Deployment of Interpretive Structural Modeling in Barriers to Industry 4.0: A Case of Small and Medium Enterprises

Abstract

:1. Introduction

1.1. Identification of Research Gaps

1.2. Research Motivation, Objectives, and Intended Contribution of the Study

- To identify the barriers to I 4.0 in the case of Indian SMEs;

- To model these barriers to I 4.0 with the help of ISM;

- To plot these I 4.0 barriers on four clusters using MICMAC analysis.

1.3. Expected Contributions of the Study

- Summarize the variables drawn from literature acting as barriers to implementing I 4.0.

- Draw the driving and dependent barriers to I 4.0 applicability in Indian SMEs.

- Help policymakers and other stakeholders make relevant decisions while implementing I 4.0 in their units.

2. Literature Review

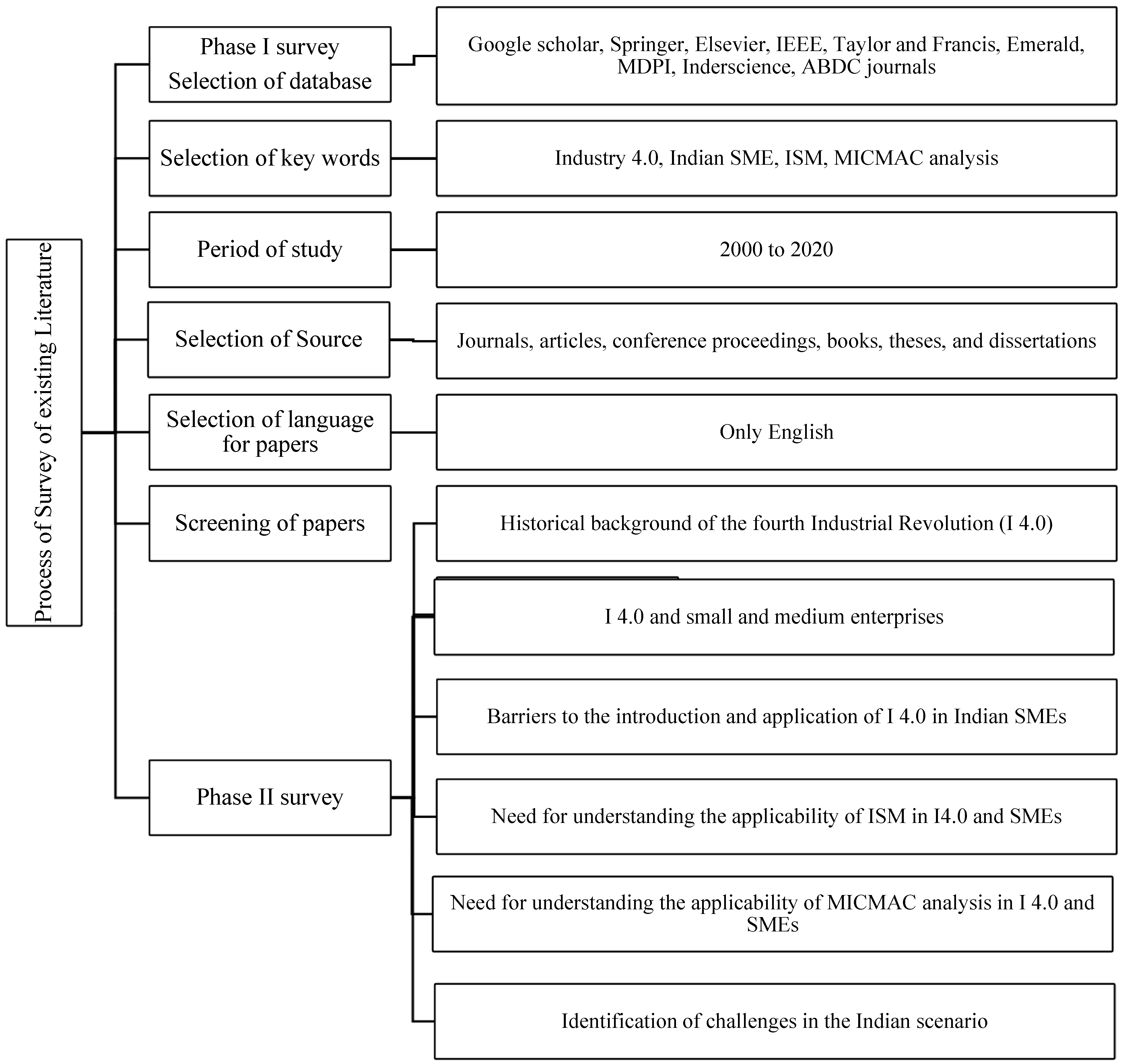

2.1. Division of Existing Published Literature

2.1.1. Exploration Phase

2.1.2. Shepherding Phase

2.1.3. Final Phase

2.2. Historical Background of the Fourth Industrial Revolution (I 4.0)

2.3. Industry 4.0 and Small and Medium Enterprises

2.4. Barriers to the Introduction and Application of I 4.0 in Indian SMEs

2.5. The Need for Understanding the Applicability of ISM in I4.0 and SMEs

2.6. Need for Understanding the Applicability of MICMAC Analysis in I 4.0 and SMEs

2.7. Identification of Challenges in the Indian Scenario

3. Material and Methods

3.1. Research Design

3.2. Brainstorming Session on Barriers and Their Inter-Dependence

3.3. Deployment of ISM on Barriers

- Step 1: Fifteen different challenges are used to apply the ISM tool.

- Step 2: A detailed relation is obtained between the challenges, and the structural self-interaction matrix (SSIM) is constructed based on the relationship in terms of V, A, X, and O.

- Step 3: This SSIM matrix is converted into binary forms (0 and 1), and an initial reachability matrix is found.

- Step 4: A transitivity check of the initial reachability matrix is performed. The transitivity rule states that if Challenge A is related to Challenge B, and Challenge B is connected to Challenge C, Challenge A is necessarily related to Challenge C.

- Step 5: Level segmentation is performed on the final reachability matrix.

- Step 6: A hierarchical structure is framed based on the level partition, which shows the type of relationship among challenges.

4. Results

4.1. Structural Self-Interaction Matrix (SSIM)

- V—Challenge A will help to achieve Challenge B;

- A—Challenge B will help to achieve Challenge A;

- X—Challenges A and B will help to achieve each other;

- O—Challenge A and B do not have any type of relation.

4.2. Reachability Matrix (RM)

4.3. Level Partitions

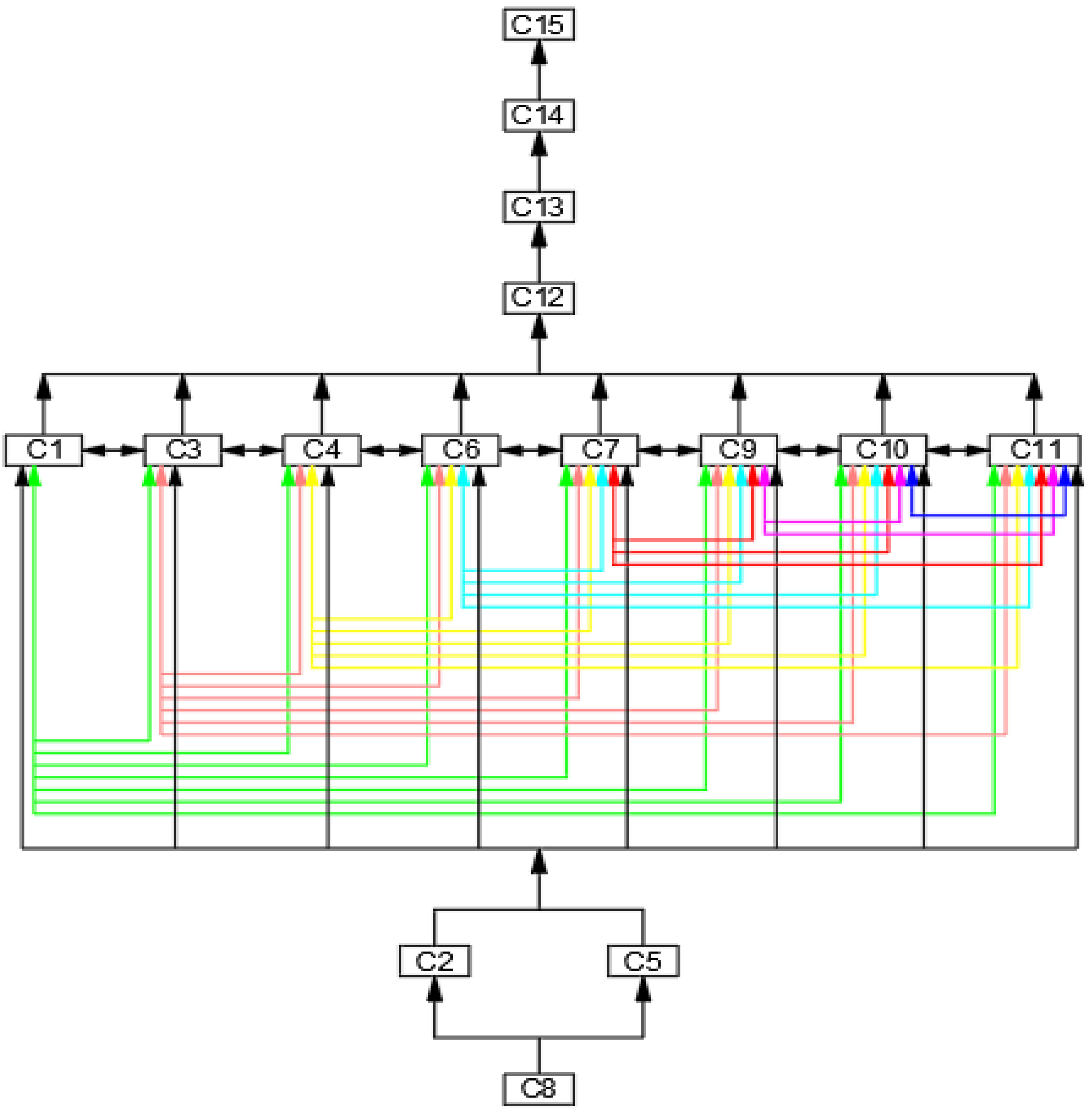

4.4. ISM Model Construction

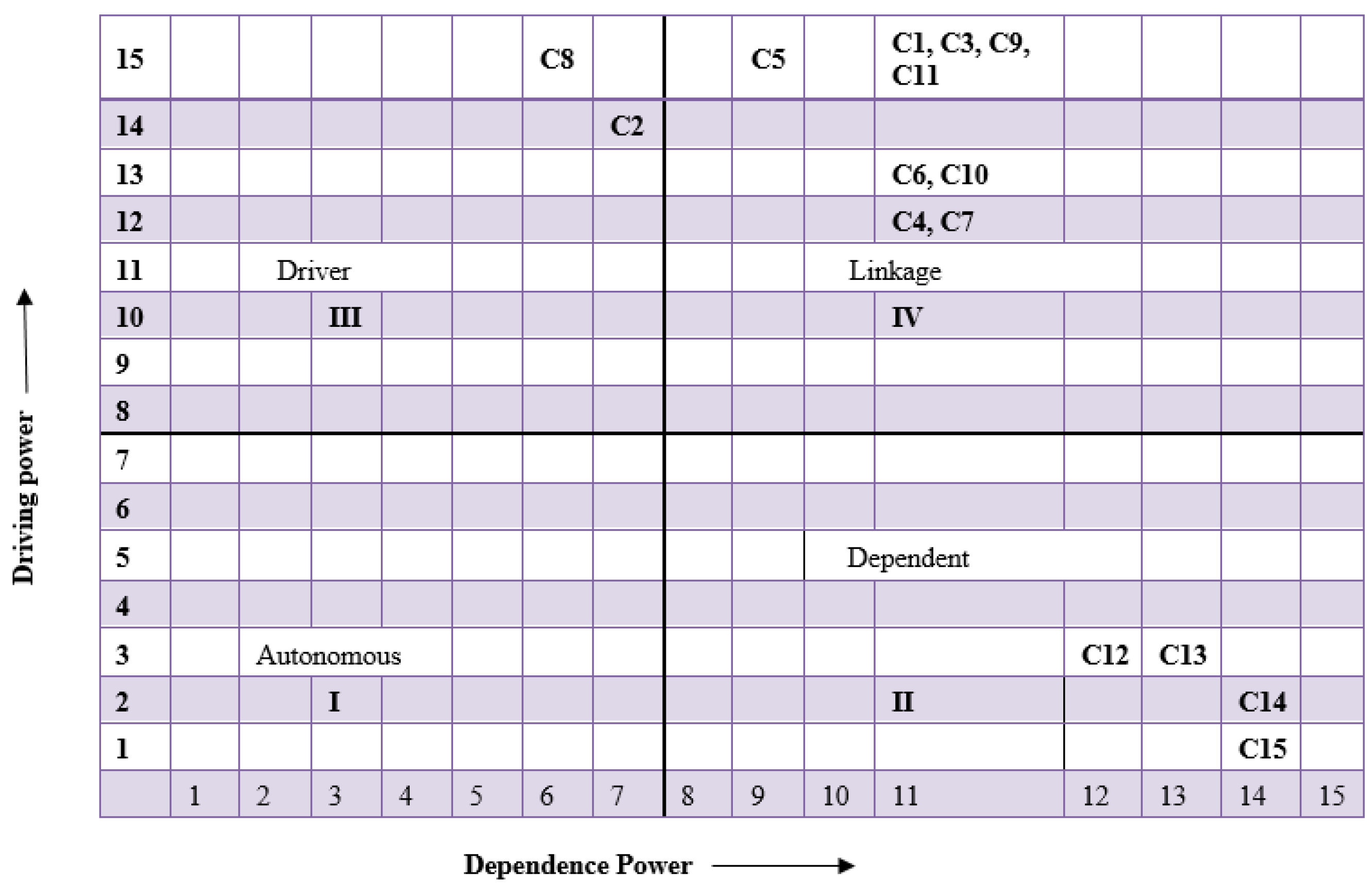

4.5. MICMAC Analysis

5. Discussion

6. Managerial Implications, Suggestions, and Future Scope

7. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Appendix A

| Challenge | Reachability Set | Antecedent Set | Intersection Set | Level |

|---|---|---|---|---|

| C1 | 1, 2, 3, 4, 5, 6, 7, 8, 9, 10, 11, 12 | 1, 2, 3, 4, 5, 6, 7, 8, 9, 10, 11 | 1, 2, 3, 4, 5, 6, 7, 8, 9, 10, 11 | |

| C2 | 1, 2, 3, 4, 5, 6, 7, 9, 10, 11, 12 | 1, 2, 3, 5, 8, 9, 11 | 1, 2, 3, 5, 9, 11 | |

| C3 | 1, 2, 3, 4, 5, 6, 7, 8, 9, 10, 11, 12 | 1, 2, 3, 4, 5, 6, 7, 8, 9, 10, 11 | 1, 2, 3, 4, 5, 6, 7, 8, 9, 10, 11 | |

| C4 | 1, 3, 4, 6, 7, 9, 10, 11, 12 | 1, 2, 3, 4, 5, 6, 7, 8, 9, 10, 11 | 1, 3, 4, 6, 7, 9, 10, 11 | |

| C5 | 1, 2, 3, 4, 5, 6, 7, 8, 9, 10, 11, 12 | 1, 2, 3, 5, 6, 8, 9, 10, 11 | 1, 2, 3, 5, 6, 8, 9, 10, 11 | |

| C6 | 1, 3, 4, 5, 6, 7, 9, 10, 11, 12 | 1, 2, 3, 4, 5, 6, 7, 8, 9, 10, 11 | 1, 3, 4, 5, 6, 7, 9, 10, 11 | |

| C7 | 1, 3, 4, 6, 7, 9, 10, 11, 12 | 1, 2, 3, 4, 5, 6, 7, 8, 9, 10, 11 | 1, 3, 4, 6, 7, 9, 10, 11 | |

| C8 | 1, 2, 3, 4, 5, 6, 7, 8, 9, 10, 11, 12 | 1, 3, 5, 8, 9, 11 | 1, 3, 5, 8, 9, 11 | |

| C9 | 1, 2, 3, 4, 5, 6, 7, 8, 9, 10, 11, 12 | 1, 2, 3, 4, 5, 6, 7, 8, 9, 10, 11 | 1, 2, 3, 4, 5, 6, 7, 8, 9, 10, 11 | |

| C10 | 1, 3, 4, 6, 7, 9, 10, 11, 12 | 1, 2, 3, 4, 5, 6, 7, 8, 9, 10, 11 | 1, 3, 4, 6, 7, 9, 10, 11 | |

| C11 | 1, 2, 3, 4, 5, 6, 7, 8, 9, 10, 11, 12 | 1, 2, 3, 4, 5, 6, 7, 8, 9, 10, 11 | 1, 2, 3, 4, 5, 6, 7, 8, 9, 10, 11 | |

| C12 | 12 | 1, 2, 3, 4, 5, 6, 7, 8, 9, 10, 11, 12 | 12 | IV |

| Factors | Reachability Set | Antecedent Set | Intersection set | Level |

|---|---|---|---|---|

| C1 | 1, 2, 3, 4, 5, 6, 7, 8, 9, 10, 11 | 1, 2, 3, 4, 5, 6, 7, 8, 9, 10, 11 | 1, 2, 3, 4, 5, 6, 7, 8, 9, 10, 11 | V |

| C2 | 1, 2, 3, 4, 5, 6, 7, 9, 10, 11 | 1, 2, 3, 5, 8, 9, 11 | 1, 2, 3, 5, 9, 11 | |

| C3 | 1, 2, 3, 4, 5, 6, 7, 8, 9, 10, 11 | 1, 2, 3, 4, 5, 6, 7, 8, 9, 10, 11 | 1, 2, 3, 4, 5, 6, 7, 8, 9, 10, 11 | V |

| C4 | 1, 3, 4, 6, 7, 9, 10, 11 | 1, 2, 3, 4, 5, 6, 7, 8, 9, 10, 11 | 1, 3, 4, 6, 7, 9, 10, 11 | V |

| C5 | 1, 2, 3, 4, 5, 6, 7, 8, 9, 10, 11 | 1, 2, 3, 5, 6, 8, 9, 10, 11 | 1, 2, 3, 5, 6, 8, 9, 10, 11 | |

| C6 | 1, 3, 4, 5, 6, 7, 9, 10, 11 | 1, 2, 3, 4, 5, 6, 7, 8, 9, 10, 11 | 1, 3, 4, 5, 6, 7, 9, 10, 11 | V |

| C7 | 1, 3, 4, 6, 7, 9, 10, 11 | 1, 2, 3, 4, 5, 6, 7, 8, 9, 10, 11 | 1, 3, 4, 6, 7, 9, 10, 11 | V |

| C8 | 1, 2, 3, 4, 5, 6, 7, 8, 9, 10, 11 | 1, 3, 5, 8, 9, 11 | 1, 3, 5, 8, 9, 11 | |

| C9 | 1, 2, 3, 4, 5, 6, 7, 8, 9, 10, 11 | 1, 2, 3, 4, 5, 6, 7, 8, 9, 10, 11 | 1, 2, 3, 4, 5, 6, 7, 8, 9, 10, 11 | V |

| C10 | 1, 3, 4, 6, 7, 9, 10, 11 | 1, 2, 3, 4, 5, 6, 7, 8, 9, 10, 11 | 1, 3, 4, 6, 7, 9, 10, 11 | V |

| C11 | 1, 2, 3, 4, 5, 6, 7, 8, 9, 10, 11 | 1, 2, 3, 4, 5, 6, 7, 8, 9, 10, 11 | 1, 2, 3, 4, 5, 6, 7, 8, 9, 10, 11 | V |

| Factors | Reachability Set | Antecedent Set | Intersection set | Level |

|---|---|---|---|---|

| C2 | 2, 5 | 2, 5, 8 | 2, 5 | VI |

| C5 | 2, 5, 8 | 2, 5, 8 | 2, 5, 8 | VI |

| C8 | 2, 5, 8 | 5, 8 | 5, 8 |

| Factors | Reachability Set | Antecedent Set | Intersection Set | Level |

|---|---|---|---|---|

| C8 | 8 | 8 | 8 | VII |

References

- Ahmad, Mahmood, Xiao-Wei Tang, Jiang-Nan Qiu, and Feezan Ahmad. 2019. Interpretive Structural Modeling and MICMAC Analysis for Identifying and Benchmarking Significant Factors of Seismic Soil Liquefaction. Applied Sciences 9: 233. [Google Scholar] [CrossRef] [Green Version]

- Almada-Lobo, Francisco. 2016. The Industry 4.0 revolution and the future of Manufacturing Execution Systems (MES). Journal of Innovation Management 3: 16–21. [Google Scholar] [CrossRef]

- Battaglia, Daniele, Paolo Neirotti, and Emilio Paolucci. 2018. The role of R&D investments and export on SMEs’ growth: A domain ambidexterity perspective. Management Decision 56: 1883–903. [Google Scholar]

- Chonsawat, Nilubon, and Apichat Sopadang. 2020. Defining SMEs’ 4.0 Readiness Indicators. Applied Sciences 10: 8998. [Google Scholar] [CrossRef]

- Dalmarco, Gustavo, Filipa R. Ramalho, Ana C. Barros, and Antonio L. Soares. 2019. Providing industry 4.0 technologies: The case of a production technology cluster. The Journal of High Technology Management Research 30: 100355. [Google Scholar] [CrossRef]

- Diabat, Ali, and Kannan Govindan. 2011. An analysis of the drivers affecting the implementation of green supply chain management. Resources, Conservation and Recycling 55: 659–67. [Google Scholar] [CrossRef]

- Dutta, Gautam, Ravinder Kumar, Rahul Sindhwani, and Rajesh Kumar Singh. 2020. Digital transformation priorities of India’s discrete manufacturing SMEs—A conceptual study in perspective of Industry 4.0. Competitiveness Review: An International Business Journal 30: 289–314. [Google Scholar] [CrossRef]

- Farris, Donald. R., and Andrew P. Sage. 1975. On the use of interpretive structural modeling for worth assessment. Computers Electrical Engineering 2: 149–74. [Google Scholar] [CrossRef]

- Feng, Lei, Xuehui Zhang, and Kaige Zhou. 2018. Current problems in China’s manufacturing and countermeasures for industry 4.0. EURASIP Journal on Wireless Communications Networking 2018: 1–6. [Google Scholar] [CrossRef]

- Haug, Anders, Søren Graungaard Pedersen, and Jan Stentoft Arlbjørn. 2011. IT readiness in small and medium-sized enterprises. Industrial Management & Data Systems 111: 490–508. [Google Scholar]

- Hofmann, Erik, and Marco Rüsch. 2017. Industry 4.0 and the current status as well as future prospects on logistics. Computers in Industry 89: 23–34. [Google Scholar] [CrossRef]

- Jain, Sanjay, Guodong Shao, and Seung-Jun Shin. 2016. Virtual factory based data analytics. Paper presented at the 2016 12th IEEE International Conference on Control and Automation (ICCA), Kathmandu, Nepal, June 1–3. [Google Scholar]

- Jain, Sanjay, Guodong Shao, and Seung-Jun Shin. 2017. Manufacturing data analytics using a virtual factory representation. International Journal of Production Research 55: 5450–64. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Janssen, Marijn, Sunil Luthra, Sachin Mangla, Nripendra P. Rana, and Yogesh K. Dwivedi. 2019. Challenges for adopting and implementing IoT in smart cities. Internet Research 29: 1589–616. [Google Scholar] [CrossRef] [Green Version]

- Kamble, Sachin S., Angappa Gunasekaran, and Rohit Sharma. 2018. Analysis of the driving and dependence power of barriers to adopt industry 4.0 in Indian manufacturing industry. Computers in Industry 101: 107–19. [Google Scholar] [CrossRef]

- Kaswan, Mahender Singh, and Rajeev Rathi. 2019. Analysis and modeling the enablers of Green Lean Six Sigma implementation using Interpretive Structural Modeling. Journal of Cleaner Production 231: 1182–91. [Google Scholar] [CrossRef]

- Kumar, Raman, Abhishek Bhattacherjee, Angad Deep Singh, Sunpreet Singh, and Catalin I. Pruncu. 2020a. Selection of portable hard disk drive based upon weighted aggregated sum product assessment method: A case of Indian market. Measurement and Control 53: 1218–30. [Google Scholar] [CrossRef]

- Kumar, Raman, Harish Kumar Banga, and Harpreet Kaur. 2020b. Internet of Things-Supported Smart City Platform. IOP Conference Series: Materials Science and Engineering 955: 012003. [Google Scholar] [CrossRef]

- Kumar, Raman, and Pankaj Goel. 2021. Exploring the Domain of Interpretive Structural Modelling (ISM) for Sustainable Future Panorama: A Bibliometric and Content Analysis. Archives of Computational Methods in Engineering, 1–30. [Google Scholar] [CrossRef]

- Kumar, Raman, Paramjit Singh Bilga, and Sehijpal Singh. 2017. Multi objective optimization using different methods of assigning weights to energy consumption responses, surface roughness and material removal rate during rough turning operation. Journal of Cleaner Production 164: 45–57. [Google Scholar] [CrossRef]

- Kumar, Vikas, Ihsan Sezersan, Jose Arturo Garza-Reyes, Ernesto D. R. S. Gonzalez, and Moh’d Anwer Al-Shboul. 2019. Circular economy in the manufacturing sector: Benefits, opportunities and barriers. Management Decision 57: 1067–86. [Google Scholar] [CrossRef] [Green Version]

- Lee, Jay, Behrad Bagheri, and Hung-An Kao. 2015. A Cyber-Physical Systems architecture for Industry 4.0-based manufacturing systems. Manufacturing Letters 3: 18–23. [Google Scholar] [CrossRef]

- Luthra, Sunil, and Sachin Kumar Mangla. 2018. Evaluating challenges to Industry 4.0 initiatives for supply chain sustainability in emerging economies. Process Safety and Environmental Protection 117: 168–79. [Google Scholar] [CrossRef]

- Mandal, Anukul, and S. G. Deshmukh. 1994. Vendor Selection Using Interpretive Structural Modelling (ISM). International Journal of Operations & Production Management 14: 52–59. [Google Scholar]

- Marques, Maria, Carlos Agostinho, Gregory Zacharewicz, and Ricardo Jardim-Gonçalves. 2017. Decentralized decision support for intelligent manufacturing in Industry 4.0. Journal of Ambient Intelligence and Smart Environments 9: 299–313. [Google Scholar] [CrossRef] [Green Version]

- Mishra, Shraddha, Surya Prakash Singh, John Johansen, Yang Cheng, and Sami Farooq. 2019. Evaluating indicators for international manufacturing network under circular economy. Management Decision 57: 811–39. [Google Scholar] [CrossRef]

- Öner, Sultan Ceren, Mahir Öner, Alp Ustundag, and Emre Cevikcan. 2018. A Conceptual Framework for Industry 4.0. In Springer Series in Advanced Manufacturing. Cham: Springer, pp. 3–23. [Google Scholar]

- Pech, Martin, and Jaroslav Vrchota. 2020. Classification of Small- and Medium-Sized Enterprises Based on the Level of Industry 4.0 Implementation. Applied Sciences 10: 5150. [Google Scholar] [CrossRef]

- Pech, Martin, and Jaroslav Vrchota. 2022. The Product Customization Process in Relation to Industry 4.0 and Digitalization. Processes 10: 539. [Google Scholar] [CrossRef]

- Pedersen, Mikkel Rath, Lazaros Nalpantidis, Rasmus Skovgaard Andersen, Casper Schou, Simon Bøgh, Volker Krüger, and Ole Madsen. 2016. Robot skills for manufacturing: From concept to industrial deployment. Robotics and Computer-Integrated Manufacturing 37: 282–91. [Google Scholar] [CrossRef]

- Pellicciari, Marcello, Angelo O. Andrisano, Francesco Leali, and Alberto Vergnano. 2009. Engineering method for adaptive manufacturing systems design. International Journal on Interactive Design and Manufacturing (IJIDeM) 3: 81–91. [Google Scholar] [CrossRef]

- Pfohl, Hans-Christian, Burak Yahsi, and Tamer Kurnaz. 2017. Concept and diffusion-factors of industry 4.0 in the supply chain. In Dynamics in Logistics. Cham: Springer, pp. 381–90. [Google Scholar]

- Phuyal, Sudip, Diwakar Bista, and Rabindra Bista. 2020. Challenges, Opportunities and Future Directions of Smart Manufacturing: A State of Art Review. Sustainable Futures 2: 100023. [Google Scholar] [CrossRef]

- Prajapati, Himanshu, Ravi Kant, and Ravi Shankar. 2019. Prioritizing the solutions of reverse logistics implementation to mitigate its barriers: A hybrid modified SWARA and WASPAS approach. Journal of Cleaner Production 240: 118219. [Google Scholar] [CrossRef]

- Rajput, Shubhangini, and Surya Prakash Singh. 2019. Identifying Industry 4.0 IoT enablers by integrated PCA-ISM-DEMATEL approach. Management Decision 57: 1784–817. [Google Scholar] [CrossRef]

- Rüßmann, Michael, Markus Lorenz, Philipp Gerbert, Manuela Waldner, Jan Justus, Pascal Engel, and Michael Harnisch. 2015. Industry 4.0: The future of productivity and growth in manufacturing industries. Boston Consulting Group 9: 54–89. [Google Scholar]

- Satapathy, Suchismita. 2017. An analysis of barriers for plastic recycling in the Indian plastic industry. Benchmarking: An International Journal 24: 415–30. [Google Scholar] [CrossRef]

- Saucedo-Martínez, Jania Astrid, Magdiel Pérez-Lara, José Antonio Marmolejo-Saucedo, Tomás Eloy Salais-Fierro, and Pandian Vasant. 2018. Industry 4.0 framework for management and operations: A review. Journal of Ambient Intelligence and Humanized Computing 9: 789–801. [Google Scholar] [CrossRef]

- Sharma, Anshuman, Haidar Abbas, and Muhammad Qutubuddin Siddiqui. 2021. Modelling the inhibitors of cold supply chain using fuzzy interpretive structural modeling and fuzzy MICMAC analysis. PLoS ONE 16: e0249046. [Google Scholar] [CrossRef]

- Sharma, Pradip Kumar, Neeraj Kumar, and Jong Hyuk Park. 2020. Blockchain Technology Toward Green IoT: Opportunities and Challenges. IEEE Network 34: 263–69. [Google Scholar] [CrossRef]

- Sima, Violeta, Ileana G. Gheorghe, Jonel Subić, and Dumitru Nancu. 2020. Influences of the Industry 4.0 Revolution on the Human Capital Development and Consumer Behavior: A Systematic Review. Sustainability 12: 4035. [Google Scholar] [CrossRef]

- Singh, Mahipal, Rajeev Rathi, and Jose Arturo Garza-Reyes. 2021. Analysis and prioritization of Lean Six Sigma enablers with environmental facets using best worst method: A case of Indian MSMEs. Journal of cleaner production 279: 123592. [Google Scholar] [CrossRef]

- Singh, Ravi Shankar, Rakesh Narain, and Ashish Agarwal. 2003. An interpretive structural modeling of knowledge management in engineering industries. Journal of Advances in Management Research 1: 28–40. [Google Scholar] [CrossRef]

- Sommer, Lutz. 2015. Industrial revolution—Industry 4.0: Are German manufacturing SMEs the first victims of this revolution? Journal of Industrial Engineering and Management 8: 1512–32. [Google Scholar] [CrossRef] [Green Version]

- Stentoft, Jan, Kent Adsbøll Wickstrøm, Kristian Philipsen, and Anders Haug. 2021. Drivers and barriers for Industry 4.0 readiness and practice: Empirical evidence from small and medium-sized manufacturers. Production Planning & Control 32: 811–28. [Google Scholar]

- Syreyshchikova, Nelli V., Danil Yurievich Pimenov, Angelos P. Markopoulos, and Liviu Moldovan. 2021a. Value Stream Maps in Clock Production. Russian Engineering Research 41: 378–81. [Google Scholar] [CrossRef]

- Syreyshchikova, Nelli V., Danil Yurievich Pimenov, Elena N. Yaroslavova, Munish K. Gupta, Shubham Sharma, and Khaled Giasin. 2021b. Product Quality Planning in Laser Metal Processing Based on Open Innovation Using Quality Function Deployment. Journal of Open Innovation: Technology, Market, and Complexity 7: 240. [Google Scholar] [CrossRef]

- Syreyshchikova, Nelli V., Danil Yurievich Pimenov, I. A. Kulygina, and Liviu Moldovan. 2021c. Hybrid Model for Calculating Quality Costs. Russian Engineering Research 41: 382–86. [Google Scholar] [CrossRef]

- Tayal, Ashwani, Nirmal S. Kalsi, Munish K. Gupta, Danil Y. Pimenov, Murat Sarikaya, and Catalin I. Pruncu. 2021. Effectiveness Improvement in Manufacturing Industry; Trilogy Study and Open Innovation Dynamics. Journal of Open Innovation: Technology, Market, and Complexity 7: 7. [Google Scholar] [CrossRef]

- Tripathi, Varun, Somnath Chattopadhyaya, Alok Bhadauria, Shubham Sharma, Changhe Li, Danil Yurievich Pimenov, Khaled Giasin, Sunpreet Singh, and Girish Dutt Gautam. 2021a. An Agile System to Enhance Productivity through a Modified Value Stream Mapping Approach in Industry 4.0: A Novel Approach. Sustainability 13: 11997. [Google Scholar] [CrossRef]

- Tripathi, Varun, Somnath Chattopadhyaya, Alok K. Mukhopadhyay, Shubham Sharma, Jujhar Singh, Danil Yurievich Pimenov, and Khaled Giasin. 2021b. An Innovative Agile Model of Smart Lean–Green Approach for Sustainability Enhancement in Industry 4.0. Journal of Open Innovation: Technology, Market, and Complexity 7: 215. [Google Scholar] [CrossRef]

- Truong, Nguyen Xuan, and Luu. Quang Khai. 2020. Factors Affecting Adoption of Industry 4.0 by Small- and Medium-Sized Enterprises: A Case in Ho Chi Minh City, Vietnam. The Journal of Asian Finance, Economics and Business 7: 255–64. [Google Scholar]

- Vaidya, Saurabh, Prashant Ambad, and Santosh Bhosle. 2018. Industry 4.0—A Glimpse. Procedia Manufacturing 20: 233–38. [Google Scholar] [CrossRef]

- Wang, Yi, Hai-Shu Ma, Jing-Hui Yang, and Ke-Sheng Wang. 2017. Industry 4.0: A way from mass customization to mass personalization production. Advances in Manufacturing 5: 311–20. [Google Scholar] [CrossRef]

- Warfield, John N. 1974. Developing Interconnection Matrices in Structural Modeling. IEEE Transactions on Systems, Man, and Cybernetics SMC-4: 81–87. [Google Scholar] [CrossRef] [Green Version]

- Yadav, Gunjan, and Tushar N. Desai. 2017. Analyzing Lean Six Sigma enablers: A hybrid ISM-fuzzy MICMAC approach. The TQM Journal 29: 488–511. [Google Scholar] [CrossRef]

- Zezulka, František, Petr Marcoň, Ivo Vesely, and Ondrej Sajdl. 2016. Industry 4.0—An Introduction in the phenomenon. IFAC-PapersOnLine 49: 8–12. [Google Scholar] [CrossRef]

| S. No. | Challenges Affecting the Implementation of I 4.0 | Reference |

|---|---|---|

| C1 | Little awareness | (Almada-Lobo 2016; Hofmann and Rüsch 2017; Luthra and Mangla 2018) |

| C2 | Little managerial support | (Feng et al. 2018; Luthra and Mangla 2018) |

| C3 | Little technical knowledge | (Marques et al. 2017; Prajapati et al. 2019) |

| C4 | Insufficient funds | (Dalmarco et al. 2019; Prajapati et al. 2019) |

| C5 | No clear government policies | (Luthra and Mangla 2018) |

| C6 | Lesser resources for research and development | (Almada-Lobo 2016; Prajapati et al. 2019) |

| C7 | No solid, long-term vision | (Feng et al. 2018; Luthra and Mangla 2018) |

| C8 | Little enthusiasm from stakeholders | (Marques et al. 2017; Prajapati et al. 2019) |

| C9 | Lack of IT-based infrastructure (software and hardware) | (Pfohl et al. 2017; Sharma et al. 2020) |

| C10 | Untrained and unskilled personnel | (Luthra and Mangla 2018; Sommer 2015) |

| C11 | Little coordination and association between SCM members | (Prajapati et al. 2019) |

| C12 | Leading to unemployment in society | (Satapathy 2017; Zezulka et al. 2016) |

| C13 | Doubt about the sustainability of I 4.0 | (Jain et al. 2016; Pfohl et al. 2017) |

| C14 | Lack of alternate solutions to the technological breakdown | (Prajapati et al. 2019) |

| C15 | Uncertain predicted demand for a product | (Luthra and Mangla 2018) |

| Sr. No | Code | Working Profile | Designation | Area of Expertise | Experience |

|---|---|---|---|---|---|

| 1 | A-1 | Academia | Associate Professor at University | Management | 22 Years |

| 2 | A-2 | Academia | Associate Professor at University | Marketing | 20 Years |

| 3 | A-3 | Academia | Associate Professor at Management Institute | Mechanical Engineer | 17 Years |

| 4 | A-4 | Academia | Assistant Professor in a college | Mechanical Engineer | 13 Years |

| 5 | A-5 | Academia | Assistant Professor in a college | Mechanical Engineer | 13 Years |

| 6 | A-6 | Academia | Assistant Professor in a college | Computer Science Engineer | 12 Years |

| 7 | I-1 | Industry | Owner of a Textile MSME Unit | Engineer by qualification | 36 Years |

| 8 | I-2 | Industry | Area Manager in a Cycle MSME Unit | Production Head in the assembly unit | 22 Years |

| 9 | I-3 | Industry | Production Manager in a Tyre Manufacturing Unit | Chemical Engineering | 21 Years |

| 10 | I-4 | Industry | Technical Engineer in a Sewing Machine Unit | Electrical Engineering | 20 Years |

| 11 | G-1 | Ministry of MSME | Assistant Director (Mechanical) | Mechanical engineer | 15 Years |

| 12 | G-2 | Ministry of MSME | Assistant Director (Electrical) | Electrical Engineer | 13 Years |

| Challenge Code | C15 | C14 | C13 | C12 | C11 | C10 | C9 | C8 | C7 | C6 | C5 | C4 | C3 | C2 | C1 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| C1 | O | V | V | V | X | V | X | V | V | V | X | V | X | V | |

| C2 | O | V | V | V | V | V | V | A | V | V | V | V | V | ||

| C3 | V | V | V | V | X | X | V | A | V | X | V | V | |||

| C4 | O | V | V | O | V | V | V | A | A | X | O | ||||

| C5 | O | V | V | V | V | V | V | A | V | V | |||||

| C6 | V | V | V | V | V | V | V | A | V | ||||||

| C7 | V | V | V | V | V | V | V | A | |||||||

| C8 | V | V | V | V | V | V | V | ||||||||

| C9 | V | V | V | V | V | V | |||||||||

| C10 | V | V | V | V | V | ||||||||||

| C11 | V | V | V | V | |||||||||||

| C12 | O | O | V | ||||||||||||

| C13 | O | V | |||||||||||||

| C14 | V | ||||||||||||||

| C15 |

| Symbol | V | A | X | O |

|---|---|---|---|---|

| For (i, j) cell | 1 | 0 | 1 | 0 |

| For (j, i) cell | 0 | 1 | 1 | 0 |

| Challenge Code | C1 | C2 | C3 | C4 | C5 | C6 | C7 | C8 | C9 | C10 | C11 | C12 | C13 | C14 | C15 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| C1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 0 |

| C2 | 0 | 1 | 1 | 1 | 1 | 1 | 1 | 0 | 1 | 1 | 1 | 1 | 1 | 1 | 0 |

| C3 | 1 | 0 | 1 | 1 | 1 | 1 | 1 | 0 | 1 | 1 | 1 | 1 | 1 | 1 | 1 |

| C4 | 0 | 0 | 0 | 1 | 0 | 1 | 0 | 0 | 1 | 1 | 1 | 0 | 1 | 1 | 0 |

| C5 | 1 | 0 | 0 | 0 | 1 | 1 | 1 | 0 | 1 | 1 | 1 | 1 | 1 | 1 | 0 |

| C6 | 0 | 0 | 1 | 1 | 0 | 1 | 1 | 0 | 1 | 1 | 1 | 1 | 1 | 1 | 1 |

| C7 | 0 | 0 | 0 | 1 | 0 | 0 | 1 | 0 | 1 | 1 | 1 | 1 | 1 | 1 | 1 |

| C8 | 0 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 |

| C9 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 1 | 1 | 1 | 1 | 1 | 1 |

| C10 | 0 | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 1 | 1 | 1 | 1 | 1 |

| C11 | 1 | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 1 | 1 | 1 | 1 |

| C12 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 1 | 0 | 0 |

| C13 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 1 | 0 |

| C14 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 1 |

| C15 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 |

| Challenge Code | C1 | C2 | C3 | C4 | C5 | C6 | C7 | C8 | C9 | C10 | C11 | C12 | C13 | C14 | C15 | Driving Power |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| C1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1* | 15 |

| C2 | 1* | 1 | 1 | 1 | 1 | 1 | 1 | 0 | 1 | 1 | 1 | 1 | 1 | 1 | 1* | 14 |

| C3 | 1 | 1* | 1 | 1 | 1 | 1 | 1 | 1* | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 15 |

| C4 | 1* | 0 | 1* | 1 | 0 | 1 | 1* | 0 | 1 | 1 | 1 | 1* | 1 | 1 | 1* | 12 |

| C5 | 1 | 1* | 1* | 1* | 1 | 1 | 1 | 1* | 1 | 1 | 1 | 1 | 1 | 1 | 1* | 15 |

| C6 | 1* | 0 | 1 | 1 | 1* | 1 | 1 | 0 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 13 |

| C7 | 1* | 0 | 1* | 1 | 0 | 1* | 1 | 0 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 12 |

| C8 | 1* | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 15 |

| C9 | 1 | 1* | 1* | 1* | 1* | 1* | 1* | 1* | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 15 |

| C10 | 1* | 0 | 1 | 1* | 1* | 1* | 1* | 0 | 1* | 1 | 1 | 1 | 1 | 1 | 1 | 13 |

| C11 | 1 | 1* | 1 | 1* | 1* | 1* | 1* | 1* | 1* | 1* | 1 | 1 | 1 | 1 | 1 | 15 |

| C12 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 1 | 1* | 0 | 3 |

| C13 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 1 | 1* | 3 |

| C14 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 1 | 2 |

| C15 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 1 |

| Dependence Power | 11 | 7 | 11 | 11 | 9 | 11 | 11 | 6 | 11 | 11 | 11 | 12 | 13 | 14 | 14 |

| Challenge | Reachability Set | Antecedent Set | Intersection Set | Level |

|---|---|---|---|---|

| C1 | 1, 2, 3, 4, 5, 6, 7, 8, 9, 10, 11, 12, 13, 14, 15 | 1, 2, 3, 4, 5, 6, 7, 8, 9, 10, 11 | 1, 2, 3, 4, 5, 6, 7, 8, 9, 10, 11 | |

| C2 | 1, 2, 3, 4, 5, 6, 7, 9, 10, 11, 12, 13, 14, 15 | 1, 2, 3, 5, 8, 9, 11 | 1, 2, 3, 5, 9, 11 | |

| C3 | 1, 2, 3, 4, 5, 6, 7, 8, 9, 10, 11, 12, 13, 14, 15 | 1, 2, 3, 4, 5, 6, 7, 8, 9, 10, 11 | 1, 2, 3, 4, 5, 6, 7, 8, 9, 10, 11 | |

| C4 | 1, 3, 4, 6, 7, 9, 10, 11, 12, 13, 14, 15 | 1, 2, 3, 4, 5, 6, 7, 8, 9, 10, 11 | 1, 3, 4, 6, 7, 9, 10, 11 | |

| C5 | 1, 2, 3, 4, 5, 6, 7, 8, 9, 10, 11, 12, 13, 14, 15 | 1, 2, 3, 5, 6, 8, 9, 10, 11 | 1, 2, 3, 5, 6, 8, 9, 10, 11 | |

| C6 | 1, 3, 4, 5, 6, 7, 9, 10, 11, 12, 13, 14, 15 | 1, 2, 3, 4, 5, 6, 7, 8, 9, 10, 11 | 1, 3, 4, 5, 6, 7, 9, 10, 11 | |

| C7 | 1, 3, 4, 6, 7, 9, 10, 11, 12, 13, 14, 15 | 1, 2, 3, 4, 5, 6, 7, 8, 9, 10, 11 | 1, 3, 4, 6, 7, 9, 10, 11 | |

| C8 | 1, 2, 3, 4, 5, 6, 7, 8, 9, 10, 11, 12, 13, 14, 15 | 1, 3, 5, 8, 9, 11 | 1, 3, 5, 8, 9, 11 | |

| C9 | 1, 2, 3, 4, 5, 6, 7, 8, 9, 10, 11, 12, 13, 14, 15 | 1, 2, 3, 4, 5, 6, 7, 8, 9, 10, 11 | 1, 2, 3, 4, 5, 6, 7, 8, 9, 10, 11 | |

| C10 | 1, 3, 4, 6, 7, 9, 10, 11, 12, 13, 14, 15 | 1, 2, 3, 4, 5, 6, 7, 8, 9, 10, 11 | 1, 3, 4, 6, 7, 9, 10, 11 | |

| C11 | 1, 2, 3, 4, 5, 6, 7, 8, 9, 10, 11, 12, 13, 14, 15 | 1, 2, 3, 4, 5, 6, 7, 8, 9, 10, 11 | 1, 2, 3, 4, 5, 6, 7, 8, 9, 10, 11 | |

| C12 | 12, 13, 14 | 1, 2, 3, 4, 5, 6, 7, 8, 9, 10, 11, 12 | 12 | |

| C13 | 13, 14, 15 | 1, 2, 3, 4, 5, 6, 7, 8, 9, 10, 11, 12, 13 | 13 | |

| C14 | 14, 15 | 1, 2, 3, 4, 5, 6, 7, 8, 9, 10, 11, 12, 13, 14 | 14 | |

| C15 | 15 | 1, 2, 3, 4, 5, 6, 7, 8, 9, 10, 11, 13, 14, 15 | 15 | I |

| Challenge | Reachability Set | Antecedent Set | Intersection Set | Level |

|---|---|---|---|---|

| C1 | 1, 2, 3, 4, 5, 6, 7, 8, 9, 10, 11, 12, 13, 14, | 1, 2, 3, 4, 5, 6, 7, 8, 9, 10, 11 | 1, 2, 3, 4, 5, 6, 7, 8, 9, 10, 11 | |

| C2 | 1, 2, 3, 4, 5, 6, 7, 9, 10, 11, 12, 13, 14, | 1, 2, 3, 5, 8, 9, 11 | 1, 2, 3, 5, 9, 11 | |

| C3 | 1, 2, 3, 4, 5, 6, 7, 8, 9, 10, 11, 12, 13, 14, | 1, 2, 3, 4, 5, 6, 7, 8, 9, 10, 11 | 1, 2, 3, 4, 5, 6, 7, 8, 9, 10, 11 | |

| C4 | 1, 3, 4, 6, 7, 9, 10, 11, 12, 13, 14, | 1, 2, 3, 4, 5, 6, 7, 8, 9, 10, 11 | 1, 3, 4, 6, 7, 9, 10, 11 | |

| C5 | 1, 2, 3, 4, 5, 6, 7, 8, 9, 10, 11, 12, 13, 14, | 1, 2, 3, 5, 6, 8, 9, 10, 11 | 1, 2, 3, 5, 6, 8, 9, 10, 11 | |

| C6 | 1, 3, 4, 5, 6, 7, 9, 10, 11, 12, 13, 14, | 1, 2, 3, 4, 5, 6, 7, 8, 9, 10, 11 | 1, 3, 4, 5, 6, 7, 9, 10, 11 | |

| C7 | 1, 3, 4, 6, 7, 9, 10, 11, 12, 13, 14, | 1, 2, 3, 4, 5, 6, 7, 8, 9, 10, 11 | 1, 3, 4, 6, 7, 9, 10, 11 | |

| C8 | 1, 2, 3, 4, 5, 6, 7, 8, 9, 10, 11, 12, 13, 14, | 1, 3, 5, 8, 9, 11 | 1, 3, 5, 8, 9, 11 | |

| C9 | 1, 2, 3, 4, 5, 6, 7, 8, 9, 10, 11, 12, 13, 14, | 1, 2, 3, 4, 5, 6, 7, 8, 9, 10, 11 | 1, 2, 3, 4, 5, 6, 7, 8, 9, 10, 11 | |

| C10 | 1, 3, 4, 6, 7, 9, 10, 11, 12, 13, 14, | 1, 2, 3, 4, 5, 6, 7, 8, 9, 10, 11 | 1, 3, 4, 6, 7, 9, 10, 11 | |

| C11 | 1, 2, 3, 4, 5, 6, 7, 8, 9, 10, 11, 12, 13, 14, | 1, 2, 3, 4, 5, 6, 7, 8, 9, 10, 11 | 1, 2, 3, 4, 5, 6, 7, 8, 9, 10, 11 | |

| C12 | 12, 13, 14 | 1, 2, 3, 4, 5, 6, 7, 8, 9, 10, 11, 12 | 12 | |

| C13 | 13, 14 | 1, 2, 3, 4, 5, 6, 7, 8, 9, 10, 11, 12, 13 | 13 | |

| C14 | 14 | 1, 2, 3, 4, 5, 6, 7, 8, 9, 10, 11, 12, 13, 14 | 14 | II |

| Challenge | Reachability Set | Antecedent Set | Intersection Set | Level |

|---|---|---|---|---|

| C1 | 1, 2, 3, 4, 5, 6, 7, 8, 9, 10, 11, 12, 13 | 1, 2, 3, 4, 5, 6, 7, 8, 9, 10, 11 | 1, 2, 3, 4, 5, 6, 7, 8, 9, 10, 11 | |

| C2 | 1, 2, 3, 4, 5, 6, 7, 9, 10, 11, 12, 13 | 1, 2, 3, 5, 8, 9, 11 | 1, 2, 3, 5, 9, 11 | |

| C3 | 1, 2, 3, 4, 5, 6, 7, 8, 9, 10, 11, 12, 13 | 1, 2, 3, 4, 5, 6, 7, 8, 9, 10, 11 | 1, 2, 3, 4, 5, 6, 7, 8, 9, 10, 11 | |

| C4 | 1, 3, 4, 6, 7, 9, 10, 11, 12, 13 | 1, 2, 3, 4, 5, 6, 7, 8, 9, 10, 11 | 1, 3, 4, 6, 7, 9, 10, 11 | |

| C5 | 1, 2, 3, 4, 5, 6, 7, 8, 9, 10, 11, 12, 13 | 1, 2, 3, 5, 6, 8, 9, 10, 11 | 1, 2, 3, 5, 6, 8, 9, 10, 11 | |

| C6 | 1, 3, 4, 5, 6, 7, 9, 10, 11, 12, 13 | 1, 2, 3, 4, 5, 6, 7, 8, 9, 10, 11 | 1, 3, 4, 5, 6, 7, 9, 10, 11 | |

| C7 | 1, 3, 4, 6, 7, 9, 10, 11, 12, 13 | 1, 2, 3, 4, 5, 6, 7, 8, 9, 10, 11 | 1, 3, 4, 6, 7, 9, 10, 11 | |

| C8 | 1, 2, 3, 4, 5, 6, 7, 8, 9, 10, 11, 12, 13 | 1, 3, 5, 8, 9, 11 | 1, 3, 5, 8, 9, 11 | |

| C9 | 1, 2, 3, 4, 5, 6, 7, 8, 9, 10, 11, 12, 13 | 1, 2, 3, 4, 5, 6, 7, 8, 9, 10, 11 | 1, 2, 3, 4, 5, 6, 7, 8, 9, 10, 11 | |

| C10 | 1, 3, 4, 6, 7, 9, 10, 11, 12, 13 | 1, 2, 3, 4, 5, 6, 7, 8, 9, 10, 11 | 1, 3, 4, 6, 7, 9, 10, 11 | |

| C11 | 1, 2, 3, 4, 5, 6, 7, 8, 9, 10, 11, 12, 13 | 1, 2, 3, 4, 5, 6, 7, 8, 9, 10, 11 | 1, 2, 3, 4, 5, 6, 7, 8, 9, 10, 11 | |

| C12 | 12, 13 | 1, 2, 3, 4, 5, 6, 7, 8, 9, 10, 11, 12 | 12 | |

| C13 | 13 | 1, 2, 3, 4, 5, 6, 7, 8, 9, 10, 11, 12, 13 | 13 | III |

| Challenge Code | Challenges | Level |

|---|---|---|

| C1 | Little awareness | V |

| C2 | Little managerial support | VI |

| C3 | Little technical knowledge | V |

| C4 | Insufficient funds | V |

| C5 | No clear government policies | VI |

| C6 | Lesser resources for research and development | V |

| C7 | No solid, long-term vision | V |

| C8 | Little enthusiasm from stakeholders | VII |

| C9 | Lack of IT-based infrastructure (software and hardware) | V |

| C10 | Untrained and unskilled personnel | V |

| C11 | Little coordination and association between SCM members | V |

| C12 | Leading to unemployment in the society | IV |

| C13 | Doubt about the sustainability of I 4.0 | III |

| C14 | Lack of alternate solutions to the technological breakdown | II |

| C15 | Uncertain predicted demand for a product | I |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Goel, P.; Kumar, R.; Banga, H.K.; Kaur, S.; Kumar, R.; Pimenov, D.Y.; Giasin, K. Deployment of Interpretive Structural Modeling in Barriers to Industry 4.0: A Case of Small and Medium Enterprises. J. Risk Financial Manag. 2022, 15, 171. https://doi.org/10.3390/jrfm15040171

Goel P, Kumar R, Banga HK, Kaur S, Kumar R, Pimenov DY, Giasin K. Deployment of Interpretive Structural Modeling in Barriers to Industry 4.0: A Case of Small and Medium Enterprises. Journal of Risk and Financial Management. 2022; 15(4):171. https://doi.org/10.3390/jrfm15040171

Chicago/Turabian StyleGoel, Pankaj, Raman Kumar, Harish Kumar Banga, Swapandeep Kaur, Rajesh Kumar, Danil Yurievich Pimenov, and Khaled Giasin. 2022. "Deployment of Interpretive Structural Modeling in Barriers to Industry 4.0: A Case of Small and Medium Enterprises" Journal of Risk and Financial Management 15, no. 4: 171. https://doi.org/10.3390/jrfm15040171