The Robust Multi-Scale Deep-SVDD Model for Anomaly Online Detection of Rolling Bearings

Abstract

:1. Introduction

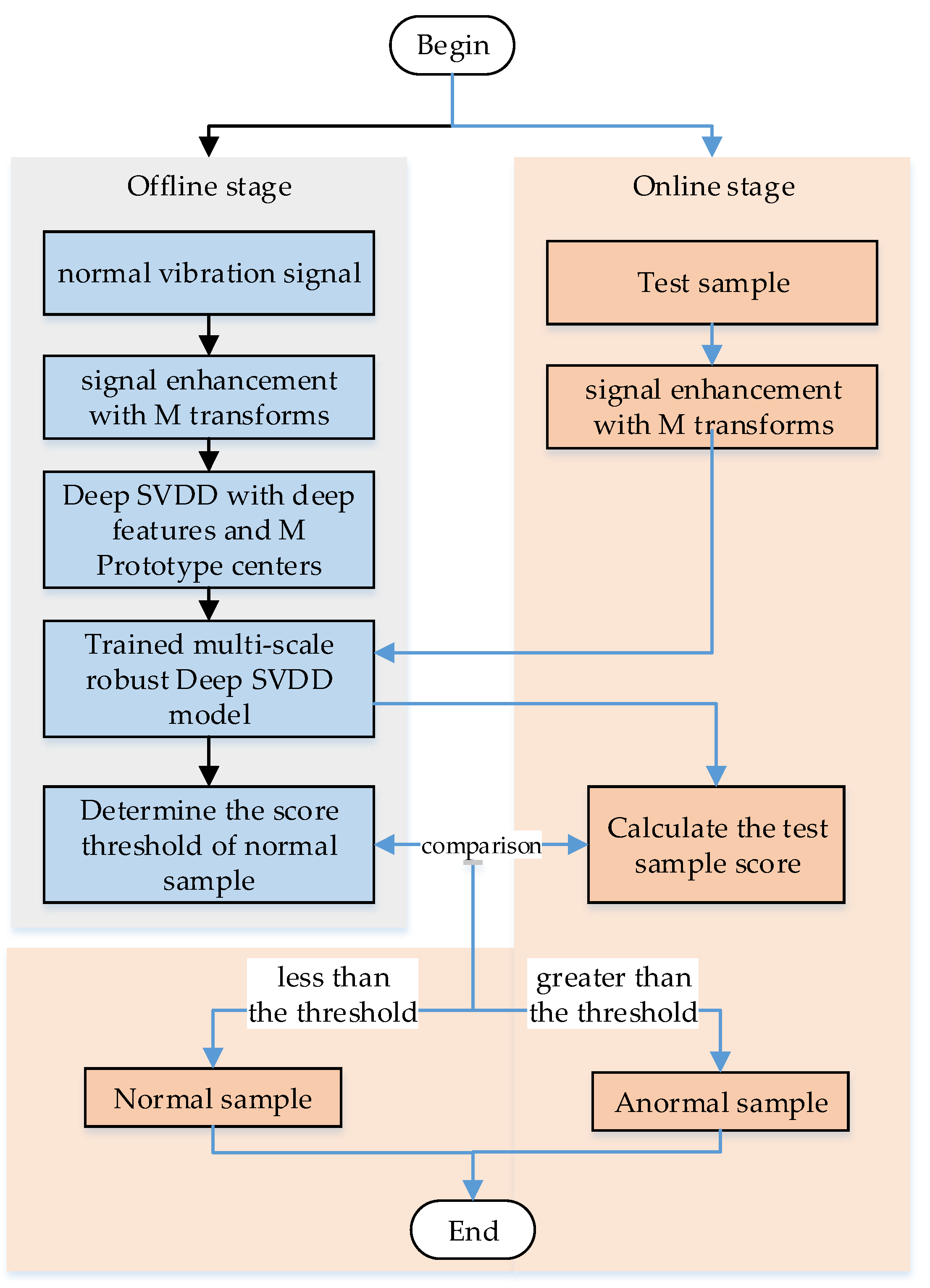

2. Deep Support Vector Data Description

3. The Robust Multi-Scale Deep-SVDD Model of Incipient Fault Detection

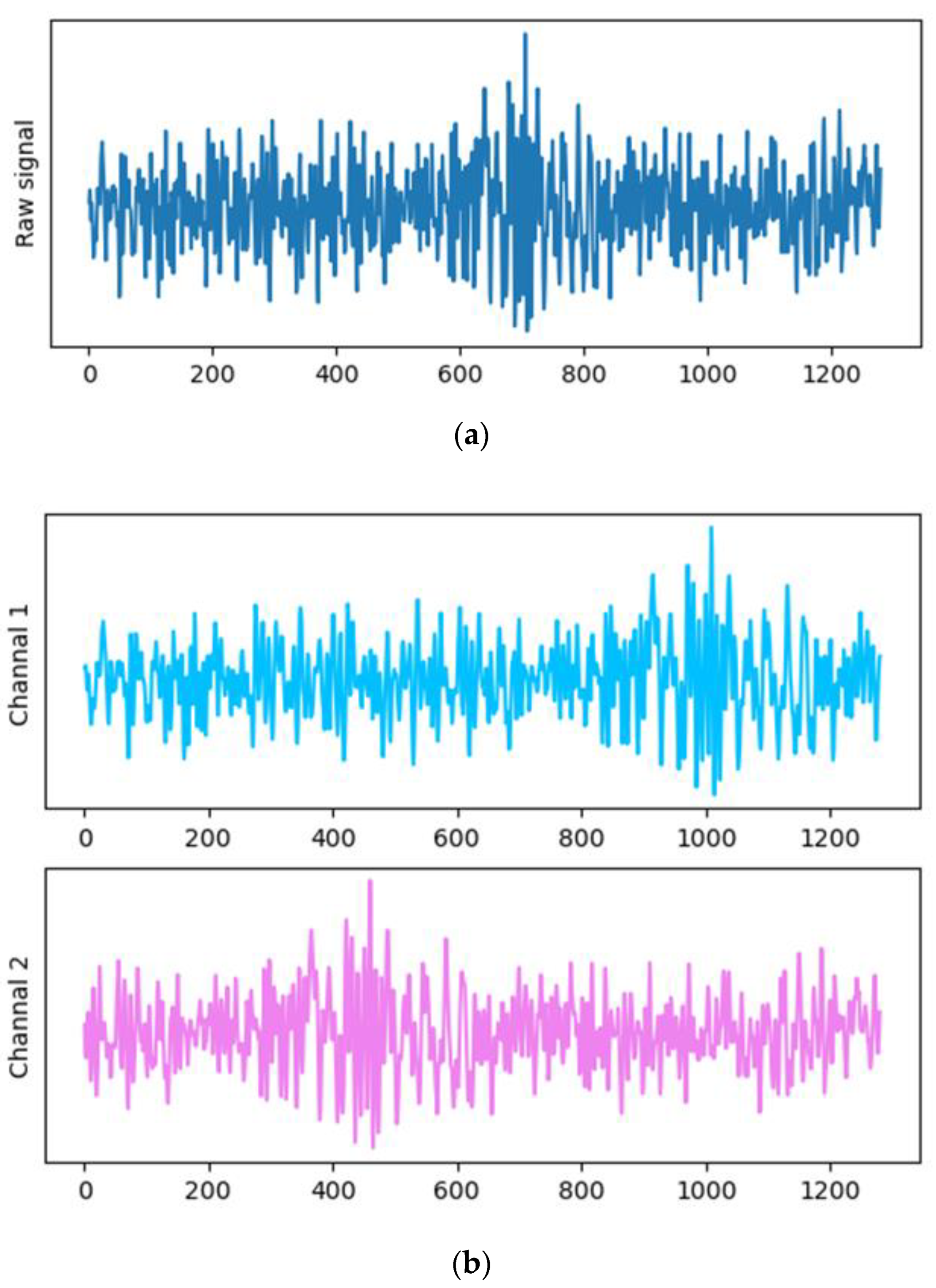

3.1. Signal Enhancement

3.1.1. Horizontal Scaling

3.1.2. Vertical Scaling

3.2. Prototype Clustering

| Algorithm 1 Learning Vector Quantization | |

| Input: | Sample set ; Suppose that, is the number of prototype vectors, is the initial category of each prototype vector, and is the learning rate. |

| Ouput: | prototype vector |

| 1: | Initialize the prototype vector . |

| 2: | Loop |

| 3: | Select samples from sample set randomly. |

| 4: | Calculate the distance between and : |

| 5: | Find the prototype vector closest to , |

| 6: | If |

| 7: | |

| 8: | Else |

| 9: | |

| 10: | End if |

| 11: | Update to |

| 12: | Until the stop criterian is reached |

3.3. Distance-Based Cross Entropy Loss

3.4. Robust Multi-Scale Deep-SVDD

3.5. Calculation of Anomaly Score

4. Experiment

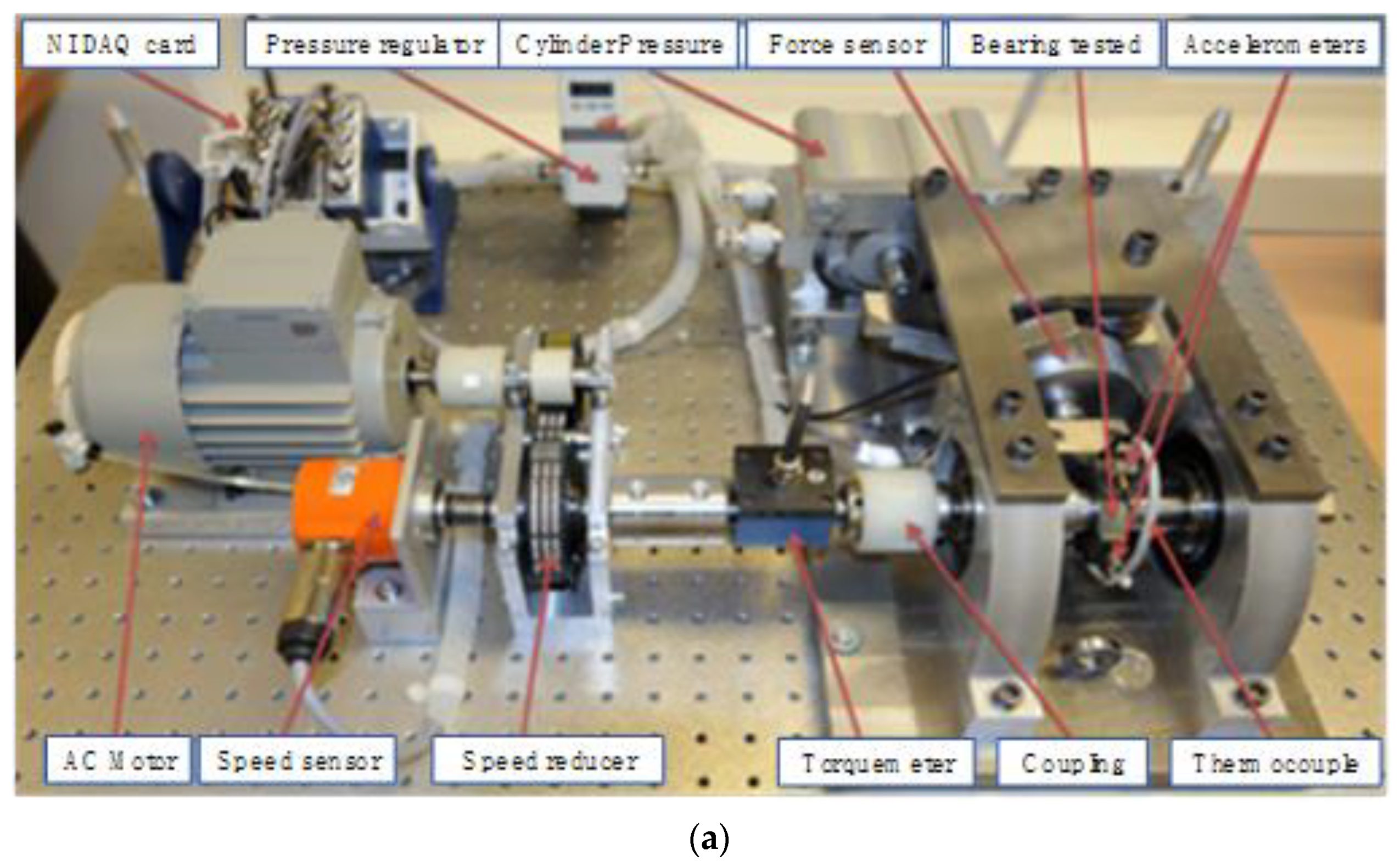

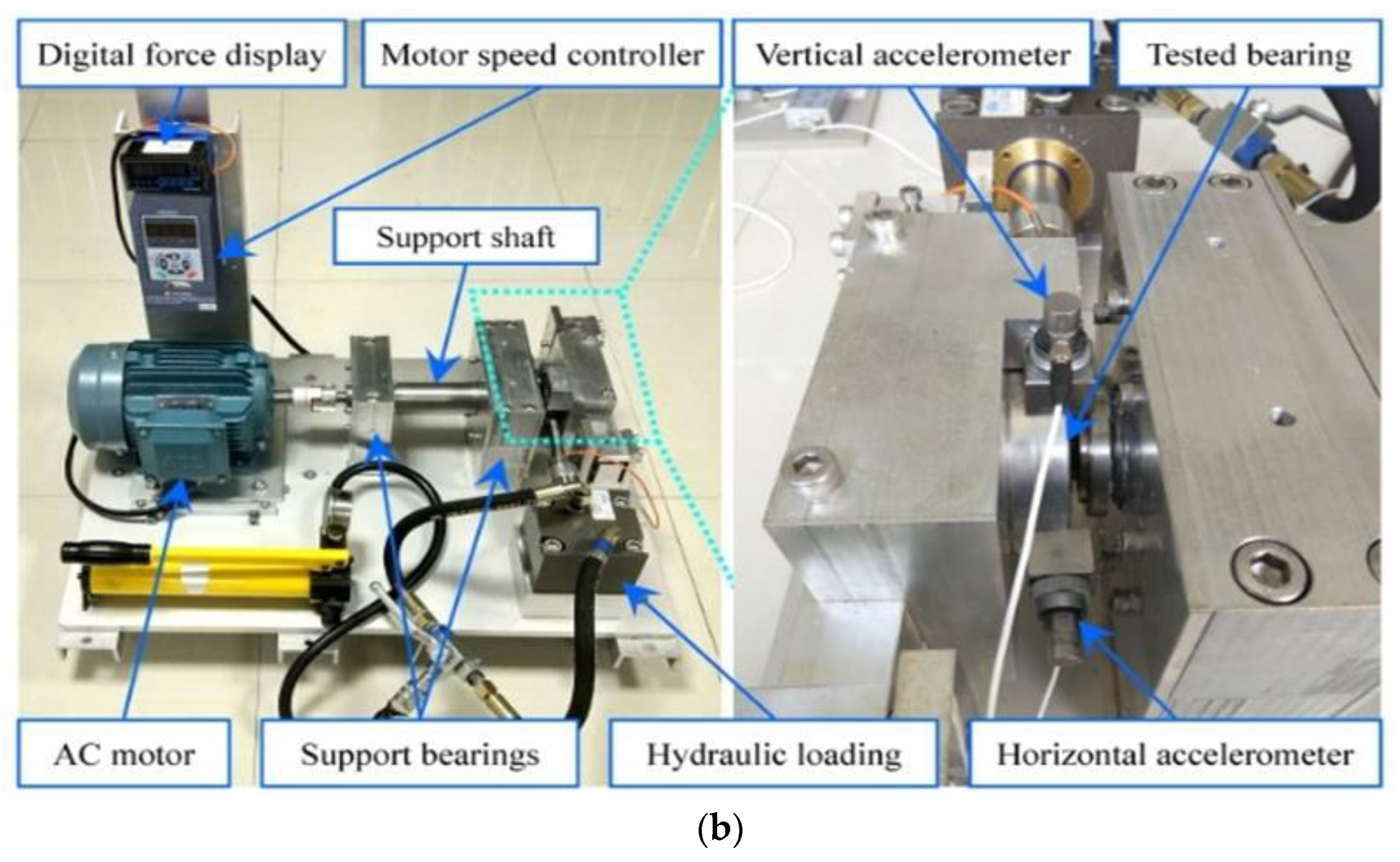

4.1. Dataset Introduction

4.2. Model Parameter Settings

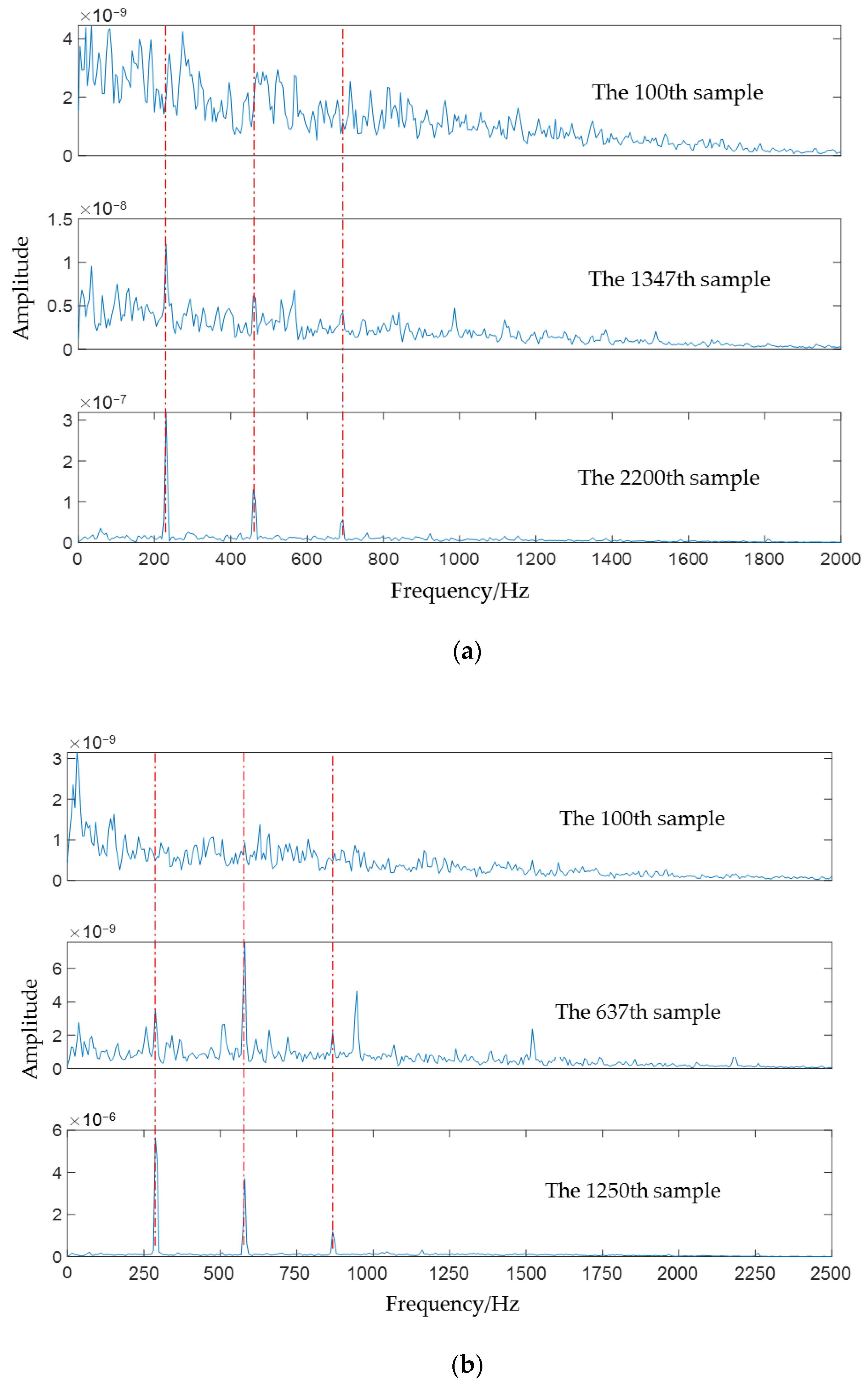

4.3. Incipient Fault Detection Results

4.4. Comparative Results

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Mao, W.; Feng, W.; Liang, X. A novel deep output kernel learning method for bearing fault structural diagnosis. Mech. Syst. Signal Process. 2019, 117, 293–318. [Google Scholar] [CrossRef]

- Tsui, K.; Chen, N.; Zhou, Q.; Hai, Y.; Wang, W. Prognostics and Health Management: A review on data driven approaches. Mathematical. Probl. Eng. 2015, 2015, 793161. [Google Scholar] [CrossRef] [Green Version]

- Lei, Y.; Qiao, Z.; Xu, X.; Lin, J.; Niu, S. An underdamped stochastic resonance method with stable-state matching for incipient fault diagnosis of rolling element bearings. Mech. Syst. Signal Process. 2017, 94, 148–164. [Google Scholar] [CrossRef]

- Huang, D.; Ke, L.; Mi, B.; Zhao, L.; Sun, G. A new incipient fault diagnosis method combining improved RLS and LMD algorithm for rolling bearings with strong background noise. IEEE Access 2018, 6, 26001–26010. [Google Scholar]

- Ma, J.; Wu, J.; Wang, X. Incipient fault feature extraction of rolling bearings based on the MVMD and Teager energy operator. ISA Trans. 2018, 80, 297–311. [Google Scholar] [CrossRef] [PubMed]

- Ambrokiewicz, B.; Syta, A.; Gassner, A.; Anthimos, G.; Grzegorz, L.; Nicolas, M. The influence of the radial internal clearance on the dynamic response of self-aligning ball bearings. Mech. Syst. Signal Process. 2022, 171, 108954. [Google Scholar] [CrossRef]

- Liu, J.; Xu, Y.; Pan, G. A combined acoustic and dynamic model of a defective ball bearing. J. Sound Vib. 2021, 501, 116029. [Google Scholar] [CrossRef]

- Chen, R.; Linlin, L.; Hu, X.; Wu, H. Fault Diagnosis Method of Low-speed Rolling Bearing Based on Acoustic Emission Signal and Subspace Embedded Feature Distribution Alignment. IEEE Trans. Ind. Inform. 2021, 17, 5402–5410. [Google Scholar] [CrossRef]

- Maroua, H.; Ramiro, M.; Carlos, F.; Jorge, S.; Mohamed, S.; Mohamed, H. Friction torque in rolling bearings lubricated with axle gear oils-ScienceDirect. Tribol. Int. 2018, 119, 419–435. [Google Scholar]

- Liu, R.; Yang, B.; Zhang, X.; Wang, S.; Chen, X. Time-frequency atoms-driven support vector machine method for bearings incipient fault diagnosis. Mech. Syst. Signal Process. 2016, 75, 345–370. [Google Scholar] [CrossRef]

- Li, F.; Wang, J.; Chyu, M.K.; Tang, B. Weak fault diagnosis of rotating machinery based on feature reduction with Supervised Orthogonal Local Fisher Discriminant Analysis. Neurocomputing 2015, 168, 505–519. [Google Scholar] [CrossRef]

- Ocak, H.; Loparo, K.A. A new bearing fault detection and diagnosis scheme based on hidden Markov modeling of vibration signals. In Proceedings of the 2001 IEEE International Conference on Acoustics, Speech, and Signal Processing, Salt Lake City, UT, USA, 7–11 May 2001; Volume 5, pp. 3141–3144. [Google Scholar]

- Jia, F.; Lei, Y.; Guo, L.; Lin, J.; Xing, S. A neural network constructed by deep learning technique and its application to intelligent fault diagnosis of machines. Neurocomputing 2018, 272, 619–628. [Google Scholar] [CrossRef]

- Shao, H.; Jiang, H.; Zhang, X.; Niu, M. Rolling bearing fault diagnosis using an optimization deep belief network. Meas. Sci. Technol. 2015, 26, 115002. [Google Scholar] [CrossRef]

- Mao, W.; He, J.; Zuo, M.J. Predicting Remaining Useful Life of Rolling Bearings Based on Deep Feature Representation and Transfer Learning. IEEE Trans. Instrum. Meas. 2020, 69, 1594–1608. [Google Scholar] [CrossRef]

- Mao, W.; Liu, Y.; Ding, L.; Safian, A.; Liang, X. A New Structured Domain Adversarial Neural Network for Transfer Fault Diagnosis of Rolling Bearings. IEEE Trans. Instrum. Meas. 2021, 70, 1–13. [Google Scholar]

- Zhang, E.; Li, M.; Yiu, S.; Du, J.; Zhu, J.; Jin, G. Fair hierarchical secret sharing scheme based on smart contract. Inf. Sci. 2021, 546, 166–176. [Google Scholar] [CrossRef]

- Lu, W.; Li, Y.; Cheng, Y.; Meng, D.; Liang, B.; Zhou, P. Early Fault Detection Approach with Deep Architectures. IEEE Trans. Instrum. Meas. 2018, 67, 1679–1689. [Google Scholar] [CrossRef]

- Zhao, R.; Wang, D.; Yan, R.; Mao, K.; Shen, F.; Wang, J.J. Machine Health Monitoring Using Local Feature-Based Gated Recurrent Unit Networks. IEEE Trans. Ind. Electron. 2018, 65, 1539–1548. [Google Scholar] [CrossRef]

- Shao, H.; Xia, M.; Han, G.; Zhang, Y.; Wan, J. Intelligent Fault Diagnosis of Rotor-Bearing System Under Varying Working Conditions With Modified Transfer Convolutional Neural Network and Thermal Images. IEEE Trans. Ind. Inform. 2021, 17, 3488–3496. [Google Scholar] [CrossRef]

- Chen, S.; Meng, Y.; Tang, H.; Tian, Y.; He, N.; Shao, C. Robust Deep Learning-Based Diagnosis of Mixed Faults in Rotating Machinery. IEEE/ASME Trans. Mechatron. 2020, 25, 2167–2176. [Google Scholar] [CrossRef]

- Mao, W.; Chen, J.; Liang, X.; Zhang, X. A New Online Detection Approach for Rolling Bearing Incipient Fault via Self-Adaptive Deep Feature Matching. IEEE Trans. Instrum. Meas. 2020, 69, 443–456. [Google Scholar] [CrossRef]

- Paschali, M.; Simson, W.; Roy, A.G.; Naeem, M.F.; G¨obl, R.; Wachinger, C.; Navab, N. Data augmentation with manifold exploring geometric transformations for increased performance and robustness. arXiv 2019, arXiv:1901.04420v1. [Google Scholar]

- Mikôajczyk, A.; Grochowski, M. Data augmentation for improving deep learning in image classification problem. In Proceedings of the 2018 International Interdisciplinary PhD Workshop, Swinoujscie, Poland, 9–12 May 2018. [Google Scholar]

- Kang, G.; Dong, X.; Zheng, L.; Yang, Y. PatchShuffle Regularization. Computer Vision and Pattern Recognition. arXiv 2017, arXiv:1707.07103. [Google Scholar]

- Goodfellow, I.J.; Shlens, J.; Szegedy, C. Explaining and Harnessing Adversarial Examples. arXiv 2014, arXiv:1412.6572. [Google Scholar]

- Gatys, L.; Ecker, A.; Bethge, M. A Neural Algorithm of Artistic Style. J. Vis. 2016, 16, 326. [Google Scholar] [CrossRef]

- Han, S.; Oh, J.; Jeong, J. Bearing Fault Detection with Data Augmentation Based on 2-D CNN and 1-D CNN. In Proceedings of the BDIOT 2020: 2020 the 4th International Conference on Big Data and Internet of Things, Singapore, 22–24 August 2020. [Google Scholar]

- Ruff, L.; Vandermeulen, R.A.; Gřnitz, N.; Deecke, L.; Siddiqui, S.A.; Binder, A.; Müller, E.; Kloft, M. Deep One-Class Classification. In Proceedings of the International Conference on Machine Learning, Stockholm, Sweden, 10–15 July 2018; pp. 4390–4399. [Google Scholar]

- Ruff, L.; Kauffmann, J.R.; Vandermeulen, R.A.; Montavon, G.; Samek, W.; Kloft, M.; Dietterich, T.G.; Müller, K.-R. A Unifying Review of Deep and Shallow Anomaly Detection. Proc. IEEE 2021, 109, 756–795. [Google Scholar]

- Li, R.P.; Masao, M. Proportional learning vector quantization. J. Jpn. Soc. Fuzzy Theory Syst. 1998, 10, 1129–1134. [Google Scholar] [CrossRef] [Green Version]

- Nectoux, P.; Gouriveau, R.; Medjaher, K. PRONOSTIA: An experimental platform for bearings accelerated life test. In Proceedings of the IEEE International Conference on Prognostics and Health Management, Denver, MA, USA, 1–8 June 2012. [Google Scholar]

- Wang, B.; Lei, Y.; Li, N.; Li, N. A Hybrid Prognostics Approach for Estimating Remaining Useful Life of Rolling Element Bearings. IEEE Trans. Reliab. 2020, 69, 401–412. [Google Scholar] [CrossRef]

- He, K.; Zhang, X.; Ren, S.; Sun, J. Deep Residual Learning for Image Recognition. In Proceedings of the 2016 IEEE Conference on Computer Vision and Pattern Recognition (CVPR), Las Vegas, NV, USA, 27–30 June 2016. [Google Scholar]

- Li, Y.; Xu, M.; Liang, X.; Huang, W. Application of Bandwidth EMD and Adaptive Multiscale Morphology Analysis for Incipient Fault Diagnosis of Rolling Bearings. IEEE Trans. Ind. Electron. 2017, 64, 6506–6517. [Google Scholar] [CrossRef]

- Guo, X.; Liu, S.; Li, Y. Fault Detection of Multi-mode Processes Employing Sparse Residual Distance. Acta Autom. Sin. 2019, 45, 617–625. [Google Scholar]

| Dataset | Sample | Number of Sample | Training Sample | Testing Sample | The Real Sample Point of Incipient Fault | Number of Early Fault Samples |

|---|---|---|---|---|---|---|

| IEEE PHM Challenge 2012 dataset | Condition 1 Bearing1_2 | 871 | The first 100 samples | The rest 771 samples | - | 479 |

| Condition 1 Bearing1_3 | 2375 | The first 100 samples | The rest 2275 samples | 1348th | 1027 | |

| XJTU-SY dataset | Condition 1 Bearing1_1 | 1476 | The first 100 samples | The rest 1376 samples | 634th | 839 |

| Condition 2 Bearing2_2 | 1932 | The first 100 samples | The rest 1832 samples | - | 942 |

| Comparison Methods | PHM1_3 | XJTU1_1 | ||

|---|---|---|---|---|

| The Detected Sample Point | Deviation Rate of Incipient Fault Detection | The Detected Sample Point | Deviation Rate of Incipient Fault Detection | |

| 1. BEMD-AMMA | 1600 | 55.79% | 1320 | 57.33% |

| 2. LOF | 1236 | 20.35% | 944 | 12.51% |

| 3. iFOREST | 1341 | 30.57% | 1041 | 24.08% |

| 4. SDFM | 1156 | 12.56% | 1137 | 35.52% |

| 5. SRD | 1160 | 12.95% | 1013 | 20.74% |

| 6. The proposed method | 997 | 2.9% | 826 | 1.55% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kou, L.; Chen, J.; Qin, Y.; Mao, W. The Robust Multi-Scale Deep-SVDD Model for Anomaly Online Detection of Rolling Bearings. Sensors 2022, 22, 5681. https://doi.org/10.3390/s22155681

Kou L, Chen J, Qin Y, Mao W. The Robust Multi-Scale Deep-SVDD Model for Anomaly Online Detection of Rolling Bearings. Sensors. 2022; 22(15):5681. https://doi.org/10.3390/s22155681

Chicago/Turabian StyleKou, Linlin, Jiaxian Chen, Yong Qin, and Wentao Mao. 2022. "The Robust Multi-Scale Deep-SVDD Model for Anomaly Online Detection of Rolling Bearings" Sensors 22, no. 15: 5681. https://doi.org/10.3390/s22155681

APA StyleKou, L., Chen, J., Qin, Y., & Mao, W. (2022). The Robust Multi-Scale Deep-SVDD Model for Anomaly Online Detection of Rolling Bearings. Sensors, 22(15), 5681. https://doi.org/10.3390/s22155681