon Cycle

Abstract

:1. Introduction

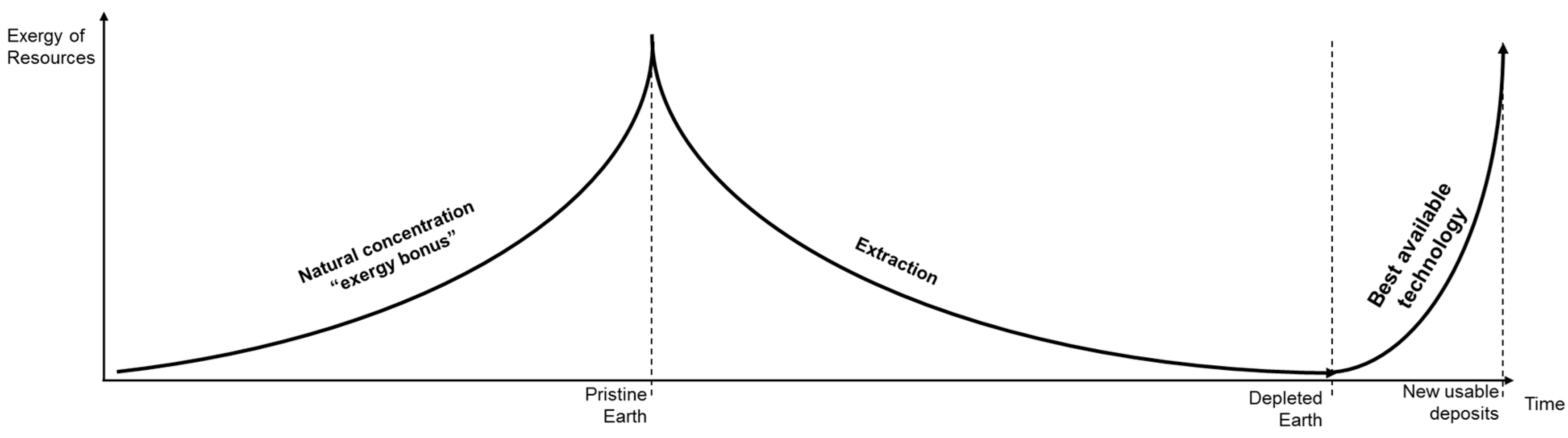

The total exergy required to mine and concentrate a mineral deposit from Thanatia, using currently available technologies [which is] what it would cost to replace, employing current technology, the mineral wealth that Man extracts, uses and finally disperses.[5] (p. 829)

It provides a measure of the amount of energy one should invest in recovering the mineral deposits to their initial conditions of composition and concentration.[6] (p. 351)

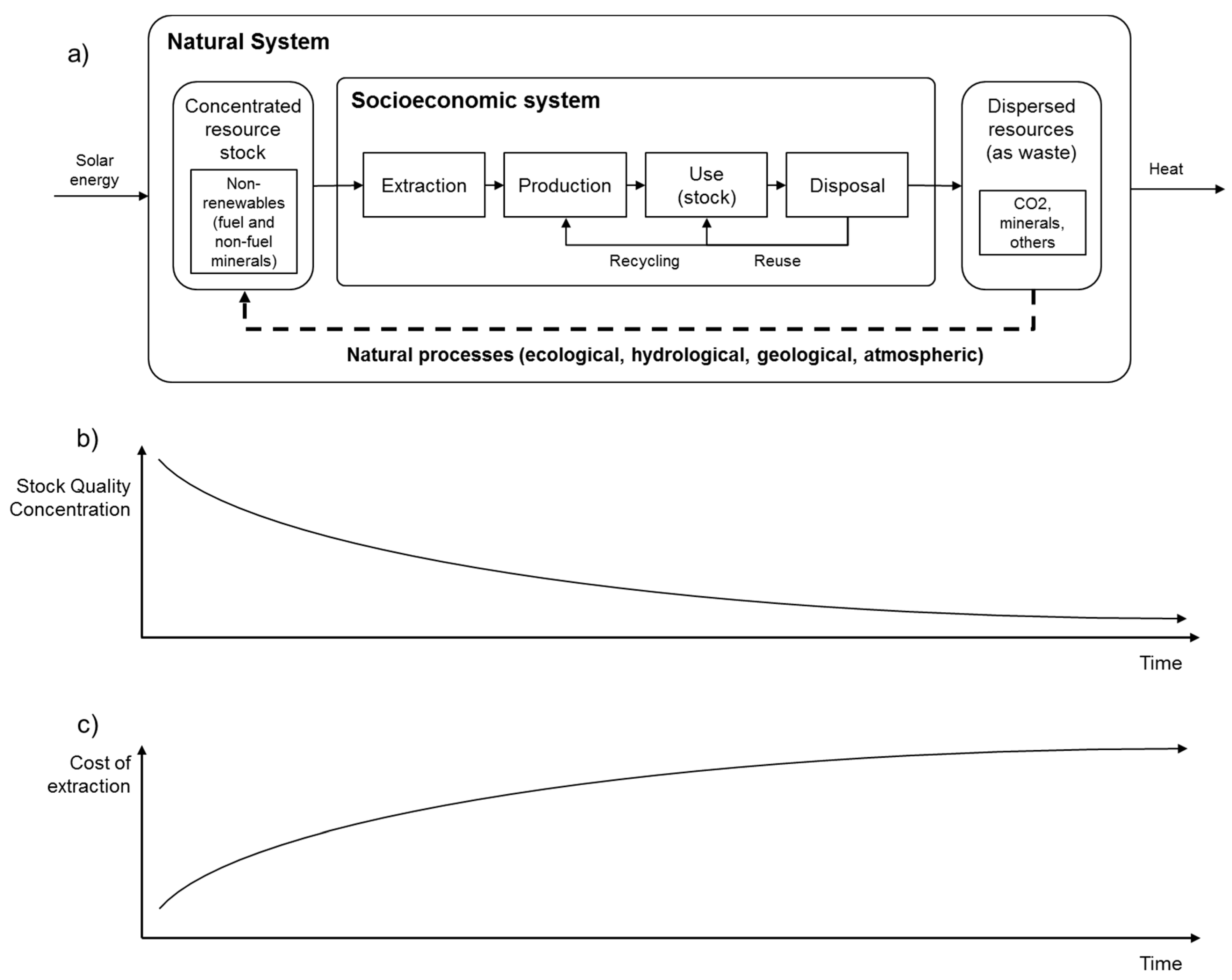

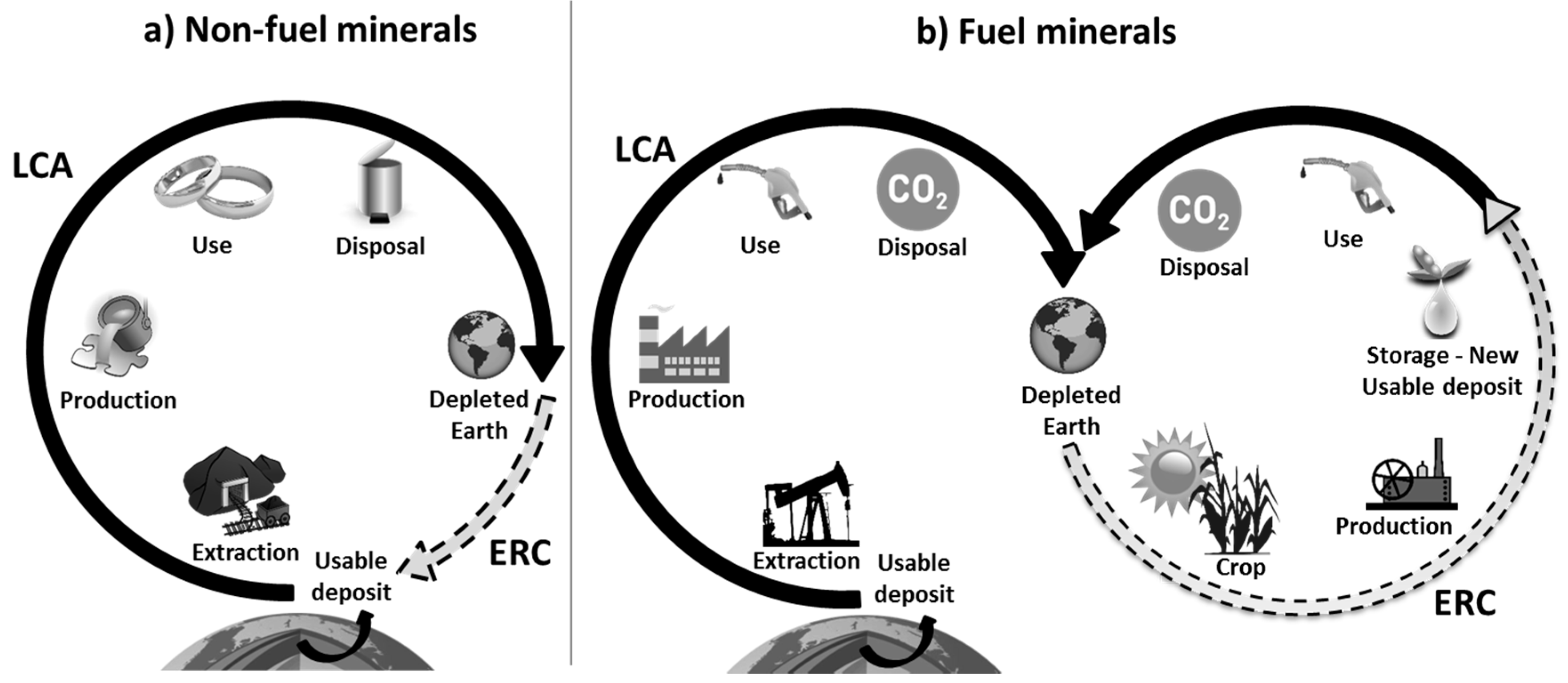

2. The Exergy Replacement Cost and Resource Depletion

It makes no sense to apply exergy replacement costs to fossil fuels, due to the impossibility of reproducing the photosynthetic process that once created the resource.

3. Substituting Fossil Fuel Functions

4. Method

4.1. Scope of the Analysis

4.2. Data Entry and Inventory

4.3. Cumulative Exergy Consumption as a Resource Indicator

4.4. Case Studies

- Valero and Valero [6], who measured the decline of the natural exergy stock as the result of global mineral extraction from 1900 to 2008. Their data set comprised of fossil fuels and 54 non-fuel minerals.

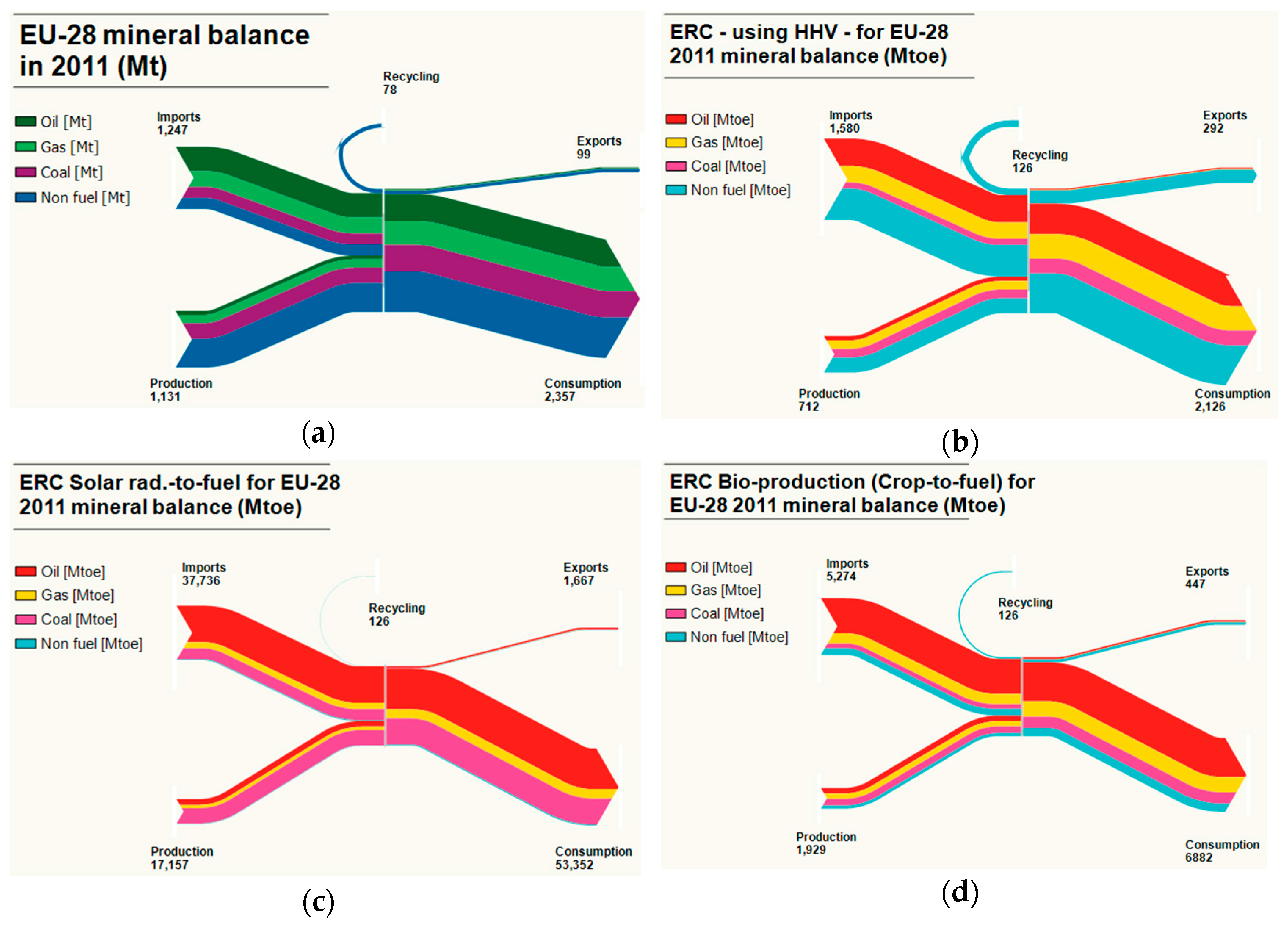

- Calvo et al. [14], who studied the trade directions in 2011 of material and exergy flows for the European Union (EU-28). Their dataset considered fossil fuels, and a total of 40 non-fuel minerals.

5. Results

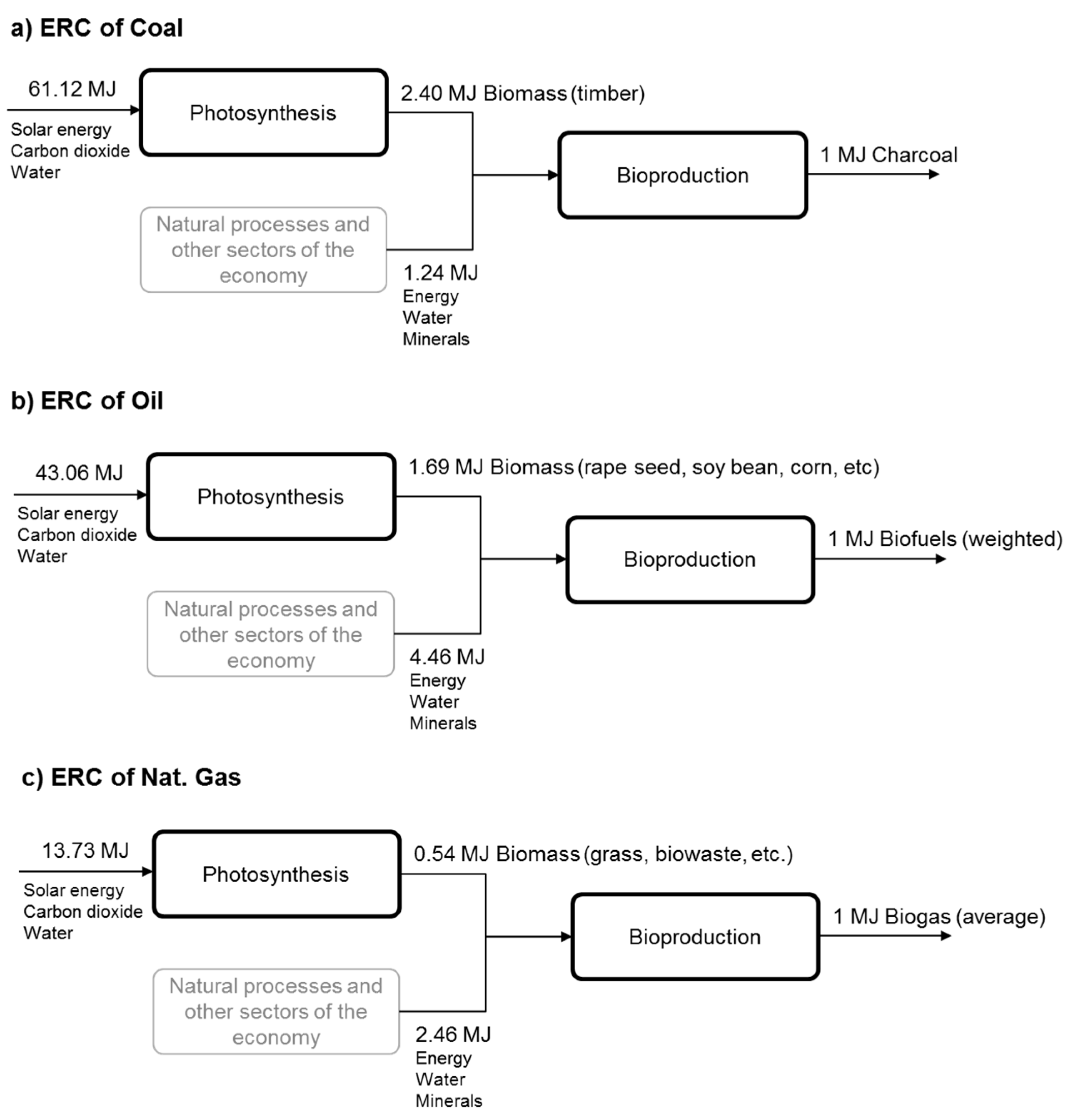

5.1. Exergy Cost of Bioproducts

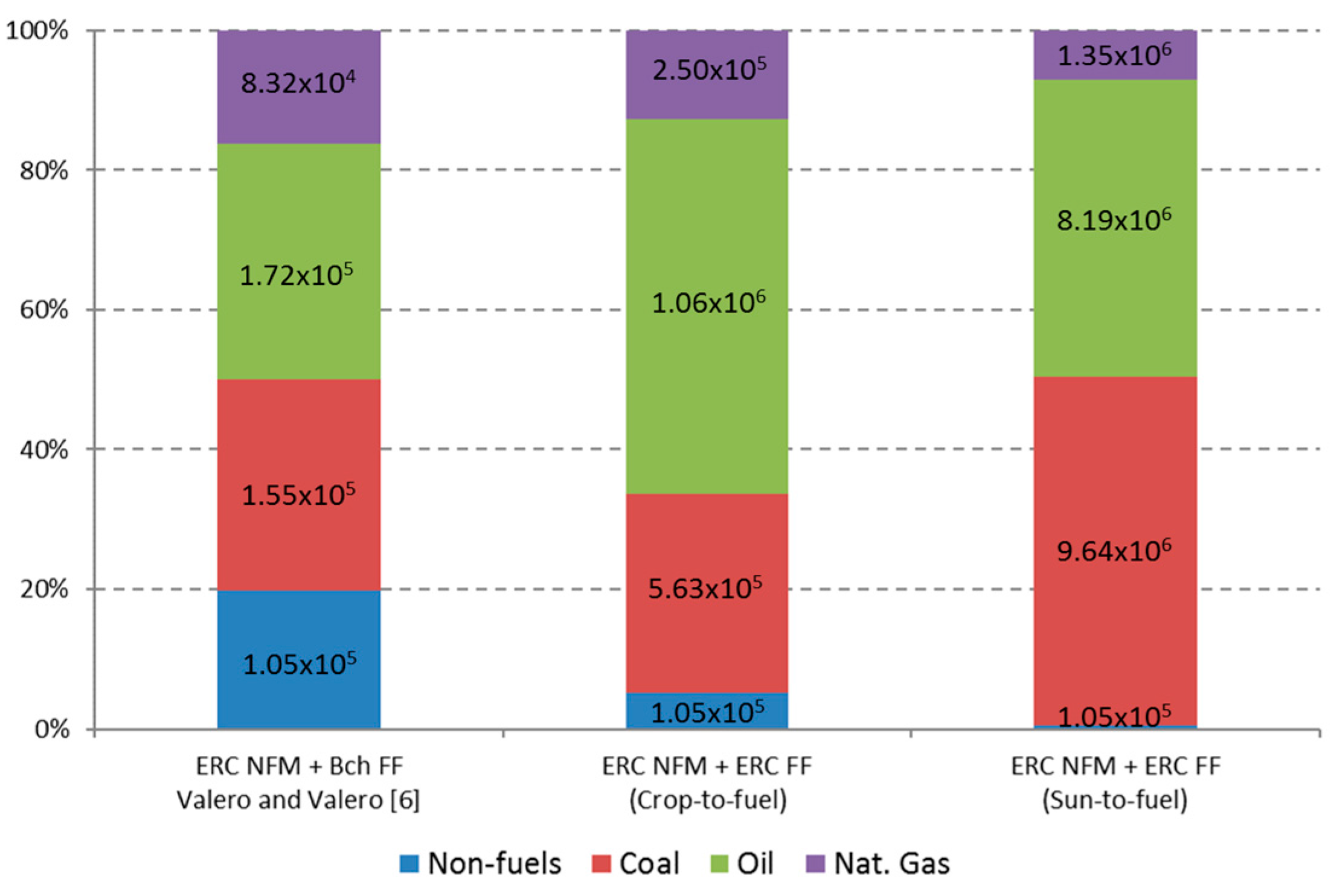

5.2. ERC of Fossil Fuels

5.3. Case Studies

6. Discussion

6.1. The Need for a Paradigm Shift in the ERC Concept

6.2. The Sustainability of Replacing Fossil Fuels with Biological Equivalents

7. Conclusions

Supplementary Materials

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Krausmann, F.; Wiedenhofer, D.; Lauk, C.; Haas, W.; Tanikawa, H.; Fishman, T.; Haberl, H. Global socioeconomic material stocks rise 23-fold over the 20th century and require half of annual resource use. Proc. Natl. Acad. Sci. USA 2017, 114, 1880–1885. [Google Scholar] [CrossRef] [PubMed]

- Raworth, K. Doughnut Economics: Seven Ways to Think Like a 21st-Century Economist; Chelsea Green Publishing: Chelsea, VT, USA, 2017. [Google Scholar]

- Valero, A.; Valero, A. From grave to cradle. J. Ind. Ecol. 2013, 17, 43–52. [Google Scholar] [CrossRef]

- Valero, A.; Botero, E.; Valero, A. Global Exergy Accounting of Natural Resources. In Exergy, Energy System Analysis, and Optimization, 1st ed.; Frangopoulos, C.A., Ed.; Eolss Publishers Co. Ltd: Oxford, UK, 2009; Volume 1, pp. 409–420. [Google Scholar]

- Valero, A.; Valero, A. Thermodynamic rarity and the loss of mineral wealth. Energies 2015, 8, 821–836. [Google Scholar] [CrossRef]

- Capilla, A.V.; Delgado, A.V. Thanatia: The Destiny of the Earth’s Mineral Resources: A Thermodynamic Cradle-to-Cradle Assessment, 1st ed.; World Scientific Publishing: Toh Tuck Link, Singapore, 2014; p. 628. ISBN 978-9814273930. [Google Scholar]

- Brundtland, G.H. Report of the World Commission on Environment and Development: “Our Common Future”. Available online: http://www.un-documents.net/our-common-future.pdf (accessed on 10 July 2017).

- Whiting, K.; Carmona, L.G.; Sousa, T. A review of the use of exergy to evaluate the sustainability of fossil fuels and non-fuel mineral depletion. Renew. Sustain. Energy Rev. 2017, 76, 202–211. [Google Scholar] [CrossRef]

- Cleveland, C.J.; Costanza, R.; Hall, C.A.; Kaufman, R. We approach macroeconomics from a thermodynamic perspective that emphasizes the production of goods, rather than the neoclassical perspective that emphasizes the exchange of goods according to. Science 1984, 225, 890. [Google Scholar] [CrossRef] [PubMed]

- Carmona, L.G.; Whiting, K. Pandora y Thanatia: Una visión termodinámica del agotamiento de los recursos minerales. Gestión y Ambiente 2014, 17, 119–127. [Google Scholar]

- Carmona, L.G.; Whiting, K.; Valero, A.; Valero, A. Colombian mineral resources: An analysis from a Thermodynamic Second Law perspective. Resour. Policy 2015, 45, 23–28. [Google Scholar] [CrossRef]

- Valero, A.; Valero, A. Physical geonomics: Combining the exergy and Hubbert peak analysis for predicting mineral resources depletion. Resour. Conserv. Recycl. 2010, 54, 1074–1083. [Google Scholar] [CrossRef]

- Valero, A.; Valero, A. A prediction of the exergy loss of the world’s mineral reserves in the 21st century. Energy 2011, 36, 1848–1854. [Google Scholar] [CrossRef]

- Calvo, G.; Valero, A.; Valero, A. Material flow analysis for Europe: An exergoecological approach. Ecol. Indic. 2016, 60, 603–610. [Google Scholar] [CrossRef]

- Calvo, G.; Valero, A.; Carmona, L.G.; Whiting, K. Physical Assessment of the Mineral Capital of a Nation: The Case of an Importing and an Exporting Country. Resources 2015, 4, 857–870. [Google Scholar] [CrossRef]

- Calvo, G.; Valero, A.; Valero, A.; Carpintero, Ó. An exergoecological analysis of the mineral economy in Spain. Energy 2015, 88, 2–8. [Google Scholar] [CrossRef]

- Valero, A.; Valero, A.; Arauzo, I. Evolution of the decrease in mineral exergy throughout the 20th century. The case of copper in the US. Energy 2008, 33, 107–115. [Google Scholar] [CrossRef]

- Valero, A.; Carpintero, Ó.; Valero, A.; Calvo, G. How to account for mineral depletion. The exergy and economic mineral balance of Spain as a case study. Ecol. Indic. 2014, 46, 548–559. [Google Scholar] [CrossRef]

- Valero, A.; Valero, A.; Calvo, G. Using thermodynamics to improve the resource efficiency indicator GDP/DMC. Resour. Conserv. Recycl. 2015, 94, 110–117. [Google Scholar] [CrossRef]

- Valero, A.; Valero, A.; von Gries, N. “Composed thermodynamic rarity” of the materials in electric and electronic equipment. In Proceedings of the 29th International Conference on Efficiency, Cost, Optimization, Simulation and Environmental Impact of Energy Systems, Portorož, Slovenia, 19–23 June 2016. [Google Scholar]

- Whiting, K.; Carmona, L.G.; Sousa, T. Bio-products: A new way to calculate fossil fuels in the grave to cradle exergy assessment. In Proceedings of the 29th International Conference on Efficiency, Cost, Optimization, Simulation and Environmental Impact of Energy Systems ECOS 2016, Portorož, Slovenia, 19–23 June 2016. [Google Scholar]

- Szargut, J. Exergy Method: Technical and Ecological Applications; WIT Press: Southampton, UK, 2005; Volume 18. [Google Scholar]

- Gaudreau, K.; Fraser, R.A.; Murphy, S. The characteristics of the exergy reference environment and its implications for sustainability-based decision-making. Energies 2012, 5, 2197–2213. [Google Scholar] [CrossRef]

- Zhou, J.; Ma, S.; Hinman, G.W. Ecological exergy analysis: A new method for ecological energetics research. Ecol. Model. 1996, 84, 291–303. [Google Scholar] [CrossRef]

- Lems, S.; Van Der Kooi, H.J.; De Swaan Arons, J. Exergy analyses of the biochemical processes of photosynthesis. Int. J. Exergy 2010, 7, 333–351. [Google Scholar] [CrossRef]

- Beal, C.M.; Hebner, R.E.; Webber, M.E. Thermodynamic analysis of algal biocrude production. Energy 2012, 44, 925–943. [Google Scholar] [CrossRef]

- Silva, C.S.; Seider, W.D.; Lior, N. Exergy efficiency of plant photosynthesis. Chem. Eng. Sci. 2015, 130, 151–171. [Google Scholar] [CrossRef]

- Keller, J.U. Thermodynamic Analysis of Photosynthesis. Available online: http://www.mb.uni-siegen.de/tts/personen/juk/biothermodynamik/photosynthese_neu.pdf (accessed on 7 July 2017).

- Albarrán-Zavala, E.; Angulo-Brown, F. A simple thermodynamic analysis of photosynthesis. Entropy 2007, 9, 152–168. [Google Scholar] [CrossRef]

- Sorgüven, E.; Özilgen, M. Thermodynamic efficiency of synthesis, storage and breakdown of the high-energy metabolites by photosynthetic microalgae. Energy 2013, 58, 679–687. [Google Scholar] [CrossRef]

- SourceOECD (Online Service). World Energy Outlook. International Energy Agency. Available online: http://www.worldenergyoutlook.org/weo2013/ (accessed on 7 July 2017).

- BP. BP Energy Outlook 2035. January 2014. Tech. Rep.. Available online: http://www.bp.com/content/dam/bp/pdf/energy-economics/energy-outlook-2016/bp-energy-outlook-2014.pdf (accessed on 10 July 2017).

- Stocker, T.F.; Qin, D.; Plattner, G.K.; Tignor, M.; Allen, S.K.; Boschung, J.; Midgley, B.M. IPCC, 2013: Climate Change 2013: The Physical Science Basis. Contribution of Working Group I to the Fifth Assessment Report of the Intergovernmental Panel on Climate Change. Available online: http://www.ipcc.ch/report/ar5/wg1/ (accessed on 7 July 2017).

- Mohr, S.H.; Evans, G.M. Long term forecasting of natural gas production. Energy Policy 2011, 39, 5550–5560. [Google Scholar] [CrossRef]

- Mohr, S.H.; Wang, J.; Ellem, G.; Ward, J.; Giurco, D. Projection of world fossil fuels by country. Fuel 2015, 141, 120–135. [Google Scholar] [CrossRef]

- Court, V.; Fizaine, F. Long-Term Estimates of the Energy-Return-on-Investment (EROI) of Coal, Oil, and Gas Global Productions. Ecol. Econ. 2017, 138, 145–159. [Google Scholar] [CrossRef]

- Piekarczyk, W.; Czarnowska, L.; Ptasiński, K.; Stanek, W. Thermodynamic evaluation of biomass-to-biofuels production systems. Energy 2013, 62, 95–104. [Google Scholar] [CrossRef]

- Fick, G.; Mirgaux, O.; Neau, P.; Patisson, F. Using biomass for pig iron production: A technical, environmental and economical assessment. Waste Biomass Valoriz. 2014, 5, 43–55. [Google Scholar] [CrossRef]

- Jahanshahi, S.; Somerville, M.; Deev, A.; Mathieson, J. Biomass: Providing a Low Capital Route to Low Net CO2. Available online: http://www.ieaghg.org/docs/General_Docs/Iron%20and%20Steel%202%20Secured%20presentations/3_1420%20John%20Mathieson.pdf (accessed on 7 July 2017).

- Reichel, T.; Demus, T.; Echterhof, T.; Pfeifer, H. Increasing the sustainability of the steel production in the electric arc furnace by substituting fossil coal with biochar. In Proceedings of the 4th Central European Biomass Conference, Graz, Austria, 16 January 2014. [Google Scholar]

- European Commision (2014) Green Fuel for Steel Furnaces. Available online: https://ec.europa.eu/programmes/horizon2020/en/news/green-fuel-steel-furnaces (accessed on 7 July 2017).

- Hari, T.K.; Yaakob, Z.; Binitha, N.N. Aviation biofuel from renewable resources: Routes, opportunities and challenges. Renew. Sustain. Energy Rev. 2015, 42, 1234–1244. [Google Scholar] [CrossRef]

- Deutsche Welle (2012) Lufthansa Suspends Biofuel Test Flights 12th January 2012. Available online: https://pdfs.semanticscholar.org/a67f/53a767b0585f5d844db5477d2b45df8ec7c4.pdf (accessed on 7 July 2017).

- Kick, T.; Herbst, J.; Kathrotia, T.; Marquetand, J.; Braun-Unkhoff, M.; Naumann, C.; Riedel, U. An experimental and modeling study of burning velocities of possible future synthetic jet fuels. Energy 2012, 43, 111–123. [Google Scholar] [CrossRef]

- Gegg, P.; Budd, L.; Ison, S. The market development of aviation biofuel: Drivers and constraints. J. Air Trans. Manag. 2014, 39, 34–40. [Google Scholar] [CrossRef]

- Osayi, J.I.; Iyuke, S.; Ogbeide, S.E. Biocrude production through pyrolysis of used tyres. J. Catal. 2014, 2014, 386371. [Google Scholar] [CrossRef]

- Marsh, G. Biofuels: Aviation alternative? Renew. Energy Focus 2008, 9, 48–51. [Google Scholar] [CrossRef]

- Zhao, S.; Huang, B.; Ye, X.P.; Shu, X.; Jia, X. Utilizing bio-char as a bio-modifier for asphalt cement: A sustainable application of bio-fuel by-product. Fuel 2014, 133, 52–62. [Google Scholar] [CrossRef]

- Kolokolova, O. Biomass Pyrolysis and Optimisation for Bio-Bitumen. Master’s Thesis, University of Canterbury, Christchurch, New Zealand, 2013. [Google Scholar]

- Guarin, A.; Khan, A.; Butt, A.A.; Birgisson, B.; Kringos, N. An extensive laboratory investigation of the use of bio-oil modified bitumen in road construction. Constr. Build. Mater. 2016, 106, 133–139. [Google Scholar] [CrossRef]

- Ribeiro, L.A.; da Silva, P.P.; Mata, T.M.; Martins, A.A. Prospects of using microalgae for biofuels production: Results of a Delphi study. Renew. Energy 2015, 75, 799–804. [Google Scholar] [CrossRef]

- Pate, R.; Klise, G.; Wu, B. Resource demand implications for US algae biofuels production scale-up. Appl. Energy 2011, 88, 3377–3388. [Google Scholar] [CrossRef]

- Ho, S.H.; Chen, C.Y.; Lee, D.J.; Chang, J.S. Perspectives on microalgal CO2-emission mitigation systems—A review. Biotechnol. Adv. 2011, 29, 189–198. [Google Scholar] [CrossRef] [PubMed]

- Wang, B.; Li, Y.; Wu, N.; Lan, C.Q. CO2 bio-mitigation using microalgae. Appl. Microbiol. Biotechnol. 2008, 79, 707–718. [Google Scholar] [CrossRef] [PubMed]

- Gouveia, L.; Marques, A.E.; Da Silva, T.L.; Reis, A. Neochloris oleabundans UTEX# 1185: A suitable renewable lipid source for biofuel production. J. Ind. Microbiol. Biotechnol. 2009, 36, 821–826. [Google Scholar] [PubMed]

- Gouveia, L.; Oliveira, A.C. Microalgae as a raw material for biofuels production. J. Ind. Microbiol. Biotechnol. 2009, 36, 269–274. [Google Scholar] [CrossRef] [PubMed]

- Li, Y.; Horsman, M.; Wang, B.; Wu, N.; Lan, C.Q. Effects of nitrogen sources on cell growth and lipid accumulation of green alga Neochloris oleoabundans. Appl. Microb. Biotechnol. 2008, 81, 629–636. [Google Scholar] [CrossRef] [PubMed]

- Pruvost, J.; Van Vooren, G.; Cogne, G.; Legrand, J. Investigation of biomass and lipids production with Neochloris oleoabundans in photobioreactor. Bioresour. Technol. 2009, 100, 5988–5995. [Google Scholar] [CrossRef] [PubMed]

- Tornabene, T.G.; Holzer, G.; Lien, S.; Burris, N. Lipid composition of the nitrogen starved green alga Neochloris oleoabundans. Enzym. Microb. Technol. 1983, 5, 435–440. [Google Scholar] [CrossRef]

- Baldisserotto, C.; Popovich, C.; Giovanardi, M.; Sabia, A.; Ferroni, L.; Constenla, D.; Pancaldi, S. Photosynthetic aspects and lipid profiles in the mixotrophic alga Neochloris oleoabundans as useful parameters for biodiesel production. Algal Res. 2016, 16, 255–265. [Google Scholar] [CrossRef]

- Giovanardi, M.; Ferroni, L.; Baldisserotto, C.; Tedeschi, P.; Maietti, A.; Pantaleoni, L.; Pancaldi, S. Morphophysiological analyses of Neochloris oleoabundans (Chlorophyta) grown mixotrophically in a carbon-rich waste product. Protoplasma 2013, 250, 161–174. [Google Scholar] [CrossRef] [PubMed]

- Liao, W.; Heijungs, R.; Huppes, G. Is bioethanol a sustainable energy source? An energy-, exergy-, and emergy-based thermodynamic system analysis. Renew. Energy 2011, 36, 3479–3487. [Google Scholar] [CrossRef]

- Giljum, S.; Burger, E.; Hinterberger, F.; Lutter, S.; Bruckner, M. A comprehensive set of resource use indicators from the micro to the macro level. Resour. Conserv. Recycl. 2011, 55, 300–308. [Google Scholar] [CrossRef]

- Liao, W.; Heijungs, R.; Huppes, G. Thermodynamic resource indicators in LCA: A case study on the titania produced in Panzhihua city, southwest China. Int. J. Life Cycle Assess. 2012, 17, 951–961. [Google Scholar] [CrossRef]

- Bösch, M.E.; Hellweg, S.; Huijbregts, M.A.; Frischknecht, R. Applying cumulative exergy demand (CExD) indicators to the ecoinvent database. Int. J. Life Cycle Assess. 2007, 12, 181–190. [Google Scholar] [CrossRef]

- Dincer, I.; Rosen, M.A. Exergy: Energy, Environment and Sustainable Development, 2nd ed.; Elsevier: Kidlington, UK, 2013; p. 424. [Google Scholar]

- Duprey, R.L. Compilation of Air Pollutant Emission Factors; National Center for Air Pollution Control: Cincinnati, OH, USA, 1968. [Google Scholar]

- Berthiaume, R.; Bouchard, C.; Rosen, M.A. Exergetic evaluation of the renewability of a biofuel. Exergy Int. J. 2001, 1, 256–268. [Google Scholar] [CrossRef]

- Font de Mora, E.; Torres, C.; Valero, A. Assessment of biodiesel energy sustainability using the exergy return on investment concept. Energy 2012, 45, 474–480. [Google Scholar] [CrossRef]

- Font de Mora, E.; Torres, C.; Valero, A. Thermoeconomic Analysis of Biodiesel Production from Used Cooking Oils. Sustainability 2015, 7, 6321–6335. [Google Scholar] [CrossRef]

- Frenzel, P.; Hillerbrand, R.; Pfennig, A. Exergetical evaluation of biobased synthesis pathways. Polymer 2014, 6, 327–345. [Google Scholar] [CrossRef]

- Frenzel, P.; Hillerbrand, R.; Pfennig, A. Increase in energy and land use by a bio-based chemical industry. Chem. Eng. Res. Des. 2014, 92, 2006–2015. [Google Scholar] [CrossRef]

- Jungbluth, N.; Chudacoff, M.; Dauriat, A.; Dinkel, F.; Doka, G.; Faist Emmenegger, M.; Gnansounou, E.; Kljun, N.; Schleiss, K.; Spielmann, M.; et al. Life Cycle Inventories of Bioenergy. Available online: https://scholar.google.co.uk/scholar?q=Life+Cycle+Inventories+of+Bioenergy&btnG=&hl=en&as_sdt=0%2C5 (accessed on 10 July 2017).

- Martin, M.; Parsapour, A. Upcycling wastes with biogas production: An exergy and economic analysis. In Proceedings of the International Symposium on Energy from Biomass and Waste, Venice, Italy, 5 December 2012. [Google Scholar]

- Patzek, T.W. Thermodynamics of the corn-ethanol biofuel cycle. Crit. Rev. Plant Sci. 2014, 23, 519–567. [Google Scholar] [CrossRef]

- Sorguven, E.; Özilgen, M. Thermodynamic assessment of algal biodiesel utilization. Renew. Energy 2010, 35, 1956–1966. [Google Scholar] [CrossRef]

- Talens-Peiró, L.; Méndez, G.V.; Sciubba, E.; Durany, X.G. Extended exergy accounting applied to biodiesel production. Energy 2010, 35, 2861–2869. [Google Scholar] [CrossRef]

- EIA (2017) Workbook Contents U.S. Refinery Yield. Available online: https://www.eia.gov/dnav/pet/xls/PET_PNP_PCT_DC_NUS_PCT_A.xls (accessed on 10 July 2017).

- Ekvall, T.; Hirschnitz-Garbers, M.; Eboli, F.; Śniegocki, A. A systemic and systematic approach to the development of a policy mix for material resource efficiency. Sustainability 2016, 8, 373. [Google Scholar] [CrossRef]

- Eurostat European Commission. Energy Balance Sheets 2011–2012, 2014 Edition. Available online: http://ec.europa.eu/eurostat/web/products-statistical-books/-/KS-EN-14-001 (accessed on 10 July 2017).

- Hoekstra, A.Y.; Chapagain, A.K. Water Footprints of Nations, Value of Water Research Report Series No. 16; UNESCO-IHE: Delft, The Netherlands, 2004. [Google Scholar]

- Hoekstra, A.Y.; Chapagain, A.K. Water footprints of nations: Water use by people as a function of their consumption pattern. In Integrated Assessment of Water Resources and Global Change, 1st ed.; Springer: Dordrecht, The Netherlands, 2006; pp. 35–48. [Google Scholar]

- Pfister, S.; Koehler, A.; Hellweg, S. Assessing the environmental impacts of freshwater consumption in LCA. Environ. Sci. Technol. 2009, 43, 4098–4104. [Google Scholar] [CrossRef] [PubMed]

- Lomborg, B. The Skeptical Environmentalist: Measuring the Real State of the World, 2nd ed.; Cambridge University Press: Cambridge, UK, 2003; pp. 94–97. [Google Scholar]

- Arodudu, O.; Helming, K.; Wiggering, H.; Voinov, A. Bioenergy from Low-Intensity Agricultural Systems: An Energy Efficiency Analysis. Energies 2016, 10, 29. [Google Scholar] [CrossRef]

- Ajanovic, A. Biofuels versus food production: Does biofuels production increase food prices? Energy 2011, 36, 2070–2076. [Google Scholar] [CrossRef]

- Pedroli, B.; Elbersen, B.; Frederiksen, P.; Grandin, U.; Heikkilä, R.; Krogh, P.H.; Izakovičová, Z.; Johansen, A.; Meiresonne, L.; Spijker, J. Is energy cropping in Europe compatible with biodiversity?–Opportunities and threats to biodiversity from land-based production of biomass for bioenergy purposes. Biomass Bioenergy 2013, 55, 73–86. [Google Scholar] [CrossRef]

- Rathmann, R.; Szklo, A.; Schaeffer, R. Land use competition for production of food and liquid biofuels: An analysis of the arguments in the current debate. Renew. Energy 2010, 35, 14–22. [Google Scholar] [CrossRef]

- Searchinger, T.; Heimlich, R. Avoiding Bioenergy Competition for Food Crops and Land. World Resources Institute. Available online: http://www.wri.org/publication/avoiding-bioenergycompetition-food-crops-and-land (accessed on 10 July 2017).

- Steer, A.; Hanson, C. Biofuels Are Not a Green Alternative to Fossil Fuels. Available online: http://www.theguardian.com/environment/2015/jan/29/biofuels-are-not-the-green-alternative-to-fossil-fuels-they-are-sold-as (accessed on 10 July 2017).

- Ackrill, R.; Kay, A. The Growth of Biofuels in the 21st Century: Policy Drivers and Market Challenges, 1st ed.; Palgrave Macmillan: London, UK, 2014; p. 250. [Google Scholar]

| Fossil Fuel | Product | Reference Information | ||

|---|---|---|---|---|

| Bio-Equivalent | Bio-Sources | Number of Studies | ||

| Oil | Gasoline | Bioethanol | Corn, spent barley, sweet sorghum, sugarcane, sugar beets, rye, whey, potatoes, grass, non-specified biomass | 22 |

| Diesel and Jet Fuel | Biodiesel | Rapeseed, sunflower, palm oil, microalgae, soy bean | 14 | |

| LPG | Bio-SNG | Wood, non-specified biomass | 3 | |

| Kerosene | Used cooking oil (UCO) | Cooking oil | 2 | |

| Polymers | Bio-PET | Wheat, rapeseed | 0 * | |

| Asphalt and Coke | Biochar | Wood | 1 | |

| Others | Methanol, FT, Oil | Sawdust, sewage sludge biomass, wheat | 2 | |

| Natural gas | Natural gas | Biogas | Agro-waste, slurry, sewage sludge, grass, biowaste | 13 |

| Coal | Charcoal | Biochar | Wood | 1 |

| Fuel | Product | Bio-Equivalent | Average κ | St Dev | Min | Max |

|---|---|---|---|---|---|---|

| Oil | Gasoline | Bioethanol | 6.93 | 2.92 | 1.91 | 12.56 |

| Diesel and Jet Fuel | Biodiesel | 5.75 | 3.61 | 1.94 | 11.97 | |

| LPG | Bio-SNG | 2.24 | 0.05 | 2.19 | 2.29 | |

| Kerosene | Used cooking oil (UCO) | 1.32 | 0.92 | 0.67 | 1.97 | |

| Asphalt/Coke | Biochar | 3.64 | - | - | - | |

| Others | Methanol | 14.08 | 0.42 | 13.78 | 14.38 | |

| Natural gas | Natural gas | Biogas | 3.00 | 2.15 | 0.87 | 6.73 |

| Coal | Charcoal | Biochar | 3.64 | - | - | - |

| Mineral | κ or ERC Photosynthesis (MJ/MJ) | κ or ERC Bioproduction (MJ/MJ) | κ or Total ERC (MJ/MJ) | Total ERC (GJ/Tonne) |

|---|---|---|---|---|

| Coal | 61.12 | 3.64 | 62.35 | 1414.7 |

| Oil | 43.06 | 6.15 | 47.52 | 2170.0 |

| Natural Gas | 13.73 | 3.00 | 16.19 | 575.3 |

| Phosphate Rock | (Lowest value of 36 minerals analysed in [6]) | 0.4 | ||

| Gold | (Highest value of 36 minerals analysed in [6]) | 583,668.0 | ||

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Whiting, K.; Carmona, L.G.; Carrasco, A.; Sousa, T. Exergy Replacement Cost of Fossil Fuels: Closing the Carbon Cycle. Energies 2017, 10, 979. https://doi.org/10.3390/en10070979

Whiting K, Carmona LG, Carrasco A, Sousa T. Exergy Replacement Cost of Fossil Fuels: Closing the Carbon Cycle. Energies. 2017; 10(7):979. https://doi.org/10.3390/en10070979

Chicago/Turabian StyleWhiting, Kai, Luis Gabriel Carmona, Angeles Carrasco, and Tânia Sousa. 2017. "Exergy Replacement Cost of Fossil Fuels: Closing the Carbon Cycle" Energies 10, no. 7: 979. https://doi.org/10.3390/en10070979