1. Introduction

European regulations establish common ground for reducing energy consumption and meeting the requirements set by the EU for 2020 [

1], with housing stock as one of the central lines of action. Most housing stock was built outside energy regulations of any sort and with little technology and funding. Approaches to the problem of housing stock in the Mediterranean area cannot be the same as those in northern Europe [

2], given the difference in climate. In southern Spain, the housing stock was built before the implementation of the first legislation for the thermal regulation of buildings, CT-79 in 1980 [

3], in a context of limited technical and economic means, with a view to providing universal access to housing for the working class. This housing stock presents deficient energy conditions requiring high energy consumption in order to maintain suitable comfort conditions [

4]. However, the socio-economic profile of a large number of users results in living conditions of energy poverty, with environmental deficiencies and discomfort [

5]. In the current economic climate, architectural retrofitting, covered by retrofitted supporting policies [

6], is a priority in the construction sector.

However, before any type of rehabilitation can be carried out on the housing stock, extensive knowledge of a building’s energy performance in its current condition and the appropriate prediction of the energy behaviour of the retrofitted proposals are required.

In fact, one of the themes proposed by the European Commission in its Horizon 2020 research and innovation policy is “new tools and methodologies to reduce the gap between predicted and actual energy performances at the level of buildings and blocks of buildings” [

7].

A protocol has been put into place [

8] for this Mediterranean housing stock to enable energy characterization through in-use monitoring of representative study cases. This is followed by an extrapolation of the results using energy simulation models previously validated with typological analysis and an evaluation of the energy responses with in situ measurements and monitoring campaigns [

9]. The data obtained are used to propose active strategies at the neighbourhood [

10] and urban levels [

11]. However, the representativeness of these studies is conditioned by use patterns, wherein users are responsible for the performance gap [

12].

In contrast to the laboratory test studies, which reproduce a steady-state regimen, the use of test cells allows results with real outdoor conditions to be obtained in a controlled indoor environment with high instrumentation levels. These also collect accurate results for each parameter evaluated, unlike the case of in-use monitoring. In a controlled setting, this analysis allows the energy optimization of the constructive solutions to be tested. Test cells cannot be seen as an end in themselves but rather as the first step of the analysis, which is to be complemented with the validation stage and the later use of energy simulation programs [

13,

14] analysing previous test cell results. This energy evaluation of test cells is presented as one of the main mechanisms for the optimization of energy retrofitting strategies based on a comparative study of different constructive options and the current state of the buildings to be rehabilitated.

Since the 1980s, the PASSYS (PASsive Solar Components and SYStems Testing) Project [

15] has been used for experiences in Europe in the field of energy efficiency and saving, making use of experimental test cells located in outdoor environments. A thermal characterization test methodology using highly insulated and real scale cells was developed [

16] by the PASSYS Project. These cells consisted of a test room with a removable facade facing south and a small room known as a service room, where control systems, measurement equipment, and HVAC (Heating, ventilation, and air conditioning) are located. These cells were used to analyse the performance of different interchangeable building envelopes in the south facade mentioned above [

17]. One of the main conclusions of this project was the existence of methodological problems caused by uncontrolled transmission through the insulated envelope. This led to the creation of the PASLINK cells [

18] and the DYNASTEE group (DYNamic Analysis, Simulation, and Testing applied to the Energy and Environmental performance of buildings) [

19], in which all results obtained are incorporated [

20].

PASLINK test cells have been frequently used [

21] for different purposes but mainly for conducting tests for the performance improvement of a specific component in building envelopes. In Europe, it is worth noting the experiences of the CSTC-BBRI (Centre Scientifique et Technique de la Construction-Belgian Building Research Institute) in Belgium while analysing several types and sizes of window apertures in the south facade [

22]; with different facade components [

23]; for photovoltaic elements [

24]; to obtain solar gain results [

25]; or to be able to evaluate different orientations using a rotary platform [

26].

PASLINK test cells are used in pairs for the comparative evaluation of the efficiency of retrofitted and existing solutions similar to real-scale facilities such as the twin houses of the IBP (Institute for Building Physics) in Germany [

27]. Attention should also be drawn to research into cells in pairs, focusing more specifically on the investigation of residential buildings in the University of California [

28]. In this case a double cell is analysed, reproducing the initial conditions of a house, contrasted with the conditions of the rehabilitation solution in order to evaluate cooling through ventilation and comfort conditions in relation to window size, thermal mass, and ventilation flow rate.

In Spain, and in a continental climate, it is worth highlighting the work carried out in Madrid [

29] by a research team studying homogeneous facade solutions without considering the window aperture, as well as that of the building quality control laboratory of the Basque Government in Alava [

30]. The solar platform installations in Almeria [

31] are used to test different types of building envelopes in a desert climate. Equally, in the case of a Mediterranean climate, it is worth highlighting the equipment of the Centre for Renewable Energy Sources and Saving in Greece [

32]. This studies homogeneous solutions in facades with no energetic or acoustic interaction of the window aperture or influence from solar protections or ventilation.

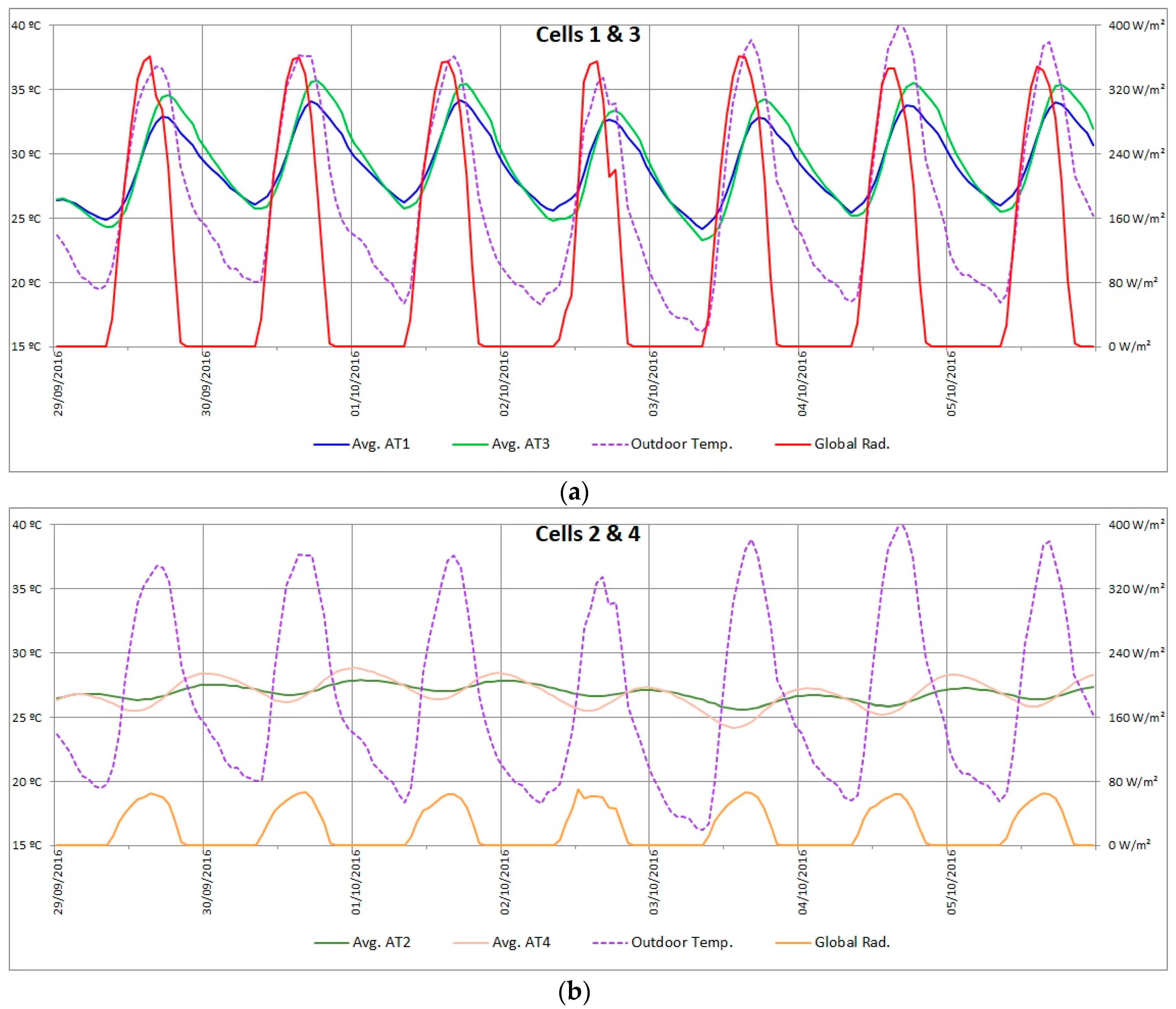

The aim of this study is to show the design and performance of one-pair test cells, which allow the optimization of vertical building envelope solutions for the retrofit of residential buildings in a Mediterranean area. The environmental conditions in a cell with an existing envelope and another retrofitted one, both with the same orientation, are simultaneously evaluated. Moreover, the suitability of the retrofitted solution is assessed from a global and simultaneous vision of energy aspects, thermal and lighting comfort, and air quality through the later development of simulation models. The use of this equipment provided a precise and real knowledge of the envelope solutions of buildings, ignoring the influence of the user but considering a fully controlled environment that can be manipulated.

2. Description of Test Cells

2.1. Location Site

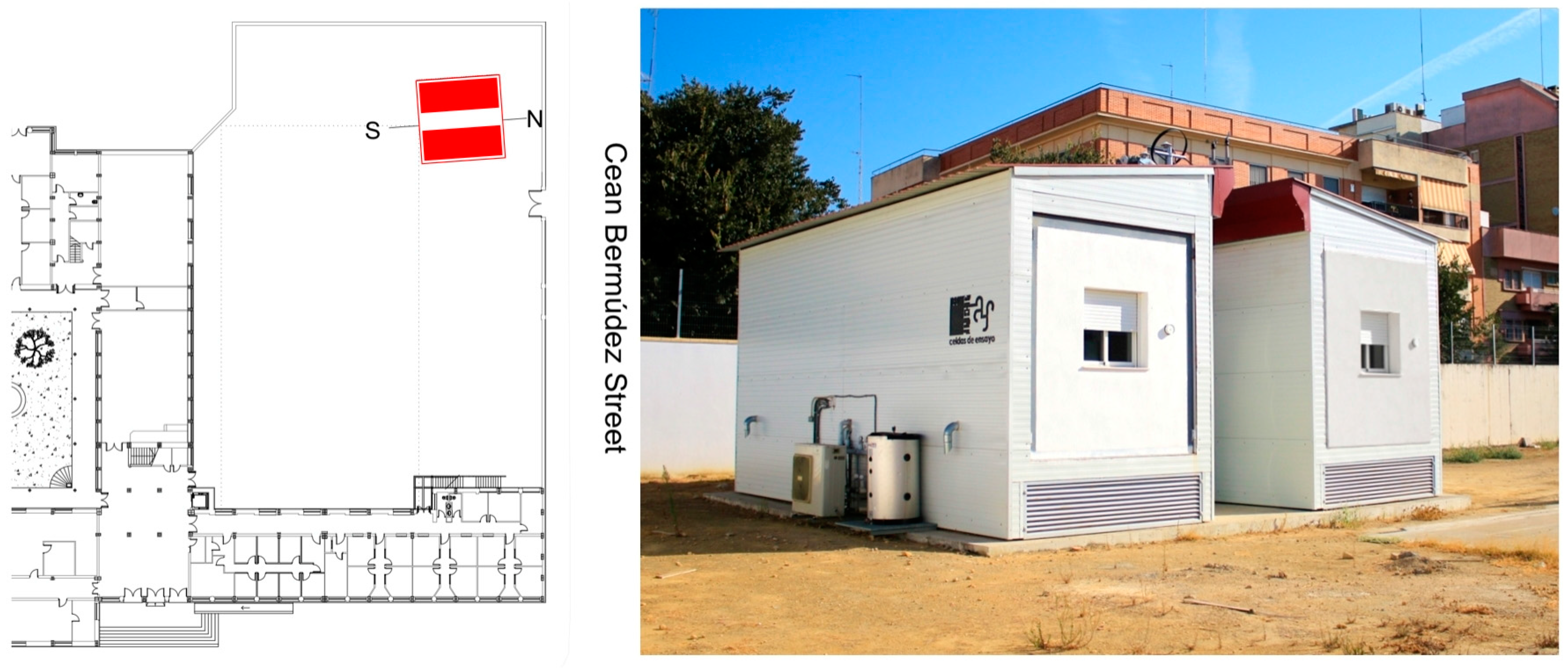

The test cells are located in an outdoor area of a building at the University of Seville, with a N-S longitudinal axis, as can be seen in

Figure 1.

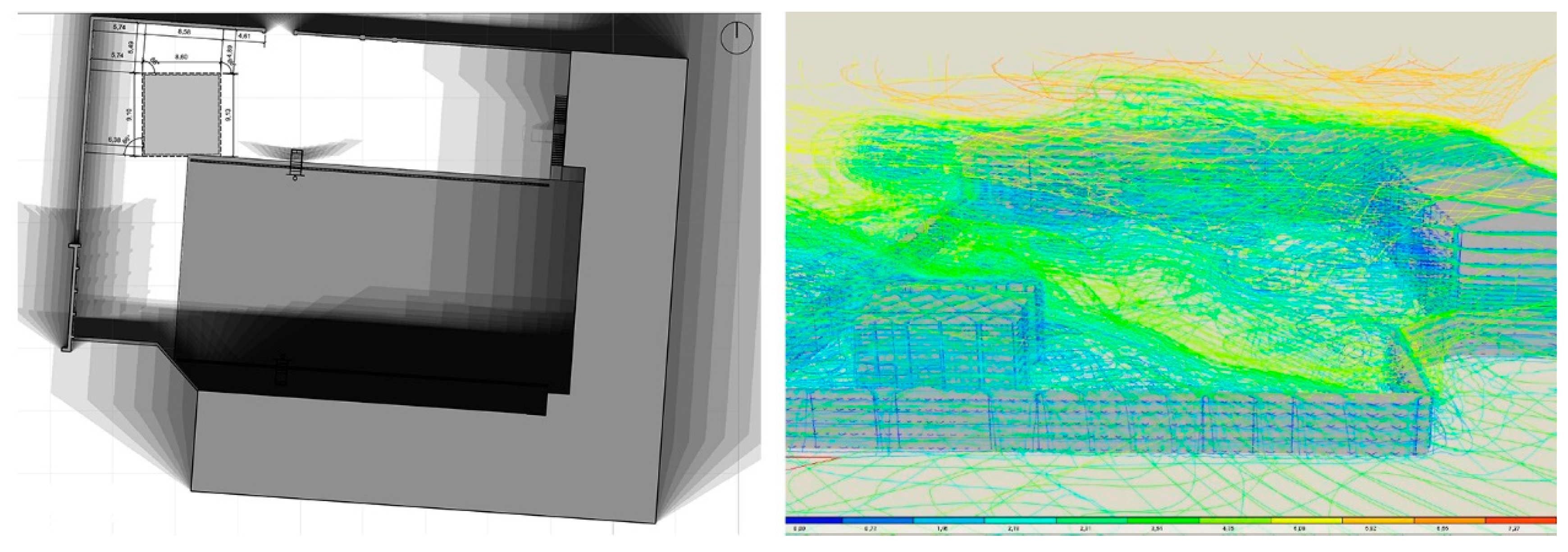

In order to determine the exact location, several sunlight and wind studies were conducted to ensure that there were no obstacles to sun or to the significant influence of wind flows in the surroundings (

Figure 2).

2.2. Spatial Description

The test cells are set up in two independent modules 90 cm off the ground and separated by an access area. Each module features two test cells facing different directions and separated by a service room for control systems, measurement equipment, and HVAC units. Each cell is an autonomous system that reproduces a housing space, with an open information system, which can determine the performance of different construction solutions in the facades tested. Four cells, two facing south and two facing north, with interior dimensions of 2.40 m wide, 3.20 m deep, and 2.70 m high, are presented. In this way, two different construction solutions can be evaluated simultaneously for the same cardinal direction (

Figure 3).

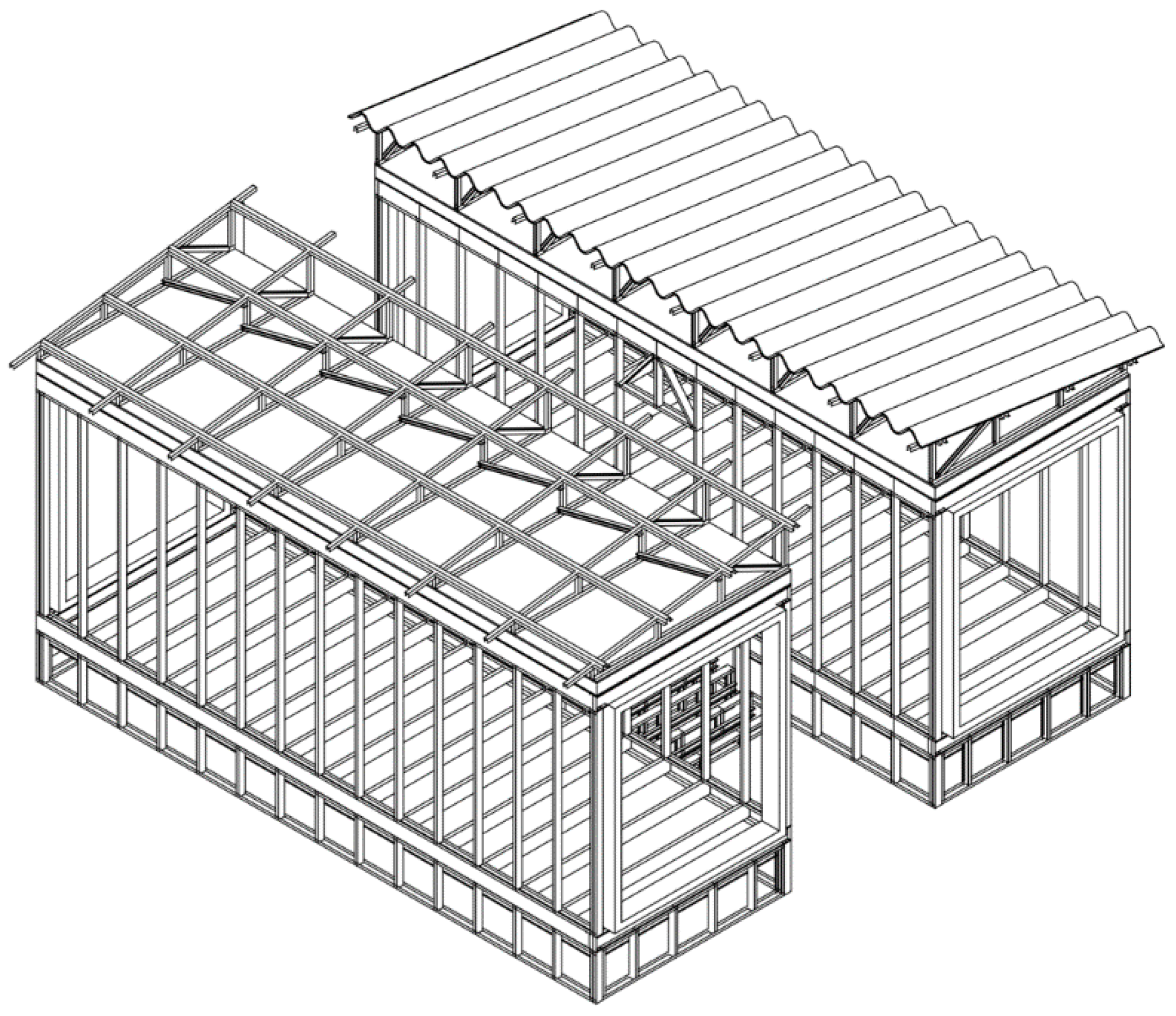

2.3. Constructive Characterization

The modules are light ‘steel frame’ structures (

Figure 4), pinned to a 10-cm-thick squared reinforced concrete slab measuring 9.30 × 9.30 m. Galvanized steel frames are cold-formed and used in the vertical building envelope as 100 mm frames and in the beams and joists as 200 mm profiles. The roof slope consists of trusses with 50 mm galvanized steel profiles, while omega profiles are used for the metallic belt structures, allowing them to support the galvanized and corrugated sheet panels used as roofs. The north and south facing facades include a metal frame made of 6 mm welded plates forming an L profile that supports the anchorage and installation of the different facade systems to be tested. The facade samples are built over a frame of steel tubes.

The thermal enclosure, consisting of the vertical envelope, the floor, and the roof, is made of high density sandwich panels, coloured in white, suitable as cold stores, and screwed to the steel frame structure. There is one interior panel that is 100 mm thick and another exterior panel that is 200 mm thick (both vertical and horizontal). The air chamber between infill pieces and metal studs is filled by wool rock panels at a density of 100 kg/m

3, and the space is 160 mm thick (80 + 80 mm). The thermal transmittance (U-values) is 0.05 W/m

2 K, which indicates a significant reduction of heat flow, with values that are not considered significant in the overall balance (

Table 1).

For the flooring solution, 3 mm of non-slip black rubber is used, with cold storage pivot access doors, both to the modules and cells, and similar thermal characteristics to those of the opaque envelope.

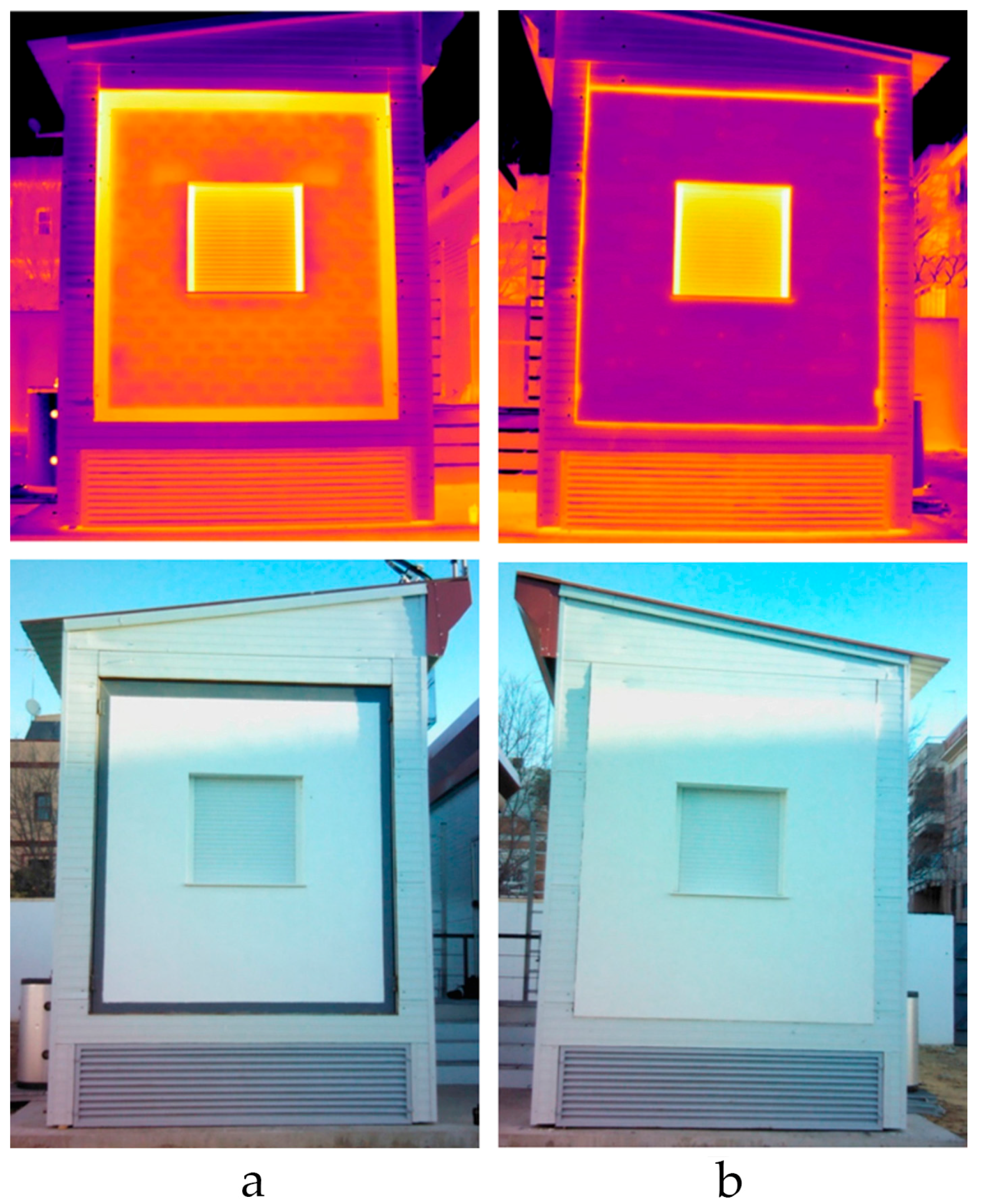

The facade panels can be easily configured with different construction solutions executed over a tubular steel frame, fitting and screwing the steel frame on the north and south sides of the modules. Cells 3 and 4 of Module 1 reproduce the conditions of a traditional facade from a Mediterranean climate dwelling (U

W1 = 1.43 W/m

2 K). In contrast, cells 1 and 2 of Module 2 represent a retrofitted solution using the same base elements as the other module but adding an External Thermal Insulation Composite System (ETICS), consisting of a 50-mm-thick Expanded Polystyrene (EPS) panel (U

W2 = 0.47 W/m

2 K) (

Table 1). Cells 1 and 3, facing south, have a window aperture of 116 × 108 cm with aluminium sliding carpentry, 4.8.4 double glazing (U

O = 3.3 W/m

2 K), and Polyvinyl Chloride (PVC) slatted shutters. Cells 2 and 4, facing north, are completely opaque (see

Video 1 in the Supplementary Materials).

2.4. Ventilation and Air Conditioning System

Ventilation is a variable that especially affects energy demand, as well as the degree of ambient comfort and the accumulation of CO

2, pollutants, and suspended particles. In the existing housing stock, ventilation usually comes from uncontrolled infiltrations through enclosures, whereas the current regulation of the Technical Building Code (CTE) [

33] establishes the need to guarantee a minimum outdoor airflow through the use of a mechanical system.

Given that the proposed test cells were designed to emulate social housing bedrooms, natural and mechanical ventilation tests are carried out using an extraction fan corresponding to each room, with an air flow rate of 187 m3/h. In order to simulate natural ventilation, this fan generates air depression, allowing outdoor air into the room through the tested envelope. In the case of mechanical ventilation, a gate valve is opened to resemble the operation of an air inlet.

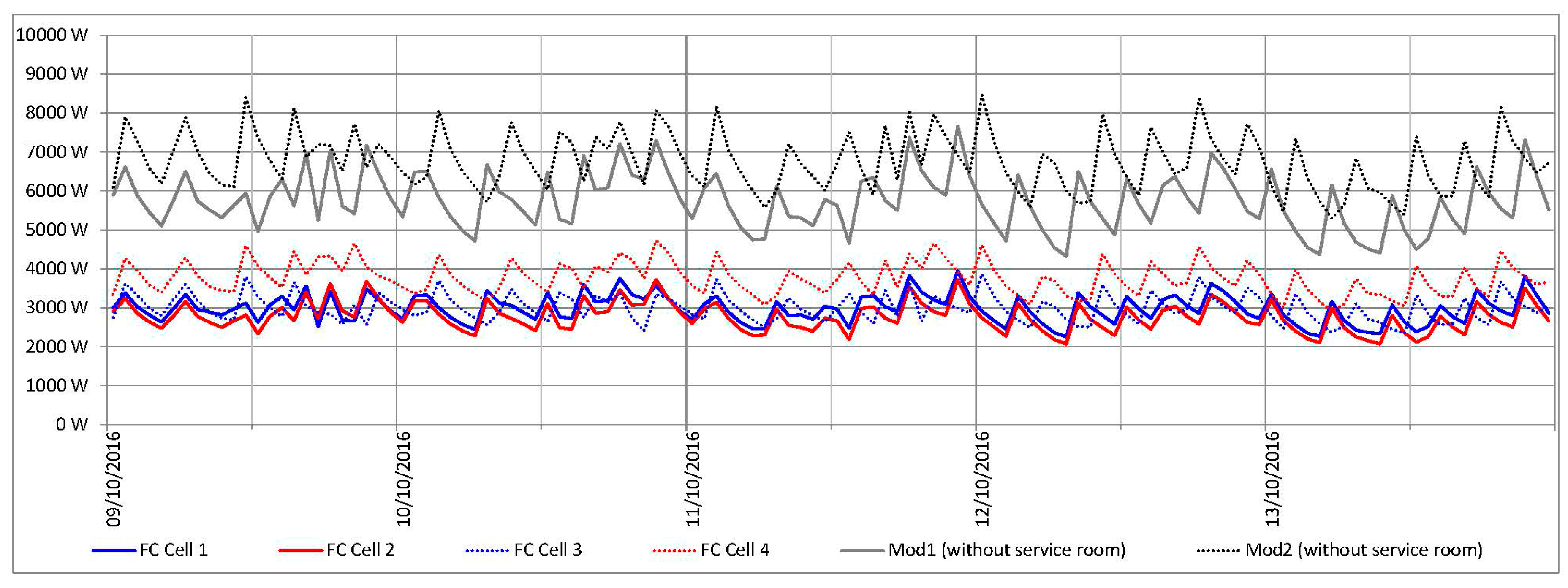

Each test module has an interior thermal control system, consisting of a reversible heat pump (air-water) and three fancoils: one per cell and a third one in the service room. This system also includes a buffer tank of 200 L capacity. The thermal capacities (cooling/heating) of the equipment are a production system of 5/5.5 kW, fancoils in the 2.5/3.5 kW tests cells, and a 1.87/2.53 kW fancoil in the service room. A hydronic system has been chosen to measure the thermal demand in each cell, as well as the final energy consumption. Demand measurement is possible thanks to thermal energy meters placed on each fancoil, whereas final electrical consumption is recorded by electricity meters.

2.5. Monitoring System

The interior monitoring system controls ambient conditions of interior air quality, lighting, consumption, and energy efficiency. A weather station placed over one of the experimental modules is used to monitor the exterior parameters.

The protocol established in EN ISO 7726:2001 [

34] has been followed in the installation process for this system, considering a 5 min time interval for the reading of monitored data and recording historic tendencies.

Monitoring probes, sensors, and meters are organized into seven systems: one for the measurement of external ambient conditions, four for the test cells, and the remaining two for air-conditioning systems.

The system that measures the external ambient conditions is controlled by the weather station and is composed of sensors for the air temperature variables, relative humidity, carbon dioxide, velocity, wind direction, direct normal and diffuse solar irradiation, and illuminance.

Most of the systems of the four test cells are similar. Each is composed of a set of sensors that measures air temperature variables, relative humidity, carbon dioxide, illuminance, and the superficial temperature of the envelope, both interior and exterior.

Finally, the two systems related to the air-conditioning systems are identical to each other. They incorporate several sensors that record the power consumed, electricity intensity, voltage, velocity, and air temperature in the ventilation ducts, water temperature in the flow and return pipes of the heat pump, and flowmeters in the interior air-conditioning units.

The monitoring installation is made up of a star network for data collection, where a set of multi-parametric sensors carry out measurements of different ambient and energy variables. This information is regularly sent to data loggers, where it is temporarily stored and uploaded every 30 min to a File Transfer Protocol (FTP) server (Universidad de Sevilla, Seville, Spain) through the RedIris network of the University of Seville. Data stored in the FTP server is periodically sent to local computer equipment for processing and interpretation before it is imported to a standard Microsoft Excel 2016® (Microsoft, Redmond, WA, USA) spreadsheet.

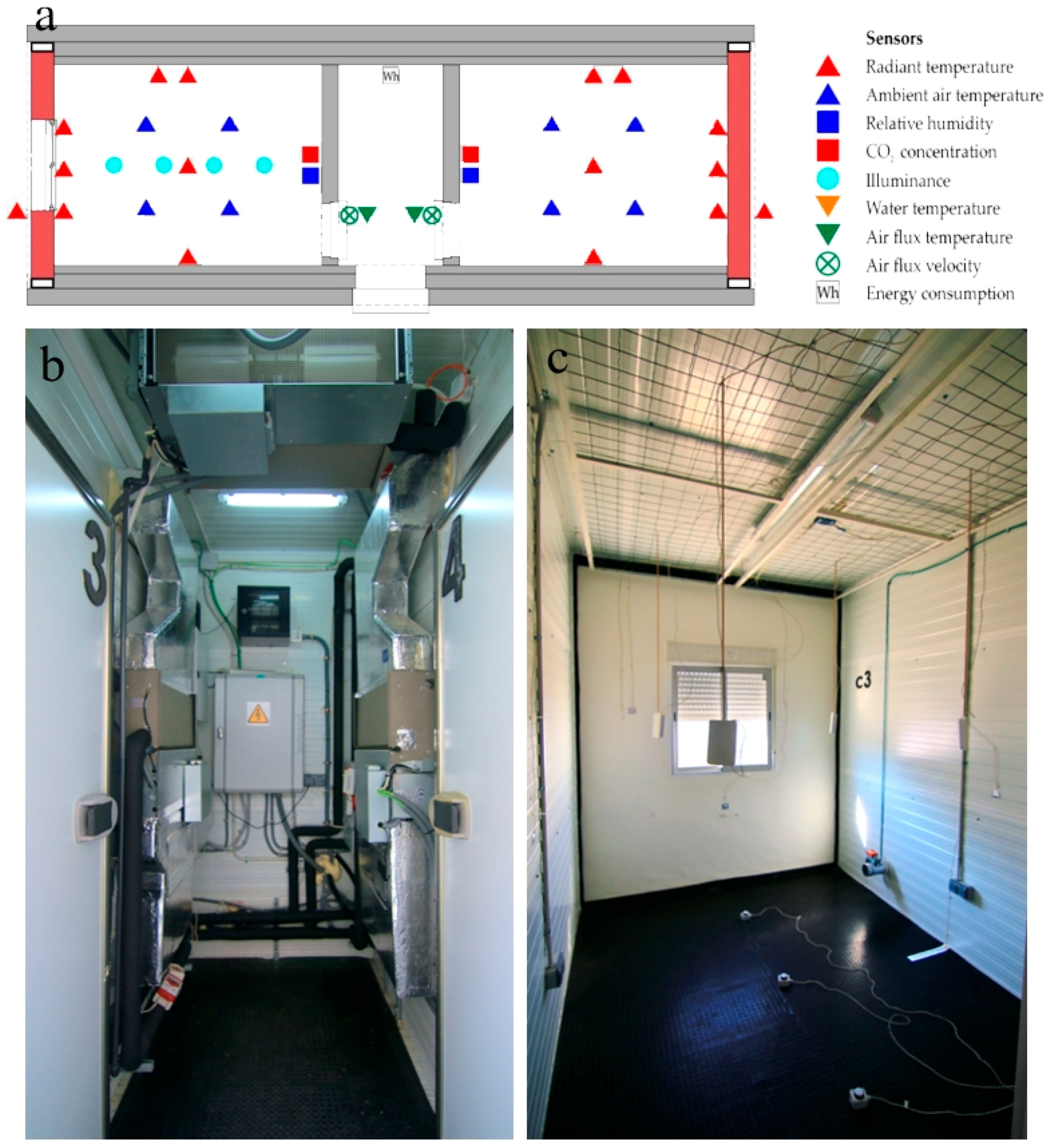

Description of Monitoring Equipment Installation

Measuring sensors used are as follows:

Test cells: ambient parameters (air temperature, velocity, relative humidity, CO

2 levels, radiant temperature, and illuminance) are measured. The sensors hang from a metal false ceiling open cell type padded with PVC, to make it possible to have a measurement matrix (

Table 2) (

Figure 5).

Air conditioning systems: These are located in the service rooms between the test cells. Electrical consumption (power, intensity, and potential difference) is recorded, and data from the air extraction fan (air velocity and temperature) and from the water circuit feeding the fancoils (water flow rate and temperature) are also collected (

Table 3).

Weather station: This is placed over an exterior metallic structure on top of Module 2 to measure the outdoor ambient parameters (air temperature and relative humidity in the north and south positions, air velocity and direction, CO

2 levels, illuminance, and incoming solar radiation, both direct and diffuse) (

Table 4).

The hubs and data loggers of each test cell, which receive measured data from the sensors, are situated in a cell panel located in the service rooms of both modules. These hubs are connected to an RJ45 plug assembled in a double superficial jack on the partial electrical power panel, connecting to the local Digital Visual Interface (DVI) network, which is in turn linked to the University of Seville campus network.

Data from the test modules can be easily downloaded from the FTP server or accessed via the Internet through an html portal. This portal also allows technical personnel to remotely access every probe and hub installed and to easily modify their configuration.

5. Conclusions

The use of test cells provided precise and tangible information to determine improvements in ambient conditions in retrofitted processes for dwellings located in a Mediterranean climate, without the influence of users. This made it possible to simultaneously evaluate demand conditions, energy consumption, and thermal comfort, comparing results both in the original solution and the retrofitted one.

The equipment in the test cells, composed of an extensive range of sensors and data acquisition systems, offers a wide variety of tests, obtaining essential empirical data on the ambient and energy variables, as well as their evolution over time. This data set will be used as an initial tool to validate and adjust energy and lighting simulation models for the more detailed and accurate use of these tools and the extrapolation of results to other climate zones and cardinal directions. The analysis of the results, combined with statistical tools, allows correlations to be established between the different variables monitored. This contributes to the optimization of retrofitted solutions in vertical envelopes, as well as the design conditions of air conditioning and lighting systems, before acting on real buildings. Moreover, all this will foster a reduction in economic costs, aiming to optimize thermal and lighting comfort conditions, as well as energy use in air conditioning and lighting installations in dwellings.

Although equipment construction must resolve some of the problems detected, including thermal bridges and infiltrations, it ensures a wide and complete operating range in realistic climate conditions with valuable and representative results of dynamic performance.