Effect of Charcoal and Kraft-Lignin Addition on Coke Compression Strength and Reactivity

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

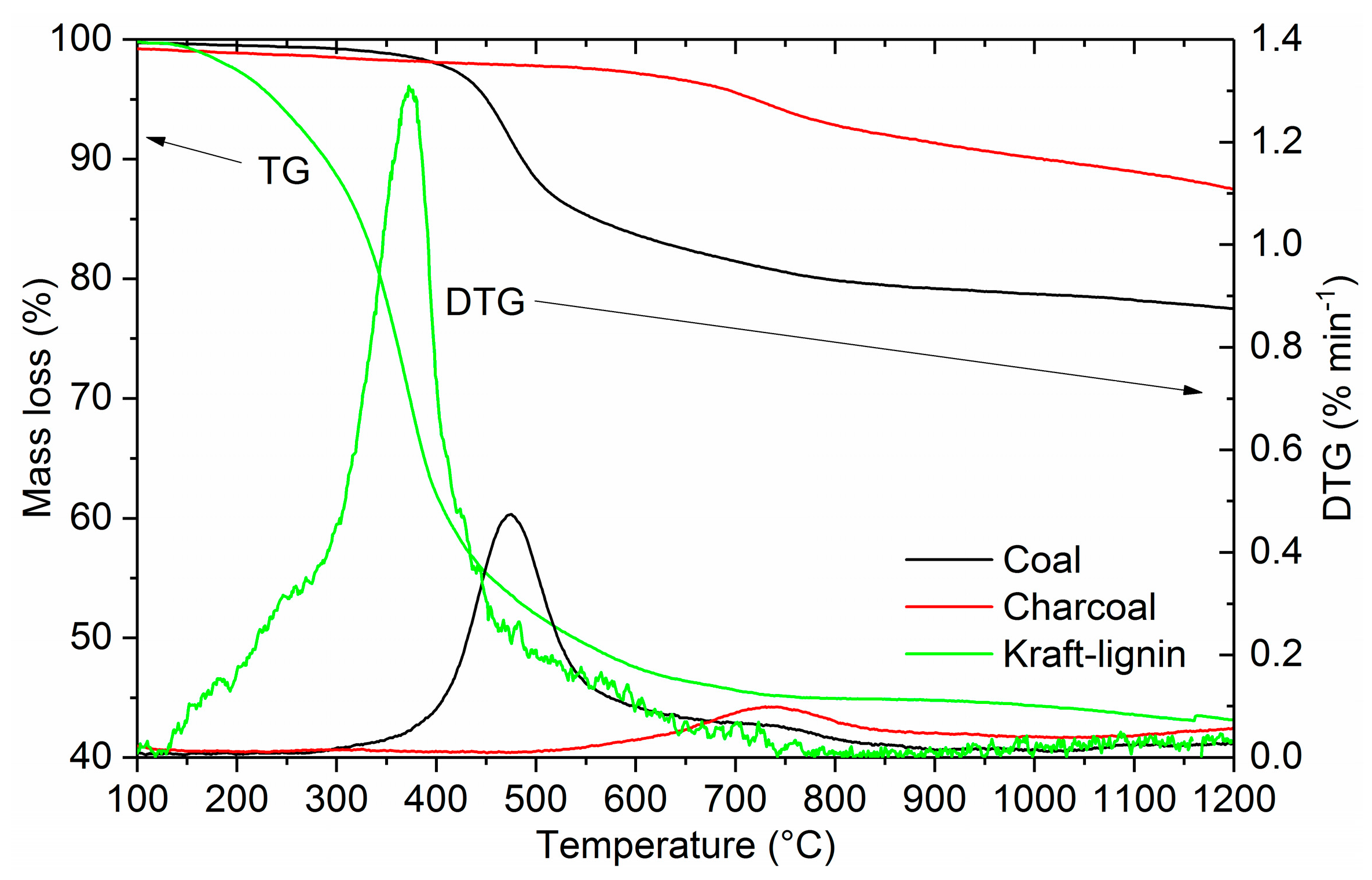

2.2. Thermogravimetric Analysis

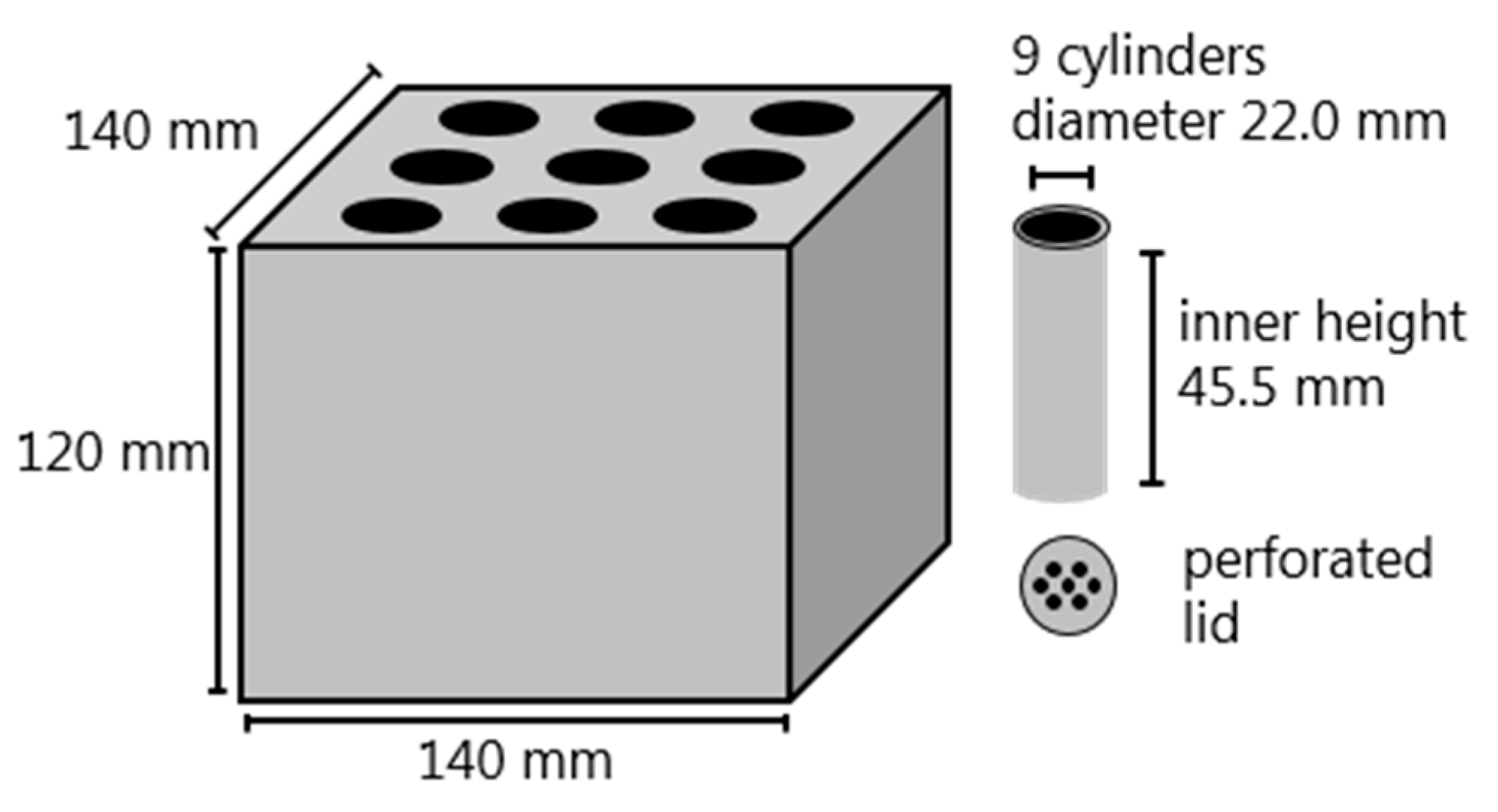

2.3. Coking Experiments

2.4. Cold Strength Measurements

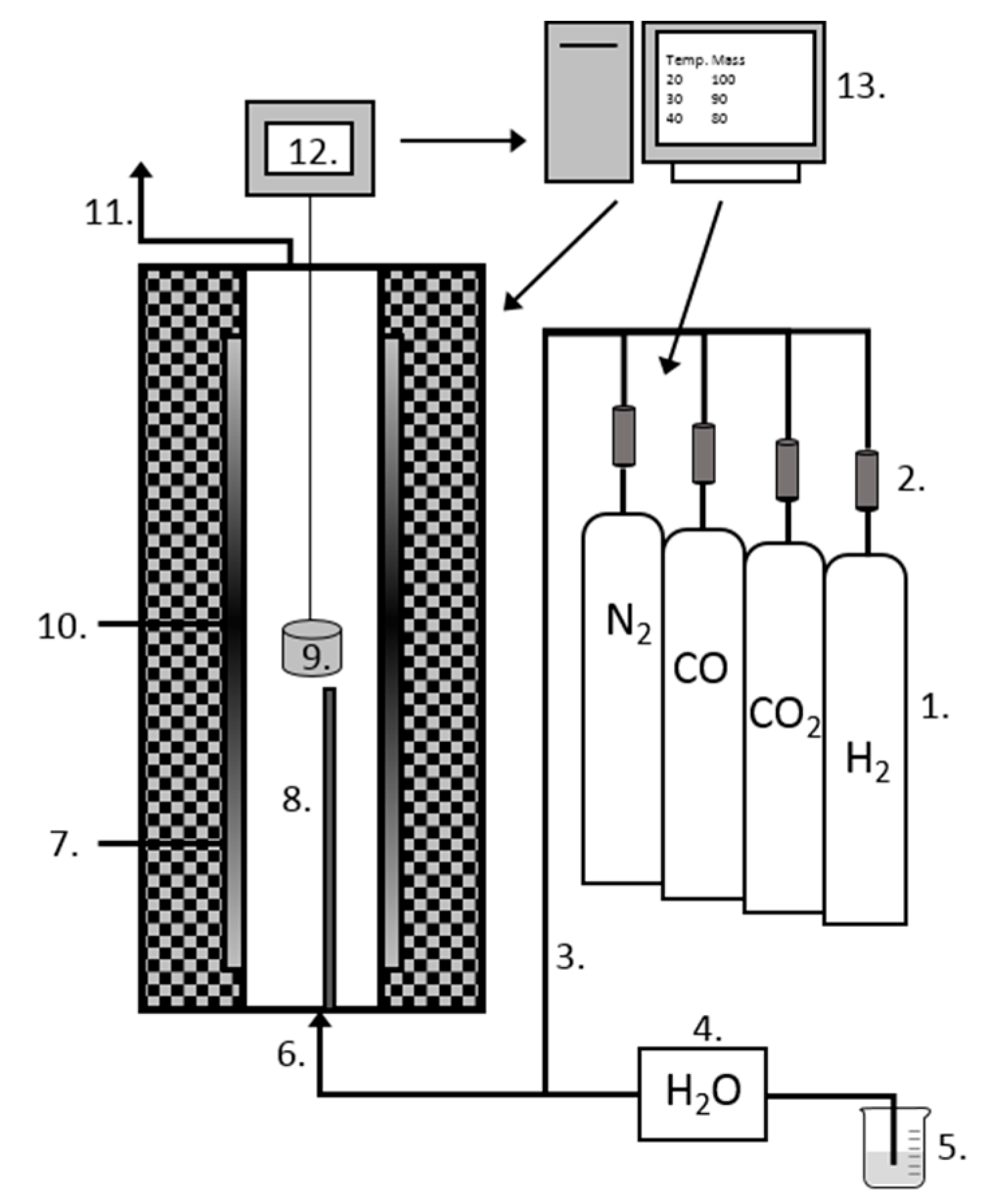

2.5. Reactivity Measurements

2.6. Optical Microscopy

3. Results and Discussion

3.1. Main Characteristics of the Raw Materials

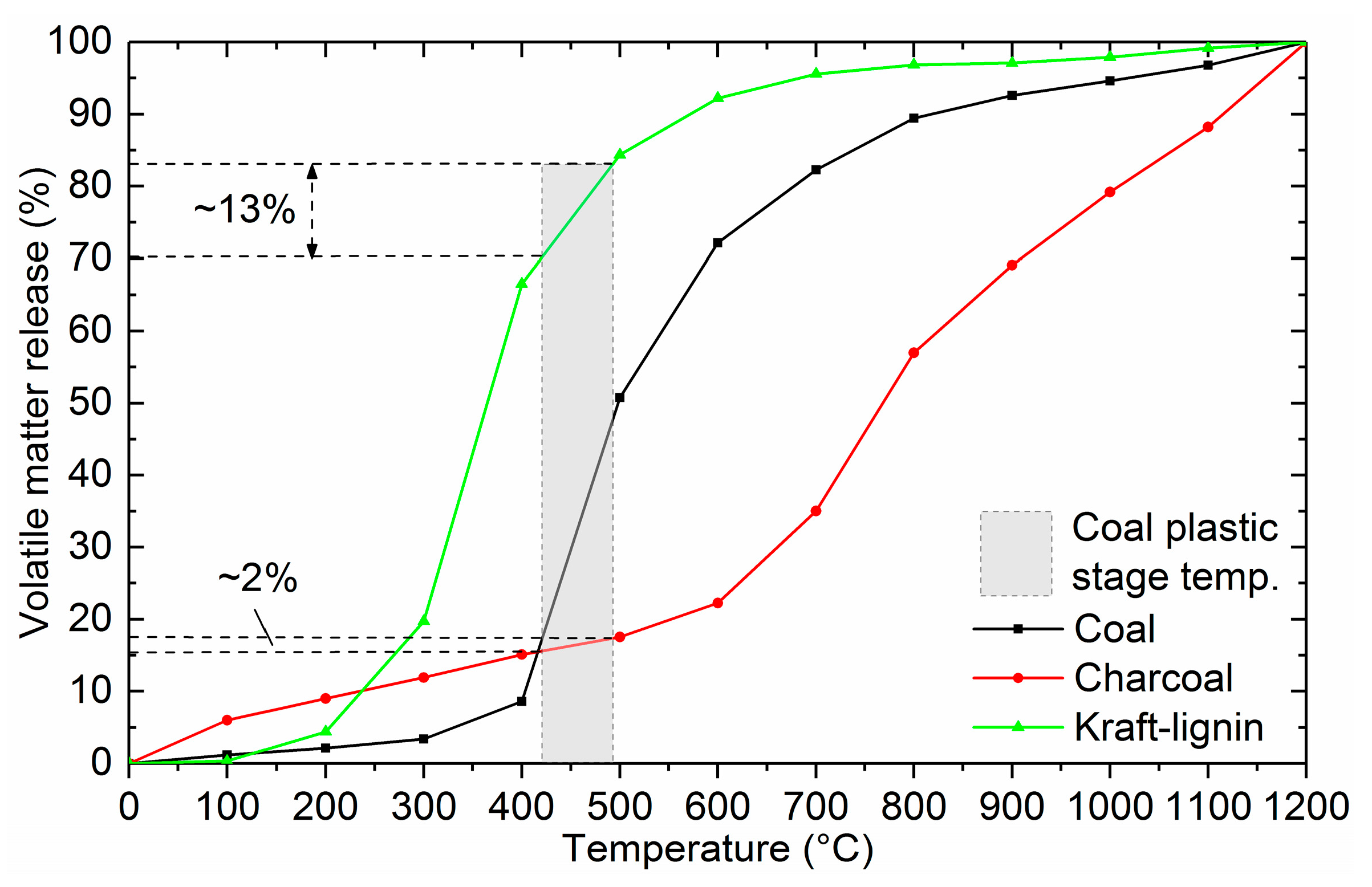

3.2. Devolatilization Behavior of the Raw Materials

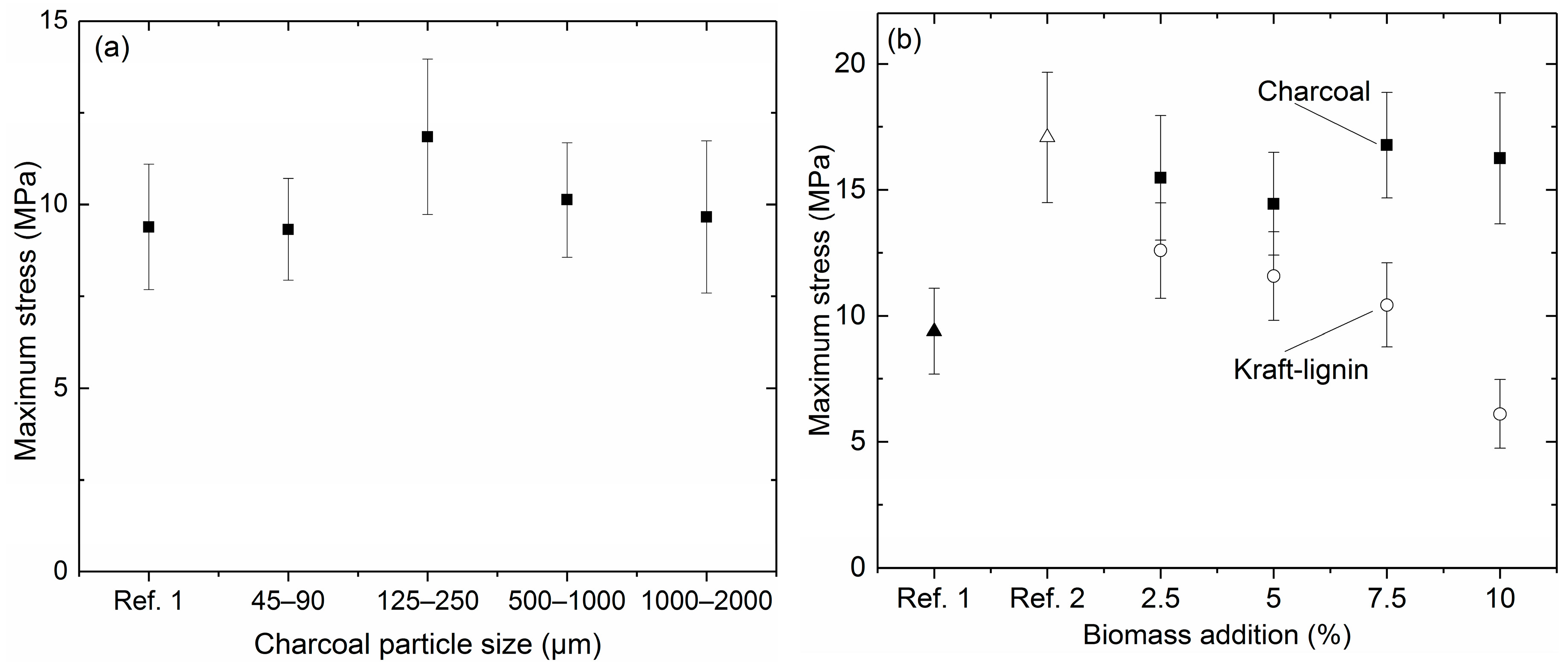

3.3. Effect of Charcoal and Kraft-Lignin Addition on Coke Cold Compression Strength

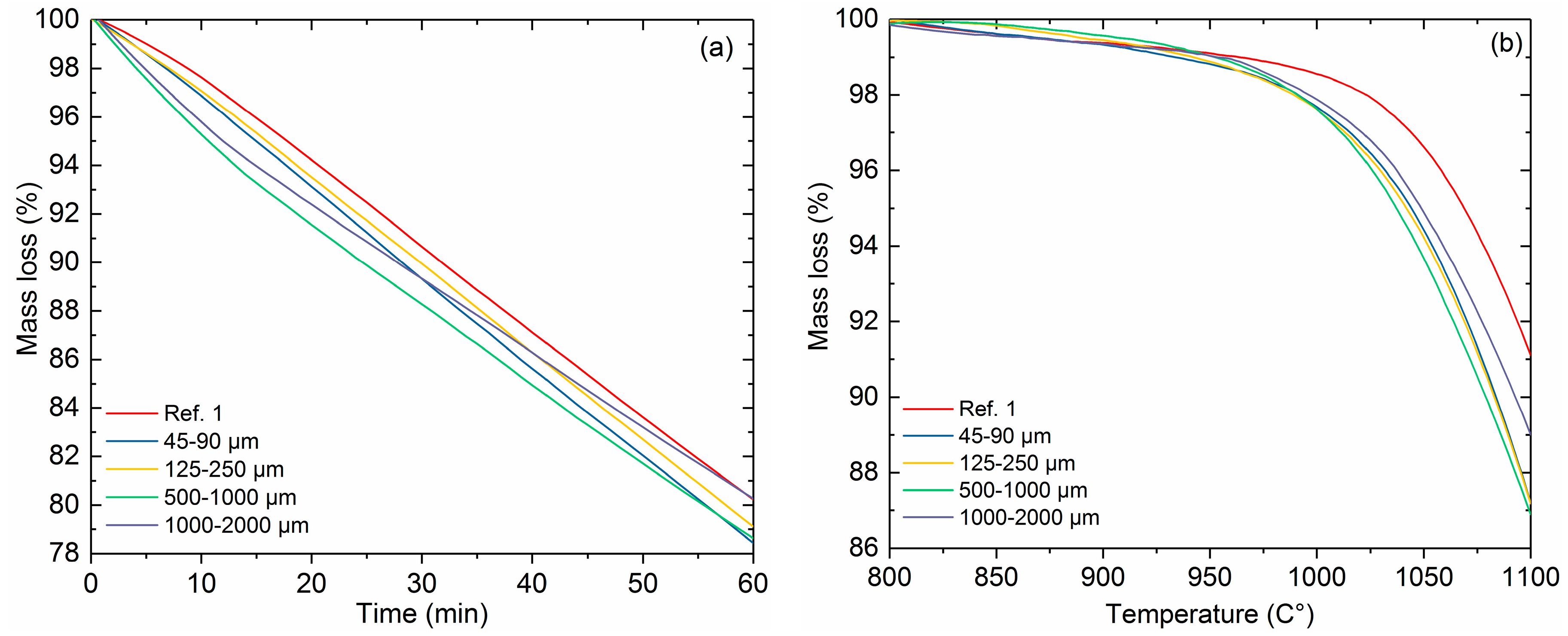

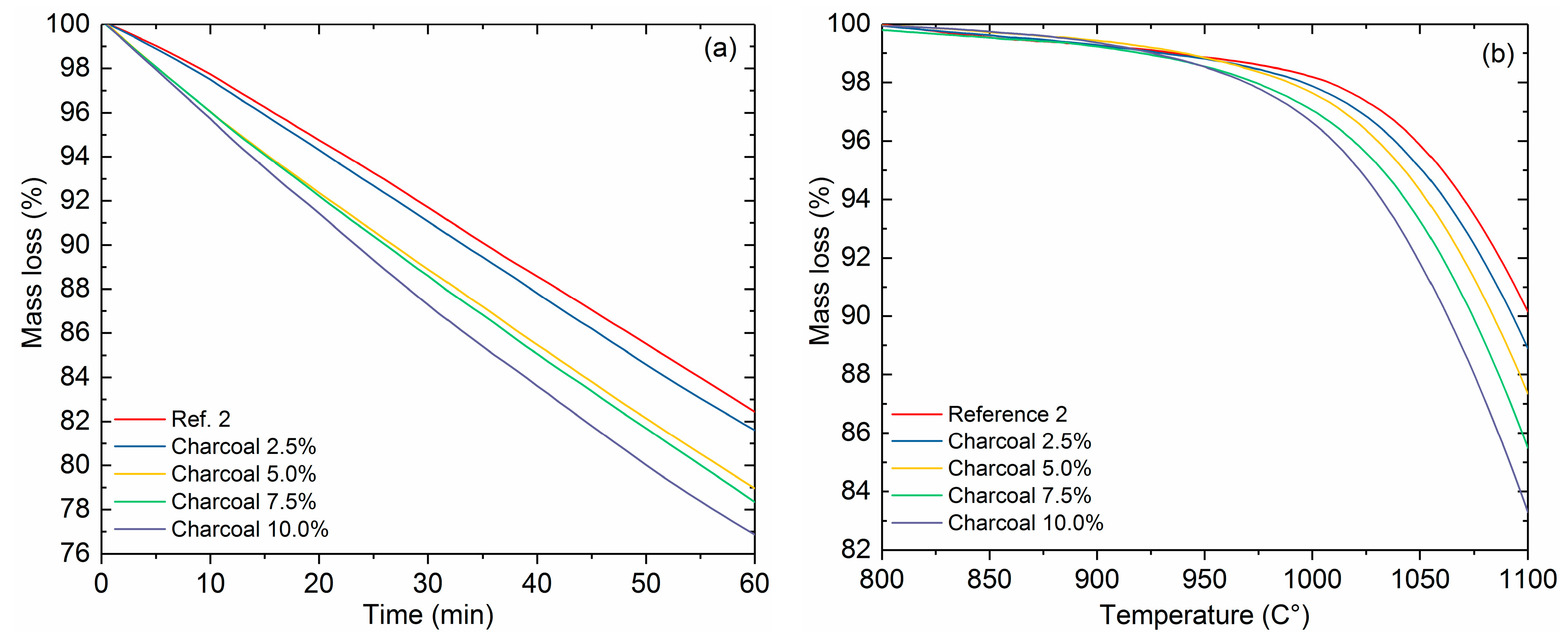

3.4. Bio-Coke Reactivity in Simulated BF Shaft Conditions

3.4.1. Impact of Charcoal Particle Size on the Reactivity

3.4.2. Impact of Charcoal and Kraft-Lignin Addition Rate on the Reactivity

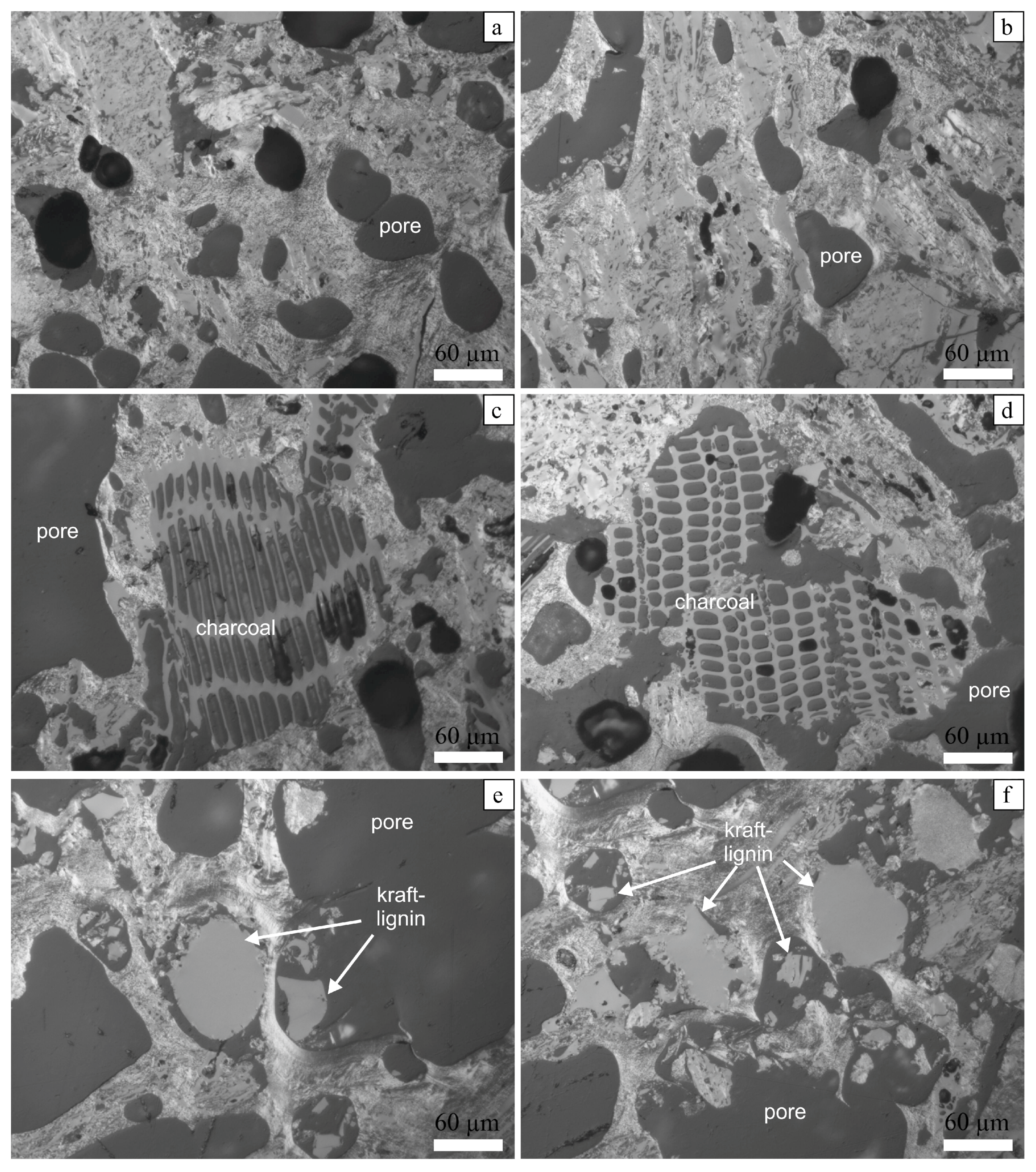

3.5. Texture of the Produced Cokes

3.6. Implications on the Blast Furnace Process and Further Development Needs

4. Conclusions

- Thermal degradation of the coal, charcoal, and Kraft-lignin differ considerably from each other. Kraft-lignin loses a major share of its mass before the coal starts to soften, thus creating empty spaces that coal has to fill. Together with the fact that oxygen-containing gases are released during the plastic stage of the coal, Kraft-lignin in coal blends has an active role in the final coke formation. Charcoal has lost the majority of its volatiles already in the pyrolysis stage and acts mainly as an inert material in the coal blend.

- Charcoal addition does not reduce the bio-coke strength compared to reference cokes when the charcoal addition rate was 5% and the particle size of the added charcoal was altered. The highest cold compression strength was obtained with bio-cokes having particle sizes of 125–250 μm. Optical microscope images showed that soft coking mass has, in some cases, penetrated into the charcoal cells and solidified there, thus contributing to cold strength development.

- Bulk density of the coal blend showed a strong effect on the cold compression strength of the cokes. The cold strength of the reference coke was increased by 83% when the bulk density was increased from 634 to 750 kg/m3. The cold strength of the bio-coke with charcoal addition remained at an acceptable level compared to reference coke 2. Charcoal addition up to 10% (particle sizes of 125–250 μm) maintains the cold strength of the bio-cokes. Bio-cokes with Kraft-lignin addition could not maintain the cold strength. The addition of 2.5 wt % Kraft-lignin to coal blend lowered the cold strength by 26.3%.

- Bio-cokes with charcoal addition showed higher reactivity compared to reference cokes. The smaller particle size of the charcoal results in higher reactivity bio-coke. The increase in charcoal content in the coal blend increased the reactivity of the coke in isothermal reactivity tests. Non-isothermal reactivity tests revealed that the gasification threshold temperature of bio-cokes with charcoal addition is considerably lower compared to the reference coke. Reactivity of the bio-cokes with Kraft-lignin addition was lower compared to bio-cokes with charcoal addition, but still higher compared to the reference coke. This implies that post-reaction strength of the bio-cokes with Kraft-lignin addition might be maintained better compared to bio-cokes with charcoal addition.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Suopajärvi, H.; Pongrácz, E.; Fabritius, T. The potential of using biomass-based reducing agents in the blast furnace: A review of thermochemical conversion technologies and assessments related to sustainability. Renew. Sustain. Energy Rev. 2013, 25, 511–528. [Google Scholar] [CrossRef]

- Suopajärvi, H.; Kemppainen, A.; Haapakangas, J.; Fabritius, T. Extensive review of the opportunities to use biomass-based fuels in iron and steelmaking processes. J. Clean. Prod. 2017, 148, 709–734. [Google Scholar] [CrossRef]

- Castro-Díaz, M.; Zhao, H.; Kokonya, S.; Dufour, A.; Snape, C.E. The effect of biomass on fluidity development in coking blends using high-temperature SAOS rheometry. Energy Fuels 2012, 26, 1767–1775. [Google Scholar]

- Montiano, M.G.; Barriocanal, C.; Alvarez, R. Effect of the addition of waste sawdust on thermoplastic properties of a coal. Fuel 2013, 106, 537–543. [Google Scholar] [CrossRef]

- Diez, M.A.; Alvarez, R.; Fernández, M. Biomass derived products as modifiers of the rheological properties of coking coals. Fuel 2012, 96, 306–313. [Google Scholar] [CrossRef]

- Kokonya, S.; Castro-Díaz, M.; Barriocanal, C.; Snape, C.E. An investigation into the effect of fast heating on fluidity development and coke quality for blends of coal and biomass. Biomass Bioenergy 2013, 56, 295–306. [Google Scholar] [CrossRef]

- MacPhee, J.A.; Gransden, J.F.; Giroux, L.; Price, J.T. Possible CO2 mitigation via addition of charcoal to coking coal blends. Fuel Proc. Technol. 2009, 90, 16–20. [Google Scholar] [CrossRef]

- Lumadue, M.R.; Cannon, F.S.; Brown, N.R. Lignin as both fuel and fusing binder in briquetted anthracite fines for foundry coke substitute. Fuel 2012, 97, 869–875. [Google Scholar] [CrossRef]

- Castro-Díaz, M.; Vega, M.F.; Barriocanal, C.; Snape, C.E. Utilization of Carbonaceous Materials to Restore the Coking Properties of Weathered Coals. Energy Fuels 2015, 29, 5744–5749. [Google Scholar] [CrossRef]

- Castro-Díaz, M.; Uguna, C.N.; Florentino, L.; Díaz-Faes, E.; Stevens, L.A. Evaluation of hydrochars from lignin hydrous pyrolysis to produce biocokes after carbonization. J. Anal. Appl. Pyrolysis 2017, 124, 742–751. [Google Scholar] [CrossRef]

- Ueki, Y.; Nunome, T.; Yoshiie, R.; Naruse, I.; Nishibata, Y.; Aizawa, S. Effect of woody biomass addition on coke properties. ISIJ Int. 2014, 54, 2454–2460. [Google Scholar] [CrossRef]

- Schwarz, M.; Babich, A.; Senk, D.; Sadiku, V.; Gbadebo, P. Usage of biomass in Cokemaking. In Proceedings of the 5th International Conference on Process Development in Iron and Steelmaking (SCANMET V), Luleå, Sweden, 12–15 June 2016. [Google Scholar]

- Xing, X.; Rogers, H.; Zhang, G.; Hockings, K.; Zulli, P.; Deev, A.; Mathieson, J.; Ostrovski, O. Effect of charcoal addition on the properties of a coke subjected to simulated blast furnace conditions. Fuel Proc. Technol. 2017, 157, 42–51. [Google Scholar] [CrossRef]

- Guerrero, A.; Diez, M.A.; Borrego, A.G. Influence of charcoal fines on the thermoplastic properties of coking coals and the optical properties of the semicoke. Int. J. Coal Geol. 2015, 147–148, 105–114. [Google Scholar] [CrossRef]

- Matsumura, T.; Ichida, M.; Nagasaka, T.; Kato, K. Carbonization behaviour of woody biomass and resulting metallurgical coke properties. ISIJ Int. 2008, 48, 572–577. [Google Scholar] [CrossRef]

- Slade, R.; Bauen, A.; Gross, R. Global bioenergy resources. Nat. Clim. Chang. 2014, 4, 99–105. [Google Scholar] [CrossRef]

- Cannatelli, M.D.; Ragauskas, A.J. Conversion of lignin into value-added materials and chemicals via laccase-assisted copolymerization. Appl. Microbiol. Biotechnol. 2016, 100, 8685–8691. [Google Scholar] [CrossRef] [PubMed]

- Barriocanal, C.; Díez, M.A.; Alvarez, R.; Casal, M.D.; Canga, C.S. On the relationship between coal plasticity and thermogravimetric analysis. J. Anal. Appl. Pyrolysis 2003, 67, 23–40. [Google Scholar] [CrossRef]

- Gornostayev, S.S.; Heino, J.J.; Kokkonen, T.M.T.; Makkonen, H.T.; Huttunen, S.M.M.; Fabritius, T.M.J. Textural changes in metallurgical coke prepared with polyethylene. Int. J. Miner. Metall. Mater. 2014, 21, 969–973. [Google Scholar] [CrossRef]

- Loison, R.; Foch, P.; Boyer, A. Coke: Quality and Production; Butterworth & Co: Cambridge, UK, 1989; pp. 278–352. ISBN 0-408-02870-X. [Google Scholar]

- Díez, M.A.; Alvarez, R.; Barriocanal, C. Coal for metallurgical coke production: Predictions of coke quality and future requirements for Cokemaking. Int. J. Coal Geol. 2002, 50, 389–412. [Google Scholar] [CrossRef]

- Amanat, N.; Tsafnat, N.; Loo, B.C.E.; Jones, A.S. Metallurgical coke: An investigation into compression properties and microstructure using X-ray microtomography. Scr. Mater. 2009, 60, 92–95. [Google Scholar] [CrossRef]

- Kim, S.Y.; Sasaki, Y. Simulation of Effect of Pore Structure on Coke Strength Using 3-dimensional Discrete Element Method. ISIJ Int. 2010, 50, 813–821. [Google Scholar] [CrossRef]

- Haapakangas, J.; Uusitalo, J.; Mattila, O.; Kokkonen, T.; Porter, D.; Fabritius, T. A method for evaluating coke hot strength. Steel Res. Int. 2013, 84, 65–71. [Google Scholar] [CrossRef]

- Haapakangas, J.A.; Uusitalo, J.A.; Mattila, O.J.; Gornostayev, S.S.; Porter, D.A.; Fabritius, T. The Hot Strength of Industrial Cokes–Evaluation of Coke Properties that Affect Its High-Temperature Strength. Steel Res. Int. 2014, 85, 1608–1619. [Google Scholar] [CrossRef]

- Roine, A.; Lamberg, P.; Katiranta, T.; Salminen, J. HSC Chemistry 7 Simulation; Outotec Research: Pori, Finland, 2009. [Google Scholar]

- Haapakangas, J.; Suopajärvi, H.; Iljana, M.; Kemppainen, A.; Mattila, O.; Heikkinen, E.P.; Samuelsson, C.; Fabritius, T. Coke Reactivity in Simulated Blast Furnace Shaft Conditions. Metall. Mater. Trans. B 2016, 47, 2357–2370. [Google Scholar] [CrossRef]

- Cao, J.; Xiao, G.; Xu, X.; Shen, D.; Jin, B. Study on carbonization of lignin by TG-FTIR and high-temperature carbonization reactor. Fuel Proc. Technol. 2013, 106, 41–47. [Google Scholar] [CrossRef]

- Qin, L.; Han, J.; Ye, W.; Zhang, S.; Yan, Q.; Yu, F. Characteristics of Coal and Pine Sawdust Co-carbonization. Energy Fuels 2014, 28, 848–857. [Google Scholar] [CrossRef]

- Ng, K.W.; Giroux, L.; MacPhee, J.A.; Todoschuk, T. Incorporation of charcoal in coking coal blend—A study of the effects on carbonization conditions and coke quality. In Proceedings of the AISTech Iron & Steel Technology Conference, Atlanta, GA, USA, 7–10 May 2012. [Google Scholar]

- Nomura, S.; Arima, T.; Kato, K. Coal blending theory for dry coal charging process. Fuel 2004, 83, 1771–1776. [Google Scholar] [CrossRef]

- Kifani-Sahban, F.; Kifani, A.; Belkbir, L.; Zoulalian, A.; Arauzo, J.; Cardero, T. A physical approach in the understanding of the phenome accompanying the thermal treatment of lignin. Thermochim. Acta 1997, 298, 199–204. [Google Scholar] [CrossRef]

- Ng, K.W.; MacPhee, J.A.; Giroux, L.; Todoschuk, T. Reactivity of bio-coke with CO2. Fuel Proc. Technol. 2011, 92, 801–804. [Google Scholar] [CrossRef]

- Flores, B.D.; Flores, I.V.; Guerrero, A.; Orellana, D.R.; Pohlmann, J.G.; Diez, M.A.; Borrego, A.G.; Osório, E.; Vilela, A.C.F. Effect of charcoal blending with a vitrinite rich coking coal on coke reactivity. Fuel Proc. Technol. 2017, 155, 97–105. [Google Scholar] [CrossRef]

- Montiano, M.G.; Díaz-Faes, E.; Barriocanal, C. Effect of briquette composition and size on the quality of the resulting coke. Fuel Proc. Technol. 2016, 148, 155–162. [Google Scholar] [CrossRef]

- Diez, M.A.; Borrego, A.G. Evaluation of CO2-reactivity patterns in cokes from coal and woody biomass blends. Fuel 2013, 113, 306–313. [Google Scholar] [CrossRef]

- Nomura, S.; Ayukawa, H.; Kitaguchi, H.; Tahara, T.; Matsuzaki, S.; Naito, M.; Koizumi, S.; Ogata, Y.; Nakayama, T.; Abe, T. Improvement in Blast Furnace Reaction Efficiency through the Use of Highly Reactive Calcium Rich Coke. ISIJ Int. 2005, 45, 316–324. [Google Scholar] [CrossRef]

- Babich, A.; Senk, D.; Gudenau, H.W. Effect of coke reactivity and nut coke on blast furnace operation. Ironmak. Steelmak. 2009, 36, 222–229. [Google Scholar] [CrossRef]

- Sun, Z.; Li, P.; Guo, R.; Liu, P.; Liang, Y. Preparation of high strength and highly reactive coke by the addition of steel slag. Coke Chem. 2014, 57, 391–397. [Google Scholar] [CrossRef]

- Tuo, B.; Wang, J.; Yao, Y.; Yang, J. Influence of Coke Reactivity on Softening-Melting Dropping Behavior of Iron-Bearing Burden. Steel Res. Int. 2015, 86, 1028–1036. [Google Scholar] [CrossRef]

- Sh, K.; Guha, M.; Kumar, D.; DP, D. Application of binder in stamp charge coke making. ISIJ Int. 2004, 44, 1150–1156. [Google Scholar]

- Johansen, J.M.; Jakobsen, J.G.; Frandsen, F.J.; Glarborg, P. Release of K, Cl, and S during pyrolysis and combustion of high-chlorine biomass. Energy Fuels 2011, 25, 4961–4971. [Google Scholar] [CrossRef]

| Coking Blend | Biomass Particle Size (μm) | Coal (wt %) | Charcoal (wt %) | Kraft-Lignin (wt %) | Mass (g) | Bulk Density (kg/m3) |

|---|---|---|---|---|---|---|

| Reference 1 | - | 100.0 | - | - | 11.0 | 634 |

| BC 1 | 45–90 | 95.0 | 5.0 | - | 11.0 | 634 |

| BC 2 | 125–250 | 95.0 | 5.0 | - | 11.0 | 634 |

| BC 3 | 500–1000 | 95.0 | 5.0 | - | 11.0 | 634 |

| BC 4 | 1000–2000 | 95.0 | 5.0 | - | 11.0 | 634 |

| Reference 2 | - | 100.0 | - | - | 13.0 | 750 |

| BC 5 | 125–250 | 97.5 | 2.5 | - | 13.0 | 750 |

| BC 6 | 125–250 | 95.0 | 5.0 | - | 13.0 | 750 |

| BC 7 | 125–250 | 92.5 | 7.5 | - | 13.0 | 750 |

| BC 8 | 125–250 | 90.0 | 10.0 | - | 13.0 | 750 |

| BC 9 | 125–250 | 97.5 | - | 2.5 | 13.0 | 750 |

| BC 10 | 125–250 | 95.0 | - | 5.0 | 13.0 | 750 |

| BC 11 | 125–250 | 92.5 | - | 7.5 | 13.0 | 750 |

| BC 12 | 125–250 | 90.0 | - | 10.0 | 13.0 | 750 |

| Gas species | N2 | CO | CO2 | H2 | H2O |

| Share (vol %) | 50 | 27.9 | 17.1 | 2.1 | 2.9 |

| Coking Coal | Charcoal | Kraft-Lignin | ||

|---|---|---|---|---|

| Ultimate analysis (wt %, db) | C | 80.0 | 91.5 | 65.0 |

| H | 4.8 | 2.3 | 5.6 | |

| O | 2.4 | 4.3 | 26.7 | |

| N | 2.2 | 0.5 | 0.13 | |

| S | 0.53 | NA | 1.94 | |

| Proximate (wt %, db) | Ash | 9.8 | 1.5 | 0.7 |

| Volatiles | 23.1 | 6.7 | 66.4 | |

| Fixed C | 67.1 | 91.8 | 32.9 | |

| Ash composition (%, db) | SiO2 | 65.90 | 12.0 | 12.6 |

| Al2O3 | 25.50 | 4.1 | 3.4 | |

| Fe2O3 | 3.52 | 9.1 | 1.1 | |

| TiO2 | 1.50 | 0.2 | 0.073 | |

| CaO | 0.84 | 44.0 | 3.0 | |

| MgO | 0.57 | 10.9 | 10.5 | |

| Na2O | 0.92 | 5.7 | 24.4 | |

| K2O | 0.39 | 2.8 | 5.7 | |

| P2O5 | 0.51 | 6.9 | 0.26 | |

| Basicity index, BI (%) | 0.67 | 6.75 | 1.96 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Suopajärvi, H.; Dahl, E.; Kemppainen, A.; Gornostayev, S.; Koskela, A.; Fabritius, T. Effect of Charcoal and Kraft-Lignin Addition on Coke Compression Strength and Reactivity. Energies 2017, 10, 1850. https://doi.org/10.3390/en10111850

Suopajärvi H, Dahl E, Kemppainen A, Gornostayev S, Koskela A, Fabritius T. Effect of Charcoal and Kraft-Lignin Addition on Coke Compression Strength and Reactivity. Energies. 2017; 10(11):1850. https://doi.org/10.3390/en10111850

Chicago/Turabian StyleSuopajärvi, Hannu, Essi Dahl, Antti Kemppainen, Stanislav Gornostayev, Aki Koskela, and Timo Fabritius. 2017. "Effect of Charcoal and Kraft-Lignin Addition on Coke Compression Strength and Reactivity" Energies 10, no. 11: 1850. https://doi.org/10.3390/en10111850

APA StyleSuopajärvi, H., Dahl, E., Kemppainen, A., Gornostayev, S., Koskela, A., & Fabritius, T. (2017). Effect of Charcoal and Kraft-Lignin Addition on Coke Compression Strength and Reactivity. Energies, 10(11), 1850. https://doi.org/10.3390/en10111850