Development of Numerical Heat Transfer and the Structural Model to Design Slim and Translucent Vacuum Layer Type Insulation Panels to Retrofitting Insulation in Existing Buildings

Abstract

:1. Introduction

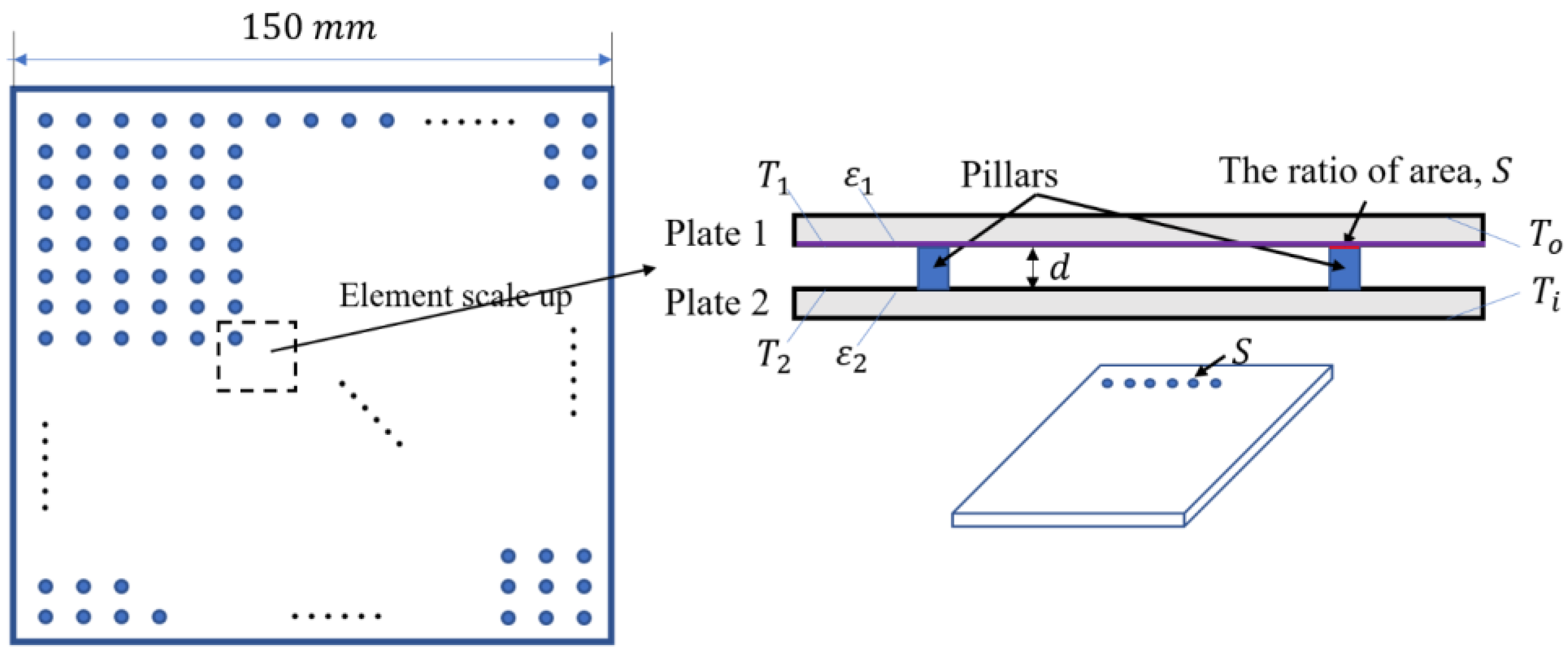

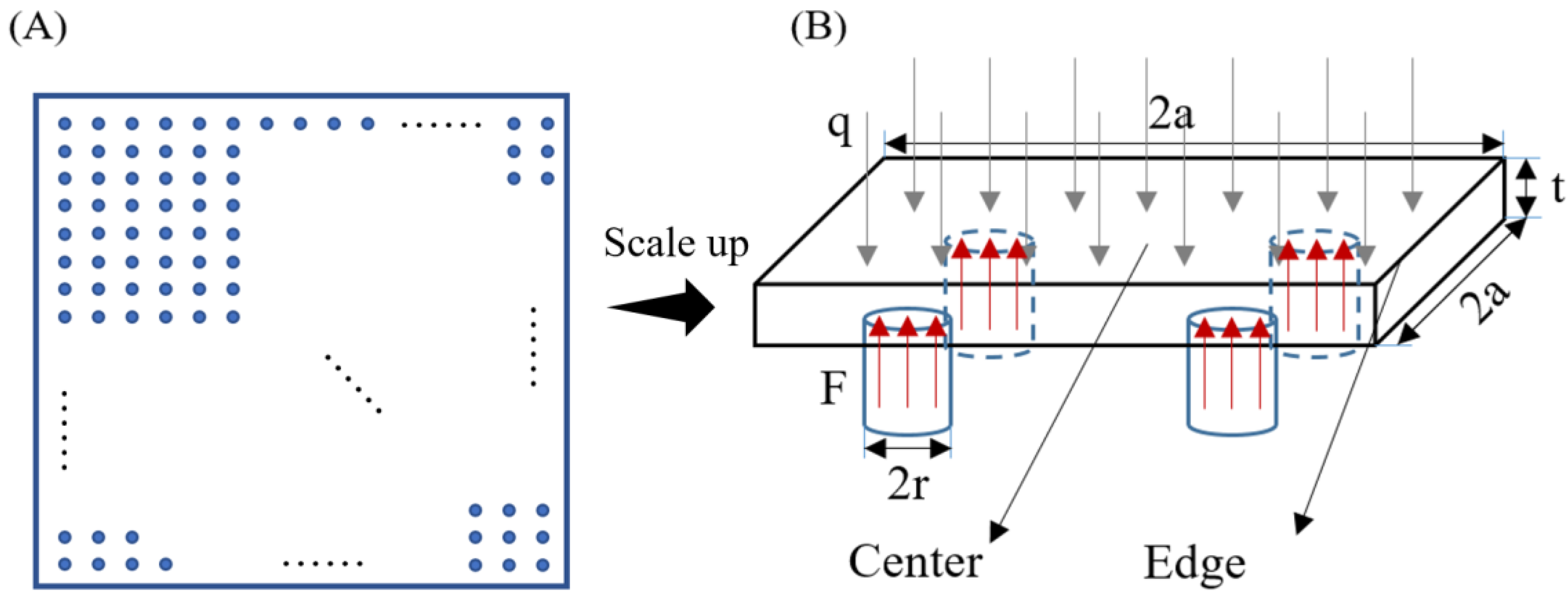

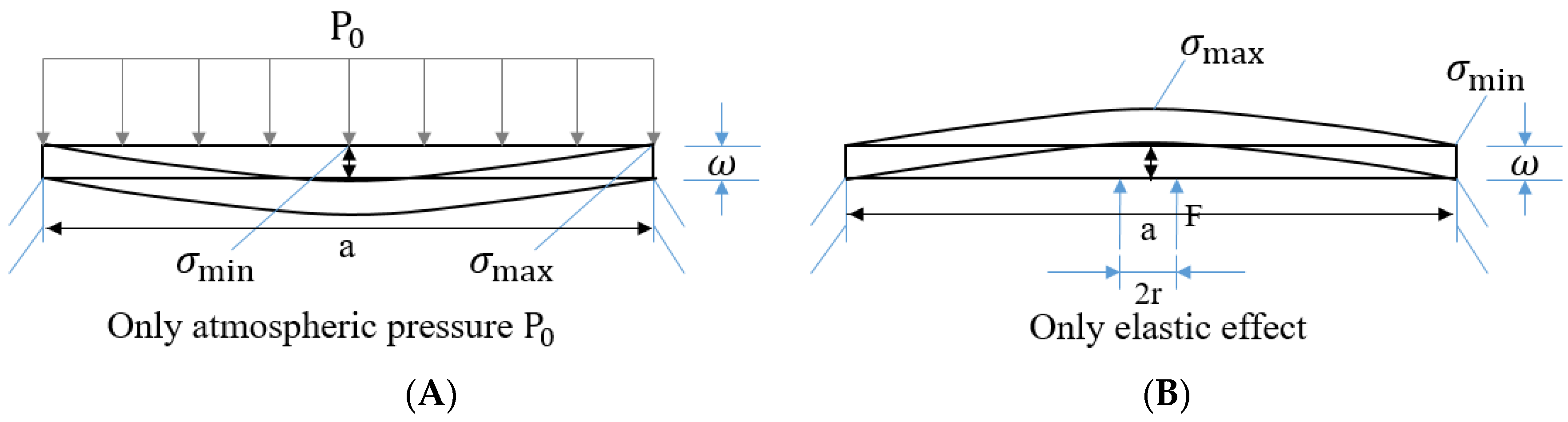

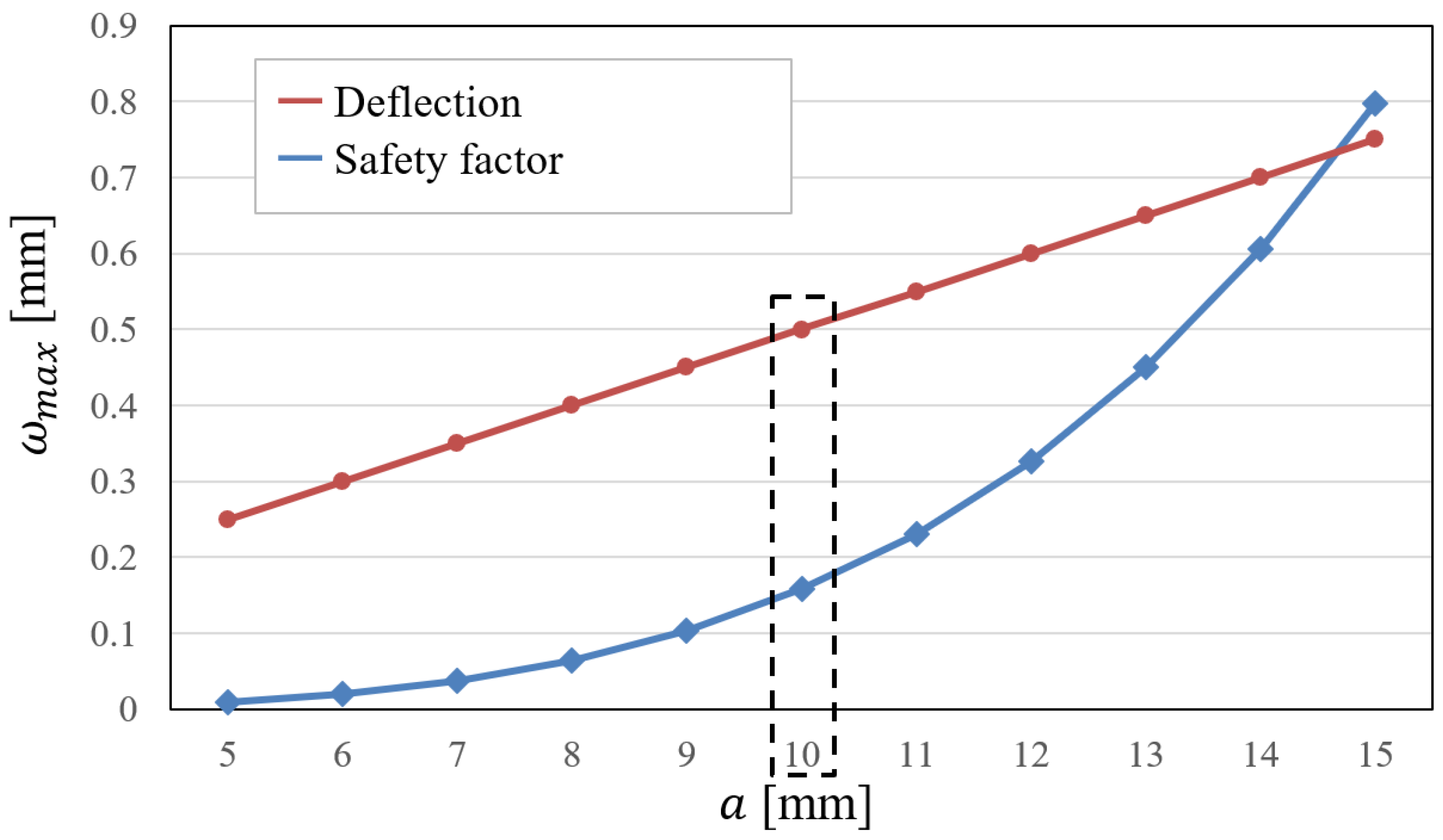

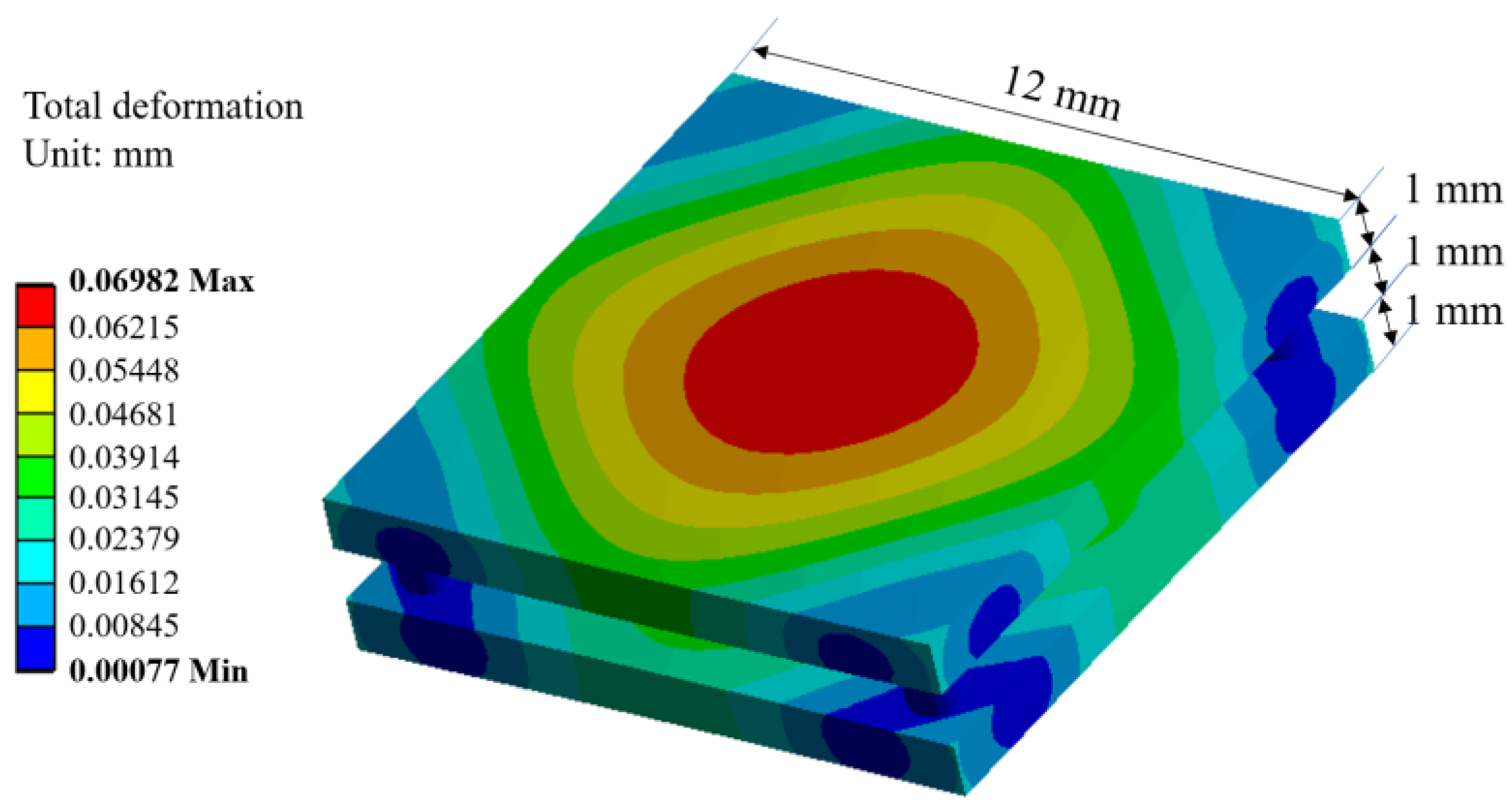

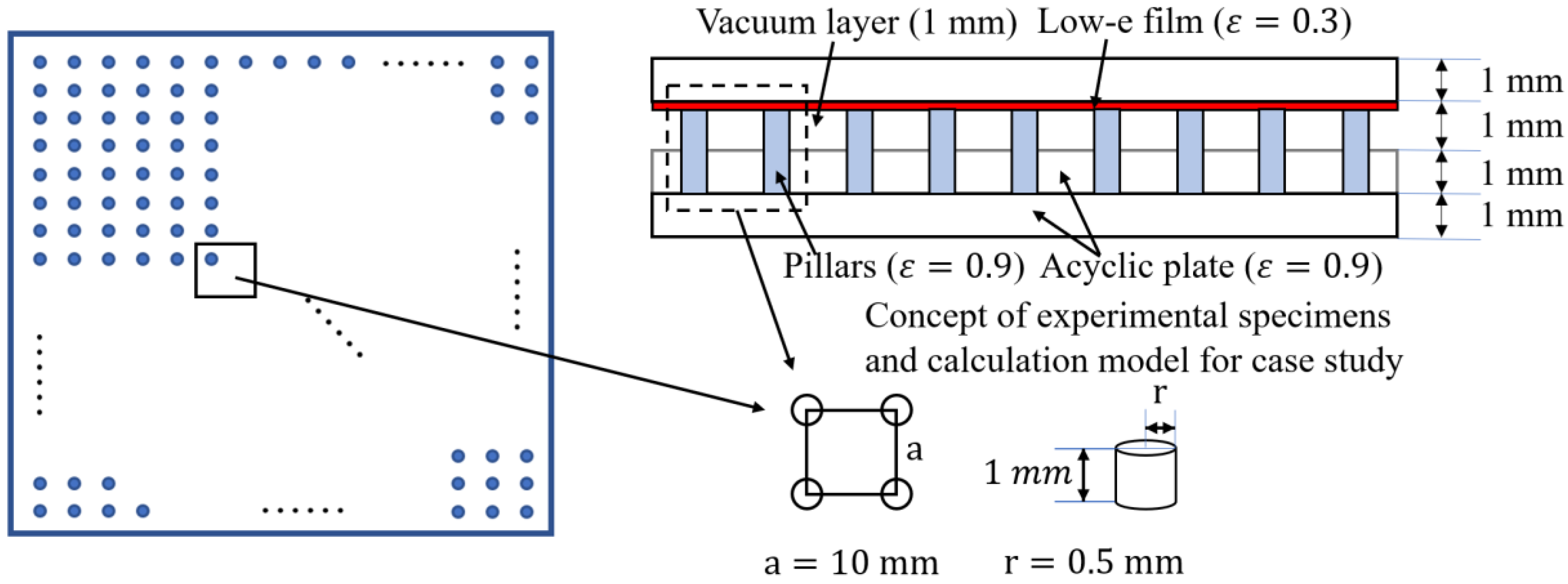

2. Mechanical Analysis and Core Structural Design for Vacuum Layer Type Slim and Translucent VIP

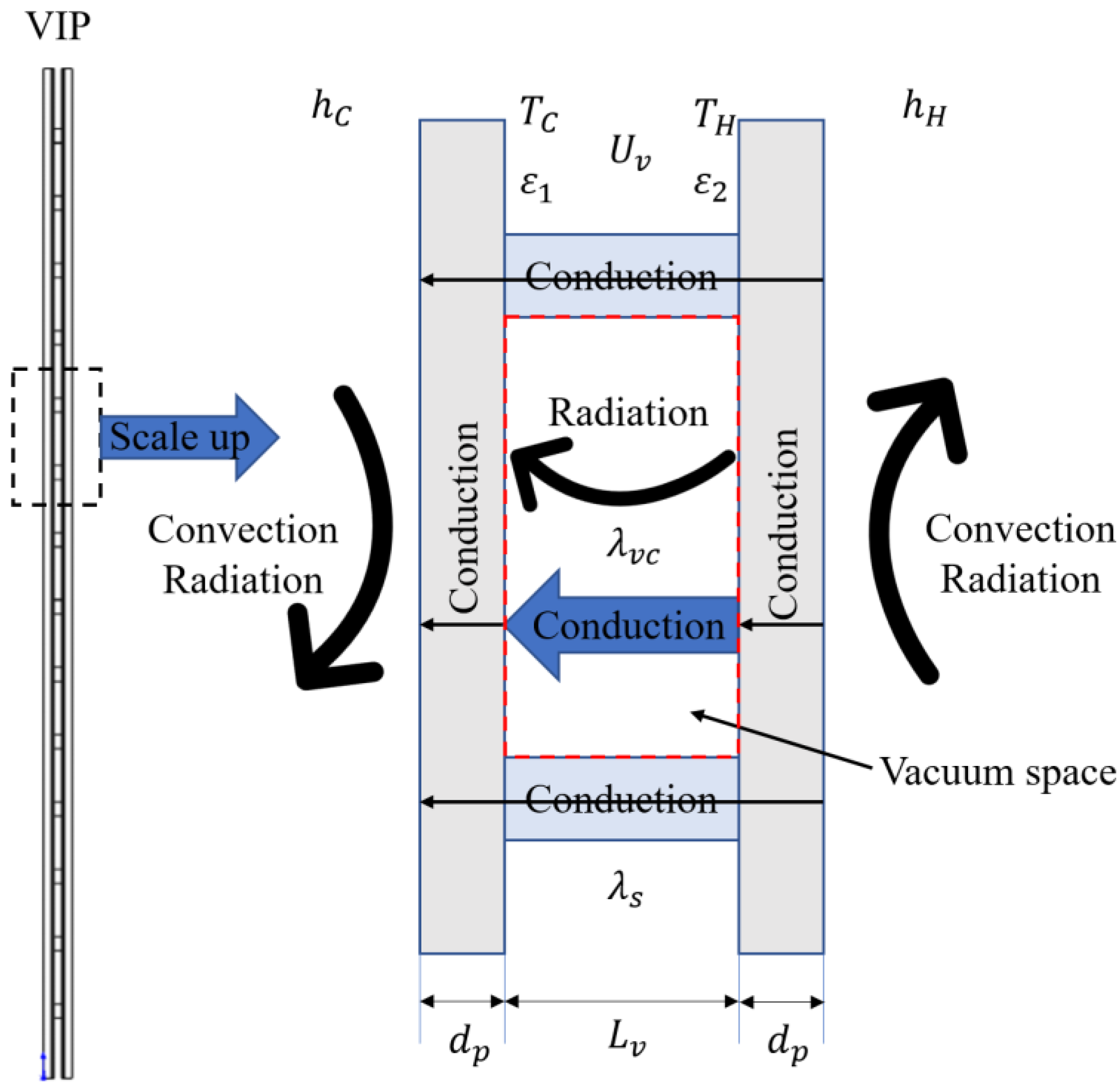

3. Framework of Heat Transfer Calculation Model

3.1. Calculation and Design of the Vacuum Layer

3.2. Establishment of Heat Transfer Calculation Model

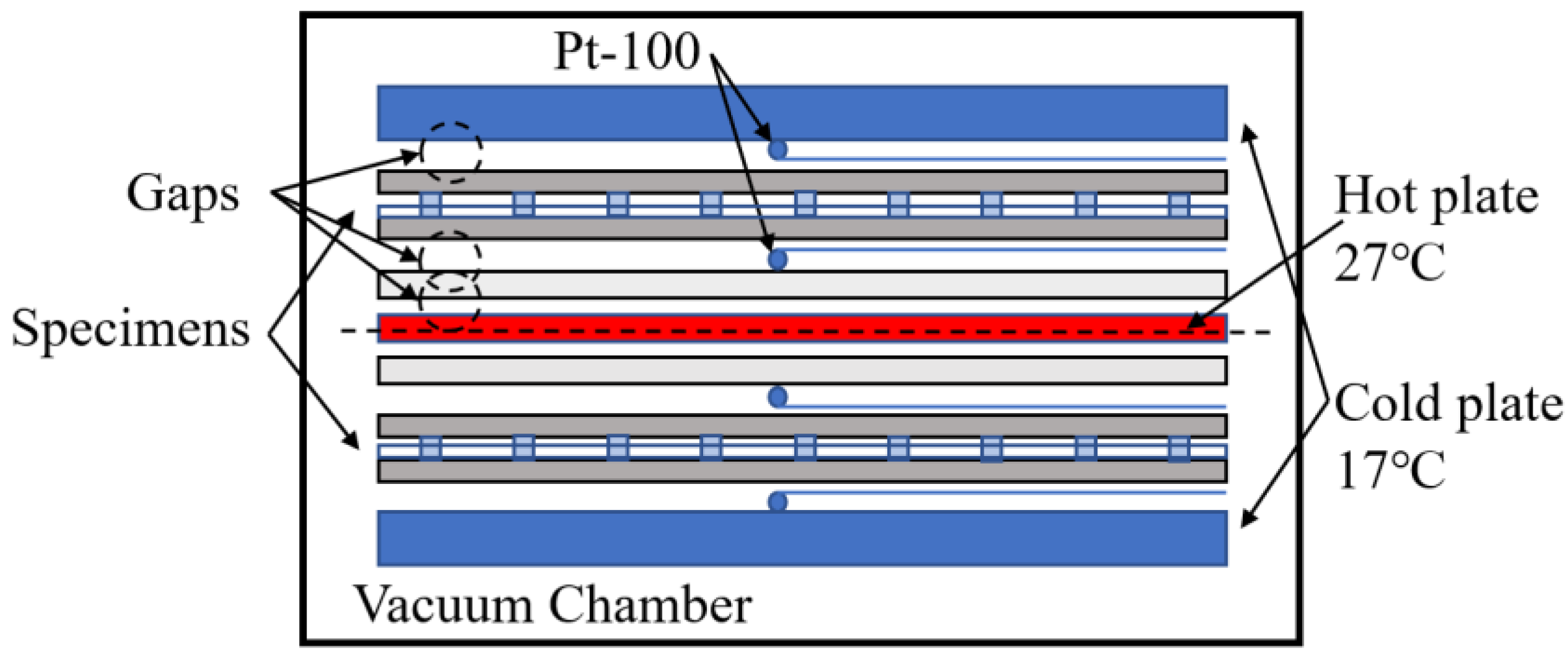

4. Validation of Numerical Model by Comparison with Experimental Results

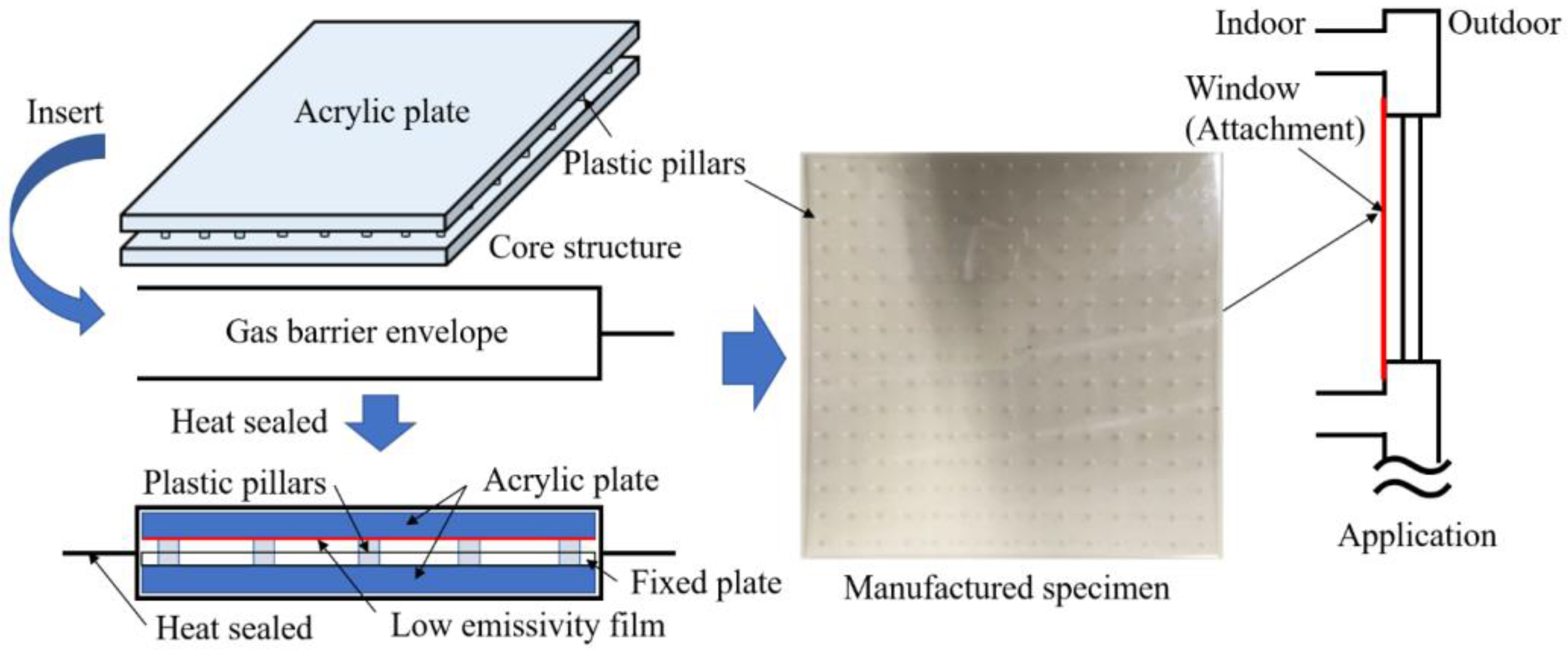

4.1. VIP Production and its Cost Performance Evaluation

4.2. Framework of Guarded Hot Plate Apparatus

4.3. Framework of VIP Specimen for GHP Method and its Calculation Conditions and Result

5. Case Studies for Vacuum Layer Type Translucent VIP

5.1. Calculation Conditions for Case Studies

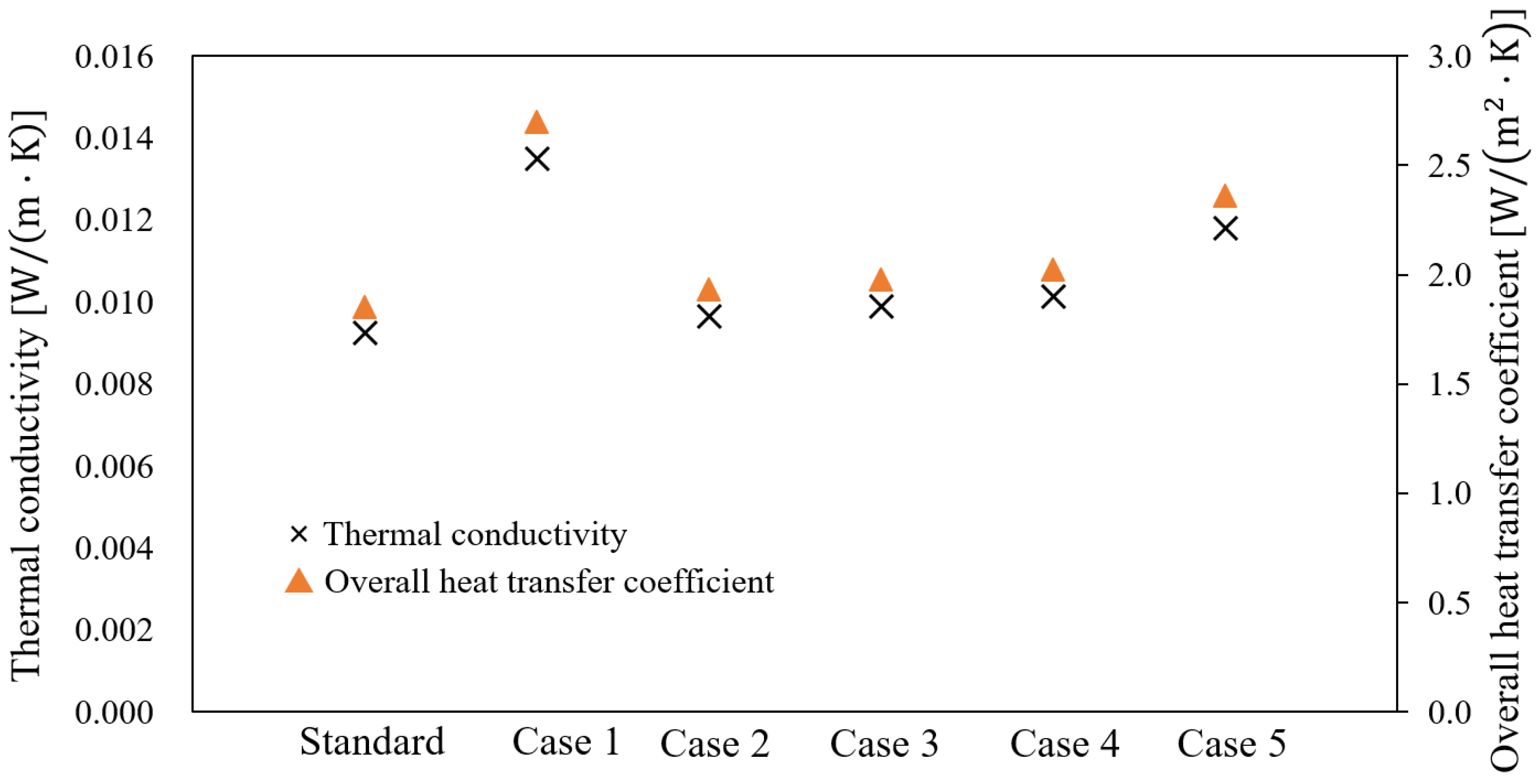

5.2. Results and Discussion

6. Conclusions

- (1)

- The authors proposed a vacuum layer type slim and translucent VIP with the advantages of a low manufacturing cost and easy application.

- (2)

- By using a structural calculation model, the specifications of the spacers and plastic plates that can hold the vacuum layer structurally were investigated. The result showed that the vacuum layer could be maintained when the span between the spacers was less than 10 mm.

- (3)

- Heat transfer models were considered for the prediction of the thermal transmittance of the VIPs. The thermal conductivities of the VIPs were calculated by varying the calculation conditions of the pressure of the vacuum layer, thermal emissivity of the surface, and number of vacuum layers. The high-insulation performance was confirmed for future applications because the overall heat transfer coefficients were less than 2.0 when the pressure of the vacuum layer was reduced to less than 0.1 Pa or a double vacuum layer was produced.

- (4)

- The result showed that the thermal conductivity of a double layer VIP under a pressure of 1.0 Pa was practically similar to that of a single VIP under a pressure of 0.1 Pa.

- (5)

- The numerical results were in better agreement with the experimental results under a pressure of 1 Pa because the numerical analysis can also consider the thermal resistance in different axis directions. Furthermore, to obtain a better insulation performance, using multiple layers instead of a lower pressure could reduce the product cost and lead to easy manufacturing of the product.

Acknowledgments

Author Contributions

Conflicts of Interest

Nomenclature

| Measurement area ( | |

| Span between spacers (mm) | |

| Thermal conductance () | |

| Stiffness (N/m) | |

| Thickness (m) | |

| Thickness of acrylic plate (mm) | |

| Molecular diameter (nm) | |

| Young’s modulus (GPa) | |

| Grashof number (-) | |

| Acceleration due to gravity () | |

| Absolute temperature (K) | |

| Boltzmann constant (J/K) | |

| Thickness of vacuum layer (m) | |

| Mean free path of air (m) | |

| Molecular mass ( | |

| Pressure (Pa) | |

| Pressure ratio (-) | |

| Atmospheric pressure (Pa) | |

| Prandtl number (-) | |

| Average electric power () | |

| ) | |

| ) | |

| Overall heat transfer coefficient ( | |

| Kinematic viscosity ( | |

| Greek Symbols | |

| Convection heat transfer rate ( | |

| Coefficient of volume expansion (-) | |

| Accommodation coefficient (-) | |

| Specific heat ratio (-) | |

| Stefan-Boltzmann constant ( | |

| Thermal conductivity ( | |

| Emissivity (-) | |

| Poisson ratio (-) | |

| Coefficient when rectangular flat plate is functioned by uniform load (-) | |

| Maximum deflection (mm) | |

| Subscripts | |

| Average | |

| Cold | |

| Conduction | |

| Mean | |

| Hot | |

| Plate | |

| Radiation | |

| 1, 2 | Surface 1 or 2 |

| Vacuum insulation panel | |

| Vacuum layer | |

| , , | Gaps in GHP apparatus |

Appendix A

References

- Nature Publishing Group. Architects of a low-energy future. Nature 2008, 452, 520–523. [Google Scholar]

- Saari, A.; Kalamees, T.; Jokisalo, J.; Michelsson, R.; Alanne, K.; Kurnitski, J. Financial viability of energy-efficiency measures in a new detached house design in Finland. Appl. Energy 2012, 92, 76–83. [Google Scholar] [CrossRef]

- Lim, T.; Seok, J.; Kim, D.D. A Comparative Study of Energy Performance of Fumed Silica Vacuum Insulation Panels in an Apartment Building. Energies 2017, 10, 2000. [Google Scholar] [CrossRef]

- Capozzoli, A.; Fantucci, S.; Favoino, F.; Perino, M. Vacuum Insulation Panels: Analysis of the Thermal Performance of Both Single Panel and Multilayer Boards. Energies 2015, 8, 2528–2547. [Google Scholar] [CrossRef]

- Park, S.; Choi, B.-H.; Lim, J.-H.; Song, S.-Y. Evaluation of Mechanically and Adhesively Fixed External Insulation Systems Using Vacuum Insulation Panels for High-Rise Apartment Buildings. Energies 2014, 7, 5764–5786. [Google Scholar] [CrossRef]

- Collins, R.E.; Turner, G.M.; Fisher-Cripps, A.C. Vacuum Glazing—A New Component for Insulating Windows. Build. Environ. 1995, 30, 459–492. [Google Scholar] [CrossRef]

- Fisher-Cripps, A.C.; Collins, R.E.; Turner, G.M.; Bezzel, E. Stress and Fracture Probability in Evacuated Glazing. Build. Environ. 1995, 30, 41–59. [Google Scholar] [CrossRef]

- Garrison, J.D.; Collins, R.E. Manufacture and cost of Vacuum Glazing. Sol. Energy 1995, 55, 151–161. [Google Scholar] [CrossRef]

- Turner, G.M.; Collins, R.E. Measurement of Heat flow through Vacuum Glazing at elevated Temperature. J. Heat Mass Transf. 1997, 40, 1437–1446. [Google Scholar] [CrossRef]

- Lenzen, M.; Collins, R.E. Long-term Field Tests of Vacuum Glazing. Sol. Energy 1997, 61, 11–15. [Google Scholar] [CrossRef]

- Collins, R.E.; Simko, T.M. Current Status of the Science and Technology of Vacuum Glazing. Sol. Energy 1998, 62, 189–213. [Google Scholar] [CrossRef]

- Simko, T.M.; Fisher-Cripps, A.C.; Collins, R.E. Temperature-induced in Vacuum Glazing Modelling and Experimental Validation. Sol. Energy 1998, 63, 1–21. [Google Scholar] [CrossRef]

- Kim, J.; Jang, C.; Song, T. Combined heat transfer in multi-layer radiation shields for vacuum insulation panels: Theoretical/numerical analysis and experiment. Appl. Energy 2012, 94, 295–302. [Google Scholar] [CrossRef]

- Kwon, J.-S.; Jang, C.; Jung, H.; Song, T.-H. Vacuum maintenance in vacuum insulation panels exemplified with a staggered beam VIP. Energy Build. 2010, 42, 590–597. [Google Scholar] [CrossRef]

- Bouquerel, M.; Duforestel, T.; Baillis, D.; Rusaouen, G. Heat transfer modelling in vacuum insulation panels containing nanoporous silica—A review. Energy Build. 2012, 54, 320–336. [Google Scholar] [CrossRef]

- Kwon, J.-S.; Jang, C.; Jung, H.; Song, T.-H. Effective thermal conductivity of various filling materials for vacuum insulation panels. Int. J. Heat Mass Transf. 2009, 52, 5525–5532. [Google Scholar]

- Johanssonn, P.; Adl-Zarrabi, B.; Hagentoft, C.-E. Using transient plane source sensor for determination of thermal properties of vacuum insulation panels. Front. Archit. Res. 2012, 1, 334–340. [Google Scholar] [CrossRef]

- Collins, R.E.; Davis, C.A.; Dey, C.J.; Robinson, S.J.; Tang, J.Z.; Turner, G.M. Measurement of local heat flow in flat evacuated glazing. Int. J. Heat Mass Transf. 1993, 36, 2553–2563. [Google Scholar] [CrossRef]

- Timoshenko, S.; Woinowsky-Krieger, S. Theory of Plate and Shell; McGraw-Hill Book Company: Columbus, OH, USA, 1959; pp. 106–108. [Google Scholar]

- Roark, R.J.; Warren, C.; Young, R.G. Budynas. Formulas for Stress and Strain, 7th ed.; McGraw-Hill Professional: New York, NY, USA, 2001; pp. 508–509. [Google Scholar]

- Gan, G. Thermal transmittance of multiple glazing: Computational fluid dynamics prediction. Appl. Therm. Eng. 2001, 21, 1583–1592. [Google Scholar] [CrossRef]

- Springer, G.S. Heat Transfer in Rare Field Gases. Adv. Heat Transf. 1971, 7, 163–218. [Google Scholar]

- Jousten, K.; Jitschin, W.; Sharipov, F.; Pumps, P.D.; Dirscherl, J.; Lachenmann, R.; Jünemann, A.; Friedrichsen, I.; Lippelt, E.; Kossek, B.; et al. Handbook of Vacuum Technology, 1st ed.; Jousten, K., Ed.; Wiley: Weinheim, Germany, 2008; pp. 51–81. [Google Scholar]

- Eckert, E.R.G.; Drake, R.M. Heat and Mass Transfer, 2nd Revised ed.; McGraw-Hill Inc.: Columbus, OH, USA, December 1959. [Google Scholar]

| Pressure (Pa) | Experimental Thermal Conductivity λm (mW/(m·K)) | Experimental Thermal Resistance Rm ((m2·K)/W) | Thermal Resistance in the Gaps Rva ((m2·K)/W) | Thermal Resistance of VIP (Calculated) RVIP ((m2·K)/W) | Thermal Conductivity of VIP (Calculated) λVIP (W/(m·K)) |

|---|---|---|---|---|---|

| 0.1 | 2.9 | 1.45 | 0.21 | 0.83 | 0.005 |

| 1 | 3.6 | 1.17 | 0.17 | 0.65 | 0.006 |

| Conditions | Lv (m) | P (Pa) | λv (W/(m·K)) | ε1 | ε2 | Layers |

|---|---|---|---|---|---|---|

| Standard | 1.0 × 10−3 | 0.1 | 0.000106 | 0.3 | 0.9 | 1 |

| Case 1 | 1 | 0.00106 | 0.9 | 0.9 | 1 | |

| Case 2 | 1 | 0.00053 | 0.3 | 0.9 | 2 | |

| Case 3 | 0.5 | 0.00053 | 0.3 | 0.9 | 1 | |

| Case 4 | 0.1 | 0.000106 | 0.9 | 0.9 | 1 | |

| Case 5 | 1 | 0.00106 | 0.3 | 0.9 | 1 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, Z.; Katsura, T.; Aihara, M.; Nakamura, M.; Nagano, K. Development of Numerical Heat Transfer and the Structural Model to Design Slim and Translucent Vacuum Layer Type Insulation Panels to Retrofitting Insulation in Existing Buildings. Energies 2017, 10, 2108. https://doi.org/10.3390/en10122108

Yang Z, Katsura T, Aihara M, Nakamura M, Nagano K. Development of Numerical Heat Transfer and the Structural Model to Design Slim and Translucent Vacuum Layer Type Insulation Panels to Retrofitting Insulation in Existing Buildings. Energies. 2017; 10(12):2108. https://doi.org/10.3390/en10122108

Chicago/Turabian StyleYang, Zhang, Takao Katsura, Masahiro Aihara, Makoto Nakamura, and Katsunori Nagano. 2017. "Development of Numerical Heat Transfer and the Structural Model to Design Slim and Translucent Vacuum Layer Type Insulation Panels to Retrofitting Insulation in Existing Buildings" Energies 10, no. 12: 2108. https://doi.org/10.3390/en10122108

APA StyleYang, Z., Katsura, T., Aihara, M., Nakamura, M., & Nagano, K. (2017). Development of Numerical Heat Transfer and the Structural Model to Design Slim and Translucent Vacuum Layer Type Insulation Panels to Retrofitting Insulation in Existing Buildings. Energies, 10(12), 2108. https://doi.org/10.3390/en10122108