1. Introduction

The aim of ventilation of the underfloor space is to prevent moisture generated in the ground from entering the living area and to improve the heating and cooling efficiency of the building, given the large heat capacity of the ground. Moisture is the main problem in wooden buildings, as it causes rotting of the wood and an unpleasant smell inside the building. Even so, the underfloor space is generally ignored by the residents, as it is not only inconspicuous, but also difficult to clean. Generally, moisture originates from the ground (soil), which absorbs water after rain, or from groundwater, and enters the building through the ventilation openings. It is important to block the source of the moisture in order to control the humidity level and to prevent the generation of condensation inside the underfloor space. Therefore, it is crucial not only to prevent ground moisture from entering, but also to eliminate any moisture forming inside from rainwater or high humidity. Since these phenomena influence the health of the occupants and the durability of the buildings, methods, such as paving of the ground or mechanical ventilation are applied occasionally. However, it is useful to predict the climate of the underfloor space in the attempt to control the humidity and to apply an appropriate method during construction, as installing such alternative methods could be costly.

In previous research, the relative humidity, temperature, and pressure inside the underfloor space were measured, the ground moisture evaporation rate was calculated, and subsequently the effects of natural and mechanical ventilation were confirmed [

1]. The results showed that the average value of moisture evaporation with unpaved ground was 3.6 g h

−1 m

−2 in a naturally ventilated condition and 5.7 g h

−1 m

−2 in a mechanically ventilated condition. Research also indicated that the optimum air change rate on the underfloor space was 1–3 air change rate per hour (ACH) throughout the year [

2]. Experiments have also been conducted with benzene in the underfloor space to identify the potential health risks associated with toxic soil vapors penetrating into the living spaces [

3,

4]. These studies employed point measurements. However, the internal humidity was excluded as a factor in the research. Several studies have attempted to confirm the presence of internal humidity by employing computational fluid dynamics (CFD) to determine the distribution of such internal humidity. However, no research has been conducted on the internal condensation of the underfloor space. In the current study, we attempt to determine the effects of internal condensation and evaporation and the probable area where condensation would occur relevant to the natural ventilation. Research on such aspects has not been conducted before.

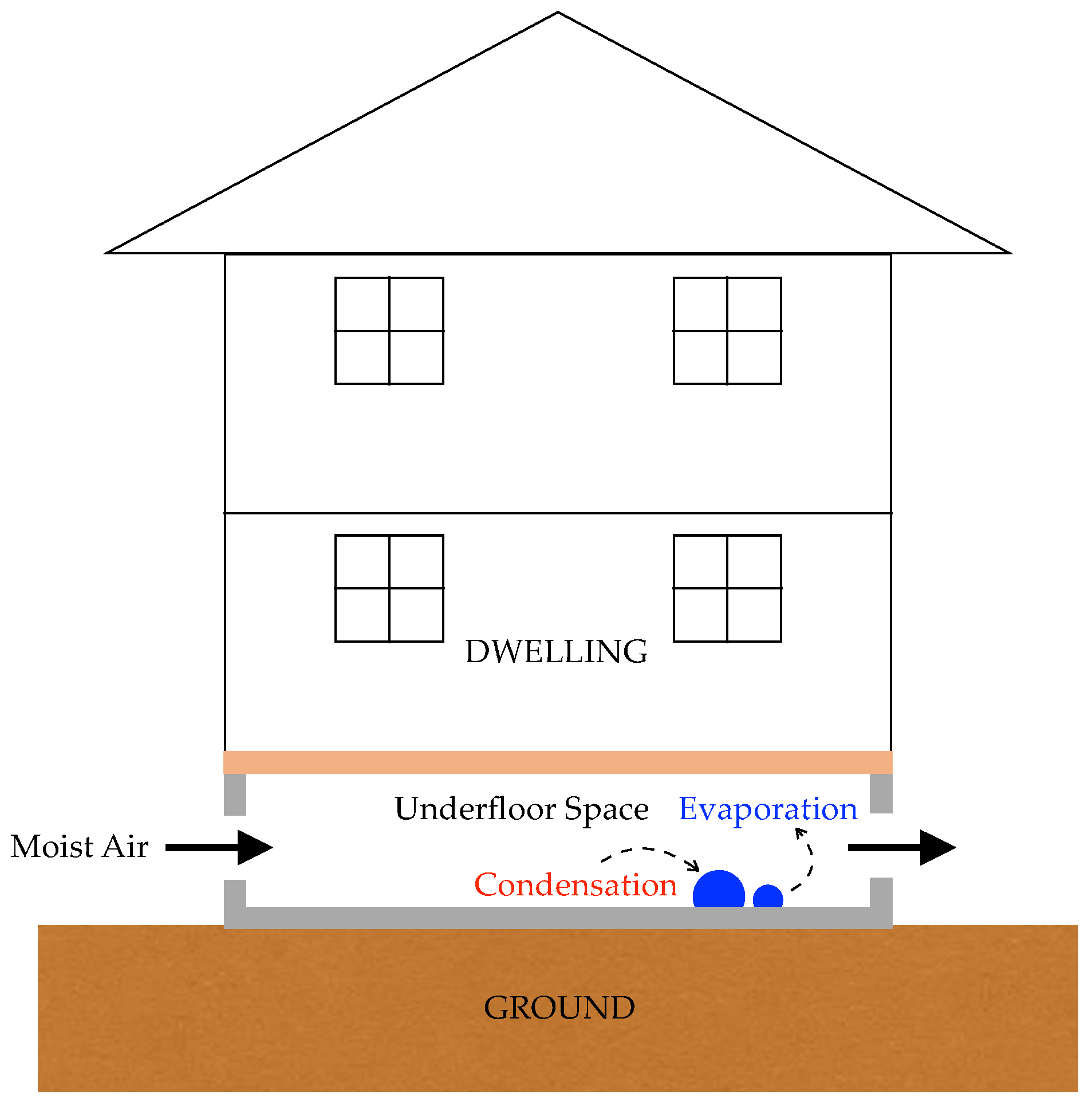

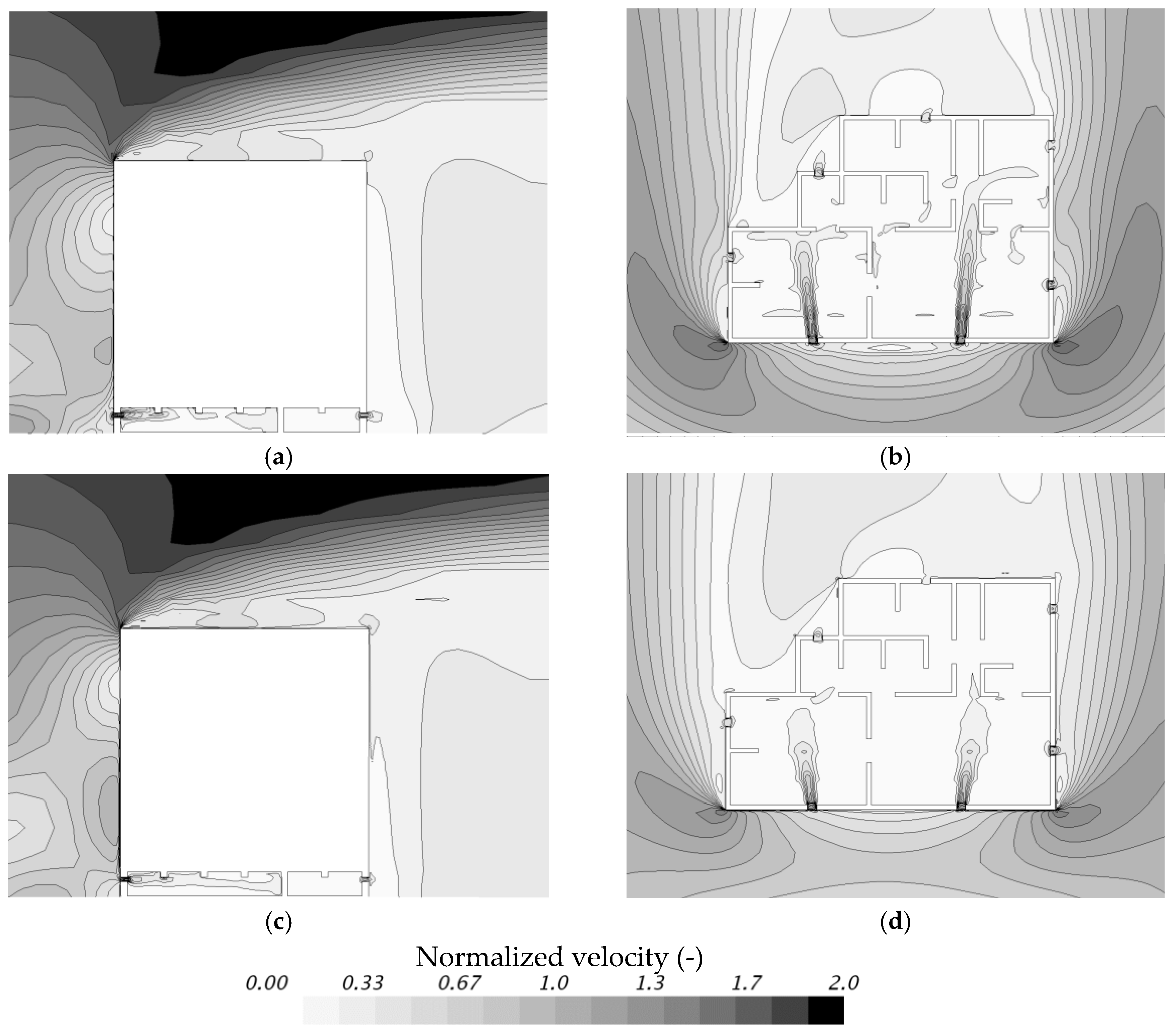

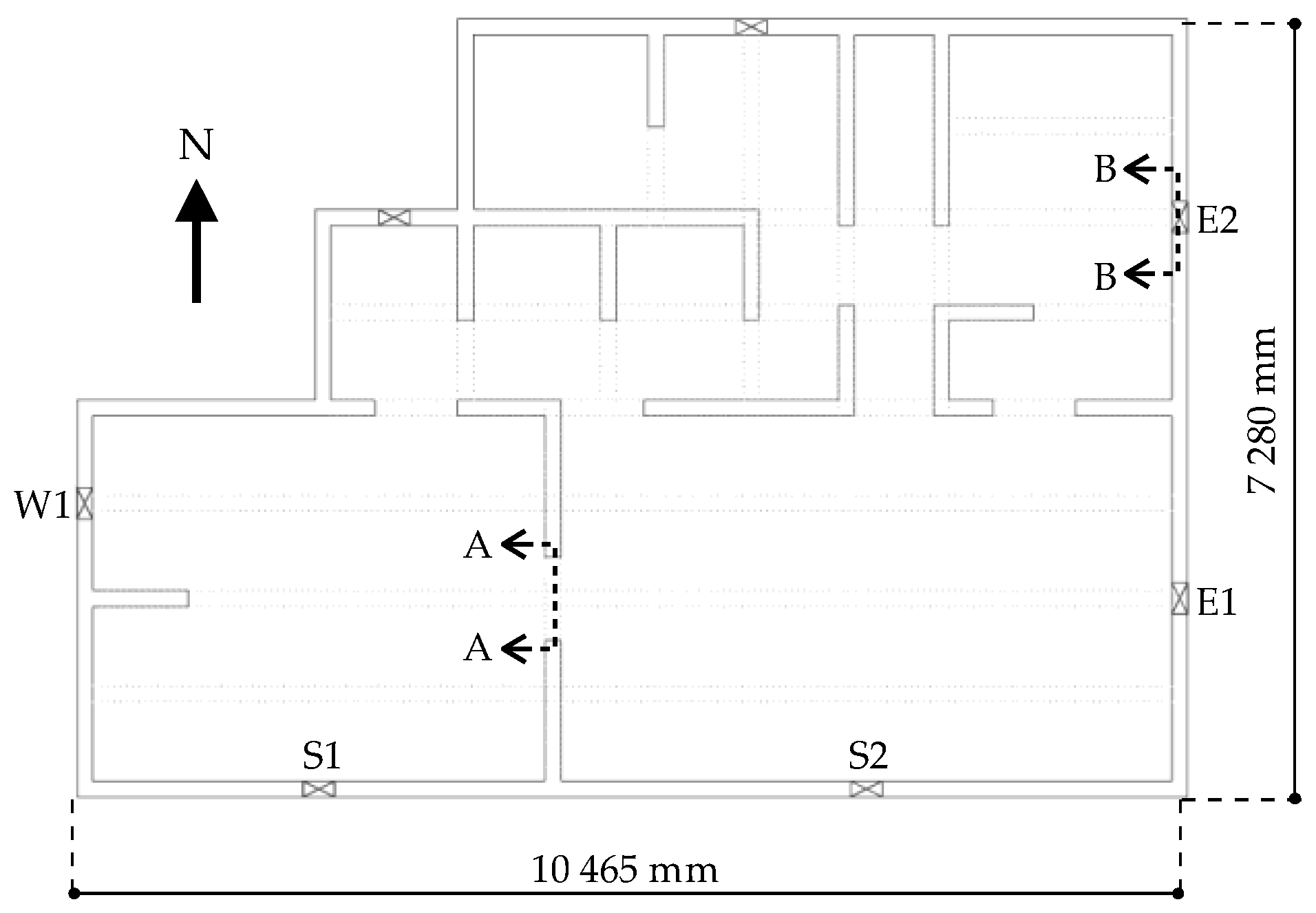

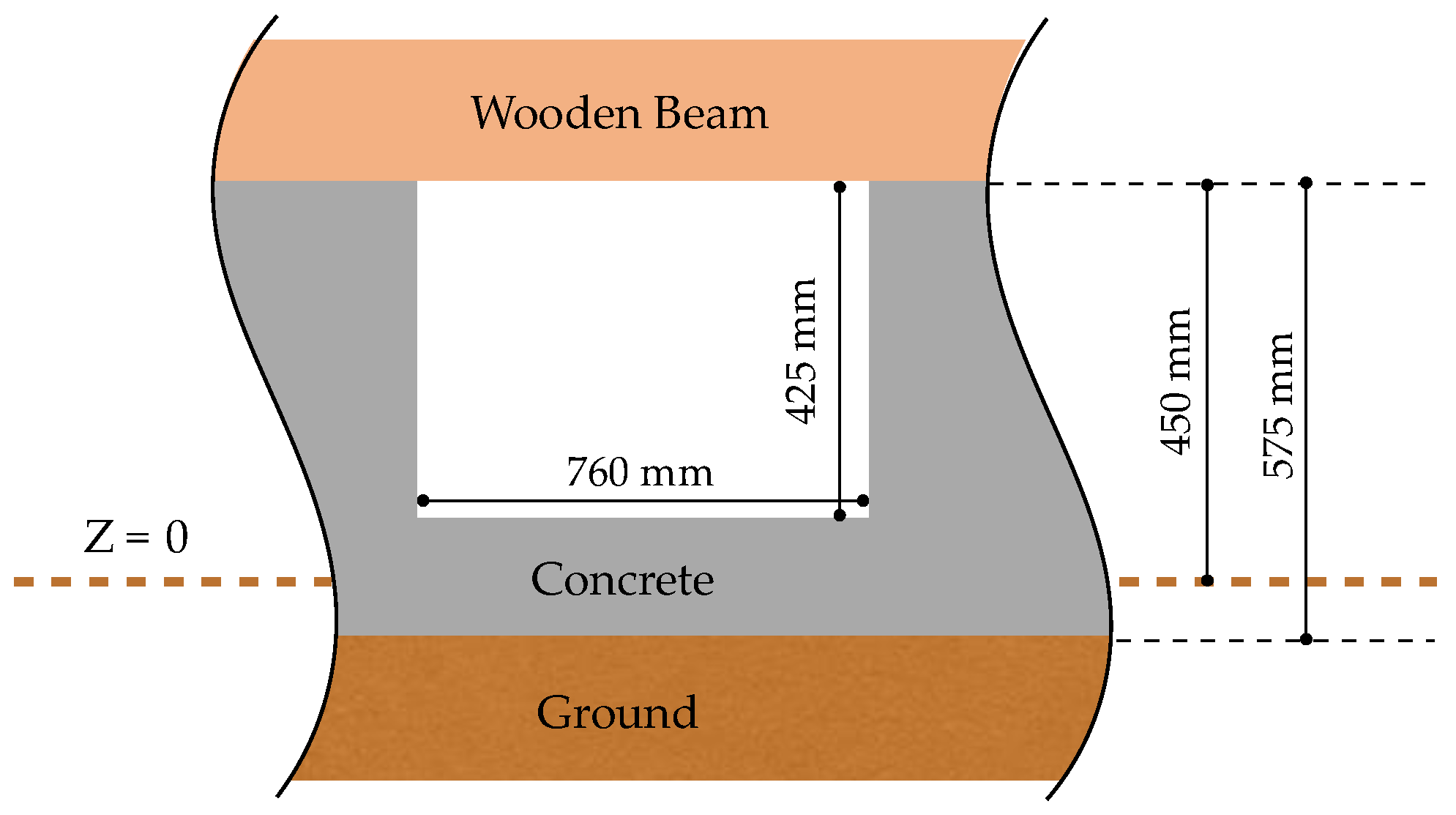

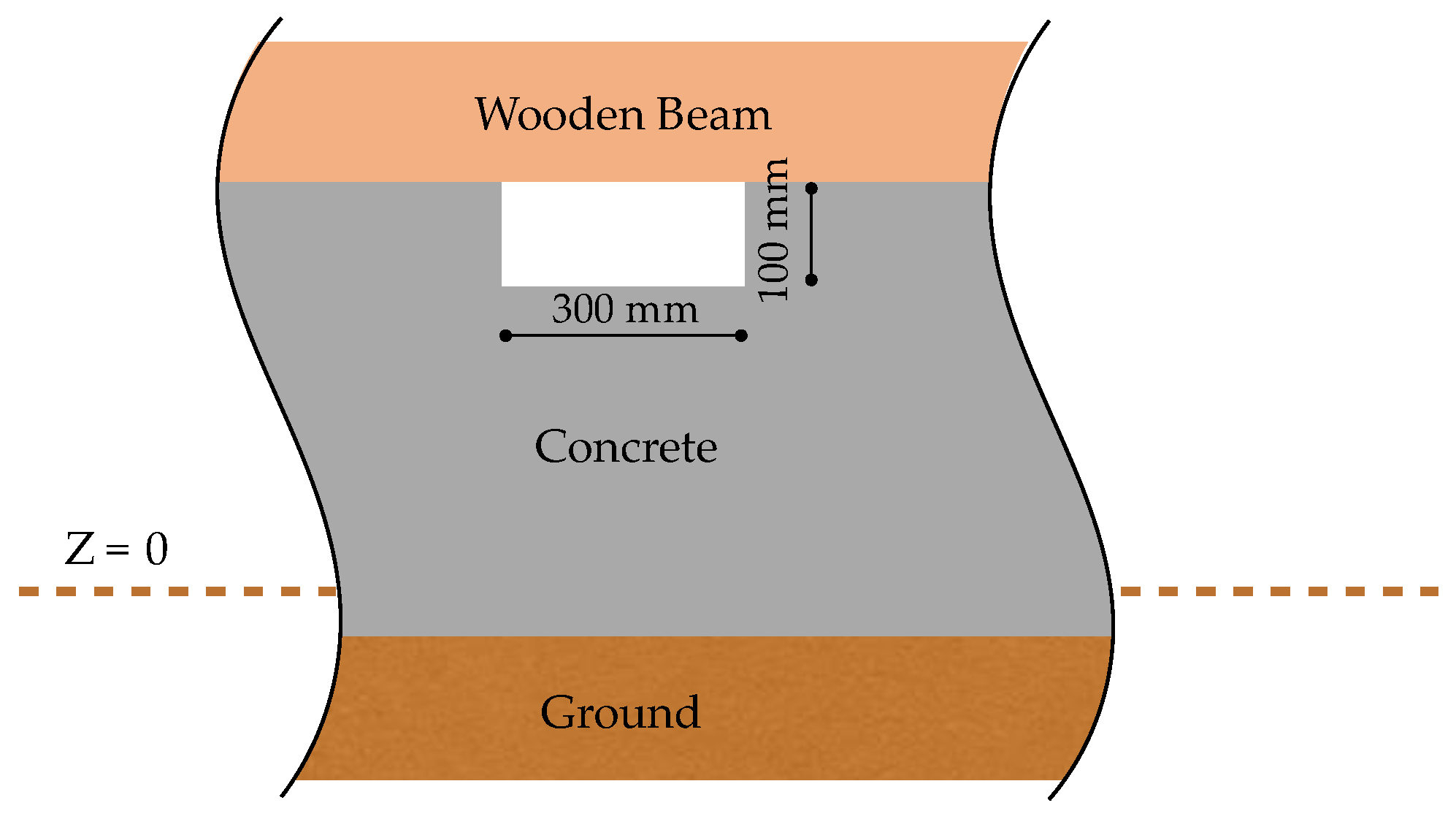

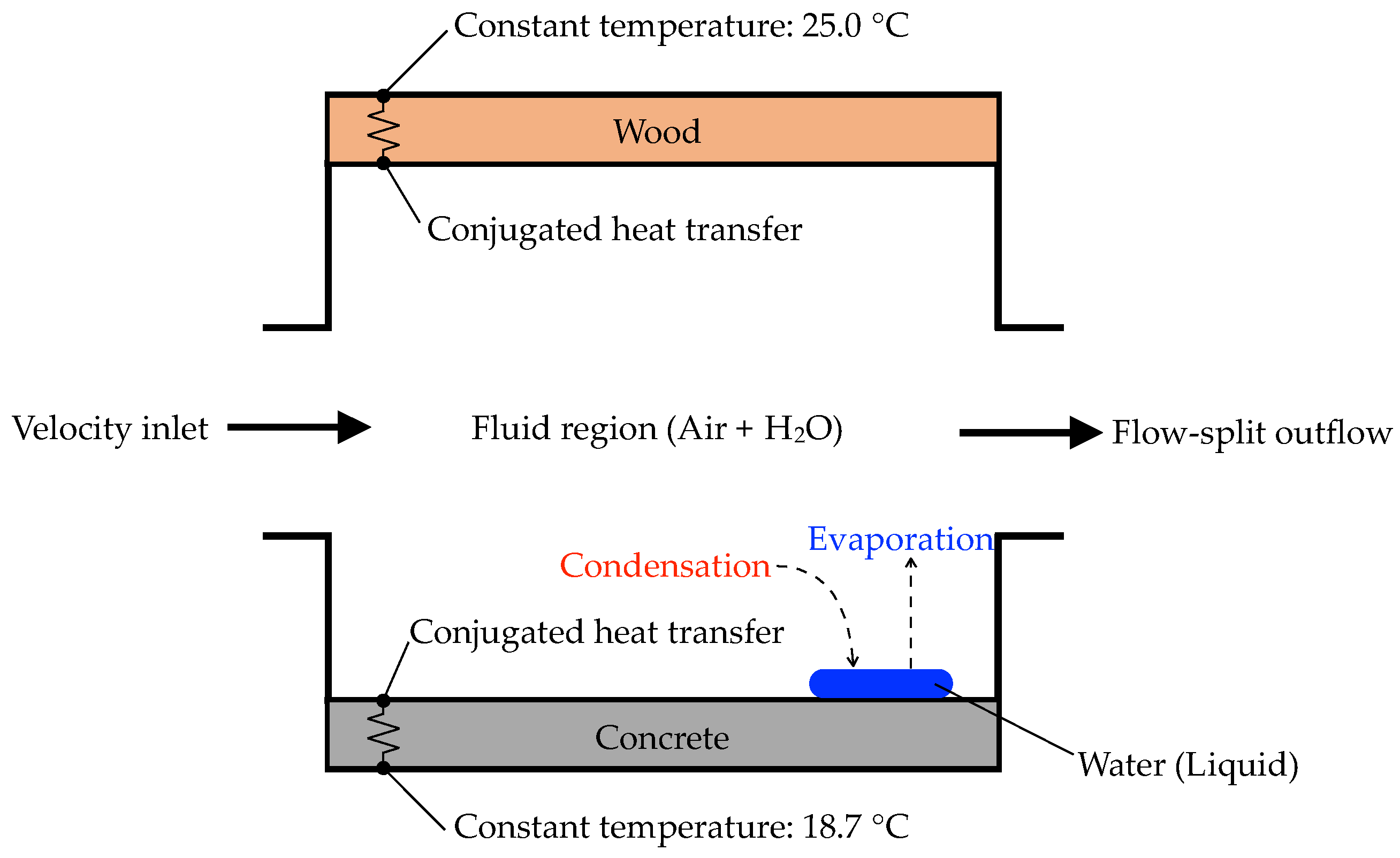

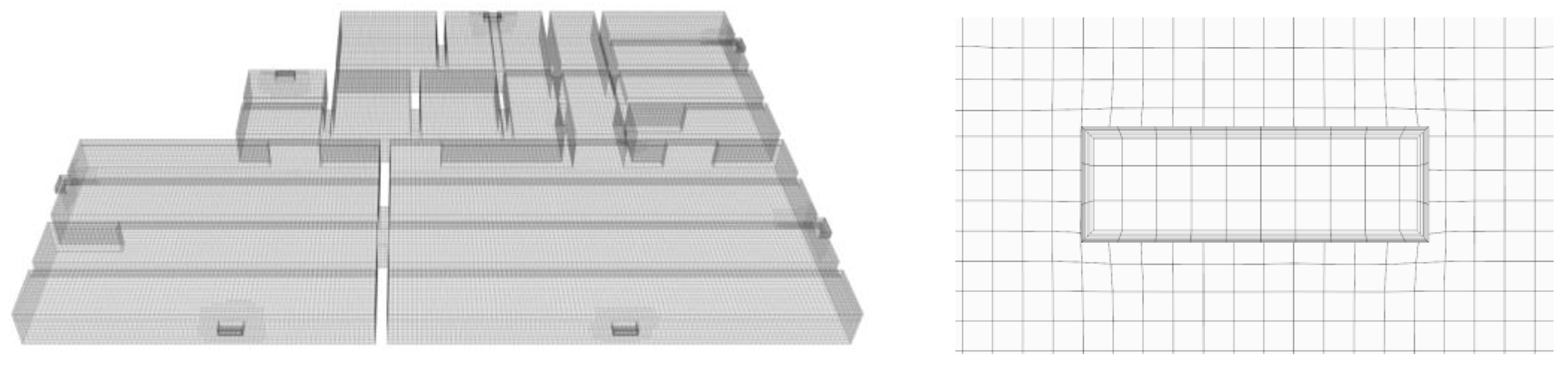

A Japanese detached house can be simply illustrated as in

Figure 1. The height of the underfloor space is 0.3–0.5 m from ground level. As openings are dispersed around the underfloor space for natural ventilation, outdoor moist air flows into the underfloor space, which gives rise to condensation and evaporation. The bottom of the underfloor space is usually paved with concrete and the ceiling, which is directly underneath the indoor occupant zone, is made of wood.

There are two main causes of condensation on the underfloor environment, namely, moisture deriving from the outside environment that condenses on the cold surface of the underfloor, and re-condensation that occurs when the condensed water inside the underfloor space evaporates. Once the condensation has been evaporated by ventilation, it becomes another moisture generation source inside the underfloor, raising the indoor humidity and significantly reducing the evaporation effect. The airflow and temperature distribution of the internal environment cause condensation and evaporation locally. Consequently, simple point measurements of the humidity cannot adequately explain the general condensation phenomena on the underfloor space or predict the probable occurrence of condensation. Furthermore, as the inside of the underfloor has a complicated shape, it is important to understand which parts would be vulnerable to condensation and to give due consideration to these vulnerable regions in the design of the house. Generally, in Japan, a detached house is a wooden building and it has an underfloor space, where its bottom touches the ground surface, which is usually paved with concrete to block water seepage from the ground. Natural ventilation is usually employed through underfloor air vents, shown in

Figure 2, and mechanical ventilation is generally not introduced.

As many previous studies have conducted research on the conditions of unpaved ground and natural ventilation, we attempted to confirm the internal condensation and evaporation effects on the underfloor space under conditions of paved ground and natural ventilation. It is difficult to determine the distribution of internal humidity by employing experimental methods; therefore, we chose CFD analysis to determine the climate inside the underfloor space. Additionally, the aim of the study is to understand the degree of evaporation and condensation arising because of underfloor ventilation and the distribution of the internal humidity, as well as to identify the area at risk of condensation.

Generally, In CFD, turbulent flows can be predicted through three approaches: direct numerical simulation (DNS), large-eddy simulation (LES), and Reynolds-averaged Navier-Stokes (RANS) equation simulated with turbulence models [

5]. DNS gives highly reliable results directly solving Navier-Stokes equations but the required calculation time will be very long. The LES approach is an intermediate modeling technique between DNS and RANS. Turbulent motion can be divided into large eddies and small eddies, where LES is a method that solves the Navier-Stokes equations with filtered large-scale eddies of the turbulent flow except for small-scale eddies. LES can give us more detailed information on turbulence than RANS. However, it still requires a considerable calculation cost. Using RANS, turbulence motion can be quickly predicted and it is the most practical approach.

Computational fluid dynamics (CFD) is also the most effective way to predict the airflow in a building. Predicting airflow patterns in an indoor room by using a CFD analysis was first applied by Nielsen [

6]. For the indoor environment prediction, the RANS k–ε turbulence model was used for many years and shows the acceptable results according to many researchers. [

7,

8,

9,

10]. The standard k–ε turbulence model showed reasonable results to predict the airflows in indoor environment [

11]. Moreover, realizable k–ε models usually provide much improved results for swirling flows and flows involving separation compared to the standard k–ε model [

5,

12,

13].

1.1. Weather Data in Tokyo, Japan

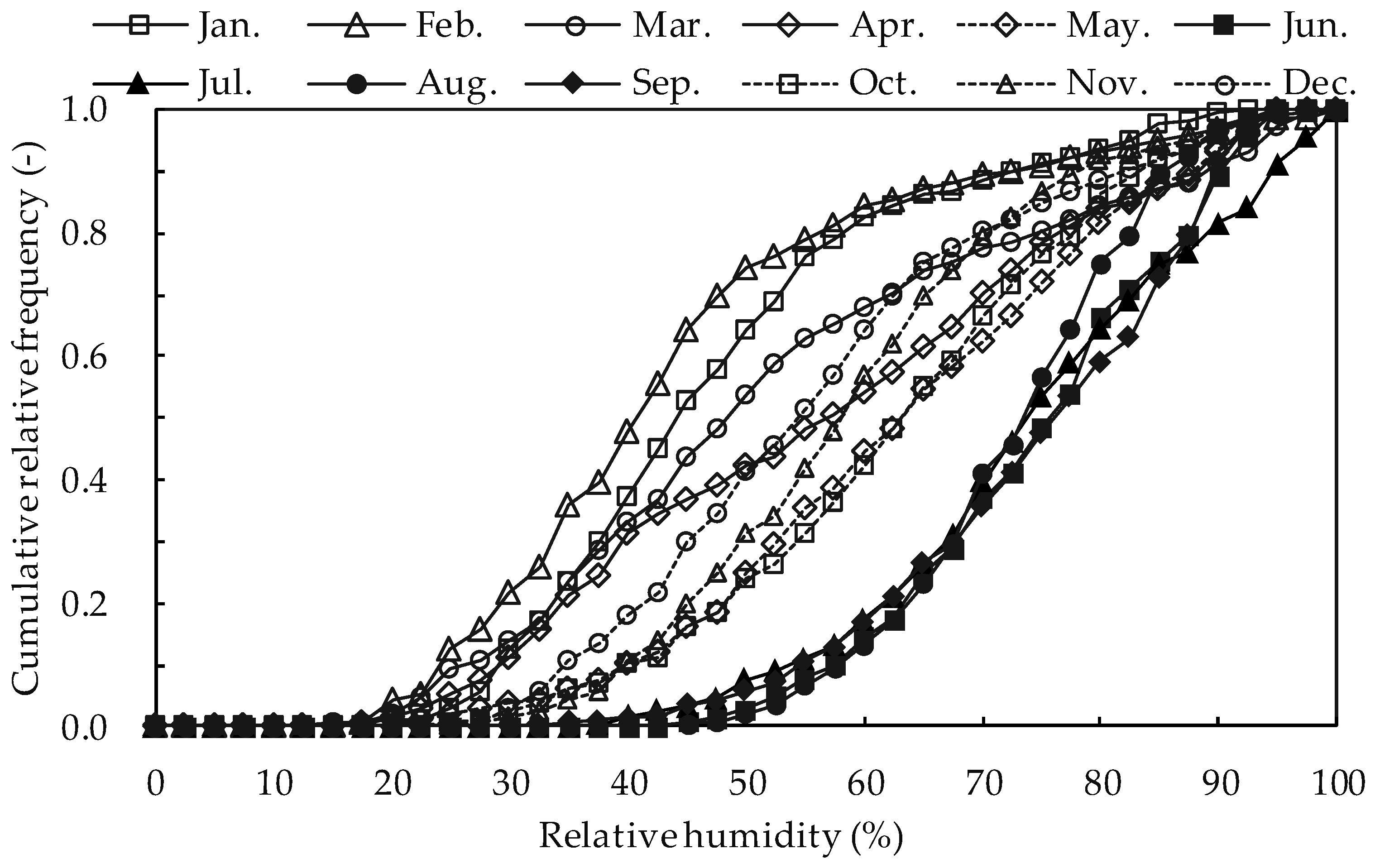

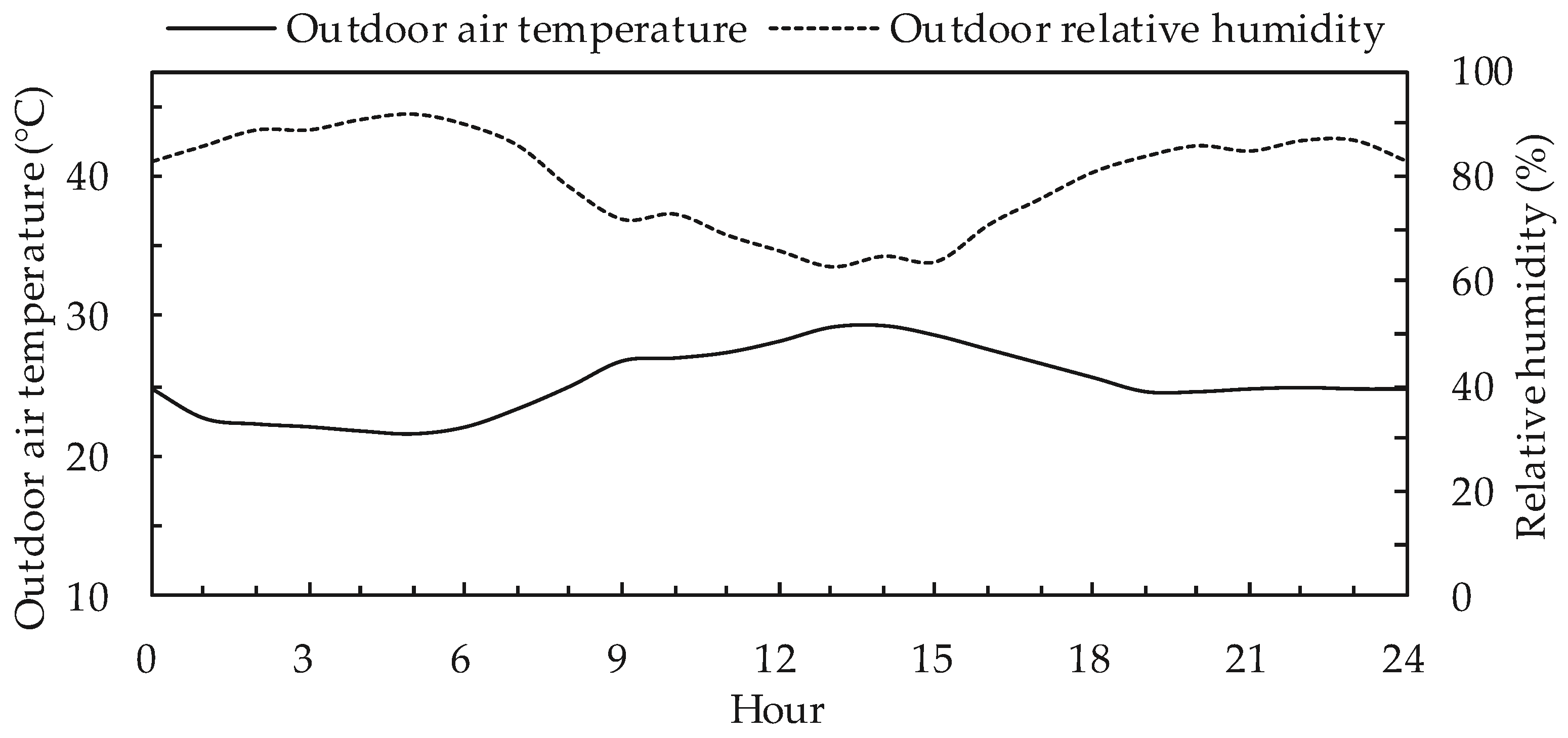

The extended Automated Meteorological Data Acquisition System (AMeDAS, 1981–2000) was used as standard-year weather data to estimate the underfloor climate. Tokyo city in Japan was selected as the representative location for our simulation. The detailed weather conditions are described in

Figure 3 and

Figure 4.

Figure 3 shows the correlation of the cumulative relative humidity per month in Tokyo. The wettest months of the year are June to September and a high-humidity climate prevails for more than half of this period, with the relative humidity being more than 75%.

To consider the worst probable weather situation, the data for 10–17 June were employed in our study, as these days represent the high humidity season in Tokyo. During the rainy season, although the external humidity increases significantly, the temperature of the internal environment remains lower than that of the external environment. This is because the influence of solar radiation is insignificant as the sky is always overcast. Therefore, the risk of internal condensation during this period is expected to increase significantly.

1.2. Research Procedure

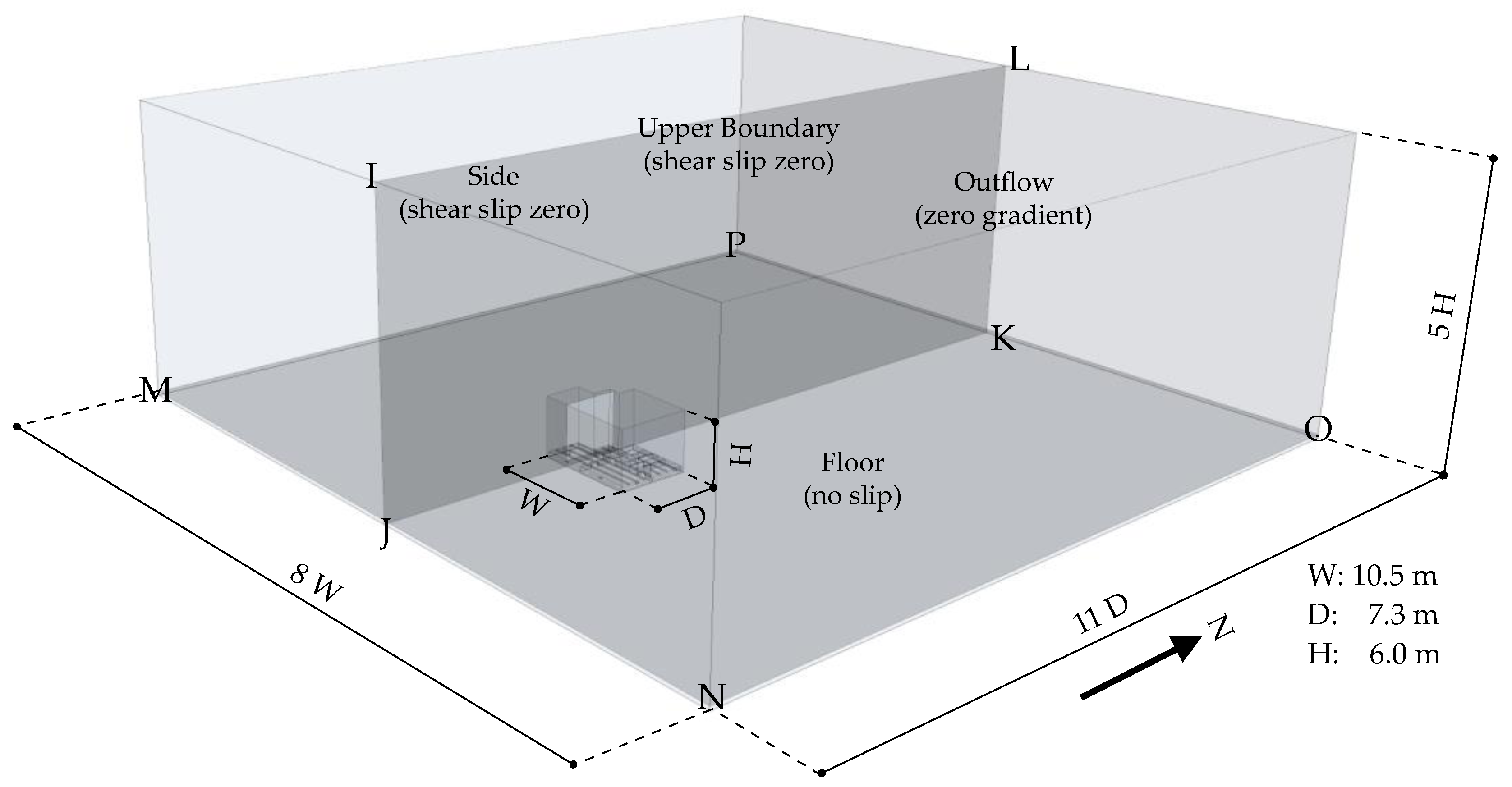

In the design of the underfloor space, it is important to consider the interior environmental characteristics and the likely location and time of condensation occurring. However, since the internal airflow is complicated, it is difficult to predict the areas where condensation could occur. Therefore, we employed CFD analyses to determine and confirm the effects of evaporation and condensation relevant to natural ventilation. The underfloor space has dispersed ventilation openings for natural ventilation, with the pattern of the airflow being complex, as this area is divided into several zones by internal partition walls. Evaporation and condensation phenomena arise because of the difference of the partial pressure of water vapor caused by the difference between the surface temperature and the adjacent air temperature right near the surface. It is difficult to confirm this phenomenon inside the whole underfloor space through experiments. This study was conducted relevant to two different circumstances, namely, a constant outdoor environmental condition for 1 h and a fluctuating outdoor environmental condition for 24 h. The rate of evaporation and condensation generated inside the underfloor space was calculated and confirmed relevant to the first condition to determine the influence of outdoor environmental factors. The influence of natural ventilation was determined by quantifying the rate of evaporation and condensation with the internal surface being completely wet (ω = 1) and completely dry (ω = 0), and with the outdoor humidity increasing at a range of 0 to 100%, with a 10–20% interval. Under this condition, the influence of different ventilation rates was also confirmed by verification at a general wind speed condition of 1.0 m/s and a stagnant wind condition at 0.05 m/s. In a fluctuating condition, the ambient air temperature near the internal surface temperature also fluctuated continuously, and evaporation and condensation easily occurred because of the temperature difference. Accordingly, based on these fluctuating conditions, the rate of evaporation and condensation over time and the accumulated volume of condensed water on the surface were determined. The information obtained from our research could be utilized at the architectural design stage to pinpoint the spots vulnerable to and the conditions conducive to the generation of condensation inside the underfloor space.

4. Daily Changes in Fluctuating Environmental Condition

In the second instance, we studied a fluctuation of outdoor environmental conditions over time, as the RWS status varied with the introduction of varying parameter values over time relevant to the outdoor environment. Accordingly, the effect of the ventilation rate of the underfloor space was confirmed by verifying the rate of evaporation and condensation, the amount of the condensed water, and the region where the condensation was likely to occur. Such information could be utilized in the architectural design of residences with underfloor spaces.

When the air conditions changed with time, the indoor conditions of evaporation and condensation fluctuated correspondingly. Furthermore, depending on the airflow, the surface temperature distribution, and moisture distribution, and the position where the condensation can occur would change, so as the RWS. When the condensed water evaporated, it acted as a generation source of water vapor, which affected the occurrence of the evaporation and condensation phenomena. Accordingly, our study confirmed variations over time in the rate of evaporation and condensation, the weight of condensed water, and the area where condensation would likely occur relevant to a rainy day during the rainy season, when the average humidity was high.

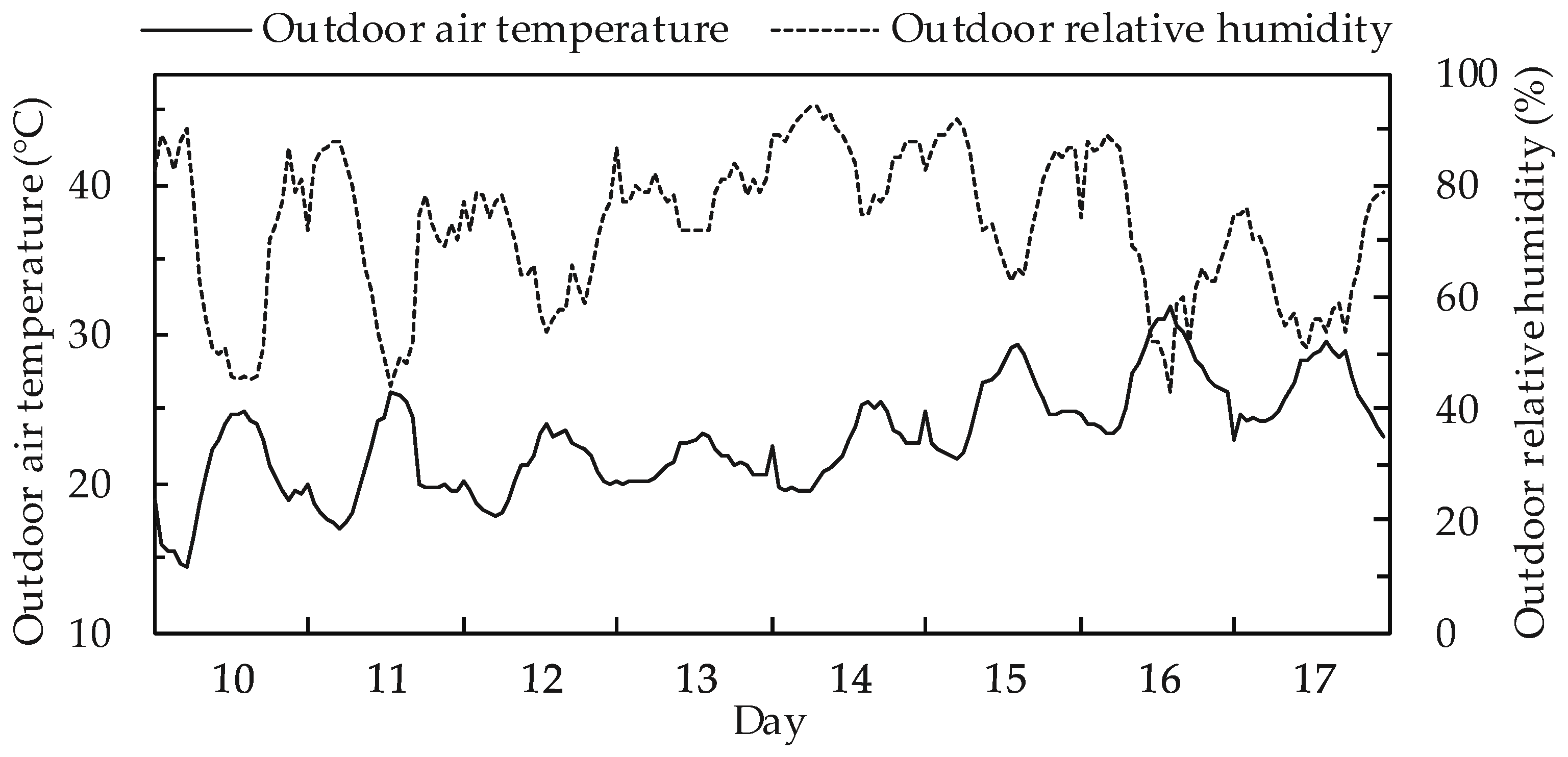

4.1. Weather Data

In this part of the study, we considered the outdoor environment during the rainy season, with the highest humidity levels and a high risk of condensation.

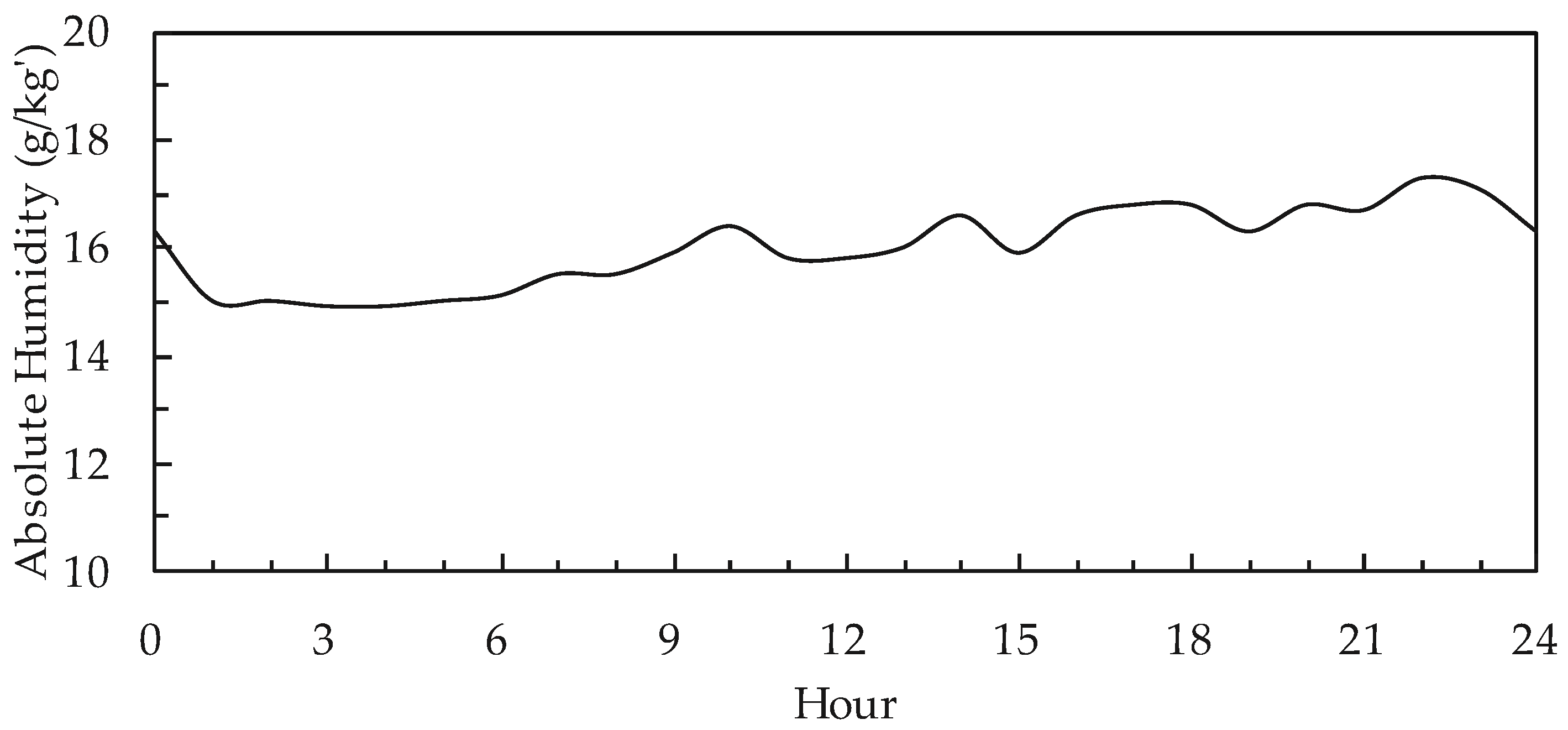

Figure 13 shows the changes in daily temperature and relative humidity in Tokyo during the rainy season, and absolute humidity is expressed in

Figure 14.

The average temperature measured was 25 °C, and the highest temperature was measured between 12:00 and 15:00. The relative humidity with the increasing temperature was approximately 65%. The average daily humidity was 74%.

Wind speed conditions of the outdoor air were assigned uniformly by using the calculated ventilation rate of the underfloor, as described in

Table 1, assuming a general wind speed and a stagnant wind speed. However, this time, changes in wind direction and wind speed as time elapses were not considered.

4.2. Analysis Method

As shown in

Figure 15, the average rate of evaporation and condensation, the amount of condensed water on the surface, and the change in the condensation area over 24 h were confirmed in our study. As changes in wind speed and direction were not taken into consideration, we utilized the values in

Table 1, representing the results of ventilation rates at 1.0 m/s and 0.05 m/s of the southern wind. In this instance, unlike the uniform condition of the outdoor environment, RWS changed continuously according to the elapse of time. The simulation calculations were conducted for 24 h, with the method reflected in

Table 3. The environmental conditions of the outdoor air complied with the temperature and humidity data of the rainy season in Tokyo, as represented in

Figure 13. The initial RWS condition of the internal surface was set at 0, which means that all the surfaces were dry.

4.3. Analysis Results

The evaporation and condensation rates, the amount of the condensed water, and the area of condensation of the underfloor space were observed at hourly intervals over time to identify the effects of the ventilation rate of the underfloor space.

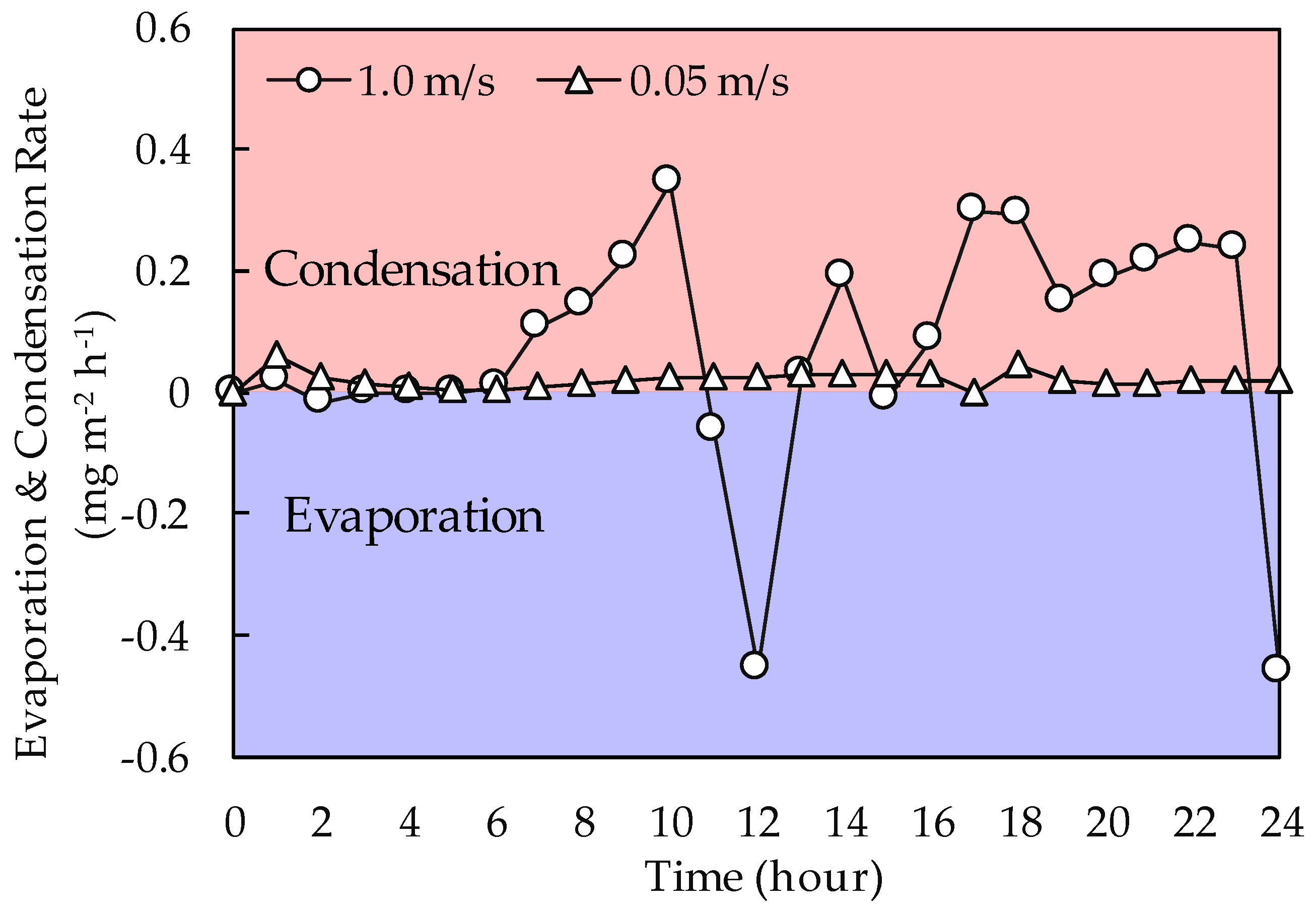

4.3.1. Evaporation and Condensation Effect

The distribution of temperature and pressure inside the underfloor was not uniform because of the influx of outdoor air introduced through the ventilation openings. The value of RWS changed continuously because of the condensation phenomenon. Furthermore, as evaporation and condensation occur differently, depending on the location, the rates of evaporation and condensation was confirmed through the average rate of the entire underfloor space.

When the amount of evaporation was greater than that of condensation, it is expressed as the total average condensation, but when the amount of condensation was greater than that of evaporation, it is expressed as the total average evaporation. The internal humidity of the underfloor would be influenced by the outdoor humidity when the volume of introduced outdoor air increased with an increase in the ventilation rate. In the instance of the outdoor air velocity being 1.0 m/s, the absolute humidity increased with the rising temperature after 6:00 in the morning. The rate of internal condensation continued to increase until 11:00, resulting in a maximum condensation rate of 0.34 mg m−2 h−1 at 10:00. From 11:00, the condensation rate gradually decreased and the condensed water on the surface evaporated between 11:00 and 12:00, whereas the evaporation rate increased significantly at 12:00 to 0.46 mg m−2 h−1. During the rainy season, the humidity remains high throughout the day. Therefore, during the calculated period, the absolute humidity increased with the rise in temperature and the condensation phenomenon appeared again after 13:00 and continued until 23:00. Furthermore, at 24:00, the humidity decreased and evaporation occurred at a largest value of 0.46 mg m−2 h−1 for the day measured. In a condition of stagnant wind velocity (0.05 m/s), it was not influenced significantly by the outdoor conditions. This means that not only was the outdoor moisture not introduced well but also that the internal moisture was not exhausted well. As time elapsed, the condensation phenomenon continued as the humidity from outside entered the underfloor space; however, the evaporation did not occur for 24 h. Furthermore, the evaporation and condensation phenomena were shown to be in equilibrium at 15:00.

4.3.2. Evaporation and Condensation Effect

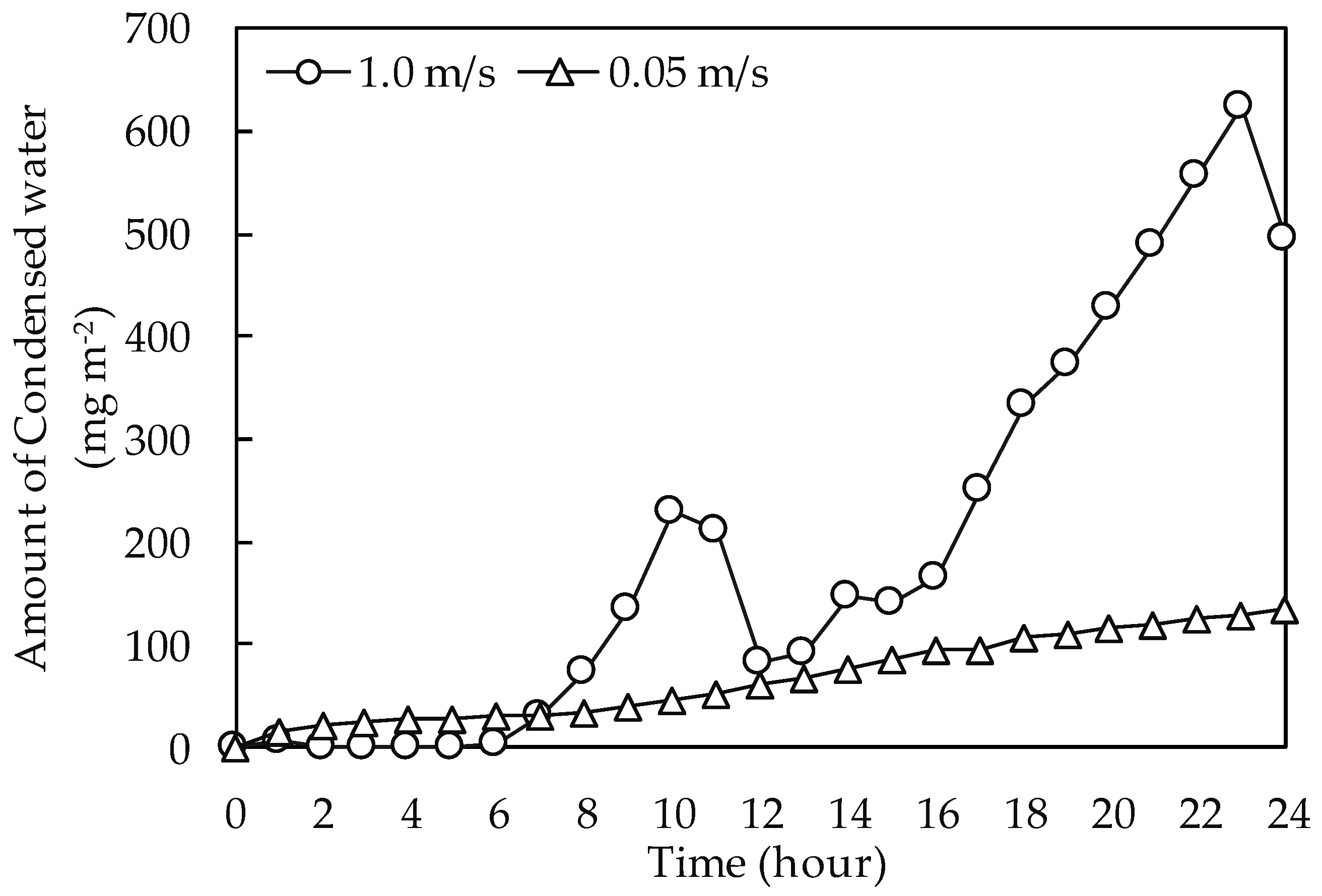

We confirmed the overall characteristics of the internal underfloor space over time according to the average value of the amount of condensed water occurring in the entire underfloor space. The occurrence of condensation initially commenced when all the internal surfaces were in the dry state and it subsequently accumulated water inside the underfloor space.

As shown in

Figure 16, in a condition of wind speed of 1.0 m/s, the condensation continued until 10:00, with evaporation starting to occur between 11:00 and 12:00, and the amount of condensed water starting to decrease. Between 13:00 and 23:00, condensation continued, with the amount of condensed water being the highest at an average value of 2.22 mg/m

2. At 24:00, the rate of evaporation was high, resulting in an average cumulative condensation of 1.76 mg/m

2 per day. Condensation occurred continuously with a wind velocity of 0.05 m/s, assuming a stagnant environment, and an amount of 0.48 mg/m

2 of cumulative condensed water was observed at 24:00.

Convective mass transfer on surface increases as the air velocity increased. The air temperature increase causes the absolute humidity rise in the moist air due to the change of saturated vapor pressure. These results affect the amount of moist introduced from the outdoor air. As the higher ventilation rate, inflow rate of water vapor into underfloor space increase. This means that the convective mass transfer in a condition of 0.05 m/s is not a dominant comparing to 1.0 m/s. Before 6 o’clock, the evaporation at 1.0 m/s was stronger than the condensation due to water vapor inflow. On the other hand, at 0.5 m/s, the condensation by convection was stronger than the evaporation. In the case of 1.0 m/s, condensation due to water vapor flow is stronger than evaporation due to forced convection as the absolute humidity flowing into the inside increases after 6 o’clock. For this reason, the amount of condensed water in the underfloor space is reversed by 1.0 m/s and 0.05 m/s after 7 o’clock.

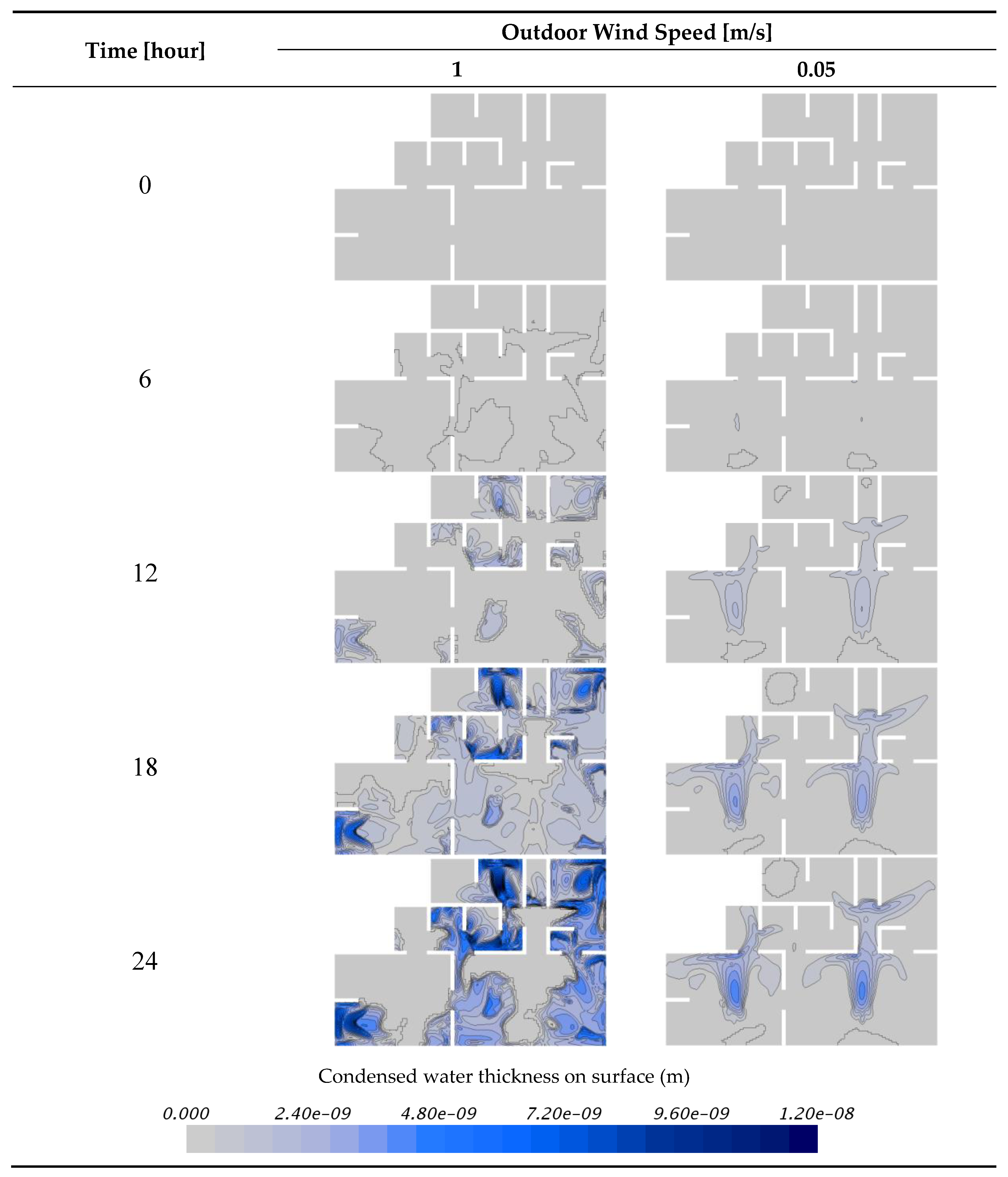

4.3.3. Condensed Water Distribution on Surface of Concrete

The area where condensation occurred differed according to the ventilation rates. As shown in

Figure 17, at a wind speed of 1.0 m/s, condensation did not occur where the airflow is strong, but did occur nearby the mainstream of the strong airflow, and was likely to occur in the corners of the underfloor space. However, in the northern zone, where the airflow does not reach, condensation hardly occurred at all. The evaporation phenomenon was likely to occur in an area of strong airflow, as mass transfer easily occurred and condensation rarely occurred. In addition, the convective heat transfer from the surface was more pronounced because of the strong airflow when the outdoor air flowed in; therefore, condensation was less likely to occur. In contrast, in a stagnant condition of 0.05 m/s wind speed, condensation occurred mostly near the zone where the airflow was generated. This is because the velocity of the incoming airflow was extremely low and the convective heat transfer on the surface was not large; therefore, the moisture of the incoming outdoor air condensed at the area where the airflow was formed.

6. Conclusions

In the case where condensed water exists inside the subfloor, the rate of evaporation was shown to be greater when the airflow rate was high. However, under extreme conditions where the outdoor humidity is 90% or more, condensation occurs instead of evaporation. When the outdoor humidity was less than 90%, the condensation did not occur, regardless of the airflow rate. This means that keeping the inside of the underfloor space free from condensed water and dry is important. In the situation when the outdoor humidity is high, such as the rainy season, internal condensation in the underfloor space easily occurs due to natural ventilation no matter what the airflow rate is. If the airflow rate is high, it is easily affected by outdoor humidity, and the evaporation and condensation phenomena are continuously changing. On the other hand, under low airflow rate conditions, only the condensation appeared steadily. If the wind velocity is strong, the convective mass transfer on a surface becomes large. When the outdoor humidity is high and the airflow rate is high, condensation mainly occurs in a corner of the underfloor space due to high evaporation by convection in the mainstream of the airflow. By contrast, when the airflow rate is low, condensation occurs along the air stream. If condensation occurs once in the corner where the airflow has not reached well, it is difficult to evaporate again. Therefore, it is necessary to control the ventilation rate according to the characteristics of the external environment and internal RWS.

We confirmed the influence of the difference in the humidity when the outdoor wind speed was assumed 1.0 m/s and the outdoor air flowing into the room remained constant according to the calculated ventilation rate. In the instance of a RWS value of 1, evaporation occurred actively and the evaporation rate was 12.3 mg m−2 h−1. The total volume of the internal evaporation rate was 726 mg/h. The evaporation phenomenon did not occur in a condition of 0–70% humidity, where the value of RWS was 0 and the entire surface was dry. When humidity was high at 90–100%, the total condensation rate of the underfloor was 0.03 g/h.

We confirmed the influence of the difference in humidity when the outdoor wind speed was assumed stagnant at 0.05 m/s and the outdoor air flowing into the room remained constant according to the calculated ventilation rate. When the value of RWS was 1, the average evaporation effect per area was determined as 0.5–0.05 mg m−2 h−1, and the total volume of the evaporation rate was 29.5–3.0 mg/h. In a condition of 90% humidity of the introduced outdoor air, a state of equilibrium was indicated, with neither evaporation nor condensation occurring. With 100% humidity, the evaporation phenomenon reversed and a condensation phenomenon of 0.7 × 10−4 mg m−2 h−1 occurred. However, the condensation phenomenon was slight, as indicated by the result of 0.4 × 10−2 mg/h. When the RWS value was zero, with all the internal surfaces dry and humidity of 90–100%, the total condensation rate of the underfloor space was 0.03 g/h.

When the outdoor wind speed was 1.0 m/s and the outdoor environmental conditions fluctuated for 24 h, the outdoor humidity remained high and condensation continued. However, with the temperature rising or humidity decreasing, evaporation occurred between 11:00 and 12:00, and at 24:00. The maximum condensation rate was 0.34 mg m−2 h−1 at 10:00 and the maximum evaporation rate was 0.46 mg m−2 h−1 at 12:00 and at 24:00.

In a stagnant environment, with an outdoor wind speed of 0.05 m/s, the rate of natural ventilation into the underfloor was low and the effect of the outdoor environment was therefore insignificant. Consequently, condensation continued for 24 h and evaporation did not occur at all.

Under a condition of 1.0 m/s wind speed, evaporation and condensation occurred continuously throughout the day and the cumulative rate of condensation of the underfloor space was 1.76 mg/m2 per day. Under a condition of 0.05 m/s wind speed, the cumulative rate of condensation of the underfloor space from natural ventilation was 0.48 mg/m2 per day.

When the wind speed was 1.0 m/s, condensation did not occur near the strong airflow, but did occur in the vicinity of the airflow, and easily occurred in the corners. Furthermore, as there was less moisture transfer through the airflow, condensation hardly occurred where the airflow could not reach. At a wind speed of 0.05 m/s, assuming a stagnant condition, moisture was transferred to the inside by the airflow and condensation occurred in accordance with the airflow.