Surface-Acoustic-Wave Sensor Design for Acceleration Measurement

Abstract

:1. Introduction

- simplicity of the sensing element kinematic scheme;

- high-level design integrity (i.e., fewer component parts and joints used);

- lack of extra discrete elastic suspensions;

- minimal use of conventional planar microelectronic technologies, thus minimizing the SSA production cost.

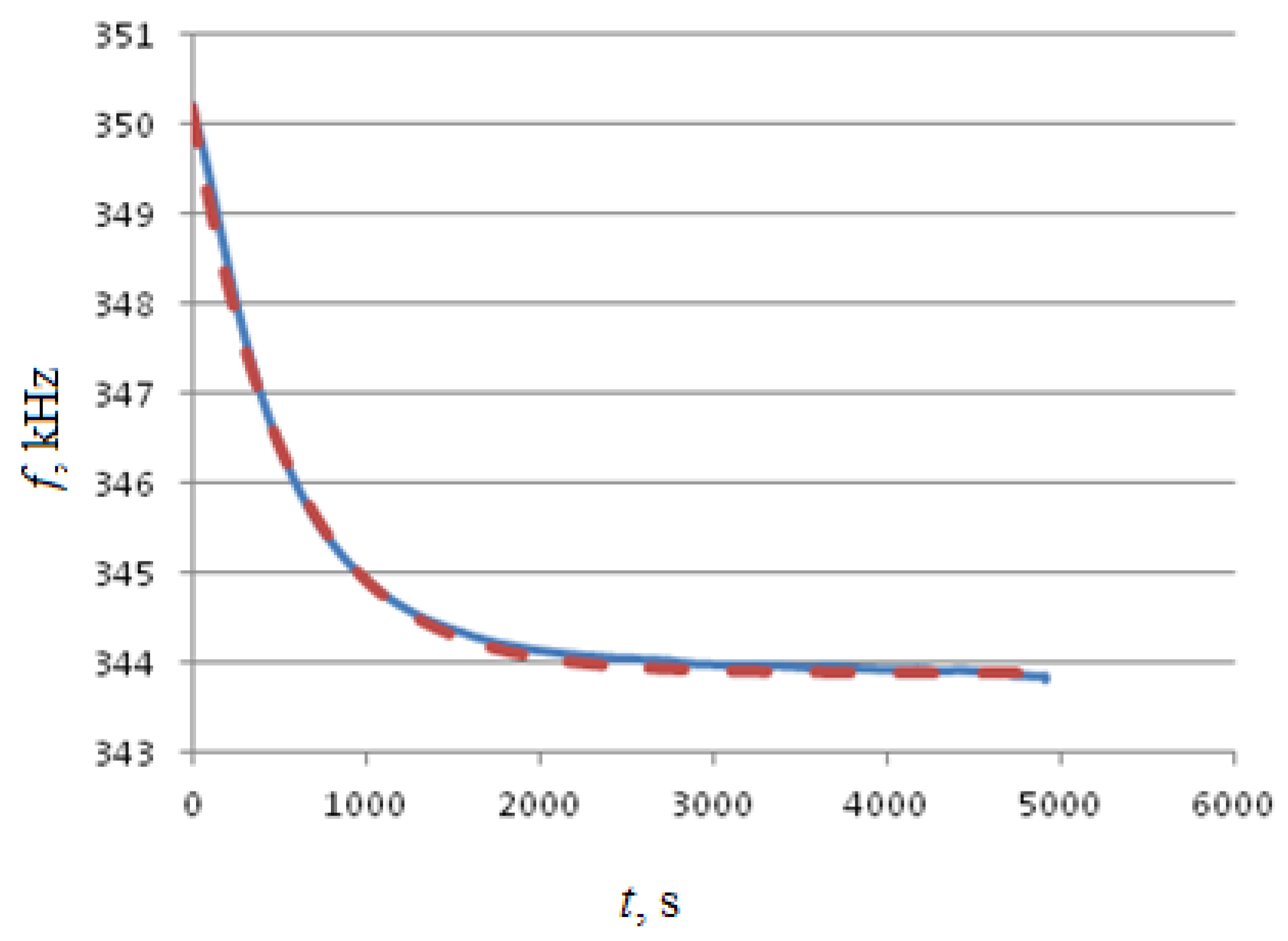

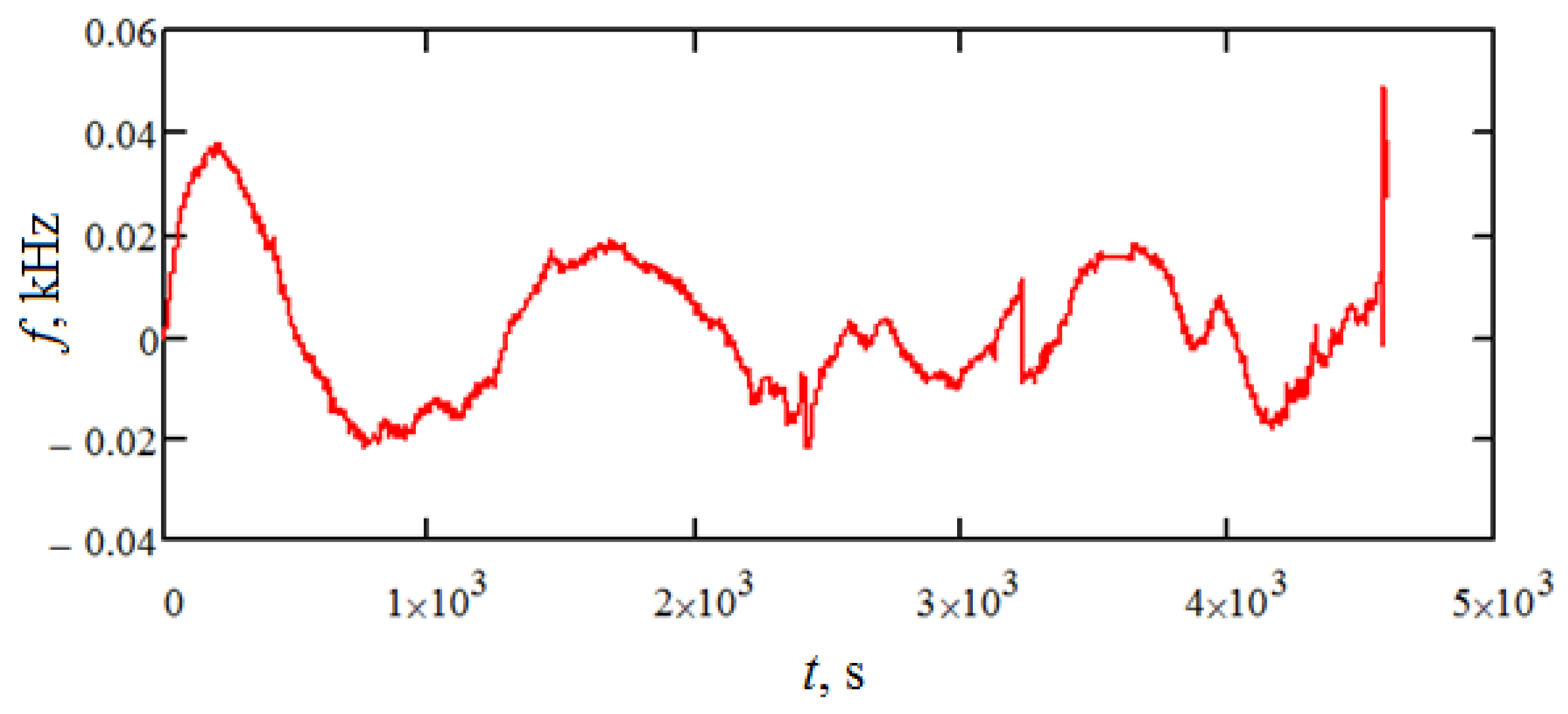

2. Results

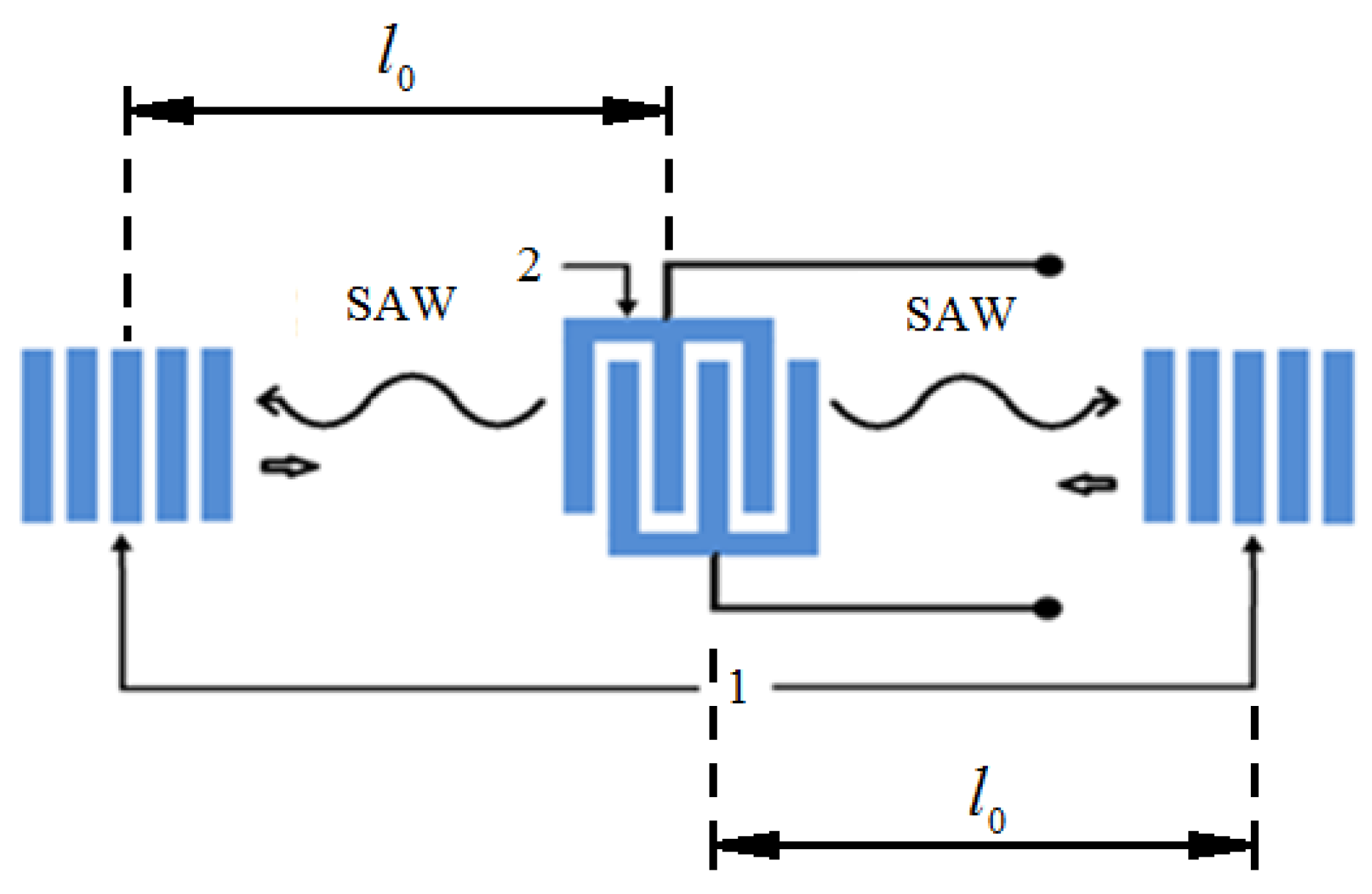

2.1. SAW Microaccelerometer Design Concept

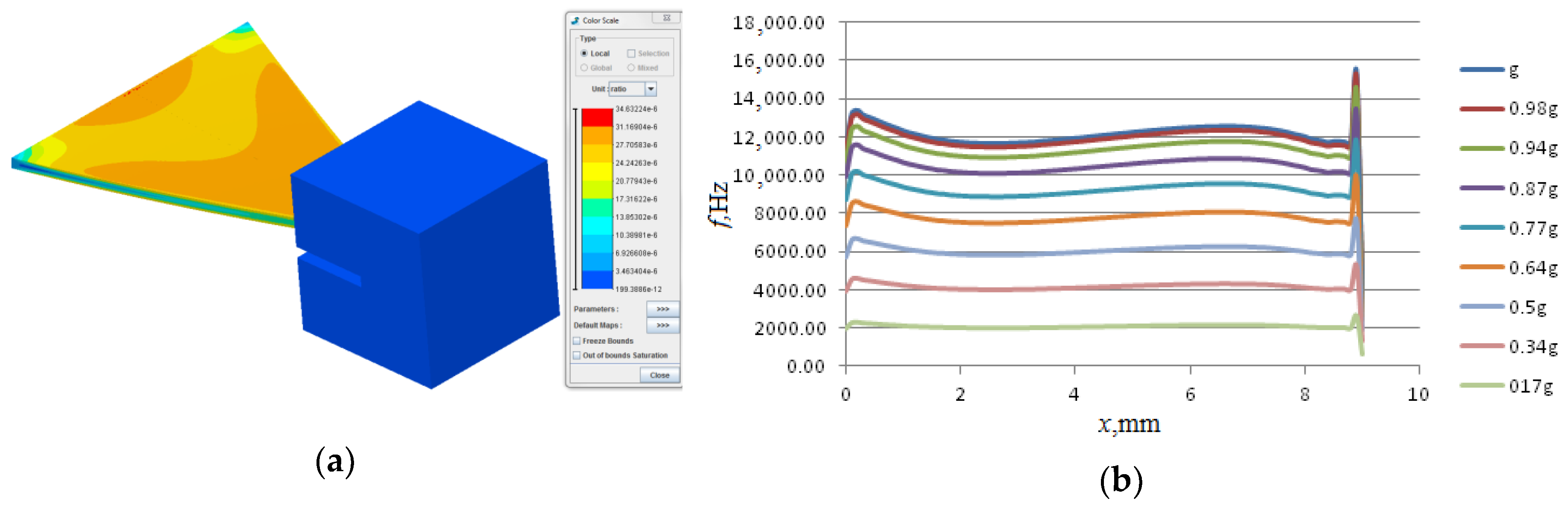

2.2. SSA Console Shape Optimization

3. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Bogue, R. Recent developments in MEMS sensors: A review of applications, markets and technologies. Sens. Rev. 2013, 33, 300–304. [Google Scholar] [CrossRef]

- Comi, R.; Corigliano, A.; Ghisi, A.; Zerbini, S. A resonant micro accelerometer based on electrostatic stiffness variation. Meccanica 2013, 48, 1893–1900. [Google Scholar] [CrossRef]

- Bustillo, J.M.; Howe, R.T.; Muller, R.S. Surface Micromachining for Microelectromechanical Systems. Proc. IEEE 1998, 86, 1552–1574. [Google Scholar] [CrossRef]

- Ghodssi, R.; Lin, P. MEMS Materials and Processes Handbook; Spring: Berlin, Germany, 2011; ISBN 978-0-387-47316-1. [Google Scholar]

- Dao, D.V.; Okada, S.; Dau, V.T.; Toriyama, T.; Sugiyama, S. Development of a 3-DOF silicon piezoresistive micro accelerometer. In Micro-Nanomechatronics and Human Science, Proceedings of the 2004 and The Fourth Symposium Micro-Nanomechatronics for Information-Based Society, Nagoya, Japan, 31 October–3 November 2004; IEEE: Piscataway, NJ, USA, 2004. [Google Scholar]

- Imenes, K.; Aasmundtveit, K.; Husa, E.M.; Høgetveit, J.O.; Halvorsen, S.; Elle, O.J.; Mirtaheri, P.; Fosse, E.; Hoff, L. Assembly and packaging of a three-axis micro accelerometer used for detection of heart infarction. Biomed. Microdevices 2007, 9, 951–957. [Google Scholar] [CrossRef] [PubMed]

- Takeda, M. Applications of MEMS to industrial inspection. In Proceedings of the 14th IEEE International Conference on Micro Electro Mechanical Systems, Interlaken, Switzerland, 25 January 2001; IEEE: Piscataway, NJ, USA, 2001. [Google Scholar]

- Chang, S.C.S. MEMS in Automobiles. In Microsystems and Nanotechnology; Spring: Berlin, Germany, 2012; pp. 721–757. [Google Scholar]

- Moshe, B.B.; Shvalb, N.; Baadani, J.; Nagar, I.; Levy, H. Indoor positioning and navigation for micro UAV drones. In Proceedings of the 2012 IEEE 27th Convention of Electrical and Electronics Engineers in Israel, Eilat, Israel, 14–17 November 2012; IEEE: Piscataway, NJ, USA, 2012. [Google Scholar]

- Chakraborty, I.; Tang, W.C.; Bame, D.P.; Tang, T.K. MEMS micro-valve for space applications. Sens. Actuators A Phys. 2000, 83, 188–193. [Google Scholar] [CrossRef] [Green Version]

- Aggarwal, P.; Syed, Z.; El-Sheimy, N. Mems-Based Integrated Navigation; Artech House: Norwood, MA, USA, 2014. [Google Scholar]

- Lukyanov, D.; Shevchenko, S.; Kukaev, A.; Filippova, E.; Safronov, D. Microaccelerometer based on surface acoustic waves. In Proceedings of the 2014 Symposium on Piezoelectricity, Acoustic Waves, and Device Applications (SPAWDA), Beijing, China, 30 October–2 November 2014; IEEE: Piscataway, NJ, USA, 2014; pp. 18–21. [Google Scholar]

- D’amico, A.; Verona, E. SAW sensors. Sens. Actuators 1989, 17, 55–66. [Google Scholar] [CrossRef]

- Venema, A.; Nieuwkoop, E.; Vellekoop, M.J.; Nieuwenhuizen, M.S.; Barendsz, A.W. Design aspects of SAW gas sensors. Sens. Actuators 1986, 10, 47–64. [Google Scholar] [CrossRef]

- Tiersten, H.F.; Stevens, D.S.; Das, P.K. Acoustic surface wave accelerometer and rotation rate sensor. In Proceedings of the 1980 Ultrasonics Symposium, Boston, MA, USA, 5–7 November 1980; IEEE: Piscataway, NJ, USA, 1980; pp. 692–695. [Google Scholar]

- Templeton, D.; Saunders, D. Acoustic Design; Elsevier: Amsterdam, The Netherlands, 2014. [Google Scholar]

- Wang, W.; Huang, Y.; Liu, X.; Liang, Y. Surface acoustic wave acceleration sensor with high sensitivity incorporating st-x quartz cantilever beam. Smart Mater. Struct. 2014, 24, 015015. [Google Scholar] [CrossRef]

- Balysheva, O.L. Filters on surface acoustic waves: Opportunities of miniaturization and functional integration. Radio Eng. Electron. 2009, 54, 1512–1523. [Google Scholar]

- Shevchenko, S.Y.; Lukyanov, D.P.; Kukaev, A.S. Micro rate gyros for highly dynamic objects. Microsyst. Technol. 2014, 20, 2137–2146. [Google Scholar]

- Lukyanov, D.; Shevchenko, S.; Kukaev, A.; Filippova, E.; Khivrich, M. Application of surface acoustic wave devices for acceleration sensing. In Proceedings of the 2014 International Conference on Mechanical Engineering, Automation and Control Systems, Tomsk, Russia, 16–18 October 2014. [Google Scholar]

- Boronakhin, A.M.; Ivanov, P.A.; Bokhman, E.D.; Filatov, Y.V.; Surov, I.L. Test beds for small-sized inertial systems and sensors. Gyroscopy Navig. 2012, 3, 188–193. [Google Scholar] [CrossRef]

- Saigusa, Y. Quartz-based piezoelectric materials. In Advanced Piezoelectric Materials, 2nd ed.; Elsevier: New York, NY, USA, 2017; pp. 197–233. [Google Scholar]

- Lukyanov, D.; Shevchenko, S.; Kukaev, A.; Khivrich, M. Surface acoustic wave accelerometer for high-G applications. In Proceedings of the Ultrasonics Symposium (IUS), Taibei, Taiwan, 21–24 October 2015; IEEE: Piscataway, NJ, USA; pp. 1–3. [Google Scholar]

- Precise Robust Inertial Guidance for Munitions (PRIGM): Advanced Inertial Micro Sensors (AIMS); DARPA-BAA-15-38; Microsystems Technology Office: San Francisco, CA, USA, 2015.

| Sample Mean, kHz | 1.425 × 10−3 |

| Sample Variance, (kHz)2 | 1.823 × 10−4 |

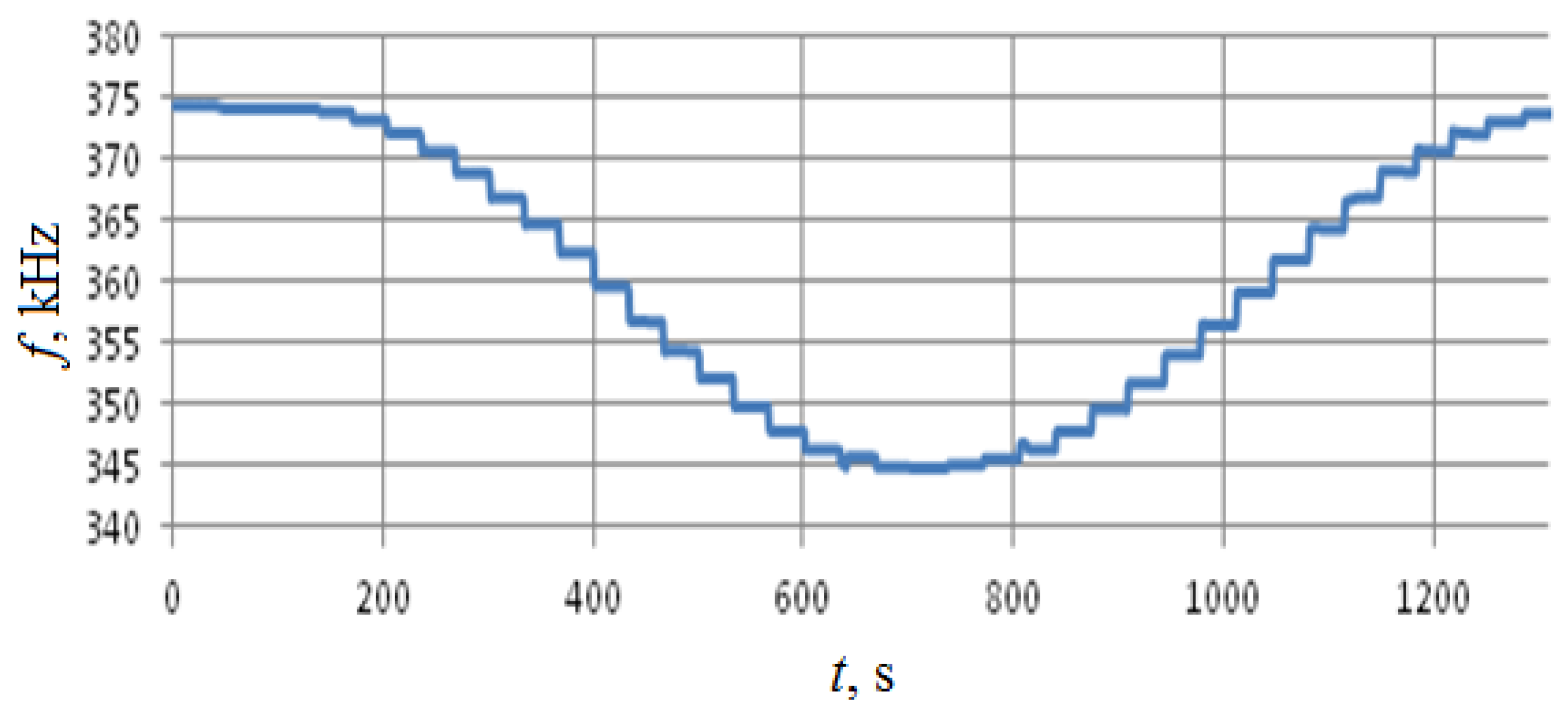

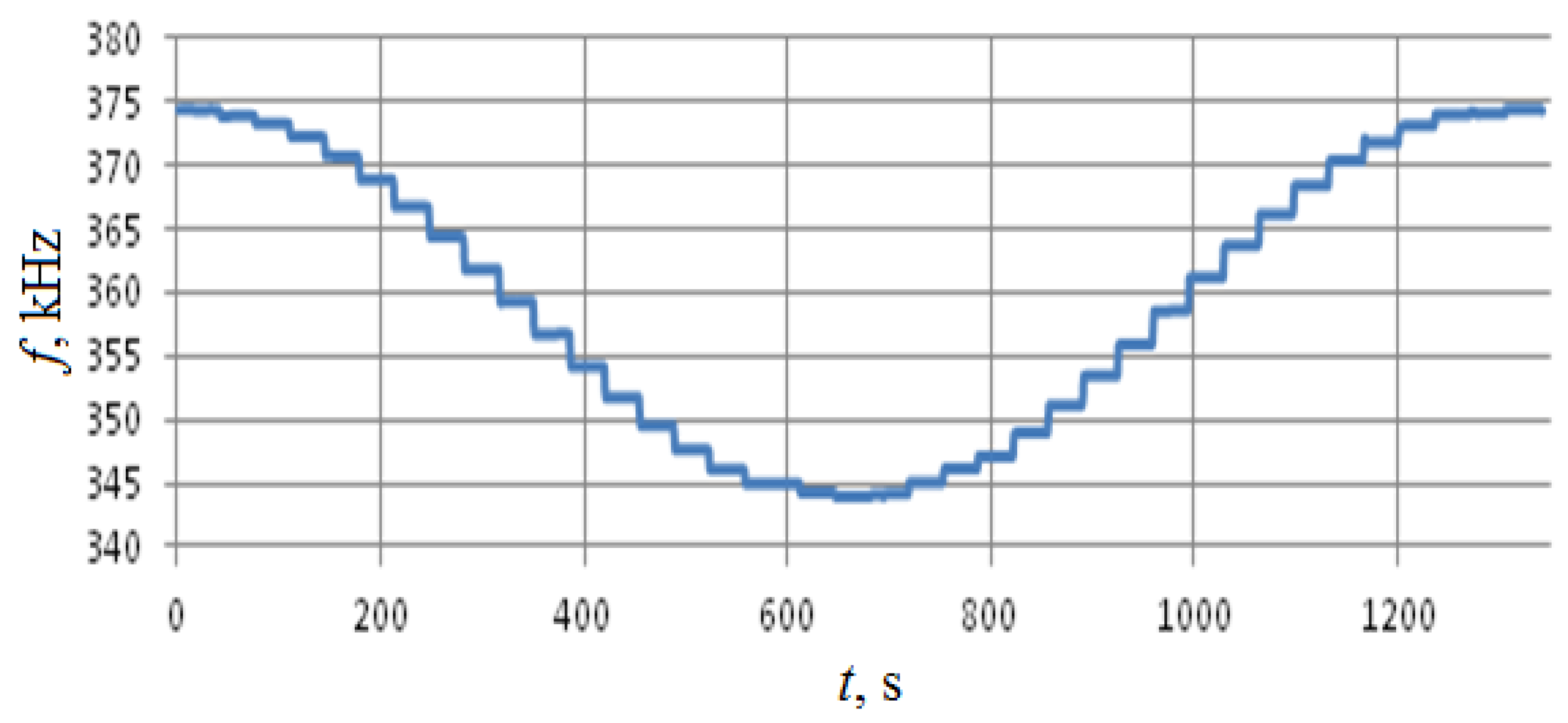

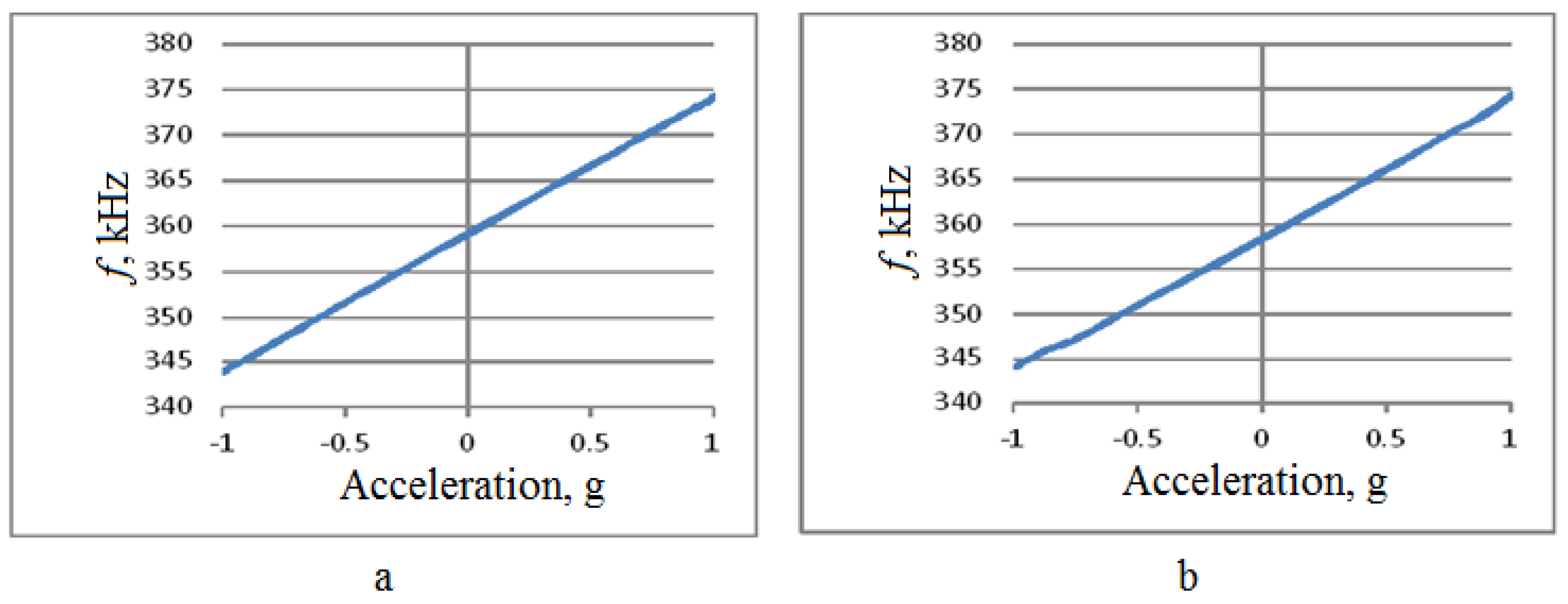

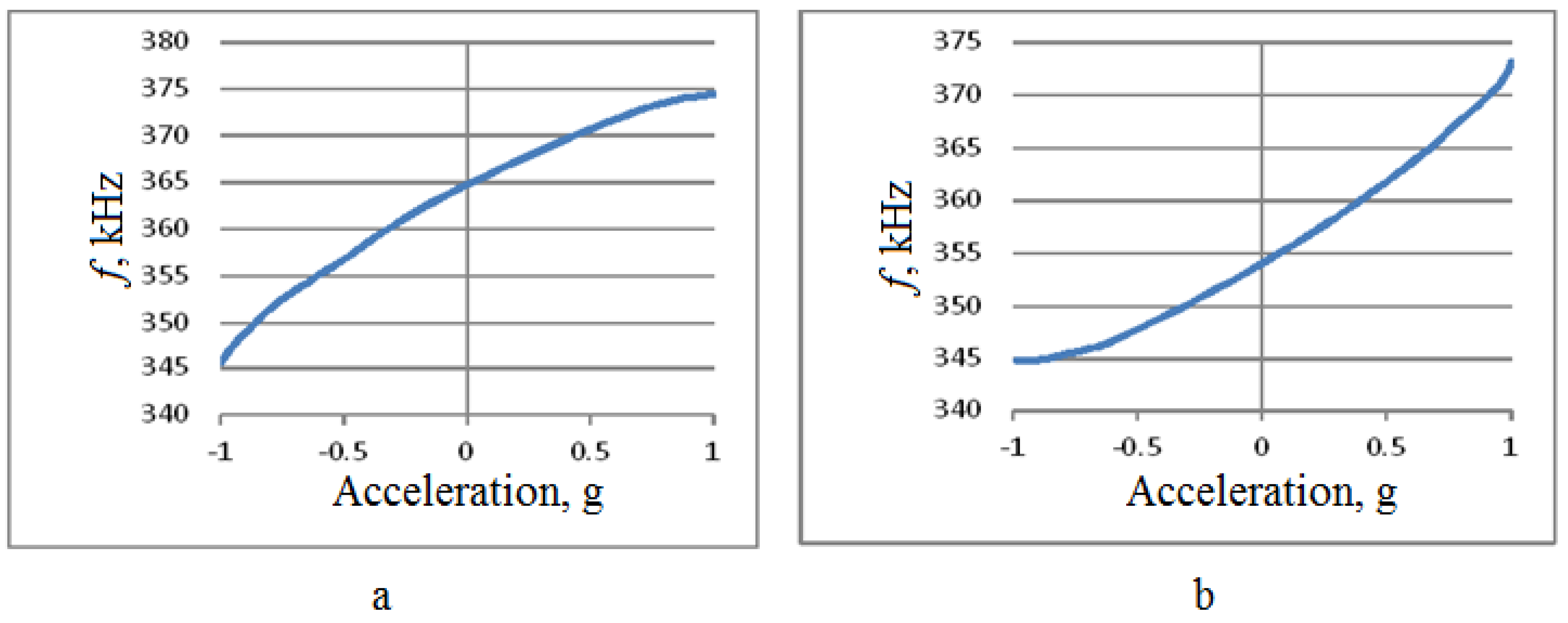

| Characteristics | Rotations around the z-axis | Rotations around the x-axis |

|---|---|---|

| k0, kHz | 358.785 | 359.408 |

| km, kHz | 15.23 | 14.25 |

| Nonlinearity, % | 0.25 | 2.5 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shevchenko, S.; Kukaev, A.; Khivrich, M.; Lukyanov, D. Surface-Acoustic-Wave Sensor Design for Acceleration Measurement. Sensors 2018, 18, 2301. https://doi.org/10.3390/s18072301

Shevchenko S, Kukaev A, Khivrich M, Lukyanov D. Surface-Acoustic-Wave Sensor Design for Acceleration Measurement. Sensors. 2018; 18(7):2301. https://doi.org/10.3390/s18072301

Chicago/Turabian StyleShevchenko, Sergey, Alexander Kukaev, Maria Khivrich, and Dmitry Lukyanov. 2018. "Surface-Acoustic-Wave Sensor Design for Acceleration Measurement" Sensors 18, no. 7: 2301. https://doi.org/10.3390/s18072301