Numeric Investigation of Gas Distribution in the Intake Manifold and Intake Ports of a Multi-Cylinder Diesel Engine Refined for Exhaust Gas Stratification

Abstract

:1. Introduction

2. Apparatus and Simulation

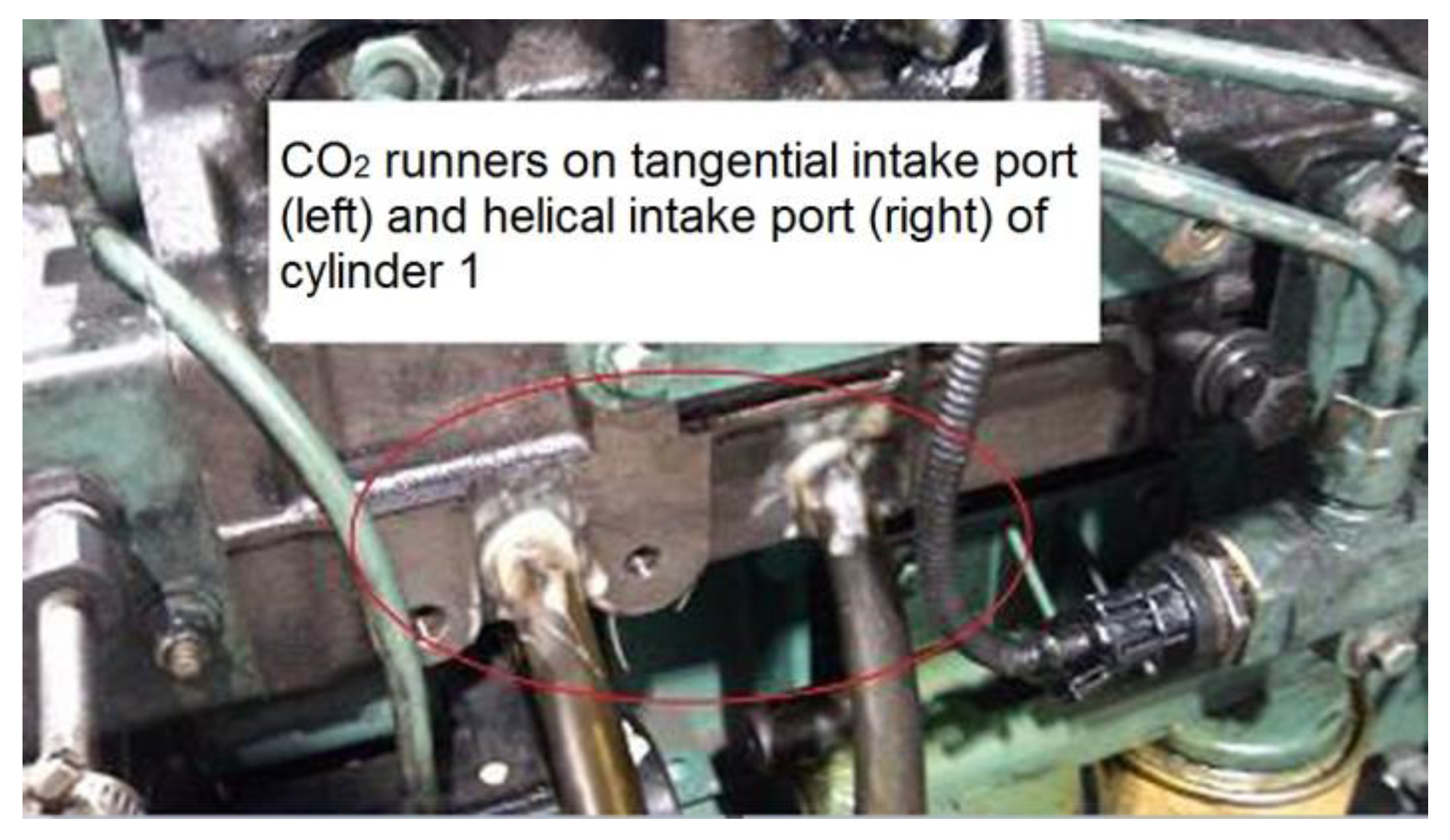

2.1. Apparatus

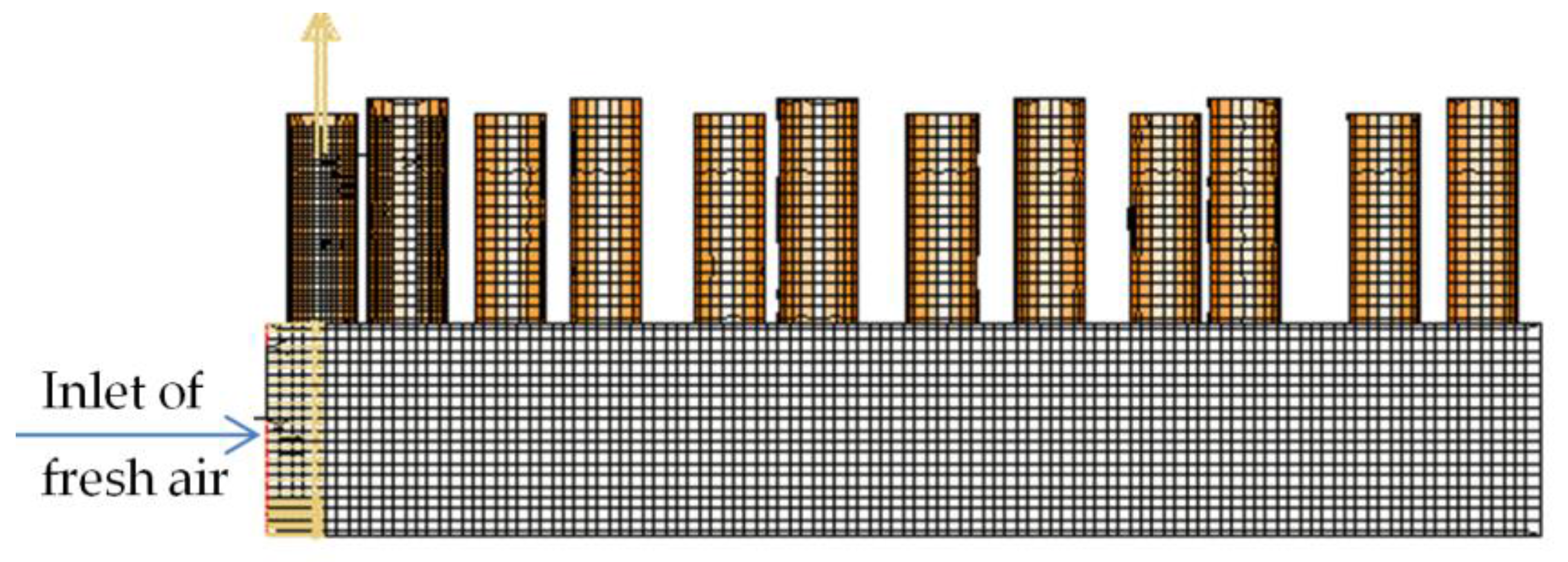

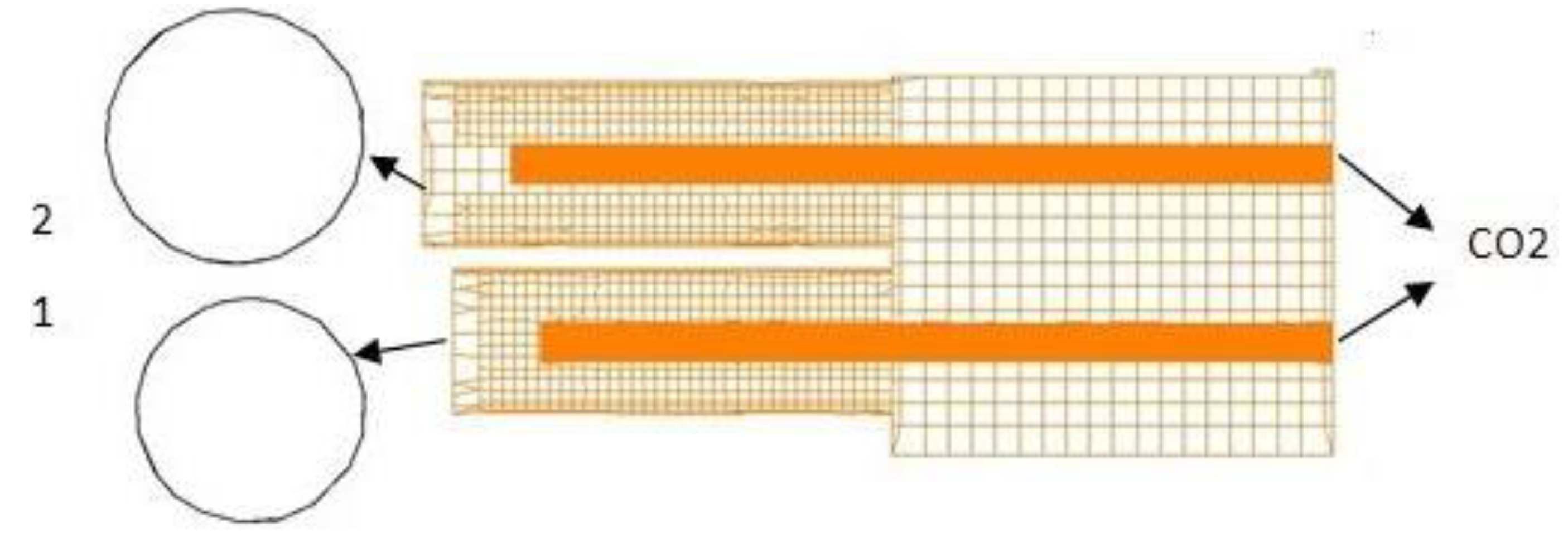

2.2. Numerical Methods and Initial Conditions

2.3. Turbulence and Mass Transfer

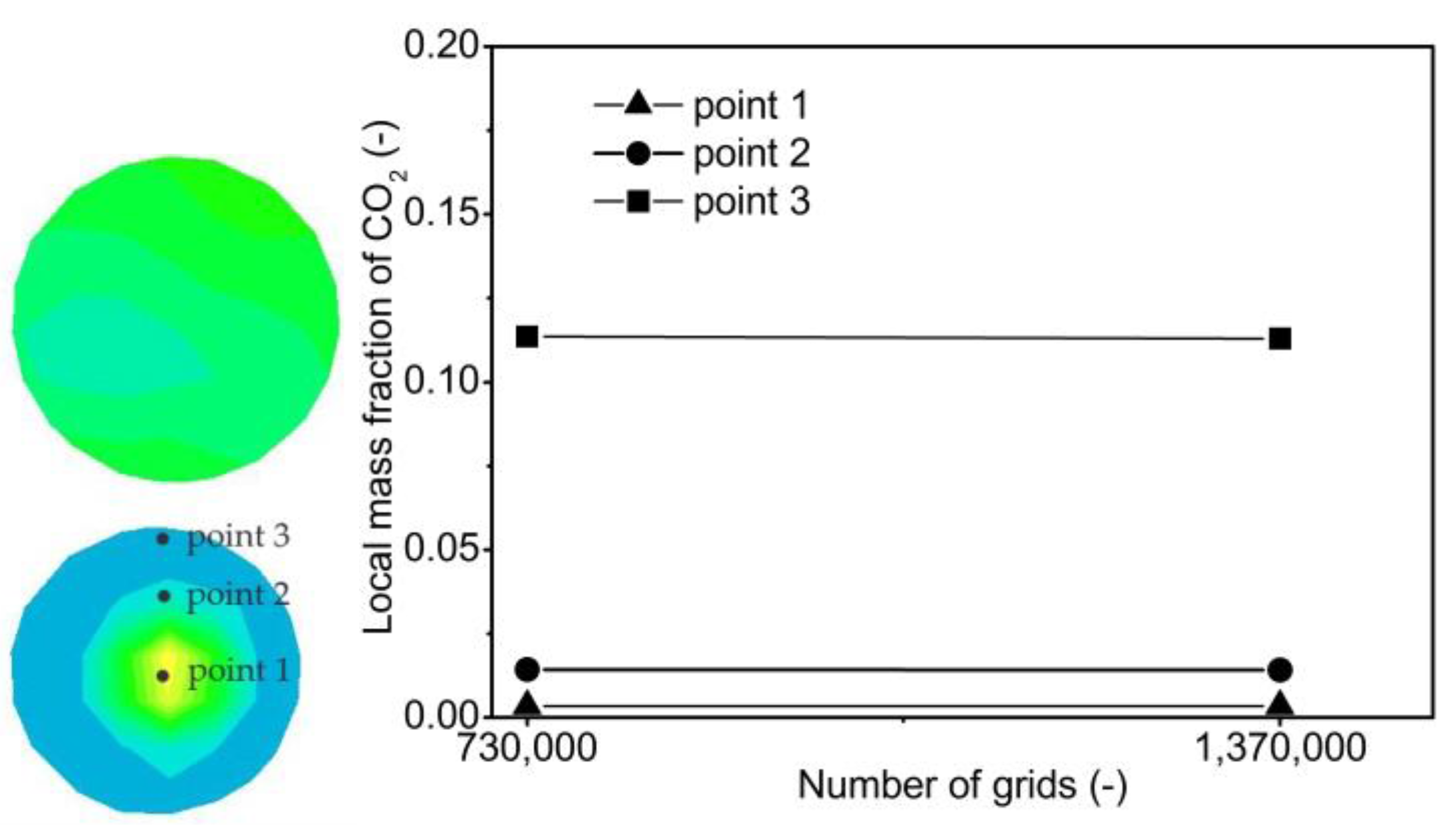

2.4. Independent Validaton

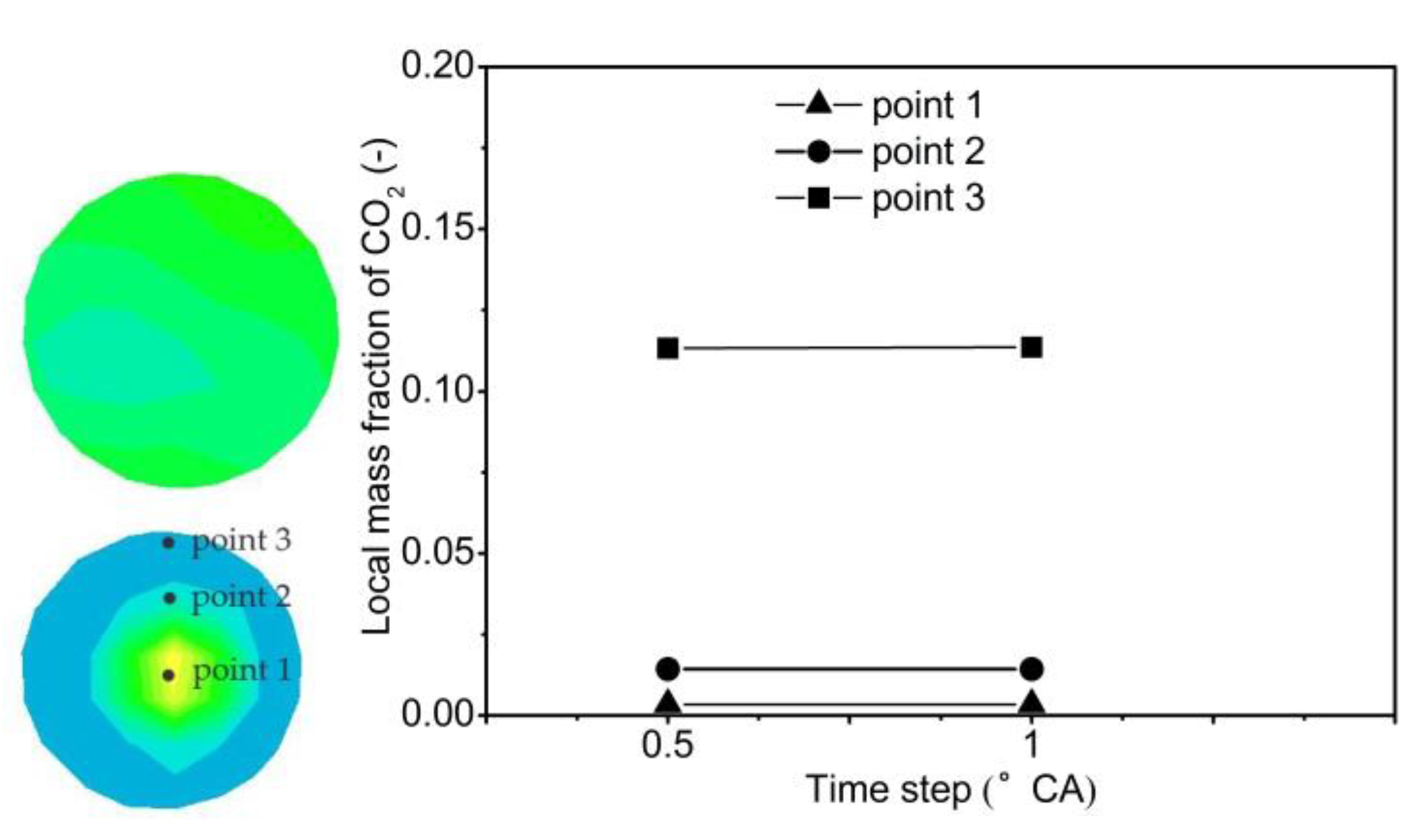

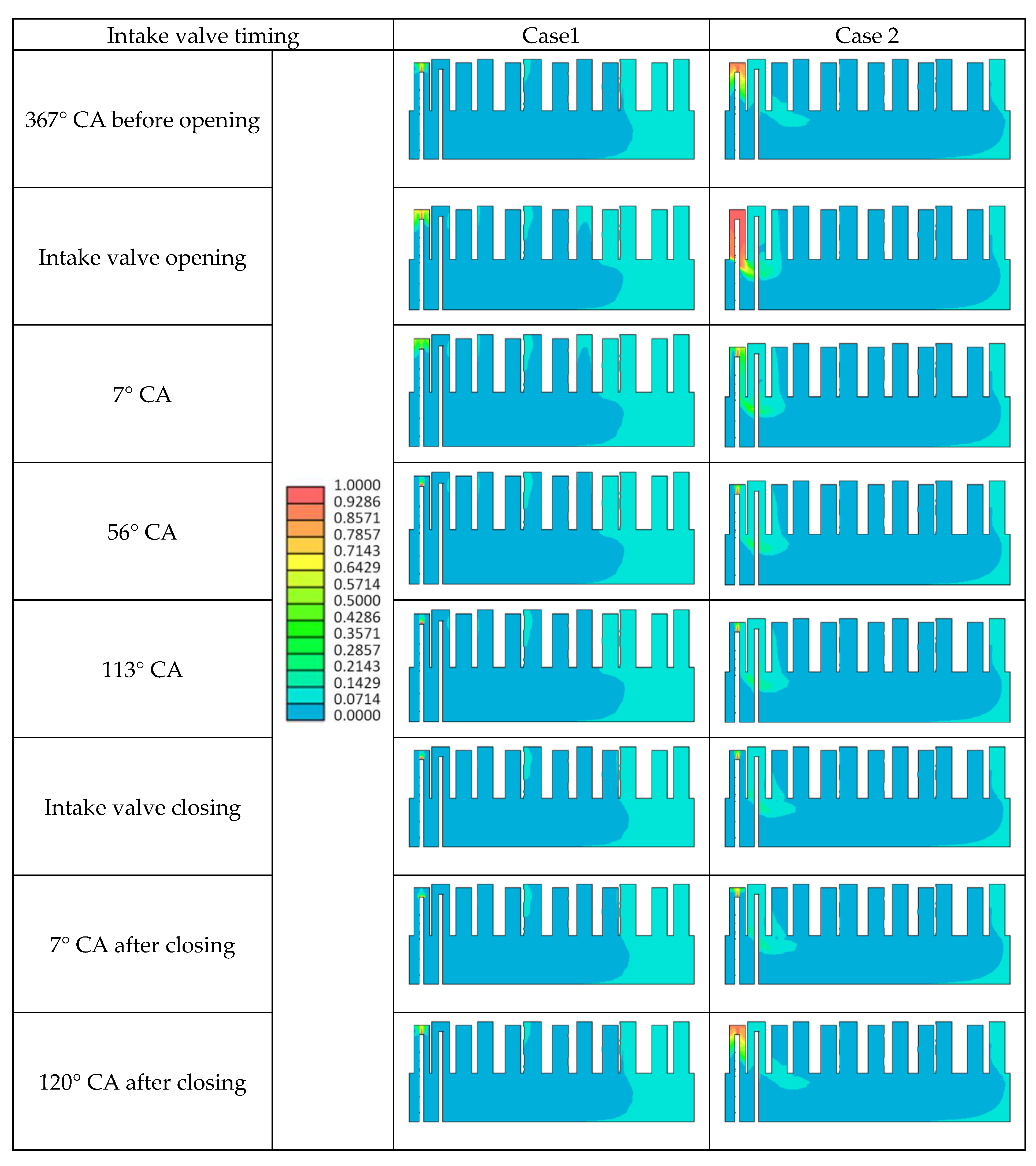

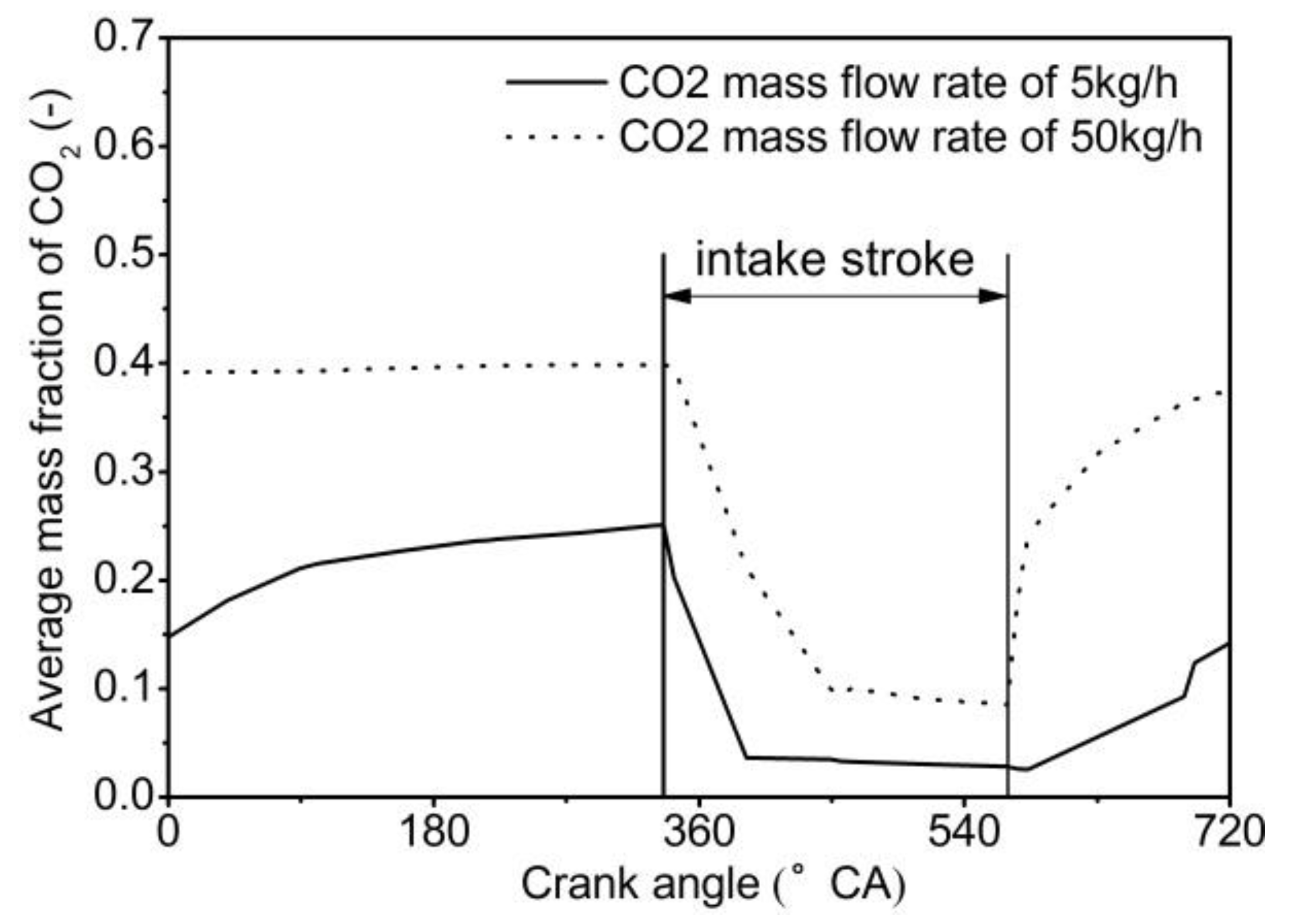

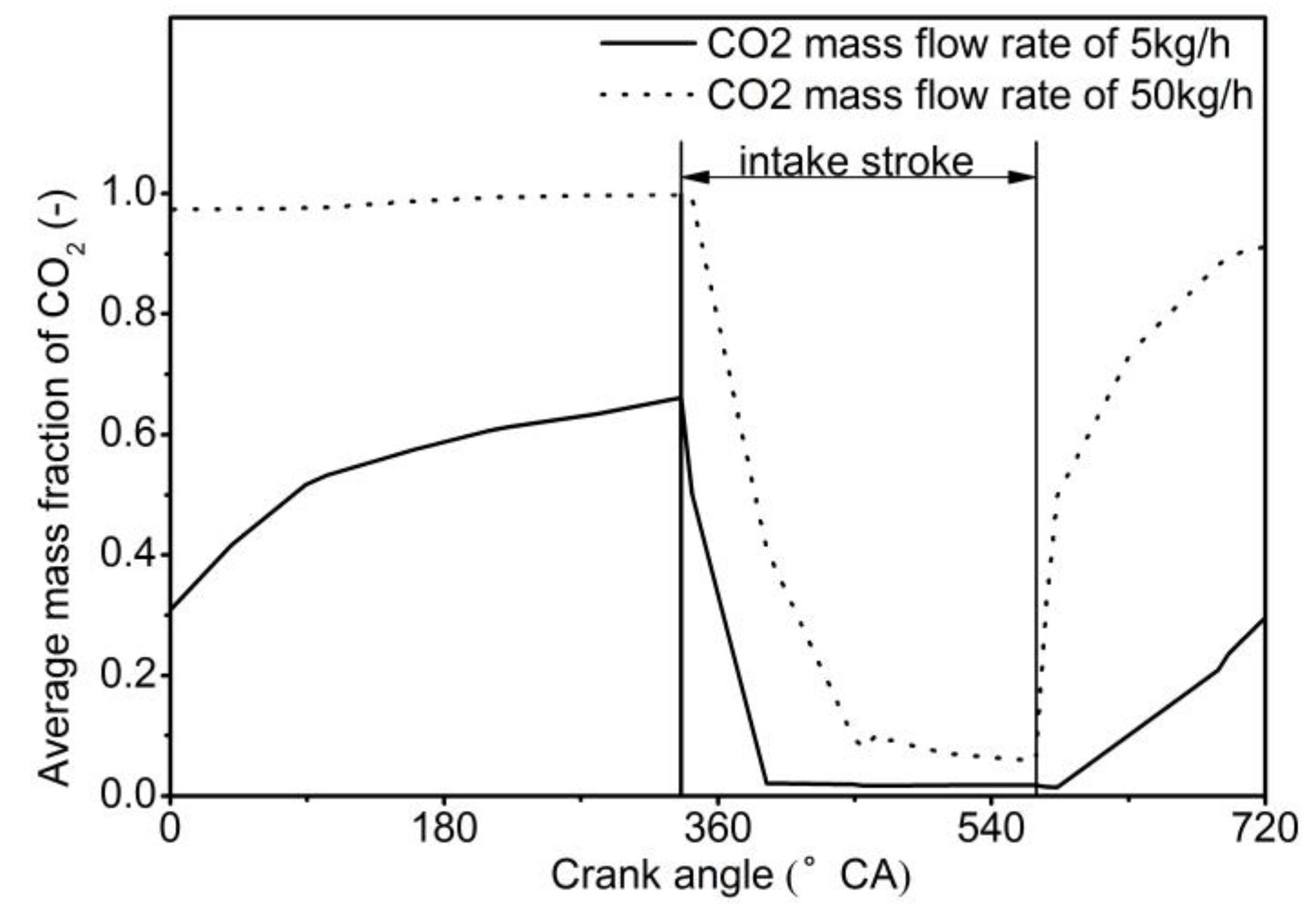

3. Results and Discussion

4. Conclusions

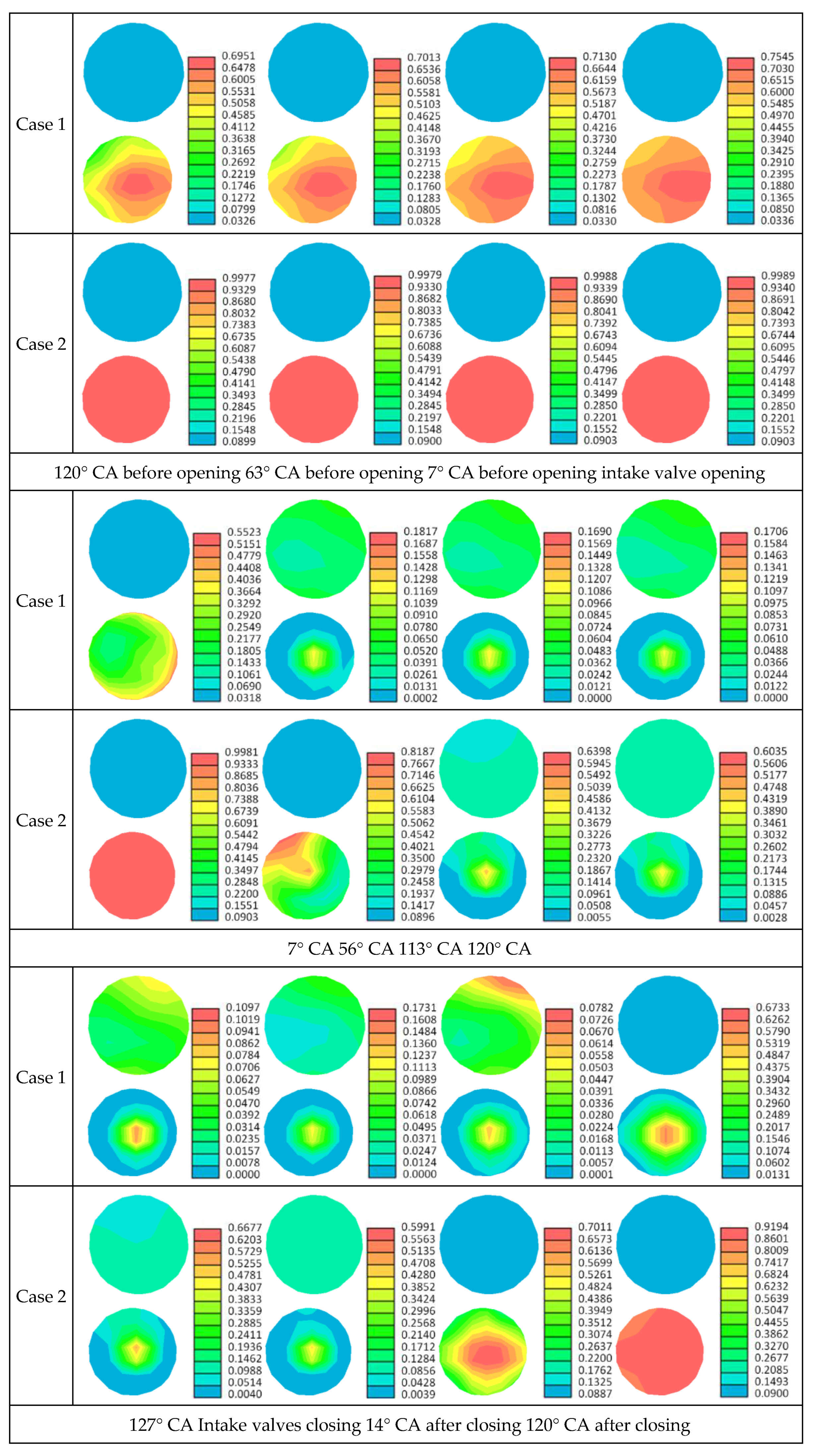

- CO2 supplied to one intake port alone escapes to the other intake port, which not only weakens the CO2 stratification in cylinder 1, but also influences the total mass of CO2 that is supplied to the cylinder. Fortunately, there is still an obvious difference in the CO2 mass fraction between the two intake ports.

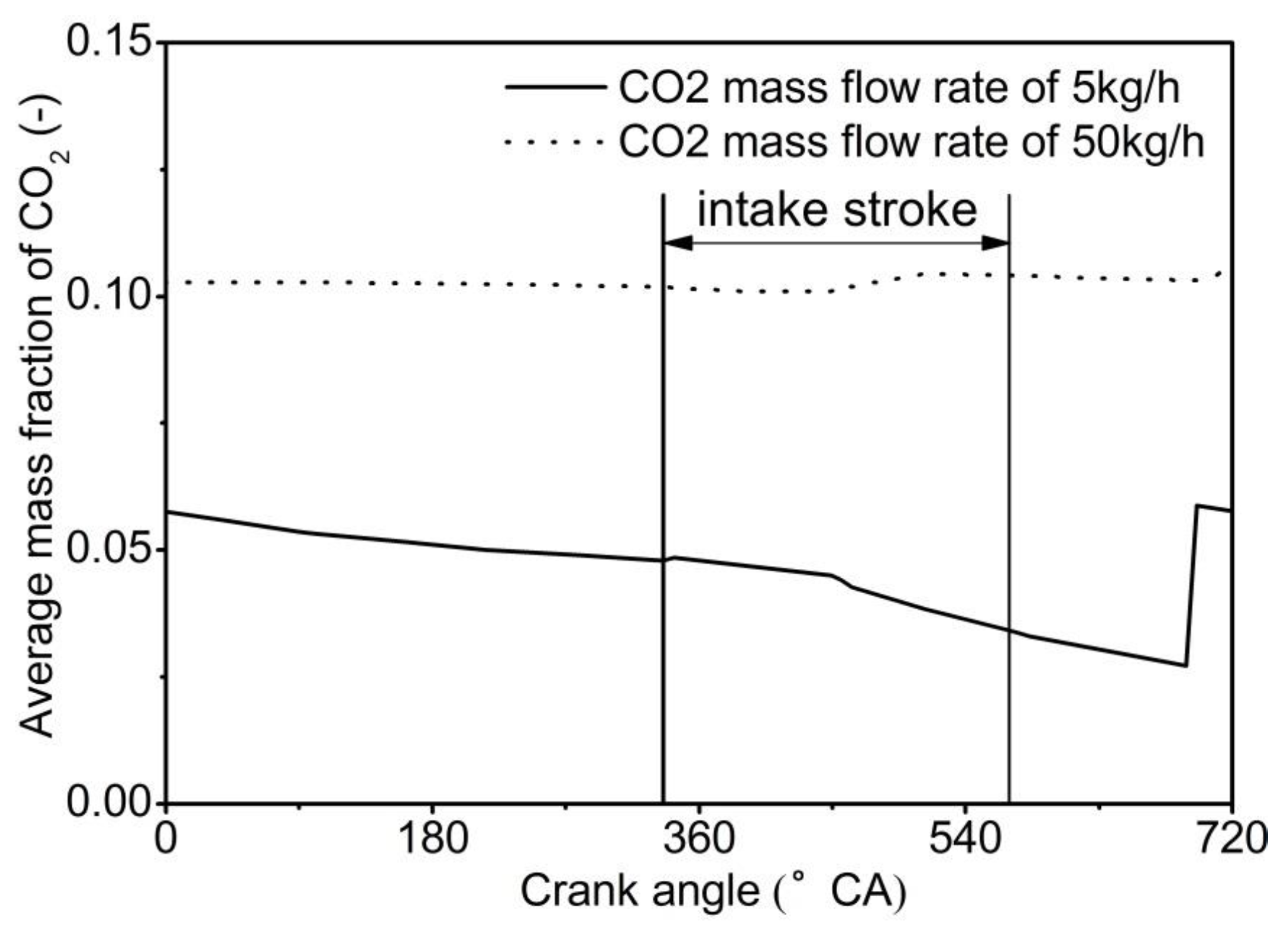

- The average mass fraction of CO2 at the outlet of intake port 1 increases sharply due to the continuous supply of CO2 and fresh air after the intake process, and reaches a maximum when the intake valves open, and then decreases to the target value after trapped CO2 flows into cylinder 1.

- There is 4% CO2 by mass fraction in the intake mixture that is fed into cylinder 1 through the outlet of intake port 2 under the condition of Case 1 (a CO2 mass flow rate of 5 kg/h) during the intake process, and 10% CO2 under the condition of 50 kg/h.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Kim, G.; Moon, S.; Lee, S.; Min, K. Numerical Analysis of the Combustion and Emission Characteristics of Diesel Engines with Multiple Injection Strategies Using a Modified 2-D Flamelet Model. Energies 2017, 10, 1292. [Google Scholar] [CrossRef]

- Merola, S.S.; Irimescu, A.; Di Iorio, S.; Vaglieco, B.M. Effect of Fuel Injection Strategy on the Carbonaceous Structure Formation and Nanoparticle Emission in a DISI Engine Fuelled with Butanol. Energies 2017, 10, 832. [Google Scholar] [CrossRef]

- Shi, L.; Cui, Y.; Deng, K.Y.; Peng, H.Y.; Chen, Y.Y. Study of low emission homogeneous charge compression ignition (HCCI) engine using combined internal and external exhaust gas recirculation (EGR). Energy 2006, 31, 2665–2676. [Google Scholar] [CrossRef]

- Bendu, H.; Murugan, S. Homogeneous charge compression ignition (HCCI) combustion: Mixture preparation and control strategies in diesel engines. Renew. Sustain. Energy Rev. 2014, 38, 732–746. [Google Scholar] [CrossRef]

- Yao, M.F.; Zheng, Z.L.; Liu, H.F. Progress and recent trends in homogeneous charge compression ignition (HCCI) engines. Prog. Energy Combust. 2009, 35, 398–437. [Google Scholar] [CrossRef]

- Cheng, A.S.; Upatnieks, A.; Mueller, C.J. Investigation of fuel effects on dilute, mixing-controlled combustion in an optical direct-injection diesel engine. Energy Fuel 2007, 21, 1989–2002. [Google Scholar] [CrossRef]

- Zhang, J.; Jing, W.; Roberts, W.L.; Fang, T.G. Soot measurements for diesel and biodiesel spray combustion under high temperature highly diluted ambient conditions. Fuel 2014, 137, 340–351. [Google Scholar] [CrossRef]

- Musculus, M.P.B.; Miles, P.C.; Pickett, L.M. Conceptual models for partially premixed low-temperature diesel combustion. Prog. Energy Combust. 2014, 39, 246–283. [Google Scholar] [CrossRef]

- Genzale, C.L.; Reitz, R.D.; Musculus, M.P.B. Effects of spray targeting on mixture development and emissions formation in late-injection low-temperature heavy-duty diesel combustion. Proc. Combust. Inst. 2009, 32, 2767–2774. [Google Scholar] [CrossRef]

- Liu, H.F.; Ma, S.Y.; Zhang, Z.; Zheng, Z.Q.; Yao, M.F. Study of the control strategies on soot reduction under early-injection conditions on a diesel engine. Fuel 2015, 139, 472–481. [Google Scholar] [CrossRef]

- Shi, X.C.; Liu, B.L.; Zhang, C.; Hu, J.C.; Zeng, Q.Q. A study on combined effect of high EGR rate and biodiesel on combustion and emission performance of a diesel engine. Appl. Therm. Eng. 2017, 125, 1272–1279. [Google Scholar] [CrossRef]

- Kumar, B.R.; Saravanan, S. Effects of iso-butanol/diesel and n-pentanol/diesel blends on performance and emissions of a DI diesel engine under premixed LTC (low temperature combustion) mode. Fuel 2016, 170, 49–59. [Google Scholar] [CrossRef]

- Divekar, P.S.; Chen, X.; Tjong, J.; Zheng, M. Energy efficiency impact of EGR on organizing clean combustion in diesel engines. Energy Convers. Manag. 2016, 112, 369–381. [Google Scholar] [CrossRef]

- Yang, F.Y.; Yao, C.S.; Wang, J.L.; Ouyang, M.G. Load expansion of a dieseline compression ignition engine with multi-mode combustion. Fuel 2016, 171, 5–17. [Google Scholar] [CrossRef]

- Hebbar, G.S.; Bhat, A.K. Control of NOx from a DI diesel engine with hot EGR and ethanol fumigation: An experimental investigation. Int. J. Automot. Technol. 2013, 3, 333–341. [Google Scholar] [CrossRef]

- Asad, U.; Tjong, J.; Zheng, M. Exhaust gas recirculation—Zero dimensional modelling and characterization for transient diesel combustion control. Energy Convers. Manag. 2014, 86, 309–324. [Google Scholar] [CrossRef]

- Cha, J.; Kwon, J.; Cho, Y.; Park, S. The effect of exhaust gas recirculation (EGR) on combustion stability, engine performance and exhaust emissions in a gasoline engine. KSME Int. J. 2001, 10, 1442–1450. [Google Scholar] [CrossRef]

- Kamimoto, T.; Bae, M.H. High combustion temperature for the reduction of particulate in diesel engines. SAE Pap. 1988, 880423. [Google Scholar] [CrossRef]

- Akihama, K.; Takatori, Y.; Inagaki, K.; Sasaki, S.; Dean, A.M. Mechanism of the smokeless rich combustion by reducing temperature. SAE Pap. 2001. [Google Scholar] [CrossRef]

- Shen, Z.J.; Liu, Z.C.; Tian, T.; Li, K.; Liu, J.W. Simulation of EGR stratification on timing-sequential regionalized diesel combustion. In Proceedings of the FISITA 2012 World Automotive Congress; Springer: Berlin/Heidelberg, Germany, 2012; Volume 190, pp. 827–838. [Google Scholar] [CrossRef]

- Rothamer, D.A.; Snyder, J.A.; Hanson, R.K.; Steeper, R.R.; Fitzgerald, R.P. Simultaneous imaging of exhaust gas residuals and temperature during HCCI combustion. Proc. Combust. Inst. 2009, 32, 2869–2876. [Google Scholar] [CrossRef]

- Desantes, J.M.; Lopez, J.J.; Garcia-Oliver, J.M.; Lopez-Pintor, D. A phenomenological explanation of the autoignition propagation under HCCI conditions. Fuel 2017, 206, 43–57. [Google Scholar] [CrossRef]

- Wang, Z.W.; Wu, S.; Huang, Y.H.; Chen, Y.L.; Shi, S.G.; Cheng, X.B.; Huang, R.H. Evaporation and Ignition Characteristics of Water Emulsified Diesel under Conventional and Low Temperature Combustion Conditions. Energies 2017, 10, 1109. [Google Scholar] [CrossRef]

- Fuyuto, T.; Nagata, M.; Hotta, Y.; Inagaki, K.; Nakakita, K.; Sakata, I. In-cylinder stratification of external exhaust gas recirculation for controlling diesel combustion. Int. J. Engine Res. 2010, 11, 1–15. [Google Scholar] [CrossRef]

- Nanda, S.K.; Jia, B.; Smallbone, A.; Roskilly, A.P. Investigation on the Effect of the Gas Exchange Process on the Diesel Engine Thermal Overload with Experimental Results. Energies 2017, 10, 766. [Google Scholar] [CrossRef]

- Choi, S.; Park, W.; Lee, S.; Min, K.; Choi, H. Methods for in-cylinder EGR stratification and its effects on combustion and emission characteristics in a diesel engine. Energy 2011, 36, 6948–6959. [Google Scholar] [CrossRef]

- Jeong, K.; Lee, D.; Park, S.; Lee, C.S. Effect of Two-Stage Fuel Injection Parameters on NOx Reduction Characteristics in a DI Diesel Engine. Energies 2011, 4, 2049–2060. [Google Scholar] [CrossRef]

- Baskovic, U.Z.; Vihar, R.; Mele, I.; Katrasnik, T. A New Method for Simultaneous Determination of the TDC Offset and the Pressure Offset in Fired Cylinders of an Internal Combustion Engine. Energies 2017, 10, 143. [Google Scholar] [CrossRef]

- Zamboni, G.; Moggia, S.; Capobianco, M. Effects of a Dual-Loop Exhaust Gas Recirculation System and Variable Nozzle Turbine Control on the Operating Parameters of an Automotive Diesel Engine. Energies 2017, 10, 47. [Google Scholar] [CrossRef]

- Andre, M.; Walter, B.; Bruneaux, G.; Foucher, F.; Mounaım-Rousselle, C. Exhaust gas recirculation stratification to control diesel homogeneous charge compression ignition combustion. Int. J. Engine Res. 2012, 13, 429–447. [Google Scholar] [CrossRef]

- Shen, Z.; Liu, Z.; Tian, J.; Liu, J. Investigation of the in-cylinder gas stratification of diesel engine during intake and compression stroke. Energy 2014, 72, 671–679. [Google Scholar] [CrossRef]

- Luong, M.B.; Sankaran, R.; Yu, G.H.; Chung, S.H.; Yoo, C.S. On the effect of injection timing on the ignition of lean PRF/air/EGR mixtures under direct dual fuel stratification conditions. Combust. Flame 2017, 183, 309–321. [Google Scholar] [CrossRef]

- Sjeric, M.; Taritas, I.; Tomic, R.; Blazic, M.; Kozarac, D.; Lulic, Z. Efficiency improvement of a spark-ignition engine at full load conditions using exhaust gas recirculation and variable geometry turbocharger—Numerical study. Energy Convers. Manag. 2016, 125, 26–39. [Google Scholar] [CrossRef]

- Park, W.; Min, K. Flamelet combustion model for stratified EGR distribution in a diesel engine. Int. J. Automot. Technol. 2016, 17, 739–750. [Google Scholar] [CrossRef]

- Zhang, F.; Liu, H.F.; Yu, R.; Yao, M.; Bai, X.S. Direct numerical simulation of H2/air combustion with composition stratification in a constant volume enclosure relevant to HCCI engines. Int. J. Hydrogen Energy 2016, 41, 13758–13770. [Google Scholar] [CrossRef]

- Dec, J.E.; Yang, Y.; Dernotte, J.; Ji, C.S. Effects of Gasoline Reactivity and Ethanol Content on Boosted, Premixed and Partially Stratified Low-Temperature Gasoline Combustion (LTGC). SAE Int. J. Engines 2015, 8, 935–955. [Google Scholar] [CrossRef]

- Yakhot, V.; Orszag, S.A. Renormalization group analysis of turbulence—I: Basic theory. J. Sci. Comput. 1986, 1, 3–51. [Google Scholar] [CrossRef]

- Yakhot, V.; Orszag, S.A.; Thangam, S.; Gatski, T.B.; Speziale, C.G. Development of turbulence models for shear flows by a double expansion technique. Phys. Fluids 1992, A4, 1510–1520. [Google Scholar] [CrossRef]

- STAR-CD, version 4.28; CD-adapco: London, UK, 2017.

| Tested Engine | Heavy Duty Diesel Engine |

|---|---|

| Valves | 4 |

| Cylinders | 6 |

| Piston bowl | ω |

| Supercharge | Turbocharging |

| EGR cooling | Intercooling |

| Bore × Stroke (mm × mm) | 112 × 145 |

| Displacement (L) | 8.6 |

| Compression Ratio | 17.0:1 |

| Swirl ratio | 1.1 |

| IVO (° CA BTDC) | 23 |

| IVC (° CA ABDC) | 30 |

| EVO (° CA BBDC) | 60 |

| EVC (° CA ATDC) | 33 |

| Rated power/Speed (kW/rpm) | 257/2100 |

| Intake air temperature (K) | 313 |

| Engine speed (rpm) | 1330 |

| Fuel consumption(kg/h) | 22.99 |

| Conditions | Case 1 | Case 2 |

|---|---|---|

| speed | 1330 r/min | |

| load | 50% | |

| Intake temperature | 313 K | |

| Density of fresh air | 1.35 kg/m3 | |

| Density of CO2 | 2 kg/m3 | |

| Mass flow rate of fresh air | 481 kg/h | |

| Mass flow rate of CO2 | 5 kg/h | 50 kg/h |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shen, Z.; Cui, W.; Ju, X.; Liu, Z.; Wu, S.; Yang, J. Numeric Investigation of Gas Distribution in the Intake Manifold and Intake Ports of a Multi-Cylinder Diesel Engine Refined for Exhaust Gas Stratification. Energies 2017, 10, 1888. https://doi.org/10.3390/en10111888

Shen Z, Cui W, Ju X, Liu Z, Wu S, Yang J. Numeric Investigation of Gas Distribution in the Intake Manifold and Intake Ports of a Multi-Cylinder Diesel Engine Refined for Exhaust Gas Stratification. Energies. 2017; 10(11):1888. https://doi.org/10.3390/en10111888

Chicago/Turabian StyleShen, Zhaojie, Wenzheng Cui, Xiaodong Ju, Zhongchang Liu, Shaohua Wu, and Jianguo Yang. 2017. "Numeric Investigation of Gas Distribution in the Intake Manifold and Intake Ports of a Multi-Cylinder Diesel Engine Refined for Exhaust Gas Stratification" Energies 10, no. 11: 1888. https://doi.org/10.3390/en10111888