Feasibility of Biochar Derived from Sewage Sludge to Promote Sustainable Agriculture and Mitigate GHG Emissions—A Review

Abstract

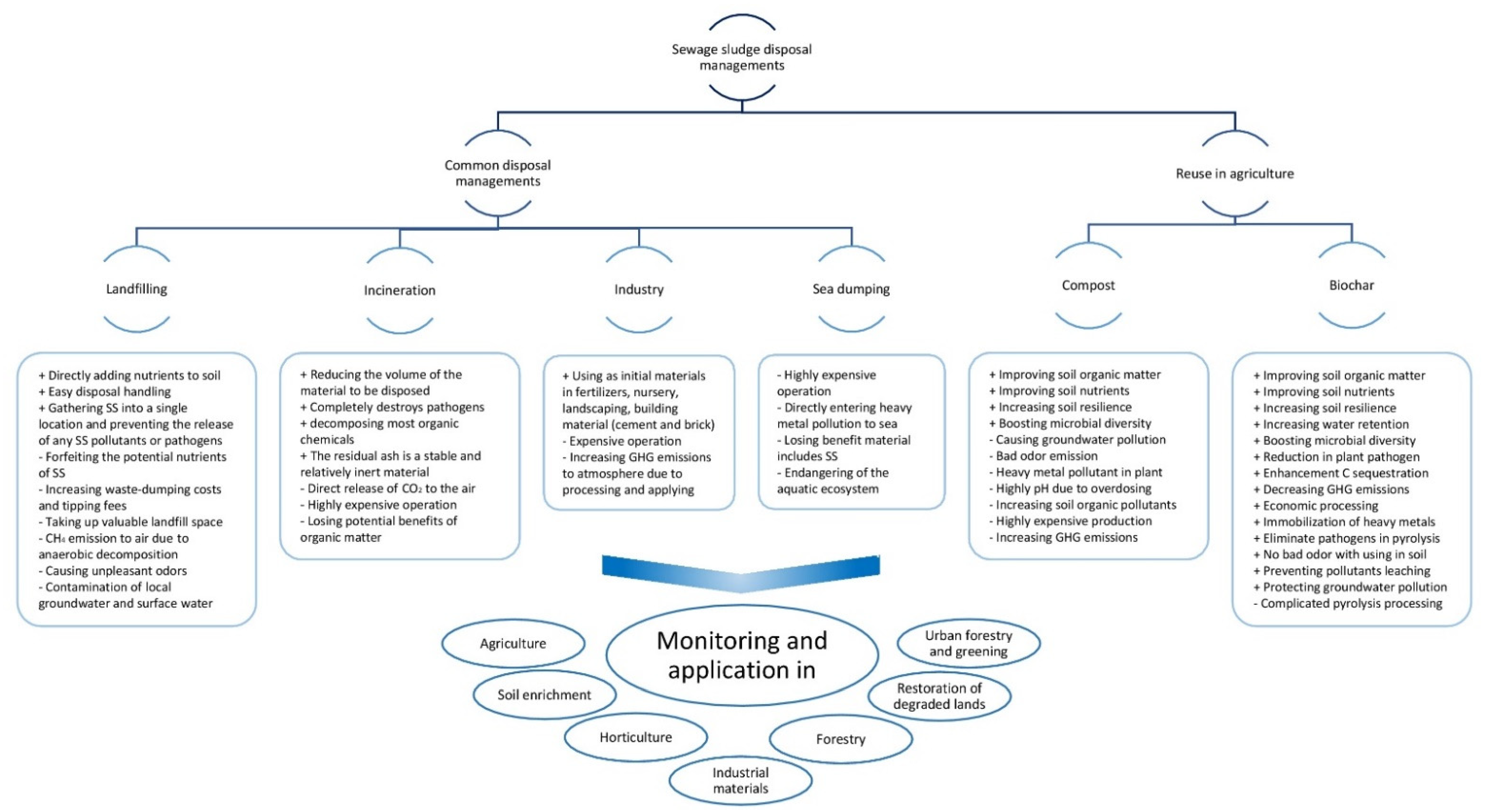

:1. Introduction

2. Importance of SS as Feedstock for Biochar Production

3. SSB Production and Characterization

4. Characteristics of SSB

4.1. PH

4.2. Elemental Composition

5. Sewage Sludge Biochar as Soil Amendment

6. Comparison between SSB and Sewage Sludge Compost (SSC) for Agricultural Purposes

6.1. Nutrient Status

6.2. Plant Growth

6.3. Heavy Metals and Pesticides

6.4. Organic Pollutants

6.5. Processing

7. Importance of SS Conversion from the Perspective of GHG Emission Concerns

7.1. SSB Potential to Reduce GHG Emissions

7.2. Comparison between SSB and Other SS Methods for Managing GHG Emissions

7.2.1. Landfilling

7.2.2. Incineration

7.2.3. Composting

7.2.4. Industrial Recovery

8. Socio-Economic Potential of SSB

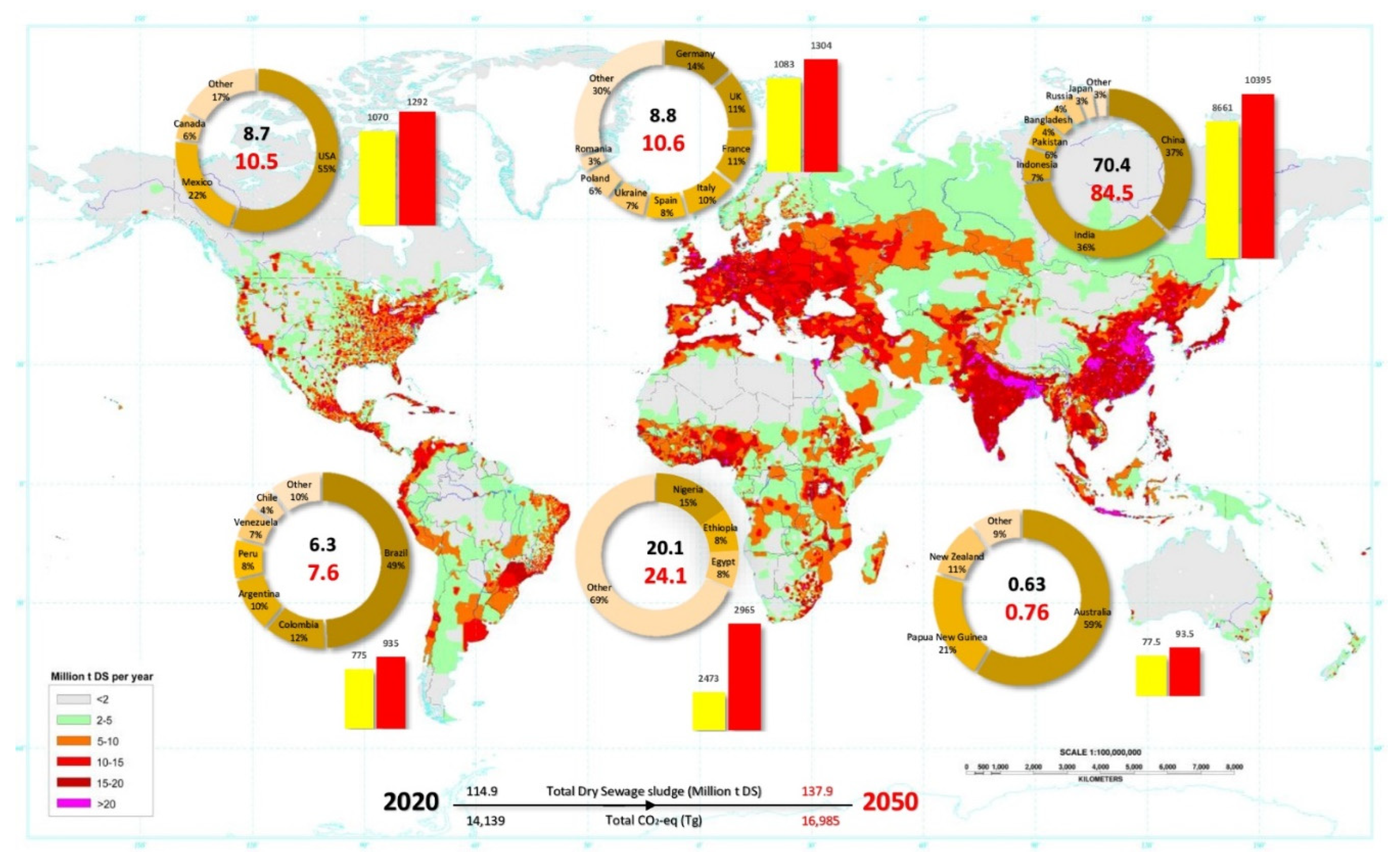

9. Approximate Prediction of Global SS and CO2-eq Emissions from it in 2050

10. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

References

- Kacprzak, M.; Neczaj, E.; Fijałkowski, K.; Grobelak, A.; Grosser, A.; Worwag, M.; Rorat, A.; Brattebo, H.; Almås, Å.; Singh, B.R. Sewage Sludge Disposal Strategies for Sustainable Development. Environ. Res. 2017, 156, 39–46. [Google Scholar] [CrossRef] [PubMed]

- Inoue, S.; Sawayama, S.; Ogi, T.; Yokoyama, S. Organic Composition of Liquidized Sewage Sludge. Biomass Bioenergy 1996, 10, 37–40. [Google Scholar] [CrossRef]

- Christodoulou, A.; Stamatelatou, K. Overview of Legislation on Sewage Sludge Management in Developed Countries Worldwide. Water Sci. Technol. 2016, 73, 453–462. [Google Scholar] [CrossRef] [PubMed]

- Wang, J.; Zhang, D.; Stabnikova, O.; Tay, J. Evaluation of Electrokinetic Removal of Heavy Metals from Sewage Sludge. J. Hazard. Mater. 2005, 124, 139–146. [Google Scholar] [CrossRef] [PubMed]

- Di Giacomo, G.; Romano, P. Evolution and Prospects in Managing Sewage Sludge Resulting from Municipal Wastewater Purification. Energies 2022, 15, 5633. [Google Scholar] [CrossRef]

- Rorat, A.; Courtois, P.; Vandenbulcke, F.; Lemiere, S. Sanitary and Environmental Aspects of Sewage Sludge Management. In Industrial and Municipal Sludge; Elsevier: Amsterdam, The Netherlands, 2019; pp. 155–180. [Google Scholar] [CrossRef]

- Mateo-Sagasta, J.; Raschid-Sally, L.; Thebo, A. Global Wastewater and Sludge Production, Treatment and Use. In Wastewater; Springer: Dordrecht, The Netherlands, 2015; pp. 15–38. [Google Scholar] [CrossRef]

- Zhang, Q.; Hu, J.; Lee, D.-J.; Chang, Y.; Lee, Y.-J. Sludge Treatment: Current Research Trends. Bioresour. Technol. 2017, 243, 1159–1172. [Google Scholar] [CrossRef]

- Piippo, S.; Lauronen, M.; Postila, H. Greenhouse Gas Emissions from Different Sewage Sludge Treatment Methods in North. J. Clean. Prod. 2018, 177, 483–492. [Google Scholar] [CrossRef] [Green Version]

- Koutsou, O.P.; Gatidou, G.; Stasinakis, A.S. Domestic Wastewater Management in Greece: Greenhouse Gas Emissions Estimation at Country Scale. J. Clean. Prod. 2018, 188, 851–859. [Google Scholar] [CrossRef]

- Shaddel, S.; Bakhtiary-Davijany, H.; Kabbe, C.; Dadgar, F.; Østerhus, S. Sustainable Sewage Sludge Management: From Current Practices to Emerging Nutrient Recovery Technologies. Sustainability 2019, 11, 3435. [Google Scholar] [CrossRef] [Green Version]

- Badgett, A.; Newes, E.; Milbrandt, A. Economic Analysis of Wet Waste-to-Energy Resources in the United States. Energy 2019, 176, 224–234. [Google Scholar] [CrossRef]

- US EPA. Handbook Estimating Sludge Management Costs; US EPA: Dayton, OH, USA, 2015. [Google Scholar]

- Xu, Y.; Naidoo, A.R.; Zhang, X.-F.; Meng, X.-Z. Optimizing Sampling Strategy for Chinese National Sewage Sludge Survey (CNSSS) Based on Urban Agglomeration, Wastewater Treatment Process, and Treatment Capacity. Sci. Total Environ. 2019, 696, 133998. [Google Scholar] [CrossRef]

- Cameron, K.C.; Di, H.J.; Moir, J.L. Nitrogen Losses from the Soil/Plant System: A Review. Ann. Appl. Biol. 2013, 162, 145–173. [Google Scholar] [CrossRef]

- Lamastra, L.; Suciu, N.A.; Trevisan, M. Sewage Sludge for Sustainable Agriculture: Contaminants’ Contents and Potential Use as Fertilizer. Chem. Biol. Technol. Agric. 2018, 5, 10. [Google Scholar] [CrossRef] [Green Version]

- Lü, H.; Chen, X.-H.; Mo, C.-H.; Huang, Y.-H.; He, M.-Y.; Li, Y.-W.; Feng, N.-X.; Katsoyiannis, A.; Cai, Q.-Y. Occurrence and Dissipation Mechanism of Organic Pollutants during the Composting of Sewage Sludge: A Critical Review. Bioresour. Technol. 2021, 328, 124847. [Google Scholar] [CrossRef] [PubMed]

- Wei, L.; Zhu, F.; Li, Q.; Xue, C.; Xia, X.; Yu, H.; Zhao, Q.; Jiang, J.; Bai, S. Development, Current State and Future Trends of Sludge Management in China: Based on Exploratory Data and CO2-Equivaient Emissions Analysis. Environ. Int. 2020, 144, 106093. [Google Scholar] [CrossRef]

- Lu, Y.; Zheng, G.; Zhou, W.; Wang, J.; Zhou, L. Bioleaching Conditioning Increased the Bioavailability of Polycyclic Aromatic Hydrocarbons to Promote Their Removal during Co-Composting of Industrial and Municipal Sewage Sludges. Sci. Total Environ. 2019, 665, 1073–1082. [Google Scholar] [CrossRef]

- Fijalkowski, K.; Rorat, A.; Grobelak, A.; Kacprzak, M.J. The Presence of Contaminations in Sewage Sludge—The Current Situation. J. Environ. Manag. 2017, 203, 1126–1136. [Google Scholar] [CrossRef]

- Oni, B.A.; Oziegbe, O.; Olawole, O.O. Significance of Biochar Application to the Environment and Economy. Ann. Agric. Sci. 2019, 64, 222–236. [Google Scholar] [CrossRef]

- Méndez, A.; Cárdenas-Aguiar, E.; Paz-Ferreiro, J.; Plaza, C.; Gascó, G. The Effect of Sewage Sludge Biochar on Peat-Based Growing Media. Biol. Agric. Hortic. 2017, 33, 40–51. [Google Scholar] [CrossRef]

- Phoungthong, K.; Zhang, H.; Shao, L.-M.; He, P.-J. Leaching Characteristics and Phytotoxic Effects of Sewage Sludge Biochar. J. Mater. Cycles Waste Manag. 2018, 20, 2089–2099. [Google Scholar] [CrossRef]

- You, J.; Sun, L.; Liu, X.; Hu, X.; Xu, Q. Effects of Sewage Sludge Biochar on Soil Characteristics and Crop Yield in Loamy Sand Soil. Pol. J. Environ. Stud. 2019, 28, 2973–2980. [Google Scholar] [CrossRef]

- Chagas, J.K.M.; de Figueiredo, C.C.; da Silva, J.; Paz-Ferreiro, J. The Residual Effect of Sewage Sludge Biochar on Soil Availability and Bioaccumulation of Heavy Metals: Evidence from a Three-Year Field Experiment. J. Environ. Manag. 2021, 279, 111824. [Google Scholar] [CrossRef] [PubMed]

- Lasaridi, K.-E.; Manios, T.; Stamatiadis, S.; Chroni, C.; Kyriacou, A. The Evaluation of Hazards to Man and the Environment during the Composting of Sewage Sludge. Sustainability 2018, 10, 2618. [Google Scholar] [CrossRef] [Green Version]

- Havukainen, J.; Zhan, M.; Dong, J.; Liikanen, M.; Deviatkin, I.; Li, X.; Horttanainen, M. Environmental Impact Assessment of Municipal Solid Waste Management Incorporating Mechanical Treatment of Waste and Incineration in Hangzhou, China. J. Clean. Prod. 2017, 141, 453–461. [Google Scholar] [CrossRef]

- Li, Y.; Shi, S.; Zhang, L.; Liu, Y. Global Trends and Performances of Publication on Sewage Sludge from 1991 to 2012. Procedia Environ. Sci. 2016, 31, 65–74. [Google Scholar] [CrossRef] [Green Version]

- Eggleston, H.; Leandro, B.; Kyoko, M.; Todd, N.; Kiyoto, T. 2006 IPCC Guidelines for National Greenhouse Gas Inventories; U.S. Department of Energy Office of Scientific and Technical Information: Washington, DC, USA, 2006. [Google Scholar]

- Eurostat. Sewage Sludge Production and Disposal from Urban Wastewater; Eurostat: Luxembourg, 2019. [Google Scholar]

- Nakao, S.; Akita, K.; Ozaki, A.; Masumoto, K.; Okuda, T. Circulation of Fibrous Microplastic (Microfiber) in Sewage and Sewage Sludge Treatment Processes. Sci. Total Environ. 2021, 795, 148873. [Google Scholar] [CrossRef]

- Shan, Y.; Lv, M.; Zuo, W.; Tang, Z.; Ding, C.; Yu, Z.; Shen, Z.; Gu, C.; Bai, Y. Sewage Sludge Application Enhances Soil Properties and Rice Growth in a Salt-Affected Mudflat Soil. Sci. Rep. 2021, 11, 1402. [Google Scholar] [CrossRef]

- Ai, Y.-J.; Li, F.-P.; Gu, H.-H.; Chi, X.-J.; Yuan, X.-T.; Han, D.-Y. Combined Effects of Green Manure Returning and Addition of Sewage Sludge Compost on Plant Growth and Microorganism Communities in Gold Tailings. Environ. Sci. Pollut. Res. 2020, 27, 31686–31698. [Google Scholar] [CrossRef]

- Jakubus, M.; Graczyk, M. Microelement Variability in Plants as an Effect of Sewage Sludge Compost Application Assessed by Different Statistical Methods. Agronomy 2020, 10, 642. [Google Scholar] [CrossRef]

- Buta, M.; Hubeny, J.; Zieliński, W.; Harnisz, M.; Korzeniewska, E. Sewage Sludge in Agriculture—The Effects of Selected Chemical Pollutants and Emerging Genetic Resistance Determinants on the Quality of Soil and Crops—A Review. Ecotoxicol. Environ. Saf. 2021, 214, 112070. [Google Scholar] [CrossRef]

- De Souza Souza, C.; Bomfim, M.R.; da Conceição de Almeida, M.; de Souza Alves, L.; de Santana, W.N.; da Silva Amorim, I.C.; Santos, J.A.G. Induced Changes of Pyrolysis Temperature on the Physicochemical Traits of Sewage Sludge and on the Potential Ecological Risks. Sci. Rep. 2021, 11, 974. [Google Scholar] [CrossRef] [PubMed]

- Jin, J.; Li, Y.; Zhang, J.; Wu, S.; Cao, Y.; Liang, P.; Zhang, J.; Wong, M.H.; Wang, M.; Shan, S.; et al. Influence of Pyrolysis Temperature on Properties and Environmental Safety of Heavy Metals in Biochars Derived from Municipal Sewage Sludge. J. Hazard. Mater. 2016, 320, 417–426. [Google Scholar] [CrossRef] [PubMed]

- Tian, Y.; Cui, L.; Lin, Q.; Li, G.; Zhao, X. The Sewage Sludge Biochar at Low Pyrolysis Temperature Had Better Improvement in Urban Soil and Turf Grass. Agronomy 2019, 9, 156. [Google Scholar] [CrossRef] [Green Version]

- Lin, Y.-Y.; Chen, W.-H.; Liu, H.-C. Aging and Emulsification Analyses of Hydrothermal Liquefaction Bio-Oil Derived from Sewage Sludge and Swine Leather Residue. J. Clean. Prod. 2020, 266, 122050. [Google Scholar] [CrossRef]

- Xiao, Y.; Raheem, A.; Ding, L.; Chen, W.-H.; Chen, X.; Wang, F.; Lin, S.-L. Pretreatment, Modification and Applications of Sewage Sludge-Derived Biochar for Resource Recovery—A Review. Chemosphere 2022, 287, 131969. [Google Scholar] [CrossRef]

- Khanmohammadi, Z.; Afyuni, M.; Mosaddeghi, M.R. Effect of Pyrolysis Temperature on Chemical and Physical Properties of Sewage Sludge Biochar. Waste Manag. Res. J. Sustain. Circ. Econ. 2015, 33, 275–283. [Google Scholar] [CrossRef]

- Zielińska, A.; Oleszczuk, P.; Charmas, B.; Skubiszewska-Zięba, J.; Pasieczna-Patkowska, S. Effect of Sewage Sludge Properties on the Biochar Characteristic. J. Anal. Appl. Pyrolysis 2015, 112, 201–213. [Google Scholar] [CrossRef]

- Raynaud, M.; Vaxelaire, J.; Olivier, J.; Dieudé-Fauvel, E.; Baudez, J.-C. Compression Dewatering of Municipal Activated Sludge: Effects of Salt and PH. Water Res. 2012, 46, 4448–4456. [Google Scholar] [CrossRef]

- Zhang, C.; Ho, S.-H.; Chen, W.-H.; Eng, C.F.; Wang, C.-T. Simultaneous Implementation of Sludge Dewatering and Solid Biofuel Production by Microwave Torrefaction. Environ. Res. 2021, 195, 110775. [Google Scholar] [CrossRef]

- Fytili, D.; Zabaniotou, A. Utilization of Sewage Sludge in EU Application of Old and New Methods—A Review. Renew. Sustain. Energy Rev. 2008, 12, 116–140. [Google Scholar] [CrossRef]

- Naqvi, S.R.; Tariq, R.; Hameed, Z.; Ali, I.; Naqvi, M.; Chen, W.-H.; Ceylan, S.; Rashid, H.; Ahmad, J.; Taqvi, S.A.; et al. Pyrolysis of High Ash Sewage Sludge: Kinetics and Thermodynamic Analysis Using Coats-Redfern Method. Renew. Energy 2019, 131, 854–860. [Google Scholar] [CrossRef]

- Paz-Ferreiro, J.; Gascó, G.; Gutiérrez, B.; Méndez, A. Soil Biochemical Activities and the Geometric Mean of Enzyme Activities after Application of Sewage Sludge and Sewage Sludge Biochar to Soil. Biol. Fertil. Soils 2012, 48, 511–517. [Google Scholar] [CrossRef]

- Devi, P.; Saroha, A.K. Effect of Pyrolysis Temperature on Polycyclic Aromatic Hydrocarbons Toxicity and Sorption Behaviour of Biochars Prepared by Pyrolysis of Paper Mill Effluent Treatment Plant Sludge. Bioresour. Technol. 2015, 192, 312–320. [Google Scholar] [CrossRef] [PubMed]

- Wang, Z.; Shu, X.; Zhu, H.; Xie, L.; Cheng, S. Characteristics of Biochars Prepared by Co- Pyrolysis of Sewage Sludge and Cotton Stalk Intended for Use as Soil Amendments. Environ. Technol. 2018, 41, 1347–1357. [Google Scholar] [CrossRef]

- Zhang, X.; Zhao, B.; Liu, H.; Zhao, Y.; Li, L. Environmental Technology & Innovation Effects of Pyrolysis Temperature on Biochar’ s Characteristics and Speciation and Environmental Risks of Heavy Metals in Sewage Sludge Biochars. Environ. Technol. Innov. 2022, 26, 102288. [Google Scholar] [CrossRef]

- Titova, J.; Baltrėnaitė, E. Physical and Chemical Properties of Biochar Produced from Sewage Sludge Compost and Plants Biomass, Fertilized with That Compost, Important for Soil Improvement. Waste Biomass Valorization 2021, 12, 3781–3800. [Google Scholar] [CrossRef]

- Sousa, A.A.T.C.; Figueiredo, C.C. Sewage Sludge Biochar: Effects on Soil Fertility and Growth of Radish. Biol. Agric. Hortic. 2016, 32, 127–138. [Google Scholar] [CrossRef]

- Zhang, J.; Lü, F.; Zhang, H.; Shao, L.; Chen, D.; He, P. Multiscale Visualization of the Structural and Characteristic Changes of Sewage Sludge Biochar Oriented towards Potential Agronomic and Environmental Implication. Sci. Rep. 2015, 5, 9406. [Google Scholar] [CrossRef]

- Rehman, R.A.; Rizwan, M.; Qayyum, M.F.; Ali, S.; Zia-ur-Rehman, M.; Zafar-ul-Hye, M.; Hafeez, F.; Iqbal, M.F. Efficiency of Various Sewage Sludges and Their Biochars in Improving Selected Soil Properties and Growth of Wheat (Triticum Aestivum). J. Environ. Manag. 2018, 223, 607–613. [Google Scholar] [CrossRef]

- Lu, H.; Zhang, W.; Wang, S.; Zhuang, L.; Yang, Y.; Qiu, R. Journal of Analytical and Applied Pyrolysis Characterization of Sewage Sludge-Derived Biochars from Different Feedstocks and Pyrolysis Temperatures. J. Anal. Appl. Pyrolysis 2013, 102, 137–143. [Google Scholar] [CrossRef]

- Mierzwa-Hersztek, M.; Gondek, K.; Klimkowicz-Pawlas, A.; Baran, A.; Bajda, T. Sewage Sludge Biochars Management-Ecotoxicity, Mobility of Heavy Metals, and Soil Microbial Biomass. Environ. Toxicol. Chem. 2018, 37, 1197–1207. [Google Scholar] [CrossRef] [PubMed]

- Méndez, A.; Terradillos, M.; Gascó, G. Physicochemical and Agronomic Properties of Biochar from Sewage Sludge Pyrolysed at Different Temperatures. J. Anal. Appl. Pyrolysis 2013, 102, 124–130. [Google Scholar] [CrossRef]

- Khan, S.; Chao, C.; Waqas, M.; Arp, H.P.H.; Zhu, Y.-G. Sewage Sludge Biochar Influence upon Rice (Oryza sativa L.) Yield, Metal Bioaccumulation and Greenhouse Gas Emissions from Acidic Paddy Soil. Environ. Sci. Technol. 2013, 47, 8624–8632. [Google Scholar] [CrossRef] [PubMed]

- Gwenzi, W.; Muzava, M.; Mapanda, F.; Tauro, T.P. Comparative Short-Term Effects of Sewage Sludge and Its Biochar on Soil Properties, Maize Growth and Uptake of Nutrients on a Tropical Clay Soil in Zimbabwe. J. Integr. Agric. 2016, 15, 1395–1406. [Google Scholar] [CrossRef] [Green Version]

- Shao, Q.; Ju, Y.; Guo, W.; Xia, X.; Bian, R.; Li, L.; Li, W.; Liu, X.; Zheng, J.; Pan, G. Pyrolyzed Municipal Sewage Sludge Ensured Safe Grain Production While Reduced C Emissions in a Paddy Soil under Rice and Wheat Rotation. Environ. Sci. Pollut. Res. 2019, 26, 9244–9256. [Google Scholar] [CrossRef] [PubMed]

- Goldan, E.; Nedeff, V.; Barsan, N.; Culea, M.; Tomozei, C.; Panainte-Lehadus, M.; Mosnegutu, E. Evaluation of the Use of Sewage Sludge Biochar as a Soil Amendment—A Review. Sustainability 2022, 14, 5309. [Google Scholar] [CrossRef]

- Tarayre, C.; De Clercq, L.; Charlier, R.; Michels, E.; Meers, E.; Camargo-valero, M.; Delvigne, F. Bioresource Technology New Perspectives for the Design of Sustainable Bioprocesses for Phosphorus Recovery from Waste. 2016, 206, 264–274. Bioresour. Technol. [CrossRef] [Green Version]

- Ghorbani, M.; Amirahmadi, E.; Zamanian, K. In-situ Biochar Production Associated with Paddies: Direct Involvement of Farmers in Greenhouse Gases Reduction Policies besides Increasing Nutrients Availability and Rice Production. Land Degrad. Dev. 2021, 32, 3893–3904. [Google Scholar] [CrossRef]

- Spokas, K.A. Review of the Stability of Biochar in Soils: Predictability of O:C Molar Ratios. Carbon Manag. 2010, 1, 289–303. [Google Scholar] [CrossRef] [Green Version]

- Opatokun, S.A.; Strezov, V.; Kan, T. Product Based Evaluation of Pyrolysis of Food Waste and Its Digestate. Energy 2015, 92, 349–354. [Google Scholar] [CrossRef]

- Song, X.D.; Xue, X.Y.; Chen, D.Z.; He, P.J.; Dai, X.H. Application of Biochar from Sewage Sludge to Plant Cultivation: Influence of Pyrolysis Temperature and Biochar-to-Soil Ratio on Yield and Heavy Metal Accumulation. Chemosphere 2014, 109, 213–220. [Google Scholar] [CrossRef] [PubMed]

- Yuan, J.; Chadwick, D.; Zhang, D.; Li, G.; Chen, S.; Luo, W.; Du, L.; He, S.; Peng, S. Effects of Aeration Rate on Maturity and Gaseous Emissions during Sewage Sludge Composting. Waste Manag. 2016, 56, 403–410. [Google Scholar] [CrossRef] [PubMed]

- Yue, Y.; Cui, L.; Lin, Q.; Li, G.; Zhao, X. Efficiency of Sewage Sludge Biochar in Improving Urban Soil Properties and Promoting Grass Growth. Chemosphere 2017, 173, 551–556. [Google Scholar] [CrossRef]

- Faria, W.M.; de Figueiredo, C.C.; Coser, T.R.; Vale, A.T.; Schneider, B.G. Is Sewage Sludge Biochar Capable of Replacing Inorganic Fertilizers for Corn Production? Evidence from a Two-Year Field Experiment. Arch. Agron. Soil Sci. 2018, 64, 505–519. [Google Scholar] [CrossRef]

- Yu, O.-Y.; Raichle, B.; Sink, S. Impact of Biochar on the Water Holding Capacity of Loamy Sand Soil. Int. J. Energy Environ. Eng. 2013, 4, 44. [Google Scholar] [CrossRef] [Green Version]

- Filipović, V.; Černe, M.; Šimůnek, J.; Filipović, L.; Romić, M.; Ondrašek, G.; Bogunović, I.; Mustać, I.; Krevh, V.; Ferenčević, A.; et al. Modeling Water Flow and Phosphorus Sorption in a Soil Amended with Sewage Sludge and Olive Pomace as Compost or Biochar. Agronomy 2020, 10, 1163. [Google Scholar] [CrossRef]

- Razzaghi, F.; Obour, P.B.; Arthur, E. Does Biochar Improve Soil Water Retention? A Systematic Review and Meta-Analysis. Geoderma 2020, 361, 114055. [Google Scholar] [CrossRef]

- Velli, P.; Manolikaki, I.; Diamadopoulos, E. Effect of Biochar Produced from Sewage Sludge on Tomato (Solanum lycopersicum L.) Growth, Soil Chemical Properties and Heavy Metal Concentrations. J. Environ. Manag. 2021, 297, 113325. [Google Scholar] [CrossRef]

- Zhang, Y.; Chen, T.; Liao, Y.; Reid, B.J.; Chi, H.; Hou, Y.; Cai, C. Modest Amendment of Sewage Sludge Biochar to Reduce the Accumulation of Cadmium into Rice (Oryza Sativa L.): A Field Study. Environ. Pollut. 2016, 216, 819–825. [Google Scholar] [CrossRef] [Green Version]

- Liu, Z.; Demisie, W.; Zhang, M. Simulated Degradation of Biochar and Its Potential Environmental Implications. Environ. Pollut. 2013, 179, 146–152. [Google Scholar] [CrossRef]

- Duan, X.-Y.; Cao, Y.; Liu, T.-Z.; Li, L.; Wang, B.; Wang, X.-D. Nutrient Stability and Sorption of Sewage Sludge Biochar Prepared from Co-Pyrolysis of Sewage Sludge and Stalks/Mineral Materials. Environ. Pollut. Bioavailab. 2020, 32, 12–18. [Google Scholar] [CrossRef] [Green Version]

- De Figueiredo, C.C.; Reis, A.D.S.P.J.; de Araujo, A.S.; Blum, L.E.B.; Shah, K.; Paz-Ferreiro, J. Assessing the Potential of Sewage Sludge-Derived Biochar as a Novel Phosphorus Fertilizer: Influence of Extractant Solutions and Pyrolysis Temperatures. Waste Manag. 2021, 124, 144–153. [Google Scholar] [CrossRef] [PubMed]

- Grutzmacher, P.; Puga, A.P.; Bibar, M.P.S.; Coscione, A.R.; Packer, A.P.; de Andrade, C.A. Carbon Stability and Mitigation of Fertilizer Induced N2O Emissions in Soil Amended with Biochar. Sci. Total Environ. 2018, 625, 1459–1466. [Google Scholar] [CrossRef] [PubMed]

- Nafez, A.H.; Nikaeen, M.; Kadkhodaie, S.; Hatamzadeh, M.; Moghim, S. Sewage Sludge Composting: Quality Assessment for Agricultural Application. Environ. Monit. Assess. 2015, 187, 709. [Google Scholar] [CrossRef]

- Kumar, V.; Chopra, A.K.; Kumar, A. A Review on Sewage Sludge (Biosolids) a Resource for Sustainable Agriculture. Arch. Agric. Environ. Sci. 2017, 2, 340–347. [Google Scholar] [CrossRef]

- Song, U.; Lee, E.J. Environmental and Economical Assessment of Sewage Sludge Compost Application on Soil and Plants in a Landfill. Resour. Conserv. Recycl. 2010, 54, 1109–1116. [Google Scholar] [CrossRef]

- De Lucia, B.; Cristiano, G.; Vecchietti, L.; Bruno, L. Effect of Different Rates of Composted Organic Amendment on Urban Soil Properties, Growth and Nutrient Status of Three Mediterranean Native Hedge Species. Urban For. Urban Green. 2013, 12, 537–545. [Google Scholar] [CrossRef]

- Bowszys, T.; Wierzbowska, J.; Sternik, P.; Busse, M. Effect of the application of sewage sludge compost on the content and leaching of zinc and copper from soils under agricultural use. J. Ecol. Eng. 2015, 16, 1–7. [Google Scholar] [CrossRef]

- Farrell, M.; Jones, D.L. Critical Evaluation of Municipal Solid Waste Composting and Potential Compost Markets. Bioresour. Technol. 2009, 100, 4301–4310. [Google Scholar] [CrossRef]

- Corrêa, R.S.; White, R.E.; Weatherley, A.J. Effect of Compost Treatment of Sewage Sludge on Nitrogen Behavior in Two Soils. Waste Manag. 2006, 26, 614–619. [Google Scholar] [CrossRef]

- Chu, S.; Wu, D.; Liang, L.L.; Zhong, F.; Hu, Y.; Hu, X.; Lai, C.; Zeng, S. Municipal Sewage Sludge Compost Promotes Mangifera Persiciforma Tree Growth with No Risk of Heavy Metal Contamination of Soil. Sci. Rep. 2017, 7, 13408. [Google Scholar] [CrossRef] [Green Version]

- Sharma, B.; Sarkar, A.; Singh, P.; Singh, R.P. Agricultural Utilization of Biosolids: A Review on Potential Effects on Soil and Plant Grown. Waste Manag. 2017, 64, 117–132. [Google Scholar] [CrossRef]

- Major, N.; Schierstaedt, J.; Jechalke, S.; Nesme, J.; Ban, S.G.; Černe, M.; Sørensen, S.J.; Ban, D.; Schikora, A. Composted Sewage Sludge Influences the Microbiome and Persistence of Human Pathogens in Soil. Microorganisms 2020, 8, 1020. [Google Scholar] [CrossRef]

- Wierzbowska, J.; Sienkiewicz, S.; Krzebietke, S.; Sternik, P. Sewage Sludge as a Source of Nitrogen and Phosphorus for Virginia Fanpetals. Bulg. J. Agric. Sci. 2016, 22, 722–727. [Google Scholar]

- Qian, T.; Yang, Q.; Jun, D.C.F.; Dong, F.; Zhou, Y. Transformation of Phosphorus in Sewage Sludge Biochar Mediated by a Phosphate-Solubilizing Microorganism. Chem. Eng. J. 2019, 359, 1573–1580. [Google Scholar] [CrossRef]

- Li, L.; Zhang, Y.-J.; Novak, A.; Yang, Y.; Wang, J. Role of Biochar in Improving Sandy Soil Water Retention and Resilience to Drought. Water 2021, 13, 407. [Google Scholar] [CrossRef]

- Glaser, B.; Lehr, V.-I. Biochar Effects on Phosphorus Availability in Agricultural Soils: A Meta-Analysis. Sci. Rep. 2019, 9, 9338. [Google Scholar] [CrossRef] [Green Version]

- Siedt, M.; Schäffer, A.; Smith, K.E.C.; Nabel, M.; Roß-Nickoll, M.; van Dongen, J.T. Comparing Straw, Compost, and Biochar Regarding Their Suitability as Agricultural Soil Amendments to Affect Soil Structure, Nutrient Leaching, Microbial Communities, and the Fate of Pesticides. Sci. Total Environ. 2021, 751, 141607. [Google Scholar] [CrossRef]

- Černe, M.; Palčić, I.; Major, N.; Pasković, I.; Perković, J.; Užila, Z.; Filipović, V.; Romić, M.; Goreta Ban, S.; Jaćimović, R.; et al. Effect of Sewage Sludge Derived Compost or Biochar Amendment on the Phytoaccumulation of Potentially Toxic Elements and Radionuclides by Chinese Cabbage. J. Environ. Manag. 2021, 293, 112955. [Google Scholar] [CrossRef]

- Uzinger, N.; Takács, T.; Szili-Kovács, T.; Radimszky, L.; Füzy, A.; Draskovits, E.; Szűcs-Vásárhelyi, N.; Molnár, M.; Farkas, É.; Kutasi, J.; et al. Fertility Impact of Separate and Combined Treatments with Biochar, Sewage Sludge Compost and Bacterial Inocula on Acidic Sandy Soil. Agronomy 2020, 10, 1612. [Google Scholar] [CrossRef]

- Kumar, V.; Chopra, A.K. Accumulation and Translocation of Metals in Soil and Different Parts of French Bean (Phaseolus Vulgaris L.) Amended with Sewage Sludge. Bull. Environ. Contam. Toxicol. 2014, 92, 103–108. [Google Scholar] [CrossRef]

- Casado-Vela, J.; Sellés, S.; Navarro, J.; Bustamante, M.A.; Mataix, J.; Guerrero, C.; Gomez, I. Evaluation of Composted Sewage Sludge as Nutritional Source for Horticultural Soils. Waste Manag. 2006, 26, 946–952. [Google Scholar] [CrossRef]

- Smith, S. A Critical Review of the Bioavailability and Impacts of Heavy Metals in Municipal Solid Waste Composts Compared to Sewage Sludge. Environ. Int. 2009, 35, 142–156. [Google Scholar] [CrossRef]

- Feng, L.; Zhang, L.; Feng, L. Dissipation of Polycyclic Aromatic Hydrocarbons in Soil Amended with Sewage Sludge Compost. Int. Biodeterior. Biodegrad. 2014, 95, 200–207. [Google Scholar] [CrossRef]

- Liu, H. Achilles Heel of Environmental Risk from Recycling of Sludge to Soil as Amendment: A Summary in Recent Ten Years (2007–2016). Waste Manag. 2016, 56, 575–583. [Google Scholar] [CrossRef]

- Fang, W.; Delapp, R.C.; Kosson, D.S.; van der Sloot, H.A.; Liu, J. Release of Heavy Metals during Long-Term Land Application of Sewage Sludge Compost: Percolation Leaching Tests with Repeated Additions of Compost. Chemosphere 2017, 169, 271–280. [Google Scholar] [CrossRef]

- He, Y.; Liu, C.; Tang, X.Y.; Xian, Q.S.; Zhang, J.Q.; Guan, Z. Biochar Impacts on Sorption-Desorption of Oxytetracycline and Florfenicol in an Alkaline Farmland Soil as Affected by Field Ageing. Sci. Total Environ. 2019, 671, 928–936. [Google Scholar] [CrossRef]

- Qi, G.; Jia, Y.; Liu, W.; Wei, Y.; Du, B.; Fang, W.; Guo, Y.; Guo, F.; Wu, Y.; Zou, Q.; et al. Leaching Behavior and Potential Ecological Risk of Heavy Metals in Southwestern China Soils Applied with Sewage Sludge Compost under Acid Precipitation Based on Lysimeter Trials. Chemosphere 2020, 249, 126212. [Google Scholar] [CrossRef]

- Perezmurcia, M.; Moral, R.; Morenocaselles, J.; Perezespinosa, A.; Paredes, C. Use of Composted Sewage Sludge in Growth Media for Broccoli. Bioresour. Technol. 2006, 97, 123–130. [Google Scholar] [CrossRef]

- Zheljazkov, V.D.; Warman, P.R. Phytoavailability and Fractionation of Copper, Manganese, and Zinc in Soil Following Application of Two Composts to Four Crops. Environ. Pollut. 2004, 131, 187–195. [Google Scholar] [CrossRef]

- Wei, Y.; Liu, Y. Effects of Sewage Sludge Compost Application on Crops and Cropland in a 3-Year Field Study. Chemosphere 2005, 59, 1257–1265. [Google Scholar] [CrossRef]

- Manara, P.; Zabaniotou, A. Towards Sewage Sludge Based Biofuels via Thermochemical Conversion—A Review. Renew. Sustain. Energy Rev. 2012, 16, 2566–2582. [Google Scholar] [CrossRef]

- Zoghlami, R.I.; Hechmi, S.; Weghlani, R.; Jedidi, N.; Moussa, M. Biochar Derived from Domestic Sewage Sludge: Influence of Temperature Pyrolysis on Biochars’ Chemical Properties and Phytotoxicity. J. Chem. 2021, 2021, 1818241. [Google Scholar] [CrossRef]

- Méndez, A.; Gómez, A.; Paz-Ferreiro, J.; Gascó, G. Effects of Sewage Sludge Biochar on Plant Metal Availability after Application to a Mediterranean Soil. Chemosphere 2012, 89, 1354–1359. [Google Scholar] [CrossRef]

- Cotxarrera, L.; Trillas-Gay, M.I.; Steinberg, C.; Alabouvette, C. Use of Sewage Sludge Compost and Trichoderma Asperellum Isolates to Suppress Fusarium Wilt of Tomato. Soil Biol. Biochem. 2002, 34, 467–476. [Google Scholar] [CrossRef]

- Tang, S.; Shao, N.; Zheng, C.; Yan, F.; Zhang, Z. Amino-Functionalized Sewage Sludge-Derived Biochar as Sustainable Efficient Adsorbent for Cu(II) Removal. Waste Manag. 2019, 90, 17–28. [Google Scholar] [CrossRef]

- Gopinath, A.; Divyapriya, G.; Srivastava, V.; Laiju, A.R.; Nidheesh, P.V.; Kumar, M.S. Conversion of Sewage Sludge into Biochar: A Potential Resource in Water and Wastewater Treatment. Environ. Res. 2021, 194, 110656. [Google Scholar] [CrossRef]

- Nguyen, T.T.N.; Wallace, H.M.; Xu, C.-Y.; Xu, Z.; Farrar, M.B.; Joseph, S.; Van Zwieten, L.; Bai, S.H. Short-Term Effects of Organo-Mineral Biochar and Organic Fertilisers on Nitrogen Cycling, Plant Photosynthesis, and Nitrogen Use Efficiency. J. Soils Sediments 2017, 17, 2763–2774. [Google Scholar] [CrossRef]

- Borchard, N.; Schirrmann, M.; Cayuela, M.L.; Kammann, C.; Wrage-Mönnig, N.; Estavillo, J.M.; Fuertes-Mendizábal, T.; Sigua, G.; Spokas, K.; Ippolito, J.A.; et al. Biochar, Soil and Land-Use Interactions That Reduce Nitrate Leaching and N2O Emissions: A Meta-Analysis. Sci. Total Environ. 2019, 651, 2354–2364. [Google Scholar] [CrossRef]

- Cayuela, M.L.; Sánchez-Monedero, M.A.; Roig, A.; Hanley, K.; Enders, A.; Lehmann, J. Biochar and Denitrification in Soils: When, How Much and Why Does Biochar Reduce N2O Emissions? Sci. Rep. 2013, 3, 1732. [Google Scholar] [CrossRef] [Green Version]

- Nguyen, T.T.N.; Xu, C.-Y.; Tahmasbian, I.; Che, R.; Xu, Z.; Zhou, X.; Wallace, H.M.; Bai, S.H. Effects of Biochar on Soil Available Inorganic Nitrogen: A Review and Meta-Analysis. Geoderma 2017, 288, 79–96. [Google Scholar] [CrossRef] [Green Version]

- Dong, W.; Walkiewicz, A.; Bieganowski, A.; Oenema, O.; Nosalewicz, M.; He, C.; Zhang, Y.; Hu, C. Biochar Promotes the Reduction of N2O to N2 and Concurrently Suppresses the Production of N2O in Calcareous Soil. Geoderma 2020, 362, 114091. [Google Scholar] [CrossRef]

- Kubaczyński, A.; Walkiewicz, A.; Pytlak, A.; Grządziel, J.; Gałązka, A.; Brzezińska, M. Biochar Dose Determines Methane Uptake and Methanotroph Abundance in Haplic Luvisol. Sci. Total Environ. 2022, 806, 151259. [Google Scholar] [CrossRef]

- Spokas, K.; Reicosky, D. Impacts of Sixteen Different Biochars on Soil Greenhouse Gas Production. Ann. Environ. Sci. 2009, 3, 179–193. [Google Scholar]

- Kubaczyński, A.; Walkiewicz, A.; Pytlak, A.; Brzezińska, M. New Biochars from Raspberry and Potato Stems Absorb More Methane than Wood Offcuts and Sunflower Husk Biochars. Int. Agrophysics 2020, 34, 355–364. [Google Scholar] [CrossRef]

- Walkiewicz, A.; Kalinichenko, K.; Kubaczyński, A.; Brzezińska, M.; Bieganowski, A. Usage of Biochar for Mitigation of CO2 Emission and Enhancement of CH4 Consumption in Forest and Orchard Haplic Luvisol (Siltic) Soils. Appl. Soil Ecol. 2020, 156, 103711. [Google Scholar] [CrossRef]

- Sun, H.; Luo, L.; Wang, D.; Liu, W.; Lan, Y.; Yang, T.; Gai, C.; Liu, Z. Carbon Balance Analysis of Sewage Sludge Biochar-to-Soil System. J. Clean. Prod. 2022, 358, 132057. [Google Scholar] [CrossRef]

- Miller-Robbie, L.; Ulrich, B.A.; Ramey, D.F.; Spencer, K.S.; Herzog, S.P.; Cath, T.Y.; Stokes, J.R.; Higgins, C.P. Life Cycle Energy and Greenhouse Gas Assessment of the Co-Production of Biosolids and Biochar for Land Application. J. Clean. Prod. 2015, 91, 118–127. [Google Scholar] [CrossRef]

- Teoh, S.K.; Li, L.Y. Feasibility of Alternative Sewage Sludge Treatment Methods from a Lifecycle Assessment (LCA) Perspective. J. Clean. Prod. 2020, 247, 119495. [Google Scholar] [CrossRef]

- Mayer, F.; Bhandari, R.; Gäth, S.A. Life Cycle Assessment of Prospective Sewage Sludge Treatment Paths in Germany. J. Environ. Manag. 2021, 290, 112557. [Google Scholar] [CrossRef]

- Przydatek, G.; Wota, A.K. Analysis of the Comprehensive Management of Sewage Sludge in Poland. J. Mater. Cycles Waste Manag. 2020, 22, 80–88. [Google Scholar] [CrossRef] [Green Version]

- Rizzardini, C.; Goi, D. Sustainability of Domestic Sewage Sludge Disposal. Sustainability 2014, 6, 2424–2434. [Google Scholar] [CrossRef] [Green Version]

- Grobelak, A.; Czerwińska, K.; Murtaś, A. General Considerations on Sludge Disposal, Industrial and Municipal Sludge. In Industrial and Municipal Sludge; Elsevier: Amsterdam, The Netherlands, 2019; pp. 135–153. [Google Scholar] [CrossRef]

- Liu, B.; Wei, Q.; Zhang, B.; Bi, J. Life Cycle GHG Emissions of Sewage Sludge Treatment and Disposal Options in Tai Lake Watershed, China. Sci. Total Environ. 2013, 447, 361–369. [Google Scholar] [CrossRef]

- Houillon, G.; Jolliet, O. Life Cycle Assessment of Processes for the Treatment of Wastewater Urban Sludge: Energy and Global Warming Analysis. J. Clean. Prod. 2005, 13, 287–299. [Google Scholar] [CrossRef]

- Hallaji, S.M.; Kuroshkarim, M.; Moussavi, S.P. Enhancing Methane Production Using Anaerobic Co-Digestion of Waste Activated Sludge with Combined Fruit Waste and Cheese Whey. BMC Biotechnol. 2019, 19, 19. [Google Scholar] [CrossRef]

- Villegas, M.; Huiliñir, C. Biodrying of Sewage Sludge: Kinetics of Volatile Solids Degradation under Different Initial Moisture Contents and Air-Flow Rates. Bioresour. Technol. 2014, 174, 33–41. [Google Scholar] [CrossRef]

- Yuan, H.; Lu, T.; Wang, Y.; Chen, Y.; Lei, T. Sewage Sludge Biochar: Nutrient Composition and Its Effect on the Leaching of Soil Nutrients. Geoderma 2016, 267, 17–23. [Google Scholar] [CrossRef]

- Moënne-Loccoz, P.; Fee, J.A. Catalyzing NO to N2O in the Nitrogen Cycle. Science 2010, 330, 1632–1633. [Google Scholar] [CrossRef] [Green Version]

- Guo, L.; Zhang, H.; Jiang, X.; Wang, Y.; Liu, Z.; Fang, S.; Zhang, Z. Classification and Disposal Strategy of Excess Sludge in the Petrochemical Industry. Appl. Sci. 2019, 9, 1186. [Google Scholar] [CrossRef]

- Conesa, J.A. Sewage Sludge as Inhibitor of the Formation of Persistent Organic Pollutants during Incineration. Sustainability 2021, 13, 10935. [Google Scholar] [CrossRef]

- Kanhar, A.H.; Chen, S.; Wang, F. Incineration Fly Ash and Its Treatment to Possible Utilization: A Review. Energies 2020, 13, 6681. [Google Scholar] [CrossRef]

- Kim, J.; Jeong, S. Economic and Environmental Cost Analysis of Incineration and Recovery Alternatives for Flammable Industrial Waste: The Case of South Korea. Sustainability 2017, 9, 1638. [Google Scholar] [CrossRef] [Green Version]

- Li, Y.B.; Liu, T.T.; Song, J.L.; Lv, J.H.; Jiang, J.S. Effects of Chemical Additives on Emissions of Ammonia and Greenhouse Gas during Sewage Sludge Composting. Process Saf. Environ. Prot. 2020, 143, 129–137. [Google Scholar] [CrossRef]

- Thomazini, A.; Spokas, K.; Hall, K.; Ippolito, J.; Lentz, R.; Novak, J. GHG Impacts of Biochar: Predictability for the Same Biochar. Agric. Ecosyst. Environ. 2015, 207, 183–191. [Google Scholar] [CrossRef]

- Chen, Y.-C.; Kuo, J. Potential of Greenhouse Gas Emissions from Sewage Sludge Management: A Case Study of Taiwan. J. Clean. Prod. 2016, 129, 196–201. [Google Scholar] [CrossRef]

- Jiang, T.; Ma, X.; Yang, J.; Tang, Q.; Yi, Z.; Chen, M.; Li, G. Effect of Different Struvite Crystallization Methods on Gaseous Emission and the Comprehensive Comparison during the Composting. Bioresour. Technol. 2016, 217, 219–226. [Google Scholar] [CrossRef]

- Fukumoto, Y.; Osada, T.; Hanajima, D.; Haga, K. Patterns and Quantities of NH3, N2O and CH4 Emissions during Swine Manure Composting without Forced Aeration––Effect of Compost Pile Scale. Bioresour. Technol. 2003, 89, 109–114. [Google Scholar] [CrossRef]

- Đurđević, D.; Blecich, P.; Jurić, Ž. Energy Recovery from Sewage Sludge: The Case Study of Croatia. Energies 2019, 12, 1927. [Google Scholar] [CrossRef] [Green Version]

- Wang, Q.; Wang, Z.; Awasthi, M.K.; Jiang, Y.; Li, R.; Ren, X.; Zhao, J.; Shen, F.; Wang, M.; Zhang, Z. Evaluation of Medical Stone Amendment for the Reduction of Nitrogen Loss and Bioavailability of Heavy Metals during Pig Manure Composting. Bioresour. Technol. 2016, 220, 297–304. [Google Scholar] [CrossRef]

- Shen, Y.; Ren, L.; Li, G.; Chen, T.; Guo, R. Influence of Aeration on CH4, N2O and NH3 Emissions during Aerobic Composting of a Chicken Manure and High C/N Waste Mixture. Waste Manag. 2011, 31, 33–38. [Google Scholar] [CrossRef]

- Beck-Friis, B.; Pell, M.; Sonesson, U.; Jönsson, H.; Kirchmann, H. Formation and Emission of N2O and CH4 from Compost Heaps of Organic Household Waster. Environ. Monit. Assess. 2000, 62, 317–331. [Google Scholar] [CrossRef]

- Sommer, S.G.; Møller, H.B. Emission of Greenhouse Gases during Composting of Deep Litter from Pig Production—Effect of Straw Content. J. Agric. Sci. 2000, 134, 327–335. [Google Scholar] [CrossRef] [Green Version]

- Bubalo, A.; Vouk, D.; Stirmer, N.; Nad, K. Use of Sewage Sludge Ash in the Production of Innovative Bricks—An Example of a Circular Economy. Sustainability 2021, 13, 9330. [Google Scholar] [CrossRef]

- Vochozka, M.; Maroušková, A.; Váchal, J.; Straková, J. Biochar Pricing Hampers Biochar Farming. Clean Technol. Environ. Policy 2016, 18, 1225–1231. [Google Scholar] [CrossRef]

- Ahmed, M.B.; Zhou, J.L.; Ngo, H.H.; Guo, W. Insight into Biochar Properties and Its Cost Analysis. Biomass Bioenergy 2016, 84, 76–86. [Google Scholar] [CrossRef]

- Singh, S.; Kumar, V.; Dhanjal, D.S.; Datta, S.; Bhatia, D.; Dhiman, J.; Samuel, J.; Prasad, R.; Singh, J. A Sustainable Paradigm of Sewage Sludge Biochar: Valorization, Opportunities, Challenges and Future Prospects. J. Clean. Prod. 2020, 269, 122259. [Google Scholar] [CrossRef]

- Callegari, A.; Capodaglio, A. Properties and Beneficial Uses of (Bio)Chars, with Special Attention to Products from Sewage Sludge Pyrolysis. Resources 2018, 7, 20. [Google Scholar] [CrossRef] [Green Version]

- Barry, D.; Barbiero, C.; Briens, C.; Berruti, F. Pyrolysis as an Economical and Ecological Treatment Option for Municipal Sewage Sludge. Biomass Bioenergy 2019, 122, 472–480. [Google Scholar] [CrossRef]

- Maroušek, J. Significant Breakthrough in Biochar Cost Reduction. Clean Technol. Environ. Policy 2014, 16, 1821–1825. [Google Scholar] [CrossRef]

- Fernando-Foncillas, C.; Estevez, M.M.; Uellendahl, H.; Varrone, C. Co-Management of Sewage Sludge and Other Organic Wastes: A Scandinavian Case Study. Energies 2021, 14, 3411. [Google Scholar] [CrossRef]

- Shahbeig, H.; Nosrati, M. Pyrolysis of Municipal Sewage Sludge for Bioenergy Production: Thermo-Kinetic Studies, Evolved Gas Analysis, and Techno-Socio-Economic Assessment. Renew. Sustain. Energy Rev. 2020, 119, 109567. [Google Scholar] [CrossRef]

- Dickinson, D.; Balduccio, L.; Buysse, J.; Ronsse, F.; van Huylenbroeck, G.; Prins, W. Cost-Benefit Analysis of Using Biochar to Improve Cereals Agriculture. GCB Bioenergy 2015, 7, 850–864. [Google Scholar] [CrossRef]

- Maroušek, J.; Strunecký, O.; Stehel, V. Biochar Farming: Defining Economically Perspective Applications. Clean Technol. Environ. Policy 2019, 21, 1389–1395. [Google Scholar] [CrossRef]

- Shackley, S.; Hammond, J.; Gaunt, J.; Ibarrola, R. The Feasibility and Costs of Biochar Deployment in the UK. Carbon Manag. 2011, 2, 335–356. [Google Scholar] [CrossRef] [Green Version]

- Canatoy, R.C.; Jeong, S.T.; Galgo, S.J.C.; Kim, P.J.; Cho, S.R. Biochar as Soil Amendment: Syngas Recycling System Is Essential to Create Positive Carbon Credit. Sci. Total Environ. 2022, 809, 151140. [Google Scholar] [CrossRef]

- Yao, Z.; You, S.; Ge, T.; Wang, C.-H. Biomass Gasification for Syngas and Biochar Co-Production: Energy Application and Economic Evaluation. Appl. Energy 2018, 209, 43–55. [Google Scholar] [CrossRef] [Green Version]

- Wang, T.; Liu, H.; Duan, C.; Xu, R.; Zhang, Z.; She, D.; Zheng, J. The Eco-Friendly Biochar and Valuable Bio-Oil from Caragana Korshinskii: Pyrolysis Preparation, Characterization, and Adsorption Applications. Materials 2020, 13, 3391. [Google Scholar] [CrossRef]

- Trabelsi, A.B.H.; Zaafouri, K.; Friaa, A.; Abidi, S.; Naoui, S.; Jamaaoui, F. Municipal Sewage Sludge Energetic Conversion as a Tool for Environmental Sustainability: Production of Innovative Biofuels and Biochar. Environ. Sci. Pollut. Res. 2021, 28, 9777–9791. [Google Scholar] [CrossRef]

- Karaca, C.; Sözen, S.; Orhon, D.; Okutan, H. High Temperature Pyrolysis of Sewage Sludge as a Sustainable Process for Energy Recovery. Waste Manag. 2018, 78, 217–226. [Google Scholar] [CrossRef]

- Djandja, O.S.; Wang, Z.-C.; Wang, F.; Xu, Y.-P.; Duan, P.-G. Pyrolysis of Municipal Sewage Sludge for Biofuel Production: A Review. Ind. Eng. Chem. Res. 2020, 59, 16939–16956. [Google Scholar] [CrossRef]

- Ro, K.S.; Hunt, P.G.; Jackson, M.A.; Compton, D.L.; Yates, S.R.; Cantrell, K.; Chang, S. Co-Pyrolysis of Swine Manure with Agricultural Plastic Waste: Laboratory-Scale Study. Waste Manag. 2014, 34, 1520–1528. [Google Scholar] [CrossRef] [PubMed]

- Pokorna, E.; Postelmans, N.; Jenicek, P.; Schreurs, S.; Carleer, R.; Yperman, J. Study of Bio-Oils and Solids from Flash Pyrolysis of Sewage Sludges. Fuel 2009, 88, 1344–1350. [Google Scholar] [CrossRef] [Green Version]

- Papiernik, S.K.; Yates, S.R.; Chellemi, D.O. A Standardized Approach for Estimating the Permeability of Plastic Films to Soil Fumigants under Various Field and Environmental Conditions. J. Environ. Qual. 2011, 40, 1375–1382. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Nations, U. World Population Prospects the 2020 Revision-Key Findings and Advance Tables; United Nations: New York, NY, USA, 2020. [Google Scholar]

- Karagiannidis, A.; Samaras, P.; Kasampalis, T.; Perkoulidis, G.; Ziogas, P.; Zorpas, A. Evaluation of Sewage Sludge Production and Utilization in Greece in the Frame of Integrated Energy Recovery. Desalin. Water Treat. 2011, 33, 185–193. [Google Scholar] [CrossRef]

- Semiyaga, S.; Okure, M.A.E.; Niwagaba, C.B.; Katukiza, A.Y.; Kansiime, F. Decentralized Options for Faecal Sludge Management in Urban Slum Areas of Sub-Saharan Africa: A Review of Technologies, Practices and End-Uses. Resour. Conserv. Recycl. 2015, 104, 109–119. [Google Scholar] [CrossRef] [Green Version]

- Xenarios, S.; Shenhav, R.; Abdullaev, I.; Mastellari, A. Current and Future Challenges of Water Security in Central Asia; Springer: Singapore, 2018; pp. 117–142. [Google Scholar] [CrossRef]

- Singh, B.P.; Hatton, B.J.; Singh, B.; Cowie, A.L.; Kathuria, A. Influence of Biochars on Nitrous Oxide Emission and Nitrogen Leaching from Two Contrasting Soils. J. Environ. Qual. 2010, 39, 1224–1235. [Google Scholar] [CrossRef]

- Bondarczuk, K.; Markowicz, A.; Piotrowska-Seget, Z. The Urgent Need for Risk Assessment on the Antibiotic Resistance Spread via Sewage Sludge Land Application. Environ. Int. 2016, 87, 49–55. [Google Scholar] [CrossRef]

- Collivignarelli, M.; Abbà, A.; Frattarola, A.; Carnevale Miino, M.; Padovani, S.; Katsoyiannis, I.; Torretta, V. Legislation for the Reuse of Biosolids on Agricultural Land in Europe: Overview. Sustainability 2019, 11, 6015. [Google Scholar] [CrossRef]

| PT (°C) | Yield (%) | Ash (%) | P | K | Ca | Mg | C | H | N | O | O/C | H/C | C/N | pH | EC (ds cm−1) | SSA (m2 g−1) | Ref | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| (mg g−1) | ||||||||||||||||||

| SS | - | - | 32.8–76.14 | 3.4–28.4 | 0.54–2.05 | 4.04–7.4 | 0.57–4.1 | 21.6–33.2 | 1.24–5.2 | 1.32–5.74 | 4.4–22.5 | - | - | - | 5.87–7.39 | 2.2–4.7 | 1.1–7.6 | [42,49,50] |

| SSB | 300 | - | - | - | - | - | - | 18.6 | - | 3.1 | - | - | - | 6.00 | 8.65 | - | - | [51] |

| SSB | 300 | - | - | - | - | - | - | 22.1 | - | 2.9 | - | - | - | 7.62 | 7.84 | - | - | [51] |

| SSB | 500 | - | - | 41.1 | 1.61 | 9.71 | 4.32 | 23.4 | - | 3.3 | - | - | - | 7.09 | 6 | - | - | [52] |

| SSB | 300 | 64.3 | 37.4 | 10.4 | 2.25 | 5.33 | 1.35 | 17.1 | 10.3 | 6.2 | 13.4 | 0.78 | 0.60 | 2.76 | 6.2 | 3.3 | 2.88 | [53] |

| SSB | 400 | 56.5 | 49.2 | 11.5 | 2.48 | 5.59 | 1.42 | 15.1 | 9.1 | 4.9 | 7.15 | 0.47 | 0.60 | 3.08 | 7.5 | 0.4 | 7.56 | [53] |

| SSB | 500 | 55.3 | 57.4 | 16.6 | 2.75 | 6.01 | 1.68 | 30.1 | 7.7 | 4.3 | 5.91 | 0.20 | 0.26 | 7.00 | 8.1 | 0.5 | 10.8 | [53] |

| SSB | 600 | 53.4 | 63.2 | 18.2 | 2.83 | 6.45 | 2.24 | 26.5 | 7.1 | 3.5 | 5.29 | 0.20 | 0.27 | 7.57 | 10.8 | 0.3 | 12.2 | [53] |

| SSB | 700 | 46.6 | 66.6 | 20.1 | 2.91 | 7.8 | 2.56 | 27.2 | 6.9 | 3.1 | 1.63 | 0.06 | 0.25 | 8.77 | 11.9 | 1.3 | 18.3 | [53] |

| SSB | 800 | 42.8 | 68.3 | 19.1 | 3.43 | 8.55 | 2.85 | 26.8 | 6.7 | 2.5 | 1.24 | 0.05 | 0.25 | 10.7 | 11.7 | 0.7 | 19.1 | [53] |

| SSB | 900 | 42.2 | 71.2 | 19.5 | 3.35 | 9.14 | 3.19 | 29.2 | 6.6 | 1.2 | 1.16 | 0.04 | 0.23 | 24.3 | 11.4 | 0.4 | 34.2 | [53] |

| SSB | 450 | - | - | - | - | - | - | - | - | 1.2 | - | - | - | - | 8.25 | 1.6 | - | [54] |

| SSB | 300 | - | - | 42.6 | 2.1 | 8.1 | 8.2 | 21.5 | 9.3 | 5.4 | - | - | 0.43 | 3.98 | - | - | 4.1 | [55] |

| SSB | 400 | - | - | 58.8 | 2.4 | 8.4 | 8.4 | 27.5 | 8.1 | 4.4 | - | - | 0.29 | 6.25 | - | - | 8.7 | [55] |

| SSB | 500 | - | - | 59.5 | 2.4 | 8.8 | 8.2 | 26.7 | 7.9 | 3.7 | - | - | 0.30 | 7.22 | - | - | 10.2 | [55] |

| SSB | 600 | - | - | 57.6 | 2.8 | 10.4 | 9.3 | 26.1 | 7.3 | 3.4 | - | - | 0.28 | 7.68 | - | - | 6.3 | [55] |

| SSB | 500 | - | - | - | - | - | - | - | - | 1.7 | - | - | - | - | 8.5 | 5.5 | - | [54] |

| SSB | 500 | - | - | - | - | - | - | 26.3 | - | 2.6 | - | - | - | 10.1 | 7.06 | 0.5 | - | [56] |

| SSB | 300 | - | - | - | - | - | - | 22.2 | 8.1 | 3.1 | - | - | 0.36 | 7.16 | 8.8 | - | 15.6 | [49] |

| SSB | 400 | - | - | - | - | - | - | 24.3 | 7.7 | 3.1 | - | - | 0.32 | 7.84 | 8.9 | - | 16.3 | [49] |

| SSB | 500 | - | - | - | - | - | - | 20.1 | 7.1 | 2.3 | - | - | 0.35 | 8.74 | 9.3 | - | 9.43 | [49] |

| SSB | 600 | - | - | - | - | - | - | 22.6 | 6.4 | 1.3 | - | - | 0.28 | 17.4 | 10.7 | - | 24.7 | [49] |

| SSB | 350 | - | - | - | - | - | - | - | - | - | - | - | - | - | 8.72 | 3.04 | - | [57] |

| SSB | 300 | 91.1 | 83.2 | - | - | - | - | 7.53 | 6.78 | 1.3 | 7.13 | 0.95 | 0.90 | 5.79 | 6.43 | - | 5.11 | [50] |

| SSB | 500 | 85.7 | 87.9 | - | - | - | - | 5.63 | 6.48 | 0.7 | 5.21 | 0.93 | 1.15 | 8.04 | 6.96 | - | 15.2 | [50] |

| SSB | 700 | 81.2 | 91.9 | - | - | - | - | 3.96 | 6.29 | 0.4 | 3.36 | 0.85 | 1.59 | 9.90 | 10.5 | - | 13.6 | [50] |

| SSB | 450 | - | - | 58.2 | 1.78 | - | - | 28.1 | - | 3.2 | - | - | - | 8.78 | 7.22 | 1.73 | - | [58] |

| SSB | 450 | - | - | 11.1 | 3.01 | 19.9 | 3.59 | 26.2 | - | 1.7 | - | - | - | 15.4 | 8.54 | 1.1 | - | [59] |

| SSB | 500 | - | - | 29.2 | 8.01 | - | - | 26.1 | - | 2.1 | - | - | - | 12.4 | 8.06 | - | - | [60] |

| SSB | 500 | 54.3 | 73.6 | 54.1 | 9.21 | 8.27 | 0.94 | 18.9 | 6.72 | 2.7 | 4.08 | 0.22 | 0.36 | 7.00 | 7.13 | - | 31.8 | [42] |

| SSB | 600 | 51.3 | 77.8 | 59.2 | 10.1 | 9.18 | 1.08 | 18.4 | 6.38 | 2.2 | 1.91 | 0.10 | 0.35 | 8.36 | 11.1 | - | 24.1 | [42] |

| SSB | 700 | 48.7 | 79.1 | 63.1 | 10.9 | 9.71 | 1.13 | 18.1 | 6.24 | 1.2 | 0.68 | 0.04 | 0.34 | 15.1 | 12.2 | - | 54.1 | [42] |

| SSB | 500 | 50.4 | 68.1 | 58.8 | 14.1 | 6.75 | 1.47 | 23.1 | 6.77 | 3.6 | 4.41 | 0.19 | 0.29 | 6.42 | 7.08 | - | 16.3 | [42] |

| SSB | 600 | 46.4 | 70.3 | 64.8 | 15.5 | 6.02 | 1.65 | 23.7 | 6.44 | 3.3 | 2.29 | 0.10 | 0.27 | 7.18 | 11.4 | - | 9.01 | [42] |

| SSB | 700 | 43.7 | 74.3 | 68.6 | 16.4 | 7.42 | 1.78 | 22.8 | 6.33 | 2.2 | 0.31 | 0.01 | 0.28 | 10.36 | 12.4 | - | 29.9 | [42] |

| SSB | 500 | 54.4 | 69.1 | 54.7 | 12.5 | 1.2 | 1.13 | 22.4 | 6.67 | 3.1 | 4.94 | 0.22 | 0.30 | 7.23 | 7.17 | - | 34.2 | [42] |

| SSB | 600 | 51.1 | 70.2 | 53.1 | 13.4 | 1.14 | 1.25 | 22.5 | 6.63 | 2.7 | 4.02 | 0.18 | 0.29 | 8.33 | 11.3 | - | 16.2 | [42] |

| SSB | 700 | 49.5 | 72.1 | 56.1 | 13.4 | 1.2 | 1.27 | 21.7 | 6.56 | 2.4 | 3.34 | 0.15 | 0.30 | 9.04 | 12.4 | - | 9.21 | [42] |

| SSB | 500 | 45.1 | 64.1 | 96.1 | 1.06 | 1.02 | 3.29 | 26.6 | 7.08 | 3.9 | 4.29 | 0.16 | 0.27 | 6.82 | 7.25 | - | 35.7 | [42] |

| SSB | 600 | 43.2 | 63.9 | 92.2 | 1.12 | 1.08 | 2.57 | 27.7 | 6.82 | 3.8 | 3.89 | 0.14 | 0.25 | 7.29 | 8.05 | - | 16.2 | [42] |

| SSB | 700 | 40.2 | 68.1 | 95.1 | 1.22 | 1.19 | 2.44 | 27.9 | 6.48 | 2.9 | 0.79 | 0.03 | 0.23 | 9.62 | 13.1 | - | 18.1 | [42] |

| SSB | 400 | - | - | - | - | - | - | 25.9 | - | 3.6 | - | - | - | 7.19 | 7.18 | 0.67 | - | [56] |

| Min | - | 40.2 | 37.4 | 10.4 | 1.06 | 1.02 | 0.94 | 3.96 | 6.24 | 0.4 | 0.31 | 0.014 | 0.23 | 2.76 | 6 | 0.3 | 2.88 | |

| Max | - | 91.1 | 91.9 | 96.1 | 16.4 | 19.9 | 9.3 | 30.1 | 10.3 | 6.2 | 13.4 | 0.95 | 1.59 | 24.3 | 13.1 | 5.5 | 54.1 | |

| Mean | - | 54.4 | 69.4 | 47.8 | 6.0 | 6.7 | 3.1 | 22.4 | 7.2 | 2.9 | 3.9 | 0.3 | 0.41 | 8.7 | 9.1 | 1.5 | 17.6 | |

| Effects | References | |

|---|---|---|

| Effects on soil properties | ↑ enzyme activity | [47] |

| ↑ pH, N, C, ↓ bioavailable As, Cr, Co, Ni, and Pb (but not Cd, Cu, and Zn) | [58] | |

| ↑ N, P, K | [67] | |

| ↑ pH, EC ↓ heavy metal uptake (Pb, Zn) | [59] | |

| ↑ N, C, P, amount of heavy metals but with low availability | [68] | |

| ↑ P, Mg, CEC, base saturation | [69] | |

| ↑ P, EC, pH | [54] | |

| ↑ pH, N, C, efficiency of microbial C use, ↓ content of Pb, Cd | [56] | |

| ↑ pH, EC, enzyme activity, the concentrations of bacteria, fungi, ammonia-oxidizing archaea, and ammonia-oxidizing bacteria, immobilization of Cr, Ni, and Cd | [70] | |

| ↑ C, soil microbial biomass, ↓ mobility of Cd, | [60] | |

| ↑ C, N, P, K | [38] | |

| ↑ water retention, P sorption | [71] | |

| ↑ field capacity, wilting point, available water in coarse- and medium-textured soils ↓ bulk density | [72] | |

| ↑ C, N, P | [73] | |

| Effects on plant growth | ↑ shoot biomass, grain yield of rice Oryza sativa L. | [58,74] |

| ↑ growth and yield of garlic Allium sativum L. | [66] | |

| ↑ growth and yield of Chinese cabbage | [75] | |

| ↑ turf grass growth | [68] | |

| ↑ corn yield | [59,69] | |

| ↑ biomass of Poa pratensis L. | [56] | |

| ↑ biomass and yield of wheat (Triticum aestivum) | [54] | |

| ↑ biomass of Chinese cabbage | [76] | |

| ↑ grain yield of rice; no change in grain yield of wheat | [60] | |

| ↑ dry weight of the aboveground (stems) and belowground (roots) tomato (Solanum lycopersicum L.); the yield was not increased significantly | [73] | |

| Effects on GHGs emissions | ↓ or ↑ CO2 emission depending on pyrolysis temp. | [57,77] |

| ↓ N2O emission and ↑ CH4 uptake | [58] | |

| ↓ CO2 and N2O emission in fertilized soils | [78] | |

| ↓ CH4 and N2O emissions | [60] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ghorbani, M.; Konvalina, P.; Walkiewicz, A.; Neugschwandtner, R.W.; Kopecký, M.; Zamanian, K.; Chen, W.-H.; Bucur, D. Feasibility of Biochar Derived from Sewage Sludge to Promote Sustainable Agriculture and Mitigate GHG Emissions—A Review. Int. J. Environ. Res. Public Health 2022, 19, 12983. https://doi.org/10.3390/ijerph191912983

Ghorbani M, Konvalina P, Walkiewicz A, Neugschwandtner RW, Kopecký M, Zamanian K, Chen W-H, Bucur D. Feasibility of Biochar Derived from Sewage Sludge to Promote Sustainable Agriculture and Mitigate GHG Emissions—A Review. International Journal of Environmental Research and Public Health. 2022; 19(19):12983. https://doi.org/10.3390/ijerph191912983

Chicago/Turabian StyleGhorbani, Mohammad, Petr Konvalina, Anna Walkiewicz, Reinhard W. Neugschwandtner, Marek Kopecký, Kazem Zamanian, Wei-Hsin Chen, and Daniel Bucur. 2022. "Feasibility of Biochar Derived from Sewage Sludge to Promote Sustainable Agriculture and Mitigate GHG Emissions—A Review" International Journal of Environmental Research and Public Health 19, no. 19: 12983. https://doi.org/10.3390/ijerph191912983