1. Introduction

The Diesel engines have been used in light and heavy transport for many decades. Ever stricter requirements for lower fuel consumption and reduced emissions call for better solutions to be found by designers. Improvement of the combustion process is definitively a method to optimize consumption and reduce emissions. One of the key elements affecting this process in a Diesel engine is the injection nozzle that plays an important role in dispersion of the fuel in the droplet – fuel vapour – air mixture in the combustion chamber. The adequate optimization of the injection nozzle then results in lower emission and fuel consumption. The injection nozzle has the greatest influence on the injection rate that is crucial for fuel distribution in the combustion chamber. Knowing the injection rate, is thus crucial in understanding the combustion in the engine.

Nowadays various measuring devices for injection rate measuring are available. Measuring of the injection rate is accomplished on test benches for testing Diesel fuel injection systems. One of the oldest and the most frequently used method of measuring the injection rate is the Bosch measuring method [

1]. With Zeuch's measuring method the criterion for the injection rate is the pressure rise in the chamber into which the fuel is injected. [

2]. With the charge measuring method the criterion for the injection rate is the charge created by the friction of the fuel in the nozzle, friction of the jet against the surface of the sensor, and by the Seebeck effect [

3]. Injection rate measurements have been also carried out by Laser Doppler Anemometer [

4,

5]. The Laser Doppler Anemometer measures the axial velocity to deduce from this the actual volume flow rate signal.

All the measuring methods quoted above, give accurate results of the injection rate in single-hole nozzles. With multihole nozzles, however, they give us no informations about possible differences in injection rates between individual holes of the nozzle. In order to find out the differences in injection rates between individual holes of the injection nozzle, we have developed a deformational measuring method described in detail in this paper. With multihole nozzles the deformational measuring method enables measurement of the injection rate at each hole of the nozzle.

After the completed endurance test of the engine, we noticed different traces of temperature loads in the wall of the combustion chamber (w∼ combustion process) at the spots of the contact jet-piston chamber wall, which indicates differences in injection rates between individual holes of the nozzle.

In our case, the 1000, 2000 and 3000-hour engine durability tests were carried out on test stands. Engine loads were according to ECE-R 49 regulations. We also performed the 100 000, 200 000 and 500 000 km long vehicle durability tests.

Different traces of temperature loads in the wall of the combustion chamber were the main inspiration why we decided to develop a new measuring device. The measurements of the injection rates presented in the article confirm our suppositions.

2. Zeuch measuring method

With Zeuch's measuring method the fuel is injected into a chamber filled with Diesel fuel at a certain pressure. As the mass of the fuel in the chamber increases due to the injected fuel, the chamber pressure increases in proportion to the injected mass. Through the bulk modulus of elasticity of the fuel, the derivative of the chamber pressure with respect to volume provides the injection rate signal. The bulk modulus of elasticity of the fuel is

where E is the bulk modulus of elasticity of the fuel, V the volume of chamber and p the pressure in the chamber. The bulk modulus of elasticity of the fuel depends on its pressure and temperature. The bulk modulus of elasticity is, thus, defined as the change in pressure due to the injected volume of fuel multiplied by the initial chamber volume. This is an analogous to the modulus of elasticity for metals.

The equation for the Zeuch injection rate measuring method is derived based on the conservation of mass. By inserting the fuel bulk modulus, the governing equation becomes

where m is mass of fuel and r fuel density. From

equation 2 we conclude, that the rate of injected mass is proportional to the fuel density, chamber volume, and rate of chamber pressure rise and inversely proportional to the fuel bulk modulus. Hence, the chamber volume and fuel bulk modulus must be known to a high degree of accuracy in order to obtain an accurate estimate of the injection rate. However, concerning the chamber design, its volume must be sized so that the chamber pressure rise is within the appropriate limits (1-3 MPa) for the desired volumetric injection rate. Following each injection a relief valve (solenoid) first opens discharging the fuel through a check valve and bringing the chamber pressure to the original set pressure and then the relief valve closes before the next injection starts.

3. Deformational measuring method

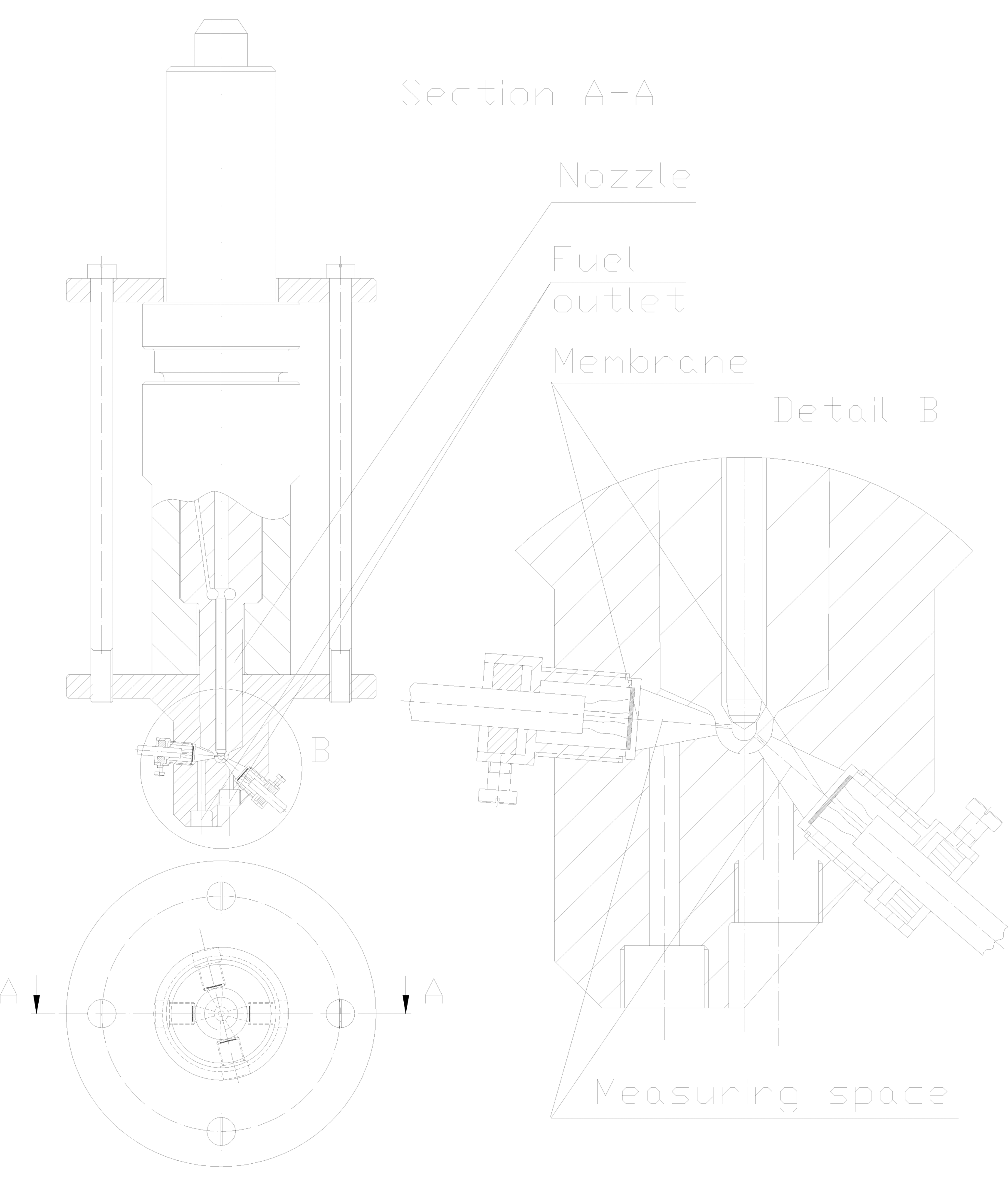

Fig. 1 shows the deformational measuring method. The criterion of the injected fuel is expressed by the deformation of membrane occurring due to the collision of the pressure wave against the membrane. The pressure wave is generated by the injection of the fuel into the measuring space. For the duration of measurements the measuring space must be filled with fuel to maintain an overpressure of 5 kPa. The overpressure is maintained by relief valve. The overpressure can be adjusted up to 5 MPa. One of the objectives of the deformational measuring method is to inject the fuel into the instrument under conditions identical to those in an operating engine. Therefore, a back pressure must be selected which approximates the combustion chamber pressure.

For each hole of the nozzle the measuring device must have a measuring space of its own into which fuel is injected as well as its measuring membrane and its own fuel outlet. Fuel escaping from the measuring device is conducted into the graduated cylinders for measuring the volumetric flow through each hole of the nozzle.

The deformational measuring method for measuring the injection rate is based on the calculation of the fuel velocity by the pressure-velocity equation [

6,

7,

8], which is valid for a single pressure wave in an instationary flow, i.e.

where a is velocity of sound in the fuel,

ρ density of the fuel and v velocity of the fuel. The fuel injection nozzle discharges into the measuring space and the continuity equation indicates that the fuel quantity per unit time dQ/dt, injected from the nozzle into the measuring space produces an equivalent fuel velocity v, whose magnitude depends on the dimensions of the measuring space. This fuel flow gives rise to a pressure wave which is proportional to dQ/dt and is measured by strain gauge located on the membrane. The pressure signals obtained from strain gauges are amplified using bridge amplifier. The change in pressure is

which is derived from the hydraulic pulse theory.

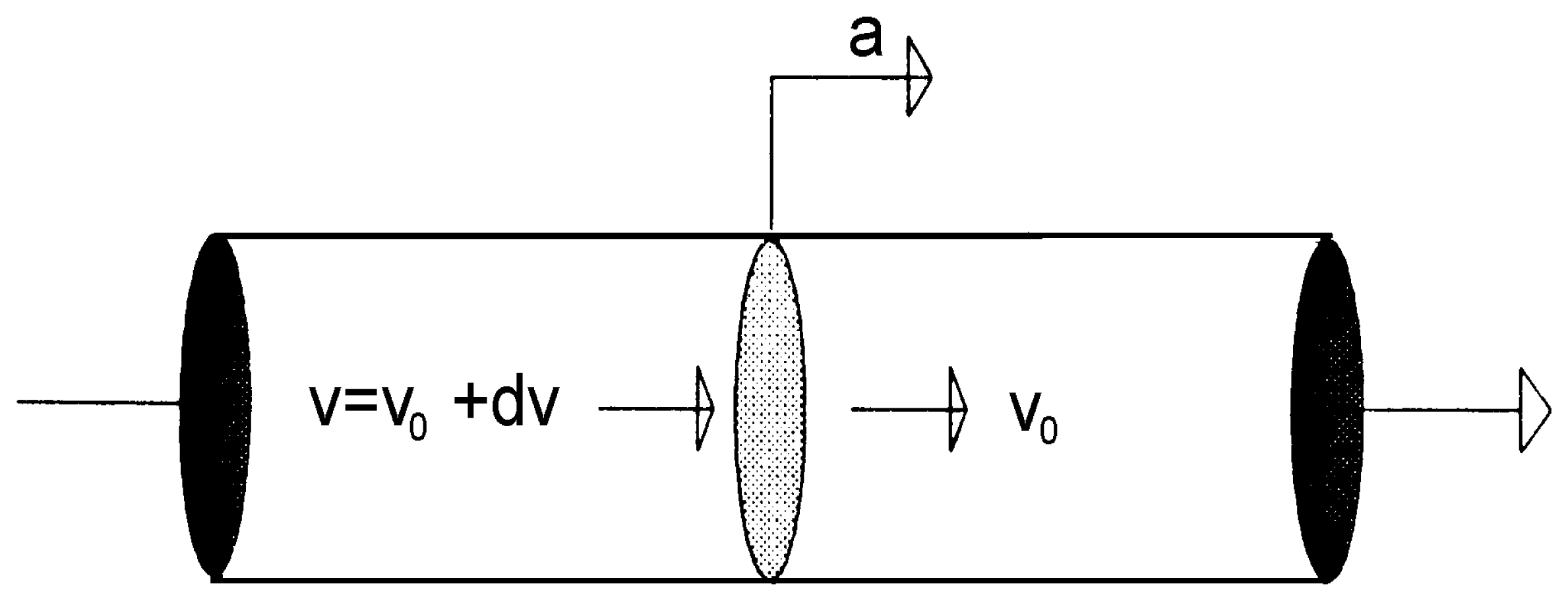

Furthermore, it is known that changes in the pressure of the fuel propagate at the velocity of sound and produce a corresponding change in the fuel flow velocity. This permits the application of the theory to a single pressure wave moving within measuring space at the velocity of sound, as shown schematically for the case of pipe in

Fig. 2.

Figure 3 also shows the changes in the fuel pressure, density and velocity due to the propagating pressure wave.

Equations 3 and

4 can then define the quantity of fuel injected as

where A is the membrane area, Q the injected fuel and t the time.

Therefore, the injected fuel quantity per unit time is a linear function of pressure [

1], which allows quantitative characterisation of individual injections. For the fuel quantity per stroke to be calculated

equation 5 has to be integrated over the injection period, i.e.:

where t

0 stands for the starts of injection and t for the end of injection, respectively.

Equation 6 gives the quantity of fuel injected per stroke as a linear function of pressure and time.

The measuring device is heated up due to the warm fuel, injected into the measuring space. The fuel is heated up due to compression in the pump and friction in the injection system. The fuel friction is most intense in injection nozzle holes. The fuel is compressed up to 1500 bar. The fuel heating up in the measuring space is due, though to a lesser extent, also to the conversion of kinetic energy of the fuel exiting the nozzle to the energy of pressure waves, acting on the membrane. The temperature of the measuring device during the measurements varied between 35 and 70 °C. As a result of the increased temperature, compressive stress occurs in the membrane, which may affect the accuracy of the measurement. The impact of this stress is diminished by using a membrane made of materials with low coefficient of thermal expansion.

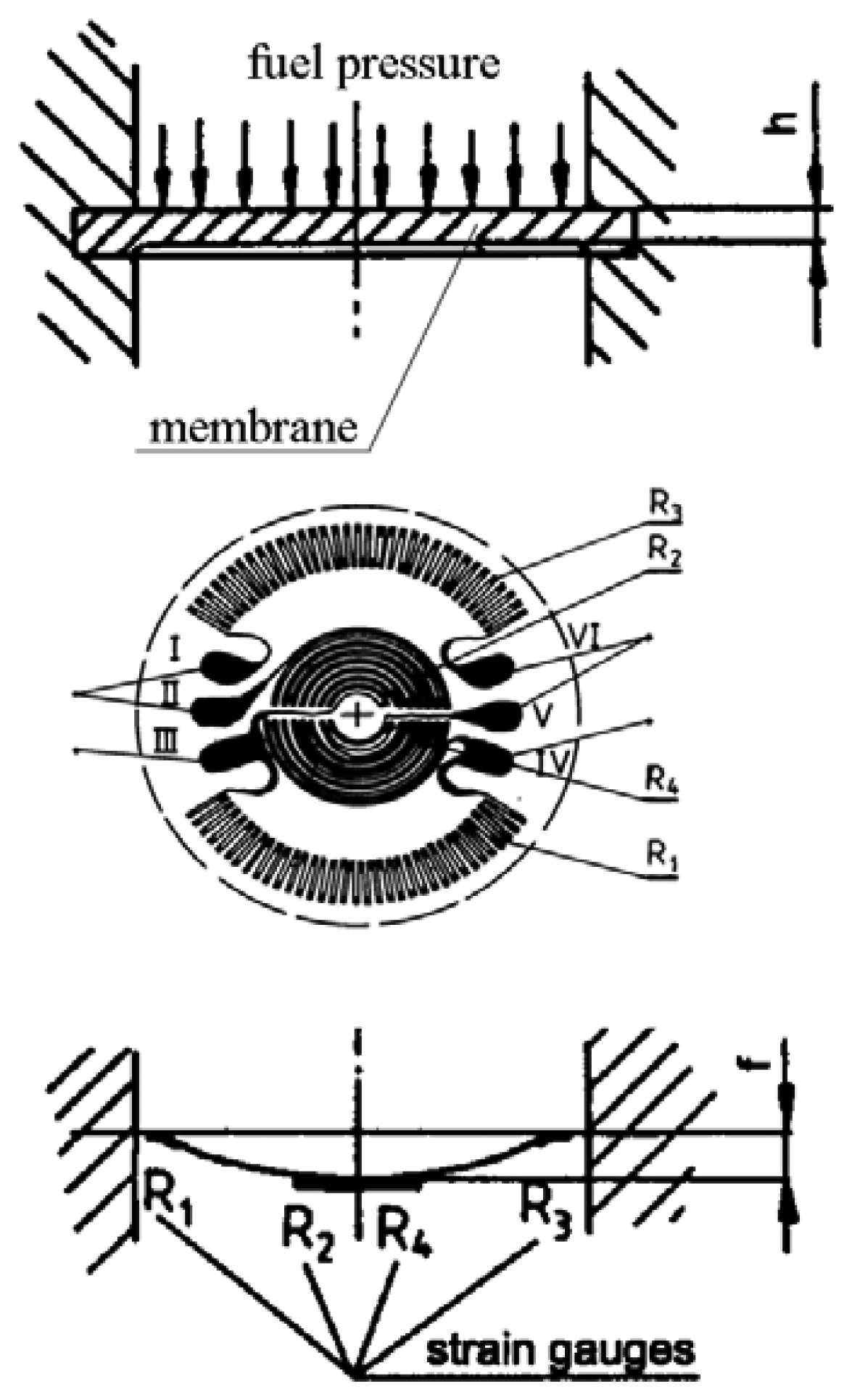

Deformations of the measuring membrane are assessed by means of strain gauges glued to the membrane (

Fig. 4). We used Hottinger Baldwin GmbH type 15/120 MY2 strain gauges, designed for membrane deformation and strain measurement. All four strain gauges were arranged in a full Wheatstone bridge configuration and glued to the membrane. The strain gauges are all exposed to identical temperature resulting in a temperature compensated Wheatstone bridge. Equally, the connections between individual strain gauges are at the same temperature to ensure the temperature compensation of the connections. The thermal expansion coefficient of the membrane material must be selected in accordance with the strain gauge properties.

Figure 4 depicts the tension exerted upon the membrane at the point of fuel injection as well as at the position of the strain gauges. Strain gauges R

1 and R

3 measure the compressive stresses at the edges of the membrane, whereas the tensile stresses in the middle of the membrane are measured by strain gauges R

2 and R

4.

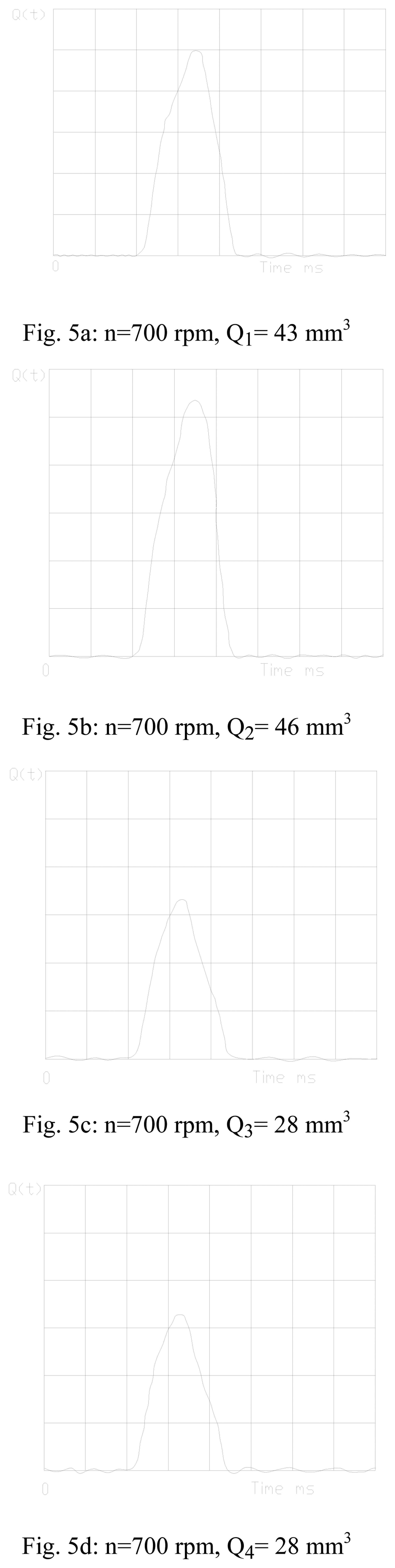

Figs. 5a, 5b, 5c and 5d feature rates for a four-hole nozzle. The plane beneath the curve constitutes the injected quantity Q of fuel:

Very important for the applicability of the measuring method is its linearity, i.e., the dependence of the surface beneath the curve upon the quantity of the injected fuel. The diagrams in

Fig. 6 and

7 depict the injected quantity of fuel on the ordinate, whereas the surface beneath the curve features on the abscissa.

Figure 6 shows the total quantity of fuel injected through all four holes of the nozzle, whereas the

figure 7 shows the quantity of fuel injected through each of the holes separately. Both figures evidence an adequate linearity, which has also been tested at different r.p.m. of the pump. Even when the measuring method was applied at different r.p.m. of the pump, the linearity proved satisfactory in all ranges.

Prior to commencing measurements, the membranes must be calibrated complete with the measuring instruments by means of compressed air, which is conducted to all measuring spaces through a fuel outlet under equal pressure. In this way both the membrane and the instruments can be calibrated at equal loads.

Table 1 quotes the calibration results. Shown in column 1 are the data of the compressed air. Maximal relative error is

The above results evidence a satisfactory linearity of membranes. Maximal relative error is less than one percentage.

The advantages of the deformational measuring method are as follows:

A disadvantage of this measuring method: each nozzle type needs its measuring device.

5. Summary

The article deals with deformational measuring method that facilitates measurement of injection rates at each hole of the multihole injection nozzles. The criterion of the injected fuel is expressed by the deformation of membrane occurring due to the rapid rise of the fuel in the measuring space and the collision of the pressure wave against the membrane. The pressure wave is generated by the injection of the fuel into the measuring space. For each hole of the nozzle the measuring device must have a measuring space of its own into which fuel is injected as well as its measuring membrane and its own fuel outlet. Fuel escaping from the measuring device is conducted into the graduated cylinders for measuring the volumetric flow through each hole of the nozzle. The deformations of the membrane are measured with strain gauges glued to membrane. Strain gauges are connected to Wheatstone bridge that has to be temperature compensated, because measuring device warms up during measurements.

Featured in the second part of the article are the results of measurements obtained by means of the deformational measuring method whereby a three-hole injection nozzle was used. The article also quotes reasons for bilateral diversity in injection rates with multihole nozzle. The reasons are divided into structural and hydraulic group.