Flexible Wearable Composite Antennas for Global Wireless Communication Systems

Abstract

:1. Introduction

2. Antenna Design

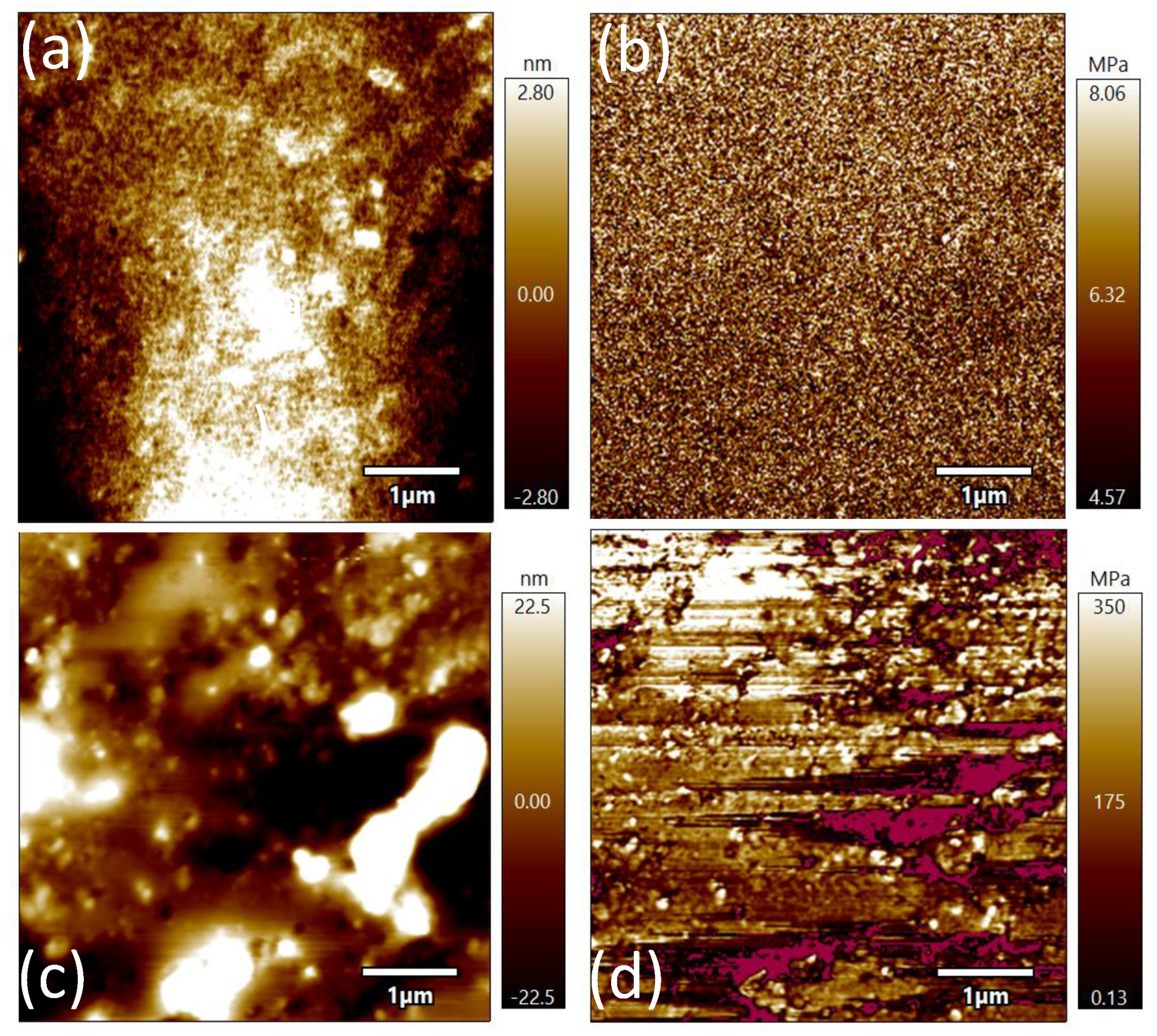

2.1. Synthesis and Manufacturing Process of Composite Materials

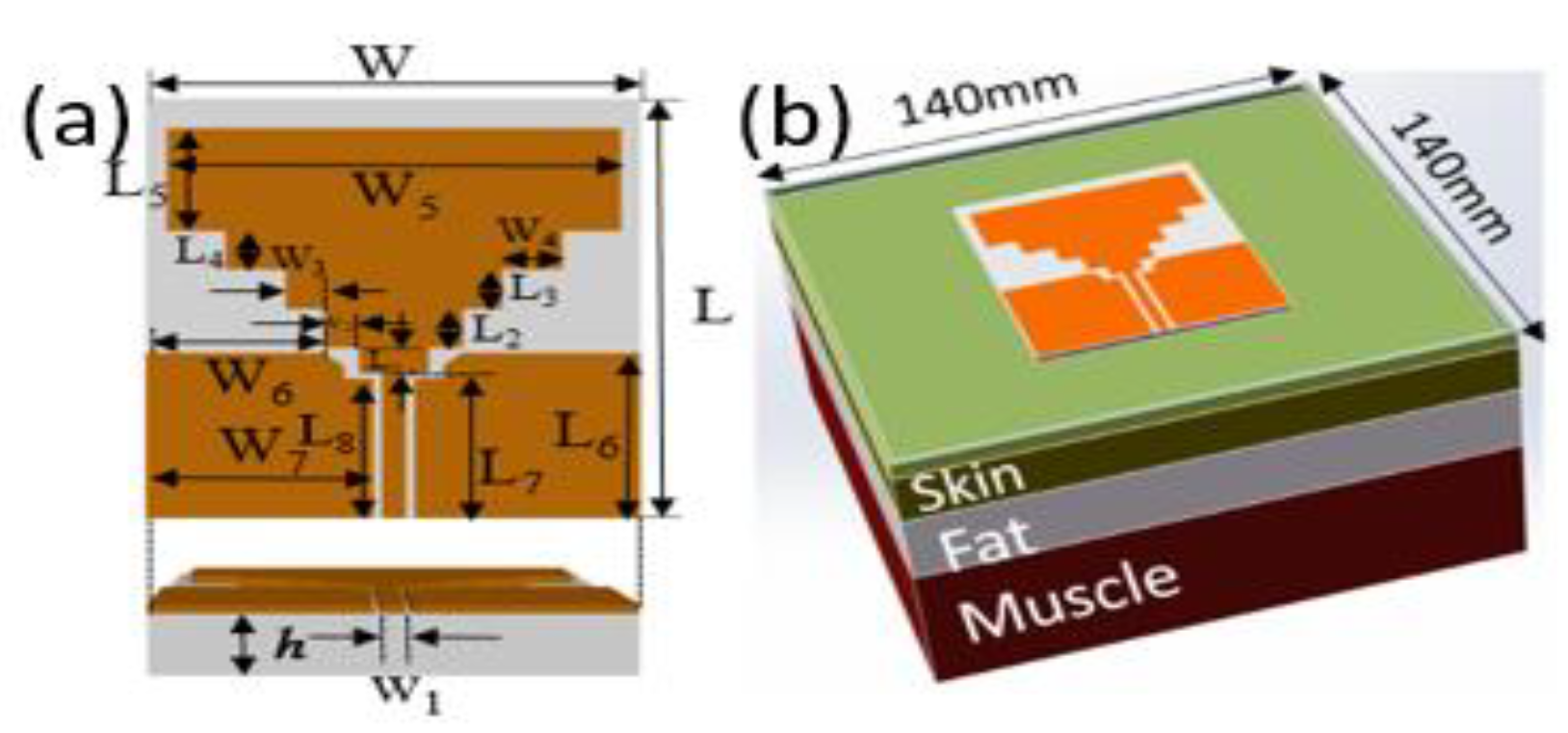

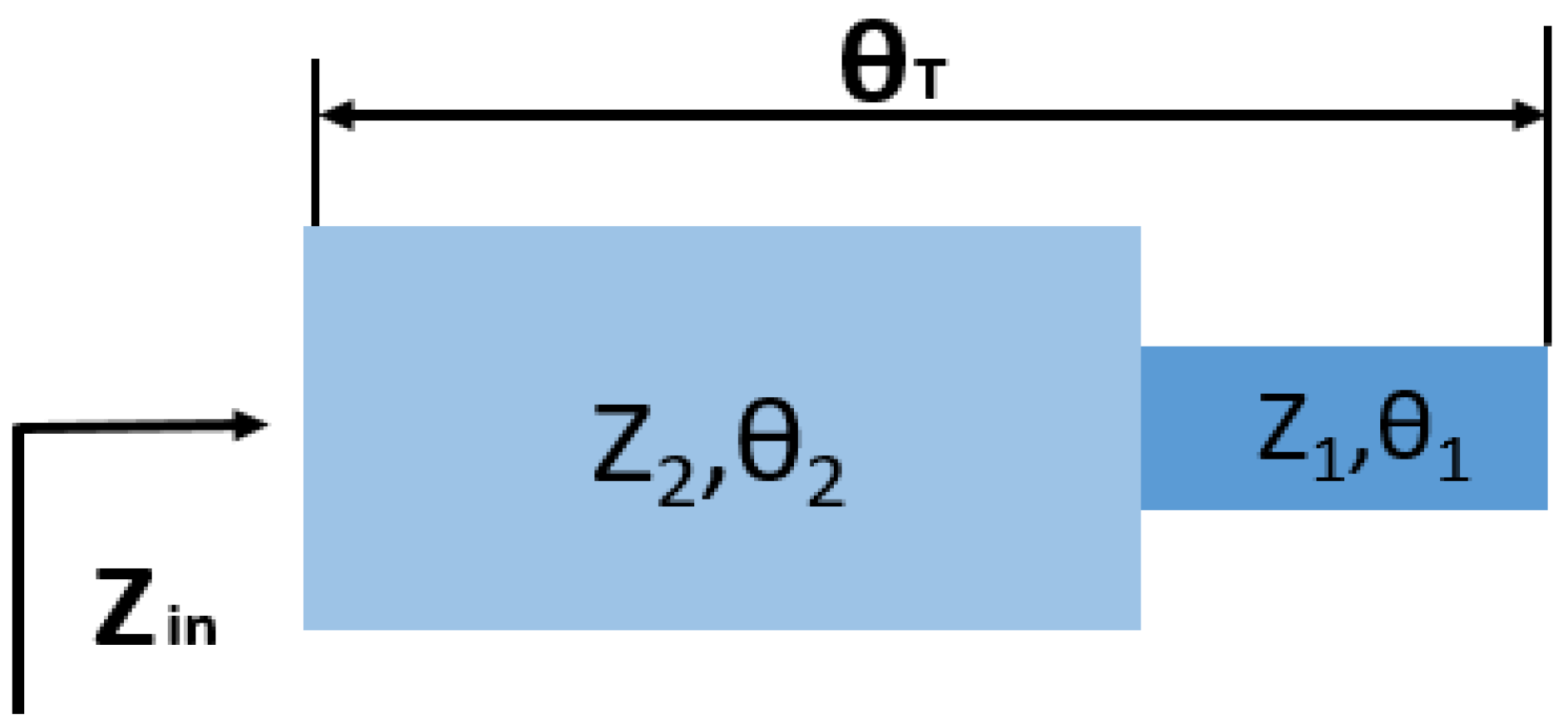

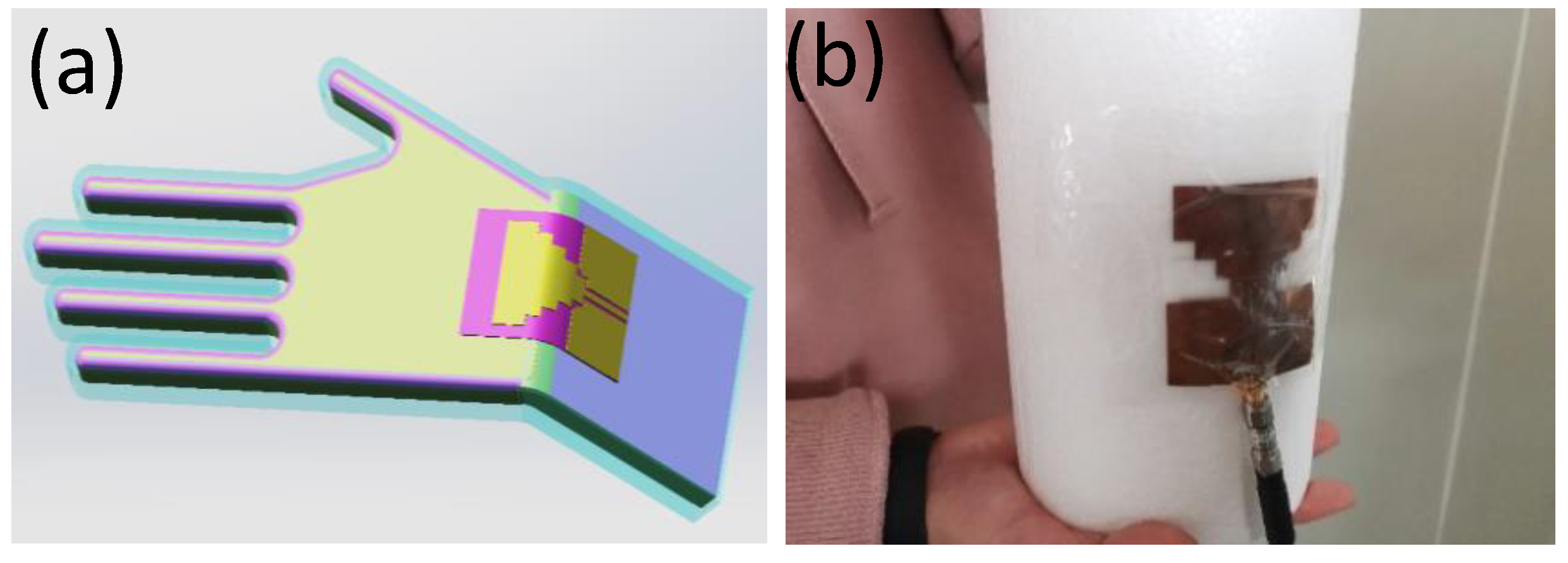

2.2. Structure Design and Theory of Antenna

3. Simulation and Test Results

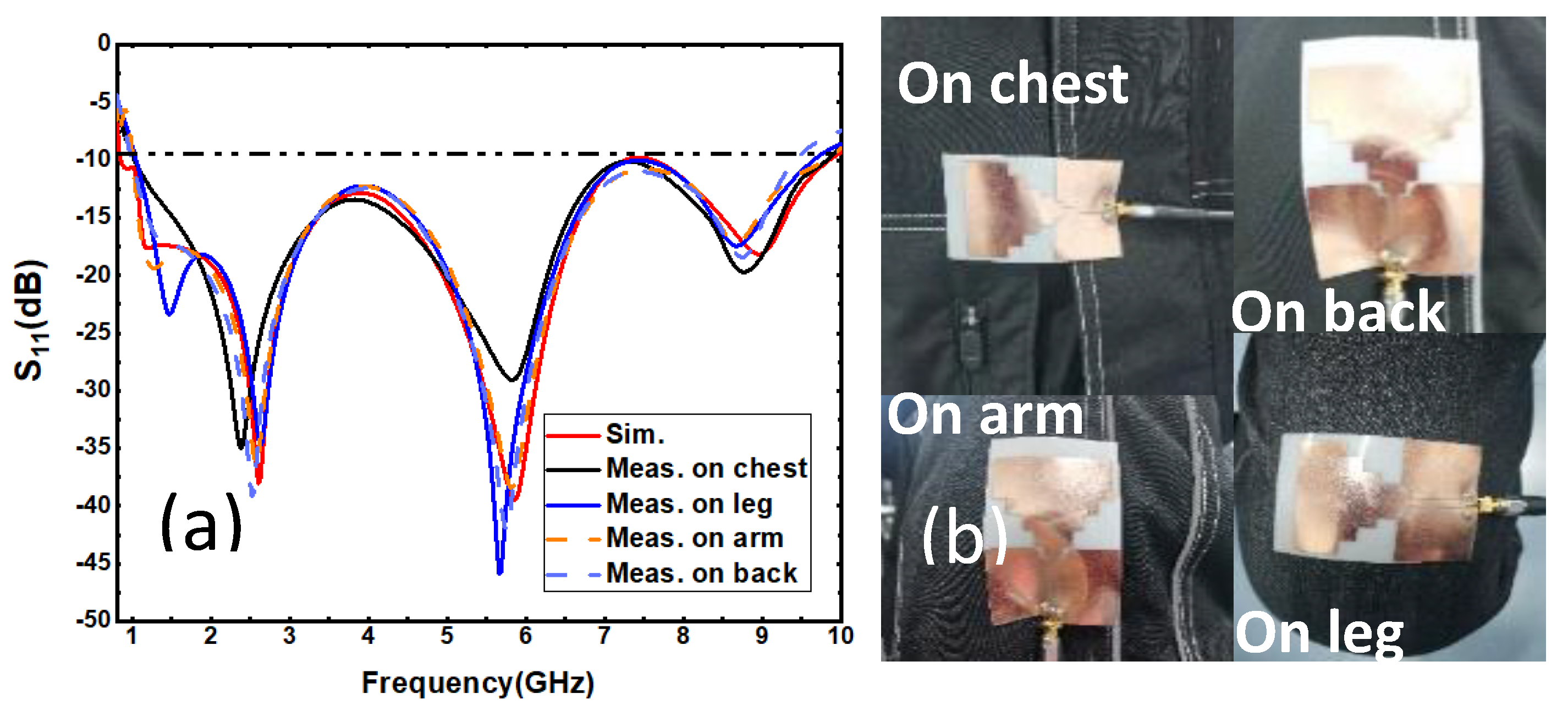

3.1. Body Wearablity Test Results

3.2. Stability Testing of Conformal Deformation

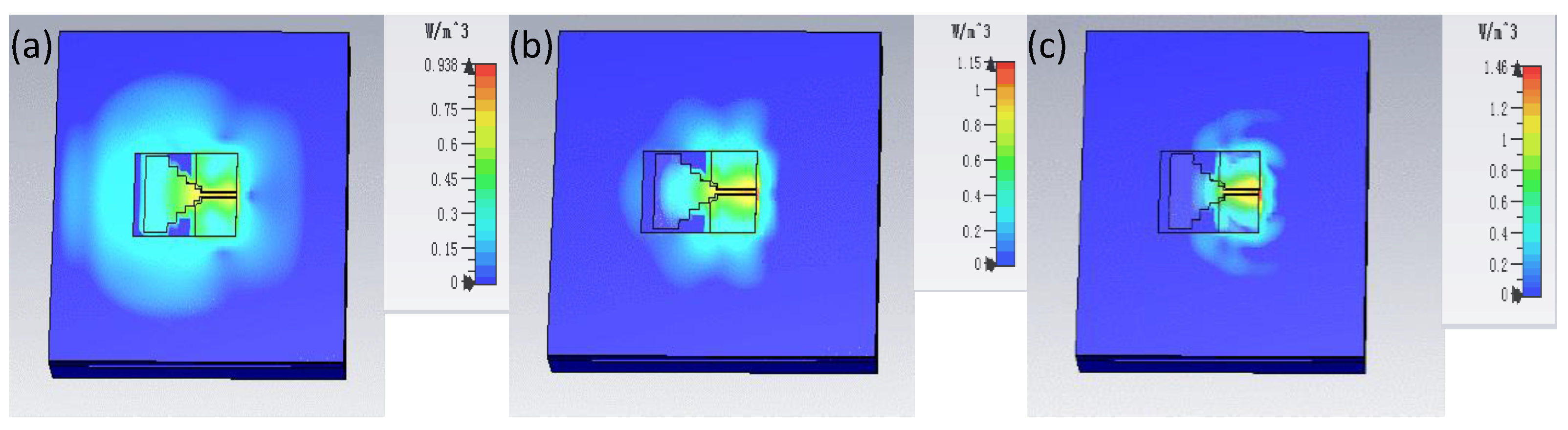

3.3. Safety Assessment of Body-Worn Antenna

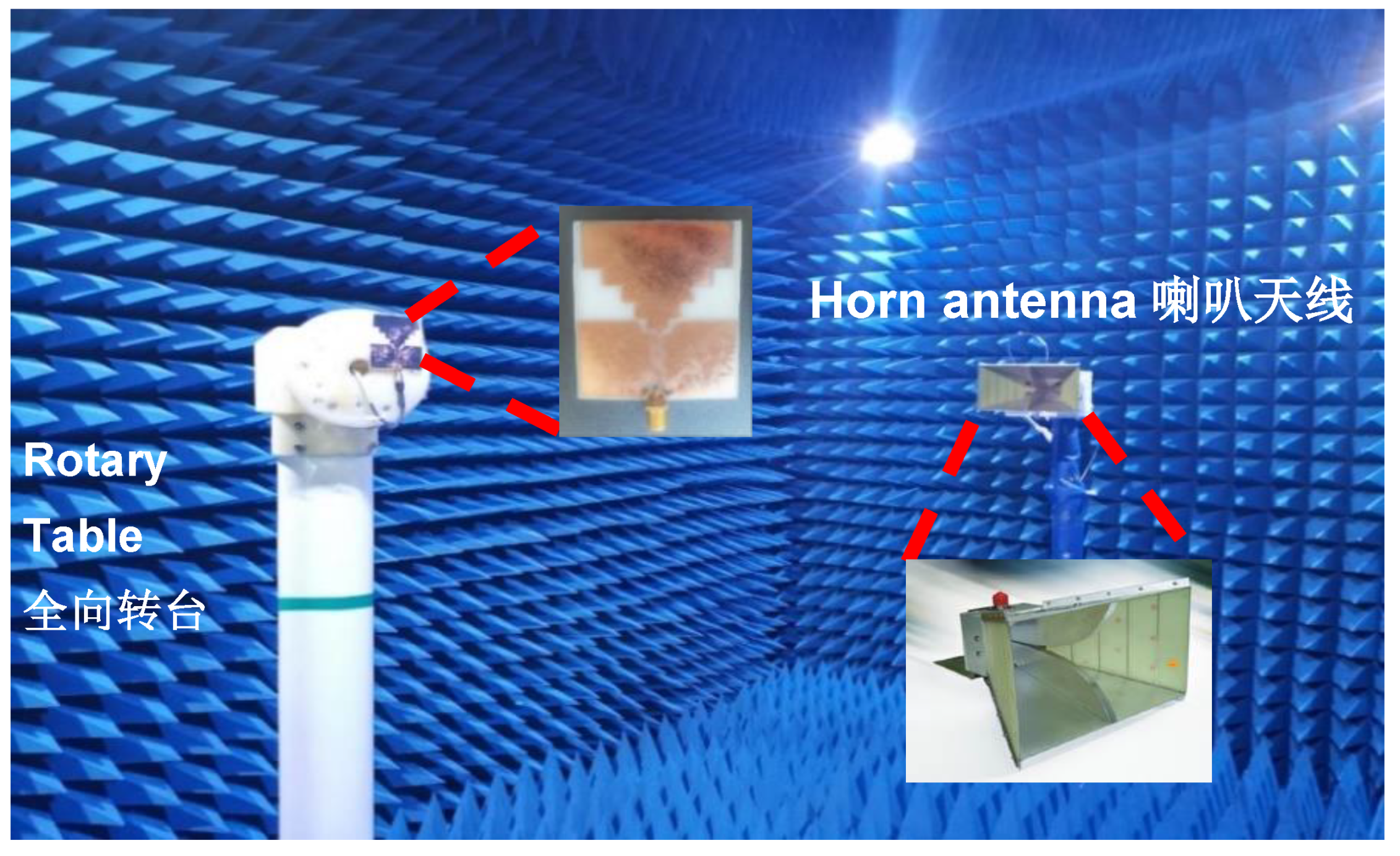

3.4. Radiation Pattern Test Results

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Mani, G.K.; Nimura, Y.; Tsuchiya, K. Advanced Artificial Electronic Skin Based pH Sensing System for Heatstroke Detection. ACS Sens. 2020, 5, 911–916. [Google Scholar] [CrossRef] [PubMed]

- Cao, X.; Halder, A.; Tang, Y.; Hou, C.; Wang, H.; Duus, J.Ø.; Chi, Q. Engineering two-dimensional layered nanomaterials for wearable biomedical sensors and power devices. Mater. Chem. Front. 2018, 2, 1944–1986. [Google Scholar] [CrossRef]

- Ho, C.D.; Nguyen, T.-V.; Huynh-The, T.; Nguyen, T.-T.; da Costa, D.B.; An, B. Short-Packet Communications in Wireless-Powered Cognitive IoT Networks: Performance Analysis and Deep Learning Evaluation. IEEE Trans. Veh. Technol. 2021, 70, 2894–2899. [Google Scholar] [CrossRef]

- Kamalaveni, A.; Ganesh Madhan, M. A compact TRM antenna with high impedance surface for SAR reduction at 1800 MHz. AEU-Int. J. Electron. Commun. 2016, 70, 1192–1198. [Google Scholar] [CrossRef]

- El Atrash, M.; Abdalla, M.A.; Elhennawy, H.M. A Compact Highly Efficient Π-Section CRLH Antenna Loaded with Textile AMC for Wireless Body Area Network Applications. IEEE Trans. Antennas Propag. 2021, 69, 648–657. [Google Scholar] [CrossRef]

- Kaim, V.; Kanaujia, B.K.; Rambabu, K. Quadrilateral Spatial Diversity Circularly Polarized MIMO Cubic Implantable Antenna System for Biotelemetry. IEEE Trans. Antennas Propag. 2021, 69, 1260–1272. [Google Scholar] [CrossRef]

- Ashyap, A.Y.I.; Elamin, N.I.M.; Dahlan, S.H.; Abidin, Z.Z.; See, C.H.; Majid, H.A.; Al-Fadhali, N.; Mukred, J.A.A.; Saleh, G.; Esmail, B.A.F. Via-less electromagnetic band-gap-enabled antenna based on textile material for wearable applications. PLoS ONE 2021, 16, e0246057. [Google Scholar] [CrossRef] [PubMed]

- Hertleer, C.; Rogier, H.; Vallozzi, L.; Van Langenhove, L. A Textile Antenna for Off-Body Communication Integrated into Protective Clothing for Firefighters. IEEE Trans. Antennas Propag. 2009, 57, 919–925. [Google Scholar] [CrossRef]

- Park, J.; Kim, J.K.; Patil, S.J.; Park, J.K.; Park, S.; Lee, D.W. A Wireless Pressure Sensor Integrated with a Biodegradable Polymer Stent for Biomedical Applications. Sensors 2016, 16, 809. [Google Scholar] [CrossRef] [Green Version]

- Mao, C.X.; Khalily, M.; Zhang, L.; Xiao, P.; Sun, Y.; Werner, D.H. Compact Patch Antenna with Vertical Polarization and Omnidirectional Radiation Characteristics. IEEE Trans. Antennas Propag. 2021, 69, 1158–1161. [Google Scholar] [CrossRef]

- Yang, H.; Liu, X. Wearable Dual-Band and Dual-Polarized Textile Antenna for On-and Off-Body Communications. IEEE Antennas Wirel. Propag. Lett. 2020, 19, 2324–2328. [Google Scholar] [CrossRef]

- Zhan, Y.; Li, L. Low-permittivity and high-Q value Li2Mg3Ti1-x(Zn1/3Nb2/3)xO6 microwave dielectric ceramics for microstrip antenna applications in 5G millimeter wave. J. Alloys Compd. 2021, 857, 157608. [Google Scholar] [CrossRef]

- Chen, W.-S.; Hung, M.-L.; Hsu, C.-H. Effects of (Co1/3Nb2/3)4+ Substitution on Microstructure and Microwave Dielectric Properties of Li2Ti1-x(Co1/3Nb2/3)xO3 Ceramics for Applications in Ceramic Antenna. J. Asian Ceram. Soc. 2021, 9, 433–442. [Google Scholar] [CrossRef]

- Roshni, S.B.; Arun, S.; Sebastian, M.T.; Mohanan, P.; Surendran, K.P. Low κ Mg2SiO4 ceramic tapes and their role as screen printed microstrip patch antenna substrates. Mater. Sci. Eng. B 2021, 264, 114947. [Google Scholar] [CrossRef]

- Tan, Z.; Song, K.; Bafrooei, H.B.; Liu, B.; Wu, J.; Xu, J.; Lin, H.; Wang, D. The effects of TiO2 addition on microwave dielectric properties of Y3MgAl3SiO12 ceramic for 5G application. Ceram. Int. 2020, 46, 15665–15669. [Google Scholar] [CrossRef]

- Vilarinho, P.M.; Fu, Z.; Kingon, A.I.; Tkach, A. Low loss tunable dielectric BaNd2Ti5O14-(Ba0.5Sr0.5)TiO3 composite thick films. Scr. Mater. 2018, 155, 160–163. [Google Scholar] [CrossRef]

- Muhamad, W.A.W.; Ngah, R.; Jamlos, M.F.; Soh, P.J.; Ali, M.T. High-gain dipole antenna using polydimethylsiloxane–glass microsphere (PDMS-GM) substrate for 5G applications. Appl. Phys. A 2016, 123. [Google Scholar] [CrossRef]

- Sayem, A.S.M.; Simorangkir, R.B.V.B.; Esselle, K.P.; Hashmi, R.M. Development of Robust Transparent Conformal Antennas Based on Conductive Mesh-Polymer Composite for Unobtrusive Wearable Applications. IEEE Trans. Antennas Propag. 2019, 67, 7216–7224. [Google Scholar] [CrossRef]

- Hamouda, Z.; Wojkiewicz, J.-L.; Pud, A.A.; Kone, L.; Bergheul, S.; Lasri, T. Magnetodielectric Nanocomposite Polymer-Based Dual-Band Flexible Antenna for Wearable Applications. IEEE Trans. Antennas Propag. 2018, 66, 3271–3277. [Google Scholar] [CrossRef]

- Xu, F.; Zhang, D.; Liao, Y.; Xie, F.; Zhang, H. Dispersion of LiZnTiBi ferrite particles into PMDS film for miniaturized flexible antenna application. Ceram. Int. 2019, 45, 8914–8918. [Google Scholar] [CrossRef]

- Lin, X.; Chen, Y.; Gong, Z.; Seet, B.-C.; Huang, L.; Lu, Y. Ultrawideband Textile Antenna for Wearable Microwave Medical Imaging Applications. IEEE Trans. Antennas Propag. 2020, 68, 4238–4249. [Google Scholar] [CrossRef]

- Catarinucci, L.; Chietera, F.P.; Colella, R. Permittivity-Customizable Ceramic-Doped Silicone Substrates Shaped With 3-D-Printed Molds to Design Flexible and Conformal Antennas. IEEE Trans. Antennas Propag. 2020, 68, 4967–4972. [Google Scholar] [CrossRef]

- Yang, Y.; Zhang, H.; Li, J.; Rao, Y.; Wang, G.; Gan, G. Bi3+ doping-adjusted microstructure, magnetic, and dielectric properties of nickel zinc ferrite ceramics for high frequency LTCC antennas. Ceram. Int. 2020, 46, 25697–25704. [Google Scholar] [CrossRef]

- Samsuzzaman, M.; Islam, M.T.; Arshad, H.; Mandeep, J.S.; Misran, N. Circularly polarized S band dual frequency square patch antenna using glass microfiber reinforced PTFE composite. Sci. World J. 2014, 2014, 345190. [Google Scholar] [CrossRef] [PubMed]

- Li, H.; Meng, N.; Lyu, W.; Cheng, Z.; Chen, S.; Zhang, W.; Liao, Y. Solvothermal synthesis of porphyrin-ferrocenyl conjugated microporous polymer nanospheres for shape-stable phase change materials with improved latent heat and cyclability. J. Colloid Interface Sci. 2021, 595, 178–186. [Google Scholar] [CrossRef]

- Liu, Y.; Wu, P.; Kang, P.; Li, L.; Shi, J.; Zhou, Z.; Chen, G.-X.; Li, Q. PDMS-based composites with stable dielectric properties at varied frequency via Sr-doped CaCu3Ti4O12 nanowires for flexible wideband antenna substrate. J. Mater. Sci. Mater. Electron. 2020, 32, 430–441. [Google Scholar] [CrossRef]

- Palvolgyi, P.S.; Nelo, M.; Pitkanen, O.; Perantie, J.; Liimatainen, H.; Myllymaki, S.; Jantunen, H.; Kordas, K. Ultra-low permittivity porous silica-cellulose nanocomposite substrates for 6G telecommunication. Nanotechnology 2020, 31, 435203. [Google Scholar] [CrossRef] [PubMed]

- Zhang, L.; Zhang, J.; Yue, Z.; Li, L. New three-phase polymer-ceramic composite materials for miniaturized microwave antennas. AIP Adv. 2016, 6. [Google Scholar] [CrossRef] [Green Version]

- Alqadami, A.S.M.; Mohammed, B.; Bialkowski, K.S.; Abbosh, A. Fabrication and Characterization of Flexible Polymer Iron Oxide Composite Substrate for the Imaging Antennas of Wearable Head Imaging Systems. IEEE Antennas Wirel. Propag. Lett. 2018, 17, 1364–1368. [Google Scholar] [CrossRef]

- Zhang, L.; Zhang, J.; Yue, Z.; Li, L. Thermally stable polymer–ceramic composites for microwave antenna applications. J. Adv. Ceram. 2016, 5, 269–276. [Google Scholar] [CrossRef] [Green Version]

- Sharma, P.K.; Gupta, N.; Dankov, P.I. Characterization of polydimethylsiloxane (PDMS) as a wearable antenna substrate using resonance and planar structure methods. AEU Int. J. Electron. Commun. 2020, 127. [Google Scholar] [CrossRef]

- Jin, S.; Qiu, X.; Huang, B.; Wang, L.; Zhang, Q.; Fu, Z. Dielectric properties of modified BNT/PTFE composites for microwave RF antenna applications. J. Mater. Sci. Mater. Electron. 2016, 27, 8378–8383. [Google Scholar] [CrossRef]

- Jin, S.; Wang, L.; Wang, Z.; Huang, B.; Zhang, Q.; Fu, Z. Dielectric properties of modified SrTiO3/PTFE composites for microwave RF antenna applications. J. Mater. Sci. Mater. Electron. 2015, 26, 7431–7437. [Google Scholar] [CrossRef]

- Ullah, M.H.; Islam, M.T. A compact square loop patch antenna on high dielectric ceramic–PTFE composite material. Appl. Phys. A 2013, 113, 185–193. [Google Scholar] [CrossRef]

- Ma, Z.H.; Jiang, Y.F. L-Shaped Slot-Loaded Stepped-Impedance Microstrip Structure UWB Antenna. Micromachines 2020, 11, 828. [Google Scholar] [CrossRef] [PubMed]

| Ref. | Bandwidth | Gain | Composite Material? | Flexible? |

|---|---|---|---|---|

| [19] | 1.75–3 4.6–6.7 | 2 dBi | Yes | No |

| [20] | 0.1–1.0 | - | Yes | Yes |

| [21] | 1.198–4.055 | 2.9 dBi | No | Yes |

| [22] | 2.35–2.45 | 2 dBi | Yes | Yes |

| [23] | 0.1–1.0 | - | Yes | No |

| [24] | 2.16–2.19 3.29–3.33 | 5.52 dBi | Yes | No |

| This work | 0.99–9.41 | 2 dBi–3 dBi | Yes | Yes |

| Parameter | Value (mm) | Parameter | Value (mm) |

|---|---|---|---|

| L | 70 | W | 50 |

| L1 | 3.8 | W1 | 2.5 |

| L2 | 6 | W2 | 3.5 |

| L3 | 6 | W3 | 3.5 |

| L4 | 6 | W4 | 3.5 |

| L5 | 15.8 | W5 | 46 |

| L6 | 25 | W6 | 18 |

| L7 | 28 | W7 | 23 |

| L8 | 24 | h | 0.5 |

| Tissue | 1.0 GHz–9.5 GHz | Thickness (mm) | |

|---|---|---|---|

| εr | σ | ||

| Skin | 39.2–31.0 | 0.8–5.6 | 1.5 |

| Fat | 5.3–4.2 | 0.04–0.52 | 8.5 |

| Muscle | 53.0–44.0 | 0.8–7.9 | 18 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, R.; Liu, J.; Wang, Y.; Luo, Z.; Zhang, B.; Duan, J. Flexible Wearable Composite Antennas for Global Wireless Communication Systems. Sensors 2021, 21, 6083. https://doi.org/10.3390/s21186083

Zhang R, Liu J, Wang Y, Luo Z, Zhang B, Duan J. Flexible Wearable Composite Antennas for Global Wireless Communication Systems. Sensors. 2021; 21(18):6083. https://doi.org/10.3390/s21186083

Chicago/Turabian StyleZhang, Rui, Jingwen Liu, Yangyang Wang, Zhongbao Luo, Binzhen Zhang, and Junping Duan. 2021. "Flexible Wearable Composite Antennas for Global Wireless Communication Systems" Sensors 21, no. 18: 6083. https://doi.org/10.3390/s21186083