Combining Fourier Transform Mid-Infrared Spectroscopy with Chemometric Methods to Detect Adulterations in Milk Powder

Abstract

:1. Introduction

2. Materials and Methods

2.1. Sample Preparation

2.2. Mid-Infrared Spectra Acquisition

2.3. Chemometric Methods

2.3.1. Principal Component Analysis

2.3.2. Calibration Models

2.4. Variable Selection

2.5. Software and Model Evaluation

3. Results and Discussion

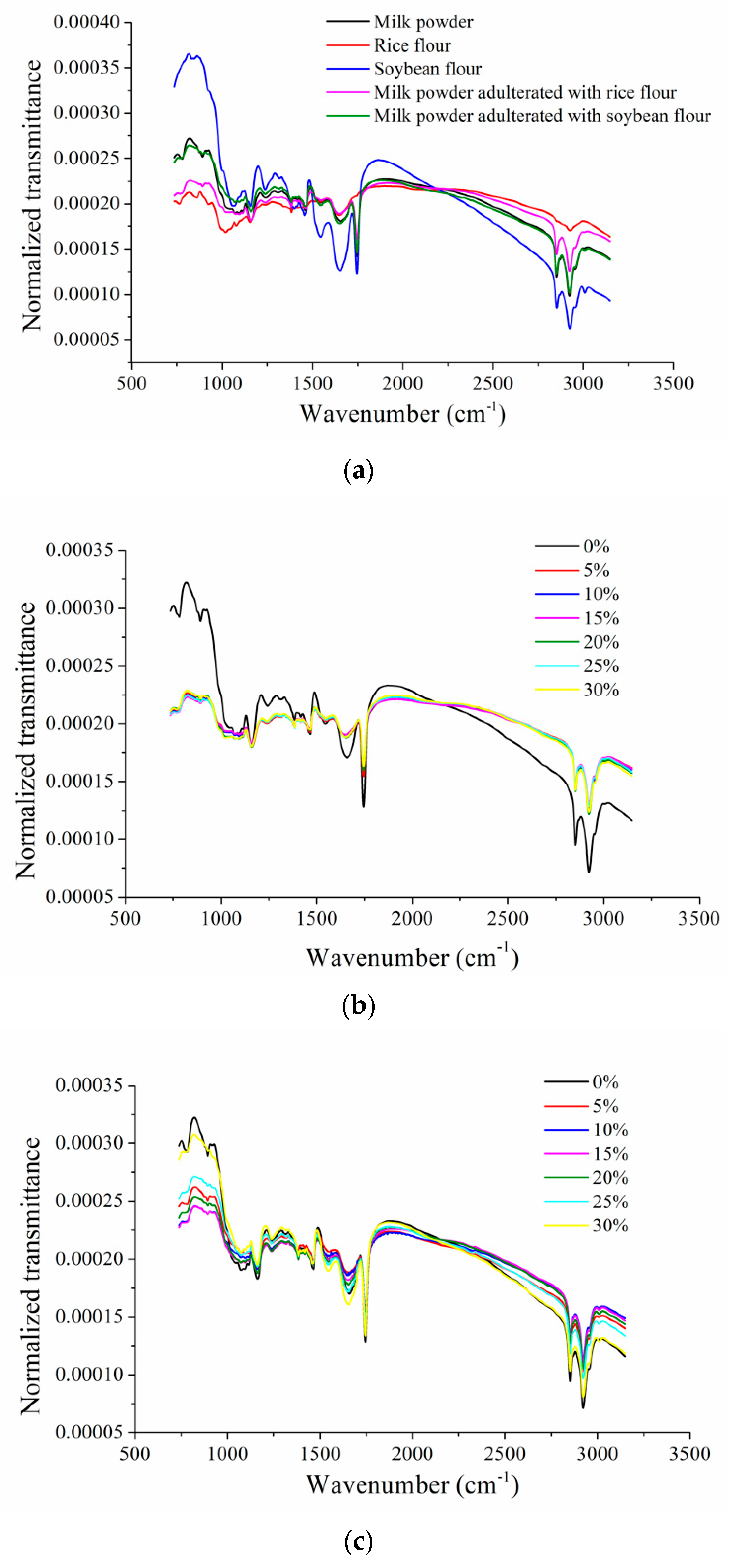

3.1. Spectra Profiles

3.2. PCA Scores Scatter Plot Analysis

3.3. Classification Models of Powder Samples

3.3.1. Classification Models Using Full Spectra

3.3.2. Optimal Wavenumbers Selection

3.3.3. Classification Models Using Optimal Wavenumbers

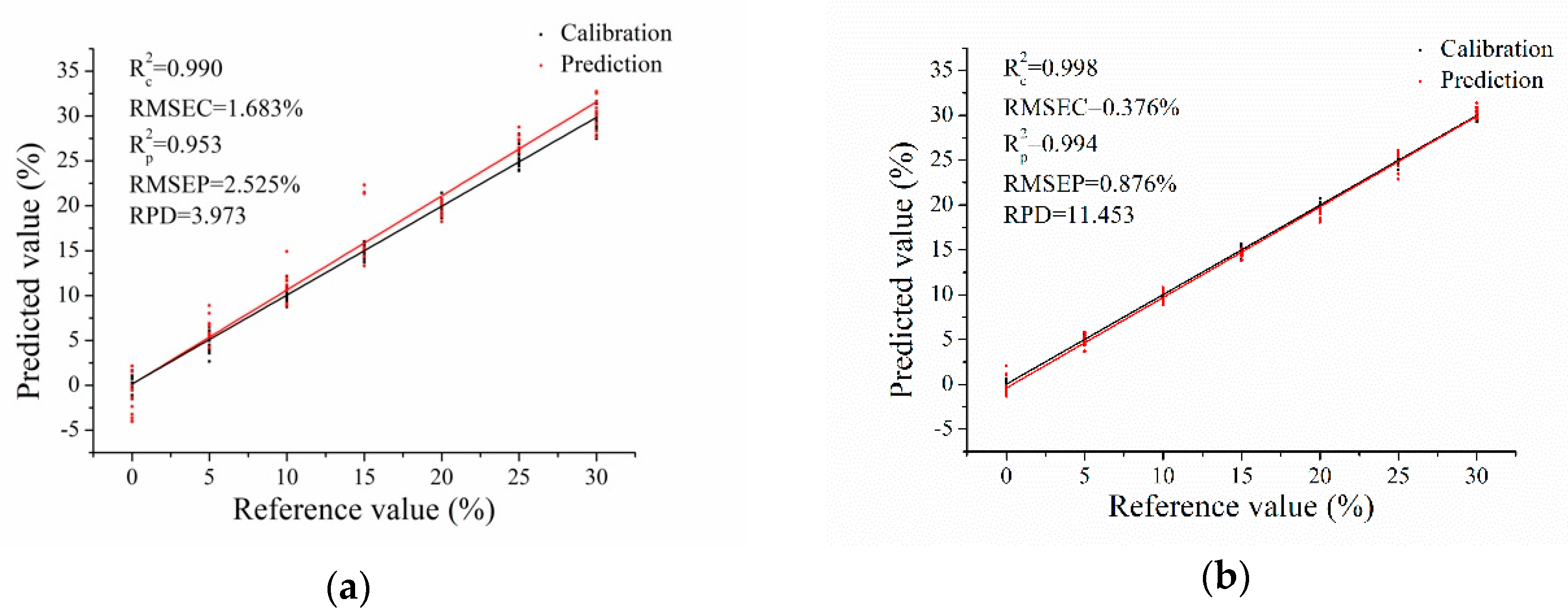

3.4. Determination of Adulterations Content in the Adulterated Milk

3.4.1. Calibration Models Using Full Spectra

3.4.2. Optimal Wavenumbers Selection

3.4.3. Calibration Models Using Optimal Wavenumbers

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Singh, P.; Gandhi, N. Milk Preservatives and Adulterants: Processing, Regulatory and Safety Issues. Food Rev. Int. 2015, 31, 236–261. [Google Scholar] [CrossRef]

- Barham, G.; Khaskheli, M.; Soomro, A.H.; Nizamani, Z. Risk of adulteration in milk consumed at Shaheed Benazirabad District of Sindh. Int. J. Adult. 2015, 1, 31–37. [Google Scholar]

- Haasnoot, W.; Olieman, K.; Cazemier, G.; Verheijen, R. Direct Biosensor Immunoassays for the Detection of Nonmilk Proteins in Milk Powder. J. Agric. Food Chem. 2001, 49, 5201–5206. [Google Scholar] [CrossRef] [PubMed]

- Azad, T.; Ahmed, S. Common milk adulteration and their detection techniques. Int. J. Food Contam. 2016, 3, 22–30. [Google Scholar] [CrossRef]

- Cecchinato, A.; Marchi, M.; Gallo, L.; Bittante, G.; Carnier, P. Mid-infrared spectroscopy predictions as indicator traits in breeding programs for enhanced coagulation properties of milk. J. Dairy Sci. 2009, 92, 5304–5313. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ye, M.P.; Zhou, R.; Shi, Y.R.; Chen, H.C.; Du, Y. Effects of heating on the secondary structure of proteins in milk powders using mid-infrared spectroscopy. J. Dairy Sci. 2017, 100, 89–95. [Google Scholar] [CrossRef] [PubMed]

- Fleming, A.; Schenkel, F.S.; Chen, J.; Malchiodi, F.; Bonfatti, V.; Ali, R.A.; Mallard, B.; Corredig, M.; Miglior, F. Prediction of milk fatty acid content with mid-infrared spectroscopy in Canadian dairy cattle using differently distributed model development sets. J. Dairy Sci. 2017, 100, 5073–5081. [Google Scholar] [CrossRef] [Green Version]

- Gondim, C.D.S.; Junqueira, R.G.; Ruisánchez, I.; Callao, M.P. Detection of several common adulterants in raw milk by MID-infrared spectroscopy and one-class and multi-class multivariate strategies. Food Chem. 2017, 230, 68–75. [Google Scholar] [CrossRef]

- He, B.; Rong, L.; Yang, R.J.; Xu, K.X. Adulteration detection in milk using infrared spectroscopy combined with two-dimensional correlation analysis. In Proceedings of the SPIE—The International Society for Optical Engineering, San Francisco, CA, USA, 26 February 2010; Volume 7572. [Google Scholar] [CrossRef]

- Santos, P.M.; Pereira-Filho, E.R.; Rodriguez-Saona, L.E. Rapid detection and quantification of milk adulteration using infrared microspectroscopy and chemometrics analysis. Food Chem. 2013, 138, 19–24. [Google Scholar] [CrossRef]

- Rodríguez-Pulido, F.J.; Barbin, D.F.; Sunb, D.W.; González-Miret, M.L.; Heredia, F.J. Grape seed characterization by NIR hyperspectral imaging. Postharvest Biol. Technol. 2013, 76, 74–82. [Google Scholar] [CrossRef]

- Liu, D.; Ma, J.; Sun, D.W.; Pu, H.; Gao, W.; Qu, J.; Zeng, X.A. Prediction of Color and pH of Salted Porcine Meats Using Visible and Near-Infrared Hyperspectral Imaging. Food Bioprocess Technol. 2014, 7, 3100–3108. [Google Scholar] [CrossRef]

- Qin, J.; Burks, T.F.; Kim, M.S.; Chao, K.; Ritenour, M.A. Citrus canker detection using hyperspectral reflectance imaging and PCA-based image classification method. Sens. Instrum. Food Qual. Saf. 2008, 2, 168–177. [Google Scholar] [CrossRef]

- Feng, L.; Zhu, S.S.; Zhang, C.; Bao, Y.D.; Gao, P.; He, Y. Variety Identification of Raisins Using Near-Infrared Hyperspectral Imaging. Molecules 2018, 23, 2907. [Google Scholar] [CrossRef] [PubMed]

- Wu, Z.Z.; Xu, E.B.; Jie, L.; Zhang, Y.J.; Wang, F.; Xu, X.M.; Jin, Z.Y.; Jiao, A.Q. Monitoring of fermentation process parameters of Chinese rice wine using attenuated total reflectance mid-infrared spectroscopy. Food Control 2015, 50, 405–412. [Google Scholar] [CrossRef]

- Groenigen, J.W.V.; Mutters, C.S.; Horwath, W.R.; Kessel, C.V. NIR and DRIFT-MIR spectrometry of soils for predicting soil and crop parameters in a flooded field. Plant Soil 2003, 250, 155–165. [Google Scholar] [CrossRef]

- Kos, G.; Lohninger, H.; Krska, R. Validation of chemometric models for the determination of deoxynivalenol on maize by mid-infrared spectroscopy. Mycotoxin Res. 2003, 19, 149–153. [Google Scholar] [CrossRef]

- Kuligowski, J.; Carrión, D.; Quintás, G.; Garrigues, S.; Guardia, M.D.L. Sample classification for improved performance of PLS models applied to the quality control of deep-frying oils of different botanic origins analyzed using ATR-FTIR spectroscopy. Anal. Bioanal. Chem. 2011, 399, 1305–1314. [Google Scholar] [CrossRef]

- Sun, J.; Wei, A.G.; Mao, H.P.; Wu, X.H.; Zhang, X.D.; Gao, H.Y. Discrimination of Lettuce Leaves’ Nitrogen Status Based on Hyperspectral Imaging Technology and ELM. Trans. Chin. Soc. Agric. Mach. 2014, 45, 272–277. [Google Scholar] [CrossRef]

- Yang, Y.; Zhang, S.J.; He, Y. Dynamic Detection of Fresh Jujube Based on ELM and Visible/Near Infrared Spectra. Spectrosc. Spectr. Anal. 2015, 35, 1870–1874. [Google Scholar] [CrossRef]

- Bazi, Y.; Alajlan, N.; Melgani, F.; Alhichri, H.; Malek, S.; Yager, R.R. Differential Evolution Extreme Learning Machine for the Classification of Hyperspectral Images. IEEE Geosci. Remote Sens. Lett. 2014, 11, 1066–1070. [Google Scholar] [CrossRef]

- Feng, X.P.; Zhao, Y.Y.; Zhang, C.; Cheng, P.; He, Y. Discrimination of Transgenic Maize Kernel Using NIR Hyperspectral Imaging and Multivariate Data Analysis. Sensors 2017, 17, 1894. [Google Scholar] [CrossRef] [PubMed]

- Shao, Y.N.; He, Y.; Wu, C.Q. Dose detection of radiated rice by infrared spectroscopy and chemometrics. J. Agric. Food Chem. 2008, 56, 3960–3965. [Google Scholar] [CrossRef] [PubMed]

- Araújo, M.C.U.; Saldanha, T.C.B.; Galvão, R.K.H.; Yoneyama, T.; Chame, H.C.; Visani, V. The successive projections algorithm for variable selection in spectroscopic multicomponent analysis. Chemom. Intell. Lab. Syst. 2001, 57, 65–73. [Google Scholar] [CrossRef]

- Ghasemi-Varnamkhasti, M.; Mohtasebi, S.S.; Rodriguez-Mendez, M.L.; Gomes, A.A.; Araújo, M.C.U.; Galvão, R.K.H. Screening analysis of beer ageing using near infrared spectroscopy and the Successive Projections Algorithm for variable selection. Talanta 2012, 89, 286–291. [Google Scholar] [CrossRef] [PubMed]

- Liu, K.; Chen, X.J.; Li, L.M.; Chen, H.L.; Ruan, X.K.; Liu, W.B. A consensus successive projections algorithm—multiple linear regression method for analyzing near infrared spectra. Anal. Chim. Acta 2015, 858, 16–23. [Google Scholar] [CrossRef] [PubMed]

- Zhang, C.; Liu, F.; Kong, W.W.; He, Y. Application of Visible and Near-Infrared Hyperspectral Imaging to Determine Soluble Protein Content in Oilseed Rape Leaves. Sensors 2015, 15, 16576–16588. [Google Scholar] [CrossRef] [Green Version]

- Wu, D.; Wang, S.J.; Wang, N.F.; Nie, P.C.; He, Y.; Sun, D.W.; Yao, J.S. Application of Time Series Hyperspectral Imaging (TS-HSI) for Determining Water Distribution Within Beef and Spectral Kinetic Analysis During Dehydration. Food Bioprocess Technol. 2013, 6, 2943–2958. [Google Scholar] [CrossRef]

- Vitale, R.; Marini, F.; Ruckebusch, C. SIMCA Modeling for Overlapping Classes: Fixed or Optimized Decision Threshold? Anal. Chem. 2018, 90, 10738–10747. [Google Scholar] [CrossRef]

- Zornoza, R.; Guerrero, C.; Mataix-Solera, J.; Scow, K.M.; Arcenegui, V.; Mataix-Beneyto, J. Near infrared spectroscopy for determination of various physical, chemical and biochemical properties in Mediterranean soils. Soil Biol. Biochem. 2008, 40, 1923–1930. [Google Scholar] [CrossRef] [Green Version]

- Wu, Y.L.; Xian, Y.P.; Guo, X.D.; Chen, L.W.; Zhao, X.J.; Wang, B.; Wang, L. Development and validation of a screening and quantification method for simultaneous determination of seven fluorescent whitening agents in commercial flour using UPLC-MS/MS. Food Chem. 2017, 243, 162–167. [Google Scholar] [CrossRef]

- Nicolaou, N.; Xu, Y.; Goodacre, R. Fourier transform infrared spectroscopy and multivariate analysis for the detection and quantification of different milk species. J. Dairy Sci. 2010, 93, 5651–5660. [Google Scholar] [CrossRef] [PubMed]

- Di, W.; Nie, P.; Yong, H. Determination of Calcium Content in Powdered Milk Using Near and Mid-Infrared Spectroscopy with Variable Selection and Chemometrics. Food Bioprocess Technol. 2012, 5, 1402–1410. [Google Scholar] [CrossRef]

- Alexa, E.; Dragomirescu, A.; Pop, G.; Jianu, C.; Dragoş, D. The use of FT-IR spectroscopy in the identification of vegetable oils adulteration. J. Food Agric. Environ. 2009, 7, 20–24. [Google Scholar] [CrossRef]

| Component | Content (g/100g) | ||

|---|---|---|---|

| Milk Powder | Rice Flour | Soybean Flour | |

| Protein | 24 | 0.3 | 32.8 |

| Fat | 28.8 | 0.3 | 18.3 |

| Carbohydrate | 38.4 | 95.6 | 30.5 |

| Model | Par. 1 | Sample Number | Pre. 2 | Sensitivity (%) | Specificity (%) | |||||

|---|---|---|---|---|---|---|---|---|---|---|

| M.3 | R. | S. | MR. | MS. | ||||||

| PLS | 17 | Cal. 4 | M. (80) | 80 | 0 | 0 | 0 | 0 | 100.00 | 100.00 |

| R. (80) | 0 | 80 | 0 | 0 | 0 | 100.00 | 100.00 | |||

| S. (80) | 0 | 0 | 80 | 0 | 0 | 100.00 | 100.00 | |||

| MR. (120) | 0 | 0 | 0 | 120 | 0 | 100.00 | 99.72 | |||

| MS. (120) | 0 | 0 | 0 | 1 | 119 | 99.17 | 100.00 | |||

| Pre. | M. (39) | 27 | 0 | 0 | 12 | 0 | 69.23 | 100.00 | ||

| R. (39) | 0 | 39 | 0 | 0 | 0 | 100.00 | 100.00 | |||

| S. (39) | 0 | 0 | 39 | 0 | 0 | 100.00 | 100.00 | |||

| MR. (57) | 0 | 0 | 0 | 57 | 0 | 100.00 | 93.10 | |||

| MS. (57) | 0 | 0 | 0 | 0 | 57 | 100.00 | 100.00 | |||

| SVM | 147, 0.0039 | Cal. | M. (80) | 80 | 0 | 0 | 0 | 0 | 100.00 | 100.00 |

| R. (80) | 0 | 80 | 0 | 0 | 0 | 100.00 | 100.00 | |||

| S. (80) | 0 | 0 | 80 | 0 | 0 | 100.00 | 100.00 | |||

| MR. (120) | 0 | 0 | 0 | 120 | 0 | 100.00 | 99.72 | |||

| MS. (120) | 0 | 0 | 0 | 1 | 119 | 99.17 | 100.00 | |||

| Pre. | M. (39) | 29 | 0 | 0 | 10 | 0 | 74.36 | 98.44 | ||

| R. (39) | 0 | 39 | 0 | 0 | 0 | 100.00 | 100.00 | |||

| S. (39) | 0 | 0 | 39 | 0 | 0 | 100.00 | 100.00 | |||

| MR. (57) | 0 | 0 | 0 | 57 | 0 | 100.00 | 94.15 | |||

| MS. (57) | 3 | 0 | 0 | 0 | 54 | 94.74 | 100.00 | |||

| ELM | 78 | Cal. | M. (80) | 80 | 0 | 0 | 0 | 0 | 100.00 | 100.00 |

| R. (80) | 0 | 80 | 0 | 0 | 0 | 100.00 | 100.00 | |||

| S. (80) | 0 | 0 | 80 | 0 | 0 | 100.00 | 100.00 | |||

| MR. (120) | 0 | 0 | 0 | 120 | 0 | 100.00 | 99.72 | |||

| MS. (120) | 0 | 0 | 0 | 1 | 119 | 99.17 | 100.00 | |||

| Pre. | M. (39) | 34 | 0 | 0 | 5 | 0 | 87.18 | 99.48 | ||

| R. (39) | 0 | 39 | 0 | 0 | 0 | 100.00 | 100.00 | |||

| S. (39) | 0 | 0 | 39 | 0 | 0 | 100.00 | 100.00 | |||

| MR. (57) | 1 | 0 | 0 | 56 | 0 | 98.25 | 97.13 | |||

| MS. (57) | 0 | 0 | 0 | 0 | 57 | 100.00 | 100.00 | |||

| Methods | Number | Wavenumbers (cm−1) |

|---|---|---|

| PCA loadings | 42 | 784, 786, 815, 859, 877, 877, 926, 928, 997, 997, 1051,1052, |

| 1098, 1111, 1116, 1134, 1173, 1198, 1238, 1294, 1334, 1399, | ||

| 1400, 1467, 1481, 1499, 1545, 1546, 1637, 1654, 1656, 1746, | ||

| 1746, 1856, 2850, 2852, 2882, 2922, 2923, 2926, 2947, 3010 |

| Model | Par. 1 | Sample Number | Pre. 2 | Sensitivity (%) | Specificity (%) | |||||

|---|---|---|---|---|---|---|---|---|---|---|

| M.3 | R. | S. | MR. | MS. | ||||||

| PLS | 12 | Cal. 4 | M. (80) | 78 | 0 | 0 | 2 | 0 | 97.50 | 100.00 |

| R. (80) | 0 | 80 | 0 | 0 | 0 | 100.00 | 100.00 | |||

| S. (80) | 0 | 0 | 80 | 0 | 0 | 100.00 | 100.00 | |||

| MR. (120) | 0 | 0 | 0 | 117 | 3 | 97.50 | 98.89 | |||

| MS. (120) | 0 | 0 | 0 | 2 | 118 | 98.33 | 99.16 | |||

| Pre. | M. (39) | 21 | 0 | 0 | 18 | 0 | 53.85 | 100.00 | ||

| R. (39) | 0 | 38 | 0 | 1 | 0 | 97.44 | 100.00 | |||

| S. (39) | 0 | 0 | 37 | 0 | 2 | 94.87 | 100.00 | |||

| MR. (57) | 0 | 0 | 0 | 55 | 2 | 96.49 | 88.95 | |||

| MS. (57) | 0 | 0 | 0 | 0 | 57 | 100.00 | 97.42 | |||

| SVM | 256, 0.5743 | Cal. | M. (80) | 80 | 0 | 0 | 0 | 0 | 100.00 | 100.00 |

| R. (80) | 0 | 80 | 0 | 0 | 0 | 100.00 | 100.00 | |||

| S. (80) | 0 | 0 | 80 | 0 | 0 | 100.00 | 100.00 | |||

| MR. (120) | 0 | 0 | 0 | 120 | 0 | 100.00 | 99.72 | |||

| MS. (120) | 0 | 0 | 0 | 1 | 119 | 99.17 | 100.00 | |||

| Pre. | M. (39) | 24 | 0 | 0 | 15 | 0 | 61.54 | 97.92 | ||

| R. (39) | 0 | 39 | 0 | 0 | 0 | 100.00 | 100.00 | |||

| S. (39) | 0 | 0 | 39 | 0 | 0 | 100.00 | 100.00 | |||

| MR. (57) | 0 | 0 | 0 | 57 | 0 | 100.00 | 91.18 | |||

| MS. (57) | 4 | 0 | 0 | 0 | 53 | 92.98 | 100.00 | |||

| ELM | 218 | Cal. | M. (80) | 80 | 0 | 0 | 0 | 0 | 100.00 | 100.00 |

| R. (80) | 0 | 80 | 0 | 0 | 0 | 100.00 | 100.00 | |||

| S. (80) | 0 | 0 | 80 | 0 | 0 | 100.00 | 100.00 | |||

| MR. (120) | 0 | 0 | 0 | 120 | 0 | 100.00 | 99.72 | |||

| MS. (120) | 0 | 0 | 0 | 1 | 119 | 99.17 | 100.00 | |||

| Pre. | M. (39) | 36 | 0 | 0 | 3 | 0 | 92.31 | 100.00 | ||

| R. (39) | 0 | 39 | 0 | 0 | 0 | 100.00 | 100.00 | |||

| S. (39) | 0 | 0 | 39 | 0 | 0 | 100.00 | 100.00 | |||

| MR. (57) | 0 | 0 | 0 | 57 | 0 | 100.00 | 98.28 | |||

| MS. (57) | 0 | 0 | 0 | 0 | 57 | 100.00 | 100.00 | |||

| Adulterations | Model | Par. 1 | R2c 2 | RMSEC 3 | R2p 4 | RMSEP 5 | RPD 6 |

|---|---|---|---|---|---|---|---|

| Rice Flour | PLS | 7 | 0.969 | 1.772 | 0.945 | 2.719 | 3.690 |

| SVM | 64, 0.0055 | 0.997 | 0.592 | 0.915 | 3.060 | 3.279 | |

| ELM | 37 | 0.986 | 1.156 | 0.949 | 2.424 | 4.139 | |

| Soybean Flour | PLS | 3 | 0.945 | 2.335 | 0.953 | 2.350 | 4.269 |

| SVM | 16, 0.0039 | 0.999 | 0.394 | 0.939 | 2.523 | 3.977 | |

| ELM | 79 | 0.998 | 0.440 | 0.988 | 1.129 | 8.887 | |

| ELM | 79 | 0.998 | 0.440 | 0.988 | 1.129 | 8.887 |

| Adulterations | Methods | Number | Wavenumbers (cm−1) |

|---|---|---|---|

| Rice Flour | SPA | 22 | 743, 767, 759, 821, 845, 879, 895, 922, 964, 1022, 1068, 1145, 1176, 1217, 1462, 1507, 1653, 1622, 1748, 2846, 2966, 3147 |

| Soybean Flour | SPA | 33 | 744, 752, 761, 768, 794, 802, 809, 836, 852, 860, 867, 888, 903, 929, 933, 995, 1030, 1068, 1137, 1190, 1465, 1507, 1538, 1560,1615, 1644, 1704, 1734, 1739, 1748, 2839, 3010, 3147 |

| Adulterations | Model | Par. 1 | R2c 2 | RMSEC 3 | R2p 4 | RMSEP5 | RPD 6 |

|---|---|---|---|---|---|---|---|

| Rice Flour | PLS | 7 | 0.972 | 1.683 | 0.945 | 2.514 | 3.991 |

| SVM | 256, 0.2500 | 0.984 | 1.252 | 0.939 | 2.577 | 3.893 | |

| ELM | 28 | 0.990 | 1.009 | 0.953 | 2.525 | 3.973 | |

| Soybean Flour | PLS | 3 | 0.945 | 2.337 | 0.951 | 2.366 | 4.240 |

| SVM | 32, 0.1768 | 0.996 | 0.633 | 0.958 | 2.117 | 4.739 | |

| ELM | 60 | 0.998 | 0.376 | 0.994 | 0.876 | 11.453 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Feng, L.; Zhu, S.; Chen, S.; Bao, Y.; He, Y. Combining Fourier Transform Mid-Infrared Spectroscopy with Chemometric Methods to Detect Adulterations in Milk Powder. Sensors 2019, 19, 2934. https://doi.org/10.3390/s19132934

Feng L, Zhu S, Chen S, Bao Y, He Y. Combining Fourier Transform Mid-Infrared Spectroscopy with Chemometric Methods to Detect Adulterations in Milk Powder. Sensors. 2019; 19(13):2934. https://doi.org/10.3390/s19132934

Chicago/Turabian StyleFeng, Lei, Susu Zhu, Shuangshuang Chen, Yidan Bao, and Yong He. 2019. "Combining Fourier Transform Mid-Infrared Spectroscopy with Chemometric Methods to Detect Adulterations in Milk Powder" Sensors 19, no. 13: 2934. https://doi.org/10.3390/s19132934