Deep Learning-Based Acoustic Emission Scheme for Nondestructive Localization of Cracks in Train Rails under a Load

Abstract

1. Introduction

2. The Proposed Single-Sensor AE Scheme

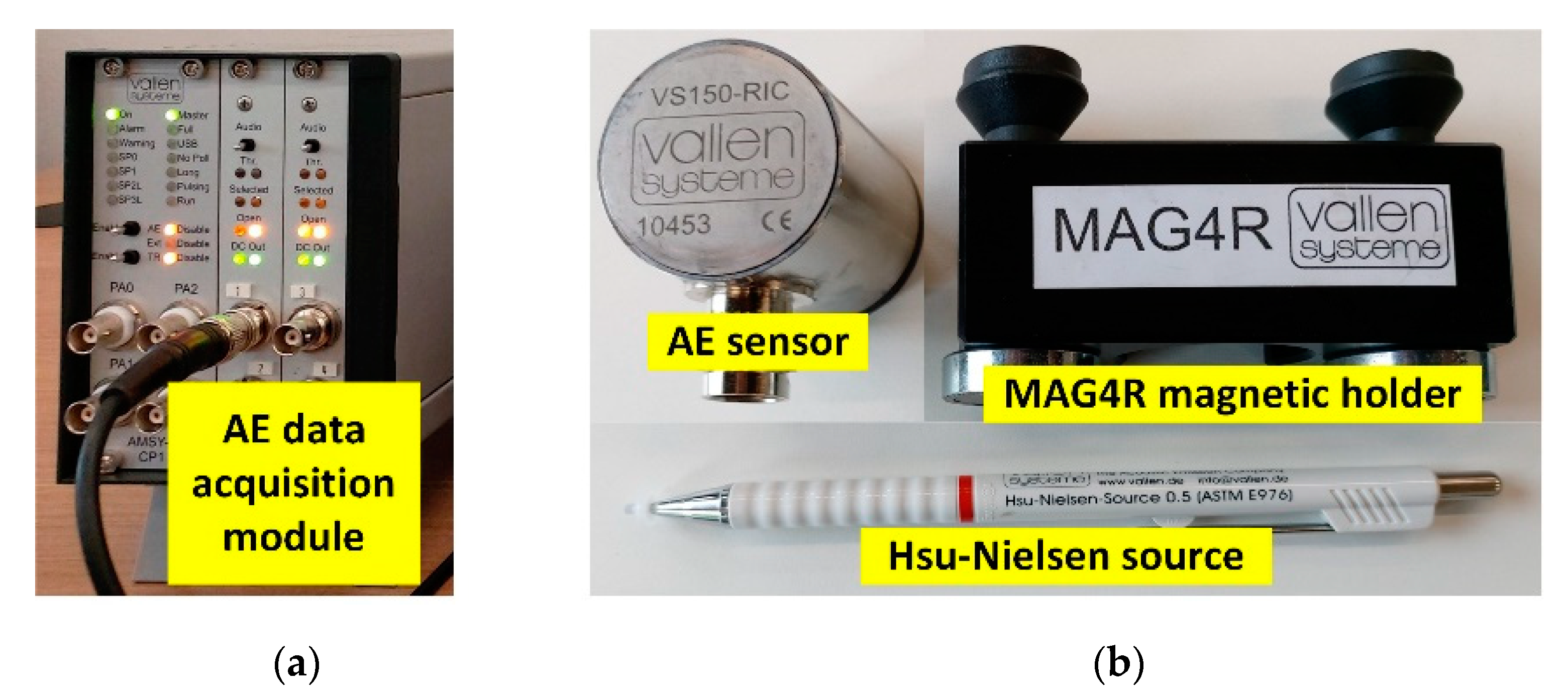

2.1. Acoustic Emission Sensor

2.2. AE Data Acquisition Module

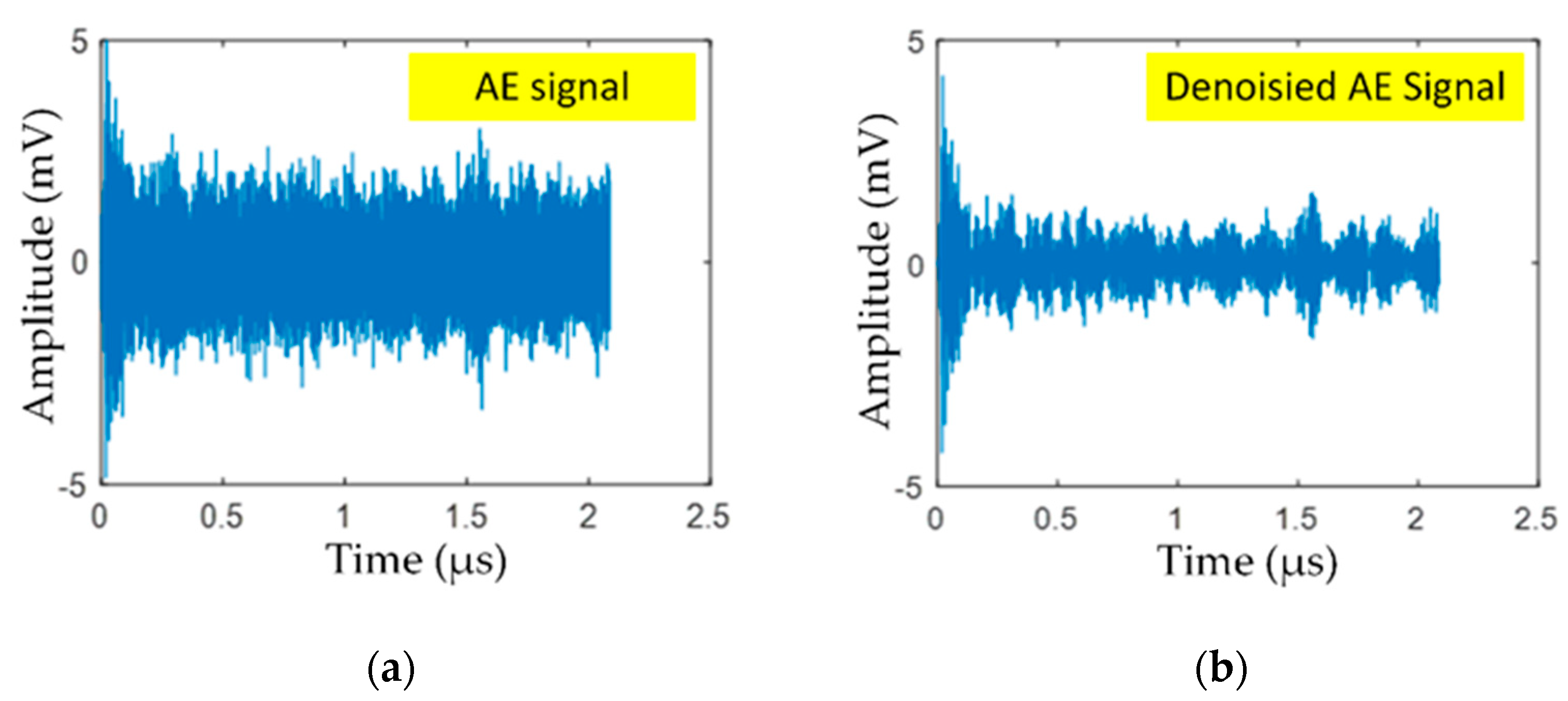

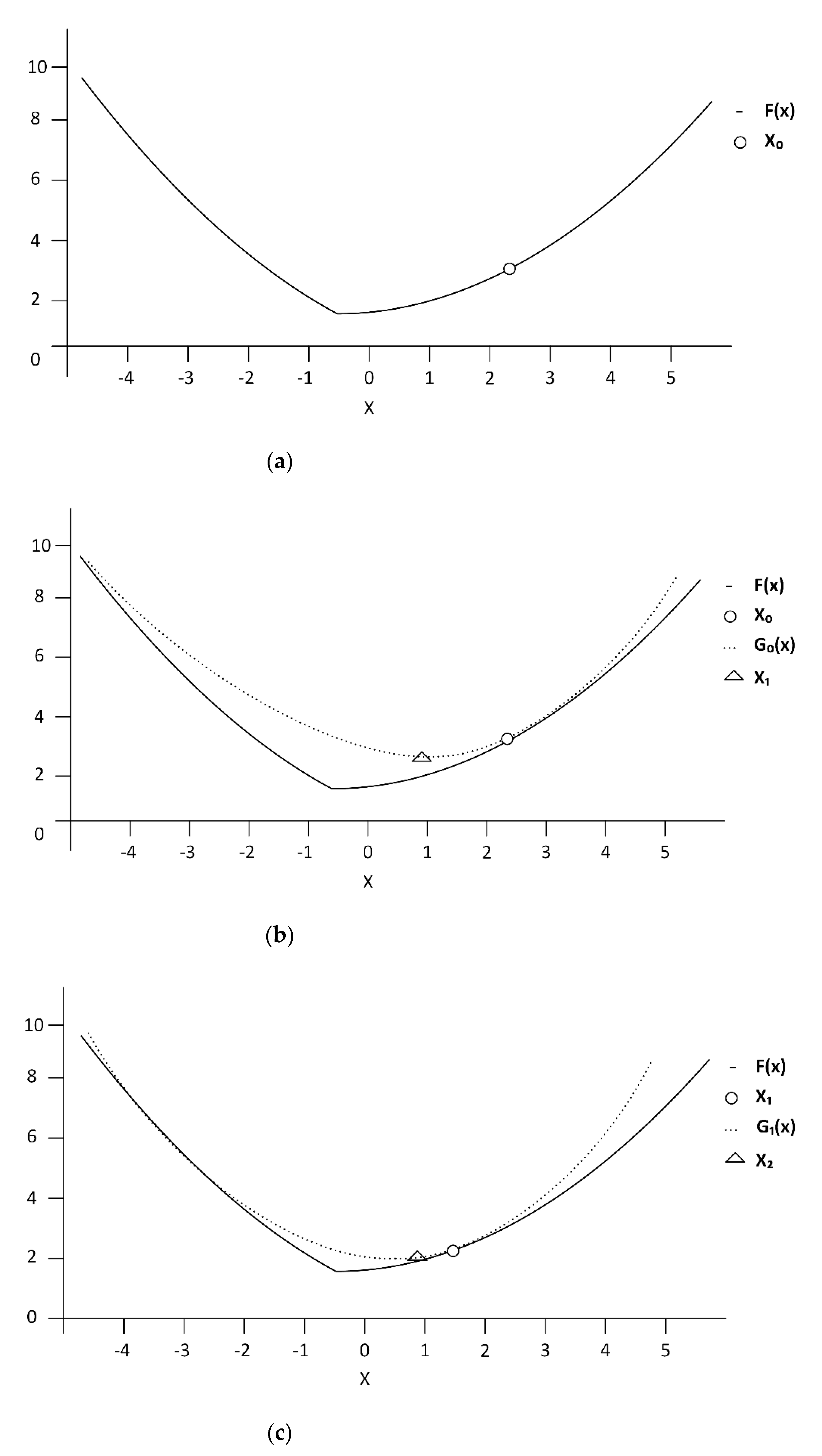

2.3. Pre-processing of AE Signal Data

| Algorithm1: The MM approach to minimize the cost function (F(x)) (i.e., the optimal denoised AE signal () can be summarized as follows [44]: |

|

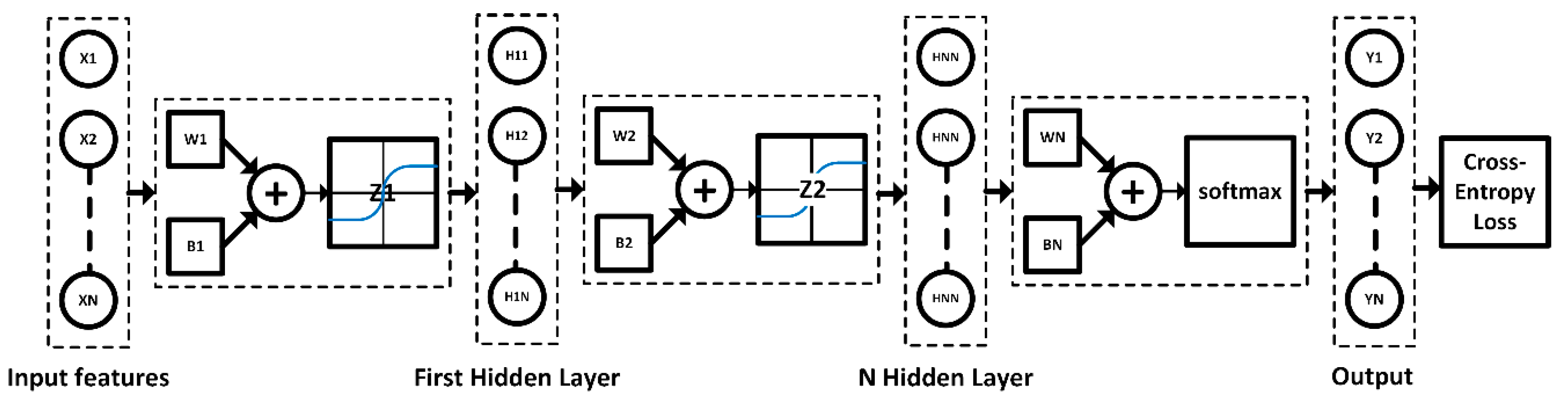

2.4. Processing and Classification

3. Experimental Material and Setup

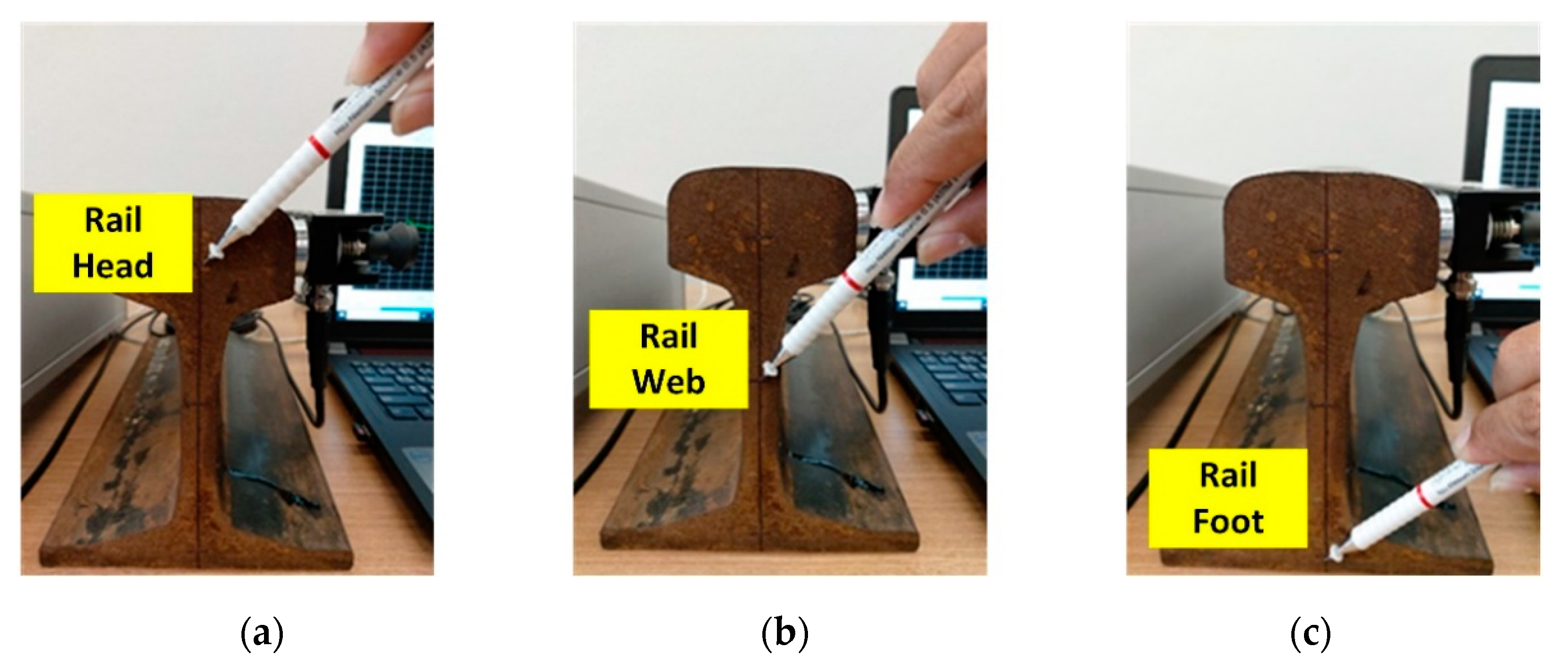

3.1. Experimental Steel Rail

3.2. AE Data Sensor and Acquisition Module

3.3. AE Sensor Amplitude Testing

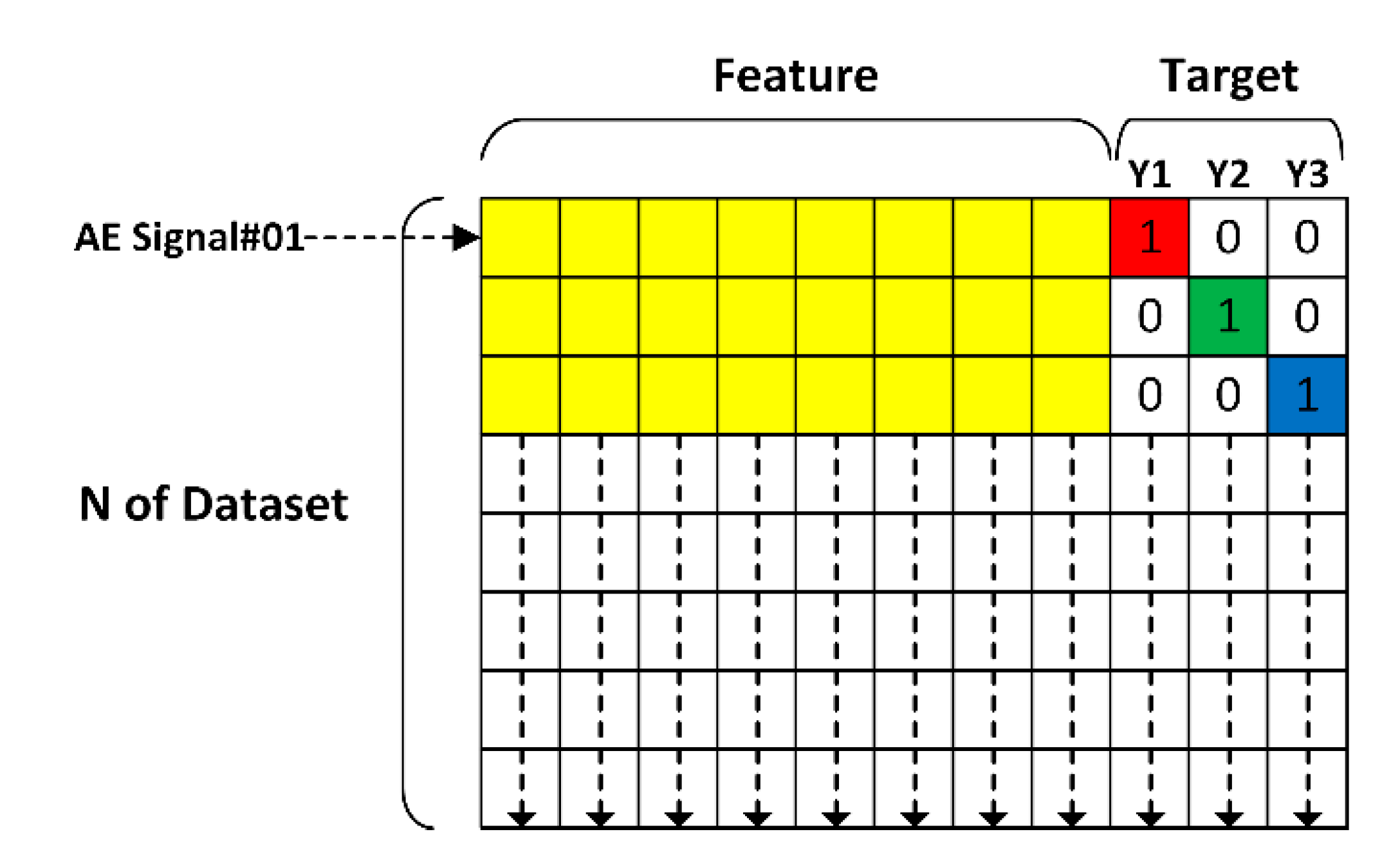

3.4. Datasets for Training and Testing the Deep Learning Algorithmic Model

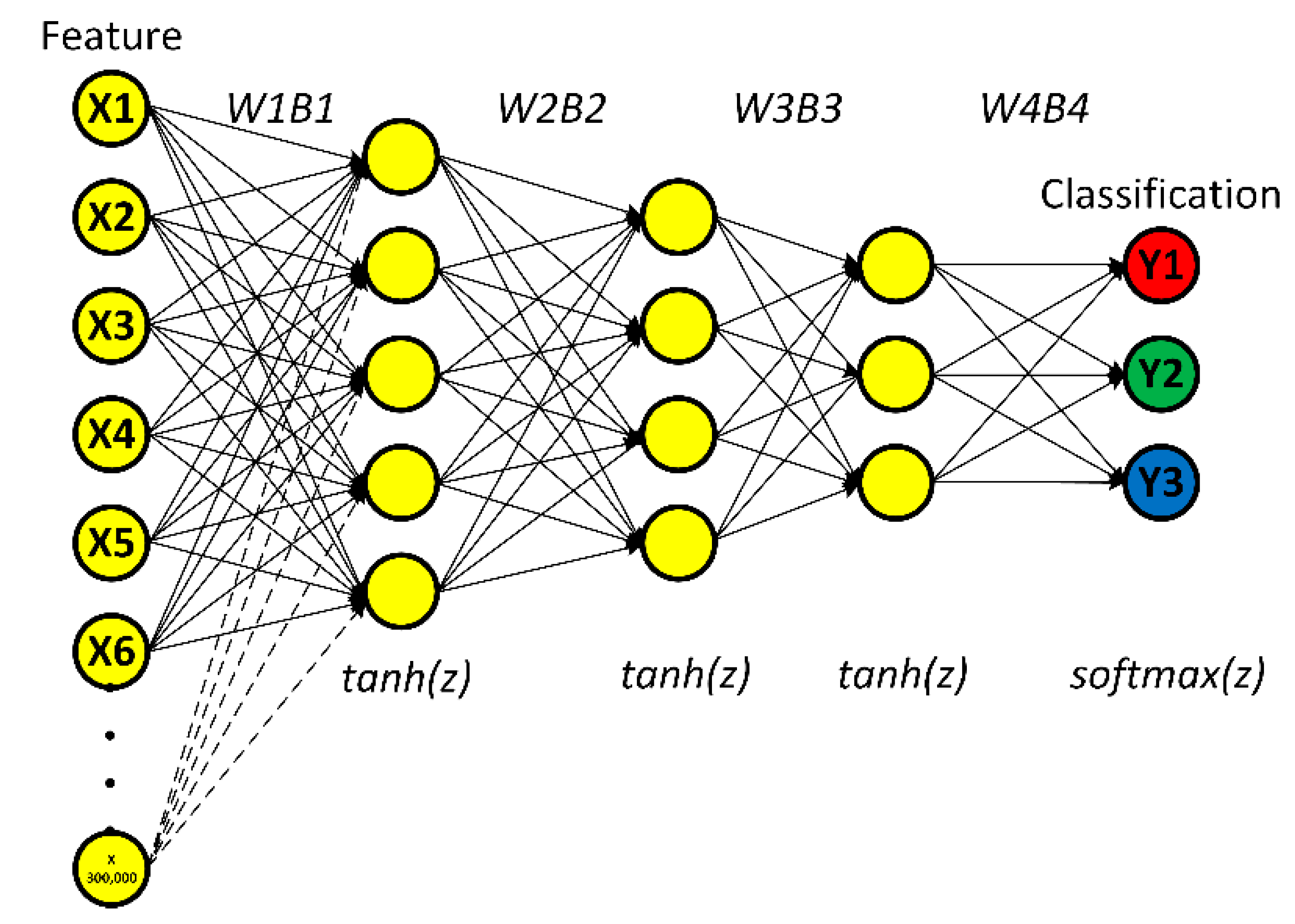

3.5. Proposed Deep Learning Algorithm for Classification

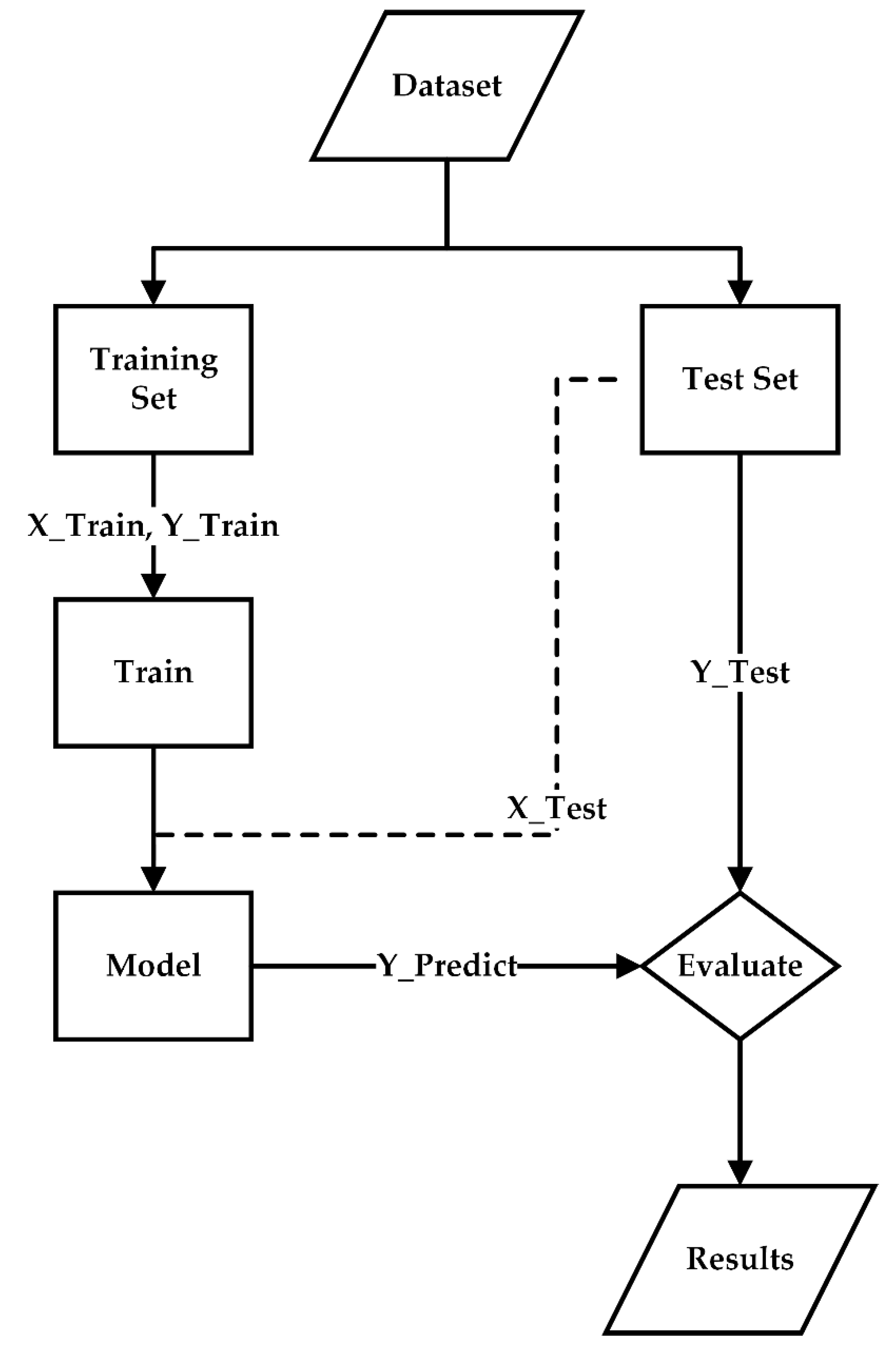

3.6. Evaluation of the Deep Learning Algorithm

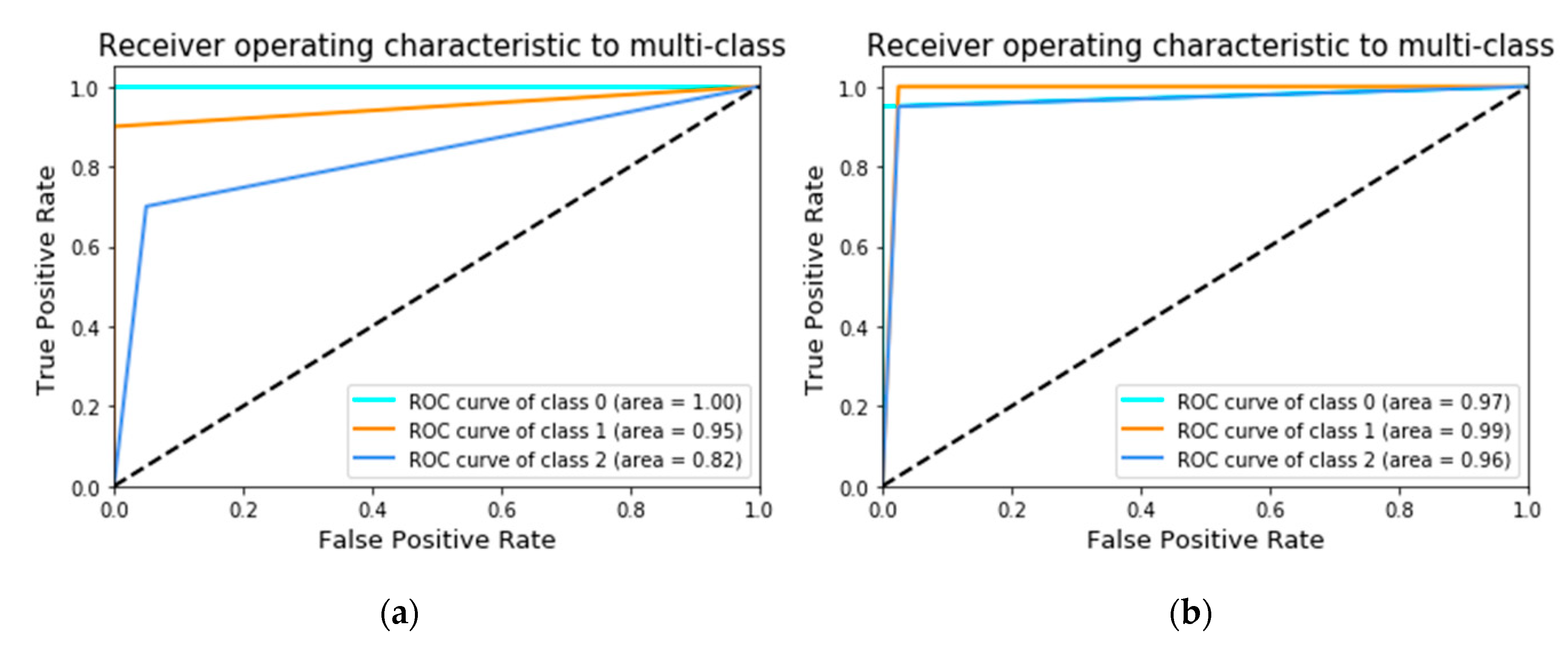

3.6.1. Receiver Operating Characteristic (ROC) Curve

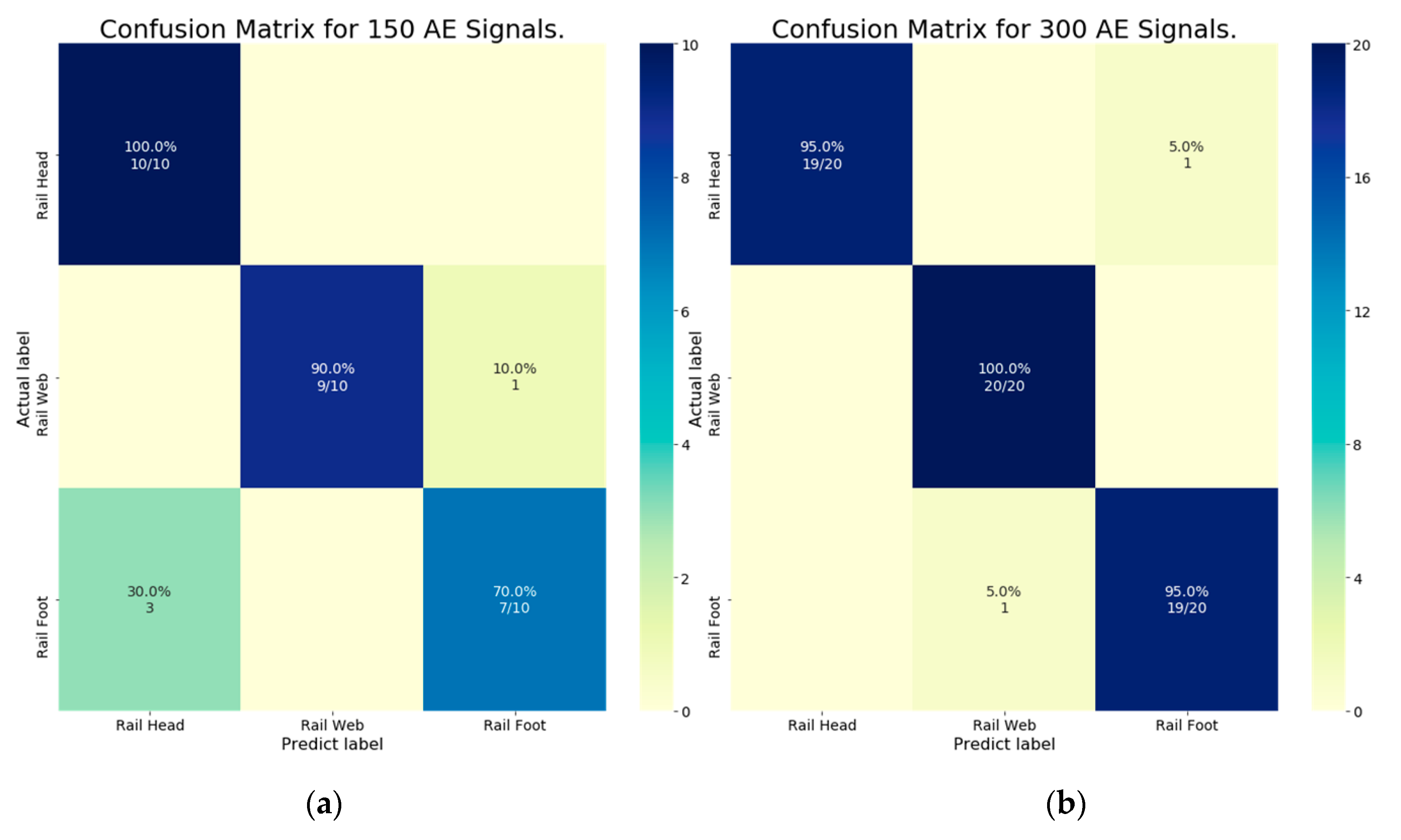

3.6.2. Confusion Matrix, F1 Score and Total Accuracy (Average F1 Score)

4. Onsite Experimental Setup

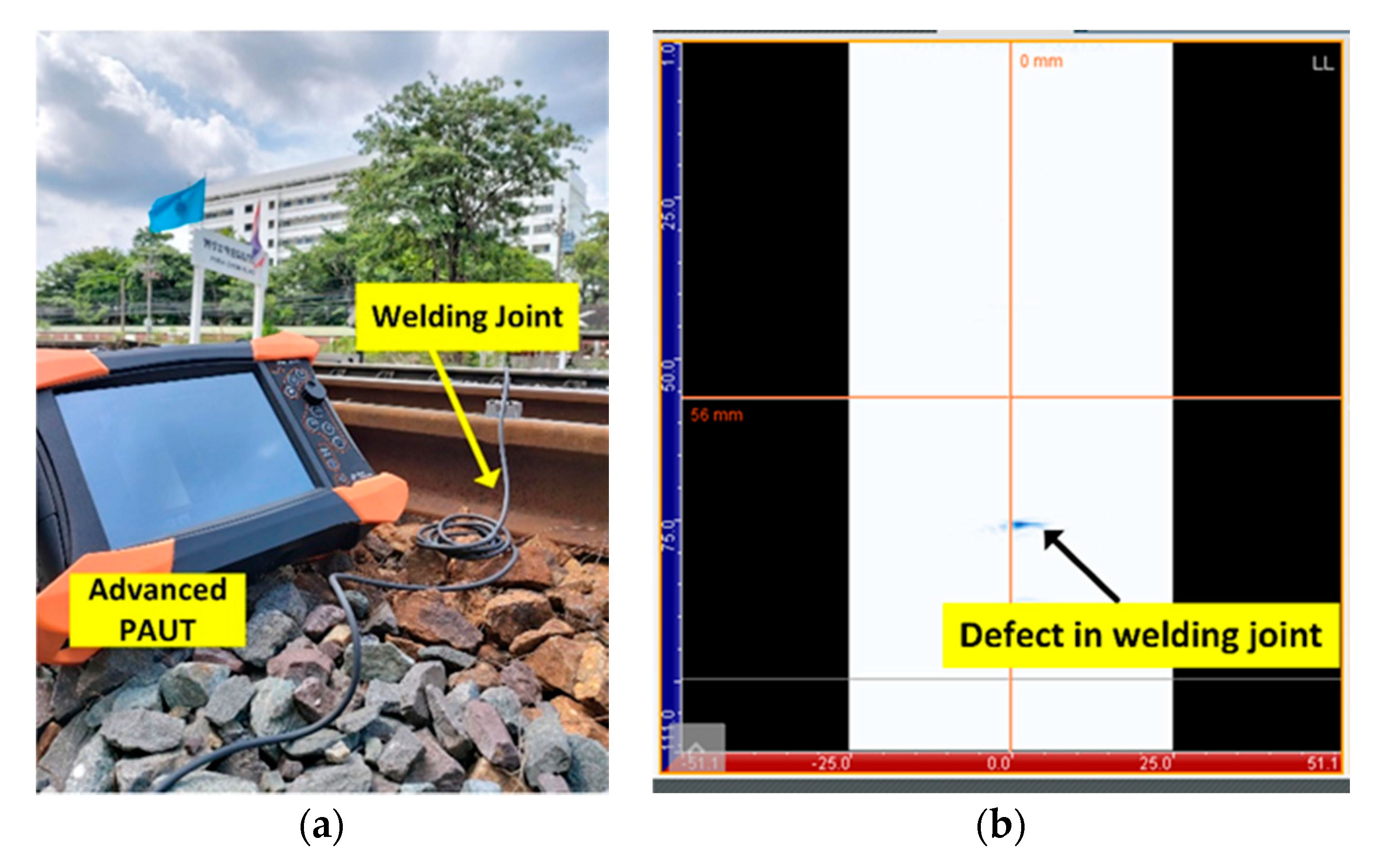

4.1. Onsite Advanced Phased Array Ultrasonic Testing (PAUT)

4.2. Steel Rail Temperatures

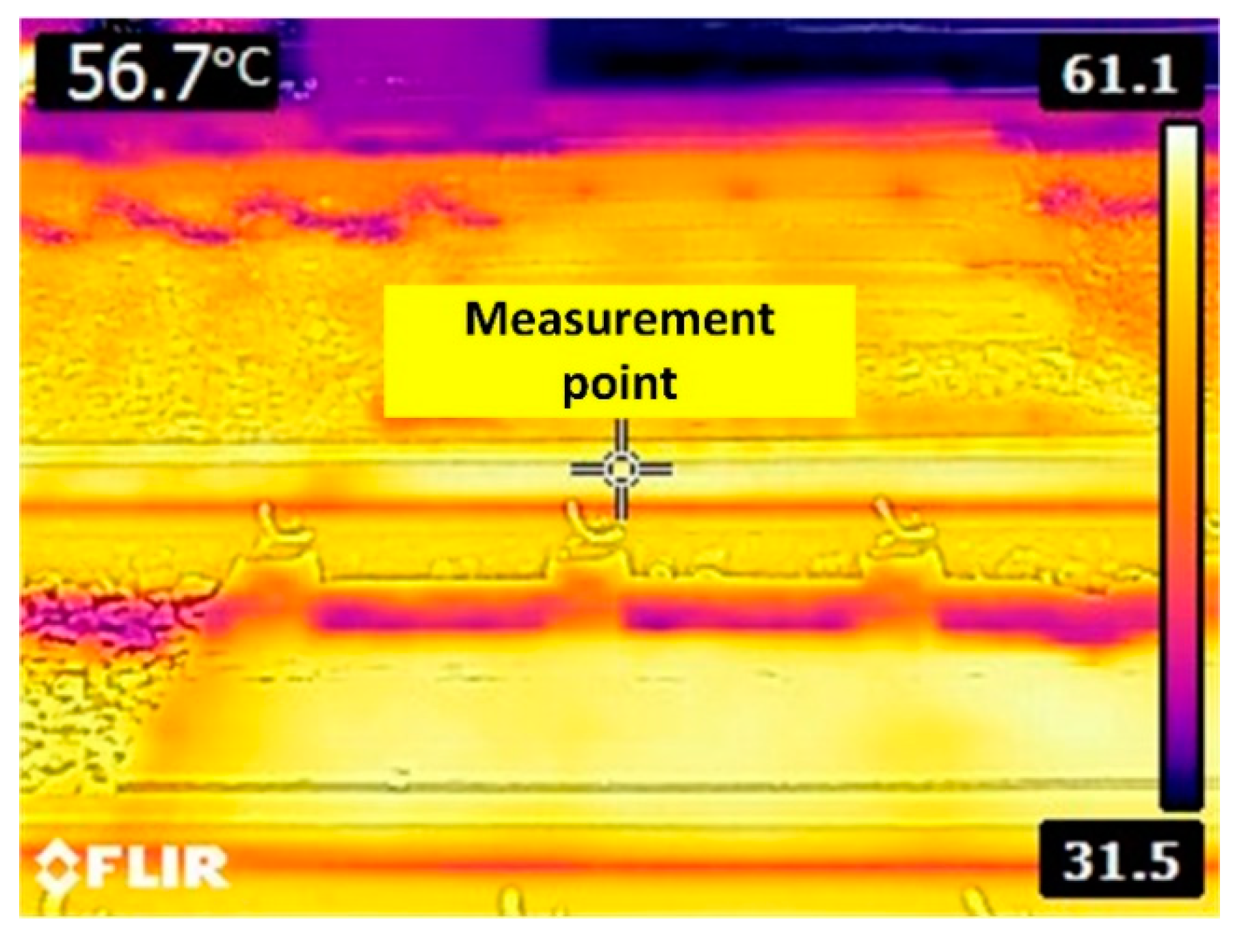

4.3. Onsite Experiment on the Steel Rail under Load

5. Results and Discussion

5.1. Receiver Operating Characteristic (ROC) Curve

5.2. Confusion Matrix of the Deep Learning Algorithmic Model

5.3. F1 Scores of the Deep Learning Algorithmic Model

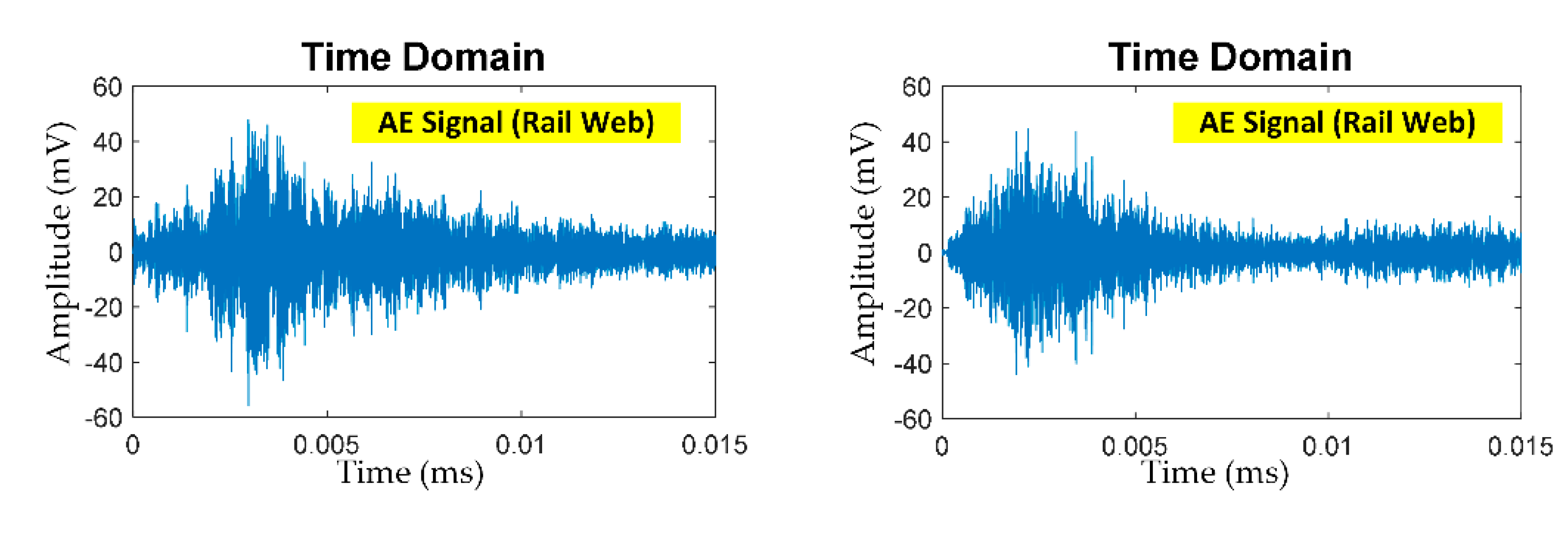

5.4. Onsite AE Signals Using the Proposed AE Scheme

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Jiang, X.; Kim, K.; Zhang, S.; Johnson, J.; Salazar, G. High-Temperature Piezoelectric Sensing. Sensors 2014, 14, 144–169. [Google Scholar] [CrossRef] [PubMed]

- Lord, A.E. Acoustic Emission. In Physical Acoustics; Elsevier: Amsterdam, The Netherlands, 1975; pp. 289–353. [Google Scholar]

- Schabowicz, K. Non-Destructive Testing of Materials in Civil Engineering. Materials 2019, 12, 3237. [Google Scholar] [CrossRef] [PubMed]

- Zaki, A.; Chai, H.K.; Aggelis, D.G.; Alver, N. Non-Destructive Evaluation for Corrosion Monitoring in Concrete: A Review and Capability of Acoustic Emission Technique. Sensors 2015, 15, 19069–19101. [Google Scholar] [CrossRef] [PubMed]

- Zhang, X.; Feng, N.; Wang, Y.; Shen, Y. An Analysis of the Simulated Acoustic Emission Sources with Different Propagation Distances, Types and Depths for Rail Defect Detection. Appl. Acoust. 2014, 86, 80–88. [Google Scholar] [CrossRef]

- Kwon, J.-R.; Lyu, G.-J.; Lee, T.-H.; Kim, J.-Y. Acoustic emission testing of repaired storage tank. Int. J. Press. Vessel. Pip. 2001, 78, 373–378. [Google Scholar] [CrossRef]

- Morhain, A.; Mba, D. Bearing defect diagnosis and acoustic emission. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2003, 217, 257–272. [Google Scholar] [CrossRef]

- Song, X.-C.; Huang, S.-L.; Zhao, W. Optimization of the magnetic circuit in the MFL inspection system for storage-tank floors. Russ. J. Nondestruct. Test. 2007, 43, 326–331. [Google Scholar] [CrossRef]

- Barke, D.; Chiu, W.K. Structural Health Monitoring in the Railway Industry: A Review. Struct. Health Monit. 2005, 4, 81–93. [Google Scholar] [CrossRef]

- Ekberg, A.; Kabo, E. Fatigue of railway wheels and rails under rolling contact and thermal loading—An overview. Wear 2005, 258, 1288–1300. [Google Scholar] [CrossRef]

- Li, Z.; Zhao, X.; Dollevoet, R. An approach to determine a critical size for rolling contact fatigue initiating from rail surface defects. Int. J. Rail Transp. 2016, 5, 16–37. [Google Scholar] [CrossRef]

- Nielsen, J.C.O.; Johansson, A. Out-of-round railway wheels—A literature survey. Proc. Inst. Mech. Eng. Part F J. Rail Rapid Transit 2000, 214, 79–91. [Google Scholar] [CrossRef]

- Zerbst, U.; Lundén, R.; Edel, K.-O.; Smith, R. Introduction to the damage tolerance behaviour of railway rails—A review. Eng. Fract. Mech. 2009, 76, 2563–2601. [Google Scholar] [CrossRef]

- Ekberg, A.; Åkesson, B.; Kabo, E. Wheel/rail rolling contact fatigue—Probe, predict, prevent. Wear 2014, 314, 2–12. [Google Scholar] [CrossRef]

- Kapoor, A.; Fletcher, D.; Franklin, F.J. The role of wear in enhancing rail life. In Tribology Series; Elsevier: Amsterdam, The Netherlands, 2003; pp. 331–340. [Google Scholar]

- Ngamkhanong, C.; Kaewunruen, S.; Costa, B.J.A. State-of-the-Art Review of Railway Track Resilience Monitoring. Infrastructures 2018, 3, 3. [Google Scholar] [CrossRef]

- Behnia, A.; Chai, H.K.; Shiotani, T. Advanced structural health monitoring of concrete structures with the aid of acoustic emission. Constr. Build. Mater. 2014, 65, 282–302. [Google Scholar] [CrossRef]

- Ledeczi, A.; Hay, T.; Volgyesi, P.; Hay, D.; Nadas, A.; Jayaraman, S. Wireless Acoustic Emission Sensor Network for Structural Monitoring. IEEE Sens. J. 2009, 9, 1370–1377. [Google Scholar] [CrossRef]

- Nair, A.; Cai, C. Acoustic emission monitoring of bridges: Review and case studies. Eng. Struct. 2010, 32, 1704–1714. [Google Scholar] [CrossRef]

- Zelenyak, A.-M.; Hamstad, M.A.; Sause, M.G.R. Modeling of Acoustic Emission Signal Propagation in Waveguides. Sensors 2015, 15, 11805–11822. [Google Scholar] [CrossRef]

- Holford, K.M.; Davies, A.; Pullin, R.; Carter, D. Damage Location in Steel Bridges by Acoustic Emission. J. Intell. Mater. Syst. Struct. 2001, 12, 567–576. [Google Scholar] [CrossRef]

- Li, D.; Ou, J.; Lan, C.; Li, H. Monitoring and Failure Analysis of Corroded Bridge Cables under Fatigue Loading Using Acoustic Emission Sensors. Sensors 2012, 12, 3901–3915. [Google Scholar] [CrossRef]

- Roberts, T.; Talebzadeh, M. Fatigue life prediction based on crack propagation and acoustic emission count rates. J. Constr. Steel Res. 2003, 59, 679–694. [Google Scholar] [CrossRef]

- Chou, H.; Mouritz, A.; Bannister, M.; Bunsell, A.R. Acoustic emission analysis of composite pressure vessels under constant and cyclic pressure. Compos. Part A Appl. Sci. Manuf. 2015, 70, 111–120. [Google Scholar] [CrossRef]

- Ennaceur, C.; Laksimi, A.; Hervé, C.; Cherfaoui, M. Monitoring crack growth in pressure vessel steels by the acoustic emission technique and the method of potential difference. Int. J. Press. Vessel. Pip. 2006, 83, 197–204. [Google Scholar] [CrossRef]

- Mostafapour, A.; Davoudi, S. Analysis of leakage in high pressure pipe using acoustic emission method. Appl. Acoust. 2013, 74, 335–342. [Google Scholar] [CrossRef]

- Shehadeh, M.; Steel, J.A.; Reuben, R.L. Acoustic Emission Source Location for Steel Pipe and Pipeline Applications: The Role of Arrival Time Estimation. Proc. Inst. Mech. Eng. Part E J. Process. Mech. Eng. 2006, 220, 121–133. [Google Scholar] [CrossRef]

- Esola, S.; Wisner, B.; Vanniamparambil, P.A.; Geriguis, J.; Kontsos, A. Part Qualification Methodology for Composite Aircraft Components Using Acoustic Emission Monitoring. Appl. Sci. 2018, 8, 1490. [Google Scholar] [CrossRef]

- Holford, K.M.; Pullin, R.; Evans, S.L.; Eaton, M.J.; Hensman, J.; Worden, K. Acoustic emission for monitoring aircraft structures. Proc. Inst. Mech. Eng. Part G J. Aerosp. Eng. 2009, 223, 525–532. [Google Scholar] [CrossRef]

- Zhang, Z.; Yang, G.; Hu, K. Prediction of Fatigue Crack Growth in Gas Turbine Engine Blades Using Acoustic Emission. Sensors 2018, 18, 1321. [Google Scholar] [CrossRef]

- Bi, H.; Li, H.; Zhang, W.; Wang, L.; Zhang, Q.; Cao, S.; Toku-Gyamerah, I. Evaluation of the acoustic emission monitoring method for stress corrosion cracking on aboveground storage tank floor steel. Int. J. Press. Vessel. Pip. 2020, 179, 104035. [Google Scholar] [CrossRef]

- Jirarungsatian, C.; Prateepasen, A. Pitting and uniform corrosion source recognition using acoustic emission parameters. Corros. Sci. 2010, 52, 187–197. [Google Scholar] [CrossRef]

- Čapek, J.; Knapek, M.; Minárik, P.; Dittrich, J.; Máthis, K. Characterization of Deformation Mechanisms in Mg Alloys by Advanced Acoustic Emission Methods. Metals 2018, 8, 644. [Google Scholar] [CrossRef]

- Ono, K. Acoustic Emission in Materials Research—A Review. J. Acoust. Emiss. 2011, 29, 284–308. [Google Scholar]

- Kostryzhev, A.G.; Davis, C.L.; Roberts, C. Detection of crack growth in rail steel using acoustic emission. Ironmak. Steelmak. 2013, 40, 98–102. [Google Scholar] [CrossRef]

- Shi, S.; Han, Z.; Liu, Z.; Vallely, P.; Soua, S.; Kaewunruen, S.; Papaelias, M. Quantitative monitoring of brittle fatigue crack growth in railway steel using acoustic emission. Proc. Inst. Mech. Eng. Part F J. Rail Rapid Transit 2018, 232, 1211–1224. [Google Scholar] [CrossRef]

- Thakkar, N.; Steel, J.; Reuben, R.L. Rail–wheel interaction monitoring using Acoustic Emission: A laboratory study of normal rolling signals with natural rail defects. Mech. Syst. Signal Process. 2010, 24, 256–266. [Google Scholar] [CrossRef]

- Ebrahimkhanlou, A.; Salamone, S. Single-Sensor Acoustic Emission Source Localization in Plate-Like Structures Using Deep Learning. Aerospace 2018, 5, 50. [Google Scholar] [CrossRef]

- Sohaib, M.; Islam, M.M.M.; Kim, J.Y.; Jeon, D.-C.; Kim, J.-M. Leakage Detection of a Spherical Water Storage Tank in a Chemical Industry Using Acoustic Emissions. Appl. Sci. 2019, 9, 196. [Google Scholar] [CrossRef]

- Mokhtari, N.; Pelham, J.G.; Nowoisky, S.; Bote-Garcia, J.-L.; Gühmann, C. Friction and Wear Monitoring Methods for Journal Bearings of Geared Turbofans Based on Acoustic Emission Signals and Machine Learning. Lubricants 2020, 8, 29. [Google Scholar] [CrossRef]

- Dobrzycki, A.; Mikulski, S.; Opydo, W. Using ANN and SVM for the Detection of Acoustic Emission Signals Accompanying Epoxy Resin Electrical Treeing. Appl. Sci. 2019, 9, 1523. [Google Scholar] [CrossRef]

- Del Val, L.; Izquierdo, A.; Villacorta, J.J.; Suárez, L. Comparison of Methodologies for the Detection of Multiple Failures Using Acoustic Images in Fan Matrices. Shock. Vib. 2020, 2020, 5816050. [Google Scholar] [CrossRef]

- Loutas, T.; Eleftheroglou, N.; Zarouchas, D. A data-driven probabilistic framework towards the in-situ prognostics of fatigue life of composites based on acoustic emission data. Compos. Struct. 2017, 161, 522–529. [Google Scholar] [CrossRef]

- Ivan, S. Total Variation Denoising (An MM Algorithm); NYU Polytechnic School of Engineering Lecture Notes 32; NYU: New York, NY, USA, 2012. [Google Scholar]

| %C | %Si | %Mn | %V | %Ni | %Cu |

|---|---|---|---|---|---|

| 0.68 | 0.22 | 1.18 | 0.003 | 0.0068 | 0.0109 |

| Sensor S/N | 1st PLB | 2nd PLB | 3rd PLB | 4th PLB | 5th PLB | Average |

|---|---|---|---|---|---|---|

| 10,453 | 93.90 | 92.40 | 95.20 | 95.00 | 93.90 | 94.08 |

| Rail Head (150 AE Signals) | Rail Head (300 AE Signals) | Rail Web (150 AE Signals) | Rail Web (300 AE Signals) | Rail Foot (150 AE Signals) | Rail Foot (300 AE Signals) | |

|---|---|---|---|---|---|---|

| Precision (%) (Equation (13)) | 76.9 | 100 | 100 | 95.2 | 87.5 | 95 |

| Recall (%) (Equation (11)) | 100 | 95 | 90 | 100 | 70 | 95 |

| F1 score (%) (Equation (14)) | 86.9 | 97.4 | 94.7 | 97.5 | 77.7 | 95 |

| Accuracy (%) (Equation (15)) | 90 | 98 | 96 | 98 | 86 | 96 |

| Total Accuracy (%) (Equation (16)) | 86.6 (150 AE signals) | |||||

| Total Accuracy (%) (Equation (16)) | 96.6 (300 AE signals) | |||||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Suwansin, W.; Phasukkit, P. Deep Learning-Based Acoustic Emission Scheme for Nondestructive Localization of Cracks in Train Rails under a Load. Sensors 2021, 21, 272. https://doi.org/10.3390/s21010272

Suwansin W, Phasukkit P. Deep Learning-Based Acoustic Emission Scheme for Nondestructive Localization of Cracks in Train Rails under a Load. Sensors. 2021; 21(1):272. https://doi.org/10.3390/s21010272

Chicago/Turabian StyleSuwansin, Wara, and Pattarapong Phasukkit. 2021. "Deep Learning-Based Acoustic Emission Scheme for Nondestructive Localization of Cracks in Train Rails under a Load" Sensors 21, no. 1: 272. https://doi.org/10.3390/s21010272

APA StyleSuwansin, W., & Phasukkit, P. (2021). Deep Learning-Based Acoustic Emission Scheme for Nondestructive Localization of Cracks in Train Rails under a Load. Sensors, 21(1), 272. https://doi.org/10.3390/s21010272