Structural Health Monitoring of Underground Structures in Reclamation Area Using Fiber Bragg Grating Sensors

Abstract

:1. Introduction

2. Experimental Study

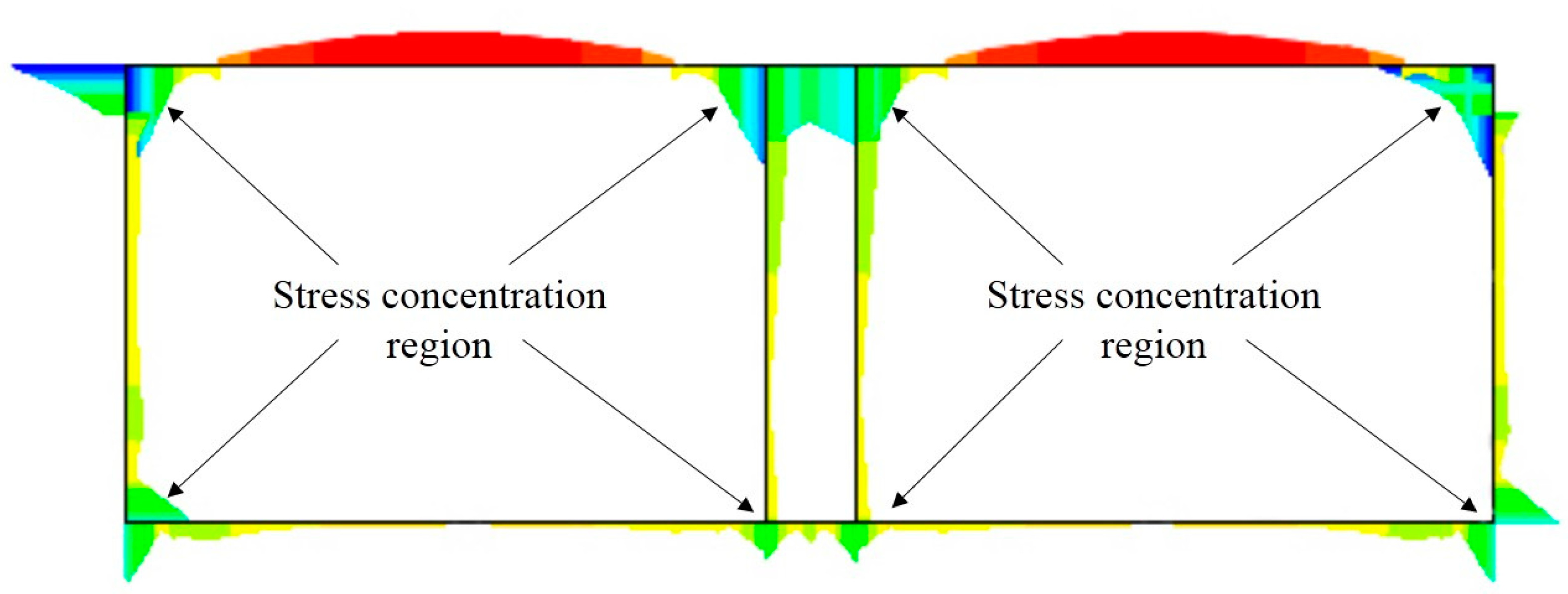

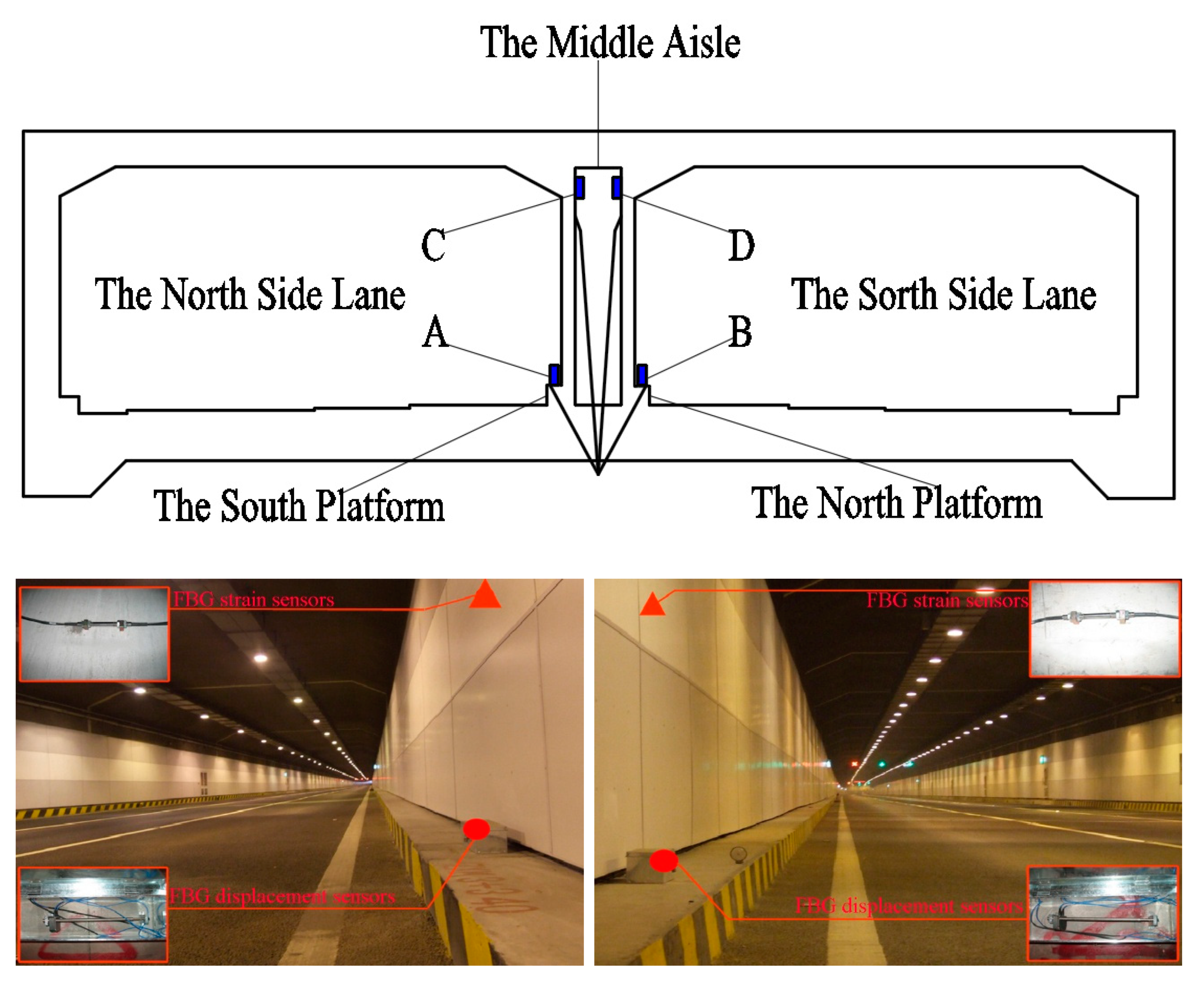

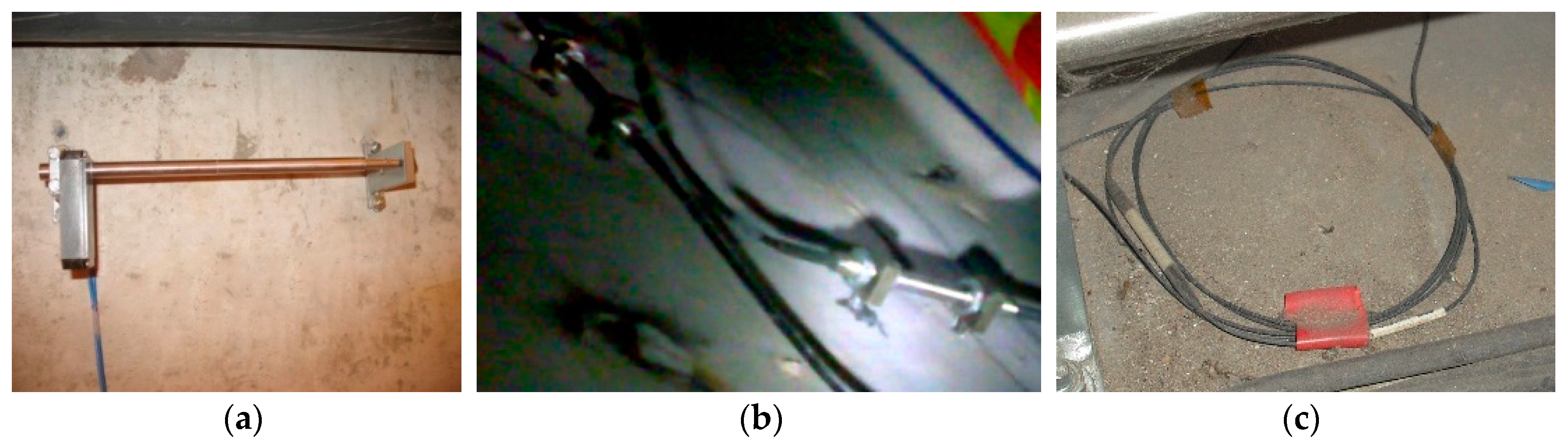

2.1. Structural Health Monitoring of the Underground Box-Type Structure Using FBG Sensors

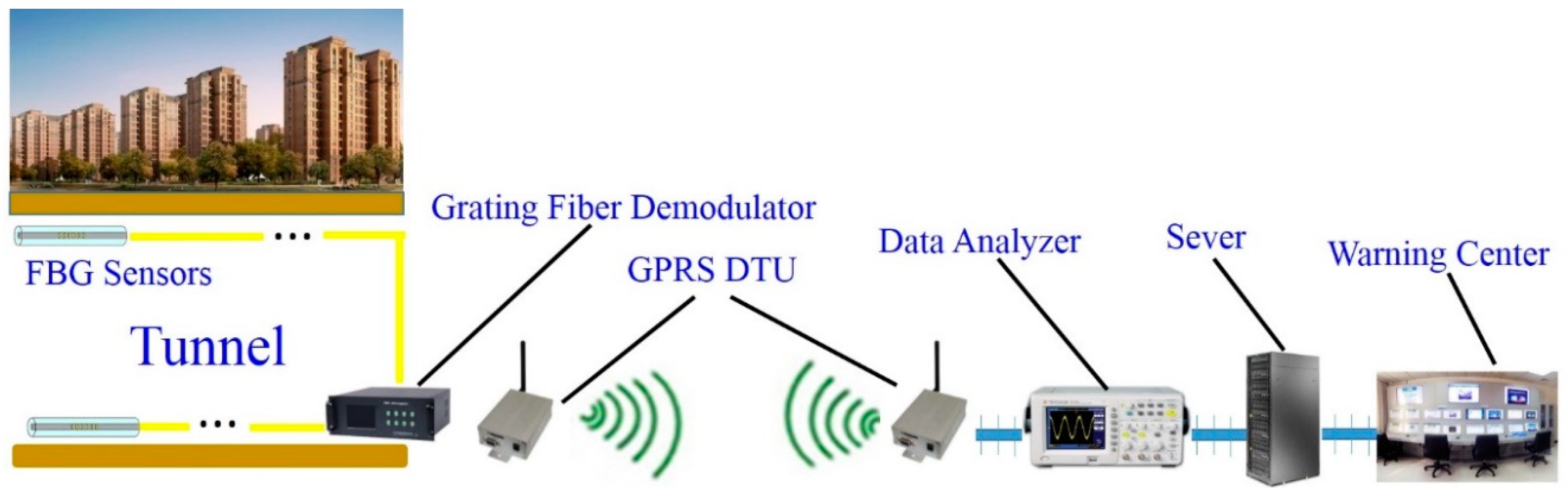

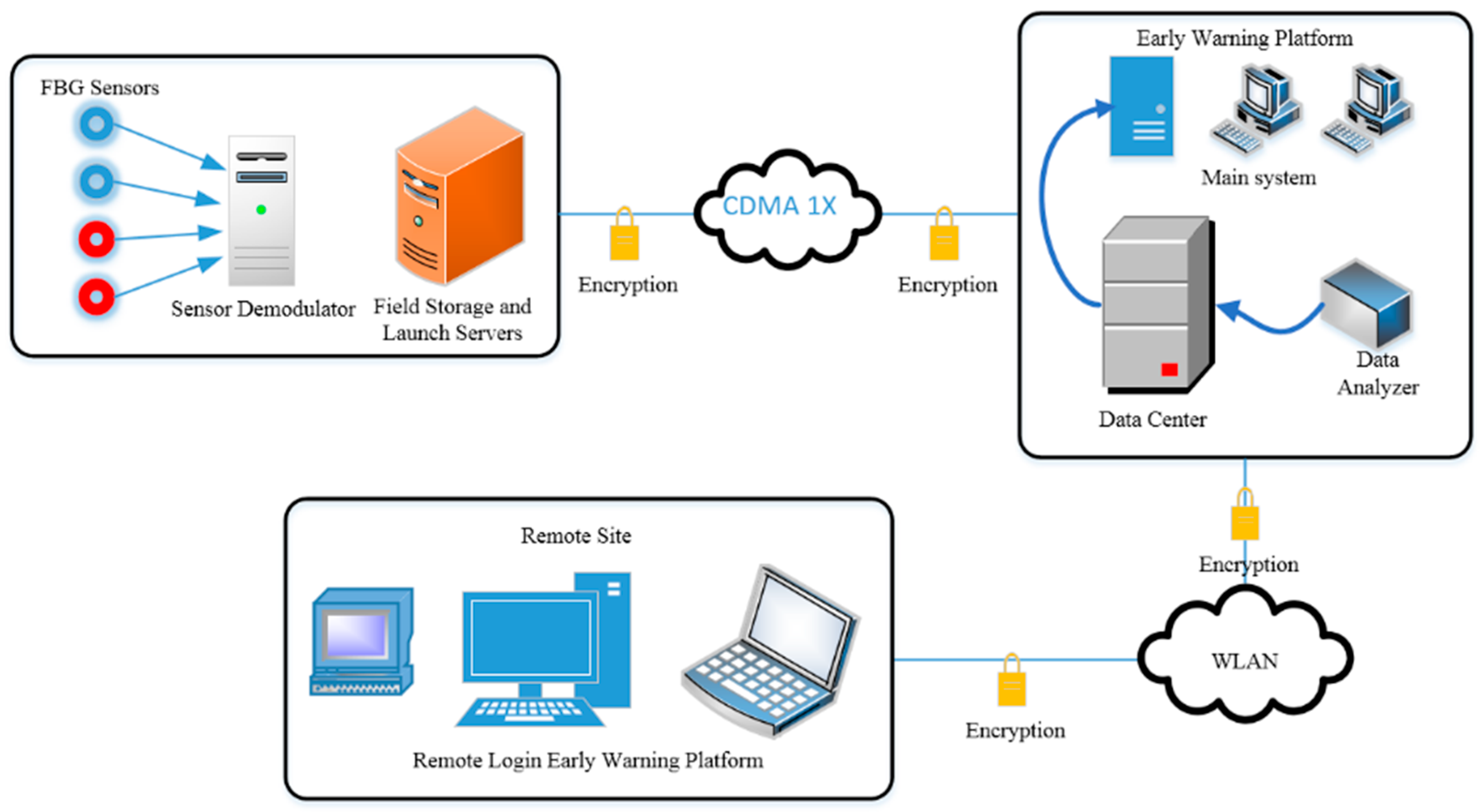

2.2. Remote Real-Time Monitoring System

2.2.1. Network Architecture

2.2.2. Data Transmission

2.2.3. Stability Analysis System

2.3. The Development of a Time Scale Method

- Effects of vehicle vibration on crack width in the box-type structure (tcar, time scale: Seconds)

- Critical time-dependent crack width can be defined when ();

- Effects of temperature on crack width in the box-type structure (ttemp, time scale: Hours)

- Critical time-dependent crack width can be defined when ();

- Effects of tide on crack width in the box-type structure (ttide, time scale: Months)

- Critical time-dependent crack width can be defined when ();

- Effects of rainfall on crack width in the box-type structure (trainfall, time scale: Days)

- Critical time-dependent crack width can be defined when ().

3. Results and Discussion

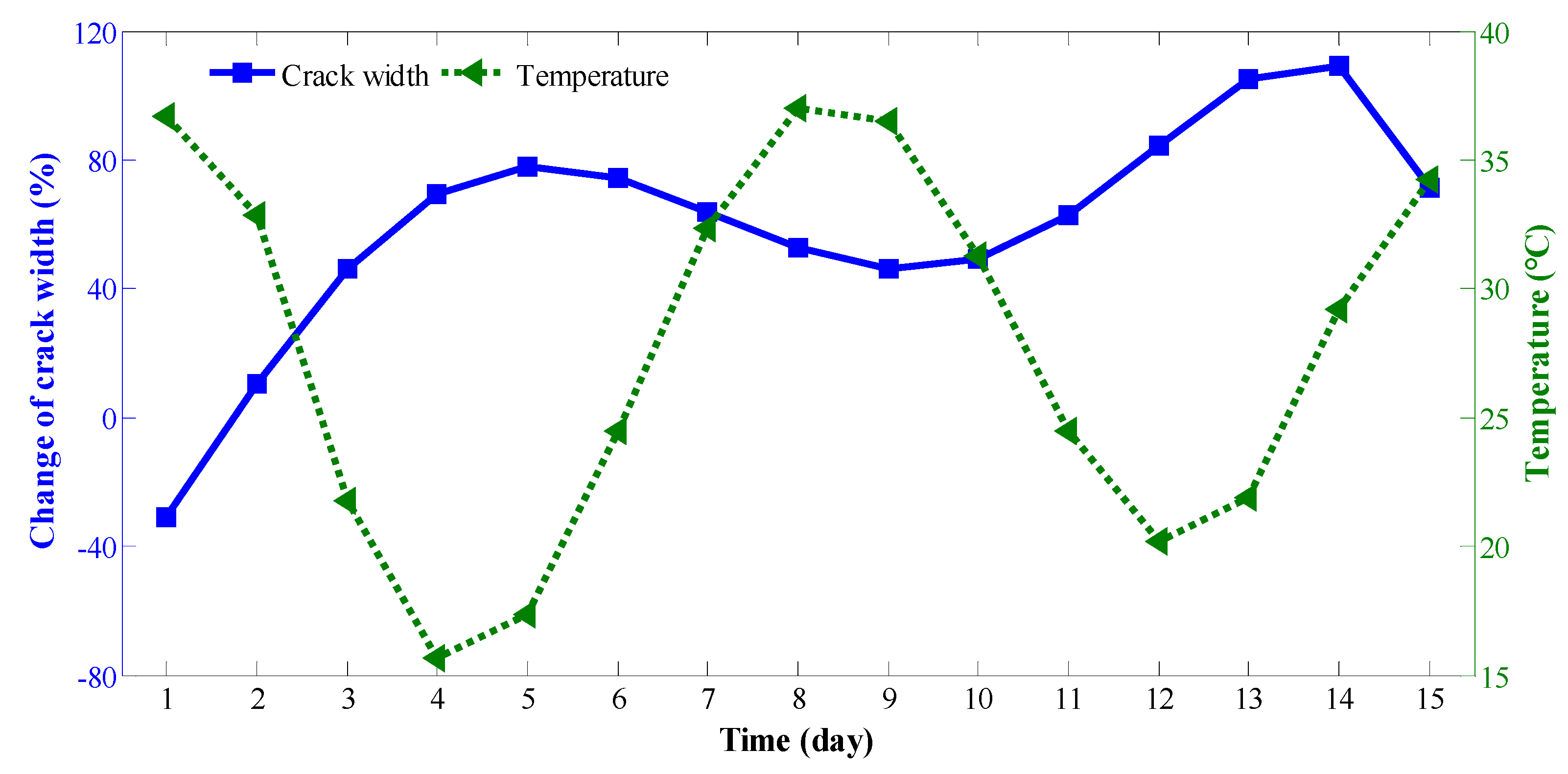

3.1. Influence of Variation in Tide Height and Temperature on the Change of Crack Width in the Box-Type Structure

3.2. Influence of Variation of Rainfall on the Change in Crack Width in the Box-Type Structure

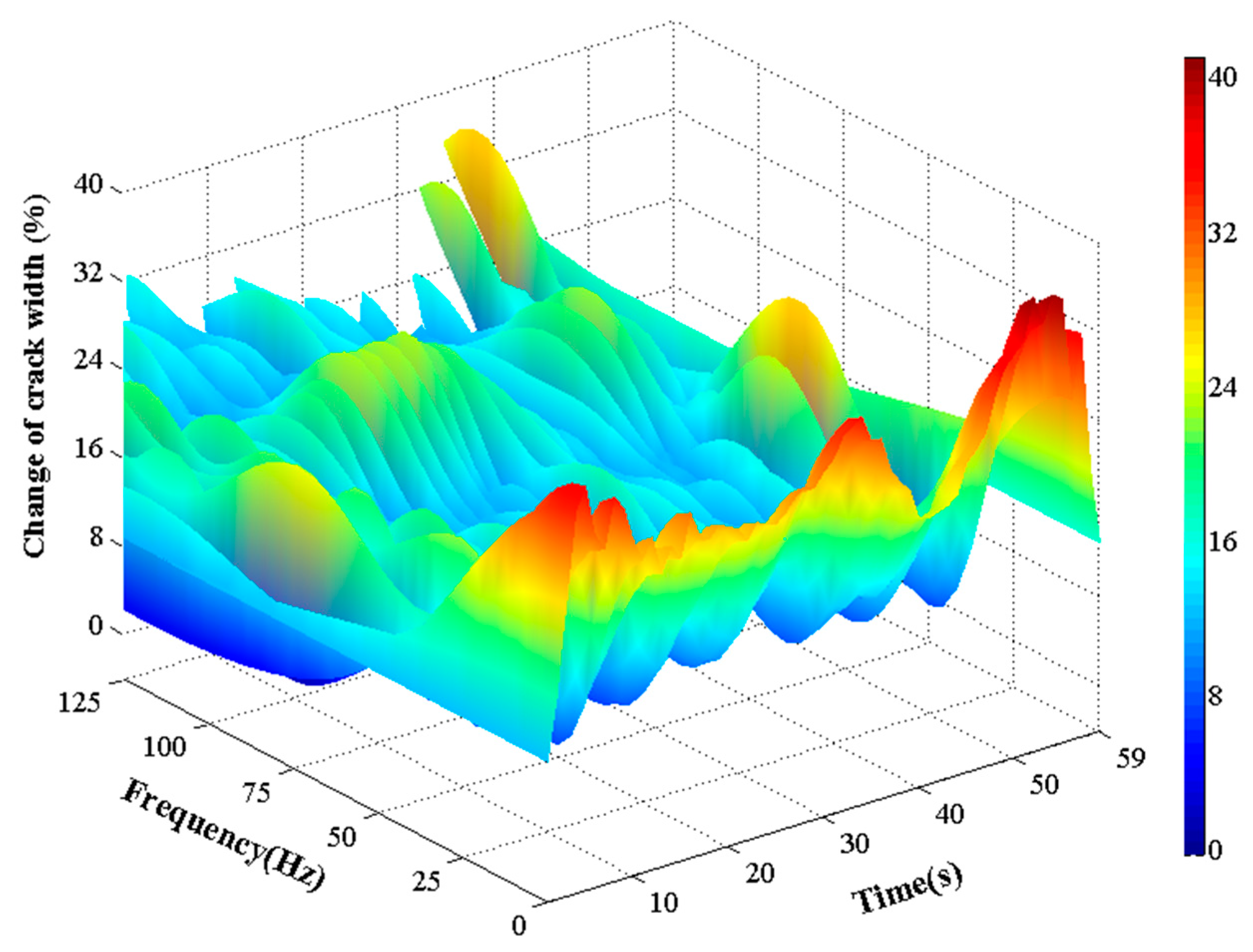

3.3. Influence of Vehicle Induced Vibration on the Change in Crack Width in the Box-Type Structure

4. Conclusions

- The change of tide levels has little influence on the change in crack width.

- Variations in temperature can significantly influence the crack width (e.g., 120% increase in crack width) with Pearson correlation coefficients of 0.65, 0.84 and 0.86 for August 1, 2 and 3 in 2009, respectively.

- There is a strong negative correlation between rainfall and the change in crack width.

- A relatively low frequency of vibration (i.e., less than 25 Hz) can result in a relatively large increase in crack width.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Bursi, O.S.; Tondini, N.; Fassin, M.; Bonelli, A. Structural monitoring for the cyclic behaviour of concrete tunnel lining sections using FBG sensors. Struct. Control Health Monit. 2016, 23, 749–763. [Google Scholar] [CrossRef]

- Brownjohn, J.M.W. Structural Health Monitoring of Civil Infrastructure. Philos. Trans. R. Soc. A Math. Phys. 2007, 365, 589–622. [Google Scholar] [CrossRef] [PubMed]

- Hong, C.Y.; Zhang, Y.F.; Zhang, M.X.; Gordon, L.L.M.; Liu, L.Q. Application of FBG sensors for geotechnical health monitoring, a review of sensor design, implementation methods and packaging techniques. Sens. Actuator A Phys. 2016, 244, 184–197. [Google Scholar] [CrossRef]

- Kontogianni, V.A.; Stiros, S.C. Induced deformation during tunnel excavation: Evidence from geodetic monitoring. Eng. Geol. 2005, 79, 115–126. [Google Scholar] [CrossRef]

- Sircoulomb, V.; Stoffels, N.; Hermand, G.; Hoblos, G. Optimal tuning for an abrupt change detection algorithm: Application to an underground gallery structure health monitoring. In Proceedings of the 2nd International Conference on Control and Fault-Tolerant Systems (SysTol), Nice, France, 9–11 October 2013. [Google Scholar]

- Walton, G.; Delaloye, D.; Diederichs, M.S. Development of an elliptical fitting algorithm to improve change detection capabilities with applications for deformation monitoring in circular tunnels and shafts. Tunn. Undergr. Space Technol. 2014, 43, 336–349. [Google Scholar] [CrossRef]

- Jiang, H.; Chen, L.; Wu, J.; Chen, S.Y.; Leung, H. A reliable and high-bandwidth multihop wireless sensor network for mine tunnel monitoring. IEEE Sens. J. 2009, 9, 1511–1517. [Google Scholar] [CrossRef]

- Li, Y.; Wang, H.P.; Zhu, W.S.; Li, S.C.; Liu, J. Structural Stability Monitoring of a Physical Model Test on, an Underground Cavern Group during Deep Excavations, Using FBG Sensors. Sensors 2015, 15, 21696–21709. [Google Scholar] [CrossRef] [PubMed]

- Kim, J.M.; Kim, C.M.; Choi, S.Y.; Lee, B.Y. Enhanced Strain Measurement Range of an FBG Sensor Embedded in Seven-Wire Steel Strands. Sensors 2017, 17, 1654. [Google Scholar] [CrossRef] [PubMed]

- Zhu, H.H.; Shi, B.; Zhang, C.C. FBG-Based Monitoring of Geohazards: Current Status and Trends. Sensors 2017, 17, 452. [Google Scholar] [CrossRef] [PubMed]

- Zhong, L.; Tang, K.H.; Li, L.; Yang, G.; Ye, J.J. An improved clustering algorithm of tunnel monitoring data for cloud computing. Sci. World J. 2014, 1, 630986. [Google Scholar] [CrossRef] [PubMed]

- Mahdevari, S.; Haghighat, H.S.; Torabi, S.R. A dynamically approach based on SVM algorithm for prediction of tunnel convergence during excavation. Tunn. Undergr. Space Technol. 2013, 38, 59–68. [Google Scholar] [CrossRef]

- Mahdevari, S.; Torabi, S.R. Prediction of tunnel convergence using artificial neural networks. Tunn. Undergr. Space Technol. 2012, 28, 218–228. [Google Scholar] [CrossRef]

- Xie, X.Y.; Wang, Q.; Huang, Z.H.; Qi, Y. Parametric analysis of mixshield tunnelling in mixed ground containing mudstone and protection of adjacent buildings: Case study in Nanning metro. Eur. J. Environ. Civ. Eng. 2018, 22 (Suppl. 1), s130–s148. [Google Scholar] [CrossRef]

- Bossi, G.; Schenato, L.; Marcato, G. Structural health monitoring of a road tunnel intersecting a large and active landslide. Appl. Sci.-Basel 2017, 7, 1271. [Google Scholar] [CrossRef]

- Liu, C.; Li, S.; Zhou, Z.; Li, L.; Wang, K.; Qin, C. Model Test Study on Spatial Deformation Law of Surrounding Rock for Super-Large Section and Shallow Buried Tunnels. Geotech. Test. J. 2018, 42, 20170243. [Google Scholar] [CrossRef]

- Hashash, Y.M.A.; Park, D.; Yao, J.I.C. Ovaling deformations of circular tunnels under seismic loading, an update on seismic design and analysis of underground structures. Tunn. Undergr. Space Technol. 2005, 20, 435–441. [Google Scholar] [CrossRef]

- Amezquita-Sanchez, J.P.; Adeli, H. Signal Processing Techniques for Vibration-Based Health Monitoring of Smart Structures. Arch. Comput. Method Eng. 2016, 23, 1–15. [Google Scholar] [CrossRef]

- Bonett, D.G.; Wright, T.A. Sample size requirements for estimating pearson, kendall and spearman correlations. Psychometrika 2000, 65, 23–28. [Google Scholar] [CrossRef]

| Types of FBG Sensors | Quantities of Sensors |

|---|---|

| strain sensor | 24 |

| displacement sensor | 17 |

| temperature sensor | 3 |

| total | 44 |

| Parameters | Time Scale | Details |

|---|---|---|

| tide | day | Groundwater level rise and fall |

| rainfall | month | Groundwater level rise and fall |

| vehicle vibration | second | Amplitude changes |

| temperature | hour | Thermal expansion |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, Z.; Liu, P.; Zhou, C.; Huang, Y.; Zhang, L. Structural Health Monitoring of Underground Structures in Reclamation Area Using Fiber Bragg Grating Sensors. Sensors 2019, 19, 2849. https://doi.org/10.3390/s19132849

Liu Z, Liu P, Zhou C, Huang Y, Zhang L. Structural Health Monitoring of Underground Structures in Reclamation Area Using Fiber Bragg Grating Sensors. Sensors. 2019; 19(13):2849. https://doi.org/10.3390/s19132849

Chicago/Turabian StyleLiu, Zhen, Pengzhen Liu, Cuiying Zhou, Yuncong Huang, and Lihai Zhang. 2019. "Structural Health Monitoring of Underground Structures in Reclamation Area Using Fiber Bragg Grating Sensors" Sensors 19, no. 13: 2849. https://doi.org/10.3390/s19132849

APA StyleLiu, Z., Liu, P., Zhou, C., Huang, Y., & Zhang, L. (2019). Structural Health Monitoring of Underground Structures in Reclamation Area Using Fiber Bragg Grating Sensors. Sensors, 19(13), 2849. https://doi.org/10.3390/s19132849