1. Introduction

Today, research and development in the field of comprehensive building solutions and the implementation of advanced forms of materials in construction are in great demand. This is primarily due to the expansion of new scientific knowledge in both fields. Furthermore, the challenge is to achieve flexibility in the manufacturing of building façade components in order to adapt them to different types of facades and meet our current needs. At present, buildings are usually constructed with a frame structure which is filled by prefabricated façade panels, these being either modular or with adaptable ways. Such panels have disadvantages, such their focus is on only some building physics features (e.g., lighting, shading, thermal insulation, acoustics, fire protection, and moisture handling), and limited (if any) integration of renewable energy sources. That is why multifunctional [

1,

2,

3], adaptive and responsive [

4,

5] façade systems are designed to be used in modular constructions and future façade design approaches with the highest possible level of prefabrication and at the same time the best possible integration of renewable energy generation (e.g., solar, photovoltaics, hybrid technologies, etc.). That is why actually switching from static to adaptable and dynamic building envelopes [

6] is seeing rapid progress. Recently, a wide range of progressive solutions have been investigated. Newly disseminated theoretical findings can be implemented in the field of building science. Another related research topic is the development and evaluation of different technical solutions and the integration of new progressive materials. Considering the most recent findings, it could be one way of improving the thermal and/or energy performance of current buildings and including new technologies [

7,

8]. New ideas and the latest developments in research into various innovative materials, for instance materials with phase change aspects (PCMs) [

9,

10], transparent insulation materials (TIMs), vacuum insulation panels (VIPs) [

11], and materials specifically based on new nano-technologies such as aerogel insulation [

12], etc., are becoming the basis for a variety of potential combinations in future building components. One possible way of developing solar technology even involves the development of materials with spectral selective functions [

13] that can principally employ individually required parameters for specific cases within the thermal radiation spectrum. Concurrently, in the near future, the directives and requirements of the Energy Performance of Buildings Directive II framework will be enforced for all building types: newly built, retrofitted and revitalized, residential and non-residential, etc. with regard to attaining near zero energy performance attributes and subsequently approaching a zero energy balance. This requires a high level of thermal insulation function throughout the whole building envelope. When we consider the opaque vertical parts of the envelope, depending on building type, basically the proportion of the walls taken up by such parts consists of more than 50% of the total area. As a result, the opaque building envelope becomes of high relevance as regards solar energy exploitation. In order to optimise building envelope thickness [

14], attention is also being focused on façade systems integrating passive or active heating and cooling systems with the aim of achieving the greatest rate of energy self-sustainability for the whole building. From this point of view, the basic requirement concerns synergy between the provision of improvements in thermal insulation functions for winter periods and, on the other hand, the elimination of overheating in the summer.

The main principle of the presented research is based on solar wall principles [

15,

16,

17], of which the most fundamental is the Trombe wall [

18,

19] design that was developed a few decades ago. Various applications of solar walls and their significance for energy savings in buildings are discussed in literature reviews. An operational framework of already developed solar-wall configurations, used technologies and their efficiency is analyzed in detail in, e.g., [

15], as well as by many other authors and research teams aiming to implement the need for this sustainable energy design approach to improving the energy efficiency of buildings [

20]. Their research typically concerns the application of passive wall systems. Recently, the use of an innovative Trombe wall as a passive heating system modified by an extra window was presented and numerically investigated in [

21]. Both [

22,

23], the numerical [

24,

25,

26,

27] and experimental [

28,

29,

30,

31] approaches, detailed in the literature, are variously taken into account. Basically, a conventional Trombe wall is a system that transforms indirect solar gain into thermal energy. It is normally composed of a massive wall painted black, an exterior glazing cover, and a ventilated air gap in between these two elements [

25].

With regard to this novel form closely related to the idea of solar walls and facades, the integration of innovative materials may be of great importance. From the basic materials perspective, transparent insulation materials (TIMs) [

32] could predominantly be used with current concepts that are trying to replace conventional insulating materials. However, their use in building envelopes only occurs in specific situations, and therefore application in building practice is currently rather rare. The earliest references relate to both theoretical and experimental work on the use of TIMs as aperture covers for flat-plate solar collectors, while later works introduce TIMs integrated into translucent building façades to provide natural lighting and solar space heating in order to reduce lighting and heating energy requirements in buildings. For instance, a stable honeycomb structure made of natural materials is the innovative element in a façade system developed in Austria. Principally, the rays of the winter sun penetrate deep into the honeycomb and increase its temperature. This autonomous zone reduces heat loss to almost zero and reduces thermal bridges. During the summer, much of the radiation is reflected due to the honeycomb structure itself. However, the installation of an excessive quantity of TIMs is not only cost-inefficient, but can also cause problems with overheating. Several studies describe the benefits of TIMs, their disadvantages and the options for their application [

33]. Various implementations are looking for integration in building compositions [

34] with the aim of analyzing their potential contribution related to energy balance and many other thermal aspects, depending on climatic conditions, and finally determining the potential payback period if using them [

35]. The environmental and energy aspects of TIMs in selected climatic zones of Austria and for a variety of building types with the influence of differing cardinal orientation have been previously studied [

36]. There is a perspective option to improve the efficiency of flat plate solar air collectors as well as novel solar façade concepts by replacing their conventional glass covers with TIMs. Dowson et al. [

37] implements a lightweight polycarbonate panels filled with high performance aerogel insulation for it to be incorporated in a solar air collector to improve its overall performance. Another approach is based on a prototype of innovative flat plate solar collector with honeycomb TIM that has been constructed and experimentally tested and in parallel, a numerical model has been implemented by Kessentini et al. A specific ventilation channel with a thermally actuated door was inserted below the absorber allowing to protect the collector from stagnation conditions, while preserving good performance during normal operation [

38]. In Dowson et al. [

39], the in-situ performance of a flat plate solar air heater connected to a dwelling’s active mechanical ventilation system with heat recovery was carried out. Again, in his concept, instead of glass, the cover was a lightweight multiwall polycarbonate panel filled with granular aerogel as the form of TIM. Concerning the specific structure of honeycomb TIM and its modelling, several works were conducted. Cadafalch [

40] addresses in detail the formulation and numerical approach adopted to solve transparently insulated layers with honeycomb structures integrated within the flat plate solar thermal device transient model. A numerical model for a honeycomb was developed by Suehrcke et al. [

41] based on the experimentally measured results whilst three-dimensional heat transfer analysis destined for improving the efficiency of flat plate solar collectors was performed by Kessentini et al [

42] to finally develop new correlations for the heat transfer coefficients through the TIM. At the novel form, our recent findings can contribute to the integration of TIM coupled with a selective absorbent technologies in façade construction as key absorbing factors that may be used to prevent heat loss in winter, decrease overheating in summer, and finally allow the conversion of incident solar energy into thermal energy. With respect to the observation of heat storage and thermal capacity layers, the integration of advanced forms of PCM-based heat storage may have significant role [

43]. In this regard, experimental research and numerical modelling are required in relation to the fundamental interaction base and final full-scale approach.

2. Methodological Approach

A new solar façade concept based on transparent insulation and a selective absorber is proposed at fundamental level, tested and confronted experimentally with conventional insulation and a non-selective type of absorber, respectively. The focus of this research is to analyze the contribution of optical properties applied in a newly proposed experimental solar prototype in order to investigate their interrelationships for a final future contemporary solar façade concept applying advanced forms of materials. Based on solar wall principles, the main objective is to measure the temperature response within proposed components at a laboratory during initial full-scale levels of exposure to solar radiation, especially via the monitoring of the response at the surfaces and in the air cavity behind transparent insulation (honeycomb transparent PMMA-based) with the integration of a selective function, both with high solar absorbance level. The main structure of this analysis is based on:

- -

Short term monitoring of the temperature response within proposed components,

- -

Analyzing the thermal benefits of optical properties involved in components,

- -

Measurements of a comparative nature with solar radiation exposure,

- -

Thermal resistance quantification of proposed components,

- -

Solar transmittance measurements of TIMs applied based on an outdoor approach.

The key aspect of this contribution resides in investigating the thermodynamic, steady state and time transient heat transfer applied in a proposed small- and full-scale solar façade concept that is to be potentially implemented in future full-scale testing modes. Laboratory, small- and full-scale tests were conducted to analyse the thermal performance of the proposed components based on the solar wall principle. The main objective of this study relies on:

- i

The determination of spectral optical properties; reflective measurement techniques and spectral methods were applied to determine the solar reflectance and thermal emissivity parameters of samples tested in small-scale mode as the predominant and most sensitive attribute in the analysis of the presented concept,

- ii

The determination of thermal resistance; the guarded hot plate method was applied in determining thermal resistance and/or equivalent thermal conductivity parameters,

- iii

The determination of total solar transmittance; dynamic outdoor principles and spectral methods were applied and compared with each other, determining the solar transmittance parameters of transparent insulation samples, both at the laboratory and small-scale outdoor level,

- iv

Monitoring of thermal performance and temperature response during solar simulator and outdoor small-scale tests,

- v

Thermodynamic testing based on initial full-scale outdoor testing of the compositions of the proposed structure with transparent insulation glazing units and spectrally selective functions with a high solar absorbance level, both at the high- and low-emissivity base.

For the purpose of spectral optical and thermal analysis samples were prepared (

Table 1) and spectral optical properties were measured. The main difference between all tested samples was in their absorber part and the form of applied thermal insulation, for both the transparent and conventional type. A spectrally selective absorber and thermal insulation of the transparent type were used as a proposed base.

Table 2 shows all the measured materials applied for this study. Two types of absorbers were tested in combination with transparent insulation. One standard conventional sample of expanded polystyrene was used as a reference (

Table 3). Basically, each concept consists of several functional layers. First represents thermal insulation based on conventional and transparent insulation type, both coupled with non-ventilated air cavity. Second is based on the type of absorber, selective and non-selective type. Last material employs the heat accumulation layer which is on a basis of gypsum board. It represents thermal accumulation mass of thermal energy in structure. External side of gypsum board is directly covered by absorber layer. Finally, transparent insulation concepts are covered by simple glass pane from external side.

For the thermodynamic experiments: a steady state and time-transient analysis was carried out based on experimental measurements of the models prepared for the testing of each concept, where at the laboratory scale the temperature response through the measured elements was analysed primarily together with the monitoring of all parameters specifically related to thermal and optical properties. The temperature response was monitored with the application of a solar simulator at the BCEE laboratories at Concordia University (Montreal, QC, Canada). Material parameters and the data obtained from outdoor testing were analysed at the AdMaS research centre at Brno University of Technology.

3. Thermal and Spectral Optical Analysis

One of the assumptions in the field of experimental approaches is based on appropriately quantifying the optical and thermal properties of the proposed model. This issue, as it relates to the presented concept, should therefore be quantified in terms of thermal performance in several specific areas. The first focuses on the model’s spectral optical properties. The solar reflectance and thermal emissivity parameters of solar absorbers were measured, whilst in the case of the transparent insulation layer, solar transmittance needed to be determined in an optimum manner at the angular and spectral optical level. From the point of view of thermal aspects, thermal resistance was analysed, whole concepts and each individual material were tested.

3.1. Spectral Reflectance and Emissivity Measurements

The measurement of solar reflectance parameters requires techniques based on measuring the fraction of incident beam light of wavelength reflected by a surface. Solar reflectance properties can basically be determined by three measurement instruments: the pyranometer, spectrophotometer and solar spectrum reflectometer [

44]. Detailed specifications and their interrelated comparison can also be found in [

44,

45]. For this analysis, spectrophotometer measurements were taken.

A Lambda 1050 UV/VIS/NIR spectrophotometer (PerkinElmer, Waltham, MA, USA) equipped with a 150 mm Spectralon integrating sphere was used to measure solar reflectance. This apparatus can register spectral reflectance properties ranging from 200 nm to 3300 nm. Spectral curves and integrated total solar reflectance (TSR) values from 280 to 2500 nm are presented. The solar reflectance is calculated by means of ASTM Standard G173 [

46] for hemispherical global tilt irradiance Equation (1) and of each specific region is demonstrated, where

R is the percent reflectance,

I is the solar irradiance and

dλ is the wavelength interval of integration. For the solar weighted hemispherical and specular reflectance evaluating, this can be calculated according to a procedure characterized by Gagliano, respectively [

47]:

The available principles for the determination of spectral emissivity (reflectance) are based on spectral analysis using infrared spectroscopy in the longwave region. Reflective measurement techniques utilising a Michaelson wave interferometer and Fourier Transform (FT-IR) are used. A Nicolet 380 infrared spectrometer from the Thermo Electron Corporation (Waltham, MA, USA) equipped with a Mid-IR™ IntegratIR integrating sphere from PIKE Technologies (Madison, WI, USA) was used. The applied instrument represents a method by which the detector can eliminate any reflected radiation loss by integrating sphere from the whole measured surface area.

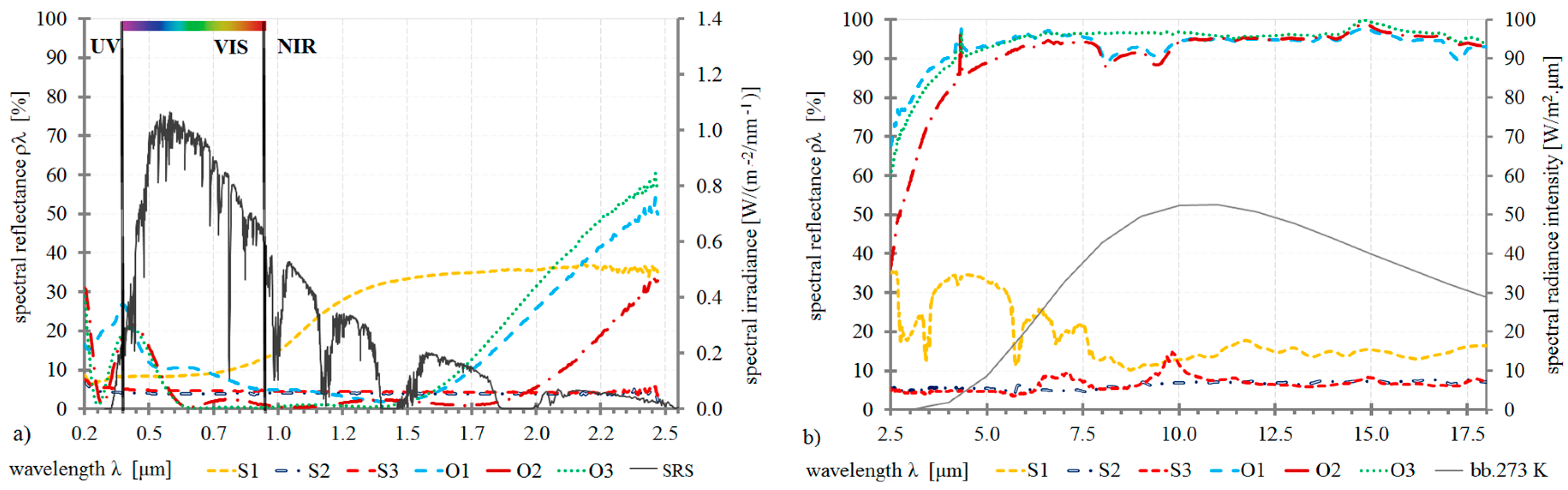

The results of the measurements are spectrally presented in a range from 200 nm to 20 μm (

Figure 1). The graphs represent all thermal regions of the spectrum. The spectral irradiance curve of the solar radiation spectrum is shown in the UV/VIS/NIR results, while the curve for the spectral radiance intensity of a 273 K black body (bb273K) represents the weighted function for the determination of emissivity in the results of the longwave infrared radiation range.

Figure 1 present the results of spectral reflectance in the solar and longwave radiation spectrum respectively. The results of the spectral reflectance analysis are finally evaluated as thermal emissivity and solar absorbance values (

Table 4) according to the method in [

48].

An equation (Equation (2)) can be used for determination of the measurement results in terms of emissivity values, which result from the law of the conservation of energy and Kirchhoff’s laws:

As a consequence, Plank’s formula (Equation (3)) of spectral radiance intensity of 273 K black body

M0,λ (

Figure 1) as the weighted function for determination of emissivity values was used (

Table 4):

3.2. Solar Transmittance Quantification

Several studies aimed to measure the directional-hemispherical (also sometimes called direct-diffuse) solar transmittance for various honeycomb-type structures with an indoor solar simulator and a 40 cm diameter integrating sphere for incidence angles up to 70° [

49,

50]. In this relation, outdoor measurements using the sun as the source might be the option. Platzer [

49] pointed out that it is not an option for Central European climates. Although there are many specific issues to take into account, such as inclined angular dependence, fluctuations of solar irradiation and overall solar distribution as well as cardinal point aspect, we employed the using of solar transmittance estimating by real outdoor measurements. This is already implemented in standard test method for solar transmittance of sheet materials using sunlight with detailed specification and procedures according to ASTM E1084-86(2015) [

51]. Overall, there is lack information regarding real outdoor measurements in literature as typically used for solar transmittance measurements. Therefore, this may represent very simple and well available way of measuring the total solar transmittance parameter. Finally, combinations of two separate methods of spectral and total solar transmittance quantification were compared with each other due to a specific property of applied transparent insulation, where an aspect of diffuse solar radiation transfer appears to play a significant role. The first method takes the form of laboratory testing based on spectrophotometer measurements. Again, a PerkinElmer Lambda 1050 UV/VIS/NIR spectrophotometer was used. The spectrally obtained results are presented in

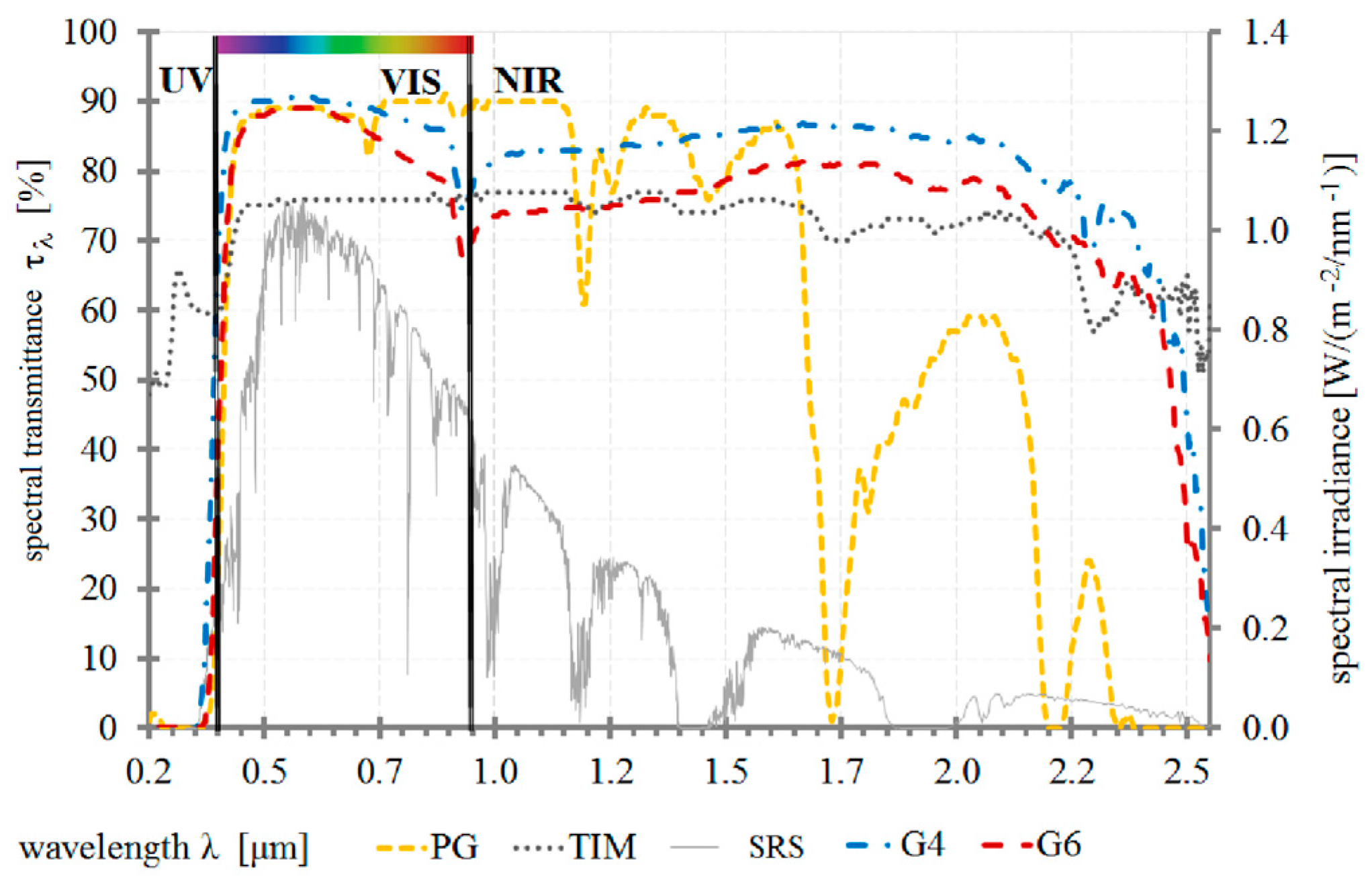

Figure 2, where the measurement data for the analyzed TIM is primarily supplemented with other transparent materials, such as Plexiglass (PG), simple glass pane 4 mm thick (G4), simple glass pane 6 mm thick (G6) and TIM based on honeycomb structure.

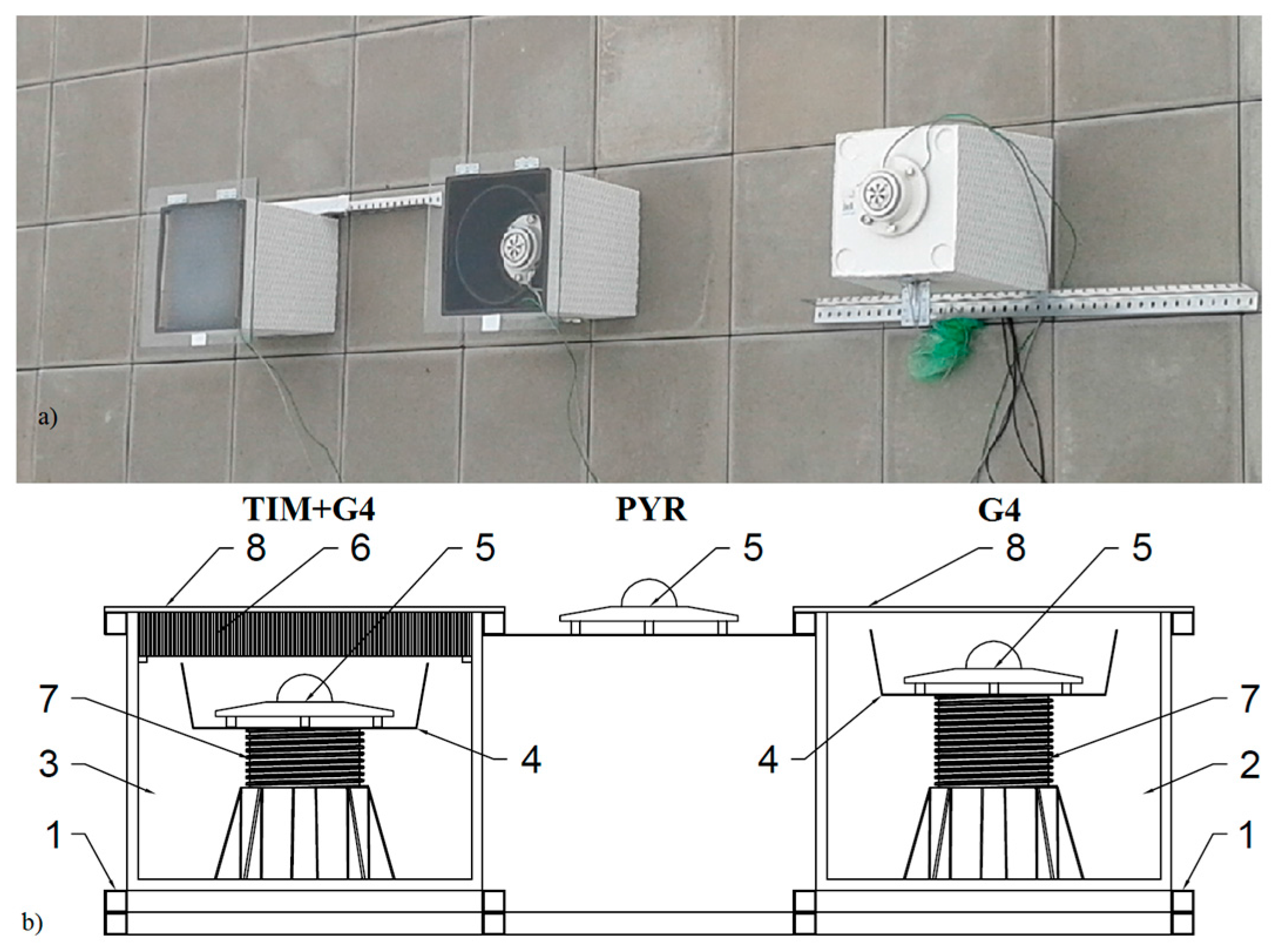

The second method is based on outdoor experiments applying the comparative in-situ measurement approach. The authors assembled their own measurement apparatus for this task taken fundamental specification of ASTM E1084-86(2015) into account. This test method also allows measurement of solar transmittance at angles other than normal incidence. In addition, it is particularly applicable to the measurement of transmittance of inhomogeneous, fiber reinforced, patterned, or corrugated materials since the transmittance is averaged over a large area. Two pyranometers were mounted in square boxes and a third additional device was left exposed to outdoor conditions (

Figure 3). The equipment was used to determine the total solar transmittance of the TIM. The experimental setup and a diagram of it are illustrated in

Figure 3 conducted at the AdMaS research centre at Brno University of Technology (longitude 16°34′, latitude 49°14′, altitude 297.23 m). All results were taken during measurements where maximum sun height above horizon has been achieved during midday at 60°, which corresponds to the 30° incline from normal incidence angle. The results presented in

Figure 4 are from two different measurement days representing two different sky conditions: overcast (

Figure 4a) and almost clear (

Figure 4b). Here, the ratio between solar intensity of opened air pyranometer sensor and those placed in both test boxes behind the measured component is presented corresponding to the total solar transmittance value (TIM + G4/PYR and G4/PYR), as well as the courses of solar intensities monitored respectively (TIM + G4, PYR ad G4). Finally, the ratio of solar intensity of TIM combined with G4 and sample G4 (TIM + G4/G4) represents a value for TIM separately. For almost clear sunny period

Figure 4b, results are strongly cloud sensitive. This aspect is observed by continuous solar transmittance varying. On the other hand, very stable progressions are observed during cloud conditions (

Figure 4a). For both test periods, higher the maximum level of solar intensity is, slightly higher the total solar transmittance obtained. All of the results were finally evaluated as tabular values (

Table 5). As can be seen, good agreement was achieved between both of the applied methods. A spectral transmittance of around 0.75 was obtained for pure transparent honeycomb insulation in the laboratory, whilst its total outdoor value reached up to 0.80. This deviation can be caused by final test setup positioning. Further improvements could be achieved, however already obtained results can demonstrate an applicable and adequate level. Regarding the real outdoor in-situ measurements using the sun as the source, this approach specifically aimed to obtain real outdoor values.

3.3. Thermal Resistance Measurements

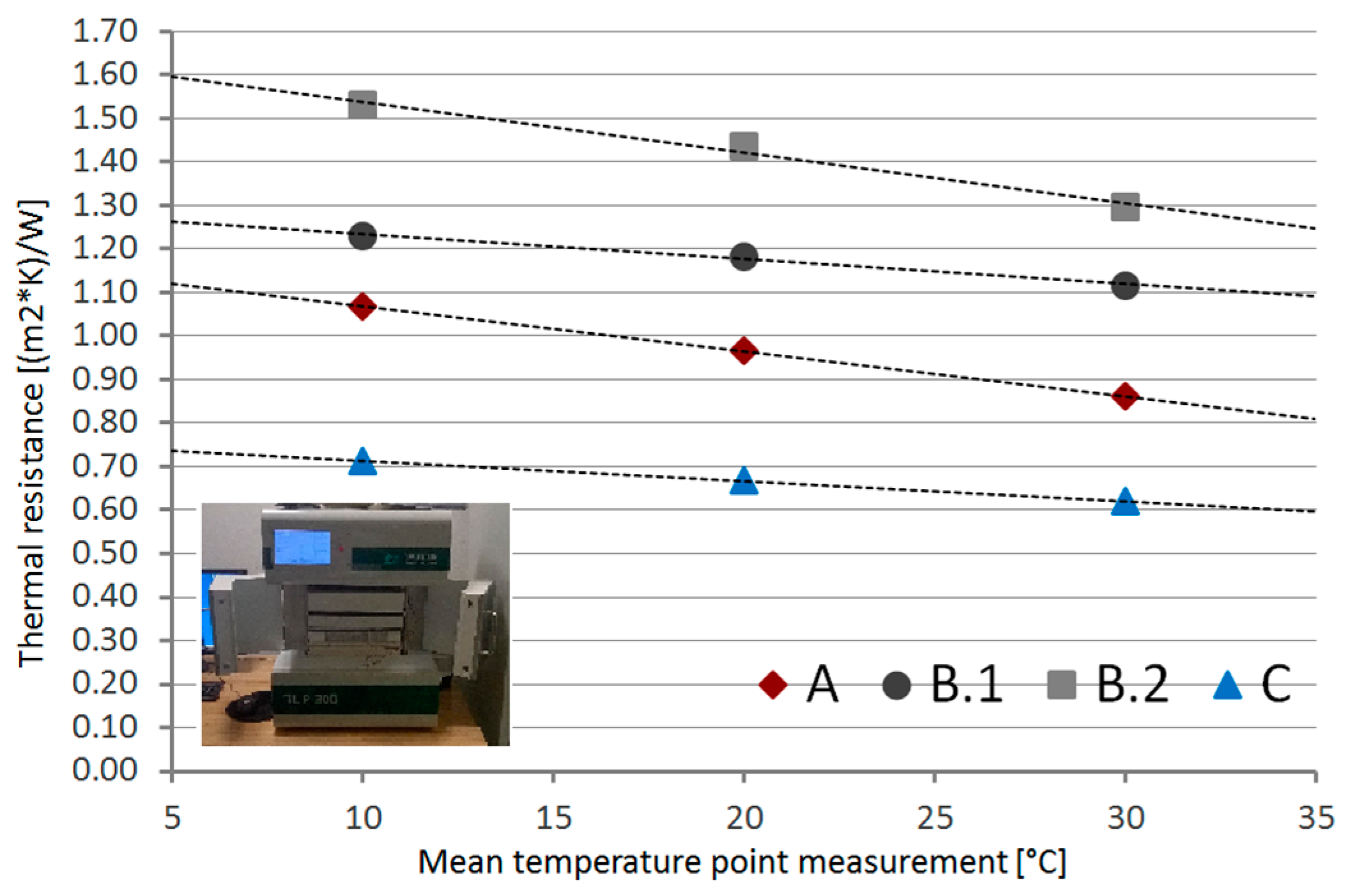

The thermal resistance of the proposed material compositions was measured by the guarded hot plate method in accordance with ISO 8302. A TLP 300 DTX-1 device (Taurus Instruments, Weimer, Germany) was used (

Figure 5). This apparatus can determine the thermal resistance of a sample with a thickness ranging from 20 mm to 80 mm. The device is equipped with two plates. A required temperature difference between both plates is maintained to activate heat flow within the tested sample. The dimensions of the applied plates are 300 mm × 300 mm; the protected measured field is 100 mm × 100 mm in area. The sample is placed between the two plates, whose temperatures are controlled by a Peltier element. The total power of the elements is maintained to achieve one dimensional steady state heat transfer. The temperature difference on the sample’s surfaces is measured via two batteries of thermocouples applied on each side. Using the equation below (Equation (4)), the thermal resistance

R is calculated from the heating power

Q, the measured area

A, and the temperature difference between the sample’s surfaces Δ

T:

Although the TLP 300 DTX-1 apparatus represents a system for the estimation of thickness, when applying the contact mat the thickness of the sample could be distorted. Before the main measurements were taken, the weight and overall thickness of the sample were measured separately. Each sample is placed between plates covered by a contact mat with a thickness of 3 mm. Plastic foil with thermocouple batteries is installed between the contact mat and the surface of the measured sample. The higher plate is slowly lowered until the pressure on the sample reaches the predefined value. Considering the 10 K temperature difference between each side of the sample, testing may utilise several measurement points, which means various temperatures are recorded in the middle of the sample. The measurement process starts by cooling and/or warming the plates until a predefined temperature is reached at a given measurement point. The top Peltier plate monitors voltage and electric current, the obtained values being used for the determination of overall heating power. Finally, as demonstrated above, the thermal resistance of the tested sample is calculated via Equation (4). The time varying power is managed by the microprocessor’s control system according to the surface temperatures of the sample. It exhibits a mainly decreasing trend until a steady state is reached, which corresponds to Fourier’s law.

Four samples of proposed components (

Table 3) based on applied materials (

Table 2) were measured.

Table 2 and

Table 3 present basic material parameters. Finally, the equivalent thermal conductivity coefficient

λekv is calculated based on whole component thickness and its thermal resistance (Equation (5)). Three measurement cases were tested at different mean temperature levels: 10 °C, 20 °C and 30 °C. The load imposed by the top plate on the sample was 200 N for all cases. In addition, the temperature dependency between the thermal resistance and the mean temperature of the sample was observed. The resistance approximated by linear function indicates the same tendency of slope: the higher the temperature level, the lower the thermal resistance of all tested samples (

Figure 5):

As a sample of a conventional type of insulation using the same structure is considered as a reference, all of the presented compositions can be compared and contrasted with each other. Based on the measured results, the conventional insulation concept (B.1) showed a maximum thermal resistance of 1.231 (m2K)/W, while the low-e material (B.2) displayed a maximum of 1.530 (m2K)/W. This means that the low-e surface inside the air gap can increase the thermal properties of the proposed conventional component type by up to 24%. In contrast, when transparent insulation material (C) is used, the thermal resistance is almost 42% less than B.1. However, with a spectrally selective absorber (A) the thermal resistance nearly approaches the conventional level, being only 14% lower at 1.067 (m2K)/W. Finally, when both TIM compositions are contrasted, the standard non-selective solar absorbent sample C has 0.712 (m2K)/W, which means its thermal resistance is almost 50% lower than the spectrally selective absorber, sample A.

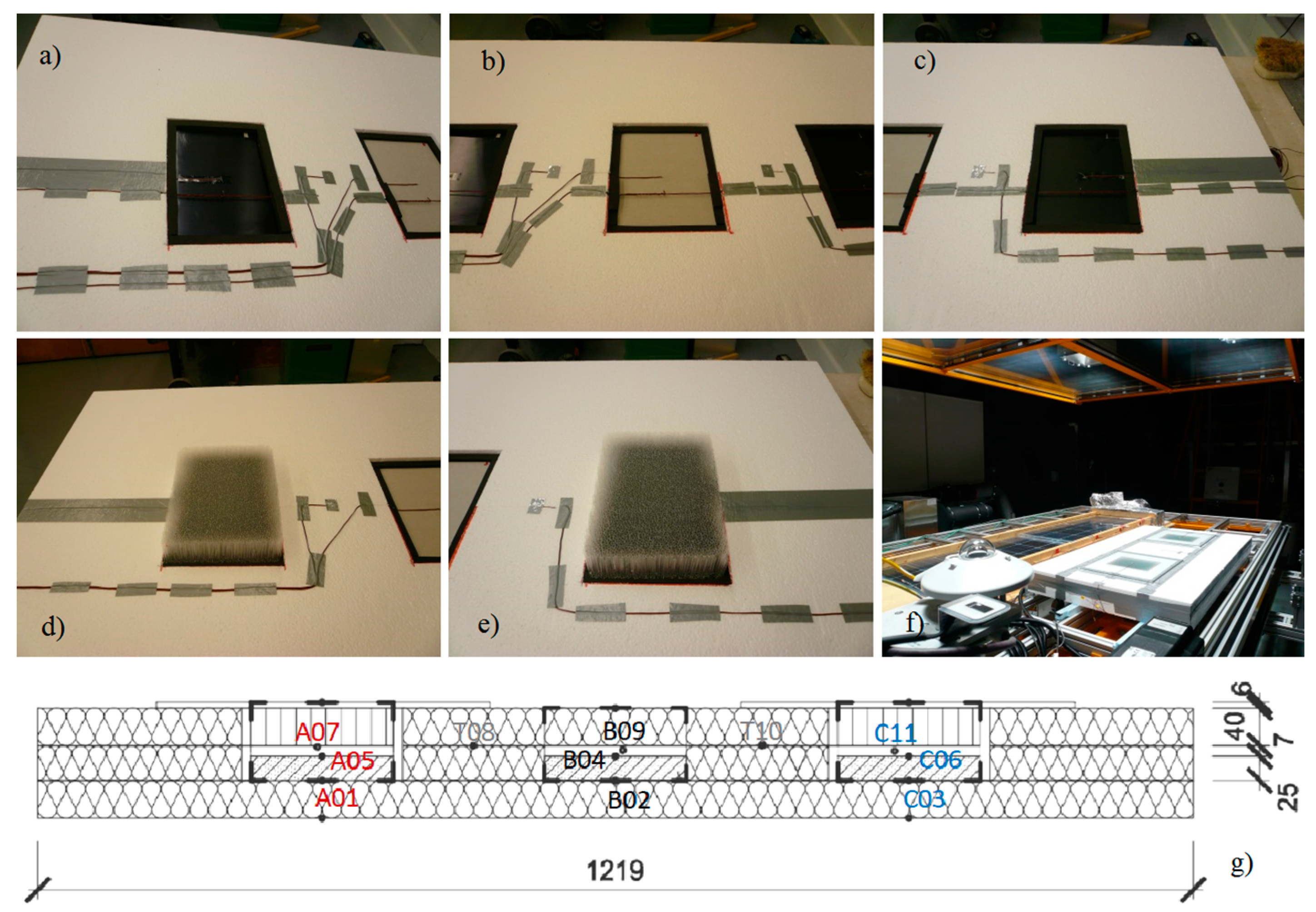

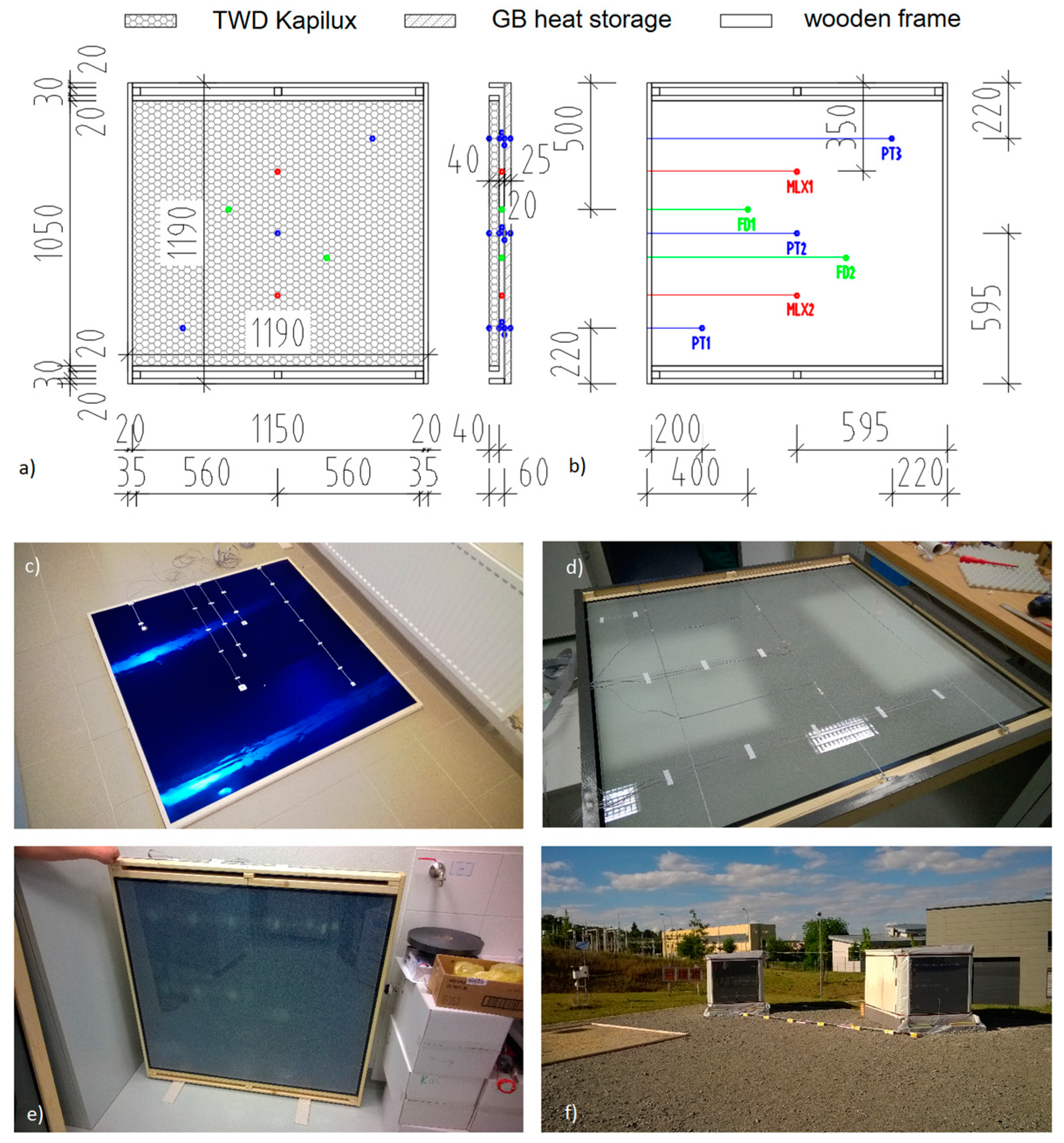

5. Full Scale Outdoor Testing

The overall results of the laboratory, solar simulator and small-scale outdoor testing were applied in the measurement of full-scale outdoor thermodynamic performance. All testing periods are specified in the thermodynamic performance analysis of the time-transient summer period. A full-scale test sample was designed (

Figure 10), after which a 1.19 m × 1.19 m test prototype (

Figure 10) was built using the system based on the Kapilux TWD transparent insulation fitted with honeycomb transparent PMMA-based insulation with a different solar absorber type, and tested outdoors. The TWD system is double low-e glazing incorporating honeycomb PMMA transparent insulation with air cavity. The declared thermal and optical properties are as follows: thermal transmittance

Ug is 0.7 W/(m

2K), total solar energy transmittance or solar heat gain coefficient is 61% and light transmission is 70%. The type of transparent insulation directly incorporated in glazing system represents the only difference as compared with small-scale prototypes.

Figure 10 shows the geometrical parameters of the prototype, the positions of all sensors and key illustrations of their construction phase. As demonstrated in

Figure 10, this prototype may allow to implement a ventilation function, however in this study it has not been applied. The last illustration (

Figure 10f) presents the prototype’s outdoor installation in two identical wall brick boxes with 50 mm thick thermal insulation, in which both samples, a reference and comparative one, were installed facing south at the AdMaS Centre at Brno University of Technology. (longitude 16°34′, latitude 49°14′, altitude 297.23 m). More detailed information about the test boxes can be found in [

55]. Measurements were taken at six positions along the test sample, with each interface being on a diagonal line consisting of three sensors. Temperatures were measured by Pt100 sensors (Type CRZ 2005-100, class A, tolerance 0.15 + 0.0002

t). Again, as previously mentioned, similar indexes were used to recognize the particular position measured, though they primarily focused on the material interface between the absorber and the heat accumulation layer (gypsum board). First, the internal surface temperatures of tested samples

si were measured, and second, the internal space temperature of each full-scale box

in. In addition, silicon pin photodiodes Fdi were installed inside the air gap to monitor solar radiation behind the TIM incident at the absorber level

Figure 11. The monitoring of outdoor ambient temperature

Tae and the solar radiation intensity inside the air gap Fdi represent an important part of the testing in relation to this stage of the presented analysis. The outdoor temperature varied from 15 °C to more than 30 °C. Solar intensities behind the TIM reached more than 200 W/m

2 in the area of the solar absorbers.

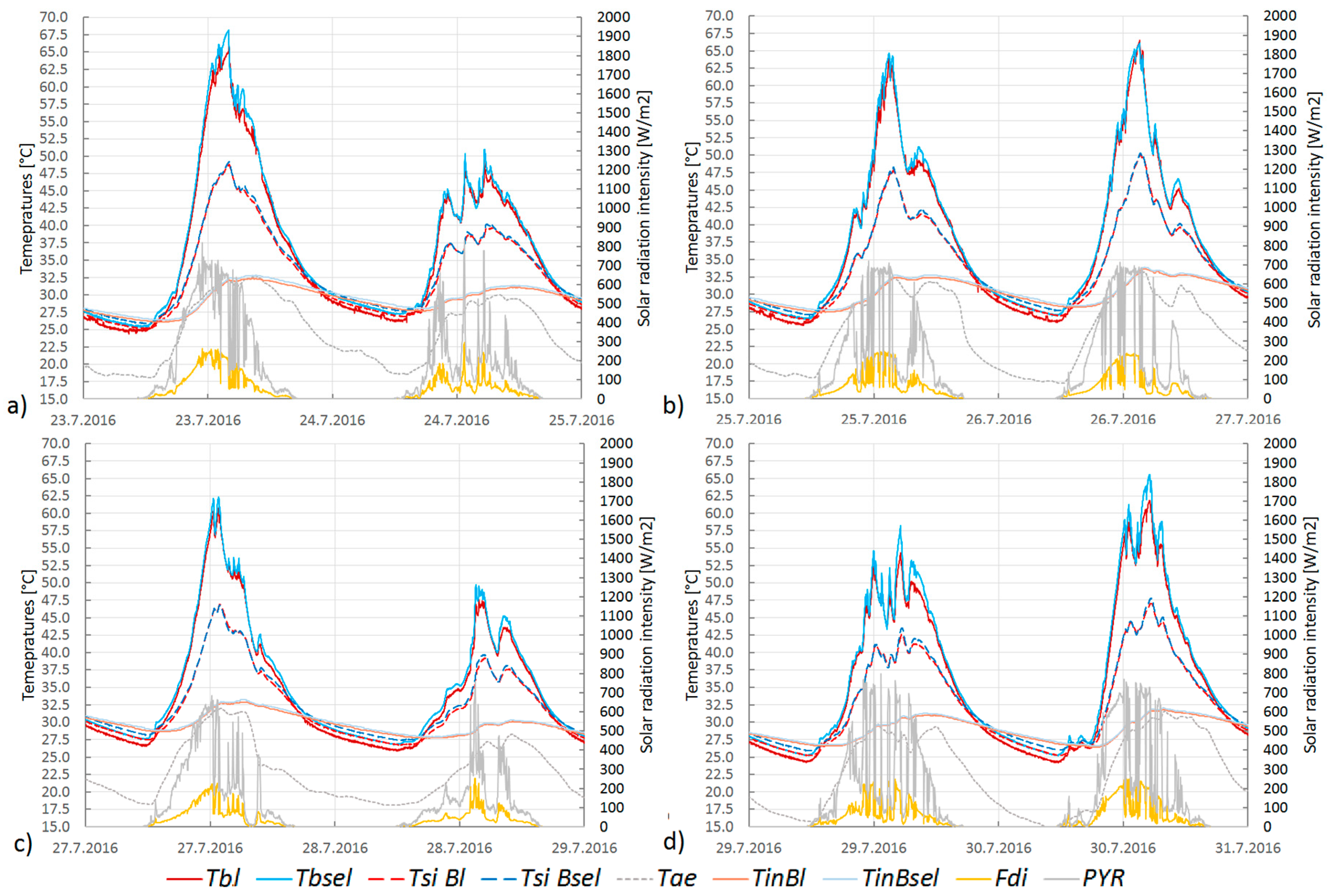

All results are taken applied for outdoor conditions where maximum sun height above horizon has been achieved during midday at 60°, which corresponds to the 60° incline from normal incidence angle. This represents accordingly a maximum solar incidence at the tested location. Looking at the results obtained during outdoor tests (

Figure 11), it is clear there is an opposite tendency in comparison with the small-scale testing. This is presumably caused by applying the TWD system that incorporates another low-e surface. Thus, the combination of two low emissivity materials can completely change its physical substance as compared to the small-scale prototype testing. The selective absorber reaches a higher temperature in comparison with the non-selective absorber behind the absorber plate, which is direct contact with the accumulation board. Depending on the solar radiation level, it represents a maximum difference of up to 3 K. On the other hand, the effect of temperature difference at internal surface temperatures of whole samples is almost negligible in daytime periods, though a phase shift occurs in the night-time, where the non-selective absorber could principally cool down more intensively. This aspect is specifically directed towards positive utilizing in winter and periods of heating. The absorber temperature at the center of the full-scale prototype reached a maximum of approximately 67.5 °C at maximum peak when the incident outdoor vertical solar radiation reached its maximum of around 700 W/m

2 in parallel with its internal transmitted part of around 250 W/m

2 and the ambient outdoor temperature was around 32.5 °C. At this moment, the corresponding inside space temperature measured reached a maximum of its outdoor level.

The solar angular or effects of the incidence angle on the solar transmittance is parametrized by

Table 8. This dependence is obtained by Matuška [

56], assuming zero transmittance for the incidence angle 90°. Theoretically, for system that combines double low-e glazing and honeycomb transparent insulation, the calculated value can be derived by their multiplying to correspond its approximate value. For outdoor tests, a specific approach of monitoring the total solar transmittance responding to the outdoor conditions can be applied.

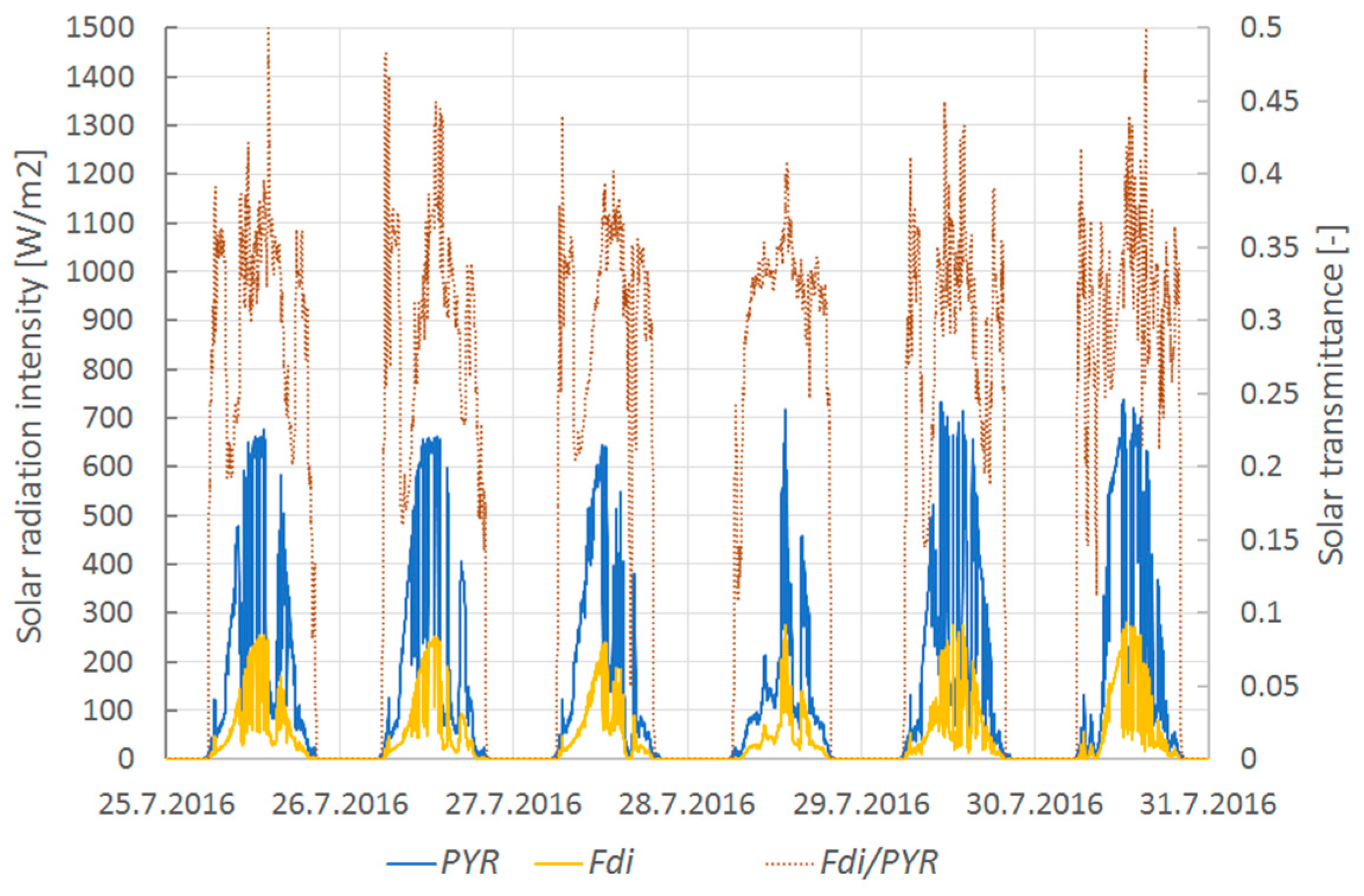

The same methodology is employed as applied in

Section 3.2 to calculate the outdoor solar transmittance of TIM. Results presented in

Figure 12 show time varying values of total solar transmittance based on real measured solar intensities. Here the ratio (Equation (6)) between two solar intensities is calculated, where PYR corresponds to the total solar radiation incident in front of measured components, whilst Fdi is its transmitted value through the TIM, both obtained by the silicon pin photodiode. Detailed application of this element can be found in [

57]. Typically, measured values are varying from 0.25 to a maximum of 0.45 depending on solar radiation intensity, its average value corresponds roughly to 0.35 achieving the theoretical calculation from

Table 8.

In general, this approach and methodology might demonstrate annual values of solar transmittance with relation to the angle of incidence and dynamic time transient conditions of outdoor climate.

6. Conclusions

The paper presents the results of an experimental analysis of a proposed non-ventilated solar façade concept. Thermal and optical parameters have been specified for it to be considered in this context. An experimental monitoring on simple based elements focuses on the dynamic response of selective absorbers coupled with TIM as a fundamental step towards understanding overall interactions influencing the heat transfer of presented concept. Selective absorber and transparent insulation functions are implemented for this study. Based on the detailed observation of all the experimental procedures involved, it is demonstrated that from the thermal point of view, the selective absorbent properties could improve thermal properties significantly compared to concepts using high emissivity absorbers. From the thermal resistance point of view, the proposed concept implementing transparent insulation and a selective absorber provides comparable performance to conventional thermal insulation. On the other hand, when comparing the temperature response invoked by solar radiation at its maximum peak, based on solar experimental models, no significant effect is observed. A difference of up to 3.0 K is principally reached at the maximum obtained temperature level. In addition, the total solar transmittance of TIM applied in small- and full-scale tests is additionally analysed to demonstrate its effect on incidence angle and other specifics.

Further research will be focused on numerical modelling as well as the application of the described concepts in full-scale mode tested outdoors via year-round testing, where heating periods are supposed to be more relevant. Based on this study, it is planned that other functions will be implemented, such as transparent selectivity, and at the heat storage level of the base of PCMs.